Energy Saving and Emission Reduction Potential Evaluation of a Coal Mine Based on Fuzzy Hierarchical Analysis

Abstract

:1. Introduction

2. Analytic Hierarchy Process and Fuzzy Comprehensive Evaluation

2.1. Fuzzy Hierarchical Analysis Flow Chart

2.2. Analytic Hierarchy Process

- (1)

- The establishment of the hierarchical structure model

- (2)

- Construction of judgment matrix

- (3)

- Square root method to find weights

- (4)

- Consistency test

2.3. Fuzzy Comprehensive Evaluation Method

- (1)

- Determine the indicator set C

- (2)

- Determine the collection of comments V

- (3)

- Build the affiliation matrix

- (4)

- Determine the weight vector W

- (5)

- Perform fuzzy calculations

- (6)

- Derive the evaluation level

3. Case Studies

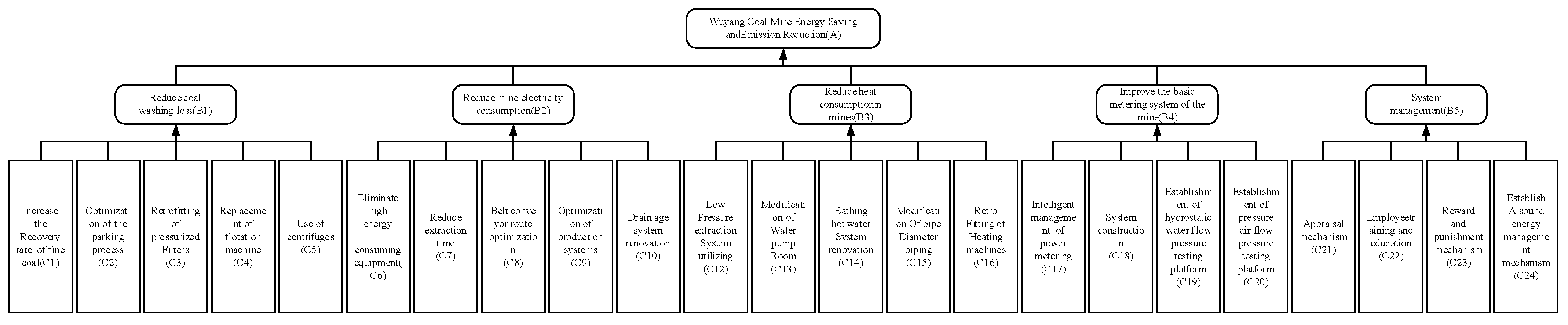

3.1. Establishment of the Indicator System

- (1)

- Reduce coal washing loss

- (2)

- Reduce mine electricity consumption

- (3)

- Reduce heat consumption in mines

- (4)

- Improve the basic metering system of the mine

- (5)

- System Management

3.2. Hierarchical Modeling

3.3. Calculation of the Weight of Each Factor

3.3.1. The Relative Weight of the Criterion Layer to the Target Layer

3.3.2. Calculation of the Relative Weights of the Alternative Layer to the Criterion Layer

- (1)

- Establish the judgment matrix of B1

- (2)

- Judgment matrix for reducing mine electricity consumption B2

- (3)

- Judgment matrix for reducing the heat consumption of the mine B3

- (4)

- Improve the judgment matrix of the mine base metering system B4

- (5)

- Judgment matrix of system management B5

3.4. Factor Ranking

3.5. Fuzzy Integrated Evaluation Method

3.5.1. The Use of Expert Scoring to Obtain a Set of Qualitative Comments

3.5.2. One-Level Comprehensive Evaluation

- (1)

- The fuzzy evaluation matrix of the alternative level can be obtained according to the qualitative index scoring table Ri

- (2)

- Find the first-order integrated parity matrix Bi

- (3)

- Secondary comprehensive evaluation

- (4)

- Grade evaluation

- (5)

- Evaluation results

4. Suggestions for Energy Saving and Emission Reduction in Mines

- (1)

- Improve the recovery rate of clean coal

- (2)

- Equipment replacement and transformation

- (3)

- Intelligent management of power metering

- (4)

- System management

5. Conclusions

- (1)

- According to the documents and information about energy saving and emission reduction in Wuyang coal mine, and the discussion of experts, the factors affecting energy saving and emission reduction can be divided into two levels. It includes five criteria layers and 24 alternative layers. According to the data, the criteria layer can be divided into reducing coal washing loss, reducing mine power consumption, reducing mine heat consumption, and improving mine basic measurement system and system management. The largest weight is to reduce coal washing loss (0.3873), reducing mine electricity consumption (0.1936), and reducing mine heat consumption (0.1936), which have equal weight, followed by improving mine basic metering system (0.1224), and the smallest weight is the system management (0.1031).

