Transforming Supply Chains: Powering Circular Economy with Analytics, Integration and Flexibility Using Dual Theory and Deep Learning with PLS-SEM-ANN Analysis

Abstract

:1. Introduction

2. Theoretical Foundations and Literature Review

2.1. Technology-Organization-Environment (TOE) Framework

2.2. Dynamic Capabilities View (DCV)

2.3. Circular Economy (CE)

- Focus on fewer input resources and minimized exploiting natural resources, like energy and material, as input and increased efficiency;

- Encourage organizations to share renewable resources, primarily focused on converting non-renewable resources into renewable resources; organizations must consider the recycling process and move towards sustainability;

- Must reduce the carbon footprint through fewer emissions in the complete material life cycle;

- Minimize wastage through fewer materials losses and save natural resources;

- Support to re-use the product, expansion in the product life cycle, and retain the product as long as possible.

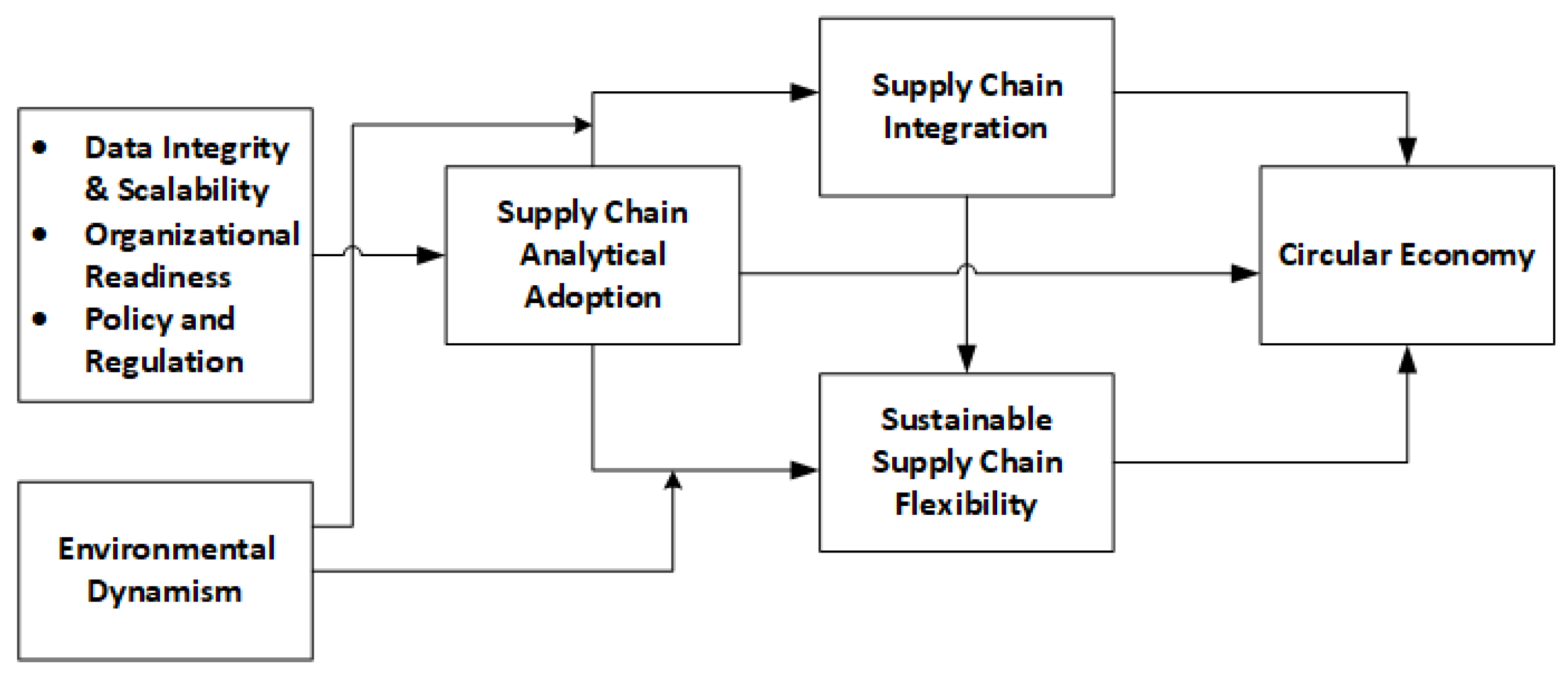

3. Hypotheses and Conceptual Framework Development

3.1. Data Integrity and Scalability (DIS)

3.2. Organizational Readiness (OR)

3.3. Policy and Regulation (PR)

3.4. Supply Chain Analytical Adoption (SCAA)

3.5. Environmental Dynamism (ED)

3.6. Supply Chain Integration (SCI)

3.7. Sustainable Supply Chain Flexibility (SSCF)

4. Methodology

4.1. Measures

4.2. Data Collection

4.3. Common Method Bias (CMB)

4.4. Research Tools

5. Results

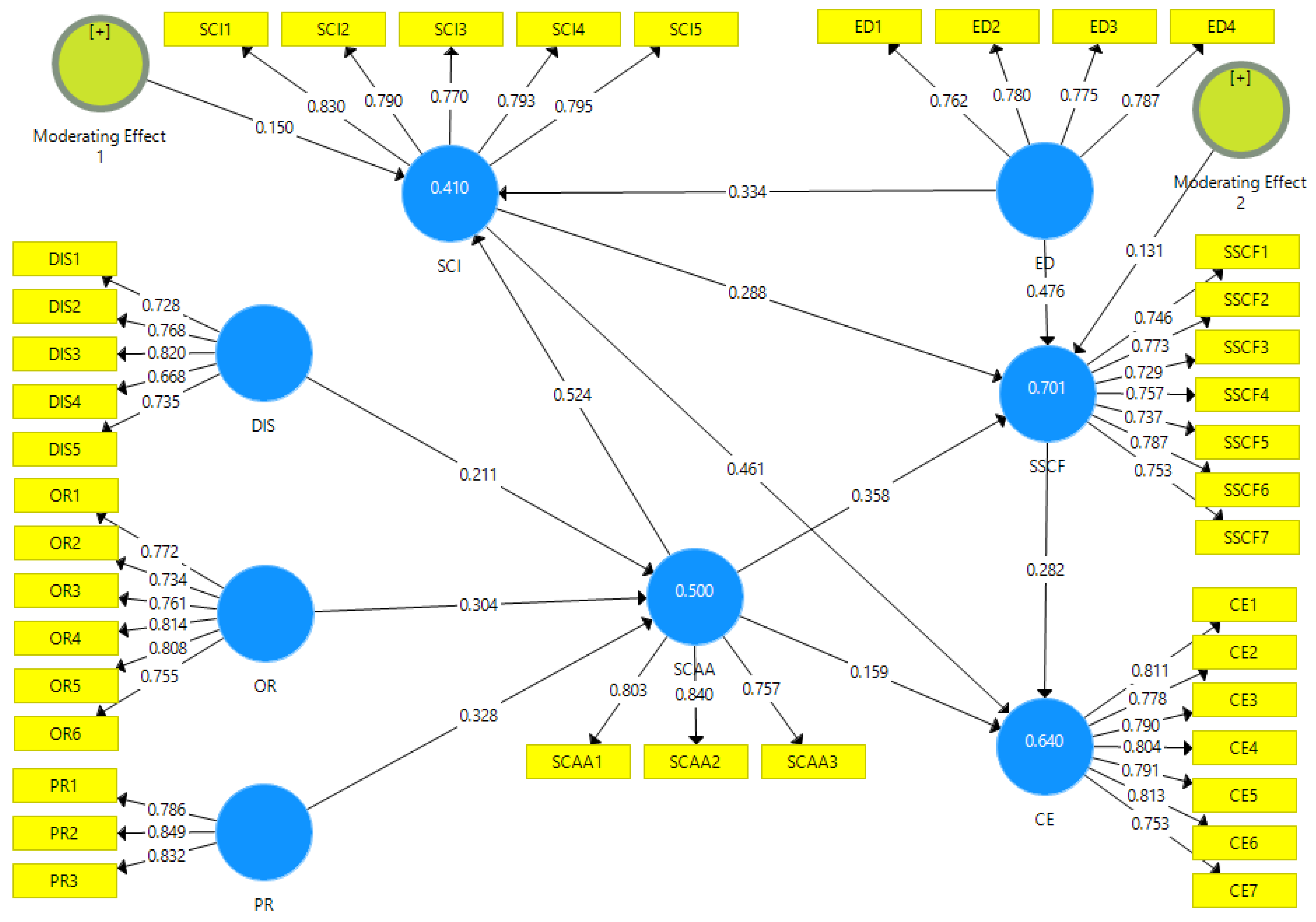

5.1. Measurement Model

5.2. Reliability

5.3. Convergent Validity

5.4. Discriminant Validity

5.5. Structural Model

5.6. Hypotheses Testing

5.7. Mediation Analysis

5.8. Effect Size and Predictive Relevance

5.9. Model Fit

5.10. Artificial Neural Network (ANN)

5.11. Sensitivity Analysis

6. Discussion

7. Conclusions and Implications

7.1. Theoretical Implications

7.2. Practical Implications

7.3. Social Implications

7.4. Limitations and Future Research Direction

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- The utilized supply chain analytics systems are compatible with the company’s existing hardware and software applications.

- Data quality issues are relevant to my organization when implementing supply chain analytics systems.

- Data interoperability issues are relevant to my organization when implementing supply chain analytics systems.

- supply chain analytics systems are supported by data quality and data integration tools.

- Customer data needs to be integrated into supply chain analytics systems and checked for quality.

- Our organization has the human capabilities and capacity on using supply chain analytics systems to support operations.

- Our organization has no difficulties in accessing all the necessary resources (e.g., funding, people, time) to adopt supply chain analytics technologies.

- Our organization employees are knowledgeable and skillful in supply chain analytics systems.

- Our organization supports ongoing personnel training schemes on supply chain analytics systems.

- The company management considers supply chain analytics systems important and supports their use.

