Improving the Energy Efficiency of an Electric Submersible Pump Installation Using an Integrated Logistics Support Approach

Abstract

:1. Introduction

- -

- diagnostics of the state of electrical equipment;

- -

- planning of logistics procedures;

- -

- support maintenance of operational documentation.

2. Materials and Methods

2.1. Elements’ Interaction Scheme

2.2. Technological Restrictions

2.2.1. Well Head Characteristic

2.2.2. Feed Stall Protection

2.2.3. Overheating Protection

2.2.4. Fittings Restrictions

2.2.5. Minimum Head Restrictions

2.2.6. Voltage Limits at Motor Terminals

2.2.7. Voltage Frequency Limits

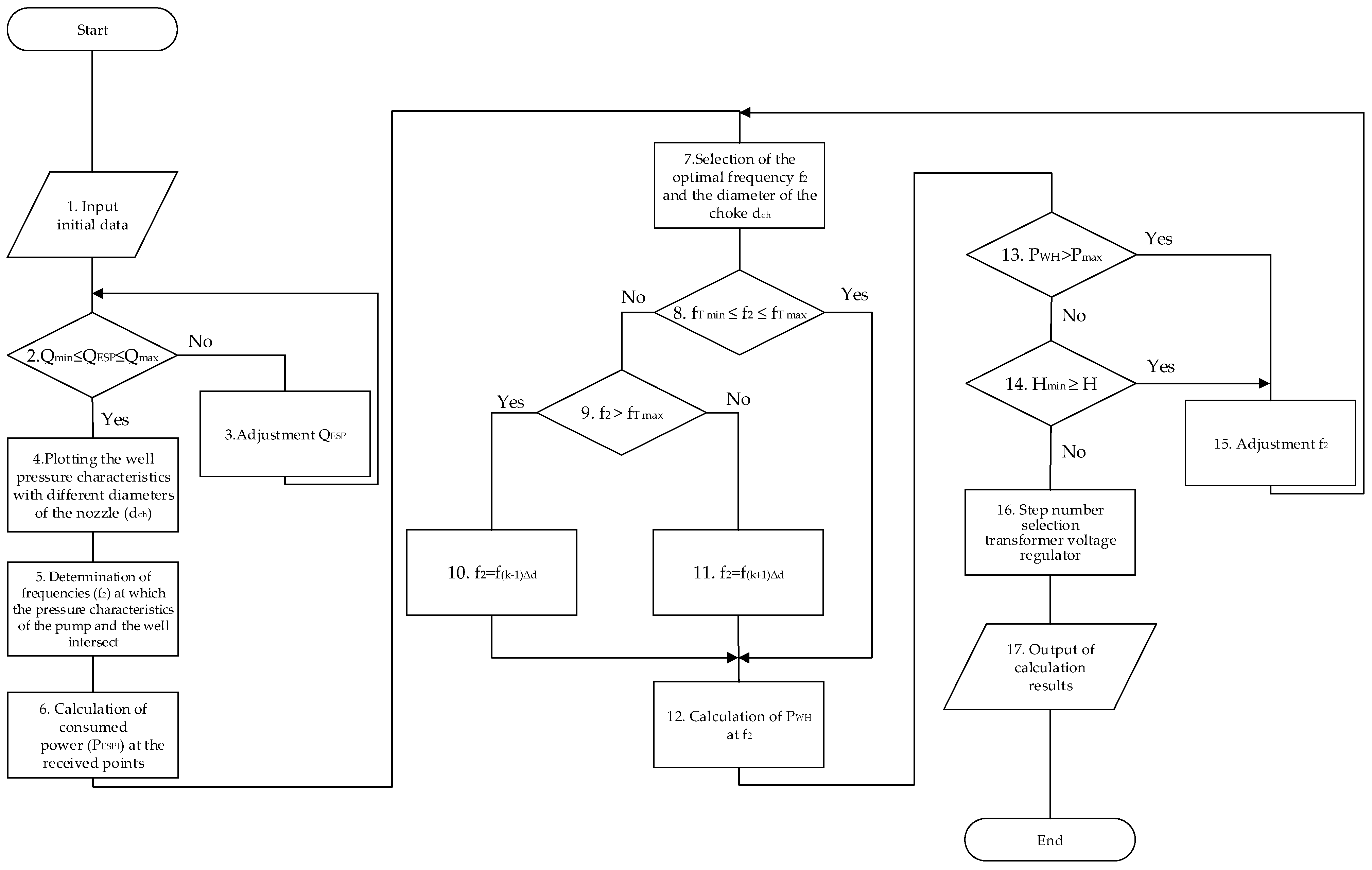

2.3. Method for Power Consumption Optimizing of an Electric Submersible Pump Installation

2.4. Assessment of the Measures’ Economic Feasibility for the Rational Parameters Selection of Electrical Equipment Modes

