Expanded Clay Production Waste as Supplementary Cementitious Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparations

2.3. Testing Methods

3. Results and Discussion

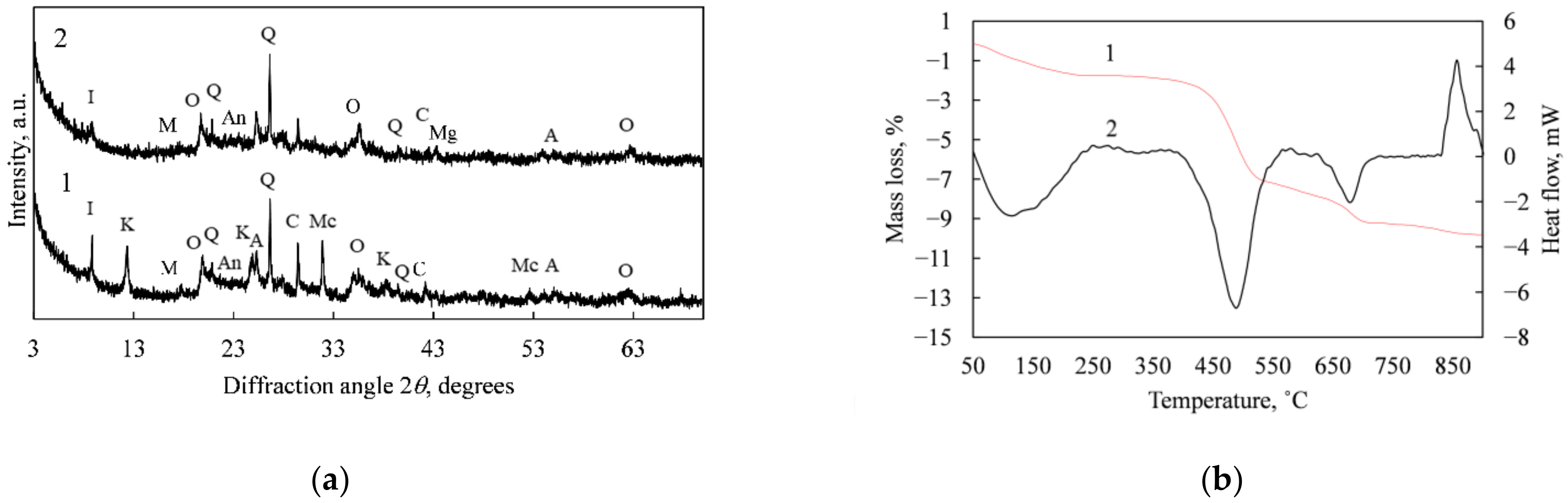

3.1. Thermal Reactivation of the Waste

3.2. The Influence of the Waste on Cement Paste Properties

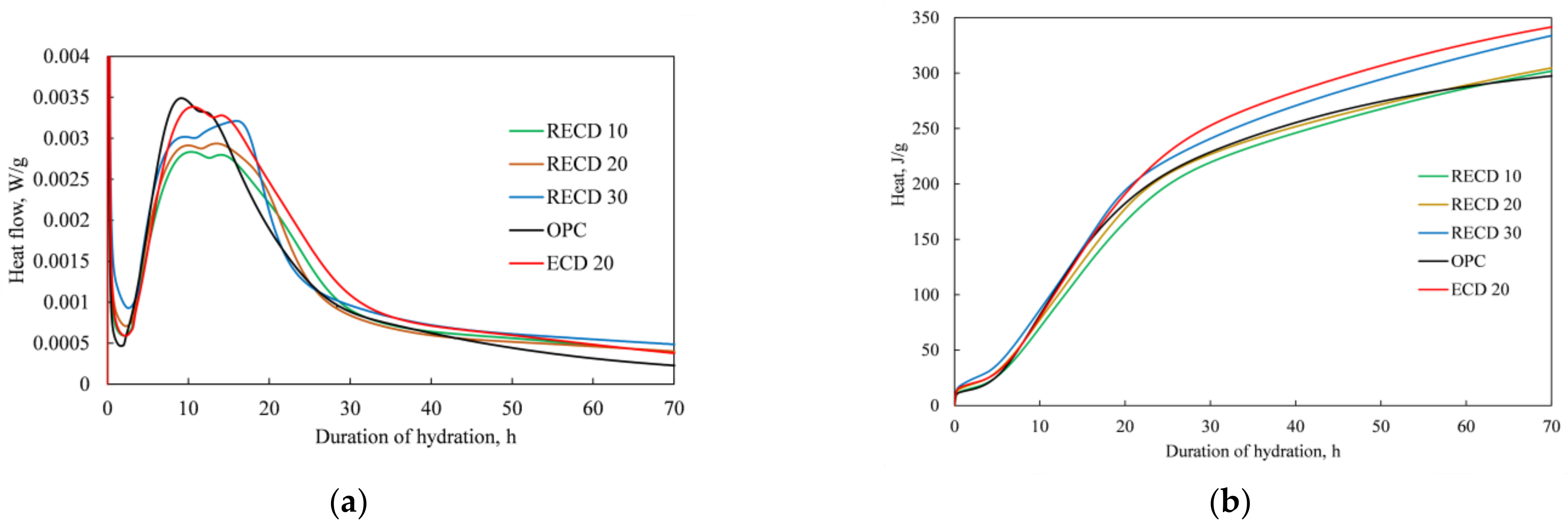

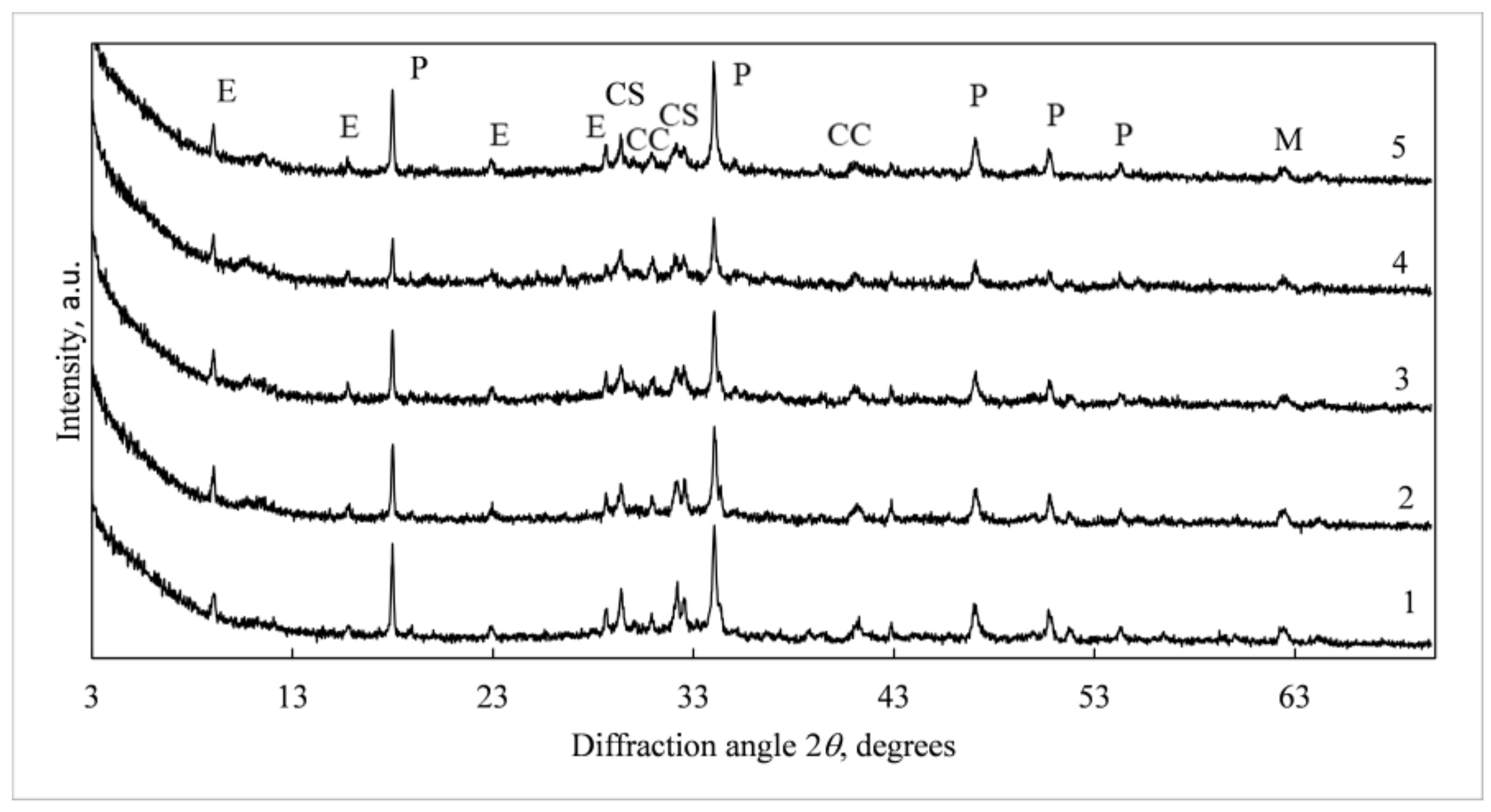

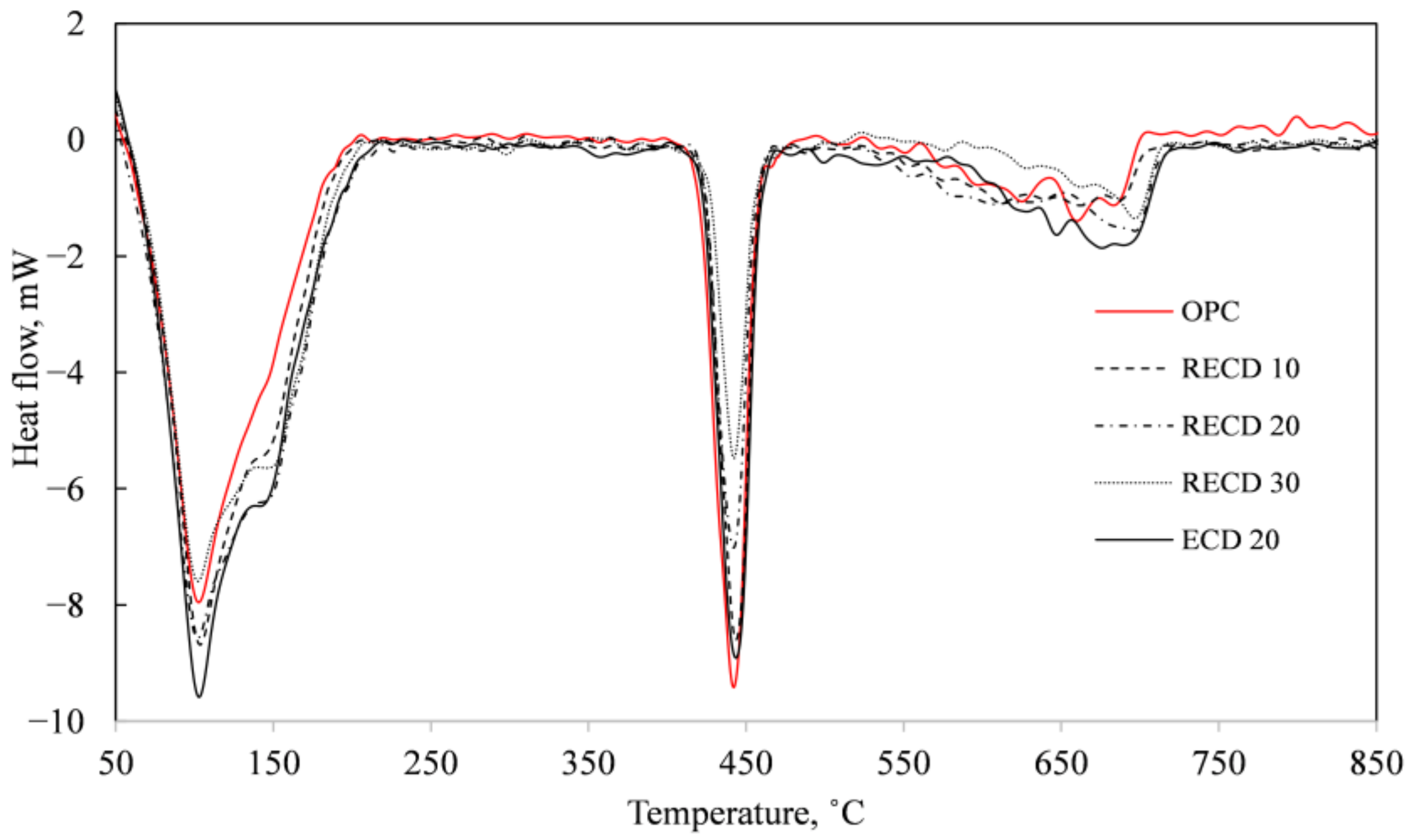

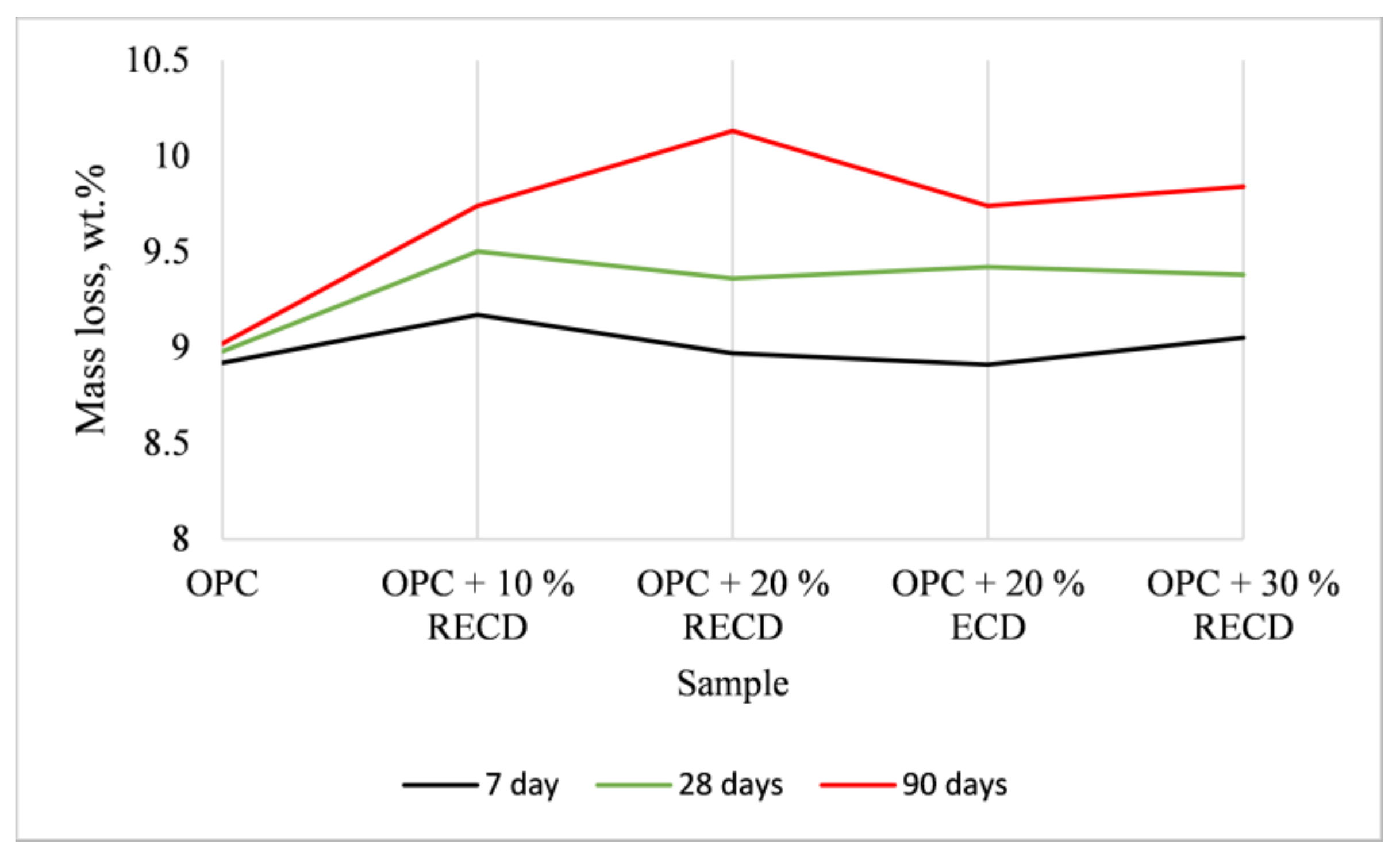

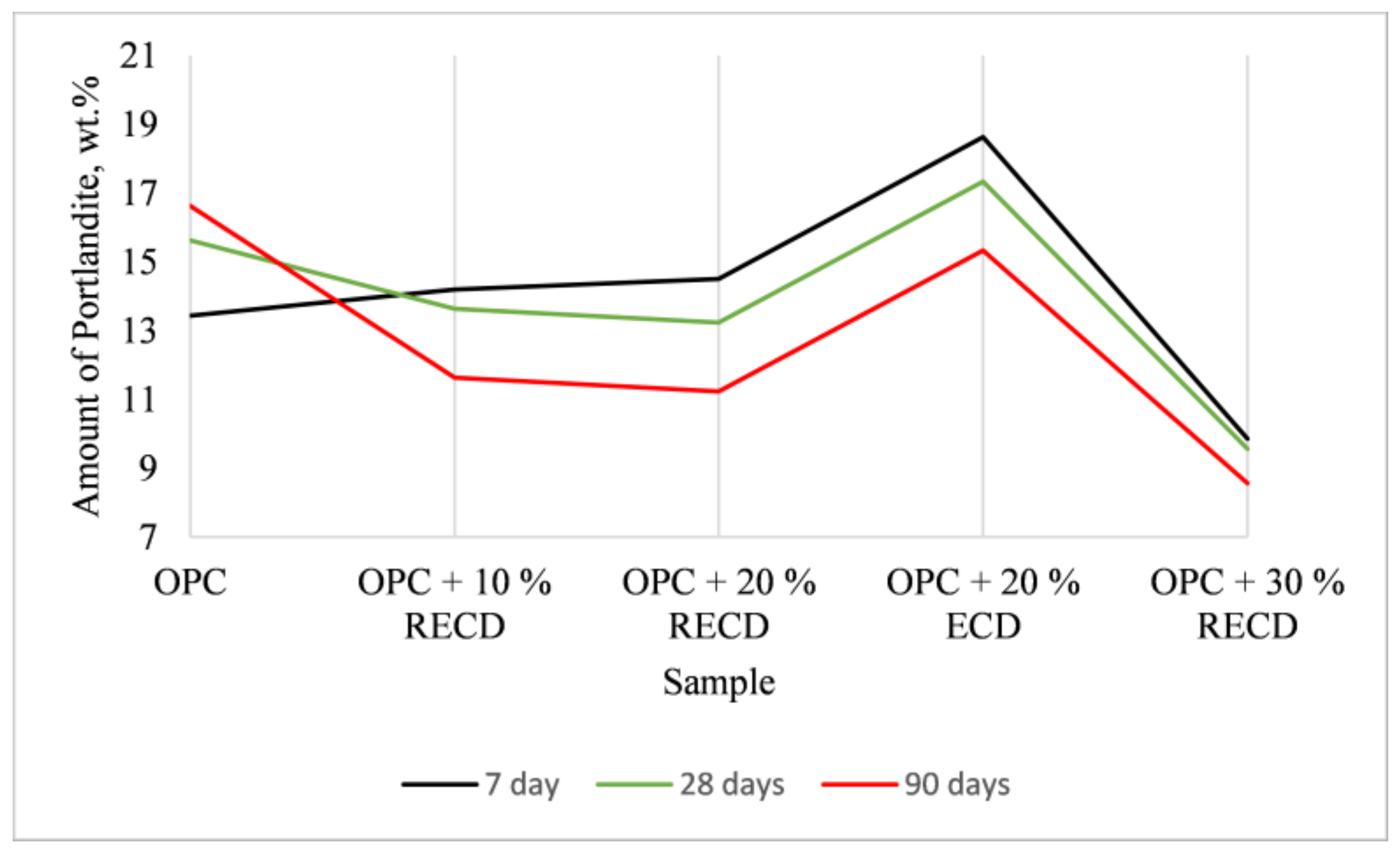

3.3. The Influence of the Waste on Portland Cement Hydration and Hardening

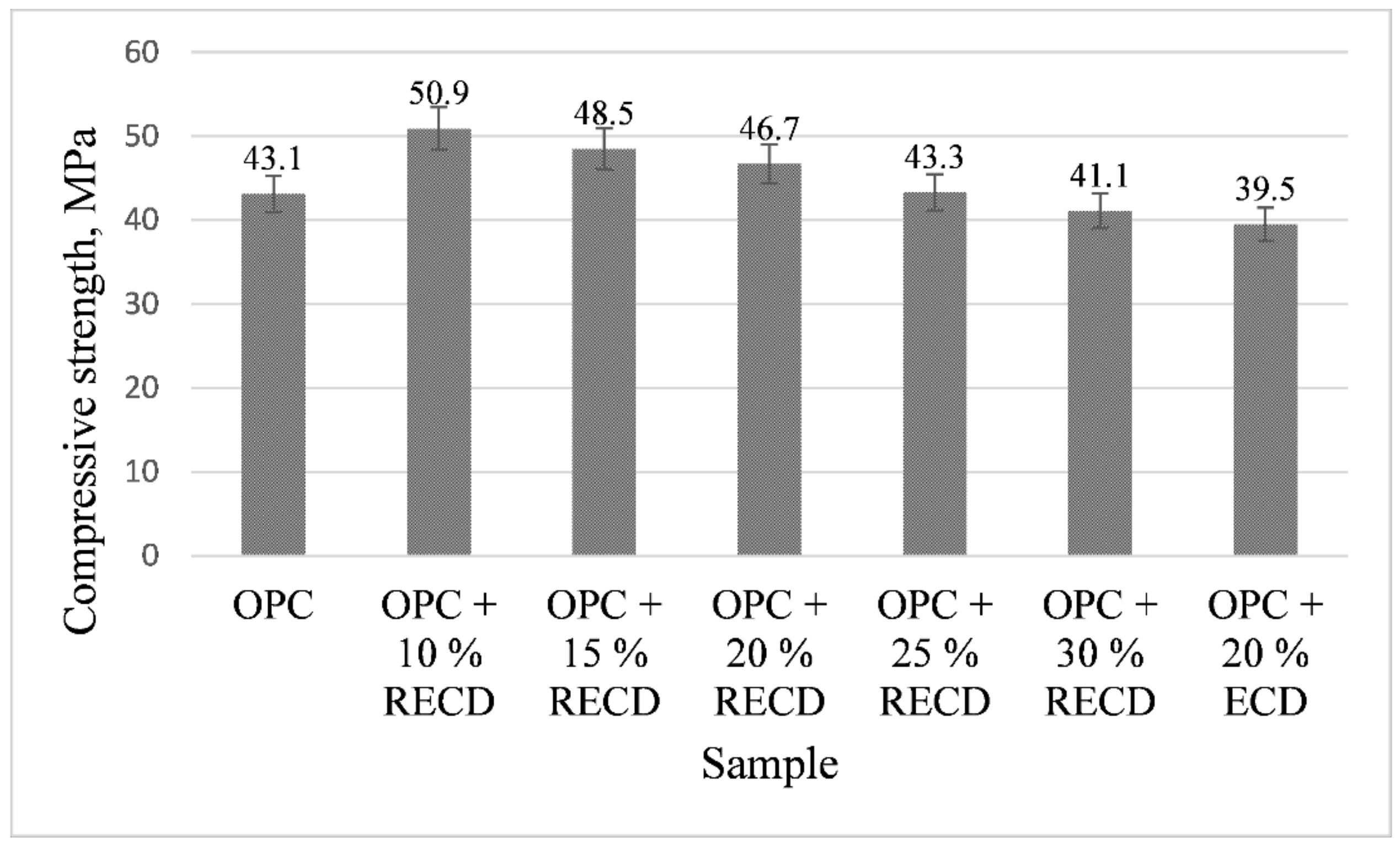

4. Conclusions

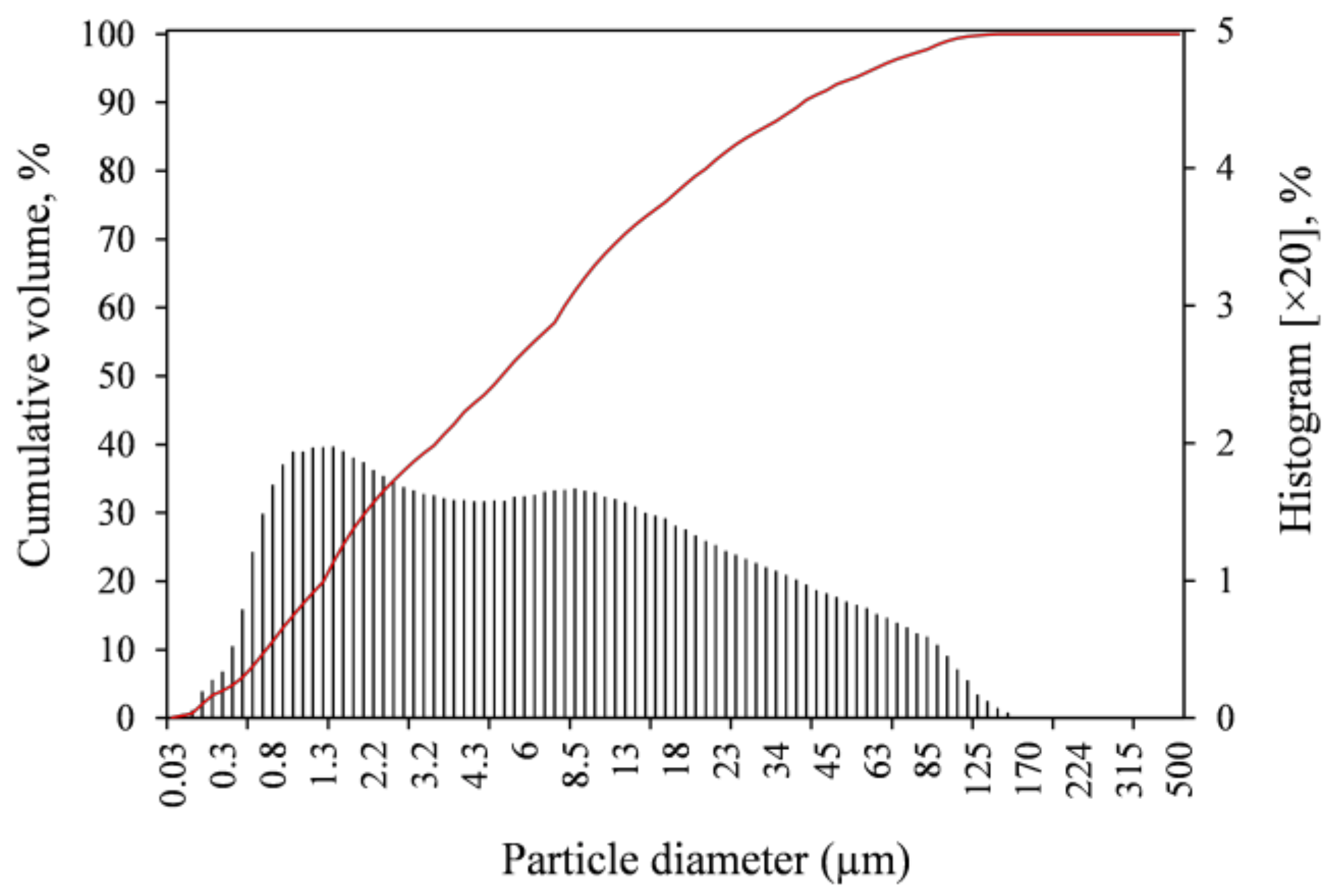

- The dust collected in e-filters during the expanded clay calcining process consists of clay minerals (kaolinite, illite and muscovite), impurities (anorthite, calcite, anatase, quartz, magnesite and olivine) and amorphous compounds. The mean diameter of the particles of this dust is 19.99 μm, and its pozzolanic activity reaches 626 mg CaO/g.

- The additional thermal activation at 600 °C temperature increases the pozzolanic activity and the amount of amorphous phases of the tested waste.

- Both additives—thermally activated and nonactivated—accelerate the hydration of cement, especially the hydration reactions of the aluminate-bearing phase, and have a double effect on cement hydration—specifically, the pozzolanic reaction and the accelerated hydration of calcium silicates occur simultaneously.

- The addition of up to 25 wt.% of activated expanded clay kiln dust waste leads to a higher compressive strength of the samples of Portland cement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G.A. Sustainable Future for the European Cement and Concrete Industry: Technology Assessment for Full Decarbonisation of the Industry by 2050; ETH Zurich: Zurich, Switzerland, 2018. [Google Scholar] [CrossRef]

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary Cementitious Materials. Rev. Mineral. Geochem. 2012, 74, 211–278. [Google Scholar] [CrossRef]

- Scrivener, K.; Gartner, E. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, H.B. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Costa, C.; Baneviciene, V.; Antonovic, V.; Vaiciene, M. The effect of nano SiO2 and spent fluid catalytic cracking catalyst on cement hydration and physical mechanical properties. Constr. Build. Mater. 2021, 299, 124281. [Google Scholar] [CrossRef]

- Baiee, A. Development of ultra-high strength cementitious characteristics using supplementary cementitious materials. J. Eng. Sci. 2021, 28, 111–115. [Google Scholar] [CrossRef]

- Sullivan, M.S.; Chorzepa, M.G.; Durham, S.A. Characterizing the Performance of Ternary Concrete Mixtures Involving Slag and Metakaolin. Infrastructures 2020, 5, 14. [Google Scholar] [CrossRef]

- Agrawal, V.M.; Savoika, P.P. Optimization of binary and ternary concrete composed of fly ash and ultra-fine slag using GRA. Adv. Concr. Constr. 2021, 12, 283–294. [Google Scholar] [CrossRef]

- Global Lightweight Aggregates Market Growth 2022–2028. Available online: https://www.marketandresearch.biz/report/226684/global-lightweight-aggregates-market-growth-2022-2028 (accessed on 1 March 2022).

- Ardakani, A.; Yazdani, M. The relation between particle density and static elastic moduli of lightweight expanded clay aggregates. Appl. Clay Sci. 2014, 93–94, 28–34. [Google Scholar] [CrossRef]

- Mlih, R.; Bydalek, F.; Klumpp, E.; Yaghi, N.; Bol, R.; Wenk, J. Light-expanded clay aggregate (LECA) as a substrate in constructed wetlands—A review. Ecol. Eng. 2020, 148, 105783. [Google Scholar] [CrossRef]

- Sverguzova, S.V.; Sapronova, Z.A.; Starostina, Y.L.; Belovodskiy, E.A. The use of expanded clay dust in paint manufacturing. IOP Conf. Ser. Earth Environ. Sci. 2018, 107, 012078. [Google Scholar] [CrossRef]

- Khlystov, A.; Isaev, D.; Suldin, V. Claydite dust—A unique technogenic raw material for heat-resistant concretes production. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1015, 012070. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Dinakar, P.; Sahoo, P.K.; Sriram, G. Effect of metakaolin content on the properties of high strength concrete. Int. J. Concr. Struct. Mater. 2013, 7, 215–223. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Kaolinitic calcined clays: Factors affecting its performance as pozzolans. Constr. Build. Mater. 2012, 28, 276–281. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Effect of montmorillonite as additive on the properties of cement-based composites. Sci. Eng. Compos. Mater. 2011, 19, 45–54. [Google Scholar] [CrossRef]

- Ptáček, P.; Frajkorová, F.; Šoukal, F.; Opravil, T. Kinetics and mechanism of three stages of thermal transformation of kaolinite to metakaolinite. Powder Technol. 2014, 264, 439–445. [Google Scholar] [CrossRef]

- Gineika, A.; Siauciunas, R.; Baltakys, K. Synthesis of wollastonite from AlF3-rich silica gel and its hardening in the CO2 atmosphere. Sci. Rep. 2019, 9, 18063. [Google Scholar] [CrossRef]

- EN 196-3:2016; Methods of Testing Cement. Determination of setting Times and Soundness. European Standard: Brussels, Belgium, 2016.

- EN 196-1:2016; Methods of Testing Cement. Determination of Strength. European Standard: Brussels, Belgium, 2016.

- NF P18-513:2012; Metakaolin. Pozzolanic Addition for Concrete. Definitions, Specifications and Conformity Criteria. Association Française de Normalisation: La Plaine Saint-Denis, France, 2012.

- Zhang, T.; Sun, Z.; Yang, H.; Yanliang, J.; Yan, Z. Enhancement of triisopropanolamine on the compressive strength development of cement paste incorporated with high content of wasted clay brick powder and its working mechanism. Constr. Build. Mater. 2021, 302, 124052. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, H.; Shen, W.; Xu, G.; Ma, B.; Ji, X. Nano-silica and silica fume modified cement mortar used as Surface Protection Material to enhance the impermeability. Cem. Concr. Compos. 2018, 92, 7–17. [Google Scholar] [CrossRef]

- Quarcioni, Y.; Chotoli, V.A.F.F.; Coelho, A.C.V.; Cincotto, M.A. Indirect and direct Chapelle’s methods for the determination of lime consumption in pozzolanic materials. Rev. IBRACON Estrut. Mater. 2015, 8, 1–7. [Google Scholar] [CrossRef]

- Luzu, B.; Trauchessec, R.; Lecomte, A. Packing density of limestone calcined clay binder. Powder Technol. 2022, 408, 117702. [Google Scholar] [CrossRef]

- Babako, M.; Apeh, J.A. Setting time and standard consistency of Portland cement binders blended with rice husk ash, calcium carbide and metakaolin admixtures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 805, 012031. [Google Scholar] [CrossRef]

- El-Diadamony, H.; Amer, A.A.; Sokkary, T.M.; El-Hoseny, S. Hydration and characteristics of metakaolin pozzolanic cement pastes. HBRC J. 2018, 14, 150–158. [Google Scholar] [CrossRef]

- Das, S.K.; Mitra, A.; Das Poddar, P.K. Thermal analysis of hydrated calcium aluminates. J. Therm. Anal. Calorim. 1996, 47, 765–774. [Google Scholar] [CrossRef]

- Rojas, M.F.; Cabrera, J. The effect of temperature on the hydration rate and stability of the hydration phases of metakaolin–lime–water systems. Cem. Concr. Res. 2002, 32, 133–138. [Google Scholar] [CrossRef]

| Component (wt.%) | ECD | Portland Cement (OPC) |

|---|---|---|

| SiO2 | 44.9 | 19.52 |

| Al2O3 | 25.3 | 5.03 |

| Fe2O3 | 9.79 | 3.05 |

| CaO | 4.83 | 61.39 |

| MgO | 1.33 | 3.93 |

| K2O | 1.46 | 1.06 |

| Na2O | 0.27 | 0.12 |

| SO3 | 0.67 | 2.5 |

| P2O5 | 0.35 | not estimated |

| TiO2 | 1.06 | not estimated |

| Other | 0.10 | 3.4 |

| Loss on ignition | 9.84 | - |

| Specific surface area (m2/kg) | 360 | 350 |

| Sample | W/C | Setting Time (min) | |

|---|---|---|---|

| Initial | Final | ||

| OPC | 0.273 | 100 | 145 |

| OPC + 10 wt.% RECD | 0.313 | 130 | 190 |

| OPC + 20 wt.% RECD | 0.345 | 235 | 285 |

| OPC + 25 wt.% RECD | 0.362 | 290 | 340 |

| OPC + 30 wt.% RECD | 0.38 | 320 | 378 |

| OPC + 20 wt.% ECD | 0.329 | 170 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaminskas, R.; Savickaite, B. Expanded Clay Production Waste as Supplementary Cementitious Material. Sustainability 2023, 15, 11850. https://doi.org/10.3390/su151511850

Kaminskas R, Savickaite B. Expanded Clay Production Waste as Supplementary Cementitious Material. Sustainability. 2023; 15(15):11850. https://doi.org/10.3390/su151511850

Chicago/Turabian StyleKaminskas, Rimvydas, and Brigita Savickaite. 2023. "Expanded Clay Production Waste as Supplementary Cementitious Material" Sustainability 15, no. 15: 11850. https://doi.org/10.3390/su151511850

APA StyleKaminskas, R., & Savickaite, B. (2023). Expanded Clay Production Waste as Supplementary Cementitious Material. Sustainability, 15(15), 11850. https://doi.org/10.3390/su151511850