- (2)

- According to the weight ranking, the main factors affecting energy saving and emission reduction can be obtained in 24 alternative schemes, such as improving the recovery rate of clean coal, reforming the pressure filter, eliminating the high energy-consuming equipment, optimizing the parking process, replacing the flotation machine, and the intelligent management of power metering. The greatest weight is to improve the recovery of clean coal (0.1187), followed by modifying the pressurized filter (0.1090) and elimination of high energy-consuming equipment (0.0614).

- (3)

- The fuzzy comprehensive evaluation of the weight obtained by the analytic hierarchy process can obtain the energy-saving and emission reduction situation of Wuyang coal mine. The evaluation grade of the five factors of the energy-saving and emission reduction scheme layer of Wuyang coal mine is ‘good’. It can be seen that Wuyang coal mine has great potential for energy conservation and emission reduction, and there is a lot of room for improvement. Corresponding countermeasures can be proposed for the factors with higher weight in Wuyang coal mine, such as improving the recovery rate of refined coal, upgrading and modernizing energy-consuming and old equipment, perfecting the basic measurement system the mine, and establishing a sound energy consumption management mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.J. Research on comprehensive utilization of nonferrous metal mineral resources under low-carbon economic model. World Nonferrous Met. 2022, 21, 187–189. [Google Scholar]

- Wang, J.H.; Gao, D.; Chen, J.F. Evaluation of Coal Seam Roof Stability Based on Analytic Hierarchy Process. Coal Technol. 2022, 41, 20–23. [Google Scholar]

- Van Laarhoven, P.J.M.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Qin, C. Research on the evaluation of building electrical energy-saving design based on the phase of hierarchical analysis fuzzy synthesis theory. Electr. Autom. 2022, 3, 113–115+118. [Google Scholar]

- Wang, X.A. Multicriteria Decision Model Based on Analytic Hierarchy Process for Managing Safety in Coal Mines. Geofluids 2022, 1–9. [Google Scholar] [CrossRef]

- Fertat, L.; Cherkaoui, A. Occupational Health Maturity by Combined AHP and Fuzzy Comprehensive Evaluation Methods. In Proceedings of the 30th IBIMA Communications, Madrid, Spain, 8–9 November 2017. [Google Scholar]

- Diao, J.X.; Guo, F.; Xun, H.Z. Energy saving evaluation of farm houses in dams based on AHP-fuzzy integrated evaluation method. Build. Energy Effic. 2021, 49, 127–133. [Google Scholar]

- Cui, S.W. Study on the evaluation of the risk of water burst from coal seam floor trap column based on fuzzy hierarchical analysis. Energy Technol. Manag. 2022, 48, 105–108. [Google Scholar]

- Gokce, C.; Merve, G.T. Sustainable Industrialization Performance Evaluation of European Union Countries: An Integrated Spherical Fuzzy Analytic Hierarchy Process and Grey Relational Analysis Approach. Taylor Fr. 2022, 29, 387–400. [Google Scholar]

- Zhang, Z.; Wang, Z.Y.; Feng, K. Study on the Adaptability of Shield Machine Based on Improved Analytic Hierarchy Process and Fuzzy Comprehensive Evaluation Method. Constr. Technol. 2021, 50, 106–111. [Google Scholar]

- Saikia Binoy, K. Value Addition to Low-grade Coal Resources: A New Avenue for its Alternative Utilization. J. Geol. Soc. India 2022, 1328. [Google Scholar] [CrossRef]

- Ramadhan, M.D. Drill Holes Spacing Analysis for Estimation and Classification of Coal Resources Based on Variogram and Kriging. IOP Conf. Ser. Earth Environ. Sci. 2021, 819, 012026. [Google Scholar] [CrossRef]

- Fawaz, A.; Meshal, A. Performance Appraisal of Urban Street-Lighting System: Drivers’ Opinion-Based Fuzzy Synthetic Evaluation. Appl. Sci. 2023, 13, 3333. [Google Scholar]

- Zhang, B.; Wu, R. Construction of equipment evaluation index system of emergency medical rescue based on Delphi method and analytic hierarchy process. Ain Shams Eng. J. 2022, 14, 101870. [Google Scholar]

