Research on the POPi Digital Model Framework for BIM Implementation in High-Rise Megaprojects

Abstract

:1. Introduction

2. Basic Connotation of VDC/BIM in Engineering Projects

2.1. Meaning of BIM

2.2. Application Characteristics of BIM

- (1)

- BIM is diverse with respect to its application, software, and hardware. Studies in China and elsewhere have demonstrated that BIM can be applied in different stages of an engineering project and involves the work content, application fields, and application points of different participants. The application of BIM in Shanghai plays a leading role nationwide. In 2017, the Shanghai BIM Guidelines were updated. They list 9 major aspects of BIM application during the full life cycle of an engineering project, with a total of 39 basic application points [29]. To implement these functions, different BIM software and hardware are needed. In addition to basic model creation and analysis and simulation software, BIM software broadly includes the following: a collaborative project management platform, an operation and maintenance system, and quantity calculations. These types of BIM software, together with the corresponding hardware, constitute the infrastructure for BIM applications.

- (2)

- The application of BIM is cross-organizational task interdependent. As a complex information interaction process, the application of BIM in engineering projects requires different participants to cooperate with and support each other, i.e., task interdependence. This arrangement is a type of cross-organizational collaboration. The cross-organization coordination of information interaction and sharing based on BIM in the project layer creates multipoint webbed communication with strong task interdependence. The individual functions of BIM, such as model creation and collision detection, can be completed by individuals. However, for design coordination, model integration, and BIM-based collaborative management, multiple participants are required for cross-organizational collaboration. Dossick and Neff [30] found that unlike the traditional management mode and information fragmentation, BIM application requires the coordination and cooperation of all participants in the project. Differences in cross-organizational cooperation can influence the effect of BIM application in engineering projects.