- The management is willing to communicate with staff and participate in the implementation process of supply chain analytics systems.

- There is legal protection in the use of supply chain analytics systems, but companies have difficulty complying with policies and regulations due to the large amount of unstructured data.

- Legislation and regulations are sufficient to guarantee the use of supply chain analytics systems.

- Financial incentives to promote the adoption of supply chain analytics systems are provided.

- Our organization is currently evaluating the usage of supply chain analytics systems.

- Our organization has evaluated and planned the adoption of supply chain analytics systems.

- Our organization has already adopted supply chain analytics systems.

- There is a collaboration between the production department and suppliers.

- There is a collaboration among shop-floor workers.

- There is a collaboration between the production department and other firms’ departments.

- Customers have an active role in new product development.

- Customers have an active role in the production process.

- Ability to minimize the cost of green products through process flexibility.

- Ability to reduce transportation time of green products through delivery flexibility.

- Ability to supply green products to customers by resorting to product flexibility.

- Ability to reconfigure the supply chain using flexible supply chain systems.

- Ability to introduce new alternative recycled resources through sourcing flexibility.

- Ability to reduce the waste generated from the supply chain through volume flexibility.

- Ability to increase the speed of acquiring environmental information and response to market flexibility.

- The rate at which your customer’s product/service needs change.

- The rate at which your supplier’s skills/capabilities change.

- The rate at which your competitors’ products/services change.

- The rate at which your firm’s products/services change.

- Reduction in inputs used (including energy or materials).

- Adoption of more sustainable inputs (e.g., recycled or recyclable materials).

- Move toward greener suppliers.

- Use of waste from other sectors/firms as inputs.

- Reduction in process-related environmental impacts (e.g., on air or water).

- Reduction in production waste.

- Use of the firm’s waste in the production process.

References

- World Economic Forum. SDG 13: CLIMATE ACTION—7 Surprising Facts to Know about the Circular Economy for COP26. Available online: https://www.weforum.org/agenda/2021/10/7-surprising-facts-to-know-about-the-circular-economy-for-cop26/ (accessed on 10 June 2023).

- European Parliament. How the EU Wants to Achieve a Circular Economy by 2050. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20210128STO96607/how-the-eu-wants-to-achieve-a-circular-economy-by-2050 (accessed on 10 June 2023).

- European Parliament. Waste Management in the EU: Infographic with Facts and Figures. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20180328STO00751/waste-management-in-the-eu-infographic-with-facts-and-figures (accessed on 10 June 2023).