- Zhou, H.Y.; Bao, Q.G.; Ye, M. Safety Evaluation of Urban Gas Pipeline Network Based on Fuzzy Analytic Hierarchy Process. Value Eng. 2022, 41, 43–45. [Google Scholar]

- Sandeepa, K.; Simarjeet, S. Risk analysis in decentralized finance (DeFi): A fuzzy-AHP approach. Risk Manag. 2023, 25, 13. [Google Scholar]

- Li, D.F.; Liu, H.C.; Zhang, J. Numerical Simulation Study of Confined Space Gas Explosion Based on Hierarchical Analysis. Coal Technol. 2022, 41, 108–111. [Google Scholar]

- Du, W.H. Discussion on the causes and management techniques of media loss in coal washing process. Min. Equipment. 2022, 6, 109–111. [Google Scholar]

- Zhu, L.; Xie, J.J.; Liu, Z.X. Exploration and practice of electricity saving technology in coal mines. Inn. Mong. Coal Econ. 2021, 14, 61–62. [Google Scholar]

- Wang, Y.M.; Li, G.; Xu, Y. Progress and Prospects of Research on Thermal Environment Regulation in Deep Mines in China in the Past 20 Years. Met. Min. 2023, 3, 1–13. [Google Scholar]

- Li, T.; Guo, C.H. Design of online metering and monitoring system for mine surface well extraction. Autom. Technol. Appl. 2021, 40, 145–159. [Google Scholar]

- Yang, W.W.; He, S.L. Coal mine management index system and environmental risk model based on sustainable operation. Sustain. Energy Technol. Assessments 2022, 53. [Google Scholar] [CrossRef]

- Li, D.; Luo, D.Z.; Li, H.T. Feasibility evaluation of barrier lake development based on fuzzy comprehensive evaluation method. China Saf. Prod. Sci. Technol. 2022, 18 (Suppl. S1), 147–153. [Google Scholar]

- Gordon, R.; Wadim, S. Consumer Attitudes toward Energy Reduction and Changing Energy Consumption Behaviors. Energies 2023, 16, 1478. [Google Scholar]

| Scale | Meaning |

|---|---|

| 1 | Indicates that the two factors are of equal importance compared to each other |

| 3 | Indicates that one is slightly more important than the other when compared to two factors |

| 5 | Indicates that one is significantly more important than the other when compared to two factors |

| 7 | Indicates that one is strongly more important than the other when compared to two factors |

| 9 | Indicates the extreme importance of one over the other when compared to two factors |

| 2, 4, 6, 8 | The median of the above two adjacent judgments |

| Reciprocal | Comparing factor i with j yields judgment bij; comparing factor j with i yields judgment bji = 1/bij |

| Matrix Orders | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.52 | 0.89 | 1.12 | 1.26 | 1.36 | 1.41 | 1.46 | 1.49 | 1.52 | 1.54 |

| Target Layer A | B1 | B2 | B3 | B4 | B5 |

|---|---|---|---|---|---|

| B1 | 1 | 2 | 2 | 3 | 4 |

| B2 | 1/2 | 1 | 1 | 3/2 | 2 |

| B3 | 1/2 | 1 | 1 | 3/2 | 2 |

| B4 | 1/3 | 1 | 2/3 | 1 | 1 |

| B5 | 1/4 | 2/3 | 2/3 | 1 | 1 |

| B1 | C1 | C2 | C3 | C4 | C5 | w′i | wi |

|---|---|---|---|---|---|---|---|

| C1 | 1 | 2 | 1 | 2 | 3 | 1.6437 | 0.3064 |

| C2 | 1/2 | 1 | 1/2 | 1 | 1 | 0.7578 | 0.1407 |

| C3 | 1 | 2 | 1 | 2 | 2 | 1.5157 | 0.2814 |

| C4 | 1/2 | 1 | 1/2 | 1 | 1 | 0.7578 | 0.1407 |

| C5 | 1/3 | 1 | 1/2 | 1 | 1 | 0.6988 | 0.1307 |

| B2 | C6 | C7 | C8 | C9 | C10 | C11 | w’i | wi |

|---|---|---|---|---|---|---|---|---|

| C6 | 1 | 4/3 | 2 | 2 | 4 | 8 | 2.3551 | 0.3171 |

| C7 | 3/4 | 1 | 3/2 | 3/2 | 3 | 6 | 1.7663 | 0.2379 |

| C8 | 1/2 | 2/3 | 1 | 1 | 2 | 4 | 1.1775 | 0.1586 |

| C9 | 1/2 | 2/3 | 1 | 1 | 2 | 4 | 1.1775 | 0.1586 |

| C10 | 1/4 | 1/3 | 1/2 | 1/2 | 1 | 4 | 0.6609 | 0.0916 |

| C11 | 1/8 | 1/6 | 1/4 | 1/4 | 1/4 | 1 | 0.2622 | 0.0362 |

| B3 | C12 | C13 | C14 | C15 | C16 | w′i | wi |

|---|---|---|---|---|---|---|---|

| C12 | 1 | 5/4 | 2 | 5/4 | 5/3 | 1.3910 | 0.2710 |

| C13 | 4/5 | 1 | 6/5 | 1 | 4/3 | 1.0506 | 0.2052 |

| C14 | 1/2 | 5/6 | 1 | 5/6 | 2/3 | 0.7462 | 0.1472 |

| C15 | 4/5 | 1 | 6/5 | 1 | 4/3 | 1.0506 | 0.2052 |

| C16 | 3/5 | 3/4 | 3/2 | 3/4 | 1 | 0.8727 | 0.1713 |

| B4 | C17 | C18 | C19 | C20 | w′i | wi |

|---|---|---|---|---|---|---|

| C17 | 1 | 2 | 3 | 3 | 2.0597 | 0.4624 |

| C18 | 1/2 | 1 | 4/3 | 3/2 | 1.0000 | 0.2246 |

| C19 | 1/3 | 3/4 | 1 | 1 | 0.7071 | 0.1588 |

| C20 | 1/3 | 2/3 | 1 | 1 | 0.6865 | 0.1541 |

| B5 | C21 | C22 | C23 | C24 | w′i | wi |

|---|---|---|---|---|---|---|

| C21 | 1 | 1 | 1 | 1/3 | 0.7598 | 0.1718 |

| C22 | 1 | 1 | 1 | 1/3 | 0.7598 | 1.1718 |

| C23 | 1 | 1 | 1 | 1/2 | 0.8408 | 0.1910 |

| C24 | 3 | 3 | 2 | 1 | 2.5097 | 0.4654 |

| Target Layer | Guideline Layer | Indicator Layer | Sorting | |

|---|---|---|---|---|

| Layering | Total Weighting | |||

| Energy-saving and emission reduction in mines | B1 (0.3873) | C1 | 0.1187 | 1 |

| C2 | 0.0545 | 4 | ||

| C3 | 0.1090 | 2 | ||

| C4 | 0.0545 | 4 | ||

| C5 | 0.0506 | 7 | ||

| B2 (0.1936) | C6 | 0.0614 | 3 | |

| C7 | 0.0461 | 9 | ||

| C8 | 0.0307 | 13 | ||

| C9 | 0.0307 | 13 | ||

| C10 | 0.0177 | 20 | ||

| C11 | 0.0070 | 24 | ||

| B3 (0.1936) | C12 | 0.0525 | 6 | |

| C13 | 0.0397 | 10 | ||

| C14 | 0.0285 | 15 | ||

| C15 | 0.0397 | 10 | ||

| C16 | 0.0332 | 12 | ||

| B4 (0.1224) | C17 | 0.0566 | 4 | |

| C18 | 0.0194 | 18 | ||

| C19 | 0.0275 | 16 | ||

| C20 | 0.0189 | 19 | ||

| B5 (0.1031) | C21 | 0.0177 | 20 | |

| C22 | 0.0177 | 20 | ||

| C23 | 0.0197 | 17 | ||

| C24 | 0.0480 | 8 | ||

| Indicator Name | Excellent (95 Points) | Good (80 Points) | Medium (65 Points) | Poor (50 Points) | Bad (30 Points) |

|---|---|---|---|---|---|

| C1 | Complete clean coal recovery system with high recovery rate | Complete clean coal recovery system with average recovery rate | The clean coal recovery system is relatively completely and the recovery rate is average | The clean coal recovery system is still incomplete and the recovery efficiency is not high | The clean coal recovery system is very incomplete and has very low recovery efficiency |

| C6 | The equipment and processes used are more advanced and do not consume energy | The equipment and process used are more advanced and slightly energy-consuming | The equipment and processes used are not advanced, and the energy consumption is average | The equipment and technology used are backward, slightly high energy-consuming | The equipment and technology used are very backward and very energy-consuming |

| C9 | The production system is very well developed | More complete production system | General perfection of production system | Imperfect production system | Very imperfect production system |

| C12 | Low pressure extraction systems are widely utilized and fully operational | Low-pressure extraction systems are more widely utilized and not fully operational | Low-pressure extraction systems are less widely utilized and operate well | Low-pressure extraction systems are not widely utilized and are in general operation | Low-pressure extraction systems are not widely utilized and not operated |

| C17 | Sound information management system and very intelligent management | Information management system is relatively sound and intelligently managed | Basic sound information management system and intelligent management | Information management system is not very sound and slightly intelligent management | Information management system is very unsound and not intelligently managed |

| C24 | The system is totally scientific, perfect, and well implemented | The system is more scientific and perfect, and the implementation is good | The system is generally scientific and sound, and the implementation is also average | The system lacks scientificity and perfection, and is poorly implemented | The system lacks science, integrity, and is very poorly implemented |

| Guideline Layer B | Alternative Solution Layer C | Excellent | Good | Medium | Poor | Bad |

|---|---|---|---|---|---|---|

| B1 | C1 | 0.2 | 0.3 | 0.4 | 0.1 | 0 |

| C2 | 0 | 0.1 | 0.5 | 0.3 | 0.1 | |

| C3 | 0.1 | 0.1 | 0.4 | 0.3 | 0.1 | |

| C4 | 0.1 | 0.3 | 0.2 | 0.4 | 0 | |

| C5 | 0.2 | 0.2 | 0.4 | 0.1 | 0.1 | |

| B2 | C6 | 0.2 | 0.3 | 0.3 | 0.1 | 0.1 |

| C7 | 0.1 | 0.5 | 0.2 | 0.2 | 0 | |

| C8 | 0 | 0.4 | 0.3 | 0.2 | 0.1 | |

| C9 | 0.3 | 0.2 | 0.3 | 0.1 | 0.1 | |

| C10 | 0 | 0.2 | 0.5 | 0.3 | 0 | |

| C11 | 0 | 0.3 | 0.4 | 0.2 | 0.1 | |

| B3 | C12 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| C13 | 0.4 | 0.1 | 0.2 | 0.3 | 0 | |

| C14 | 0.2 | 0.2 | 0.4 | 0.2 | 0 | |

| C15 | 0.1 | 0.2 | 0.6 | 0 | 0.1 | |

| C16 | 0.2 | 0.4 | 0.3 | 0.1 | 0 | |

| B4 | C17 | 0 | 0.3 | 0.5 | 0.1 | 0.1 |

| C18 | 0.1 | 0.4 | 0.4 | 0 | 0.1 | |

| C19 | 0.3 | 0.2 | 0.1 | 0.4 | 0 | |

| C20 | 0.3 | 0.1 | 0.2 | 0.2 | 0.2 | |

| B5 | C21 | 0.4 | 0.3 | 0.2 | 0 | 0.1 |

| C22 | 0.2 | 0.3 | 0.3 | 0.3 | 0 | |

| C23 | 0.1 | 0.4 | 0.4 | 0.1 | 0 | |

| C24 | 0 | 0.2 | 0.4 | 0.3 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Hu, R.; Zhang, M.; Zhang, W.; Kang, Q.; Du, M. Energy Saving and Emission Reduction Potential Evaluation of a Coal Mine Based on Fuzzy Hierarchical Analysis. Sustainability 2023, 15, 11754. https://doi.org/10.3390/su151511754

Xu F, Hu R, Zhang M, Zhang W, Kang Q, Du M. Energy Saving and Emission Reduction Potential Evaluation of a Coal Mine Based on Fuzzy Hierarchical Analysis. Sustainability. 2023; 15(15):11754. https://doi.org/10.3390/su151511754

Chicago/Turabian StyleXu, Fenfang, Ruili Hu, Minbo Zhang, Weizhong Zhang, Qinrong Kang, and Mengzhen Du. 2023. "Energy Saving and Emission Reduction Potential Evaluation of a Coal Mine Based on Fuzzy Hierarchical Analysis" Sustainability 15, no. 15: 11754. https://doi.org/10.3390/su151511754

APA StyleXu, F., Hu, R., Zhang, M., Zhang, W., Kang, Q., & Du, M. (2023). Energy Saving and Emission Reduction Potential Evaluation of a Coal Mine Based on Fuzzy Hierarchical Analysis. Sustainability, 15(15), 11754. https://doi.org/10.3390/su151511754