A New EWMA Control Chart for Monitoring Multinomial Proportions

Abstract

:1. Introduction

2. Investigation of the Property of Pearson’s Chi-Square Statistic for Correlated Quality Variables following a Multinomial Distribution

- X follows a multinomial distribution with probability mass functionwhere , and xi is the realization value of Xi for i = 1, …, m.

- (i)

- Under scenario (1), the exact means are all fixed at 3 whether n is small or large. However, the exact variance increases when n increases but converges to 5.999 when n is equal to 6000.

- (ii)

- Under scenario (2), the exact mean are all fixed at 3 whether n is small or large. However, the exact variance decreases when n increases but converges to 6.0 when n is equal to 6000.

- (iii)

- The exact variance increases or decreases heavily due to the in-control proportion vector. We can see that the change behavior of the exact variance for increasing n is different in scenarios (1) and (2).

| n | Scenario (1) | Scenario (2) | ||

|---|---|---|---|---|

| 1 | 3.000 | 0.000 | 3.000 | 9.000 |

| 2 | 3.000 | 3.000 | 3.000 | 7.500 |

| 3 | 3.000 | 4.000 | 3.000 | 7.000 |

| 4 | 3.000 | 4.500 | 3.000 | 6.750 |

| 5 | 3.000 | 4.800 | 3.000 | 6.600 |

| 6 | 3.000 | 5.000 | 3.000 | 6.500 |

| 7 | 3.000 | 5.143 | 3.000 | 6.429 |

| 8 | 3.000 | 5.250 | 3.000 | 6.375 |

| 9 | 3.000 | 5.333 | 3.000 | 6.333 |

| 10 | 3.000 | 5.400 | 3.000 | 6.300 |

| 11 | 3.000 | 5.455 | 3.000 | 6.273 |

| 12 | 3.000 | 5.500 | 3.000 | 6.250 |

| 13 | 3.000 | 5.538 | 3.000 | 6.231 |

| 14 | 3.000 | 5.571 | 3.000 | 6.214 |

| 15 | 3.000 | 5.600 | 3.000 | 6.200 |

| 16 | 3.000 | 5.625 | 3.000 | 6.188 |

| 17 | 3.000 | 5.647 | 3.000 | 6.176 |

| 18 | 3.000 | 5.667 | 3.000 | 6.167 |

| 19 | 3.000 | 5.684 | 3.000 | 6.158 |

| 20 | 3.000 | 5.700 | 3.000 | 6.150 |

| 50 | 3.000 | 5.880 | 3.000 | 6.060 |

| 100 | 3.000 | 5.940 | 3.000 | 6.030 |

| 200 | 3.000 | 5.970 | 3.000 | 6.015 |

| 400 | 3.000 | 5.985 | 3.000 | 6.008 |

| 600 | 3.000 | 5.990 | 3.000 | 6.005 |

| 800 | 3.000 | 5.993 | 3.000 | 6.004 |

| 1000 | 3.000 | 5.994 | 3.000 | 6.003 |

| 2000 | 3.000 | 5.997 | 3.000 | 6.002 |

| 4000 | 3.000 | 5.999 | 3.000 | 6.001 |

| 5000 | 3.000 | 5.999 | 3.000 | 6.000 |

| 6000 | 3.000 | 5.999 | 3.000 | 6.000 |

3. A Pearson’s Chi-Square Statistic-Based EWMA Chart for Monitoring the Multinomial Proportions

3.1. The Exact Multinomial-Proportion Control Chart

3.2. The Asymptotic Multinomial-Proportion Control Chart

- where and are computed by the above-mentioned procedure.

3.3. Comparison of the Exact and Asymptotic Multinomial-Proportion Control Charts

4. Detection Performance Measurement of the Proposed Exact and Asymptotic EWMA-Proportion Control Charts

4.1. Detection Performance of the Proposed Exact EWMA-Proportion Chart

- (i)

- For detecting any out-of-control proportion vector, ARL1 decreases when n increases;

- (ii)

- The larger the difference is between p0 and pi, the smaller is ARL1 under each n. The result is reasonable.

| 2 | 369.956 402.099 | 321.682 351.861 | 121.808 130.346 | 65.69 69.036 | 243.704 264.746 | 32.476 32.604 | 13.582 12.771 |

| 3 | 372.065 416.056 | 287.588 323.047 | 69.136 75.999 | 32.504 34.156 | 183.376 205.704 | 14.306 15.077 | 5.923 5.942 |

| 4 | 369.232 393.303 | 261.716 278.589 | 47.220 47.005 | 21.347 19.678 | 144.940 153.794 | 9.817 8.761 | 4.451 3.444 |

| 5 | 370.177 405.620 | 238.209 263.725 | 32.446 33.244 | 14.187 13.570 | 114.307 125.545 | 6.370 6.160 | 2.813 2.369 |

| 6 | 368.793 394.082 | 218.664 232.241 | 25.131 23.899 | 11.102 9.574 | 95.834 100.353 | 5.307 4.421 | 2.577 1.693 |

| 7 | 374.458 398.754 | 203.780 217.250 | 20.065 18.688 | 8.840 7.366 | 81.281 84.604 | 4.339 3.463 | 2.127 1.325 |