3. Results

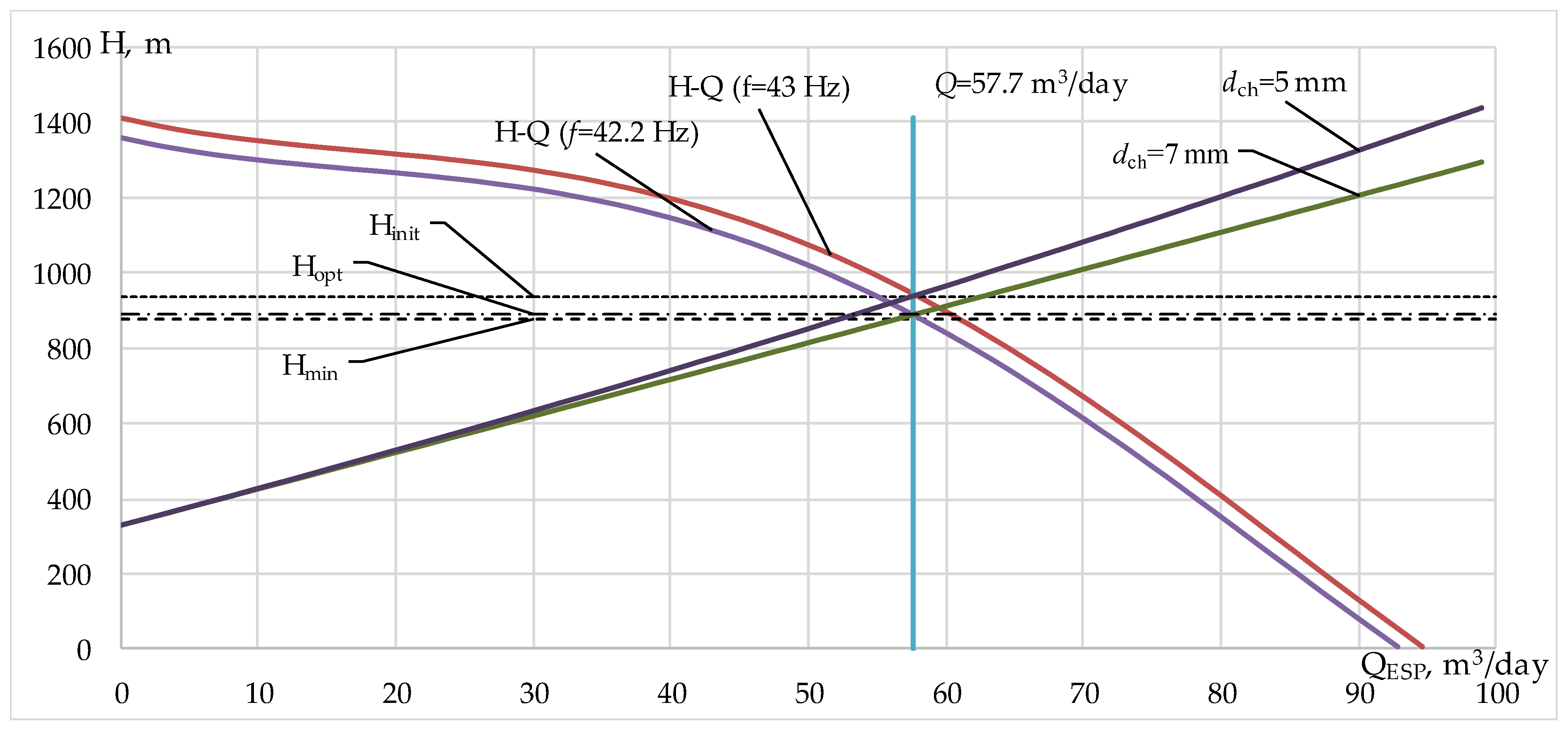

3.1. The Choice of Rational Parameters of the Electrical Equipment Modes When Optimizing the ESPI Power Consumption

3.2. Assessment of the Measures’ Economic Feasibility for the Rational Parameters Selection Modes of the Electrical Equipment

- ESPI is configured with equipment that allows the regulation of the frequency (there are no costs for the purchase of additional equipment);

- the ESPI is not configured with equipment that allows the regulation of the frequency (additional equipment purchase is required).

3.3. Integrated Logistics Support Approach to Improve the Energy Efficiency of the ESP

- Input of initial data:

- input the elements’ parameters in accordance with the installed equipment nameplate data and the results of equipment tests, as well as in accordance with the data of the records of the wells’ pumping equipment;

- setting the technological mode initial parameters in accordance with the documents fixing the technological process parameters, as well as the data of hydrodynamic studies of the wells.

- determination of voltages in the nodes of the electrotechnical complex and voltage losses in the elements;

- determination of currents in the electrotechnical complex elements;

- determination of load power and power losses in elements;

- determination of specific power consumption of ESPI.

- Rational parameters selection of electrical equipment modes and electrical parameters modeling with the selected parameters:

- determination of equipment rational parameters (frequency of supply voltage, choke diameter);

- determination of voltages in the nodes of the electrotechnical complex and voltage losses in the elements;

- determination of currents in the electrotechnical complex elements;

- determination of load power and power losses in elements;

- determination of specific power consumption of ESPI.

- Processing of calculation results:

- determination of the technical effect value from changes in equipment parameters in named and relative values;

- determination of the economic effect size from changes in equipment parameters.

- Registration of calculation results:

- report on possible technical and economic effects;

- report on the required value of the change in the modes parameters of the electrical equipment;

