CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines—A Case of Coal Shed

Abstract

:1. Introduction

2. Materials and Methods

2.1. Dust Particle Size Distribution Test

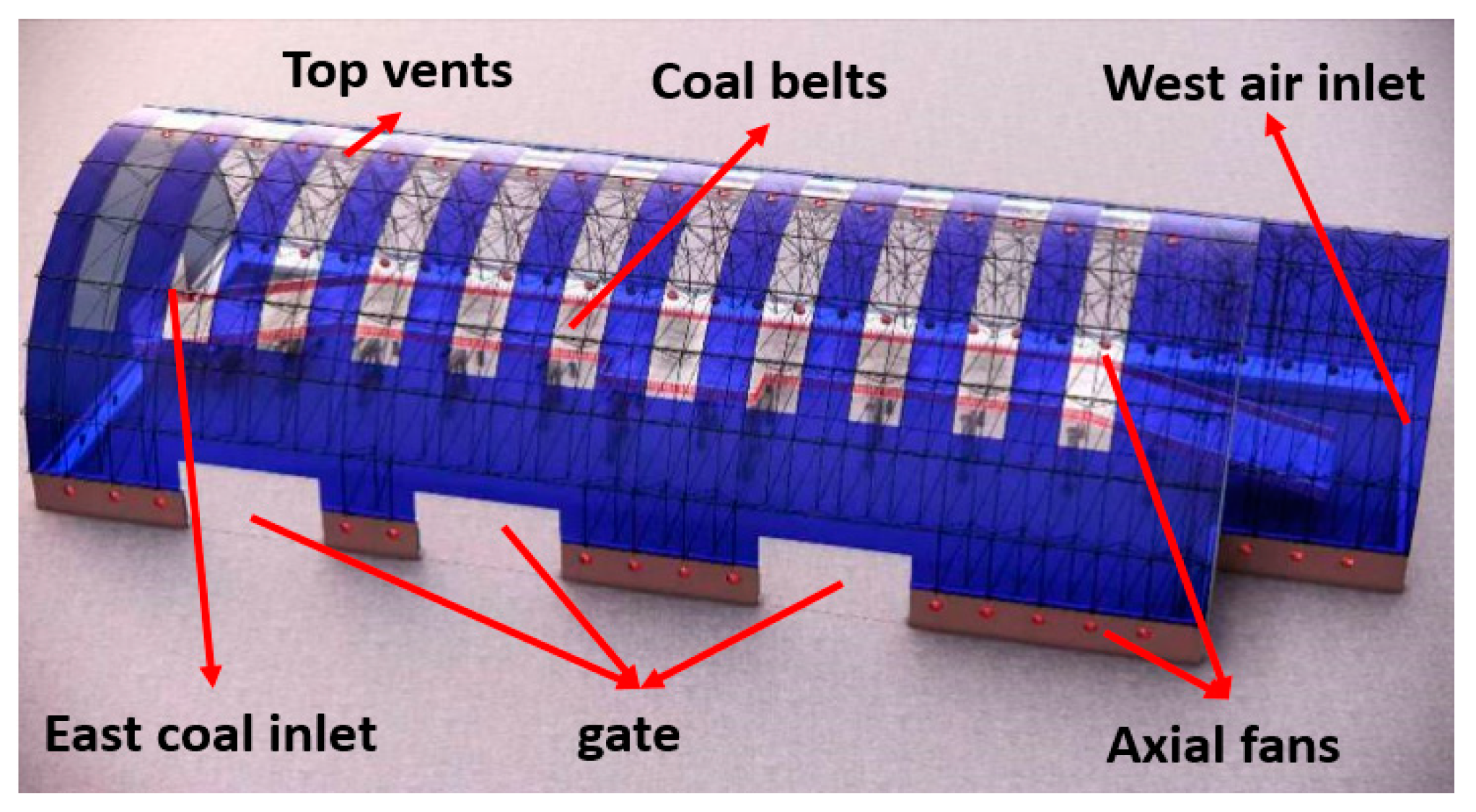

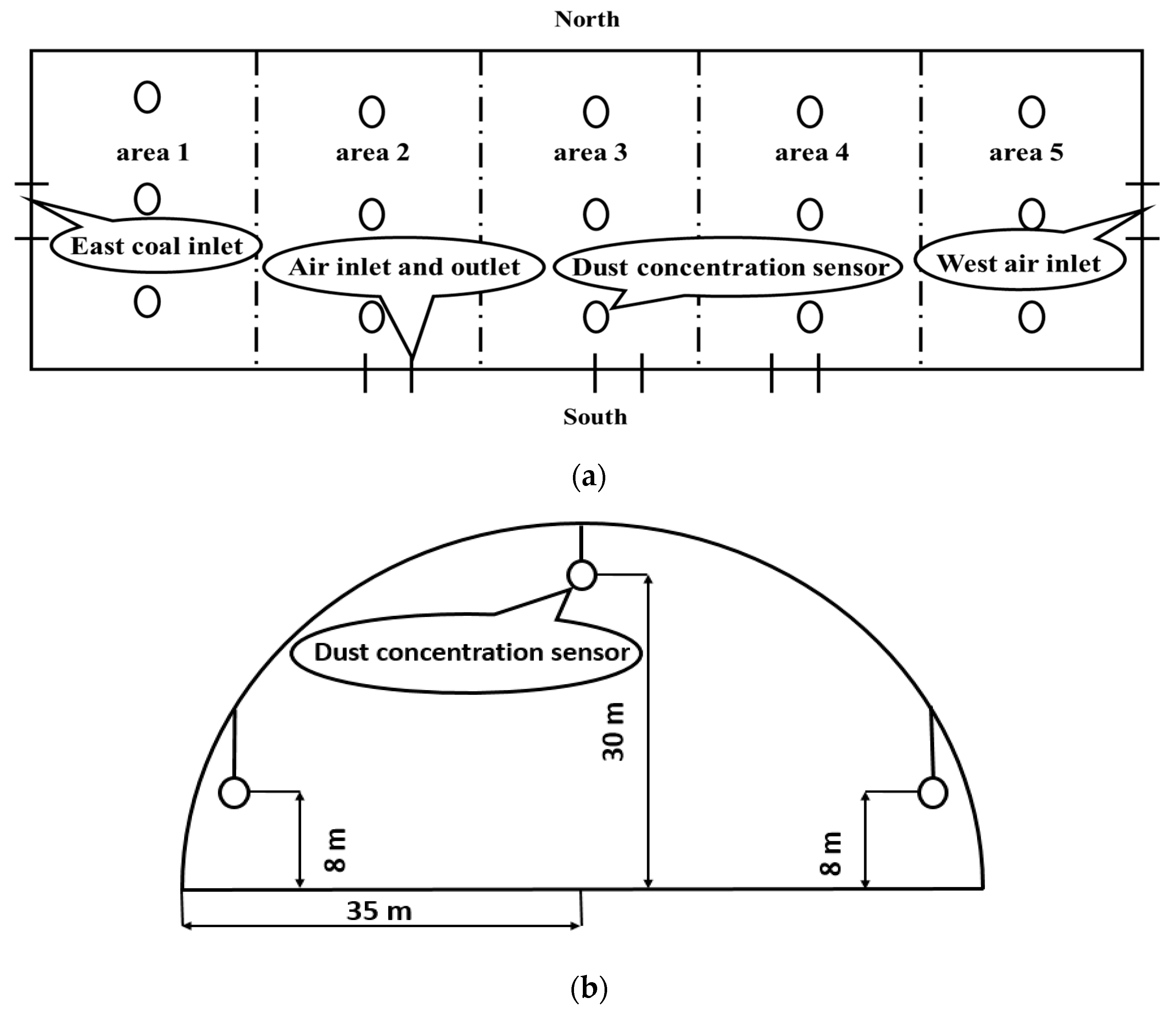

2.2. On-Site Dust Monitoring Network Layout

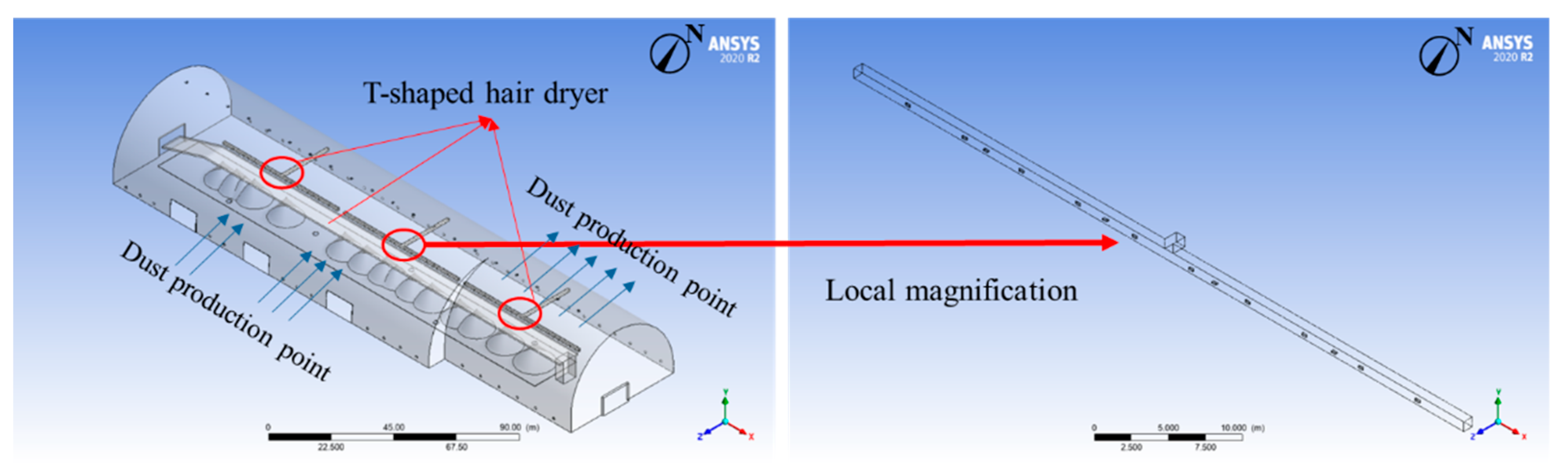

2.3. Fluent Simulation of Dust Dispersion and Transport Patterns in Coal Sheds

2.3.1. Initial and Boundary Condition Assignment of the Model

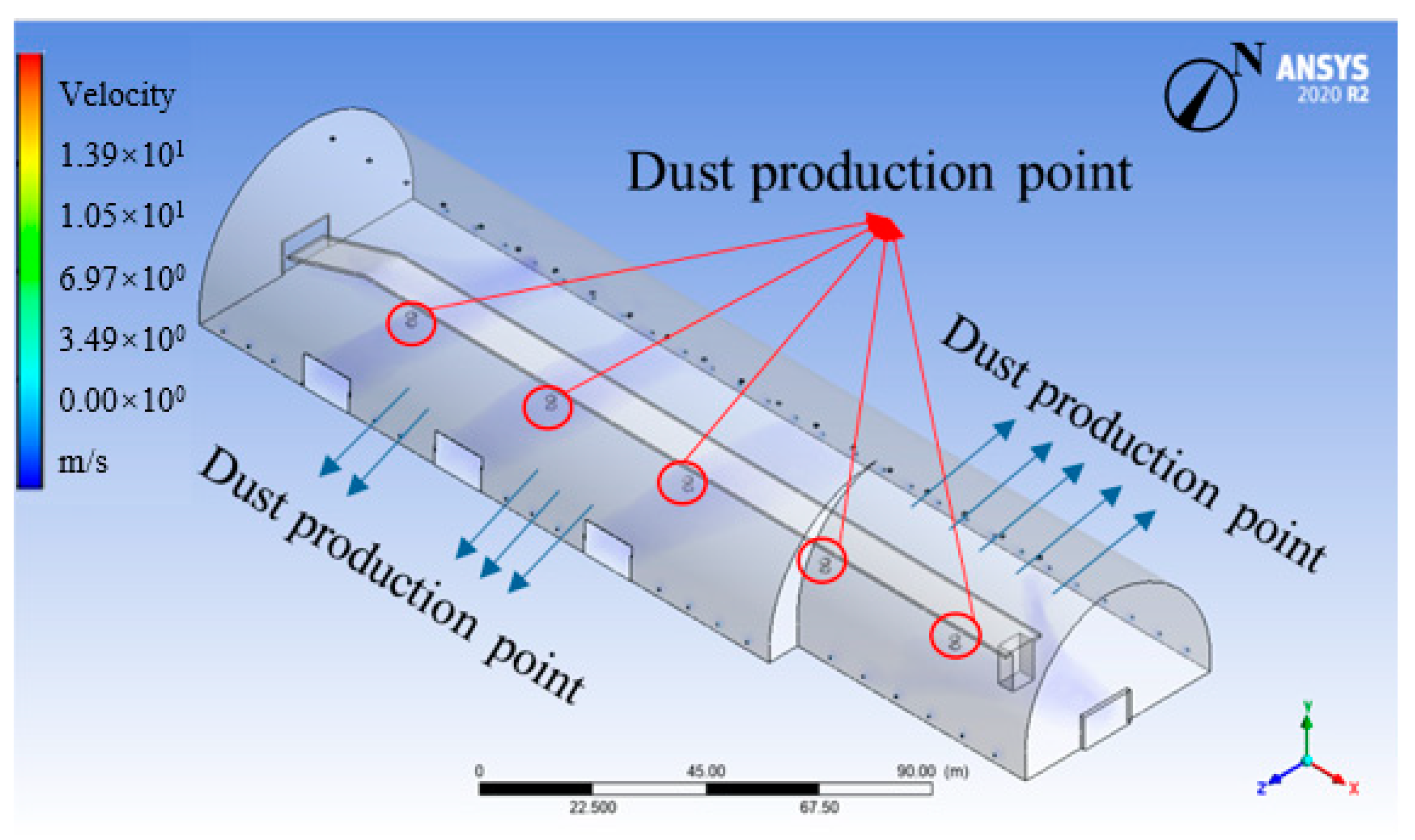

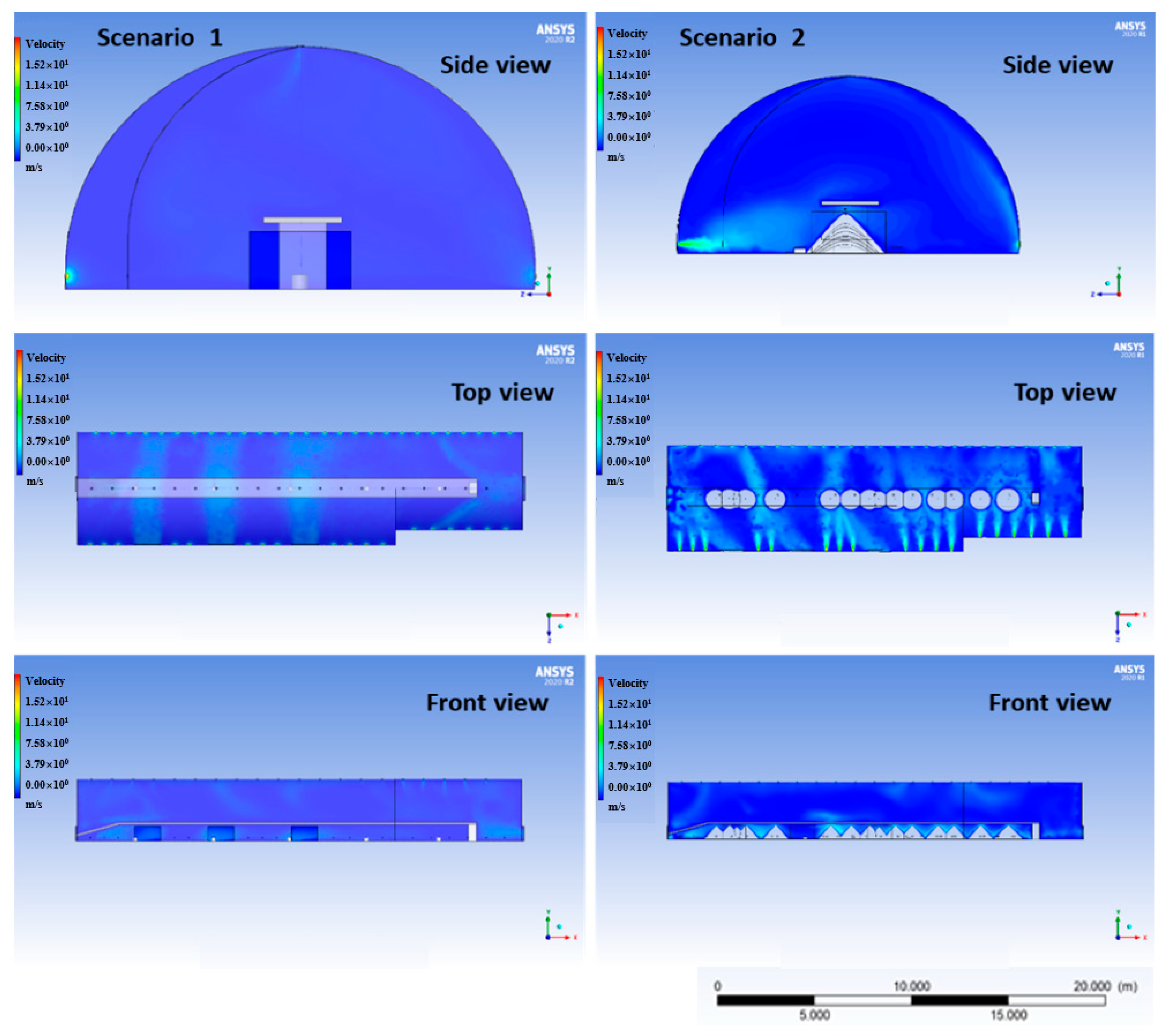

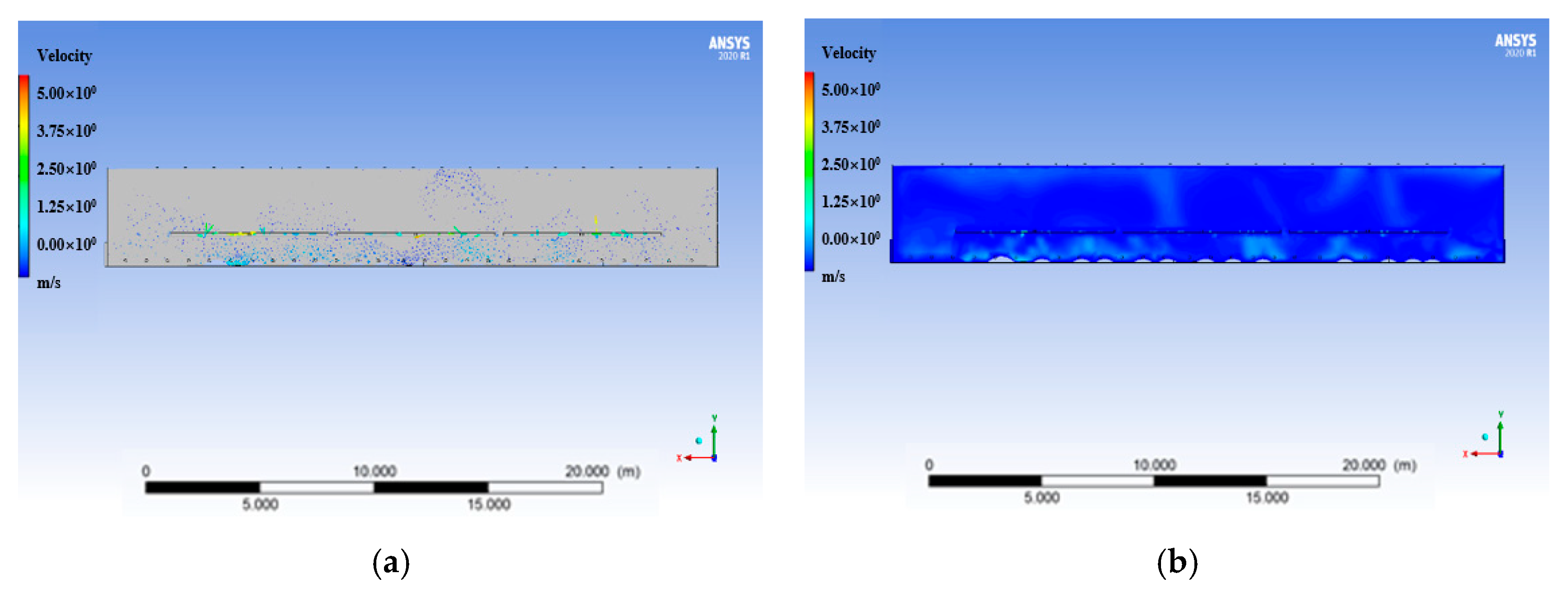

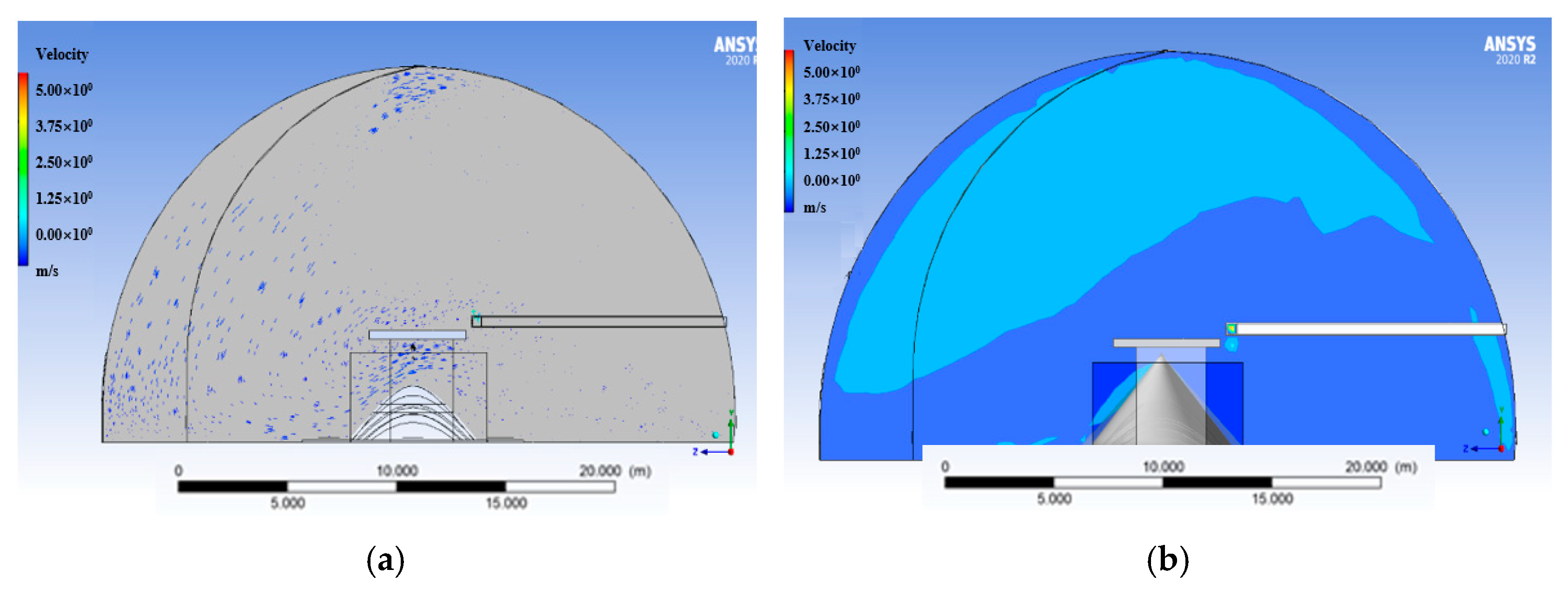

2.3.2. Simulation of Dust Transport Patterns in Scenario 1

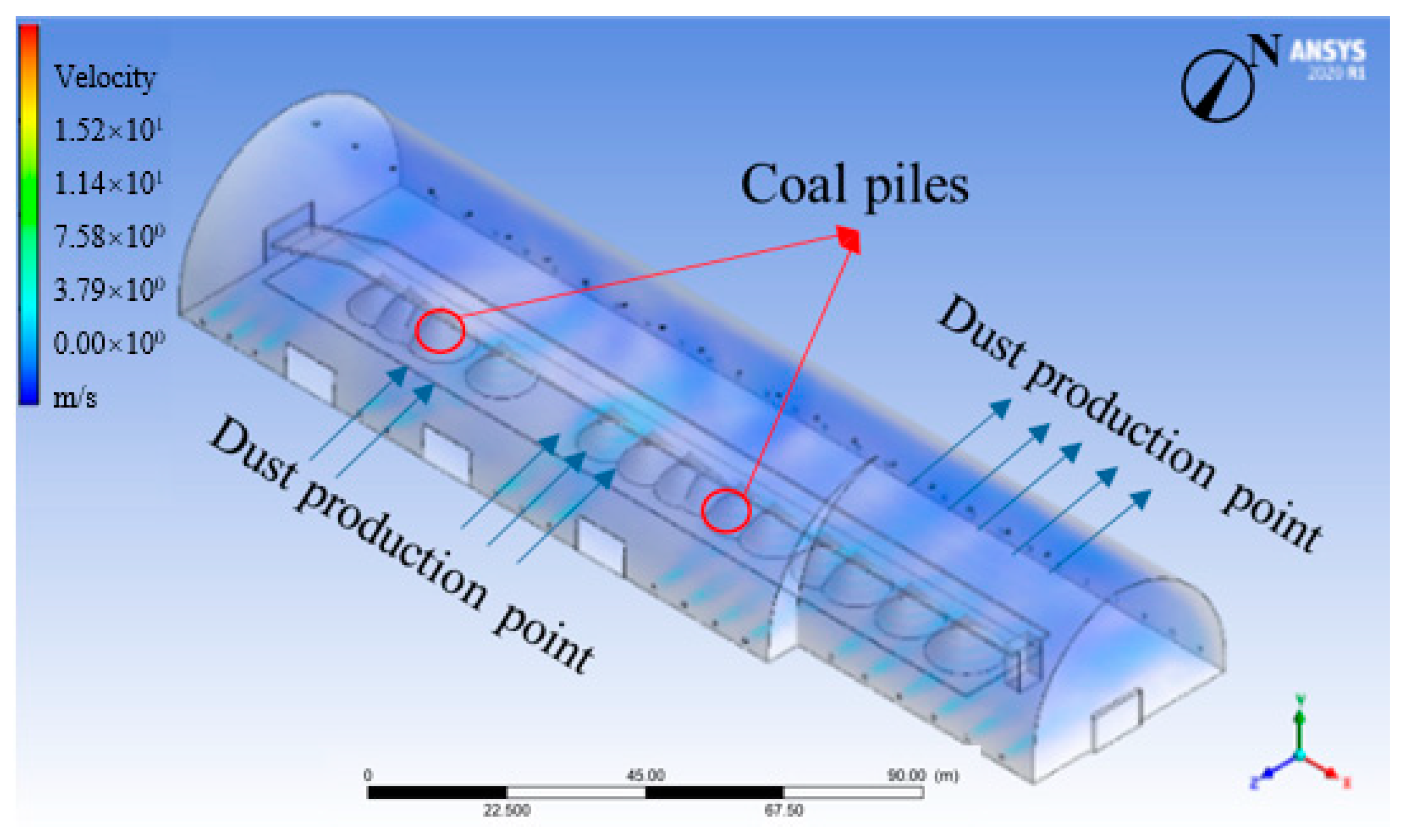

2.3.3. Simulation of Dust Transport Patterns in Scenario 2

2.3.4. Simulation of Dust Transport Patterns in Scenario 3

3. Results and Discussion

3.1. Major Dust Sources and Particle Size Distribution Tests in the Coal Shed

3.1.1. Main Dust Sources in the Coal Shed

- (1)

- There is air intake on the west side of the coal shed. When the natural wind speed is too high, the dust deposited near the air inlet is stirred up by the wind flow and blown into the coal shed, while the dust suspended in the air inside the coal shed is accelerated by the wind speed of the air inlet to increase the amount of dust inside (Figure 6).

- (2)

- Due to the large amount of coal transported on the belt, some of the coal pieces collide with each other during transportation on the belt and generate dust, while the raw coal also rubs on the belt and generates dust. Some of the dust adhering to the raw coal also generates dust due to the friction between the belt movement and the air.

- (3)

- When the truck is moving fast, it generates a wind flow at its rear with higher speed, so the dust that was originally deposited is stirred up again by the wind. In addition, the tires of the truck repeatedly shatter the road surface during transportation, causing the large stones to break into smaller dust particles and increase the amount of dust.

- (4)

- After the material passes the drop opening and moves in free fall, the dust is generated by the collision between the coal blocks during the fall and by the friction between the raw coal and the air, and the dust adhering to the raw coal is blown into the air. At the same time, the material falls to the ground and collides with the ground coal, generating dust.

- (5)

- During the loading of the coal, the external moisture evaporates more, the loader disturbs the coal pile several times during loading, generating a large amount of dust, and the material collides several times during loading and unloading, including the collision between the material and the truck.

- (6)

- The pollutants emitted from transport vehicles, mining trucks, loading shovels, etc. are carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOX), and several other solid particles such as PM (particulate matter, soot), which have a negative impact on human health.

3.1.2. Airborne Dust Test

3.2. Numerical Simulation Comparison between Scenario 1 and Scenario 2

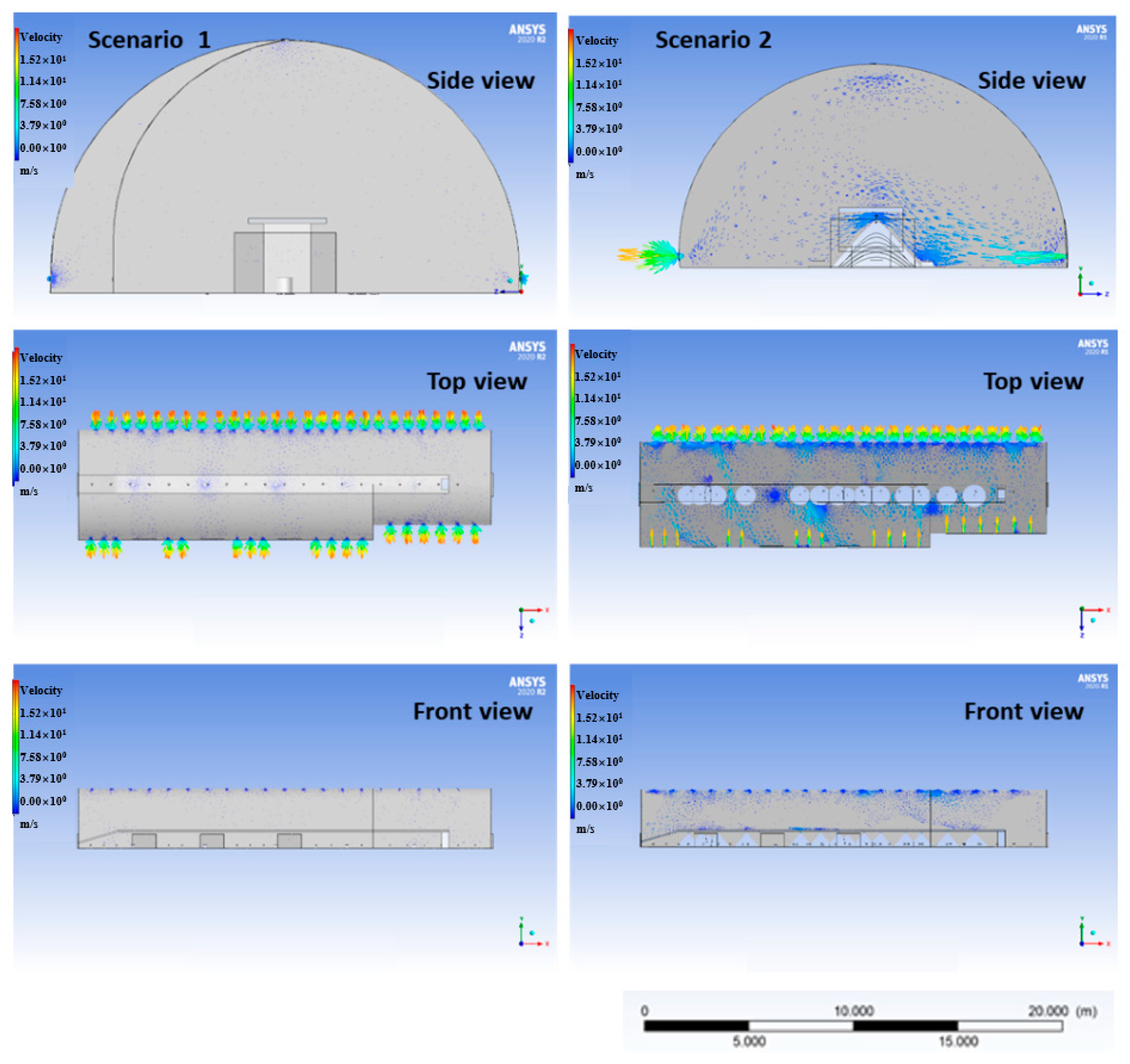

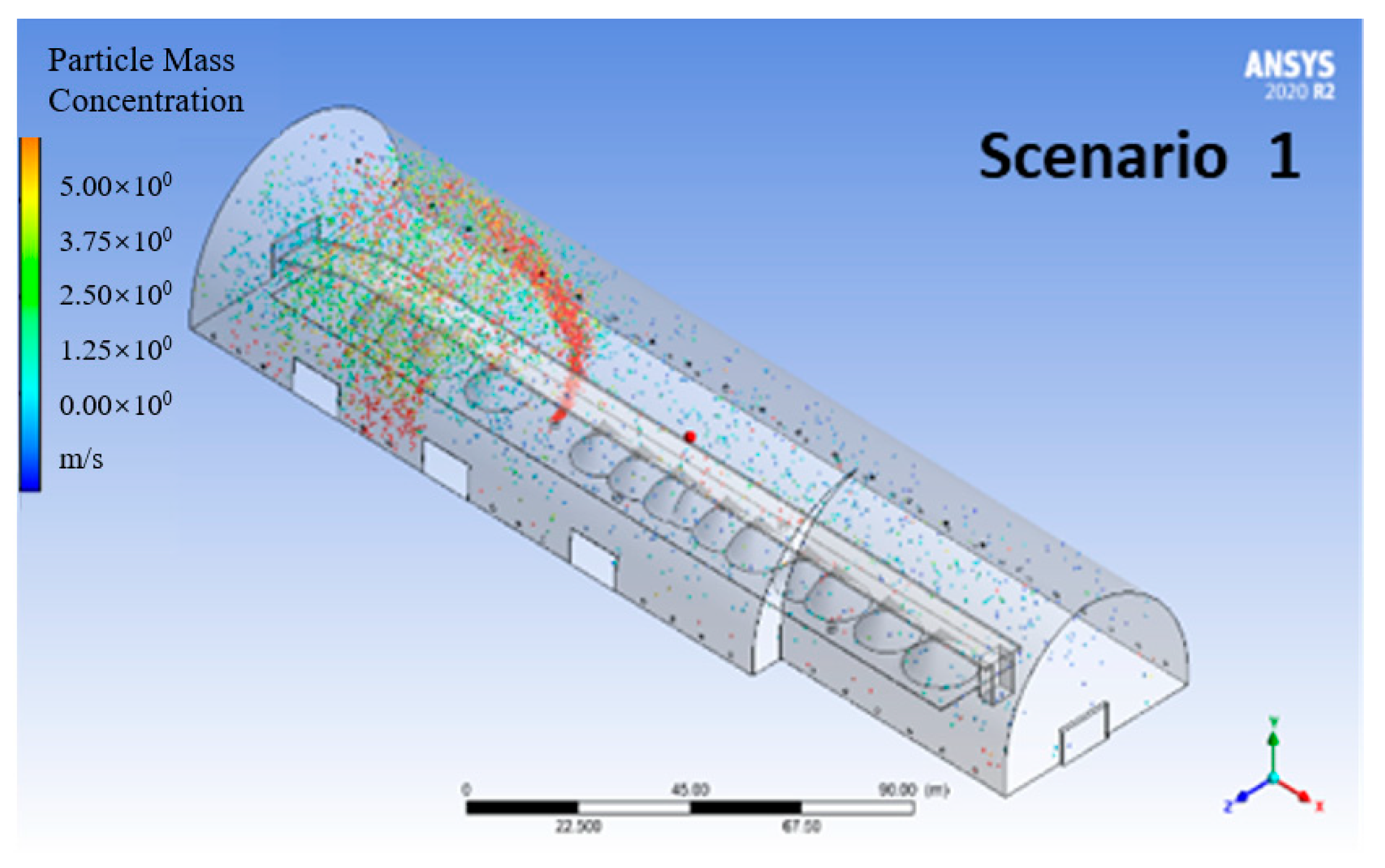

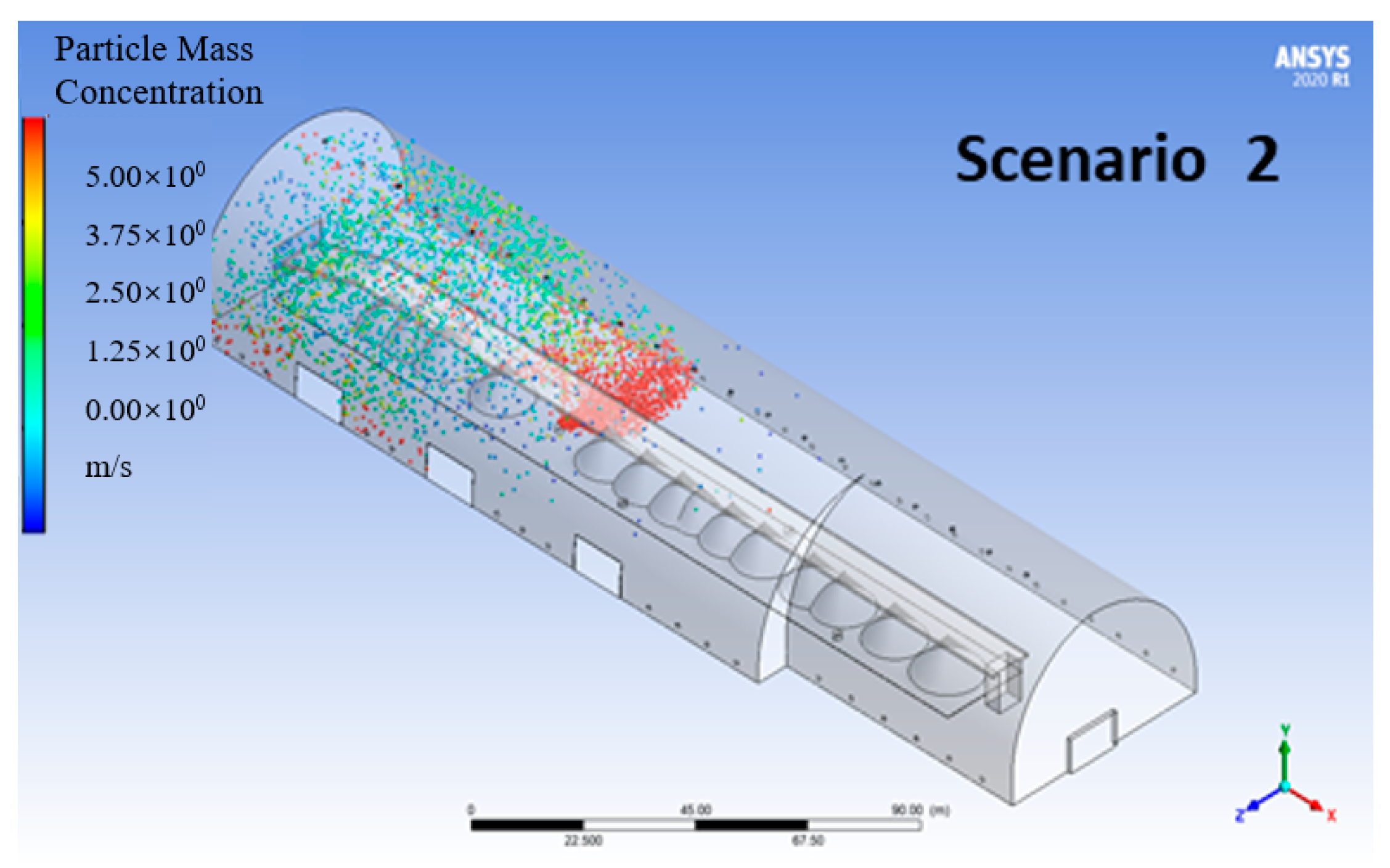

3.2.1. Comparison of Dust Transport Trajectories in Scenario 1 and Scenario 2

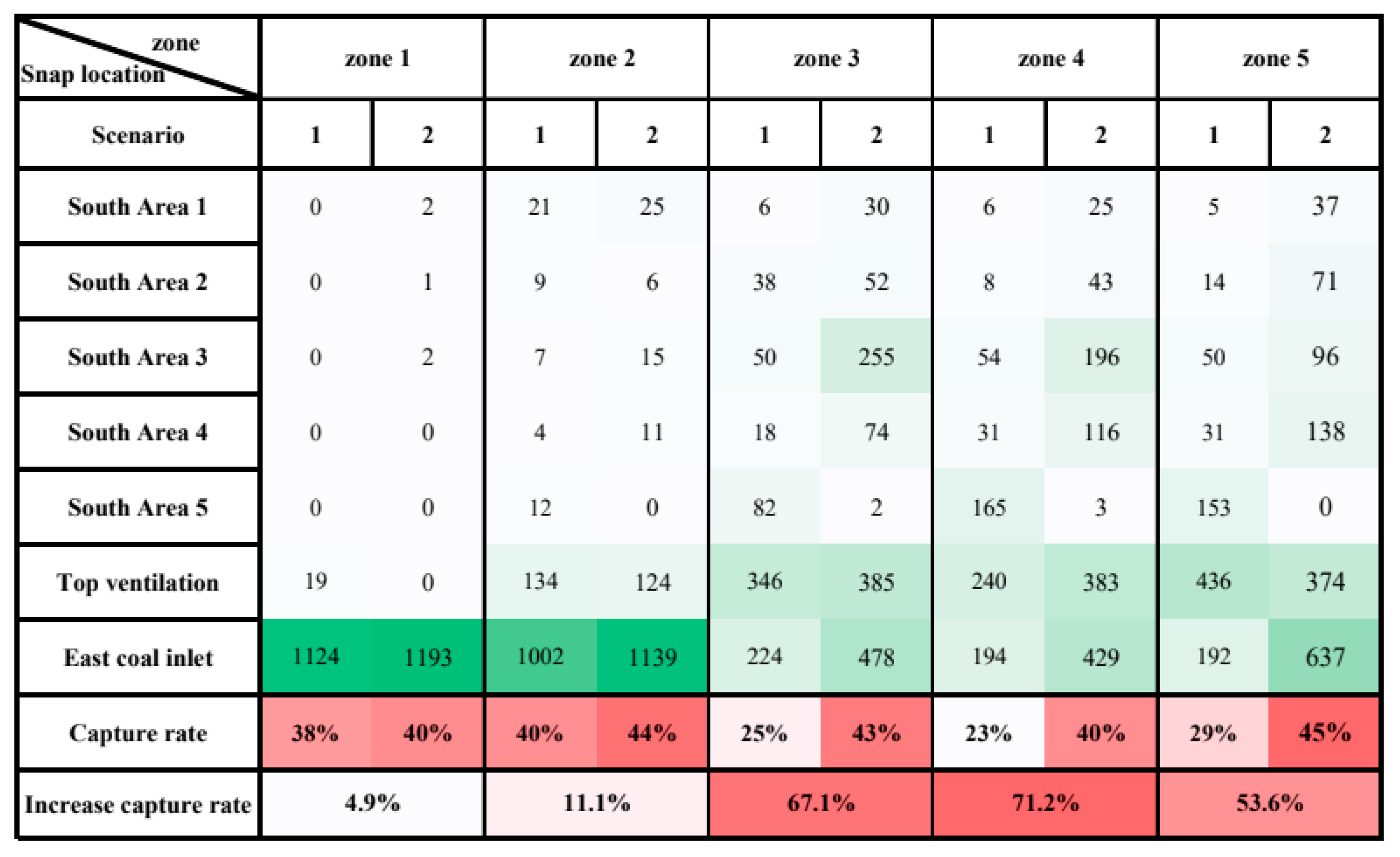

3.2.2. Comparison of Dust Capture in Scenario 1 and Scenario 2

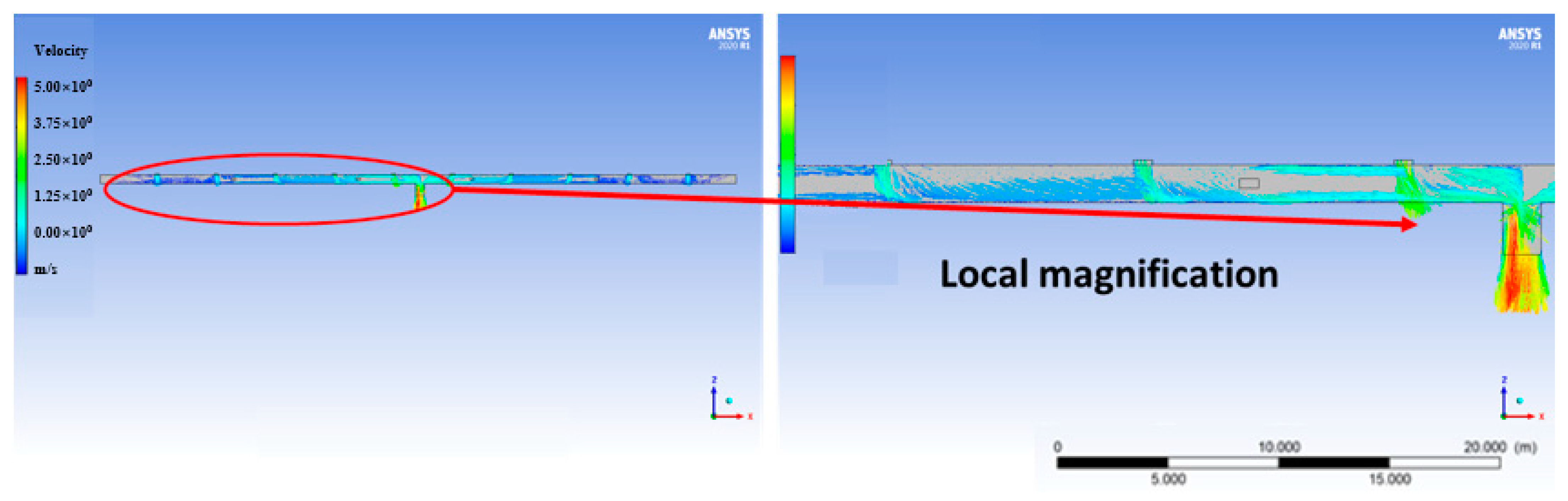

3.2.3. Full Condition Numerical Simulation Analysis for Scenario 1 and Scenario 2 States

3.3. Region 2 Dust Mass Concentration Distribution Pattern

3.4. Simulation of Dust Transport Patterns in Scenario 3

3.5. Field Test Results

Coal Shed Site Conditions with Different Fan on

4. Conclusions

- (a)

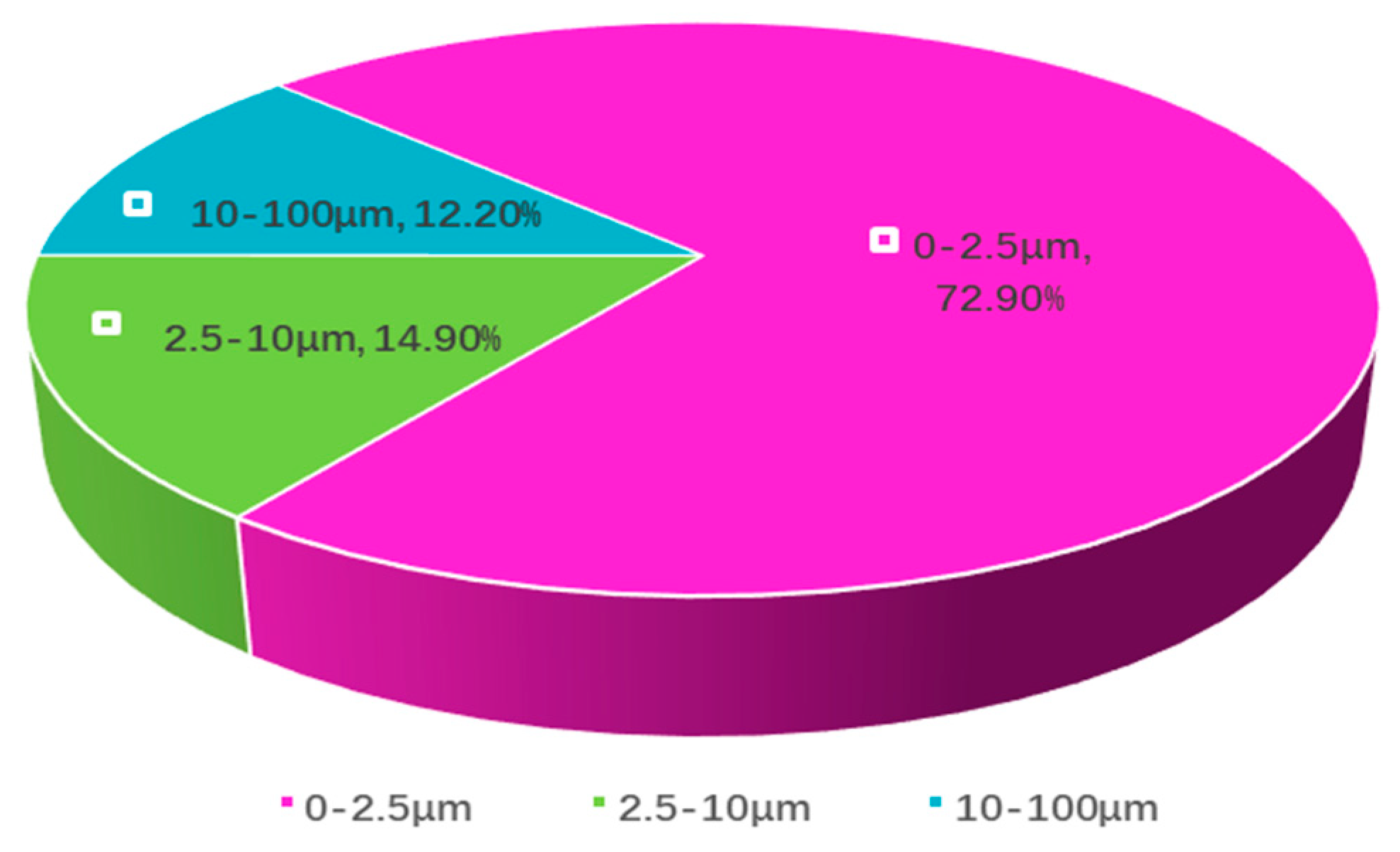

- The test of dust particle size distribution shows that dust in a coal shed with a particle size of 10–100 μm accounts for 12.2% of total dust, dust particles whose size is less than 10 μm account for 87.8% of total dust, and dust particles whose size is less than 2.5 μm account for 72.9% of total dust. Dust particles smaller than 10 μm stay in the air longer, and dust in this particle size range is most harmful to humans. Therefore, the treatment of fine dust suspended in the air in the coal shed is of utmost importance.

- (b)

- When Scenario 2 is adopted, the PM2.5 dust in the height range (0–10 μm) where personnel work in the coal shed is reduced by an average of 38.4% compared to Scenario 1, while the PM2.5 concentration in the height of the non-personnel work range (10–35 μm) is increased by an average of 39.0%, so it can be considered that the PM2.5 dust which is most harmful to personnel is transported from the height of the worker work range to the height of the non-worker work range, the fine particulate dust was effectively managed.

- (c)

- Through the collection of dust concentration data under the four scenarios on-site, it was determined that when Scenario 1 was adopted, the dust reduction efficiency was increased by 9.9% compared to the original state. When Scenario 2 was adopted, the dust reduction efficiency was increased by 23.7% compared to the original state, and 15.6% compared to Scenario 1. When Scenario 3 was adopted, the dust reduction efficiency was increased by 59.9% compared to the original state, 55.6% compared to Scenario 1, and 48.0% compared to Scenario 2.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Jiskani, I.M.; Lu, X.A.; Zhou, W.; Liu, F.M.; Zhang, C.W.; Cai, Q.X. Control mechanism of end-slope deformation in open pit mine based on discrete-continuous coupling method. Comput. Part. Mech. 2022, 13, 951–963. [Google Scholar] [CrossRef]

- Wang, Z.M.; Zhou, W.; Jiskani, I.M.; Ding, X.H.; Luo, H.T. Dust pollution in cold region Surface Mines and its prevention and control. Environ. Pollut. 2022, 292, 118293. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.M.; Zhou, W.; Jiskani, I.M.; Luo, H.T.; Ao, Z.C.; Mvula, E.M. Annual dust pollution characteristics and its prevention and control for environmental protection in surface mines. Sci. Total Environ. 2022, 825, 153949. [Google Scholar] [CrossRef] [PubMed]

- Luan, B.Y.; Zhou, W.; Jiskani, I.M.; Wang, Z.M. An Improved Machine Learning Approach for Optimizing Dust Concentration Estimation in Open-Pit Mines. Int. J. Environ. Res. Public Health 2023, 20, 1353. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.Y.; Ao, Z.C.; Wang, Z.M.; Yang, Y.Q. Study on Crust-Shaped Dust Suppressant in Non-Disturbance Area of Open-Pit Coal Mine-A Case Study. Int. J. Environ. Res. Public Health 2023, 20, 934. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, X.S.; Xia, S.F.; Li, L. Experimental Study and Numerical Simulation on Dust Concentration Distribution of Chute at Enclosed Stockyard of Steel Works. Minerals 2022, 12, 1164. [Google Scholar] [CrossRef]

- Jia, L.; Wang, D.X.; Yu, C.W.; Liang, B. Research of Dust Transport Rule of Large Difference Chute Based on FLUENT. In Proceedings of the 2018 International Conference on Energy Development and Environmental Protection (EDEP 2018), Nanjing, China, 17–19 August 2018; pp. 208–215. [Google Scholar]

- Chen, X.L.; Wheeler, C.A.; Donohue, T.J.; McLean, R.; Roberts, A.W. Evaluation of dust emissions from conveyor transfer chutes using experimental and CFD simulation. Int. J. Miner. Process. 2012, 110, 101–108. [Google Scholar] [CrossRef]

- Huang, C.H.; Lin, P.Y. Influence of spatial layout on airflow field and particle distribution on the workspace of a factory. Build. Environ. 2014, 71, 212–222. [Google Scholar] [CrossRef]

- Xiu, Z.H.; Nie, W.; Cai, P.; Chen, D.W.; Zhang, X. Partially enclosed air curtain dust control technology to prevent pollution in a fully mechanized mining face. J. Environ. Chem. Eng. 2022, 10, 108326. [Google Scholar] [CrossRef]

- Ikeguchi, A. Distribution properties of dust concentration in an enclosed model layer house. Trans. Asae 2000, 43, 399–404. [Google Scholar] [CrossRef]

- Novak, L.; Bizjan, B.; Praznikar, J.; Horvat, B.; Orbanic, A.; Sirok, B. Numerical Modeling of Dust Lifting from a Complex-Geometry Industrial Stockpile. Stroj. Vestn.-J. Mech. Eng. 2015, 61, 621–631. [Google Scholar] [CrossRef] [Green Version]

- Ma, W.W.; Du, W.Q.; Guo, J.X.; Wu, S.Y.; Li, L.Q.; Zeng, Z. Dust Dispersion Characteristics of Open Stockpiles and the Scale of Dust Suppression Shed. Appl. Sci. 2022, 12, 11568. [Google Scholar] [CrossRef]

- Zou, S.H.; Zhang, D.C.; Yin, W.; Zou, S. Study of dust production mechanisms during the rotary dumping of powdered materials in hemi-enclosed space. Appl. Mech. Mater. 2013, 295, 1624–1630. [Google Scholar] [CrossRef]

- Su, N.; Peng, S.T.; Hong, N.N.; Zhang, J.L. Experimental and numerical evaluation of wind-driven natural ventilation and dust suppression effects of coal sheds with porous gables. Build. Environ. 2020, 177, 10. [Google Scholar] [CrossRef]

- Su, N.; Peng, S.T.; Ye, Y.; Hong, N.N. Wind Environment and Loading Mitigation Effects on Coastal Enclosed Coal Yards with Porous Gables. IOP Conf. Ser. Earth Environ. Sci. 2021, 621, 012094. [Google Scholar] [CrossRef]

- Cho, M.L.; Ha, J.S.; Kim, T.K. Behavior Characteristics of Hazardous Gas and Scattering Coal Dust in Coal Storage Sheds. Appl. Sci. 2021, 11, 11771. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Ambrose, R.P.K. Modeling dust dispersion and suspension pattern under turbulence. J. Loss Prev. Process Ind. 2019, 62, 103934. [Google Scholar] [CrossRef]

- Kim, T.K.; Cho, M.-L.; Bae, Y.-W.; Kim, J.-W. Flow Analysis indoor Coal Storage Shed due to Wind Velocity and Wind Direction of Ambient Air. J. Korea Acad.-Ind. Coop. Soc. 2020, 21, 538–545. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Ambrose, R.P.K. Predicting continuous dispersion and deposition of explosive dust in confined spaces using a discrete phase model. Powder Technol. 2022, 408, 117704. [Google Scholar] [CrossRef]

- Cheng, L.; Feng, H.B.; Gu, Z.Y.; Yan, D.C.; Guo, H.B.; Xu, Q. Analysis and calculation of enclosed coal yard ventilation by using roof vortex flow natural ventilation. IOP Conf. Ser. Earth Environ. Sci. 2019, 295, 042068. [Google Scholar] [CrossRef]

- Jeong, C.H.; Lee, J.W.; Shin, D.W.; Kim, M.; Lee, S.H. Numerical Investigation on Influence of Windbreak Wall Height on Dust Scattering Characteristics. J. ILASS-Korea 2014, 19, 136–141. [Google Scholar] [CrossRef]

- Su, N.; Peng, S.T.; Hong, N.N.; Hu, T. Wind tunnel investigation on the wind load of large-span coal sheds with porous gables: Influence of gable ventilation. J. Wind Eng. Ind. Aerodyn. 2020, 204, 104242. [Google Scholar] [CrossRef]

- Jing, D.J.; Jia, X.; Ge, S.C.; Zhang, T.; Ma, M.X. Numerical simulation and experimental study of vortex blowing suction dust control in a coal yard with multiple dust production points. Powder Technol. 2021, 388, 554–565. [Google Scholar] [CrossRef]

- Wang, K.P.; Ji, W.D.; Zhang, F.F.; Yu, W.; Zheng, R.Q. Dustfall design of open coal yard in the power plant-a case study on the closed reconstruction project of coal storage yard in shengli power plant. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 032037. [Google Scholar] [CrossRef] [Green Version]

- Qiu, Y.; Yu, R.; San, B.B.; Li, J.H. Aerodynamic shape optimization of large-span coal sheds for wind-induced effect mitigation using surrogate models. Eng. Struct. 2022, 253, 113818. [Google Scholar] [CrossRef]

| Name | Model | Functional Parameters |

|---|---|---|

| Direct reading dust detector | JCF-6H | Dust measurement class: PM10, PM2.5, TSP; |

| Respirable dust measurement range: 0.001–10 mg/m3; Large range in TSP mode: 100 mg/m3; | ||

| Detection sensitivity: 0.001 mg/m3; | ||

| Repeatability error: ≤±2%; | ||

| Measuring particle size class: (0.3, 0.5, 0.7, 1.0, 2.5, 5.0) μm; | ||

| Measuring particle concentration range: 1–999,999 μm; | ||

| Air sampling flow rate: 2.0 L/min (0.1 ft 3/min); | ||

| Sampling time: 1 min, 2 min, 30 min, manual arbitrary time; |

| Name | Parameter |

|---|---|

| Model | BT35-11-5# |

| Type | Axial fans |

| Voltage | 220 V, 380 V |

| Frequency | 50 Hz |

| Rotate speed | 1450 (r/mim) |

| Air volume | 9133 m3/h |

| Wind pressure | 185 pa |

| Power | 0.75 kw |

| Name | Parameters |

|---|---|

| Explosion-proof type: | Intrinsically safe for mining ExibI Mb; |

| Measurement Range: | (0~1000) mg/m3; |

| Operating Voltage: | DC (9~24.5) V; |

| Output Signal: | RS485; |

| Rated current: | ≤110 mA @DC18V; |

| Equipment protection level: | IP54; |

| External dimensions (l × b × h) mm: | 21× 144 × 77 |

| Model | Define |

|---|---|

| Time | Transient |

| Gravity | Y = −9.81 m/s2 |

| Viscous Model | k-epsilon realizable |

| Energy | Off |

| Discrete Phase Model | ON |

| Boundary Conditions | Define |

| Inlet Boundary Type | Velocity-inlet |

| Inlet Velocity Magnitude | 5 m/s |

| Turbulence Intensity | 3.4% |

| Outlet Boundary Type | Outflow |

| Wall Shear Condition | No Slip |

| Wall Roughness | Standard |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ao, Z.; Wang, Z.; Zhou, W.; Qiao, Y.; Wahab, A.; Yang, Z.; Nie, S.; Liu, Z.; Zhu, L. CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines—A Case of Coal Shed. Sustainability 2023, 15, 11651. https://doi.org/10.3390/su151511651

Ao Z, Wang Z, Zhou W, Qiao Y, Wahab A, Yang Z, Nie S, