Revitalising Metallic Materials: A Path towards a Sustainable Circular Economy

Abstract

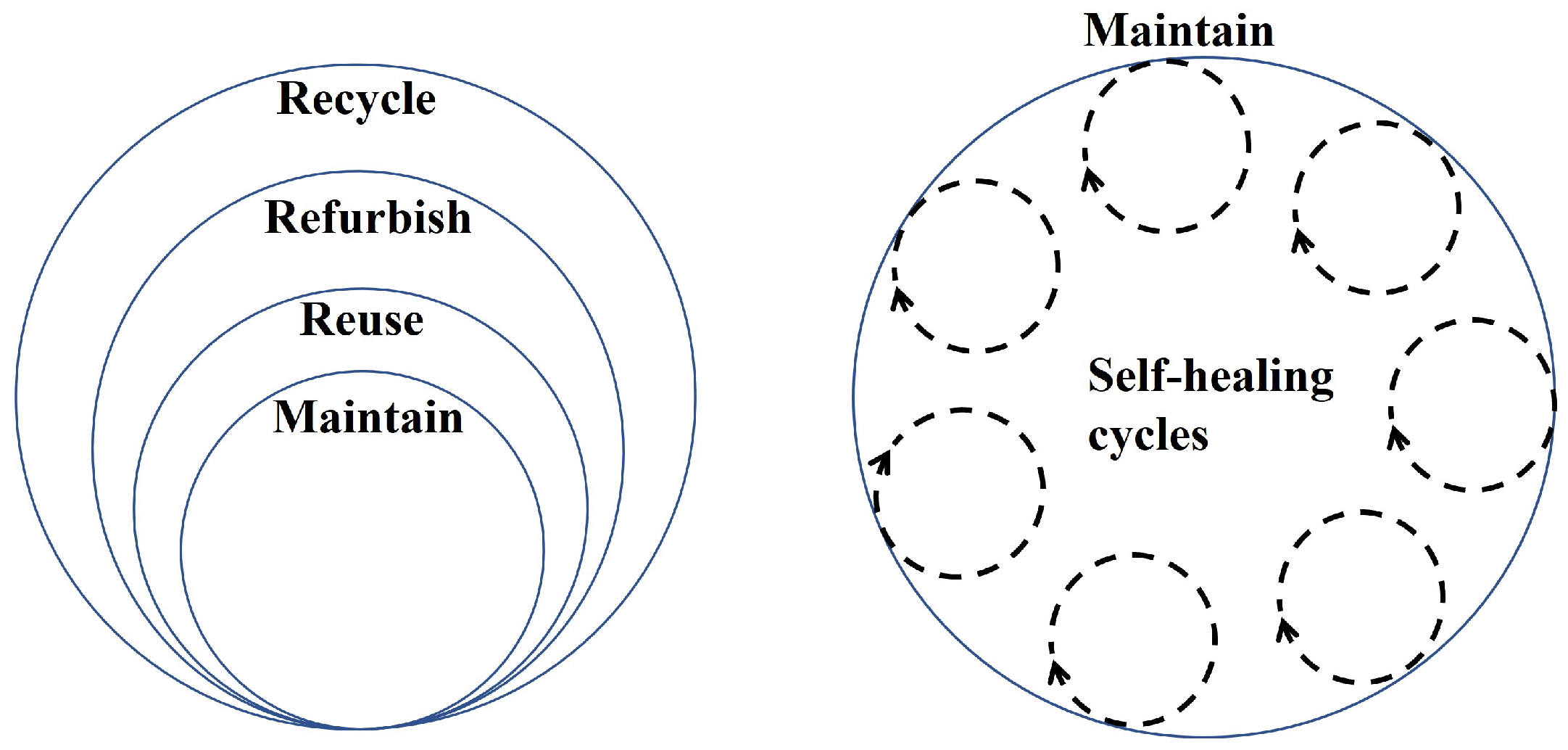

:1. Introduction

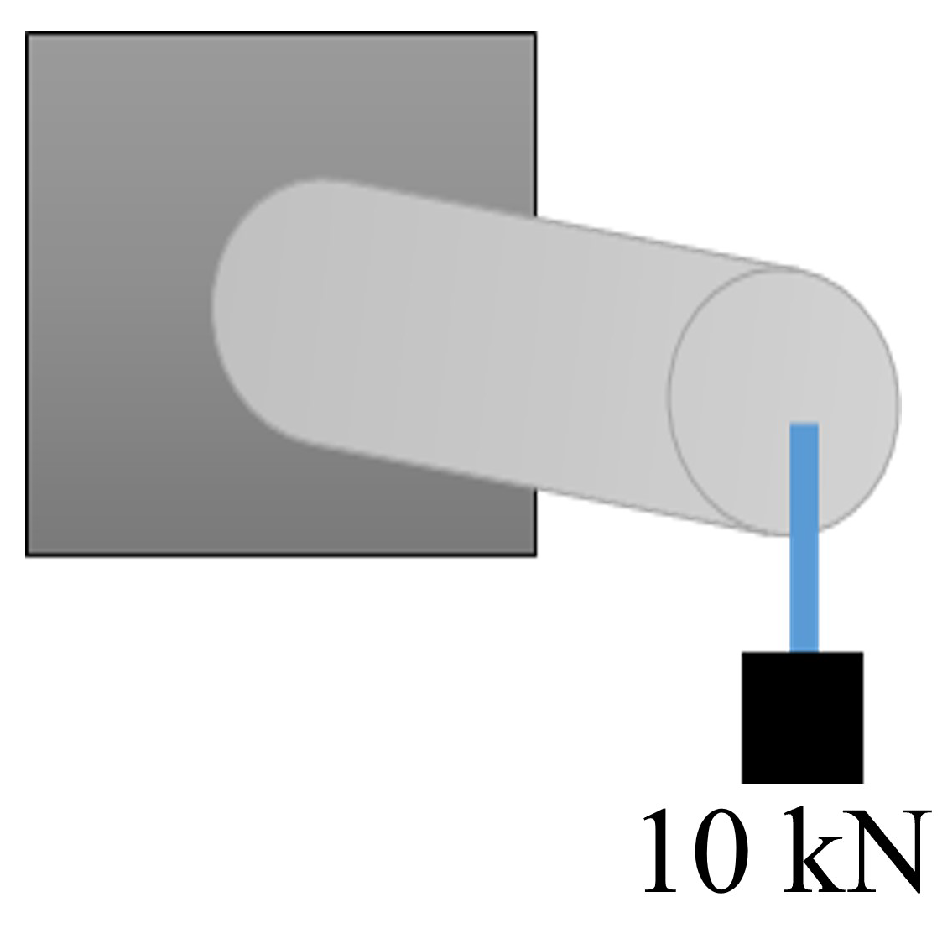

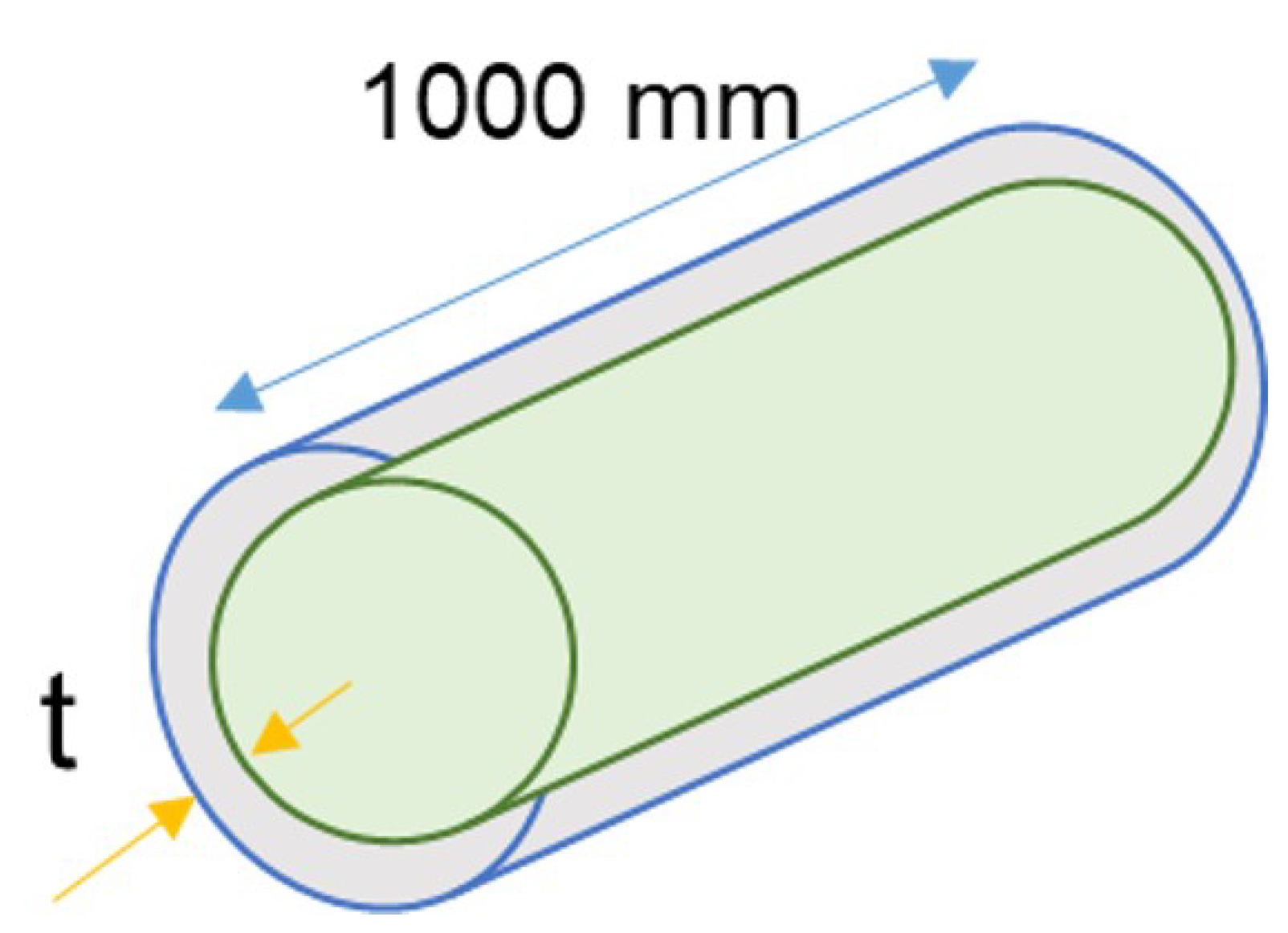

2. Methods

3. Results

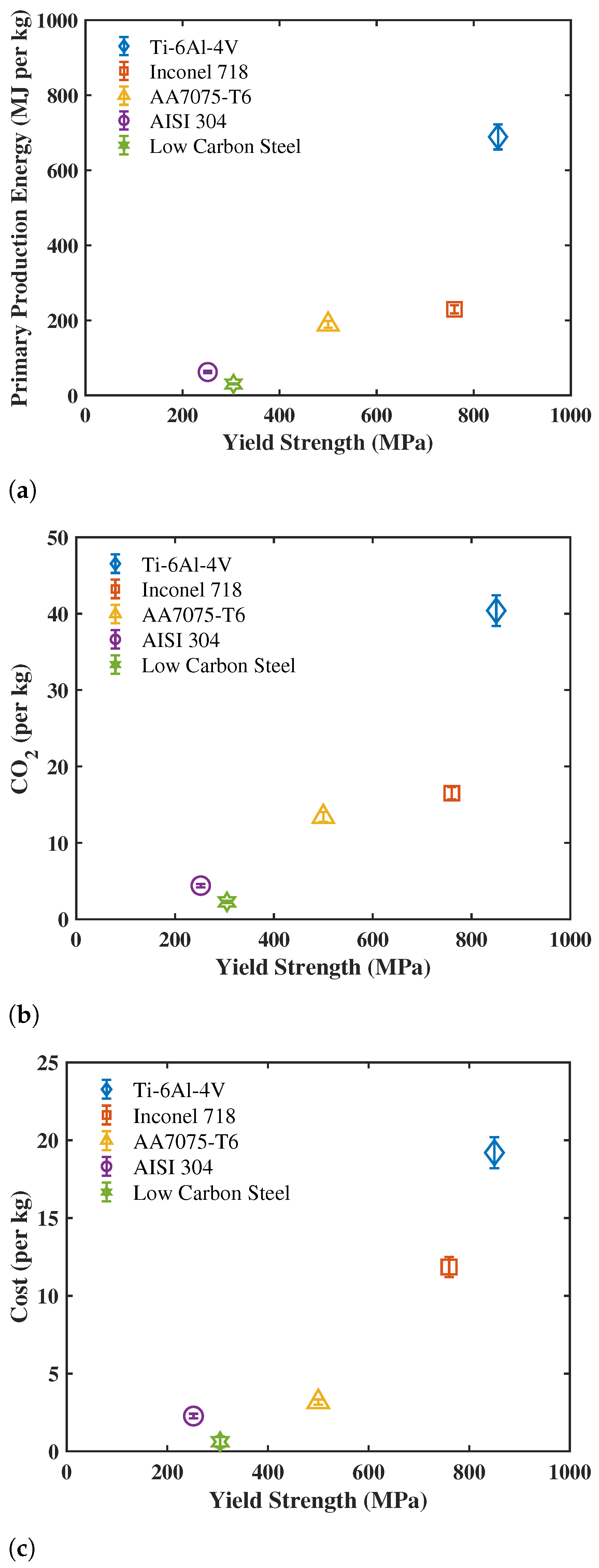

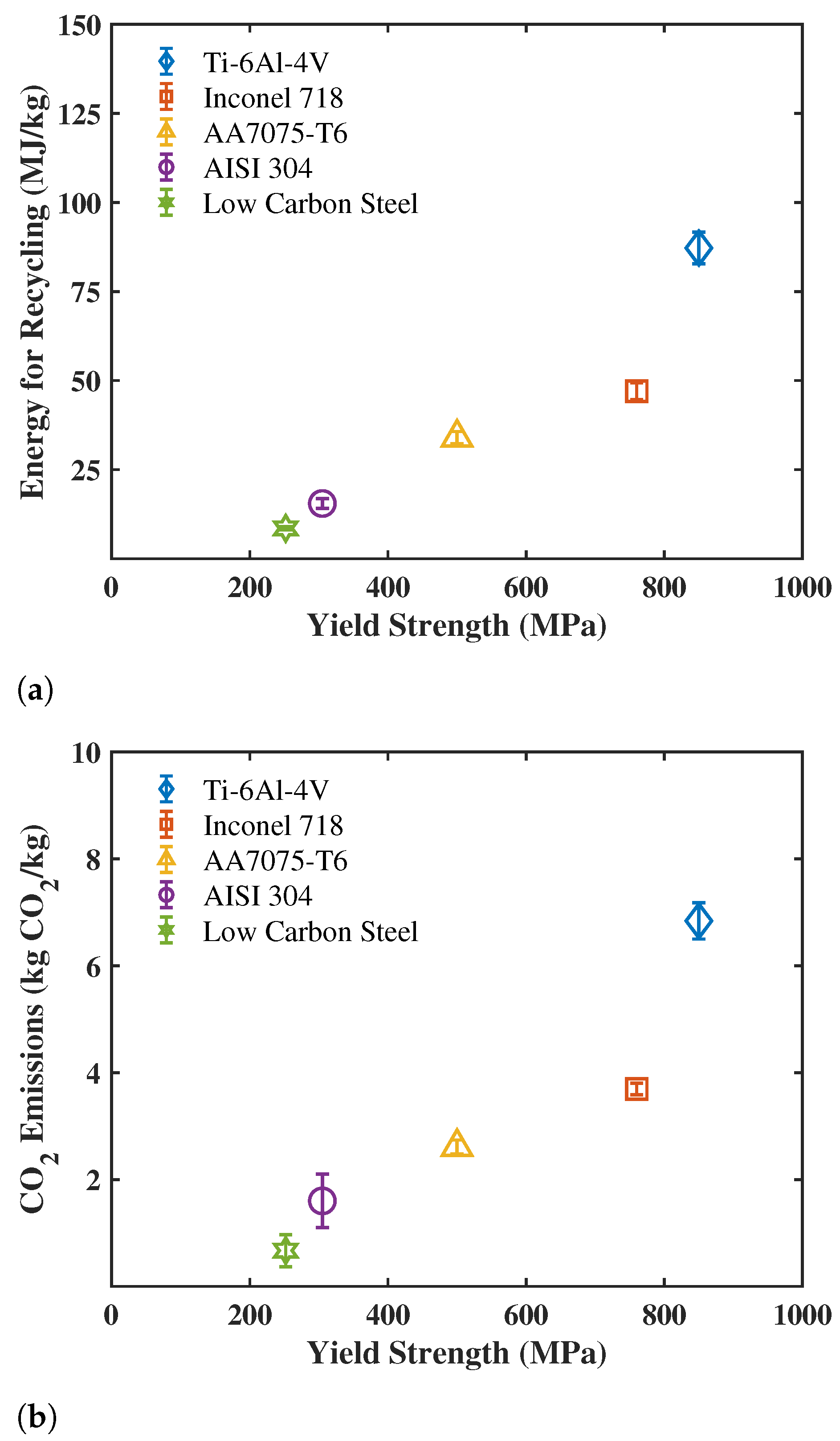

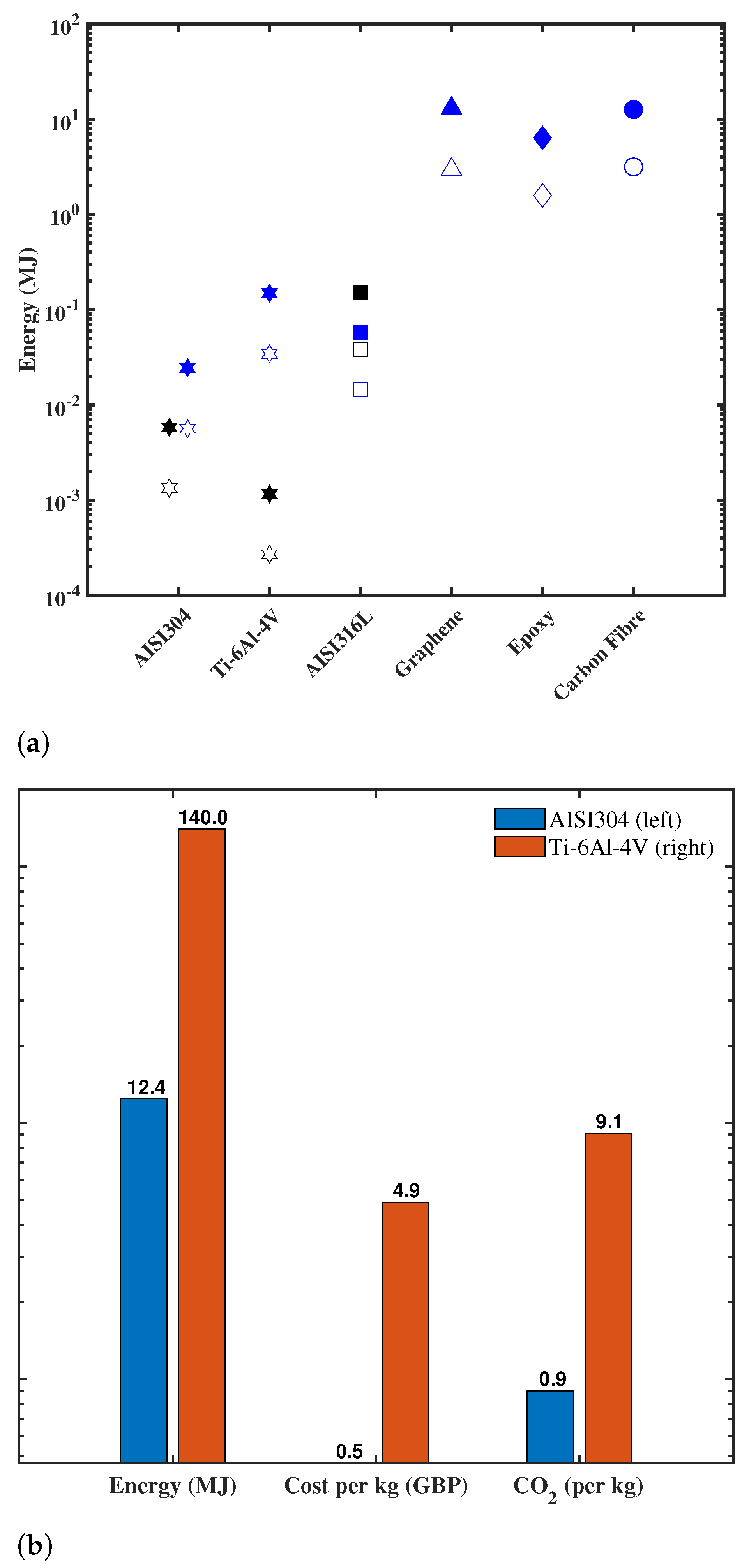

3.1. Recycling Potential of Materials

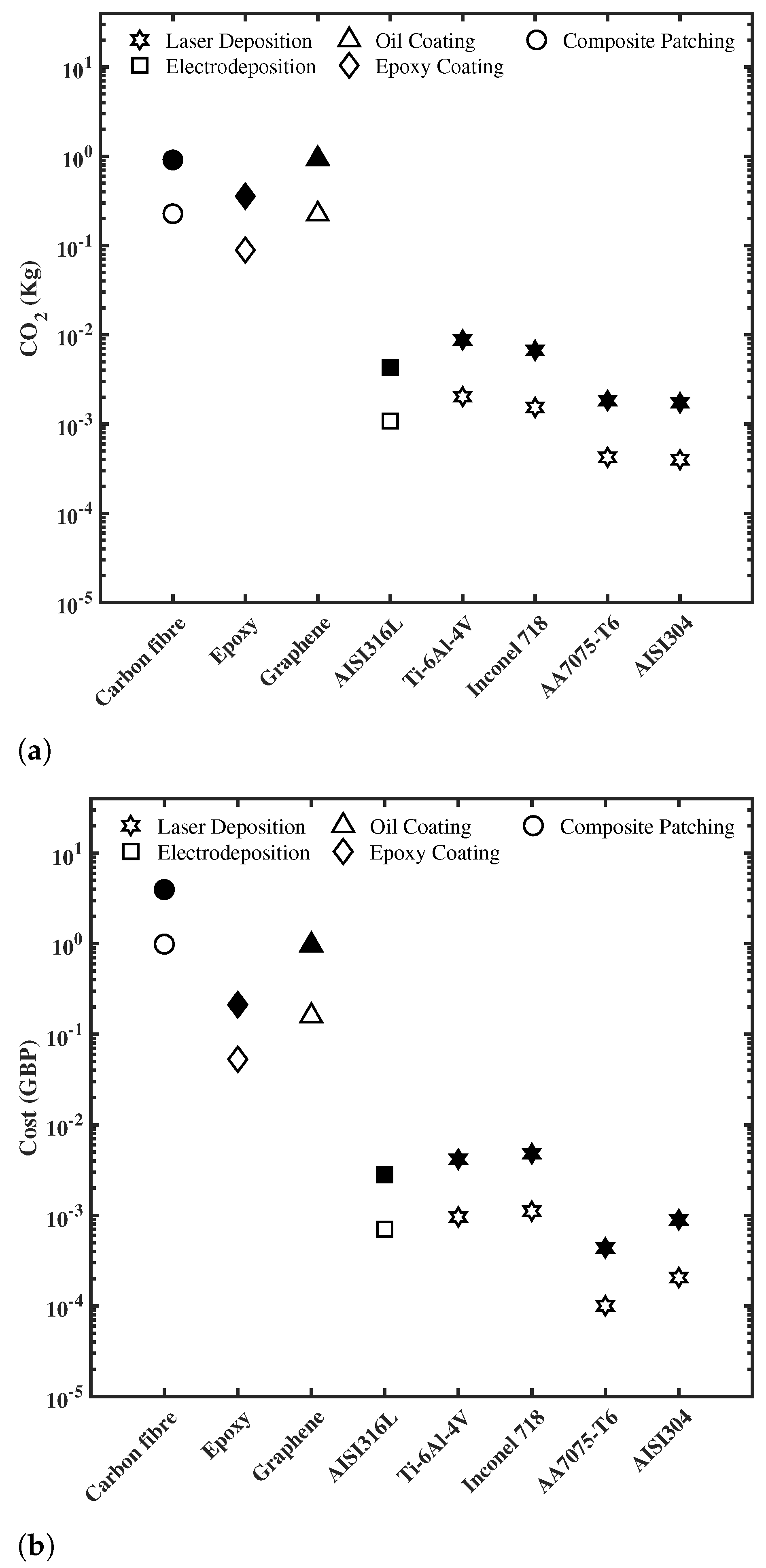

3.2. Environmental Footprint of Maintenance Techniques

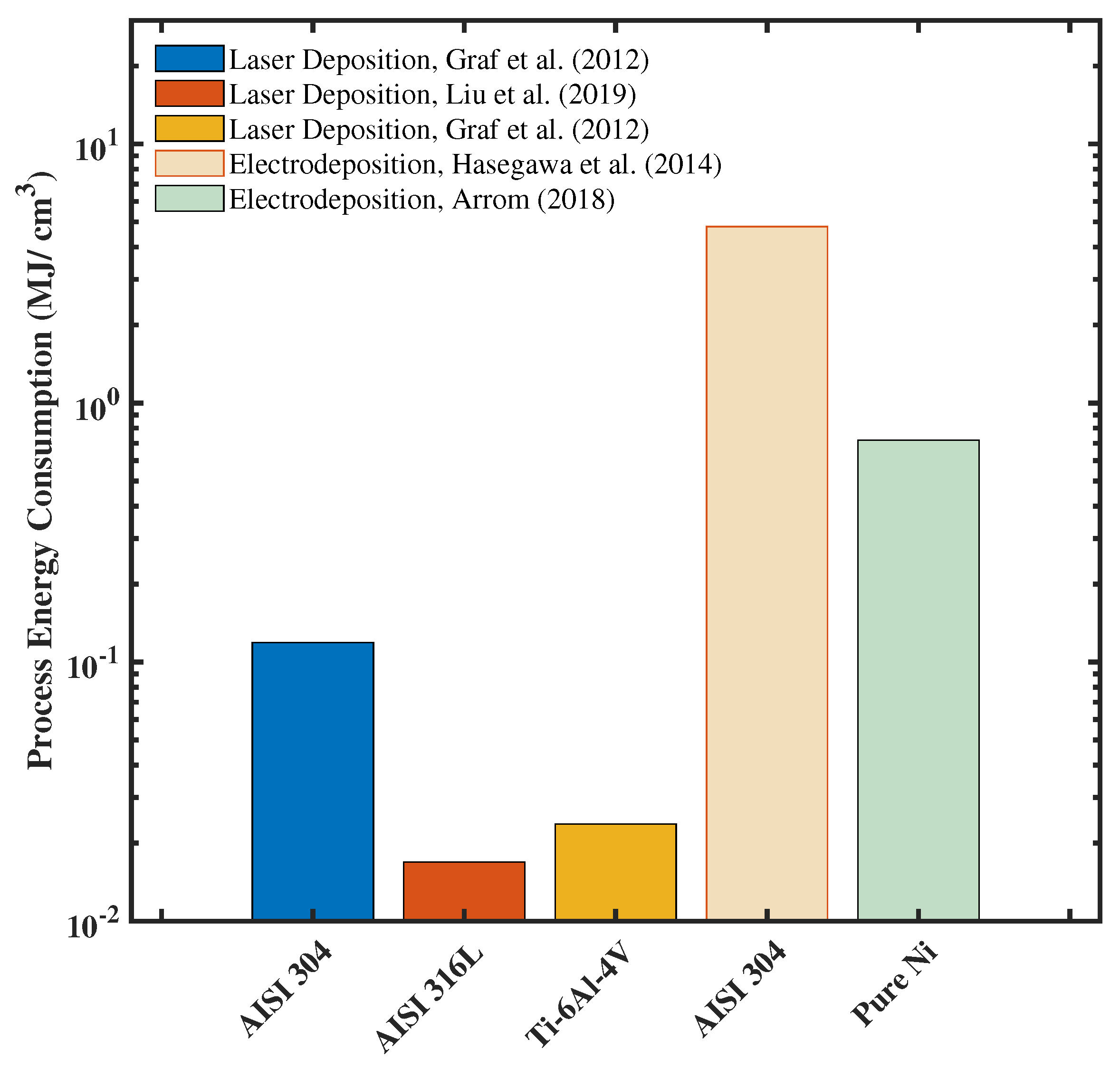

3.2.1. Coating Techniques

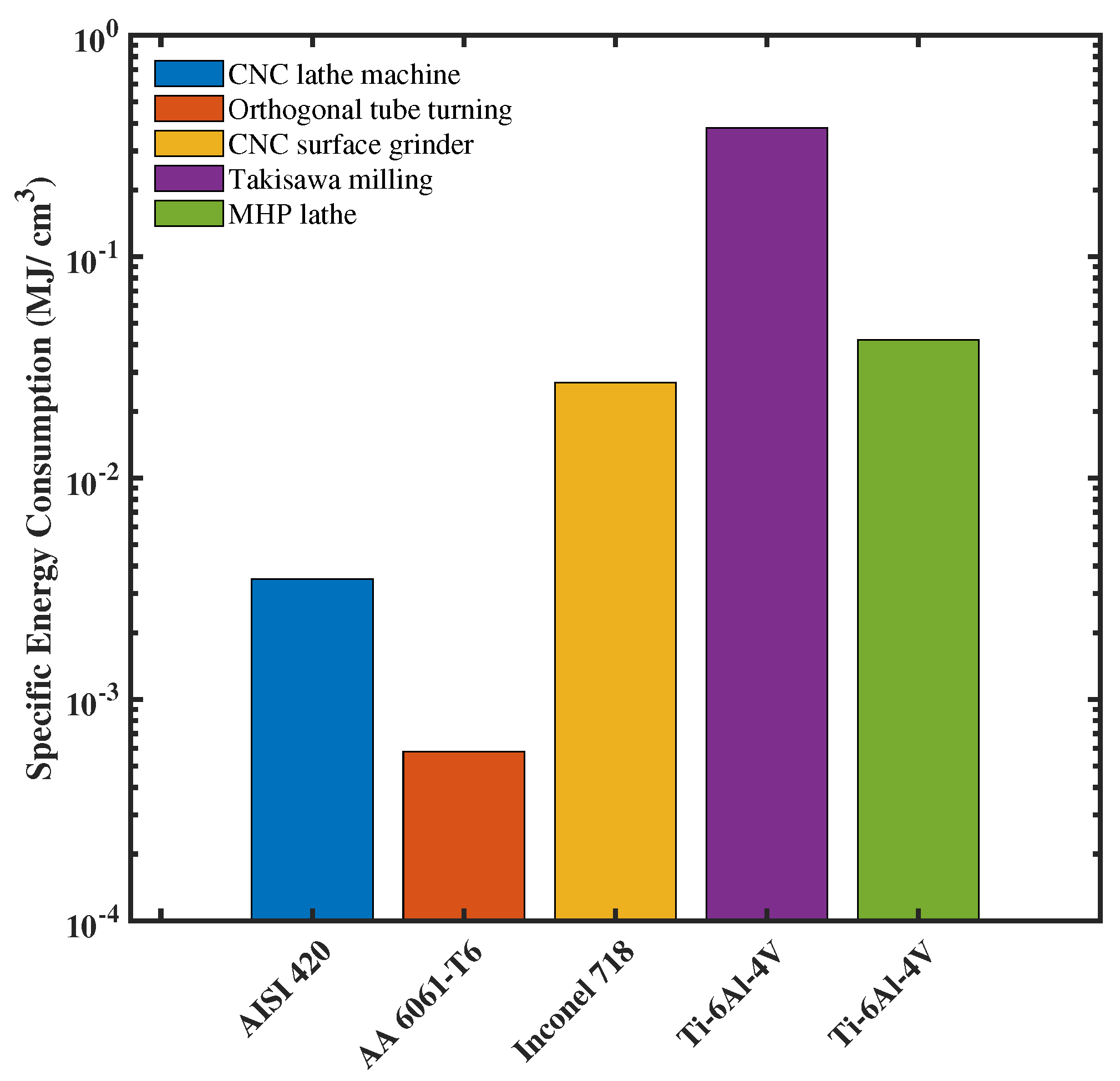

3.2.2. Mechanical Treatments

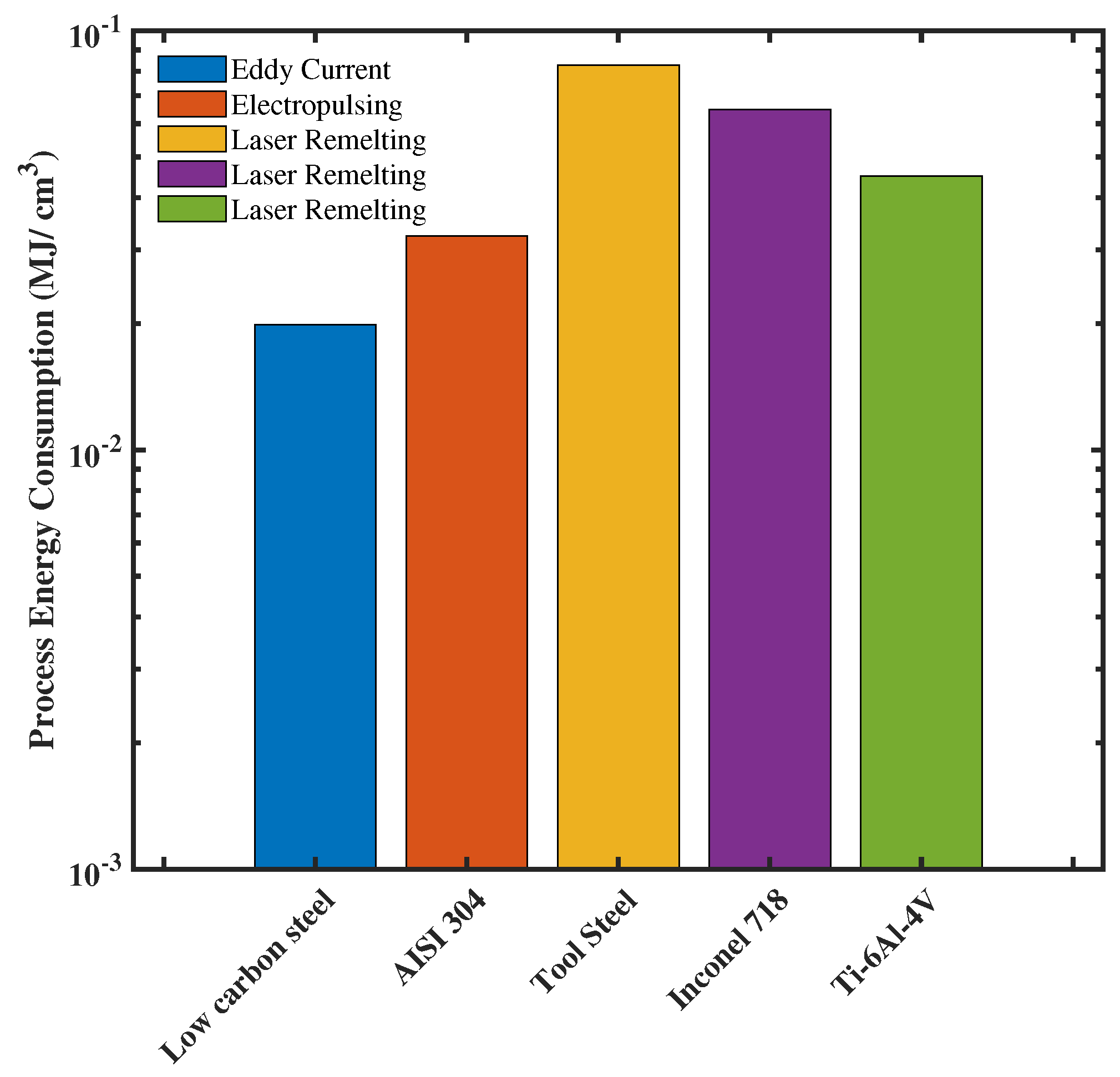

3.2.3. Thermal Treatments

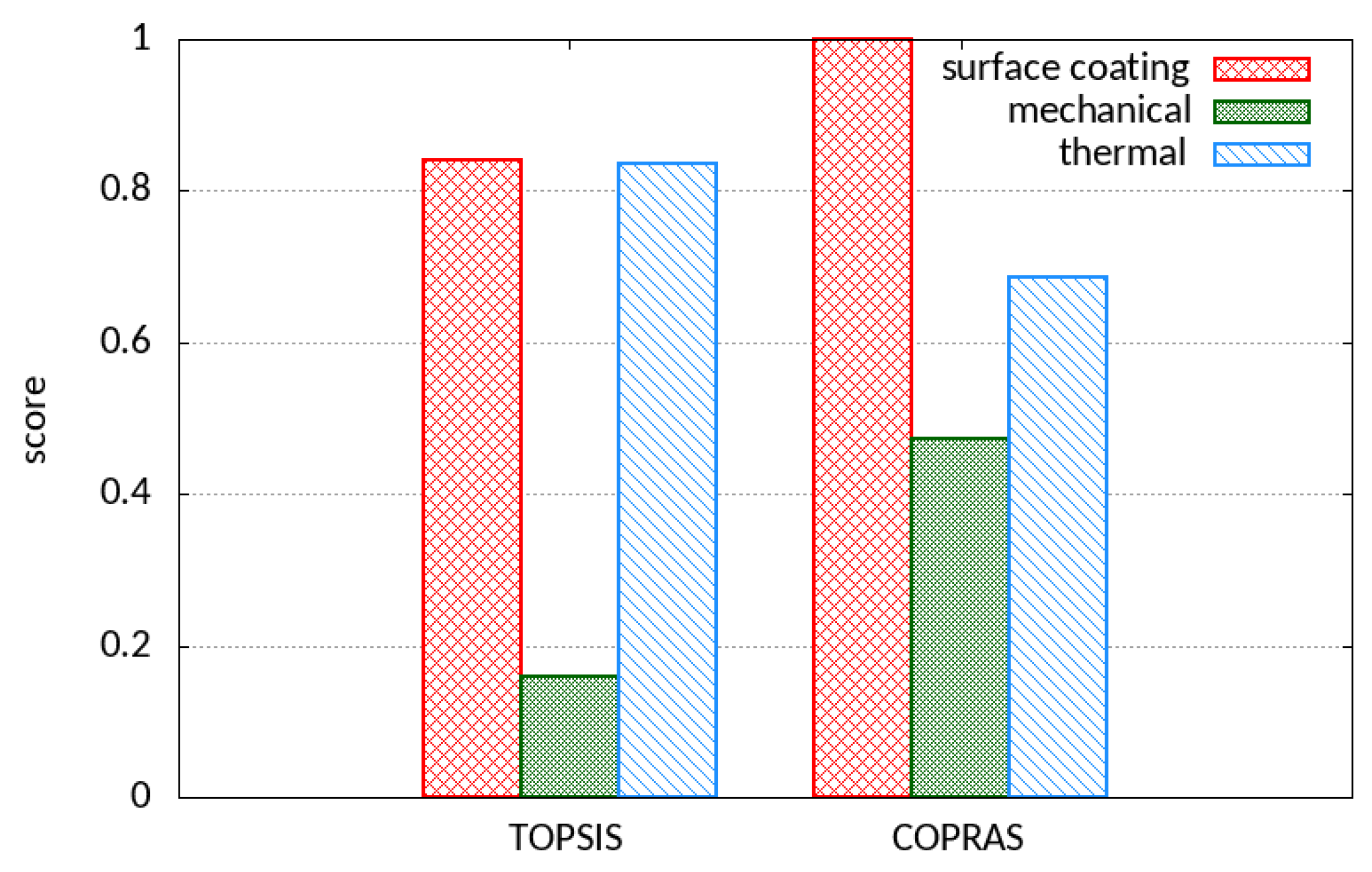

3.3. Analysis of Material Circularity Index (MCI) and Multiple-Criteria Decision Analysis (MCDA)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Charter, M.; Tischner, U. Sustainable Solutions: Developing Products and Services for the Future; Routledge: New York, NY, USA, 2017. [Google Scholar]

- Cooper, T. Slower consumption reflections on product life spans and the “throwaway society”. J. Ind. Ecol. 2005, 9, 51–67. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef] [Green Version]

- Leino, M.; Pekkarinen, J.; Soukka, R. The role of laser additive manufacturing methods of metals in repair, refurbishment and remanufacturing–enabling circular economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef] [Green Version]

- Faccoli, M.; Maestrini, D.; Marconi, G. Warm spray applied to steel component repair: Experimental study. Surf. Eng. 2016, 32, 707–711. [Google Scholar] [CrossRef]

- Akrivos, V.; Haines-Gadd, M.; Mativenga, P.; Charnley, F. Improved metrics for assessment of immortal materials and products. Procedia CIRP 2019, 80, 596–601. [Google Scholar] [CrossRef]

- Yang, S.; Yun, J.; Seok, C.S. Rejuvenation of IN738LC gas-turbine blades using hot isostatic pressing and a series of heat treatments. J. Mech. Sci. Technol. 2020, 34, 4605–4611. [Google Scholar] [CrossRef]

- Russell, J.D.; Nasr, N.Z. Value-retained vs. impacts avoided: The differentiated contributions of remanufacturing, refurbishment, repair, and reuse within a circular economy. J. Remanuf. 2023, 13, 25–51. [Google Scholar] [CrossRef]

- Xia, T.; Xi, L.; Du, S.; Xiao, L.; Pan, E. Energy-oriented maintenance decision-making for sustainable manufacturing based on energy saving window. J. Manuf. Sci. Eng. 2018, 140, 051001. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-healing materials: A pathway to immortal products or a risk to circular economy systems? J. Clean. Prod. 2021, 315, 128193. [Google Scholar] [CrossRef]

- Fiksel, J. A framework for sustainable materials management. JOM 2006, 58, 15–22. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- IEA. Net Zero by 2050; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 15 July 2021).

- Raabe, D.; Tasan, C.C.; Olivetti, E.A. Strategies for improving the sustainability of structural metals. Nature 2019, 575, 64–74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnson, J.; Reck, B.; Wang, T.; Graedel, T. The energy benefit of stainless steel recycling. Energy Policy 2008, 36, 181–192. [Google Scholar] [CrossRef]

- Climate Action. Carbon Footprint of Recycled Aluminium. Available online: https://www.climateaction.org/news/carbon-footprint-of-recycled-aluminium (accessed on 25 October 2021).

- Müller-Guttenbrunn Group. Report on the Environmental Benefits of Recycling. 2008. Available online: https://www.mgg-recycling.com/wp-content/uploads/2013/06/BIR_CO2_report.pdf (accessed on 25 October 2021).

- Priarone, P.C.; Ingarao, G.; di Lorenzo, R.; Settineri, L. Influence of material-related aspects of additive and subtractive Ti-6Al-4V manufacturing on energy demand and carbon dioxide emissions. J. Ind. Ecol. 2017, 21, S191–S202. [Google Scholar] [CrossRef]

- Moore, J. Recycling of non-ferrous metals. Int. Met. Rev. 1978, 23, 241–264. [Google Scholar] [CrossRef]

- Lim, A.T.O.; Cui, C.; Jang, H.D.; Huang, J. Self-healing microcapsule-thickened oil barrier coatings. Research 2019, 2019, 3517816. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Rong, M.; Zhang, M.; Yang, G.; Zhao, J. Self-healing of fatigue crack in epoxy materials with epoxy/mercaptan system. Express Polym. Lett. 2011, 5, 47–59. [Google Scholar] [CrossRef]

- Liu, W.; Wei, H.; Huang, C.; Yuan, F.; Zhang, Y. Energy efficiency evaluation of metal laser direct deposition based on process characteristics and empirical modeling. Int. J. Adv. Manuf. Technol. 2019, 102, 901–913. [Google Scholar] [CrossRef]

- Mohammadi, S.; Yousefi, M.; Khazaei, M. A review on composite patch repairs and the most important parameters affecting its efficiency and durability. J. Reinf. Plast. Compos. 2021, 40, 3–15. [Google Scholar] [CrossRef]

- Arrom, L.I. Brush-Plated, Nickel-Based, Metal Matrix Composite Coatings to Replace Hard Chrome. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2018. [Google Scholar]

- Hasegawa, M.; Yoon, S.; Guillonneau, G.; Zhang, Y.; Frantz, C.; Niederberger, C.; Weidenkaff, A.; Michler, J.; Philippe, L. The electrodeposition of FeCrNi stainless steel: Microstructural changes induced by anode reactions. Phys. Chem. Chem. Phys. 2014, 16, 26375–26384. [Google Scholar] [CrossRef]

- Marazani, T.; Madyira, D.M.; Akinlabi, E.T. Repair of cracks in metals: A review. Procedia Manuf. 2017, 8, 673–679. [Google Scholar] [CrossRef]