- automatic filling of the form for performing work on changing the technological equipment parameters;

- automatic filling of the permit form for the performance of work on changing the electrical equipment parameters;

- graphical presentation of calculation results.

- diagnostics of the state of electrical equipment,

- planning of logistics procedures and determination of the composition and the required volume of spare parts;

- training of service personnel;

- development and maintenance of electronic operational documentation.

4. Discussion

5. Conclusions

- -

- a program for the selection of rational equipment parameters in order to increase the energy efficiency of the electric pump installation was developed,

- -

- a structural diagram of the process of selecting optimal equipment parameters was developed.

- -

- to assess the potential of energy saving,

- -

- to assess the economic feasibility of changing the parameters of the technological regime,

- -

- for evaluation (and subsequent analysis) of improving the energy efficiency of electric submersible pumping units,

- -

- for planning and optimizing the stock of electrical equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Abbreviation | Description |

|---|---|

| ESP | Electric submersible pump |

| ESPI | Installation of electric submersible pump |

| ETC | Electrotechnical complex |

| FC | Frequency converter |

| HV | High voltage |

| IDEF | Integrated definition |

| ILS | Integrated logistics support |

| LV | Low voltage |

| OF | Oil field |

| PLC | Programmable logic controller |

| SEM | Submersible electric motor |

| TMS | Telemetry system |

References

- Energy Strategy of Russia for the Period up to 2035 Year [Approved by Order of the Government of the Russian Federation of 9 June 2020. № 1523-p]. Available online: https://minenergo.gov.ru/node/1026 (accessed on 11 June 2023). (In Russian)

- Action Plan (“Roadmap”) of EnergyNet of the National Technological Initiative: [Approved by the Presidium of the Council under the President of the Russian Federation for the Modernization of the Economy and Innovative Development of Russia on 28 September 2016, Protocol No. 4]. Available online: https://nti2035.ru/markets/docs/DK_energynet.pdf (accessed on 11 June 2023). (In Russian).

- Petrochenkov, A. Methodical bases of the integrated electrotechnical complexes life cycle logistic support. In Proceedings of the 1st International Conference on Applied Innovations in IT, Koethen, Germany, 25 March 2013; Hochschule Anhalt: Koethen, Germany, 2013; pp. 7–11. [Google Scholar] [CrossRef]

- Kopyrin, V.A.; Khamitov, R.N.; Glazyrin, A.S.; Kladiev, S.N.; Rakov, I.V.; Portnyagin, A.L.; Markova, A.A. Evaluation of Total Cost of Possessing the Electric Centrifugal Pump with Submersible Compensator. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2021, 2, 166–175. [Google Scholar] [CrossRef]

- Haque, M.E.; Islam, M.S.; Islam, M.R.; Haniu, H.; Akhter, M.S. Energy Efficiency Improvement of Submersible Pumps Using in Barind Area of Bangladesh. Energy Procedia 2019, 160, 123–130. [Google Scholar] [CrossRef]

- Petrochenkov, A.B.; Romodin, A.V.; Mishurinskikh, S.V.; Seleznev, V.V.; Shamaev, V.A. Experience in developing a physical model of submersible electrical equipment for simulator systems: Research and training tasks on the agenda of a key employer. In Proceedings of the 2018 XVII Russian Scientific and Practical Conference on Planning and Teaching Engineering Staff for the Industrial and Economic Complex of the Region, St. Petersburg, Russia, 14–15 November 2018. [Google Scholar] [CrossRef]

- Leon, J.L.V.; Ruales, F.; Miranda, S.; Godin, F.; Velasquez, E.; Shirikov, D.; Anaya, O.; Forero, N.; Estupiñan, N.D.; Peña, L.; et al. Permanent magnet motors: The future of ESP applications? In Proceedings of the SPE Gulf Coast Section Electric Submersible Pumps Symposium, Virtual and The Woodlands, TX, USA, 4–8 October 2021. [Google Scholar] [CrossRef]

- Alexeev, Y.; Shakirov, A.; Yamilov, R. Challenges and results of the first ultra-high-speed ESP rental project—A case study. Hyper speed ESP 15,000 rpm as the next step to the future. In Proceedings of the SPE Gulf Coast Section Electric Submersible Pumps Symposium, Virtual and The Woodlands, TX, USA, 4–8 October 2021. [Google Scholar] [CrossRef]

- Matheus, L.; Anaya, O.; Izquierdo, S.; Garzón, M.; Lee, W. Development and evaluation of a new electrical submersible pump for high viscosity environments. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 21–23 September 2021. [Google Scholar] [CrossRef]

- Yakimov, S.B.; Kaverin, M.N.; Tarasov, V.P. ESP Cable Cross-Section Optimization—Simple and Efficient Energy Saving Technology. Oborud. I Tekhnologii Dlya Neftegazov. Kompleks. 2012, 3, 53–56. (In Russian) [Google Scholar]

- Khakim’yanov, M.I. Investigation of Power Loss in the Cable of a Well Submersible Motor. Russ. Electr. Eng. 2018, 2, 103–106. [Google Scholar] [CrossRef]

- Shafikov, I.N.; Khakim’yanov, M.I.; Shabanov, V.A. Self-Diagnosis Method of High-Voltage Frequency. Converter. Patent RF, No. 2548015 RF, N02M 5/458, 7 May 2013. (In Russian). [Google Scholar]