- Ellen MacArthur Foundation. The Circular Economy in Detail—Deep Dive. Available online: https://ellenmacarthurfoundation.org/the-circular-economy-in-detail-deep-dive#:~:text=A%20circular%20economy%20is%20a,the%20consumption%20of%20finite%20resources (accessed on 10 June 2023).

- Bag, S.; Rahman, M.S. The role of capabilities in shaping sustainable supply chain flexibility and enhancing circular economy-target performance: An empirical study. Supply Chain. Manag. Int. J. 2023, 28, 162–178. [Google Scholar] [CrossRef]

- Modak, P. Circular economy practices in India. In An Introduction to Circular Economy; Springer Nature: Berlin/Heidelberg, Germany, 2021; pp. 555–575. [Google Scholar]

- Burmaoglu, S.; Ozdemir Gungor, D.; Kirbac, A.; Saritas, O. Future research avenues at the nexus of circular economy and digitalization. Int. J. Product. Perform. Manag. 2022, 1–23. [Google Scholar] [CrossRef]

- Kalogiannidis, S.; Kalfas, D.; Chatzitheodoridis, F.; Kontsas, S. The Impact of Digitalization in Supporting the Performance of Circular Economy: A Case Study of Greece. J. Risk Financ. Manag. 2022, 15, 349. [Google Scholar] [CrossRef]

- Rejeb, A.; Suhaiza, Z.; Rejeb, K.; Seuring, S.; Treiblmaier, H. The Internet of Things and the circular economy: A systematic literature review and research agenda. J. Clean. Prod. 2022, 350, 131439. [Google Scholar] [CrossRef]

- Khurshid, M.M.; Zakaria, N.H.; Rashid, A.; Shafique, M.N. Examining the factors of open government data usability from academician’s perspective. Int. J. Inf. Technol. Proj. Manag. 2018, 9, 72–85. [Google Scholar] [CrossRef]

- Khurshid, M.M.; Zakaria, N.H.; Rashid, A.; Kazmi, R.; Shafique, M.N.; Ahmad, M.N. Analyzing diffusion patterns of big open data as policy innovation in public sector. Comput. Electr. Eng. 2019, 78, 148–161. [Google Scholar] [CrossRef]

- Shafique, M.N.; Khurshid, M.M.; Rahman, H.; Khanna, A.; Gupta, D. The role of big data predictive analytics and radio frequency identification in the pharmaceutical industry. IEEE Access 2019, 7, 9013–9021. [Google Scholar] [CrossRef]

- Del Giudice, M.; Chierici, R.; Mazzucchelli, A.; Fiano, F. Supply chain management in the era of circular economy: The moderating effect of big data. Int. J. Logist. Manag. 2021, 32, 337–356. [Google Scholar] [CrossRef]

- Wilson, M.; Paschen, J.; Pitt, L. The circular economy meets artificial intelligence (AI): Understanding the opportunities of AI for reverse logistics. Manag. Environ. Qual. Int. J. 2022, 33, 9–25. [Google Scholar] [CrossRef]

- Kamewor, F.T. Effect of Industry 4.0 and Supply Chain Analytics on Innovation Performance among Agribusinesses Firms: The Mediated-Moderated Role of Circular Economy and Green Mindfulness; Kwame Nkrumah University of Science and Technology: Kumasi, Ghana, 2022. [Google Scholar]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Dora, M.; Liu, M. Big Data Analytics as a mediator in Lean, Agile, Resilient, and Green (LARG) practices effects on sustainable supply chains. Transp. Res. Part E Logist. Transp. Rev. 2021, 145, 102170. [Google Scholar] [CrossRef]

- Lee, I.; Mangalaraj, G. Big data analytics in supply chain management: A systematic literature review and research directions. Big Data Cogn. Comput. 2022, 6, 17. [Google Scholar] [CrossRef]

- Chen, D.Q.; Preston, D.S.; Swink, M. How the use of big data analytics affects value creation in supply chain management. J. Manag. Inf. Syst. 2015, 32, 4–39. [Google Scholar] [CrossRef]

- Alaskar, T.H.; Mezghani, K.; Alsadi, A.K. Examining the adoption of Big data analytics in supply chain management under competitive pressure: Evidence from Saudi Arabia. J. Decis. Syst. 2021, 30, 300–320. [Google Scholar] [CrossRef]

- Kalaitzi, D.; Tsolakis, N. Supply chain analytics adoption: Determinants and impacts on organisational performance and competitive advantage. Int. J. Prod. Econ. 2022, 248, 108466. [Google Scholar] [CrossRef]

- Yu, W.; Jacobs, M.A.; Chavez, R. Exploring the effect of business environment on supply chain integration and financial performance: An environment–system–performance paradigm. IEEE Trans. Eng. Manag. 2020, 69, 3197–3211. [Google Scholar] [CrossRef]

- Kim, M.; Chai, S. Assessing the impact of business uncertainty on supply chain integration. Int. J. Logist. Manag. 2016, 27, 463–485. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Seo, Y.-J.; Dinwoodie, J. Supply chain integration and logistics performance: The role of supply chain dynamism. Int. J. Logist. Manag. 2016, 27, 668–685. [Google Scholar] [CrossRef]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The performance effects of big data analytics and supply chain ambidexterity: The moderating effect of environmental dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Rojo, A.; Stevenson, M.; Montes, F.J.L.; Perez-Arostegui, M.N. Supply chain flexibility in dynamic environments: The enabling role of operational absorptive capacity and organisational learning. Int. J. Oper. Prod. Manag. 2018, 38, 636–666. [Google Scholar] [CrossRef] [Green Version]

- Cadden, T.; McIvor, R.; Cao, G.; Treacy, R.; Yang, Y.; Gupta, M.; Onofrei, G. Unlocking supply chain agility and supply chain performance through the development of intangible supply chain analytical capabilities. Int. J. Oper. Prod. Manag. 2022; ahead-of-print. [Google Scholar]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Kumar, S.; Bhatia, M.S. Environmental dynamism, industry 4.0 and performance: Mediating role of organizational and technological factors. Ind. Mark. Manag. 2021, 95, 54–64. [Google Scholar] [CrossRef]

- Chae, B.; Olson, D.; Sheu, C. The impact of supply chain analytics on operational performance: A resource-based view. Int. J. Prod. Res. 2014, 52, 4695–4710. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Fang, W.; Feng, T.; Gao, N. Bolstering green supply chain integration via big data analytics capability: The moderating role of data-driven decision culture. Ind. Manag. Data Syst. 2022; ahead-of-print. [Google Scholar]