2.3. Connotation of VDC/BIM

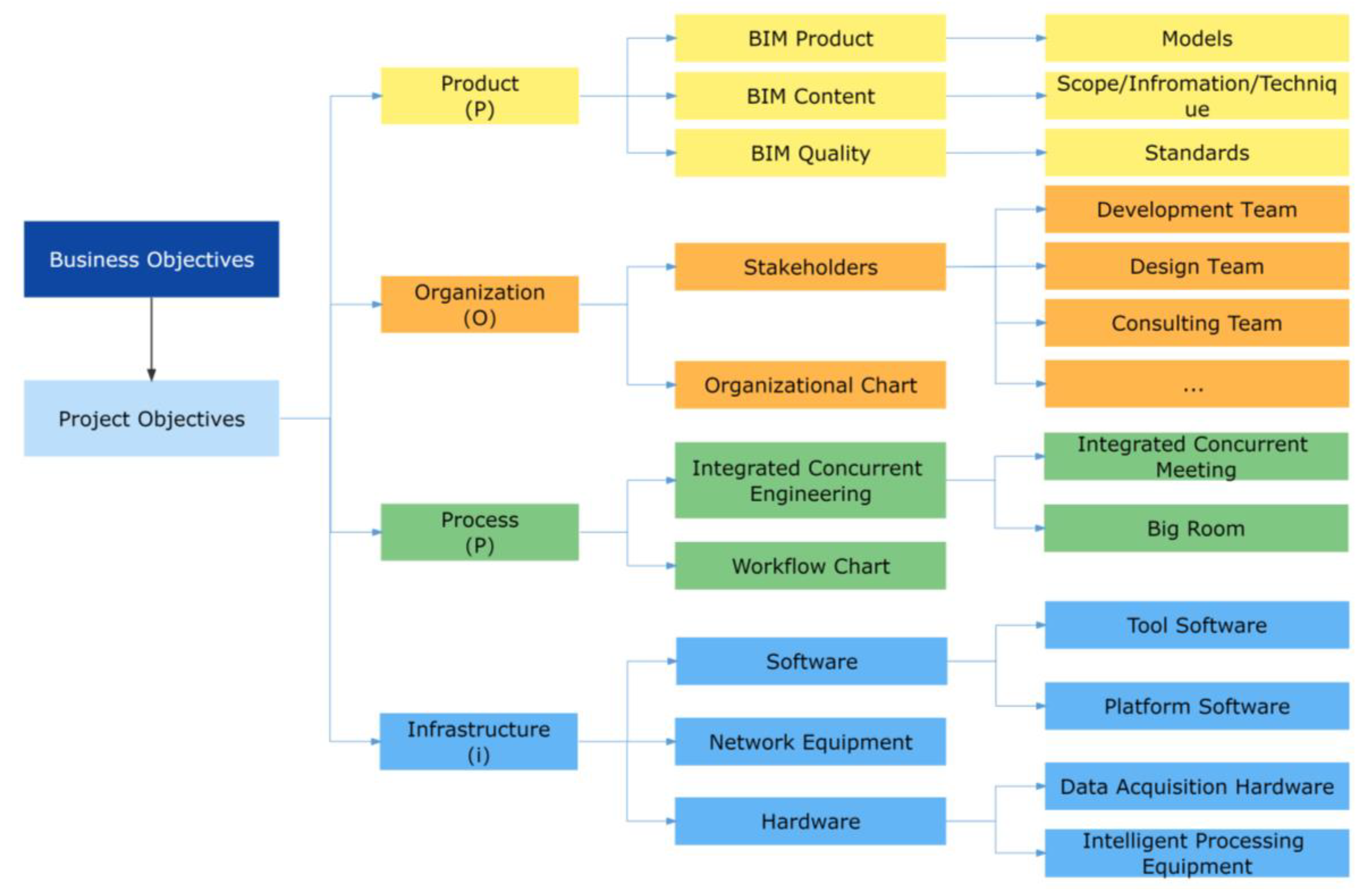

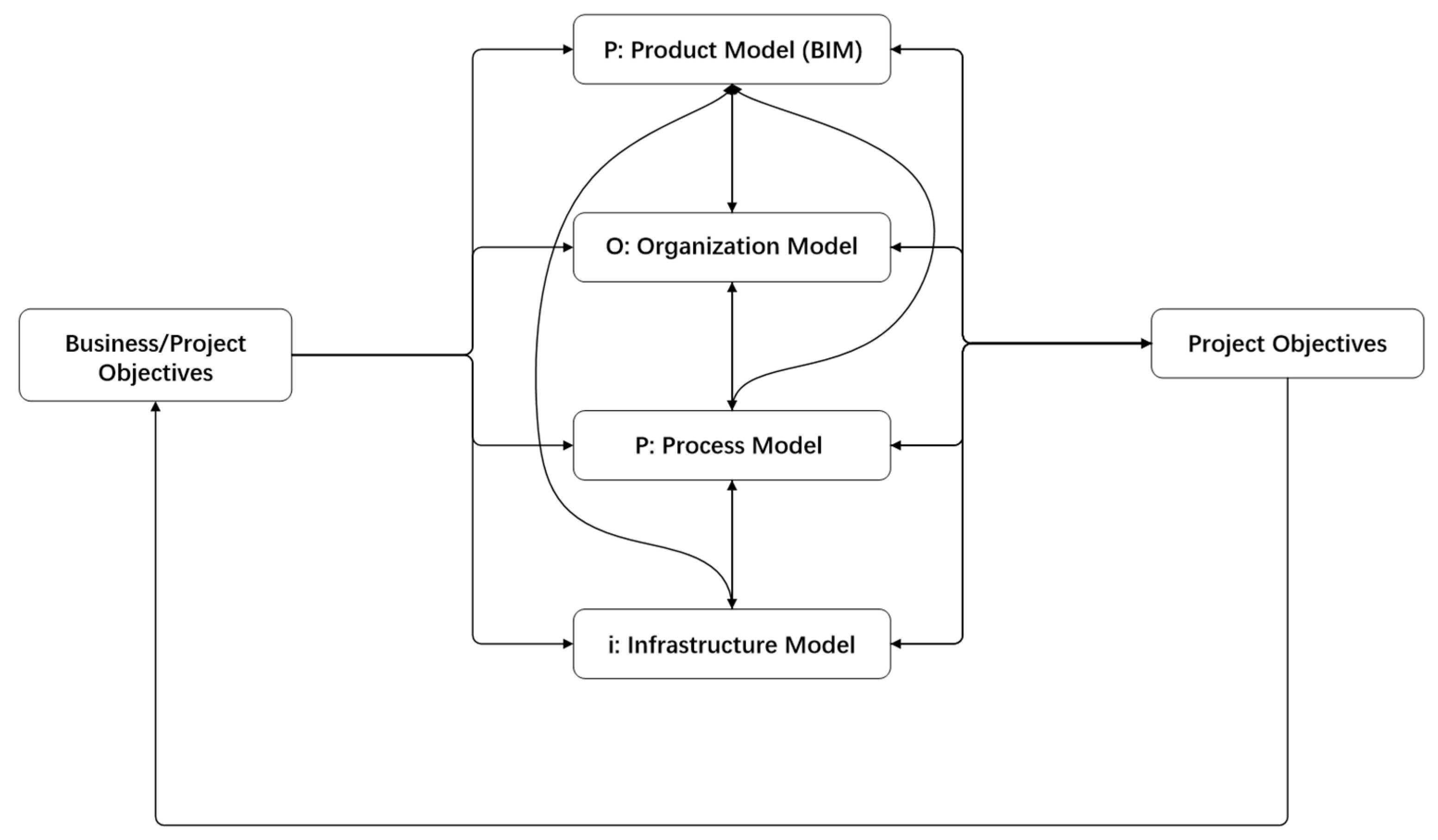

3. POPi Digital Integration Framework Based on BIM

3.1. Integrated POP Model

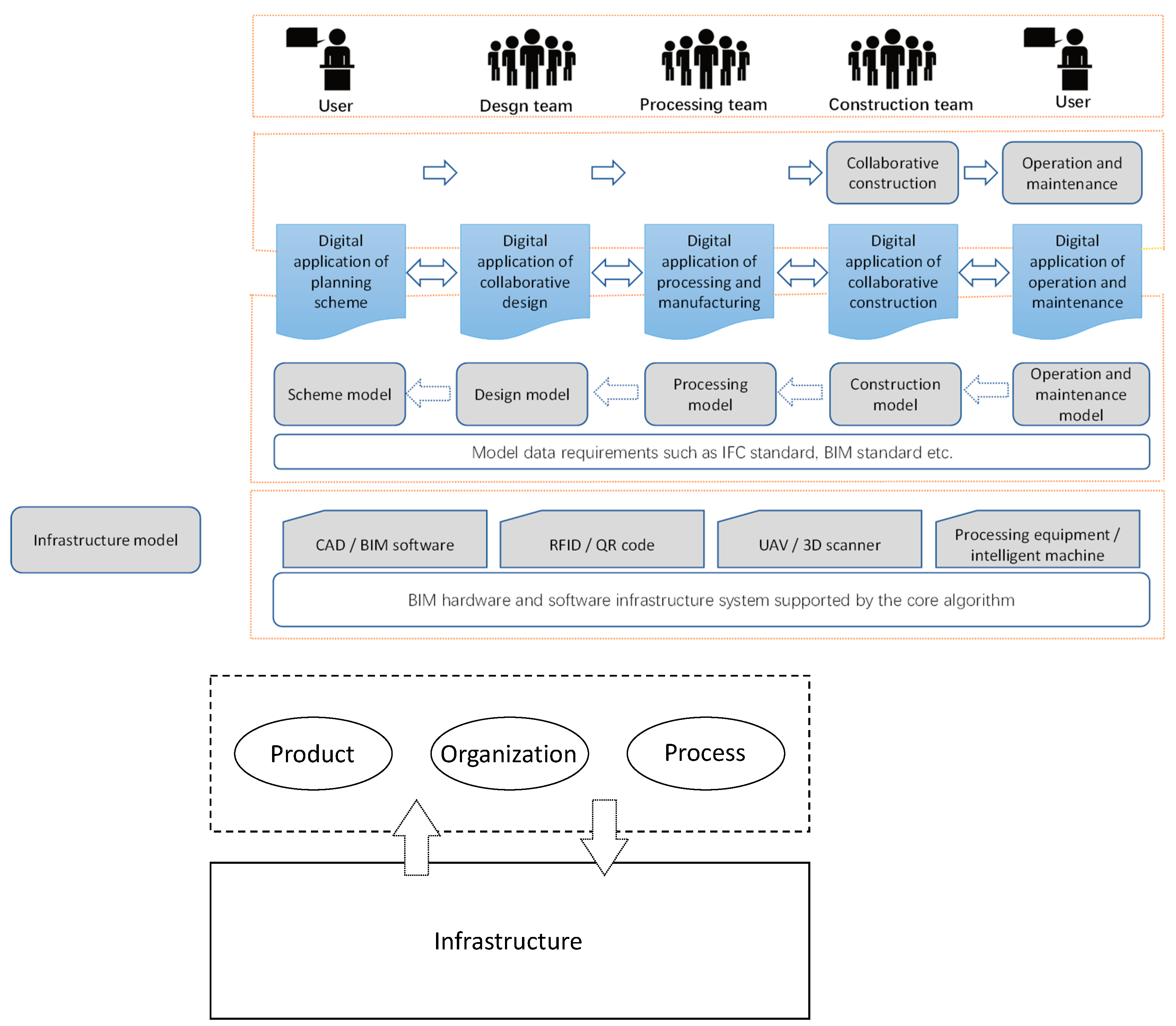

3.2. Software and Hardware Infrastructure of BIM

3.3. POPi Digital Integration Framework

3.4. Internal Mechanism of the POPi Digital Integration Framework

4. Practical Application of the POPi Framework in the Zhongnan Center

4.1. About the Project

4.1.1. Project Overview

4.1.2. Application Background

- (1)

- There are many participating parties throughout the life cycle of the project, including more than 20 major participants. Communication and coordination are difficult, requiring an efficient organizational process.