- Jung, Y.S.; Nakao, W.; Takahashi, K.; Ando, K.; Saito, S. Crack Healing of Machining Cracks Introduced by Wheel Grinding and Resultant High-Temperature Mechanical Properties in a Si3N4/SiC Composite. J. Am. Ceram. Soc. 2009, 92, 167–173. [Google Scholar] [CrossRef]

- Sinha, M.K.; Ghosh, S.; Paruchuri, V.R. Modelling of specific grinding energy for Inconel 718 superalloy. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2019, 233, 443–460. [Google Scholar] [CrossRef]

- Rajemi, M. Energy Analysis in Turning and Milling; University of Manchester: Manchester, UK, 2011. [Google Scholar]

- Nur, R.; Yusof, N.M.; Sudin, I.; Nor, F.M.; Kurniawan, D. Determination of energy consumption during turning of hardened stainless steel using resultant cutting force. Metals 2021, 11, 565. [Google Scholar] [CrossRef]

- Kalentics, N.; Sohrabi, N.; Tabasi, H.G.; Griffiths, S.; Jhabvala, J.; Leinenbach, C.; Burn, A.; Loge, R.E. Healing cracks in selective laser melting by 3D laser shock peening. Addit. Manuf. 2019, 30, 100881. [Google Scholar] [CrossRef]

- Talia, M.; Talia, J. The Effects of Scratches and Shot Peening on the High Cycle Fatigue Crack Growth of Aluminum Alloy 2024-T3; Technical Report; The Minerals, Metals and Materials Society: Warrendale, PA, USA, 1997. [Google Scholar]

- Branco, C.; Infante, V.; Baptista, R. Fatigue behaviour of welded joints with cracks, repaired by hammer peening. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 785–798. [Google Scholar] [CrossRef]

- Dexter, R.J.; Ocel, J.M. Manual for Repair and Retrofit of Fatigue Cracks in Steel Bridges; Technical Report; Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- Tejedor, T.Á.; Singh, R.; Pilidis, P. Maintenance and repair of gas turbine components. In Woodhead Publishing Series in Energy. Modern Gas Turbine Systems; Woodhead Publishing: Sawston, UK, 2013; pp. 565–634. [Google Scholar]

- Eliaz, N.; Latanision, R.M. Preventative maintenance and failure analysis of aircraft components. Corros. Rev. 2007, 25, 107–144. [Google Scholar] [CrossRef]

- Zheng, X.; Shi, Y.N.; Lu, K. Electro-healing cracks in nickel. Mater. Sci. Eng. A 2013, 561, 52–59. [Google Scholar] [CrossRef]

- Yizhou, Z.; You, Z.; Guanhu, H.; Benlian, Z. The healing of quenched crack in 1045 steel under electropulsing. J. Mater. Res. 2001, 16, 17–19. [Google Scholar] [CrossRef]

- Yang, C.; Xu, W.; Guo, B.; Shan, D.; Zhang, J. Healing of fatigue crack in 1045 steel by using eddy current treatment. Materials 2016, 9, 641. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Graf, B.; Gumenyuk, A.; Rethmeier, M. Laser metal deposition as repair technology for stainless steel and titanium alloys. Phys. Procedia 2012, 39, 376–381. [Google Scholar] [CrossRef]

- Temmler, A.; Schmickler, T.; Willenborg, E.; Wissenbach, K. Surface structuring by laser remelting of Inconel 718. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 22–25 June 2015; pp. 22–24. [Google Scholar]

- Temmler, A.; Walochnik, M.; Willenborg, E.; Wissenbach, K. Surface structuring by remelting of titanium alloy Ti6Al4V. J. Laser Appl. 2015, 27, S29103. [Google Scholar] [CrossRef] [Green Version]

- Ellen MacArthur Foundation. Circularity Indicators: An Approach to Measuring Circularity: Methodology; Ellen MacArthur Foundation: Isle of Wight, UK, 2015; Available online: https://ellenmacarthurfoundation.org/material-circularity-indicator (accessed on 27 July 2021).

- Yoon, K.; Hwang, C. Multiple Attribute Decision Making: An Introduction; Quantitative Applications in the Social Sciences; SAGE Publications: Thousand Oaks, CA, USA, 1995. [Google Scholar]

- Triantaphyllou, E.; Shu, B.; Sanchez, S.N.; Ray, T. Multi-Criteria Decision Making: An Operations Research Approach. In Encyclopedia of Electrical and Electronics Engineering; John Wiley and Sons: New York, NY, USA, 1998; Volume 15, pp. 175–186. [Google Scholar]

- Warsi, S.S.; Jaffery, H.I.; Ahmad, R.; Khan, M.; Akram, S. Analysis of power and specific cutting energy consumption in orthogonal machining of Al 6061-T6 alloys at transitional cutting speeds. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57366, p. V02BT02A057. [Google Scholar]

- Zavadskas, E.K.; Kaklauskas, A.; Šarka, V. The new method of multicriteria complex proportional assessment of projects. Technol. Econ. Dev. Econ. 1994, 1, 131–139. [Google Scholar]

- Cherrington, R.; Marshall, J.; Alexander, A.T.; Goodship, V. Exploring the circular economy through coatings in transport. Sustain. Prod. Consum. 2022, 32, 136–146. [Google Scholar] [CrossRef]

- Pagone, E.; Salonitis, K.; Jolly, M. Automatically weighted high-resolution mapping of multi-criteria decision analysis for sustainable manufacturing systems. J. Clean. Prod. 2020, 257, 120272. [Google Scholar] [CrossRef]

| Mechanisms | Techniques |

|---|---|

| Coatings | Microcapsule-thickened oil barrier coatings [21] |

| Epoxy materials with epoxy/mercaptan system [22] | |

| Laser metal deposition [23] | |

| Composite overlay [24] | |

| Electroplating [25,26] | |

| Mechanical | Metal crack stitching [27] |

| Grinding [28,29,30,31] | |

| Peening [32,33,34] | |

| Vee and Weld [35] | |

| Thermal | Heat treatment [36,37] |

| Electropulsing treatment [38,39] | |

| Eddy current treatment [40] | |

| Laser melting [41,42,43] |

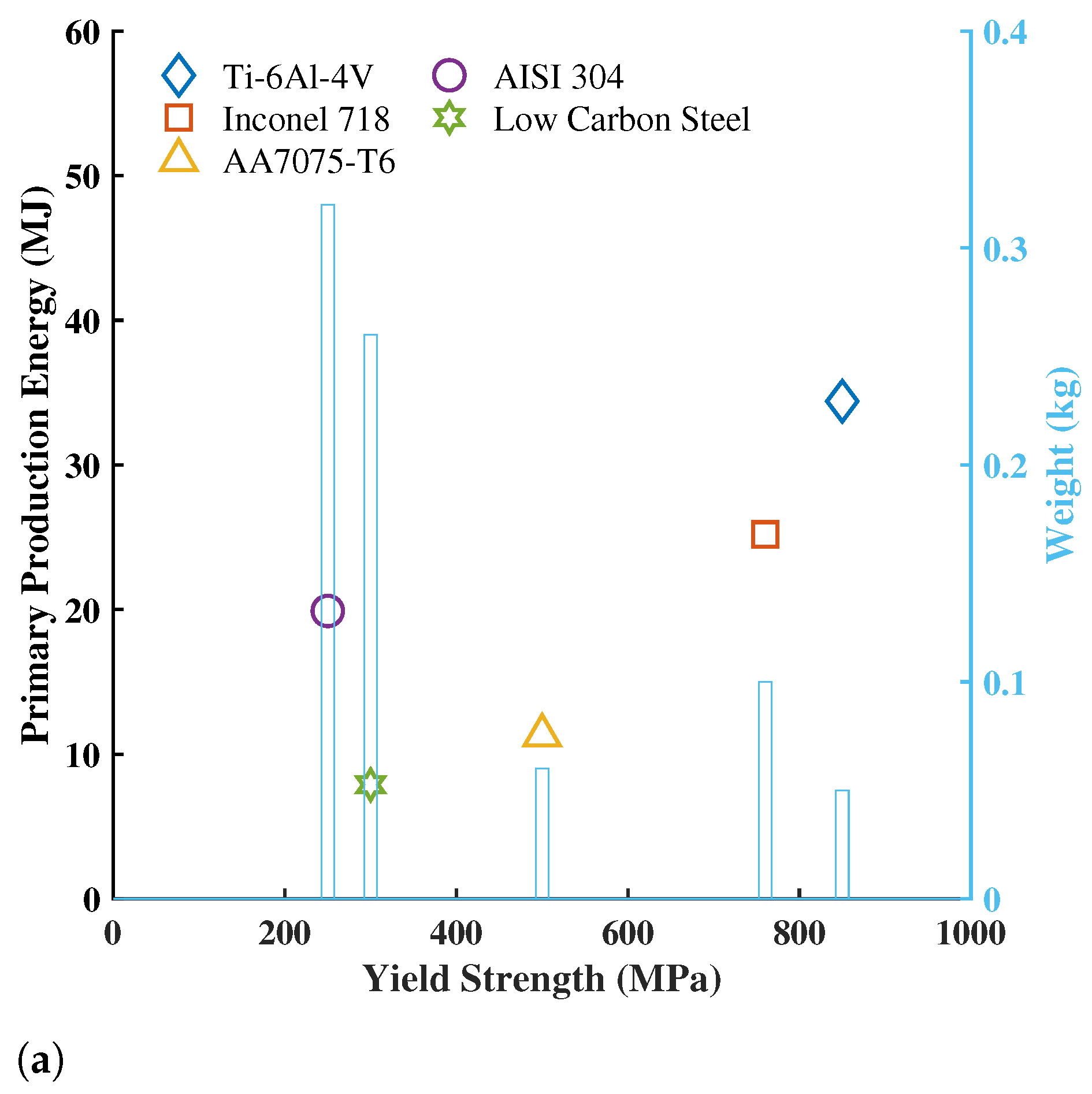

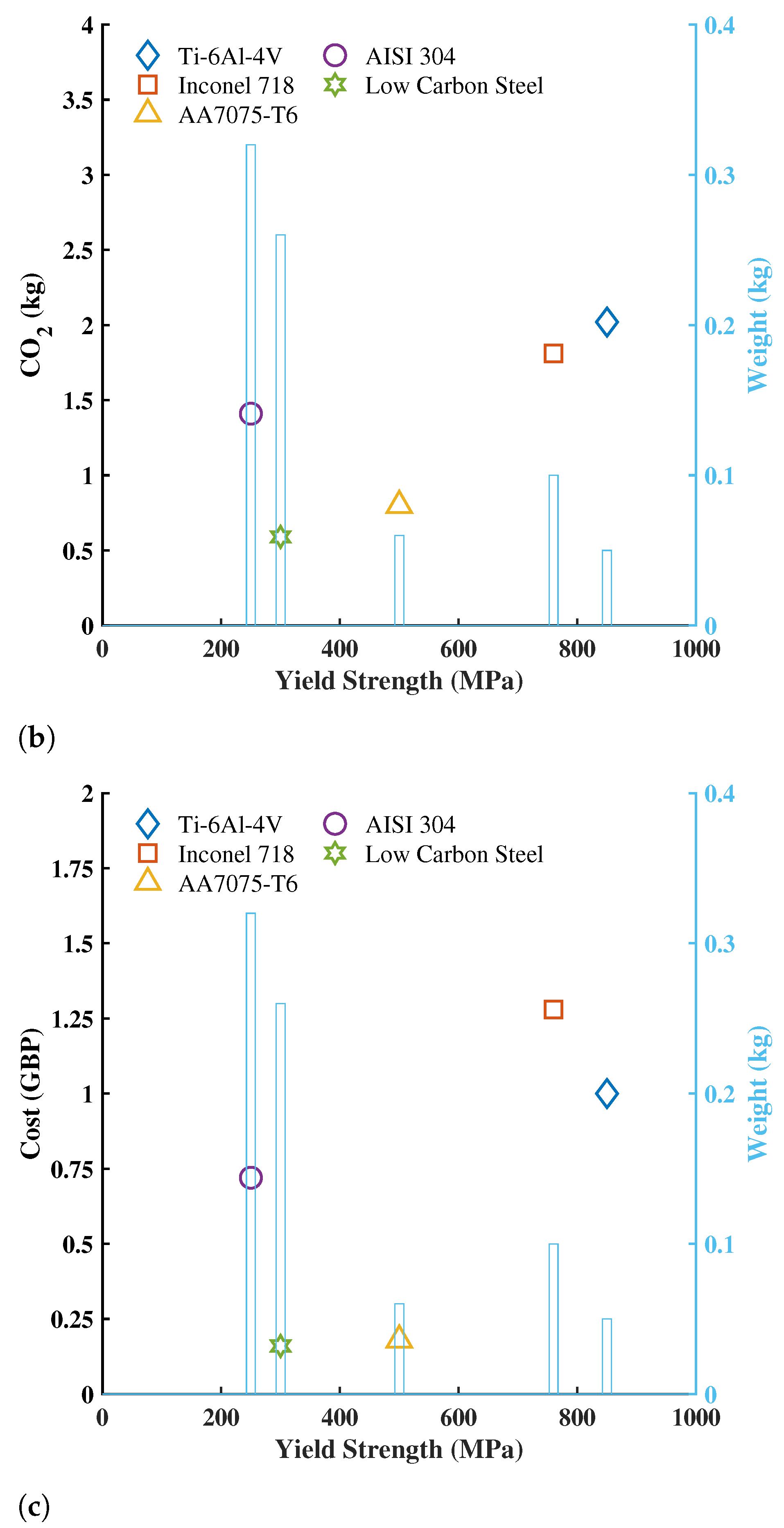

| Material | Yield Stress | Volume | Density | Weight |

|---|---|---|---|---|

| (MPa) | ( m3) | ( kg/mm3) | (kg) | |

| Low Carbon Steel | 300 | 3.30 | 7.90 | 0.25 |

| AISI304 | 252 | 4.00 | 8.00 | 0.30 |

| AA7075-T6 | 500 | 2.00 | 2.80 | 0.06 |

| Inconel 718 | 760 | 1.35 | 8.25 | 0.10 |

| Ti-6Al-4V | 850 | 1.20 | 4.40 | 0.05 |

| Technique | Thickness (mm) |

|---|---|

| Laser deposition | 0.06–0.125 |

| Electrodeposition | 0.05–0.1 |

| Oil and epoxy coating | 1.5–3 |

| Composite patching | 0.17 (3–6 layers) |

| Material | Technique | Amount Needed for | Amount Needed for |

|---|---|---|---|

| Lower Thickness Values | Upper Thickness Values | ||

| ( kg) | ( kg) | ||

| AISI304 | Laser deposition | 9 | 4 |

| AA7075-T6 | Laser deposition | 3.2 | 1.5 |

| Inconel 718 | Laser deposition | 9.5 | 4 |

| Ti-6Al-4V | Laser deposition | 5 | 2.2 |

| AISI316L | Electrodeposition | 7 | 3 |

| Graphene | Oil barrier coating | 1300 | 540 |

| Epoxy | Epoxy coating | 1400 | 570 |

| carbon fibre | Composite patching | 590 | 240 |

| Techniques | MCI | Life Extension | |

|---|---|---|---|

| Oil barrier coating | 0.72–0.77 | 60–80% | |

| Coating | Composite patching | 0.65 | 30% with each patch |

| Electrodeposition | 0.67–0.77 | 40–60% | |

| Laser metal deposition | 0.77 | 90–95% | |

| Grinding | 0.77 | 90–95% | |

| Mechanical | Crack stitching | 0.84 | 95% |

| Peening | 0.76 | 95% | |

| Heat treatment | 0.75–0.77 | 90–95% | |

| Thermal | Laser melting | 0.77 | 95% |

| Electric current | 0.63–0.75 | 20–80% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashraf, F.; Lodh, A.; Pagone, E.; Castelluccio, G.M. Revitalising Metallic Materials: A Path towards a Sustainable Circular Economy. Sustainability 2023, 15, 11675. https://doi.org/10.3390/su151511675

Ashraf F, Lodh A, Pagone E, Castelluccio GM. Revitalising Metallic Materials: A Path towards a Sustainable Circular Economy. Sustainability. 2023; 15(15):11675. https://doi.org/10.3390/su151511675

Chicago/Turabian StyleAshraf, Farhan, Arijit Lodh, Emanuele Pagone, and Gustavo M. Castelluccio. 2023. "Revitalising Metallic Materials: A Path towards a Sustainable Circular Economy" Sustainability 15, no. 15: 11675. https://doi.org/10.3390/su151511675

APA StyleAshraf, F., Lodh, A., Pagone, E., & Castelluccio, G. M. (2023). Revitalising Metallic Materials: A Path towards a Sustainable Circular Economy. Sustainability, 15(15), 11675. https://doi.org/10.3390/su151511675