| 8 | 369.532 399.416 | 185.235 197.368 | 16.036 14.924 | 6.974 5.832 | 67.638 70.737 | 3.475 2.815 | 1.737 1.051 |

| 9 | 367.247 395.453 | 170.07 184.802 | 13.245 12.332 | 5.749 4.824 | 57.690 60.603 | 2.899 2.343 | 1.487 0.846 |

| 10 | 370.275 396.203 | 158.746 167.584 | 11.551 10.170 | 5.181 3.947 | 50.98 52.264 | 2.762 1.965 | 1.509 0.754 |

| 11 | 370.450 400.534 | 146.869 157.557 | 9.862 8.811 | 4.438 3.391 | 44.622 45.979 | 2.359 1.715 | 1.350 0.635 |

| 12 | 368.108 398.165 | 135.948 146.166 | 8.451 7.626 | 3.764 2.968 | 39.605 41.012 | 2.106 1.503 | 1.215 0.504 |

| 13 | 370.740 398.013 | 127.254 134.882 | 7.674 6.678 | 3.482 2.524 | 35.619 36.202 | 1.973 1.331 | 1.195 0.461 |

| 14 | 369.888 396.682 | 119.230 125.792 | 6.936 5.874 | 3.178 2.246 | 32.176 32.313 | 1.887 1.183 | 1.170 0.418 |

| 15 | 371.409 399.734 | 110.564 117.402 | 6.162 5.318 | 2.785 2.025 | 29.037 29.353 | 1.697 1.058 | 1.110 0.341 |

| 16 | 368.316 396.150 | 103.902 110.434 | 5.658 4.771 | 2.643 1.791 | 26.366 26.366 | 1.619 0.957 | 1.086 0.300 |

| 17 | 372.261 398.352 | 97.635 102.595 | 5.250 4.308 | 2.476 1.609 | 24.342 24.132 | 1.557 0.875 | 1.074 0.274 |

| 18 | 368.650 397.644 | 92.060 97.515 | 4.764 3.962 | 2.225 1.466 | 22.313 22.202 | 1.458 0.801 | 1.050 0.225 |

| 19 | 369.787 396.360 | 86.608 91.298 | 4.394 3.594 | 2.102 1.345 | 20.668 20.551 | 1.402 0.726 | 1.035 0.189 |

| 20 | 368.262 395.554 | 81.618 85.676 | 4.127 3.323 | 2.004 1.236 | 19.156 18.807 | 1.359 0.675 | 1.030 0.173 |

| 50 | 370.723 398.263 | 24.540 24.130 | 1.476 0.778 | 1.045 0.211 | 5.338 4.713 | 1.008 0.675 | 1.000 0.001 |

| 100 | 370.097 398.439 | 9.079 8.360 | 1.041 0.203 | 1.000 0.009 | 2.309 1.678 | 1.000 0.002 | 1.000 0.000 |

| 200 | 371.126 400.019 | 3.564 2.916 | 1.000 0.011 | 1.000 0.000 | 1.286 0.587 | 1.000 0.000 | 1.000 0.000 |

| 400 | 369.493 398.541 | 1.692 1.028 | 1.000 0.000 | 1.000 0.000 | 1.021 0.143 | 1.000 0.000 | 1.000 0.000 |

| 600 | 370.632 398.363 | 1.256 0.542 | 1.000 0.000 | 1.000 0.000 | 1.001 0.033 | 1.000 0.000 | 1.000 0.000 |

| 800 | 369.187 397.229 | 1.101 0.324 | 1.000 0.000 | 1.000 0.000 | 1.000 0.007 | 1.000 0.000 | 1.000 0.000 |

| 1000 | 369.751 398.334 | 1.038 0.196 | 1.000 0.000 | 1.000 0.000 | 1.000 0.001 | 1.000 0.000 | 1.000 0.000 |

| 2000 | 369.708 398.510 | 1.000 0.013 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 4000 | 369.557 397.351 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 5000 | 369.657 398.279 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 6000 | 369.736 398.101 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 1 | 369.314 395.079 | 371.081 394.476 | 370.828 394.501 | 9.320 7.951 | 17.190 15.914 | 45.580 45.433 | 9.318 7.973 |

| 2 | 368.283 400.411 | 258.404 283.917 | 123.075 138.227 | 7.802 6.934 | 15.158 14.770 | 42.878 44.518 | 8.120 7.384 |

| 3 | 369.013 405.564 | 207.565 229.870 | 74.424 83.969 | 4.972 4.754 | 11.054 11.299 | 34.678 36.799 | 5.396 5.359 |

| 4 | 368.840 390.956 | 173.702 185.024 | 51.568 54.552 | 4.441 3.391 | 9.838 9.003 | 31.085 30.668 | 4.930 4.078 |

| 5 | 370.999 395.305 | 144.832 157.049 | 36.937 38.928 | 3.570 2.746 | 8.096 7.597 | 26.724 26.895 | 3.966 3.395 |

| 6 | 370.222 398.943 | 123.071 133.663 | 27.592 28.795 | 2.904 2.217 | 6.842 6.532 | 23.593 23.916 | 3.302 2.841 |