- Mubarik, M.; Zuraidah, R.; Rasi, B. Triad of big data supply chain analytics, supply chain integration and supply chain performance: Evidences from oil and gas sector. Humanities 2019, 7, 209–224. [Google Scholar] [CrossRef]

- Zhu, S.; Song, J.; Hazen, B.T.; Lee, K.; Cegielski, C. How supply chain analytics enables operational supply chain transparency: An organizational information processing theory perspective. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 47–68. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A.; Jain, A. Green logistics driven circular practices adoption in industry 4.0 Era: A moderating effect of institution pressure and supply chain flexibility. J. Clean. Prod. 2023, 383, 135284. [Google Scholar] [CrossRef]

- AL-Khatib, A.W. The impact of big data analytics capabilities on green supply chain performance: Is green supply chain innovation the missing link? Bus. Process Manag. J. 2023, 29, 22–42. [Google Scholar] [CrossRef]

- Di Maria, E.; De Marchi, V.; Galeazzo, A. Industry 4.0 technologies and circular economy: The mediating role of supply chain integration. Bus. Strategy Environ. 2022, 31, 619–632. [Google Scholar] [CrossRef]

- Depietro, R.; Wiarda, E.; Fleischer, M. The context for change: Organization, technology and environment. Process. Technol. Innov. 1990, 199, 151–175. [Google Scholar]

- Baker, J. The technology–organization–environment framework. Information Systems Theory: Explaining and Predicting Our Digital Society. In Information Systems Theory; University of Hamburg: Hamburg, Germany, 2012; Volume 1, pp. 231–245. [Google Scholar]

- Alshamaila, Y.; Papagiannidis, S.; Li, F. Cloud computing adoption by SMEs in the north east of England: A multi-perspective framework. J. Enterp. Inf. Manag. 2013, 26, 250–275. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.; Le, X.C.; Vu, T.H.L. An Extended Technology-Organization-Environment (TOE) Framework for Online Retailing Utilization in Digital Transformation: Empirical Evidence from Vietnam. J. Open Innov. Technol. Mark. Complex. 2022, 8, 200. [Google Scholar] [CrossRef]

- Tweneboah-Koduah, S.; Endicott-Popovsky, B.; Tsetse, A. Barriers to government cloud adoption. Int. J. Manag. Inf. Technol. 2014, 6, 1–16. [Google Scholar] [CrossRef]

- Chiu, C.-Y.; Chen, S.; Chen, C.-L. An integrated perspective of TOE framework and innovation diffusion in broadband mobile applications adoption by enterprises. Int. J. Manag. Econ. Soc. Sci. 2017, 6, 14–39. [Google Scholar]

- Abed, S.S. Social commerce adoption using TOE framework: An empirical investigation of Saudi Arabian SMEs. Int. J. Inf. Manag. 2020, 53, 102118. [Google Scholar]

- Gangwar, H.; Date, H.; Ramaswamy, R. Developing a cloud-computing adoption framework. Glob. Bus. Rev. 2015, 16, 632–651. [Google Scholar]

- Malik, S.; Chadhar, M.; Vatanasakdakul, S.; Chetty, M. Factors affecting the organizational adoption of blockchain technology: Extending the technology–organization–environment (TOE) framework in the Australian context. Sustainability 2021, 13, 9404. [Google Scholar] [CrossRef]

- Leung, D.; Lo, A.; Fong, L.H.N.; Law, R. Applying the Technology-Organization-Environment framework to explore ICT initial and continued adoption: An exploratory study of an independent hotel in Hong Kong. Tour. Recreat. Res. 2015, 40, 391–406. [Google Scholar] [CrossRef]

- Cruz-Jesus, F.; Pinheiro, A.; Oliveira, T. Understanding CRM adoption stages: Empirical analysis building on the TOE framework. Comput. Ind. 2019, 109, 1–13. [Google Scholar]

- Tornatzky, L.G.; Fleischer, M.; Chakrabarti, A.K. Processes of Technological Innovation; Lexington Books; Rowman & Littlefield: Lanham, MD, USA, 1990. [Google Scholar]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Helfat, C.E.; Peteraf, M.A. The dynamic resource-based view: Capability lifecycles. Strateg. Manag. J. 2003, 24, 997–1010. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar]

- Eisenhardt, K.M.; Martin, J.A. Dynamic capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar]

- Mikalef, P.; Krogstie, J.; Pappas, I.O.; Pavlou, P. Exploring the relationship between big data analytics capability and competitive performance: The mediating roles of dynamic and operational capabilities. Inf. Manag. 2020, 57, 103169. [Google Scholar]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar]

- Fainshmidt, S.; Pezeshkan, A.; Lance Frazier, M.; Nair, A.; Markowski, E. Dynamic capabilities and organizational performance: A meta-analytic evaluation and extension. J. Manag. Stud. 2016, 53, 1348–1380. [Google Scholar]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar]

- Webster, K. The Circular Economy: A Wealth of Flows; MacArthur, E., Stahel, W., Eds.; Ellen MacArthur Foundation Publishing: Cowes, UK, 2017. [Google Scholar]

- Agency, E.E. Circular Economy in Europe—Developing the Knowledge Base; EEA Report NO 2/2016; European Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- Batista, L.; Bourlakis, M.; Liu, Y.; Smart, P.; Sohal, A. Supply chain operations for a circular economy. Prod. Plan. Control 2018, 29, 419–424. [Google Scholar] [CrossRef]

- Fehrer, J.A.; Wieland, H. A systemic logic for circular business models. J. Bus. Res. 2021, 125, 609–620. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar]

- Chae, B.; Olson, D.L. Business analytics for supply chain: A dynamic-capabilities framework. Int. J. Inf. Technol. Decis. Mak. 2013, 12, 9–26. [Google Scholar] [CrossRef] [Green Version]

- Wamba, S.F.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘big data’can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Oliveira, T.; Martins, M.F. Understanding e-business adoption across industries in European countries. Ind. Manag. Data Syst. 2010, 110, 1337–1354. [Google Scholar] [CrossRef]

- Wang, Y.-M.; Wang, Y.-S.; Yang, Y.-F. Understanding the determinants of RFID adoption in the manufacturing industry. Technol. Forecast. Soc. Chang. 2010, 77, 803–815. [Google Scholar]

- Arya, V.; Sharma, P.; Singh, A.; De Silva, P. An exploratory study on supply chain analytics applied to spare parts supply chain. Benchmarking Int. J. 2017, 24, 1571–1580. [Google Scholar]

- Barbosa, M.W.; Ladeira, M.B.; de la Calle Vicente, A. An analysis of international coauthorship networks in the supply chain analytics research area. Scientometrics 2017, 111, 1703–1731. [Google Scholar]

- Chae, B.; Yang, C.; Olson, D.; Sheu, C. The impact of advanced analytics and data accuracy on operational performance: A contingent resource based theory (RBT) perspective. Decis. Support Syst. 2014, 59, 119–126. [Google Scholar]

- Hsu, P.-F.; Ray, S.; Li-Hsieh, Y.-Y. Examining cloud computing adoption intention, pricing mechanism, and deployment model. Int. J. Inf. Manag. 2014, 34, 474–488. [Google Scholar]

- Barbosa, M.W.; de la Calle Vicente, A.; Ladeira, M.B.; de Oliveira, M.P.V. Managing supply chain resources with Big Data Analytics: A systematic review. Int. J. Logist. Res. Appl. 2018, 21, 177–200. [Google Scholar]

- Schwartz, S. How Global Companies Factor Their Supply Chain into Data Protection, Privacy. Available online: https://www.ciodive.com/news/forrester-privacy-shield-data-protection/585846/ (accessed on 10 June 2023).

- Herden, T.T.; Nitsche, B.; Gerlach, B. Overcoming Barriers in Supply Chain Analytics—Investigating Measures in LSCM Organizations. Logistics 2020, 4, 5. [Google Scholar]

- DHL Data Protection and Its Legal Implications on Logistics. Available online: https://lot.dhl.com/data-protection-and-its-legal-implications-on-logistics/ (accessed on 10 June 2023).

- OECD. Enhancing Access to and Sharing of Data: Reconciling Risks and Benefits for Data Re-Use across Societies; OECD: Paris, France, 2019. [Google Scholar]

- Bhatiasevi, V.; Naglis, M. Elucidating the determinants of business intelligence adoption and organizational performance. Inf. Dev. 2020, 36, 78–96. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Wamba, S.F.; Childe, S.J.; Hazen, B.; Akter, S. Big data and predictive analytics for supply chain and organizational performance. J. Bus. Res. 2017, 70, 308–317. [Google Scholar]

- Shafique, M.N.; Raudeliūnienė, J.; Davidaviciene, V.; Penčik, J. Acceptance of intelligent ticketing systems in developing countries. Eng. Econ. 2019, 30, 451–460. [Google Scholar] [CrossRef]

- Shafique, M.N.; Khurshid, M.M.; Rahman, H.; Khanna, A.; Gupta, D.; Rodrigues, J.J. The role of wearable technologies in supply chain collaboration: A case of pharmaceutical industry. IEEE Access 2019, 7, 49014–49026. [Google Scholar] [CrossRef]

- Bowers, M.R.; Petrie, A.; Holcomb, M.C. Unleashing the potential of supply chain analytics. MIT Sloan Manag. Rev. 2017, 59, 14. [Google Scholar]

- Srinivasan, R.; Swink, M. An investigation of visibility and flexibility as complements to supply chain analytics: An organizational information processing theory perspective. Prod. Oper. Manag. 2018, 27, 1849–1867. [Google Scholar]

- Tiwari, S.; Wee, H.-M.; Daryanto, Y. Big data analytics in supply chain management between 2010 and 2016: Insights to industries. Comput. Ind. Eng. 2018, 115, 319–330. [Google Scholar]

- Fosso Wamba, S.; Akter, S. Understanding supply chain analytics capabilities and agility for data-rich environments. Int. J. Oper. Prod. Manag. 2019, 39, 887–912. [Google Scholar]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar]

- Shi, H.; Feng, T.; Zhu, Z. The impact of big data analytics capability on green supply chain integration: An organizational information processing theory perspective. Bus. Process Manag. J. 2023, 29, 550–577. [Google Scholar]

- Alkhatib, A.W. Fostering green innovation: The roles of big data analytics capabilities and green supply chain integration. Eur. J. Innov. Manag. 2023. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar]

- Rezaei, G.; Hosseini, S.M.H.; Sana, S.S. Exploring the Relationship between Data Analytics Capability and Competitive Advantage: The Mediating Roles of Supply Chain Resilience and Organization Flexibility. Sustainability 2022, 14, 10444. [Google Scholar] [CrossRef]

- Sood, G.; Jain, R.K. Organisational enablers of advanced analytics adoption for supply chain flexibility and agility. Int. J. Bus. Inf. Syst. 2022, 41, 379–407. [Google Scholar] [CrossRef]

- Edwin Cheng, T.; Kamble, S.S.; Belhadi, A.; Ndubisi, N.O.; Lai, K.-h.; Kharat, M.G. Linkages between big data analytics, circular economy, sustainable supply chain flexibility, and sustainable performance in manufacturing firms. Int. J. Prod. Res. 2022, 60, 6908–6922. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.; McAloone, T.C. The emergent role of digital technologies in the Circular Economy: A review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Awan, U.; Shamim, S.; Khan, Z.; Zia, N.U.; Shariq, S.M.; Khan, M.N. Big data analytics capability and decision-making: The role of data-driven insight on circular economy performance. Technol. Forecast. Soc. Chang. 2021, 168, 120766. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Chang. 2021, 163, 120420. [Google Scholar]

- Schilke, O. On the contingent value of dynamic capabilities for competitive advantage: The nonlinear moderating effect of environmental dynamism. Strateg. Manag. J. 2014, 35, 179–203. [Google Scholar]

- De Haas, M.; Faber, R.; Hamersma, M. How COVID-19 and the Dutch ‘intelligent lockdown’change activities, work and travel behaviour: Evidence from longitudinal data in The Netherlands. Transp. Res. Interdiscip. Perspect. 2020, 6, 100150. [Google Scholar] [PubMed]

- Sheth, J. Business of business is more than business: Managing during the COVID crisis. Ind. Mark. Manag. 2020, 88, 261–264. [Google Scholar] [CrossRef]

- Oehmen, J.; Locatelli, G.; Wied, M.; Willumsen, P. Risk, uncertainty, ignorance and myopia: Their managerial implications for B2B firms. Ind. Mark. Manag. 2020, 88, 330–338. [Google Scholar]

- Shafique, M.N.; Rashid, A.; Bajwa, I.S.; Kazmi, R.; Khurshid, M.M.; Tahir, W.A. Effect of IoT capabilities and energy consumption behavior on green supply chain integration. Appl. Sci. 2018, 8, 2481. [Google Scholar]

- Alfalla-Luque, R.; Medina-Lopez, C.; Dey, P.K. Supply chain integration framework using literature review. Prod. Plan. Control 2013, 24, 800–817. [Google Scholar] [CrossRef] [Green Version]

- Ataseven, C.; Nair, A. Assessment of supply chain integration and performance relationships: A meta-analytic investigation of the literature. Int. J. Prod. Econ. 2017, 185, 252–265. [Google Scholar]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar]

- De los Rios, I.C.; Charnley, F.J. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar]

- Yuan, S.; Pan, X. The effects of digital technology application and supply chain management on corporate circular economy: A dynamic capability view. J. Environ. Manag. 2023, 341, 118082. [Google Scholar]

- Grosvold, J.; Hoejmose, S.U.; Roehrich, J.K. Squaring the circle: Management, measurement and performance of sustainability in supply chains. Supply Chain. Manag. Int. J. 2014, 19, 292–305. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J.; Shibin, K.; Wamba, S.F. Sustainable supply chain management: Framework and further research directions. J. Clean. Prod. 2017, 142, 1119–1130. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.M.; Rha, J.S. Ambidextrous supply chain as a dynamic capability: Building a resilient supply chain. Manag. Decis. 2016, 54, 2–23. [Google Scholar] [CrossRef]

- Yao, J.; Zhu, S.; Cui, P. Study on flexible remanufacturing system and framework. In Proceedings of the 2010 International Conference on Intelligent Computation Technology and Automation, Changsha, China, 11–12 May 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 516–519. [Google Scholar]

- Bai, C.; Sarkis, J.; Yin, F.; Dou, Y. Sustainable supply chain flexibility and its relationship to circular economy-target performance. Int. J. Prod. Res. 2020, 58, 5893–5910. [Google Scholar] [CrossRef]

- Shafique, M.; Asghar, M.; Rahman, H. The impact of green supply chain management practices on performance: Moderating role of institutional pressure with mediating effect of green innovation. Bus. Manag. Econ. Eng. 2017, 15, 91–108. [Google Scholar]

- Nawaz, M.Z.; Nawaz, S.; Shafique, M.N.; Ali, M.; Ishfaq, M. The Role of Organizational Strategies, Social Support, and Technological Capabilities in International Marketing Channel Performance. Sarhad J. Manag. Sci. 2019, 5, 87–102. [Google Scholar] [CrossRef]

- Khan, A.; Ahmed, H.; Shafique, M.N.; Yusuf, M.Z.; Alam, F. The Interconnections of Green Motives and Corporate Social Performance: The Mediating Role of Green Practices. Sarhad J. Manag. Sci. 2020, 6, 163–186. [Google Scholar]

- Siagian, H.; Tarigan, Z.J.H.; Jie, F. Supply chain integration enables resilience, flexibility, and innovation to improve business performance in COVID-19 era. Sustainability 2021, 13, 4669. [Google Scholar] [CrossRef]

- Khanuja, A.; Jain, R.K. The mediating effect of supply chain flexibility on the relationship between supply chain integration and supply chain performance. J. Enterp. Inf. Manag. 2022, 35, 1548–1569. [Google Scholar] [CrossRef]

- Amini, M.; Jahanbakhsh Javid, N. A Multi-Perspective Framework Established on Diffusion of Innovation (DOI) Theory and Technology, Organization and Environment (TOE) Framework Toward Supply Chain Management System Based on Cloud Computing Technology for Small and Medium Enterprises. Organization and Environment (TOE) Framework Toward Supply Chain Management System Based on Cloud Computing Technology for Small and Medium Enterprises (January 2023). Int. J. Inf. Technol. Innov. Adopt. 2023, 11, 1217–1234. [Google Scholar]

- Lai, Y.; Sun, H.; Ren, J. Understanding the determinants of big data analytics (BDA) adoption in logistics and supply chain management: An empirical investigation. Int. J. Logist. Manag. 2018, 29, 676–703. [Google Scholar] [CrossRef]

- Amini, M.; Bakri, A.; Sadat Safavi, N.; Javadinia, S.A.; Tolooei, A. The role of top manager behaviours on adoption of cloud computing for small and medium enterprises. Aust. J. Basic Appl. Sci. 2014, 8, 490–498. [Google Scholar]

- Koufteros, X.A.; Cheng, T.E.; Lai, K.-H. “Black-box” and “gray-box” supplier integration in product development: Antecedents, consequences and the moderating role of firm size. J. Oper. Manag. 2007, 25, 847–870. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Del Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strategy Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.-G. Statistical power analyses using G* Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; Tao, M.; Ahmad, H.; Shafique, M.N.; Nawaz, M.Z. Revisiting green supply chain management practices: The mediating role of emotional intelligence. SAGE Open 2020, 10, 2158244020914637. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Nitzl, C.; Roldan, J.L.; Cepeda, G. Mediation analysis in partial least squares path modeling: Helping researchers discuss more sophisticated models. Ind. Manag. Data Syst. 2016, 116, 1849–1864. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Thousand Oaks, CA, USA, 2021. [Google Scholar]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Routledge: Oxfordshire, UK, 2013. [Google Scholar]

- Henseler, J.; Sarstedt, M. Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef] [Green Version]

- Tenenhaus, M.; Amato, S.; Esposito Vinzi, V. A global goodness-of-fit index for PLS structural equation modelling. In Proceedings of the XLII SIS Scientific Meeting, Padova, Italy, 9–11 June 2004; CLEUP: Padova, Italy, 2004; pp. 739–742. [Google Scholar]

- Lohmöller, J.-B. Latent Variable Path Modeling with Partial Least Squares; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hu, L.-T.; Bentler, P.M. Fit indices in covariance structure modeling: Sensitivity to underparameterized model misspecification. Psychol. Methods 1998, 3, 424. [Google Scholar] [CrossRef]

- Sheela, K.G.; Deepa, S.N. Review on methods to fix number of hidden neurons in neural networks. Math. Probl. Eng. 2013, 2013, 425740. [Google Scholar] [CrossRef] [Green Version]

- Zafar, A.U.; Shen, J.; Shahzad, M.; Islam, T. Relation of impulsive urges and sustainable purchase decisions in the personalized environment of social media. Sustain. Prod. Consum. 2021, 25, 591–603. [Google Scholar] [CrossRef]

- Shahzad, M.; Qu, Y.; Rehman, S.U.; Zafar, A.U. Adoption of green innovation technology to accelerate sustainable development among manufacturing industry. J. Innov. Knowl. 2022, 7, 100231. [Google Scholar] [CrossRef]

- Leong, L.-Y.; Jaafar, N.I.; Ainin, S. The effects of Facebook browsing and usage intensity on impulse purchase in f-commerce. Comput. Hum. Behav. 2018, 78, 160–173. [Google Scholar] [CrossRef]

- Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B.; Dwivedi, Y.K. Artificial intelligence-driven risk management for enhancing supply chain agility: A deep-learning-based dual-stage PLS-SEM-ANN analysis. Int. J. Prod. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Chong, A.Y.-L.; Liu, M.J.; Luo, J.; Keng-Boon, O. Predicting RFID adoption in healthcare supply chain from the perspectives of users. Int. J. Prod. Econ. 2015, 159, 66–75. [Google Scholar] [CrossRef]

- Zhou, J.; Shafique, M.N.; Adeel, A.; Nawaz, S.; Kumar, P. What is theoretical contribution? A narrative review. Sarhad J. Manag. Sci. 2017, 3, 261–271. [Google Scholar] [CrossRef] [Green Version]

| Constructs | Factor Loadings | VIF |

|---|---|---|

| Data Integrity and Scalability (α = 0.800, CR = 0.861, AVE = 0.555) | ||

| DIS1 | 0.728 | 1.610 |

| DIS2 | 0.768 | 1.662 |

| DIS3 | 0.820 | 1.731 |

| DIS4 | 0.668 | 1.453 |

| DIS5 | 0.735 | 1.475 |

| Organizational Readiness (α = 0.867, CR = 0.900, AVE = 0.600) | ||

| OR1 | 0.772 | 1.826 |

| OR2 | 0.734 | 1.713 |

| OR3 | 0.761 | 1.836 |

| OR4 | 0.814 | 2.16 |

| OR5 | 0.808 | 1.951 |

| OR6 | 0.755 | 1.715 |

| Policies and Regulations (α = 0.761, CR = 0.862, AVE = 0.677) | ||

| PR1 | 0.786 | 1.427 |

| PR2 | 0.849 | 1.663 |

| PR3 | 0.832 | 1.595 |

| Environmental Dynamism (α = 0.780, CR = 0.858, AVE = 0.602) | ||

| ED1 | 0.762 | 1.553 |

| ED2 | 0.780 | 1.524 |

| ED3 | 0.775 | 1.542 |

| ED4 | 0.787 | 1.551 |

| Supply Chain Analytics Adoption (α = 0.719, CR = 0.843, AVE = 0.641) | ||

| SCAA1 | 0.803 | 1.442 |

| SCAA2 | 0.840 | 1.575 |

| SCAA3 | 0.757 | 1.32 |

| Supply Chain Integration (α = 0.855, CR = 0.896, AVE = 0.633) | ||

| SCI1 | 0.830 | 2.030 |

| SCI2 | 0.790 | 1.792 |

| SCI3 | 0.770 | 1.702 |

| SCI4 | 0.793 | 1.840 |

| SCI5 | 0.795 | 1.863 |

| Sustainable Supply Chain Flexibility (α = 0.874, CR = 0.903, AVE = 0.570) | ||

| SSCF1 | 0.746 | 1.802 |

| SSCF2 | 0.773 | 1.890 |

| SSCF3 | 0.729 | 1.707 |

| SSCF4 | 0.757 | 1.877 |

| SSCF5 | 0.737 | 1.761 |

| SSCF6 | 0.787 | 1.986 |

| SSCF7 | 0.753 | 1.803 |

| Circular Economy (α = 0.901, CR = 0.922, AVE = 0.627) | ||

| CE1 | 0.811 | 2.281 |

| CE2 | 0.778 | 1.916 |

| CE3 | 0.79 | 2.072 |

| CE4 | 0.804 | 2.172 |

| CE5 | 0.791 | 2.103 |

| CE6 | 0.813 | 2.179 |

| CE7 | 0.753 | 1.809 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|

| 1. CE | 0.792 | |||||||

| 2. DIS | 0.581 | 0.745 | ||||||

| 3. ED | 0.633 | 0.364 | 0.776 | |||||

| 4. OR | 0.715 | 0.543 | 0.530 | 0.774 | ||||

| 5. PR | 0.578 | 0.602 | 0.389 | 0.514 | 0.823 | |||

| 6. SCAA | 0.618 | 0.573 | 0.530 | 0.587 | 0.611 | 0.801 | ||

| 7. SCI | 0.745 | 0.641 | 0.491 | 0.638 | 0.543 | 0.582 | 0.796 | |

| 8. SSCF | 0.702 | 0.602 | 0.701 | 0.674 | 0.503 | 0.674 | 0.678 | 0.755 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|

| 1. CE | ||||||||

| 2. DIS | 0.681 | |||||||

| 3. ED | 0.753 | 0.458 | ||||||

| 4. OR | 0.806 | 0.644 | 0.642 | |||||

| 5. PR | 0.698 | 0.771 | 0.506 | 0.625 | ||||

| 6. SCAA | 0.766 | 0.743 | 0.709 | 0.736 | 0.826 | |||

| 7. SCI | 0.848 | 0.781 | 0.596 | 0.739 | 0.674 | 0.74 | ||

| 8. SSCF | 0.789 | 0.713 | 0.846 | 0.771 | 0.614 | 0.848 | 0.785 |

| Hypotheses | Β | T Values | p Values |

|---|---|---|---|

| DIS → SCAA | 0.210 | 2.526 | 0.012 |

| ED → SCI | 0.333 | 3.697 | 0.000 |

| ED → SSCF | 0.476 | 5.803 | 0.000 |

| Moderating Effect 1 → SCI | 0.151 | 2.391 | 0.017 |

| Moderating Effect 2 → SSCF | 0.131 | 2.383 | 0.018 |

| OR → SCAA | 0.304 | 3.354 | 0.001 |

| PR → SCAA | 0.328 | 4.222 | 0.000 |

| SCAA → CE | 0.159 | 1.895 | 0.059 |

| SCAA → SCI | 0.524 | 7.332 | 0.000 |

| SCAA → SSCF | 0.357 | 4.504 | 0.000 |

| SCI → CE | 0.461 | 4.229 | 0.000 |

| SCI → SSCF | 0.289 | 3.509 | 0.000 |

| SSCF → CE | 0.282 | 2.433 | 0.015 |

| Mediations | Direct β | Indirect β | Total β | VAF | Mediation Type |

|---|---|---|---|---|---|

| SCAA → SCI → CE | 0.159 | 0.241 | 0.401 | 0.603 | Partial Mediation |

| SCAA → SSCF → CE | 0.159 | 0.101 | 0.260 | 0.388 | Partial Mediation |

| SCI → SSCF → CE | 0.461 | 0.081 | 0.542 | 0.150 | No Mediation |

| Endogenous Variables | R2 | Q2 | Exogenous Variables | F2 |

|---|---|---|---|---|

| Supply Chain Analytical Adoption | 0.5 | 0.305 | Data Integrity and Scalability | 0.05 |

| Organizational Readiness | 0.12 | |||

| Policy and Regulation | 0.126 | |||

| Supply Chain Integration | 0.41 | 0.247 | Supply Chain Analytical Adoption | 0.286 |

| Environmental Dynamism | 0.114 | |||

| Sustainable Supply Chain Flexibility | 0.701 | 0.384 | Supply Chain Integration | 0.164 |

| Supply Chain Analytical Adoption | 0.205 | |||

| Environmental Dynamism | 0.411 | |||

| Circular Economy | 0.64 | 0.395 | Sustainable Supply Chain Flexibility | 0.093 |

| Supply Chain Integration | 0.301 | |||

| Supply Chain Analytical Adoption | 0.036 |

| Constructs | AVE | R Square |

|---|---|---|

| CE | 0.627 | 0.640 |

| SCAA | 0.641 | 0.500 |

| SCI | 0.633 | 0.410 |

| SSCF | 0.570 | 0.701 |

| 0.618 | 0.56275 | |

| Goodness of Fit | 0.585 |

| Neural Network | Model 1 | Model 2 | Model 3 | Model 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Input Covariates: | Input Covariates: | Input Covariates: | Input Covariates: | |||||

| DIS, OR, PR | SCAA, ED | SCAA, ED, SCI | DIS, OR, PR, SCAA, ED, SSCF, SCI | |||||

| Output: SCAA | Output: SCI | Output: SSCF | Output: CE | |||||

| Training | Test | Training | Test | Training | Test | Training | Test | |

| ANN1 | 0.111 | 0.107 | 0.138 | 0.164 | 0.105 | 0.093 | 0.113 | 0.119 |

| ANN2 | 0.112 | 0.117 | 0.152 | 0.128 | 0.090 | 0.120 | 0.116 | 0.109 |

| ANN3 | 0.121 | 0.097 | 0.152 | 0.133 | 0.099 | 0.100 | 0.105 | 0.108 |

| ANN4 | 0.111 | 0.115 | 0.144 | 0.181 | 0.106 | 0.104 | 0.102 | 0.116 |

| ANN5 | 0.116 | 0.091 | 0.144 | 0.150 | 0.105 | 0.113 | 0.120 | 0.101 |

| ANN6 | 0.110 | 0.114 | 0.138 | 0.148 | 0.091 | 0.120 | 0.119 | 0.112 |

| ANN7 | 0.105 | 0.113 | 0.155 | 0.125 | 0.104 | 0.096 | 0.097 | 0.138 |

| ANN8 | 0.115 | 0.105 | 0.155 | 0.130 | 0.096 | 0.111 | 0.108 | 0.132 |

| ANN9 | 0.112 | 0.111 | 0.148 | 0.141 | 0.111 | 0.071 | 0.108 | 0.126 |

| ANN10 | 0.114 | 0.106 | 0.138 | 0.166 | 0.097 | 0.103 | 0.123 | 0.080 |

| Average | 0.113 | 0.108 | 0.146 | 0.147 | 0.100 | 0.103 | 0.111 | 0.114 |

| Predictor | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|

| Input Covariates: | Input Covariates: | Input Covariates: | Input Covariates: | |

| DIS, OR, PR | SCAA, ED | SCAA, ED, SCI | DIS, OR, PR, SCAA, ED, SSCF, SCI | |

| Output: SCAA | Output: SCI | Output: SSCF | Output: CE | |

| DIS | 74.63 | 33.3 | ||

| OR | 76.55 | 99.47 | ||

| PR | 100 | 46.23 | ||

| SCAA | 100 | 79.66 | 35.45 | |

| ED | 83.8 | 100 | 86.36 | |

| SCI | 60.73 | 100 | ||

| SSCF | 54.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafique, M.N.; Rashid, A.; Yeo, S.F.; Adeel, U. Transforming Supply Chains: Powering Circular Economy with Analytics, Integration and Flexibility Using Dual Theory and Deep Learning with PLS-SEM-ANN Analysis. Sustainability 2023, 15, 11979. https://doi.org/10.3390/su151511979

Shafique MN, Rashid A, Yeo SF, Adeel U. Transforming Supply Chains: Powering Circular Economy with Analytics, Integration and Flexibility Using Dual Theory and Deep Learning with PLS-SEM-ANN Analysis. Sustainability. 2023; 15(15):11979. https://doi.org/10.3390/su151511979

Chicago/Turabian StyleShafique, Muhammad Noman, Ammar Rashid, Sook Fern Yeo, and Umar Adeel. 2023. "Transforming Supply Chains: Powering Circular Economy with Analytics, Integration and Flexibility Using Dual Theory and Deep Learning with PLS-SEM-ANN Analysis" Sustainability 15, no. 15: 11979. https://doi.org/10.3390/su151511979

APA StyleShafique, M. N., Rashid, A., Yeo, S. F., & Adeel, U. (2023). Transforming Supply Chains: Powering Circular Economy with Analytics, Integration and Flexibility Using Dual Theory and Deep Learning with PLS-SEM-ANN Analysis. Sustainability, 15(15), 11979. https://doi.org/10.3390/su151511979