- (2)

- The design process is complex, and the number of drawings and other documents is immense. Determining how to improve the efficiency of design communication and coordination and ensure design quality is a great challenge.

- (3)

- The structural system is complex, and construction is difficult. The main structure is a “mega frame-core tube structure system”. The depth of the six floors of the foundation pit excavation is 33.4 m, and the reverse construction method is adopted.

- (4)

- The owner lacks experience in the development and management of similar projects. They must rely on modern technology and management methods, as well as the integrated wisdom and experience of project consultants and contractors.

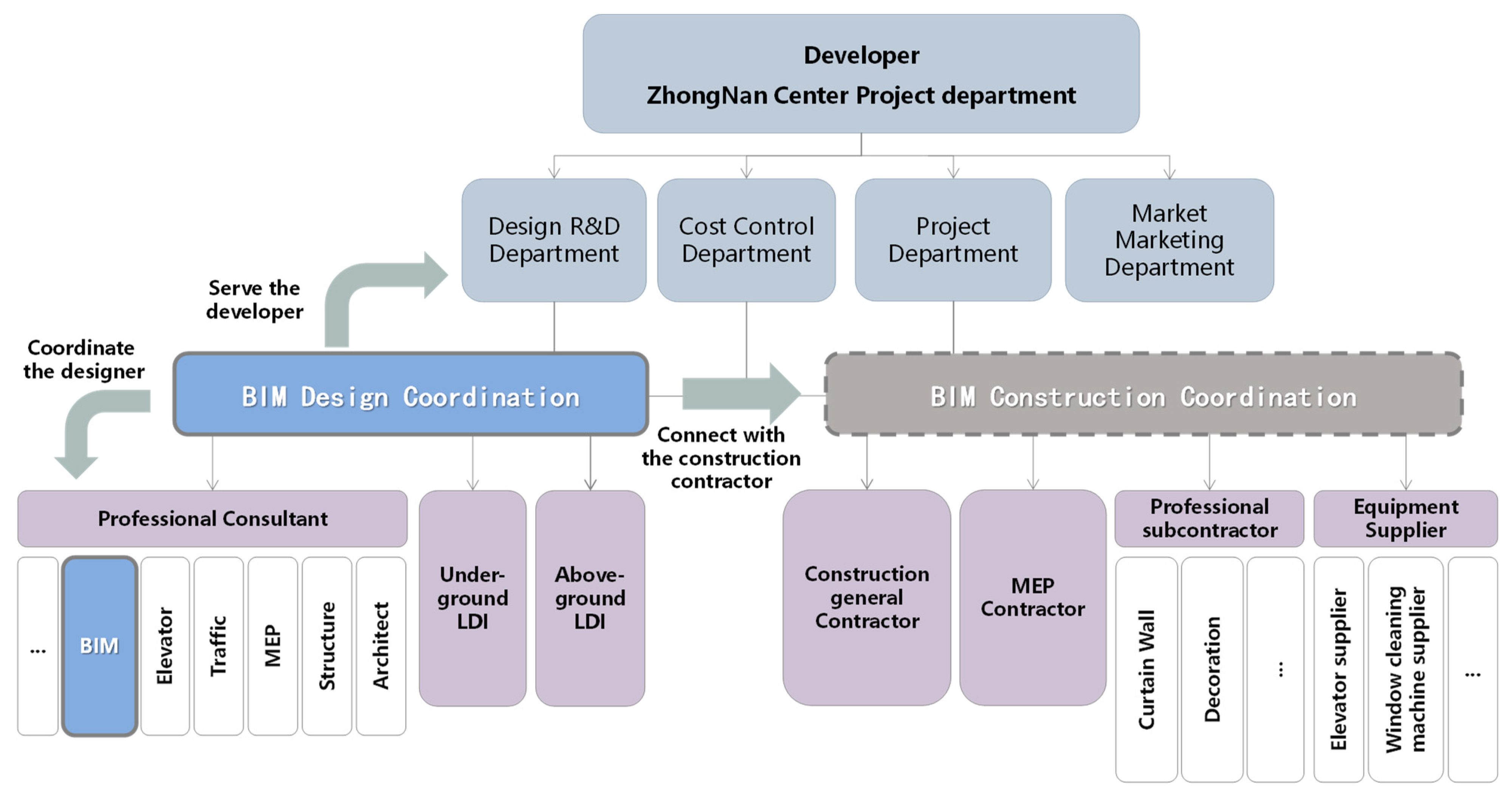

4.2. POPi Element Model for the Suzhou Zhongnan Center

- (1)

- Organization: The BIM consulting team is introduced to establish a BIM organizational structure with the owner as the core and all participants working collaboratively. The responsibilities and work responsibilities of each participant are defined.

- (2)

- Process: According to the characteristics of the Zhongnan Center project, the BIM application collaboration process is set at different stages, such as forming a “visual information sharing and problem solving mechanism” through BIM at the design phase to improve drawing quality and a “real-time comparison model and real-life construction quality management mechanism” through BIM+ scanning and BIM platform application to promote the owner’s ability to control the construction quality at the construction phase.

- (3)

- Model: To realize BIM collaboration at different stages, the overall model accuracy requirements of LOD300, LOD350, and LOD400 are set at the design, construction and operation, and maintenance stages separately.

- (4)

- Infrastructure: For the entire project, the CDE and the corresponding hardware and software platforms are set up, and the application software and versions of different scenarios are standardized. It is required to provide unmanned aerial vehicle (UAV) and laser scanning data in specific scenarios, and all software and hardware data can be exchanged.

4.2.1. Product Model

4.2.2. Organizational Model

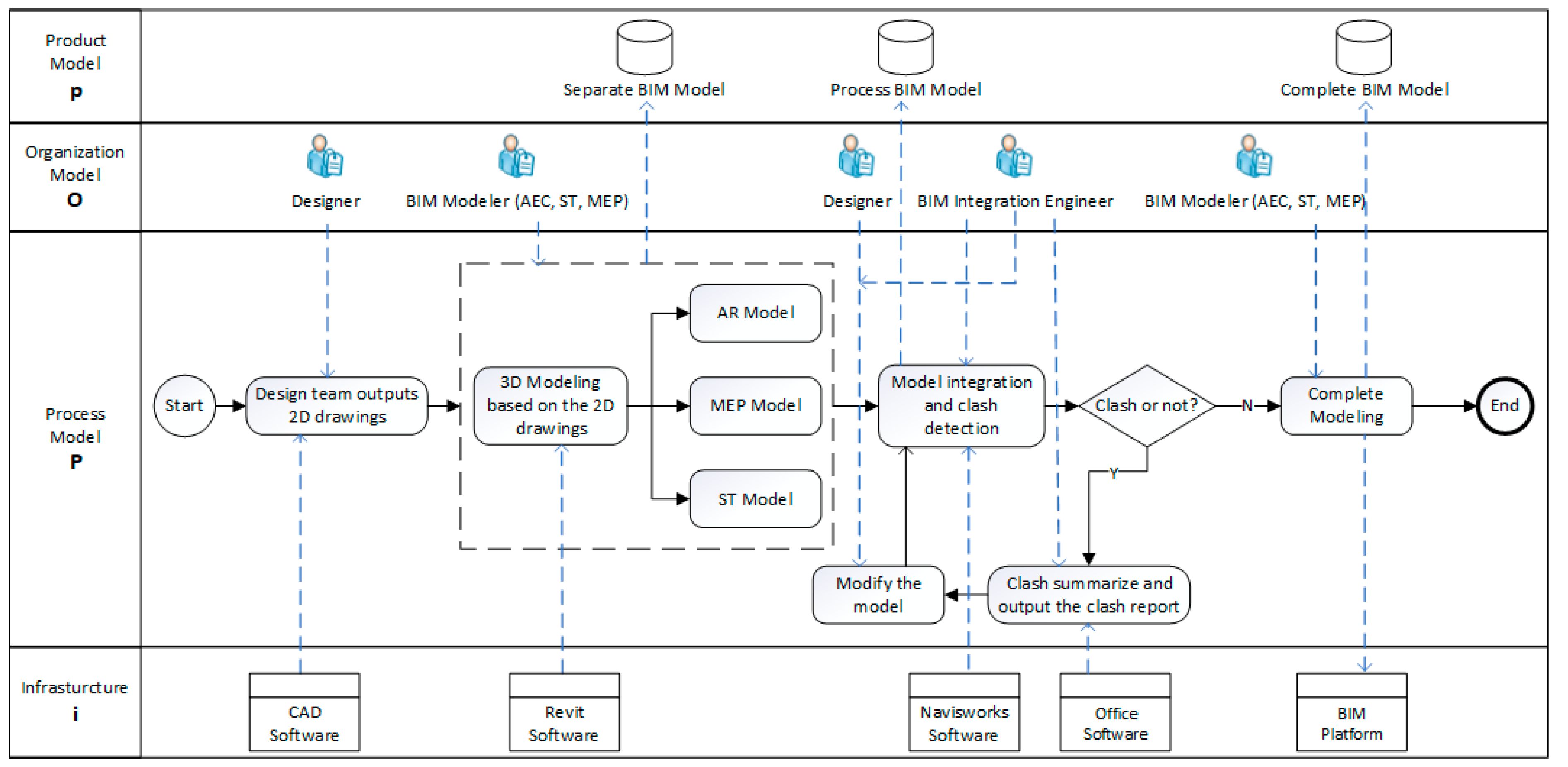

4.2.3. Process Model

4.2.4. Infrastructure Model

4.3. BIM Application

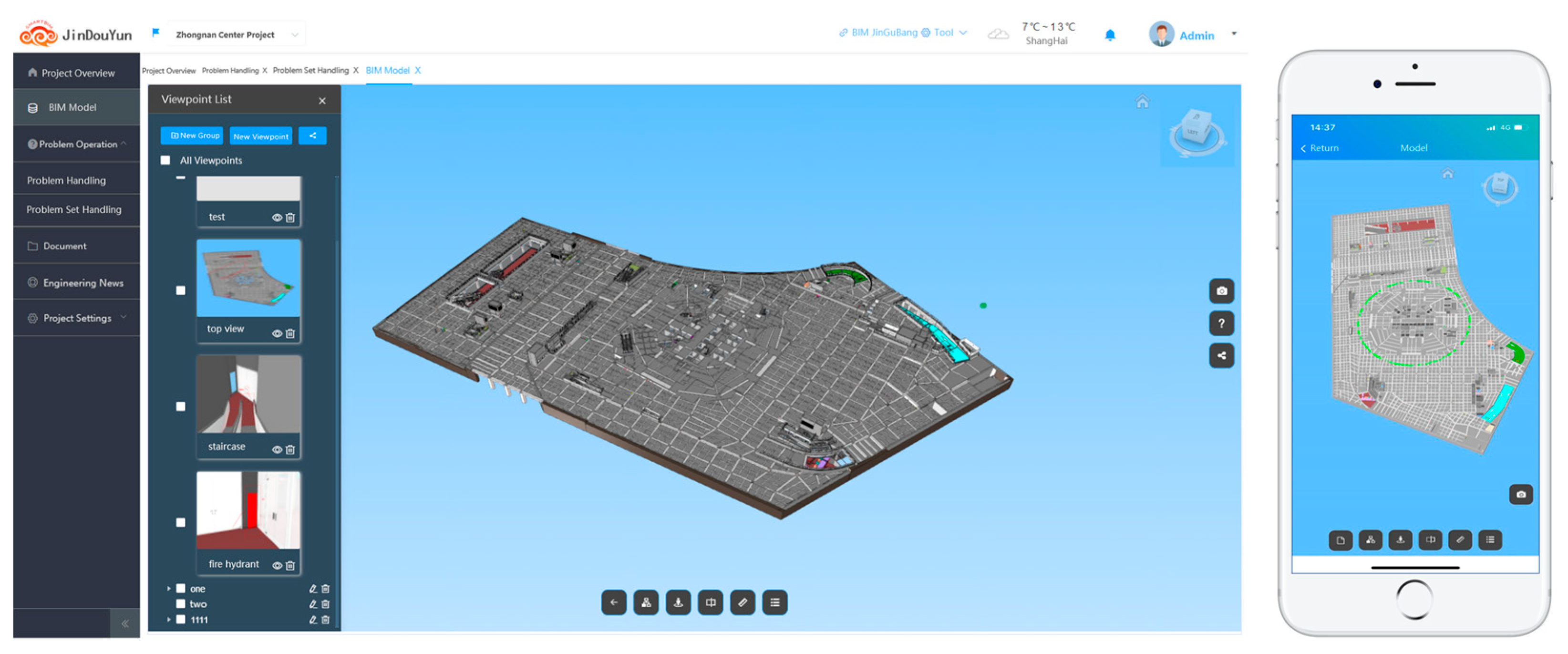

4.3.1. BIM Collaborative Platform

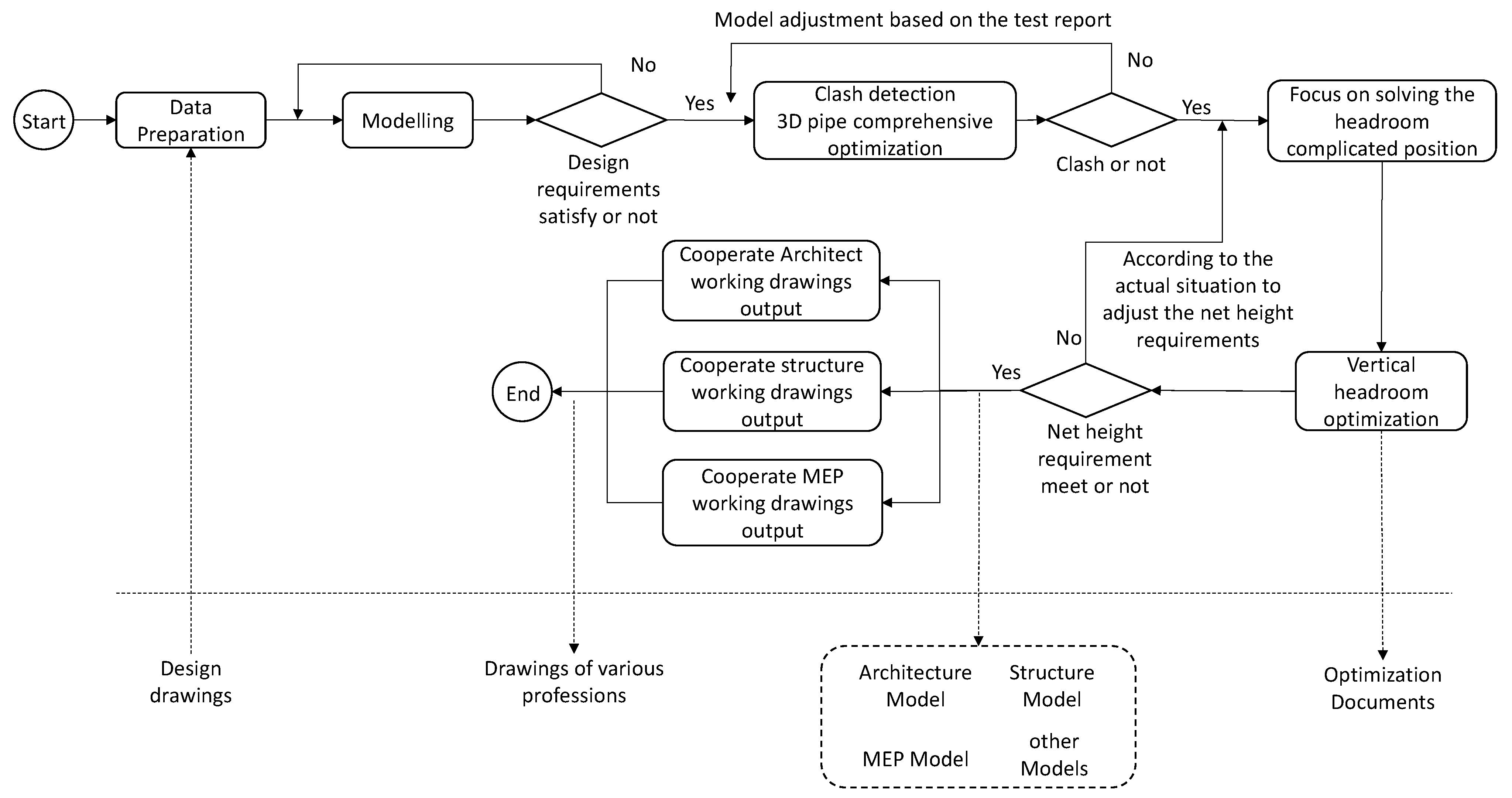

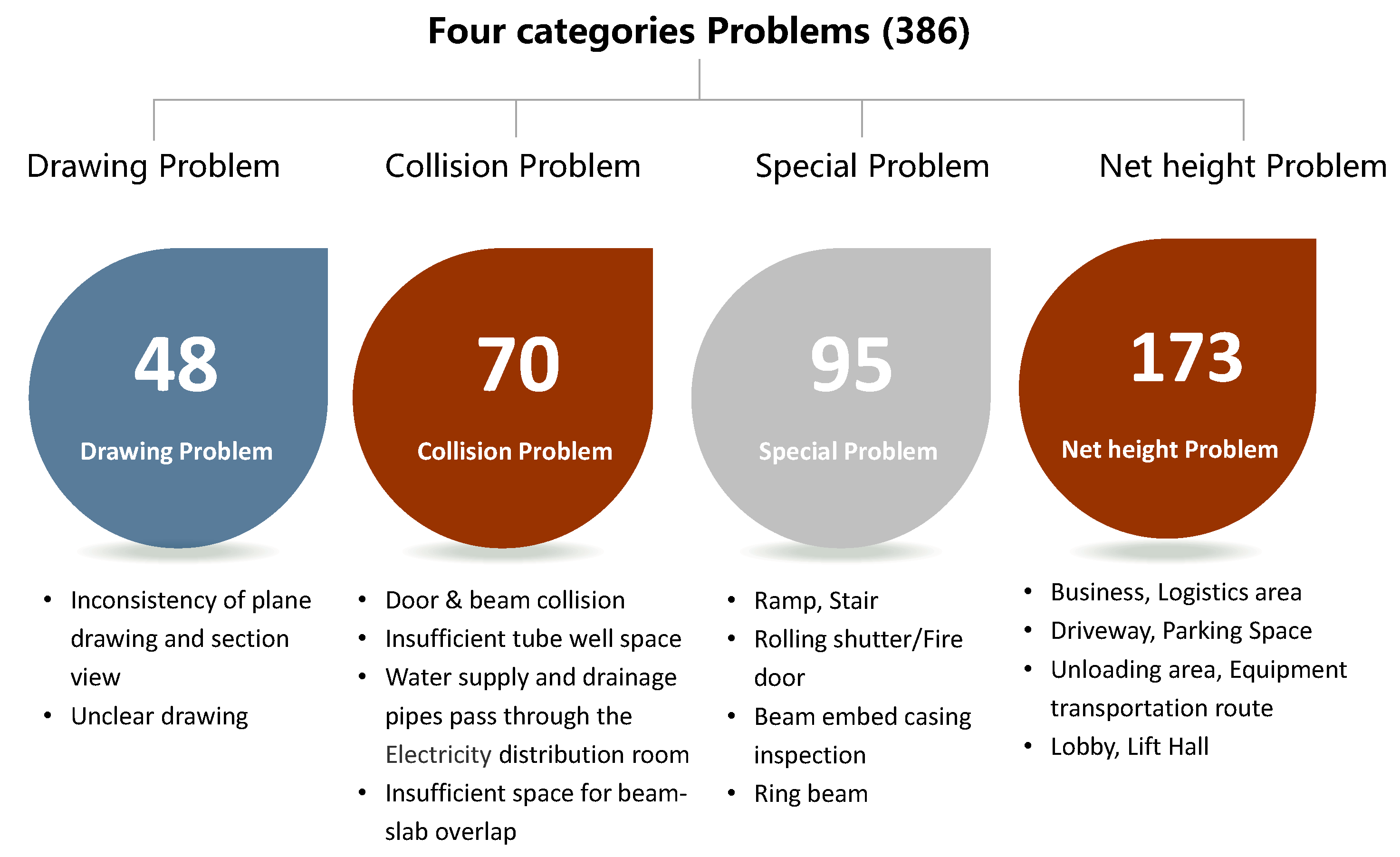

4.3.2. Collision Detection

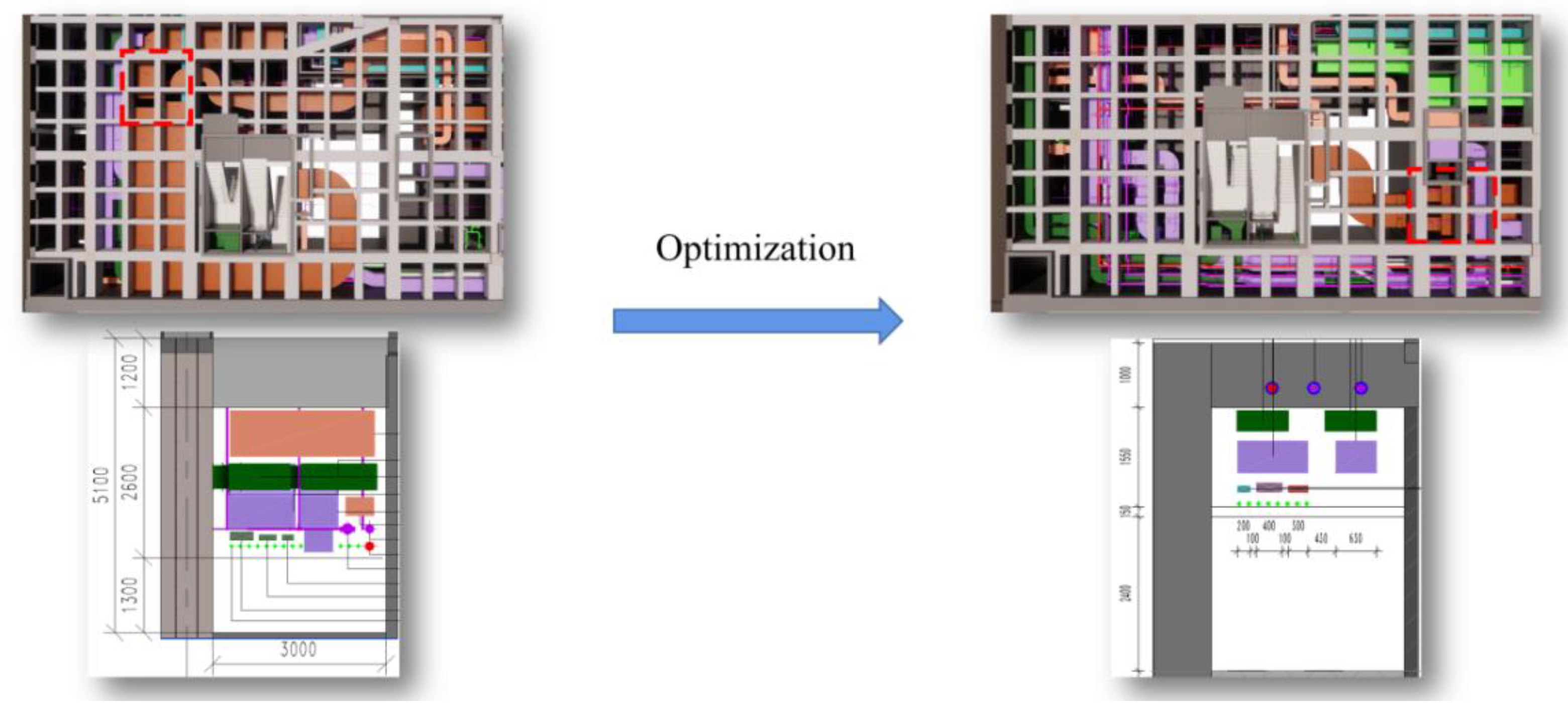

4.3.3. Head Clearance Optimization

4.3.4. Transportation Analysis

4.3.5. Template Modularization

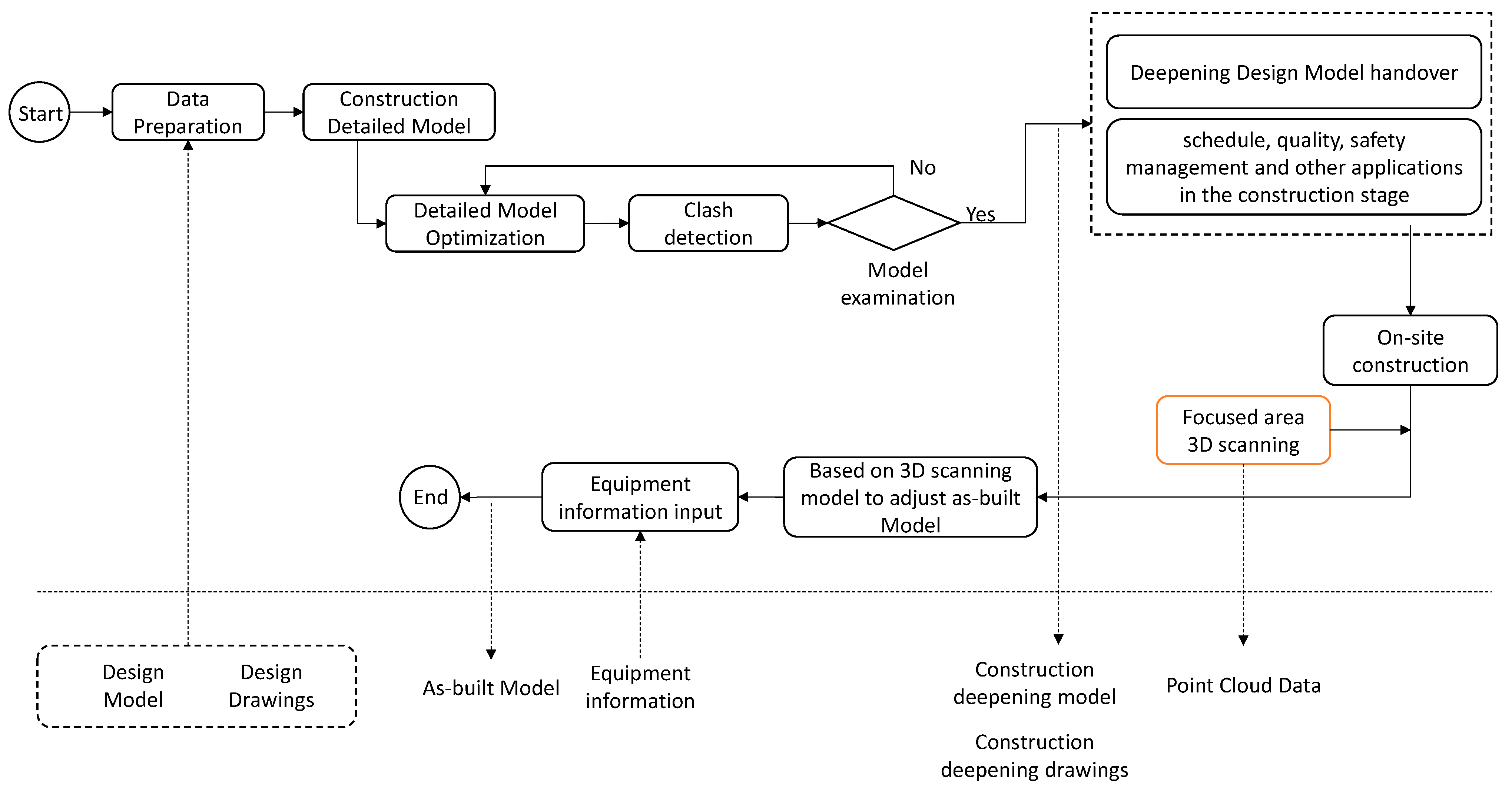

4.3.6. Automatic Monitoring of Foundation Pit

4.3.7. Indoor Three-Dimensional Scanning

4.4. Summary

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics of China. Available online: http://www.stats.gov.cn/sj/zxfb/202302/t20230228_1919011.html (accessed on 20 April 2023).

- Pekuri, A.; Haapasalo, H.; Herrala, M. Productivity and performance management–managerial practices in the construction industry. Int. J. Perform. Meas. 2011, 1, 39–58. Available online: https://www.researchgate.net/publication/265175596 (accessed on 20 April 2023).

- Frangedaki, E.; Sardone, L.; Marano, G.C.; Lagaros, N.D. Optimisation-driven design in the architectural, engineering and construction industry. Proc. Inst. Civ. Eng. 2023; ahead of print. [Google Scholar] [CrossRef]

- Dodanwala, T.; Shrestha, P.; Santoso, D. Role conflict related job stress among construction project professionals: The moderating role of age and organization tenure. Constr. Econ. Build. 2021, 21, 21–37. [Google Scholar] [CrossRef]

- Dodanwala, T.C.; Santoso, D.S. The mediating role of job stress on the relationship between job satisfaction facets and turnover intention of the construction professionals. Eng. Constr. Archit. Manag. 2022, 29, 1777–1796. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Lee, G. BIM Hand Book; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Lee, S.; Yu, J. Comparative study of BIM acceptance between Korea and the United States. J. Constr. Eng. Manag. 2016, 142, 05015016. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Lee, G. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Juan, Y.K.; Lai, W.Y.; Shih, S.G. Building information modeling acceptance and readiness assessment in Taiwanese architectural firms. J. Civ. Eng. Manag. 2017, 23, 356–367. [Google Scholar] [CrossRef] [Green Version]

- NRC (National Research Council). Advancing the Competitiveness and Efficiency of the US Construction Industry; National Academies Press: Washington, DC, USA, 2009.

- Gao, J.; Fischer, M. Framework and Case Studies Comparing Implementations and Impacts of 3D/4D Modeling Across Projects; CIFE: Stanford, CA, USA, 2008. [Google Scholar]

- Hartmann, T.; Gao, J.; Fischer, M. Areas of application for 3D and 4D models on construction projects. J. Constr. Eng. Manag. 2008, 134, 776–785. [Google Scholar] [CrossRef]

- Chin, S.; Yoon, S.; Choi, C.; Cho, C. RFID+4D CAD for progress management of structural steel works in high-rise buildings. J. Comput. Civ. Eng. 2008, 22, 74–89. [Google Scholar] [CrossRef]

- CICRP (Computer Integrated Construction Research Program). BIM Project Execution Planning Guide; Department of Architecture Engineering, Pennsylvania State University: University Park, PA, USA, 2011. [Google Scholar]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bynum, P.; Raja, R.A.I.; Olbina, S. Building information modeling in support of sustainable design and construction. J. Constr. Eng. Manag. 2013, 139, 24–34. [Google Scholar] [CrossRef]

- Bernstein, H.M. China BIM Application Value Research Report; Dodge Data and Analytics: Bedford, MA, USA, 2015. [Google Scholar]

- Musarat, M.A.; Alaloul, W.S.; Cher, L.S.; Qureshi, A.H.; Alawag, A.M.; Baarimah, A.O. Applications of Building Information Modelling in the operation and maintenance phase of construction projects: A framework for the Malaysian construction industry. Sustainability 2023, 15, 5044. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M.; Haymaker, J.; Levitt, R.E. Integrated and Automated Project Processes in Civil Engineering: Experiences of the CIFE at Stanford University; CIFE: Stanford, CA, USA, 2002. [Google Scholar]

- Sepasgozar, S.M.E.; Davis, S. Digital construction technology and job-site equipment demonstration: Modelling relationship strategies for technology adoption. Buildings 2019, 9, 158. [Google Scholar] [CrossRef] [Green Version]

- Saka, A.B.; Chan, D.W.M. Profound barriers to building information modelling (BIM) adoption in construction small and medium-sized enterprises (SMEs). Constr. Innov. 2020, 20, 261–284. [Google Scholar] [CrossRef]

- Anumba, C.J.; Duke, A. Internet and Intranet usage in a communications infrastructure for virtual construction project teams. In Proceedings of the 6th Workshop on Enabling Technologies (WET-ICE’97), Infrastructure for Collaborative Enterprises, MIT, Cambridge, MA, USA, 18–20 June 1997. [Google Scholar] [CrossRef]

- Siountri, K.; Skondras, E.; Vergados, D.D. Towards a smart museum using BIM, IoT, Blockchain and advanced digital technologies. In Proceedings of the ICVISP 2019: 3rd International Conference on Vision, Image and Signal Processing, Vancouver, BC, Canada, 26–28 August 2019. [Google Scholar] [CrossRef]

- Teizer, J.; Golovina, O.; Embers, S.; Wolf, M. A serious gaming approach to integrate BIM, IoT, and lean construction in construction education. In Construction Research Congress 2020; American Society of Civil Engineers: Reston, VA, USA, 2020. [Google Scholar] [CrossRef]

- No, S.T.; Hong, S.H.; Kim, J.Y. A study on objects information compatibility between BIM softwares for building thermal load analysis. Appl. Mech. Mater. 2012, 236–237, 646–651. [Google Scholar] [CrossRef]

- LI, Y.; He, G. BIM Softwares and Related Hardwares; China Construction Industry Press: Beijing, China, 2017. [Google Scholar]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M. Virtual design and construction. Constr. Manag. Econ. 2020, 38, 355–363. [Google Scholar] [CrossRef]

- Shanghai Municipal Commission of Housing and Urban Rural Development (SMC). Technical Guide for the Application of Building Information Model in Shanghai; 2017. Available online: https://www.shbimcenter.org/shanghaizhengce/20210022.html (accessed on 20 April 2023).

- Dossick Carrie, S.; Neff, G. Organizational divisions in BIM-enabled commercial construction. J. Constr. Eng. Manag. 2010, 136, 459–467. [Google Scholar] [CrossRef] [Green Version]

- Khanzode, A.; Fischer, M.; Reed, D.; Ballard, G. A Guide to Applying the Principles of Virtual Design and Construction (VDC) to the Lean Project Delivery Process; CIFE: Stanford, CA, USA, 2006. [Google Scholar]

- Guanpei, H. BIM and BIM related software. Civ. Eng. Inf. Technol. 2010, 4, 110–117. [Google Scholar] [CrossRef]

- Guangbin, W.; Yang, Z.; Xueying, Y.; Wenjuan, Z. New direction to informatization of construction projects—virtual design and construction. Eng. J. Wuhan Univ. 2008, 2, 90–93. Available online: https://www.webofscience.com/wos/alldb/full-record/CSCD:3277754 (accessed on 20 April 2023).

- Yansong, L.; Yajie, S.H.; Wei, Z. Application research of virtual design and construction (VDC) technology. Proj. Manag. Technol. 2016, 14, 46–51. [Google Scholar] [CrossRef]

- Mahmoud, B.B.; Lehoux, N.; Blanchet, P.; Cloutier, C. Barriers, strategies, and best practices for BIM adoption in quebec prefabrication small and medium-sized enterprises (SMEs). Buildings 2022, 12, 390. [Google Scholar] [CrossRef]

- Faghihi, V.; Nejat, A.; Reinschmidt, K.F.; Kang, J.H. Automation in construction scheduling: A review of the literature. Int. J. Adv. Manuf. Technol. 2015, 81, 1845–1856. [Google Scholar] [CrossRef]

- Martínez-Rojas, M.; Marín, N.; Vila, M.A. The role of information technologies to address data handling in construction project management. J. Comput. Civ. Eng. 2016, 30, 04015064. [Google Scholar] [CrossRef]

- Martínez-Rojas, M.; Del Carmen Pardo-Ferreira, M.; Rubio-Romero, J.C. Twitter as a tool for the management and analysis of emergency situations: A systematic literature review. Int. J. Inf. Manag. 2018, 43, 196–208. [Google Scholar] [CrossRef]

- Blázquez, M. Fashion shopping in multichannel retail: The role of technology in enhancing the customer experience. Int. J. Electron. Commer. 2014, 18, 97–116. [Google Scholar] [CrossRef] [Green Version]

- Demirkan, H.; Bess, C.; Spohrer, J.; Rayes, A.; Allen, D.; Moghaddam, Y. Innovations with smart service systems: Analytics, big data, cognitive assistance, and the internet of everything. Commun. Assoc. Inf. Syst. 2015, 37, 35. [Google Scholar] [CrossRef]

- Pantano, E.; Rese, A.; Baier, D. Enhancing the online decision-making process by using augmented reality: A two country comparison of youth markets. J. Retail. Consum. Serv. 2017, 38, 81–95. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (BIM) and digital twinning for sustainable construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, G. Cooperation between building information modeling and integrated project delivery method leads to paradigm shift of AEC industry. In 2009 International Conference on Management and Service Science; IEEE: Beijing, China, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Integrated implementation of virtual design and construction (VDC) and lean project delivery system (LPDS). J. Build. Eng. 2021, 39, 102252. [Google Scholar] [CrossRef]

- Mésároš, P.; Spišáková, M.; Mandičák, T.; Čabala, J.; Oravec, M.M. Adaptive design of formworks for building renovation considering the sustainability of construction in BIM environment—Case study. Sustainability 2021, 13, 799. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, Y.; Wu, J.; Zhang, Q.; Jin, J.; Wang, P. Research on the POPi Digital Model Framework for BIM Implementation in High-Rise Megaprojects. Sustainability 2023, 15, 11720. https://doi.org/10.3390/su151511720

Ying Y, Wu J, Zhang Q, Jin J, Wang P. Research on the POPi Digital Model Framework for BIM Implementation in High-Rise Megaprojects. Sustainability. 2023; 15(15):11720. https://doi.org/10.3390/su151511720

Chicago/Turabian StyleYing, Yuken, Jie Wu, Qilin Zhang, Jin Jin, and Pengfei Wang. 2023. "Research on the POPi Digital Model Framework for BIM Implementation in High-Rise Megaprojects" Sustainability 15, no. 15: 11720. https://doi.org/10.3390/su151511720

APA StyleYing, Y., Wu, J., Zhang, Q., Jin, J., & Wang, P. (2023). Research on the POPi Digital Model Framework for BIM Implementation in High-Rise Megaprojects. Sustainability, 15(15), 11720. https://doi.org/10.3390/su151511720