| 7 | 368.671 398.112 | 107.071 114.893 | 21.611 22.220 | 2.494 1.823 | 6.081 5.613 | 21.262 21.481 | 2.970 2.394 |

| 8 | 370.126 395.952 | 93.134 99.214 | 17.970 17.581 | 2.167 1.546 | 5.363 4.940 | 19.289 19.300 | 2.592 2.081 |

| 9 | 370.868 396.084 | 81.428 86.310 | 14.823 14.296 | 2.029 1.318 | 4.915 4.388 | 17.743 17.596 | 2.446 1.829 |

| 10 | 369.120 398.684 | 71.317 76.376 | 12.402 11.947 | 1.789 1.151 | 4.354 3.959 | 16.071 16.203 | 2.139 1.630 |

| 11 | 370.757 398.200 | 63.001 67.485 | 10.537 10.107 | 1.671 1.004 | 4.013 3.569 | 14.954 14.947 | 2.026 1.454 |

| 12 | 368.926 396.388 | 57.180 59.868 | 9.521 8.605 | 1.595 0.889 | 3.802 3.222 | 14.066 13.791 | 1.960 1.306 |

| 13 | 371.755 398.458 | 51.611 53.654 | 8.408 7.491 | 1.449 0.792 | 3.475 2.966 | 12.980 12.832 | 1.782 1.190 |

| 14 | 369.361 398.027 | 46.467 48.400 | 7.471 6.571 | 1.406 0.715 | 3.292 2.725 | 12.146 11.953 | 1.741 1.096 |

| 15 | 366.476 398.999 | 42.014 43.662 | 6.654 5.823 | 1.331 0.641 | 3.002 2.526 | 11.312 11.217 | 1.599 0.998 |

| 16 | 369.623 398.93 | 38.371 39.606 | 5.875 1.197 | 1.268 0.57 | 2.852 2.342 | 10.702 10.512 | 1.536 0.915 |

| 17 | 372.149 397.024 | 35.721 36.112 | 5.585 4.611 | 1.249 0.531 | 2.783 2.171 | 10.282 9.860 | 1.537 0.862 |

| 18 | 369.494 397.07 | 32.851 33.070 | 5.151 4.163 | 1.215 0.486 | 2.634 2.03 | 9.769 9.296 | 1.461 0.794 |

| 19 | 369.044 398.317 | 30.160 30.550 | 4.714 3.802 | 1.185 0.442 | 2.441 1.907 | 9.156 8.822 | 1.369 0.726 |

| 20 | 369.159 399.616 | 27.988 28.106 | 4.392 3.473 | 1.159 0.410 | 2.365 1.797 | 8.657 8.356 | 1.365 0.690 |

| 50 | 370.314 397.494 | 7.236 6.396 | 1.420 0.618 | 1.000 0.025 | 1.242 0.532 | 3.407 2.825 | 1.019 0.136 |

| 100 | 369.737 398.007 | 2.819 2.120 | 1.000 0.000 | 1.000 0.000 | 1.018 0.135 | 1.757 1.119 | 1.000 0.007 |

| 200 | 369.376 397.284 | 1.405 0.709 | 1.000 0.000 | 1.000 0.000 | 1.000 0.007 | 1.141 0.391 | 1.000 0.000 |

| 400 | 370.64 399.136 | 1.031 0.170 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.005 0.069 | 1.000 0.000 |

| 600 | 370.225 398.276 | 1.002 0.041 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.009 | 1.000 0.000 |

| 800 | 370.060 397.990 | 1.000 0.008 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.001 | 1.000 0.000 |

| 1000 | 369.657 398.683 | 1.000 0.001 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 2000 | 370.317 398.111 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 4000 | 370.794 399.123 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 5000 | 370.790 399.038 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 6000 | 369.862 398.246 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

4.2. Detection Performance of the Asymptotic EWMA-Proportion Chart

- (i)

- Most ARL0s are far away from the specified 370.4 for small n. In Table 5, we find many ARL0s are larger than the specified 370.4 for n < 400, and some ARL1s are larger than the specified 370.4 for very small n. However, in Table 6, we find all ARL0s are smaller than the specified 370.4 for n < 6000. These results indicate that the proposed asymptotic control chart is not in-control robust, it becomes ARL biased, and its detection performance is worse for small n.

- (ii)

- When n is large (n 400 for scenario (1) or n = 6000 for scenario (2)), the calculated ARL0 close to the specified ARL0, and ARL1 decreases when n increases for detecting any out-of-control proportion vector.

- (iii)

- The larger the difference is between p0 and pi, i = 1, 2, …, 6, the smaller is ARL1 under each n.

5. Monitoring Under-Specification Proportions of a Continuous Multivariate Process Using the Proposed EWMA-Proportion Chart and Its Application

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- (a)

- .

- (b)

- .

Appendix B. R Program Language

| Algorithm A1. The Monte Carlo simulation steps to find of the exact multinomial-proportion control chart in given ARL0 |

| 1: For a given in-control, , and specified ARL0 (e.g., ARL0≈370). 2: Set , e.g., and for ARL0 ≈ 370. 3: Monte Carlo procedure: 4: For from 1 to ,set = 1,000,000 and perform the following: 5: Let , and . 6: Simulate Xt from multinomial distribution with p0 and size n,and calculate , 7: if then 8: . 9: end if 10: if then 11: . 12: end if 13: Given , and calculate , 14: if , then 15: . Go to step line 6. 16: end if 17: if , then 18: take as run length, let and go to step 5. 19: end if 20: end for 21: Calculate , and determine by |

Appendix C. R Program Language

| Algorithm A2. The Monte Carlo simulation steps to calculate ARL1 of the exact multinomial-proportion control chart |

| 1: obtained by Algorithm A1 above. 2: Monte Carlo procedure: 3: For from 1 to , set = 1,000,000 and perform the following: 4: Let , and . 5: Simulate Xt from multinomial distribution with p1 and size n, and calculate . 6: if then 7: . 8: end if 9: if then 10: . 11: end if 12: , and calculate , 13: if , then 14: . Go to step 5. 15: end if 16: if , then 17: and go to step 4. 18: end if 19: end for 20: , take it as an estimator of ARL1. |

References

- Sikdar, S.K. Sustainable development and sustainability metrics. AIChE J. 2003, 49, 1928–1932. [Google Scholar] [CrossRef]

- Bakshi, B.R.; Fiksel, J. The quest for sustainability: Challenges for processsystems engineering. AIChE J. 2003, 49, 1350–1358. [Google Scholar] [CrossRef]

- Cabezas, H.; Pawlowski, C.W.; Mayer, A.L.; Hoagland, N. Sustainable systemstheory: Ecological and other aspects. J. Clean. Prod. 2005, 13, 455–467. [Google Scholar] [CrossRef]

- Daoutidis, P.; Zachar, M.; Jogwar, S.S. Sustainability and process control: A survey and perspective. J. Process Control 2016, 44, 184–206. [Google Scholar] [CrossRef]

- Anderson, M.J.; Thompson, A.A. Multivariate control charts for ecological and environmental monitoring. Ecol. Appl. 2004, 14, 1921–1935. [Google Scholar] [CrossRef]

- Morrison, L.W. The use of control charts to interpret environmental monitoring data. Nat. Areas J. 2008, 28, 66–73. [Google Scholar] [CrossRef]

- Gove, A.D.; Sadler, R.; Matsuki, M.; Archibald, R.; Pearse, S.; Garkaklis, M. Control charts for improved decisions in environmental management: A case study of catchment water supply in south-west Western Australia. Ecol. Manag. Restor. 2013, 14, 127–134. [Google Scholar] [CrossRef]

- Oliveira da Silva, F.M.; Silvério, K.S.; Castanheira, M.I.; Raposo, M.; Imaginário, M.J.; Simões, I.; Almeida, M.A. Construction of control charts to help in the stability and reliability of results in an accredited water quality control laboratory. Sustainability 2022, 14, 15392. [Google Scholar] [CrossRef]

- Shafqat, A.; Sabir, A.; Yang, S.-F.; Aslam, M.; Albassam, M.; Abbas, K. Monitoring and comparing air and green House Gases Emissions of various vountries. J. Agric. Biol. Environ. Stat. 2023. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Reynolds, M.R.; Stoumbos, Z.G. The SPRT chart for monitoring a proportion. IIE Trans. 1998, 30, 545–561. [Google Scholar] [CrossRef]

- Reynolds, M.R.; Stoumbos, Z.G. Monitoring a proportion using CUSUM and SPRT control charts. In Frontiers in Statistical Quality Control 6; Physica: Heidelberg, Germany, 2001; pp. 155–175. [Google Scholar]

- Qiu, P. Distribution-free multivariate process control based on log-linear modeling. IIE Trans. 2008, 40, 664–677. [Google Scholar] [CrossRef]

- Marcucci, M. Monitoring multinomial processes. J. Qual. Technol. 1985, 17, 86–91. [Google Scholar] [CrossRef]

- Nelson, L.S. A chi-square control chart for several proportions. J. Qual. Technol. 1987, 19, 229–231. [Google Scholar] [CrossRef]

- Crosier, R.B. Multivariate generalizations of cumulative sum quality-control schemes. Technometrics 1988, 30, 291–303. [Google Scholar] [CrossRef]

- Qiu, P. Introduction to Statistical Process Control, 1st ed.; Chapman and Hall/CRC Press: New York, NY, USA, 2013. [Google Scholar]

- Ryan, A.G.; Wells, L.J.; Woodall, W.H. Methods for monitoring multiple proportions when inspecting continuously. J. Qual. Technol. 2011, 43, 237–248. [Google Scholar] [CrossRef]

- Li, J.; Tsung, F.; Zou, C. Multivariate binomial/multinomial control chart. IIE Trans. 2014, 46, 526–542. [Google Scholar] [CrossRef]

- Huang, W.; Reynolds, M.R., Jr.; Wang, S. A binomial GLR control chart for monitoring a proportion. J. Qual. Technol. 2012, 44, 192–208. [Google Scholar] [CrossRef]

- Huang, W.; Wang, S.; Reynolds, M.R., Jr. A generalized likelihood ratio chart for monitoring Bernoulli processes. Qual. Reliab. Eng. Int. 2013, 29, 665–679. [Google Scholar] [CrossRef]

- Lee, J.; Peng, Y.; Wang, N.; Reynolds, M.R., Jr. A GLR control chart for monitoring a multinomial process. Qual. Reliab. Eng. Int. 2017, 33, 1773–1782. [Google Scholar] [CrossRef]

- Yang, S.-F.; Chen, L.-P.; Lin, J.-K. Adjustment of measurement error effects on dispersion control chart with distribution-free quality variable. Sustainability 2023, 15, 4337. [Google Scholar] [CrossRef]

- Lucas, J.M.; Saccucci, M.S. Exponentially weighted moving average control schemes: Properties and enhancements. Technometrics 1990, 32, 1–12. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; English, J.R.; Disney, R.L. Modeling and analysis of EWMA control schemes with variance-adjusted control limits. IIE Trans. 1995, 27, 282–290. [Google Scholar] [CrossRef]

- McCann, M.; Johnston, A. UCI Machine Learning Repository. Available online: https://archive.ics.uci.edu/ml/datasets/SECOM (accessed on 1 December 2021).

| n | Ln | |

|---|---|---|

| Scenario (1) | Scenario (2) | |

| 1 | - | 2.414 |

| 2 | 2.382 | 2.605 |

| 3 | 2.377 | 2.600 |

| 4 | 2.388 | 2.550 |

| 5 | 2.401 | 2.537 |

| 6 | 2.388 | 2.525 |

| 7 | 2.394 | 2.513 |

| 8 | 2.398 | 2.501 |

| 9 | 2.403 | 2.492 |

| 10 | 2.395 | 2.489 |

| 11 | 2.404 | 2.485 |

| 12 | 2.409 | 2.474 |

| 13 | 2.403 | 2.471 |

| 14 | 2.403 | 2.467 |

| 15 | 2.409 | 2.468 |

| 16 | 2.407 | 2.464 |

| 17 | 2.406 | 2.456 |

| 18 | 2.408 | 2.452 |

| 19 | 2.408 | 2.454 |

| 20 | 2.406 | 2.453 |

| 50 | 2.413 | 2.430 |

| 100 | 2.414 | 2.423 |

| 200 | 2.416 | 2.419 |

| 400 | 2.418 | 2.419 |

| 600 | 2.419 | 2.419 |

| 800 | 2.419 | 2.420 |

| 1000 | 2.419 | 2.420 |

| 2000 | 2.418 | 2.419 |

| 4000 | 2.416 | 2.418 |

| 5000 | 2.416 | 2.417 |

| 6000 | 2.416 | 2.417 |

| n | |||||||

|---|---|---|---|---|---|---|---|

| 2 | 3880.926 3896.139 | 3123.472 3131.111 | 720.986 713.365 | 280.329 267.982 | 2074.137 2077.971 | 100.033 87.278 | 32.574 23.585 |

| 3 | 1078.071 1157.757 | 791.313 852.399 | 135.773 143.038 | 54.859 54.858 | 449.865 486.158 | 21.522 20.860 | 8.127 7.673 |

| 4 | 757.384 789.150 | 509.243 530.552 | 69.903 67.986 | 29.123 25.865 | 255.223 264.734 | 12.387 10.735 | 5.275 4.127 |

| 5 | 648.207 671.590 | 398.79 412.093 | 44.919 41.702 | 18.887 15.778 | 178.058 181.867 | 8.516 6.820 | 3.906 2.517 |

| 6 | 569.374 600.160 | 321.301 338.397 | 30.593 28.619 | 12.860 10.987 | 129.408 134.551 | 5.840 4.960 | 2.674 1.853 |

| 7 | 535.804 565.679 | 277.828 292.373 | 23.219 21.278 | 9.835 8.174 | 102.369 105.892 | 4.649 3.783 | 2.184 1.425 |

| 8 | 506.336 538.152 | 241.435 255.351 | 18.239 16.578 | 7.768 6.409 | 82.654 85.335 | 3.753 3.033 | 1.818 1.155 |

| 9 | 483.561 518.434 | 212.767 227.899 | 14.599 13.408 | 6.212 5.205 | 68.121 71.033 | 3.058 2.507 | 1.524 0.909 |

| 10 | 476.051 503.278 | 194.730 204.614 | 12.641 11.060 | 5.506 4.240 | 59.056 59.678 | 2.837 2.081 | 1.515 0.774 |

| 11 | 458.735 490.911 | 173.615 184.745 | 10.581 9.367 | 4.643 3.601 | 50.003 51.157 | 2.415 1.800 | 1.356 0.653 |

| 12 | 455.017 481.168 | 160.708 168.485 | 9.410 8.035 | 4.172 3.048 | 44.605 44.578 | 2.298 1.549 | 1.322 0.577 |

| 13 | 446.672 476.889 | 146.102 154.694 | 8.163 7.040 | 3.641 2.673 | 38.955 39.251 | 2.015 1.383 | 1.200 0.475 |

| 14 | 439.888 468.259 | 134.735 141.612 | 7.318 6.176 | 3.300 2.341 | 34.911 34.699 | 1.919 1.230 | 1.173 0.427 |

| 15 | 437.203 465.765 | 125.143 131.462 | 6.589 5.493 | 3.032 2.066 | 31.407 31.184 | 1.775 1.100 | 1.134 0.372 |

| 16 | 428.399 458.844 | 115.217 121.453 | 5.884 4.944 | 2.715 1.867 | 28.267 28.076 | 1.636 0.989 | 1.086 0.302 |

| 17 | 425.681 454.903 | 107.603 112.808 | 5.423 4.465 | 2.523 1.674 | 25.919 25.447 | 1.573 0.902 | 1.073 0.274 |

| 18 | 420.922 451.455 | 100.071 105.644 | 4.913 4.088 | 2.287 1.532 | 23.522 23.301 | 1.465 0.815 | 1.050 0.228 |

| 19 | 417.849 448.075 | 93.837 98.522 | 4.547 3.733 | 2.148 1.394 | 21.729 21.368 | 1.411 0.745 | 1.036 0.192 |

| 20 | 416.766 445.050 | 88.216 92.002 | 4.277 3.407 | 2.062 1.270 | 20.240 19.673 | 1.385 0.692 | 1.035 0.187 |

| 50 | 386.868 415.975 | 25.082 24.631 | 1.480 0.785 | 1.044 0.21 | 5.391 4.773 | 1.008 0.090 | 1.000 0.000 |

| 100 | 378.202 406.259 | 9.145 8.405 | 9.082 0.204 | 1.000 0.009 | 2.319 1.688 | 1.000 0.002 | 1.000 0.000 |

| 200 | 374.087 403.003 | 3.575 2.921 | 1.000 0.011 | 1.000 0.000 | 1.288 0.590 | 1.000 0.000 | 1.000 0.000 |

| 400 | 370.638 399.267 | 1.692 1.028 | 1.000 0.000 | 1.000 0.000 | 1.020 0.143 | 1.000 0.000 | 1.000 0.000 |

| 600 | 369.798 398.157 | 1.256 0.543 | 1.000 0.000 | 1.000 0.000 | 1.001 0.032 | 1.000 0.000 | 1.000 0.000 |

| 800 | 369.017 397.659 | 1.100 0.323 | 1.000 0.000 | 1.000 0.000 | 1.000 0.005 | 1.000 0.000 | 1.000 0.000 |

| 1000 | 368.672 397.161 | 1.038 0.197 | 1.000 0.000 | 1.000 0.000 | 1.000 0.002 | 1.000 0.000 | 1.000 0.000 |

| 2000 | 369.183 398.185 | 1.000 0.013 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 4000 | 369.313 398.385 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 5000 | 369.596 398.369 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 6000 | 369.646 397.875 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 1 | 149.100 190.427 | 149.131 190.656 | 149.435 190.444 | 5.099 6.226 | 9.434 11.788 | 23.891 30.444 | 5.091 6.220 |

| 2 | 211.107 232.441 | 156.108 174.418 | 81.979 94.030 | 6.891 5.926 | 12.582 12.043 | 31.619 32.925 | 7.071 6.270 |

| 3 | 234.377 261.884 | 141.543 160.014 | 56.129 64.268 | 4.239 4.098 | 9.132 9.570 | 26.670 28.990 | 4.632 4.644 |

| 4 | 254.595 278.088 | 128.980 140.884 | 42.294 45.288 | 3.612 3.110 | 8.095 8.012 | 24.825 25.974 | 4.000 3.723 |

| 5 | 270.693 292.512 | 114.659 124.793 | 31.555 33.353 | 3.292 2.500 | 7.366 6.881 | 23.010 23.390 | 3.731 3.122 |

| 6 | 278.487 305.263 | 100.133 110.100 | 24.204 25.650 | 2.654 2.071 | 6.237 6.021 | 20.532 21.291 | 3.071 2.669 |

| 7 | 287.245 315.190 | 88.690 97.624 | 19.511 20.162 | 2.287 1.712 | 5.416 5.256 | 18.594 19.448 | 2.658 2.267 |

| 8 | 297.024 320.759 | 80.086 85.897 | 16.506 16.214 | 2.091 1.454 | 5.043 4.642 | 17.515 17.787 | 2.494 1.970 |

| 9 | 300.812 326.830 | 70.928 76.427 | 13.705 13.386 | 1.919 1.251 | 4.657 4.157 | 16.204 16.357 | 2.369 1.746 |

| 10 | 306.108 331.928 | 63.493 68.176 | 11.661 11.222 | 1.724 1.097 | 4.157 3.778 | 14.883 15.099 | 2.087 1.564 |

| 11 | 309.943 337.242 | 56.698 60.932 | 9.940 9.547 | 1.580 0.959 | 3.788 3.422 | 13.764 14.016 | 1.934 1.400 |

| 12 | 316.717 342.484 | 52.133 55.010 | 9.015 8.221 | 1.539 0.860 | 3.694 3.120 | 13.238 13.089 | 1.936 1.271 |

| 13 | 320.280 346.034 | 47.283 49.674 | 7.963 7.166 | 1.435 0.762 | 3.361 2.858 | 12.291 12.203 | 1.753 1.151 |

| 14 | 321.785 348.787 | 42.931 44.946 | 7.119 6.303 | 1.360 0.683 | 3.138 2.637 | 11.508 11.437 | 1.672 1.055 |

| 15 | 324.025 351.660 | 39.232 40.889 | 6.411 5.595 | 1.324 0.623 | 2.937 2.449 | 10.800 10.737 | 1.583 0.971 |

| 16 | 326.148 353.893 | 35.968 37.359 | 5.705 5.013 | 1.262 0.559 | 2.775 2.274 | 10.223 10.121 | 1.510 0.890 |

| 17 | 329.612 356.022 | 33.574 34.347 | 5.438 4.462 | 1.232 0.514 | 2.665 2.118 | 9.756 9.515 | 1.474 0.830 |

| 18 | 331.238 357.644 | 31.008 31.556 | 4.978 4.048 | 1.189 0.463 | 2.541 1.986 | 9.284 9.023 | 1.432 0.774 |

| 19 | 331.958 359.795 | 28.646 29.015 | 4.585 3.687 | 1.165 0.426 | 2.400 1.866 | 8.792 8.556 | 1.360 0.712 |

| 20 | 333.886 361.667 | 26.651 26.966 | 4.261 3.367 | 1.147 0.395 | 2.318 1.751 | 8.365 8.096 | 1.350 0.675 |

| 50 | 355.057 381.753 | 7.161 6.34 | 1.417 0.611 | 1.001 0.025 | 1.241 0.529 | 3.38 2.797 | 1.019 0.137 |

| 100 | 362.178 391.087 | 2.801 2.107 | 1.000 0.000 | 1.000 0.000 | 1.018 0.134 | 1.751 1.113 | 1.000 0.007 |

| 200 | 366.135 393.971 | 1.404 0.708 | 1.000 0.000 | 1.000 0.000 | 1.000 0.007 | 1.140 0.390 | 1.000 0.000 |

| 400 | 367.412 396.169 | 1.031 0.177 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.005 0.000 | 1.000 0.000 |

| 600 | 367.196 396.301 | 1.002 0.042 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.009 | 1.000 0.000 |

| 800 | 367.608 396.326 | 1.000 0.008 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.001 | 1.000 0.000 |

| 1000 | 367.333 395.985 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 2000 | 367.691 396.363 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 4000 | 368.637 397.286 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 5000 | 368.955 397.586 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| 6000 | 370.236 399.095 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 | 1.000 0.000 |

| Number | |||||||

|---|---|---|---|---|---|---|---|

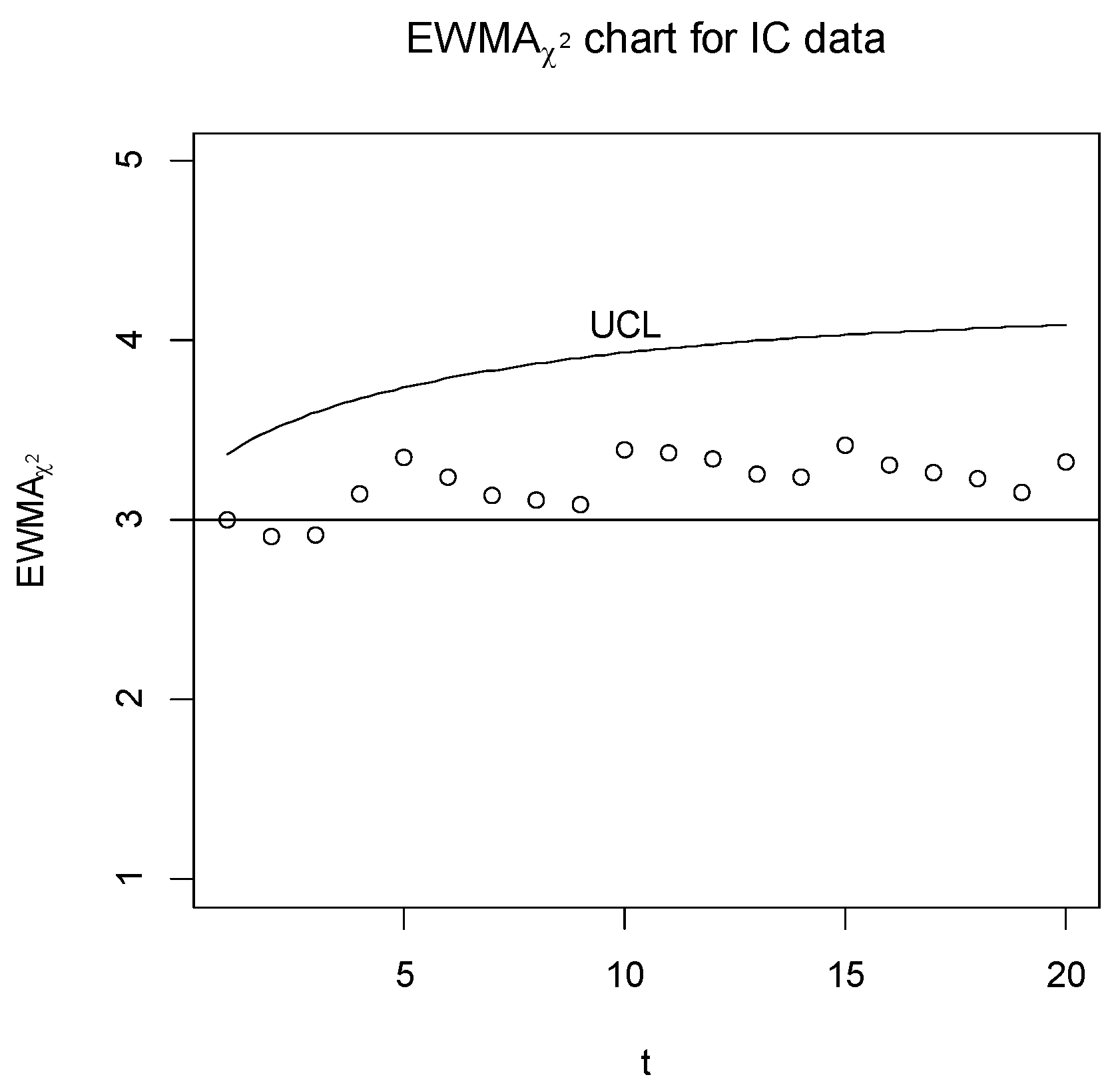

| 1 | 4 | 0 | 0 | 1 | 3.084 | 3.004 | 3.363 |

| 2 | 3 | 0 | 0 | 2 | 1.146 | 2.911 | 3.500 |

| 3 | 4 | 0 | 0 | 1 | 3.084 | 2.92 | 3.598 |

| 4 | 2 | 2 | 0 | 1 | 7.37 | 3.142 | 3.674 |

| 5 | 1 | 2 | 0 | 2 | 7.337 | 3.352 | 3.735 |

| 6 | 2 | 0 | 0 | 3 | 1.091 | 3.239 | 3.787 |

| 7 | 3 | 0 | 0 | 2 | 1.146 | 3.134 | 3.831 |

| 8 | 1 | 1 | 1 | 2 | 2.694 | 3.112 | 3.869 |

| 9 | 1 | 0 | 1 | 3 | 2.519 | 3.083 | 3.901 |

| 10 | 0 | 2 | 0 | 3 | 9.186 | 3.388 | 3.930 |

| 11 | 4 | 0 | 0 | 1 | 3.084 | 3.373 | 3.955 |

| 12 | 1 | 1 | 1 | 2 | 2.694 | 3.339 | 3.977 |

| 13 | 2 | 0 | 1 | 2 | 1.622 | 3.253 | 3.999 |

| 14 | 1 | 0 | 0 | 4 | 2.918 | 3.236 | 4.017 |

| 15 | 5 | 0 | 0 | 0 | 6.905 | 3.42 | 4.032 |

| 16 | 2 | 0 | 0 | 3 | 1.091 | 3.303 | 4.046 |

| 17 | 1 | 0 | 1 | 3 | 2.519 | 3.264 | 4.058 |

| 18 | 3 | 0 | 1 | 1 | 2.608 | 3.231 | 4.069 |

| 19 | 2 | 0 | 1 | 2 | 1.622 | 3.151 | 4.078 |

| 20 | 0 | 0 | 0 | 5 | 6.628 | 3.325 | 4.087 |

| Sampling Time | ||||||

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 2 | 3 | 10.615 | 3.381 |

| 2 | 0 | 0 | 1 | 4 | 5.299 | 3.477 |

| 3 | 0 | 0 | 1 | 4 | 5.299 | 3.568 |

| 4 | 0 | 0 | 2 | 3 | 10.615 | 3.92 |

| 5 | 0 | 0 | 2 | 3 | 10.615 | 4.255 |

| 6 | 0 | 0 | 2 | 3 | 10.615 | 4.573 |

| 7 | 0 | 0 | 0 | 5 | 6.628 | 4.676 |

| 8 | 0 | 0 | 2 | 3 | 10.615 | 4.973 |

| 9 | 0 | 0 | 1 | 4 | 5.299 | 4.989 |

| 10 | 0 | 0 | 0 | 5 | 6.628 | 5.071 |

| 11 | 0 | 0 | 0 | 5 | 6.628 | 5.149 |

| 12 | 0 | 0 | 0 | 5 | 6.628 | 5.223 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, S.; Yang, S.-F.; Chen, L.-P. A New EWMA Control Chart for Monitoring Multinomial Proportions. Sustainability 2023, 15, 11797. https://doi.org/10.3390/su151511797

Gan S, Yang S-F, Chen L-P. A New EWMA Control Chart for Monitoring Multinomial Proportions. Sustainability. 2023; 15(15):11797. https://doi.org/10.3390/su151511797

Chicago/Turabian StyleGan, Shengjin, Su-Fen Yang, and Li-Pang Chen. 2023. "A New EWMA Control Chart for Monitoring Multinomial Proportions" Sustainability 15, no. 15: 11797. https://doi.org/10.3390/su151511797

APA StyleGan, S., Yang, S.-F., & Chen, L.-P. (2023). A New EWMA Control Chart for Monitoring Multinomial Proportions. Sustainability, 15(15), 11797. https://doi.org/10.3390/su151511797