- Starikov, A.; Tabachnikova, T.; Kosorlukov, I. Calculation of the rotation speed of a submersible induction motor for the tasks of determining the optimal value of the supply voltage. In Proceedings of the 2020 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 6–9 October 2020. [Google Scholar] [CrossRef]

- Sukhanov, A.; Gansheng, A.Y.; Jichao, Y.; Perelman, O.; Derkach, N. Enhancement of Electric Submersible Pump Energy Efficiency by Replacing an Inductive Motor with a Permanent Magnet Motor. Oil Gas Eur. Mag. 2020, 3, 146–150. [Google Scholar] [CrossRef]

- Musorina, A.; Safonov, B.; Terebennikov, V. ESP energy efficiency management as a key to cost savings and runlife improvement. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 22 October 2019. [Google Scholar] [CrossRef]

- Almukhtar, M.A.; Alabdulmohsin, Y.A.; Shawly, A.S.; Shehri, A.M.; Shammari, N.S.; Al-Kuhlani, M. Innovative approach to optimize ESP power consumption through developed software. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24 April 2017. [Google Scholar] [CrossRef]

- Sardjono, P.; Saputra, M.N.W. ESP optimal bottomhole pressure control on oil well production using PID-linear hybrid control on electric submersible pump. In Proceedings of the 8th International Conference on Information Technology and Electrical Engineering (ICITEE), Yogyakarta, Indonesia, 5–6 October 2016. [Google Scholar] [CrossRef]

- Hastings, N.A.J. Physical Asset Management; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Mine, H.; Osaki, S. Markovian Decision Processes; AEPCI: New York, NY, USA, 1970; Nauka: Moscow, Russia, 1977. [Google Scholar]

- Marchuk, V.Y.; Dzwigol, H. Integrated Logistics Support for the Life Cycle of Building Objects. Intellectualization Logist. Supply Chain. Manag. 2020, 1, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Lambert, K.R. Integrated logistics support in high-technology complex systems that are used beyond their designed life. S. Afr. J. Ind. Eng. 2020, 31, 84–91. [Google Scholar] [CrossRef]

- Veretekhina, S.V. Methodological Foundations of Mathematical Modeling of the Basic System of Indicators of Information Integrated Logistic Support of Exported Knowledge-Intensive Products. Contemp. Probl. Soc. Work. 2021, 7, 32–38. [Google Scholar] [CrossRef]

- Fadeev, A.; Babyr, A.; Kostuchenko, A. Digital Technologies in the Production Logistic Support System of the Arctic Fields. Lect. Notes Netw. Syst. 2022, 246, 565–572. [Google Scholar]

- Gevorkov, L.; Domínguez-García, J.L.; Romero, L.T. Review on Solar Photovoltaic-Powered Pumping Systems. Energies 2023, 16, 94. [Google Scholar] [CrossRef]

- Gevorkov, L.; Domínguez-García, J.L.; Rassõlkin, A.; Vaimann, T. Comparative Simulation Study of Pump System Efficiency Driven by Induction and Synchronous Reluctance Motors. Energies 2022, 15, 4068. [Google Scholar] [CrossRef]

- Lyakhomskii, A.; Petrochenkov, A.; Romodin, A.; Perfil’eva, E.; Mishurinskikh, S.; Kokorev, A.; Kokorev, A.; Zuev, S. Assessment of the Harmonics Influence on the Power Consumption of an Electric Submersible Pump Installation. Energies 2022, 15, 2409. [Google Scholar] [CrossRef]

- Petrochenkov, A.B.; Mishurinskikh, S.V. Development of a Method for Optimizing Power Consumption of an Electric Driven Centrifugal Pump. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Russia, 26–29 January 2021. [Google Scholar] [CrossRef]

- Ciontea, C.I.; Iov, F. A Study of Load Imbalance Influence on Power Quality Assessment for Distribution Networks. Electricity 2021, 2, 77–90. [Google Scholar] [CrossRef]

- Kavalerov, B.V.; Petrochenkov, A.B.; Odin, K.A.; Tarasov, V.A. A method for development of software packages for mathematical simulation of electric power systems. Russ. Electr. Eng. 2015, 86, 331–338. [Google Scholar] [CrossRef]

- Takacs, G. Electrical Submersible Pumps Manual: Design, Operations, and Maintenance; Gulf Professional Publishing: Burlington, MA, USA, 2009; 440p. [Google Scholar]

- Anuchin, A.; Demidova, G.L.; Vagapov, Y.; Strzelecki, R. Research of electric drive systems with real time software configurable control. Sci. Tech. J. Inf. Technol. Mech. Opt. 2020, 20, 290–300. [Google Scholar] [CrossRef]

- Gevorkov, L.; Rassõlkin, A.; Kallaste, A.; Vaimann, T. Simulation study of a centrifugal pumping plant’s power consumption at throttling and speed control. In Proceedings of the 2017 IEEE 58th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 October 2017; pp. 1–5. [Google Scholar]

| Mode | Parameter | Well Number | ||

|---|---|---|---|---|

| 115 | 120 | 318 | ||

| Initial | dch, mm | 5 | 4 | 5 |

| f, Hz | 43 | 56 | 48 | |

| PWH, MPa | 1.4 | 2.6 | 1.5 | |

| Hdyn, m | 764 | 750 | 908 | |

| WESPI, kW·h/day | 648.0 | 895.2 | 700.8 | |

| Wsp, kW·h/m3 | 11.24 | 13.95 | 10.46 | |

| Optimized | dch, mm | 7 | 7 | 8 |

| f, Hz | 42.3 | 54.6 | 47 | |

| PWH, MPa | 1.050 | 1.000 | 0.917 | |

| Hdyn, m | 767 | 755 | 900 | |

| WESPI, kW·h/day | 631.0 | 781.9 | 680.2 | |

| Wsp, kW·h/m3 | 10.95 | 12.18 | 10.15 | |

| Reducing specific power consumption, % | 2.59 | 12.68 | 2.74 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrochenkov, A.; Lyakhomskii, A.; Romodin, A.; Perfil’eva, E.; Mishurinskikh, S.; Zuev, S.; Butorin, I.; Kolesnikov, N.; Lelekov, A.; Shabunin, A. Improving the Energy Efficiency of an Electric Submersible Pump Installation Using an Integrated Logistics Support Approach. Sustainability 2023, 15, 11845. https://doi.org/10.3390/su151511845

Petrochenkov A, Lyakhomskii A, Romodin A, Perfil’eva E, Mishurinskikh S, Zuev S, Butorin I, Kolesnikov N, Lelekov A, Shabunin A. Improving the Energy Efficiency of an Electric Submersible Pump Installation Using an Integrated Logistics Support Approach. Sustainability. 2023; 15(15):11845. https://doi.org/10.3390/su151511845

Chicago/Turabian StylePetrochenkov, Anton, Aleksandr Lyakhomskii, Alexander Romodin, Evgeniia Perfil’eva, Sergey Mishurinskikh, Sergei Zuev, Iurii Butorin, Nikolai Kolesnikov, Aleksandr Lelekov, and Andrey Shabunin. 2023. "Improving the Energy Efficiency of an Electric Submersible Pump Installation Using an Integrated Logistics Support Approach" Sustainability 15, no. 15: 11845. https://doi.org/10.3390/su151511845

APA StylePetrochenkov, A., Lyakhomskii, A., Romodin, A., Perfil’eva, E., Mishurinskikh, S., Zuev, S., Butorin, I., Kolesnikov, N., Lelekov, A., & Shabunin, A. (2023). Improving the Energy Efficiency of an Electric Submersible Pump Installation Using an Integrated Logistics Support Approach. Sustainability, 15(15), 11845. https://doi.org/10.3390/su151511845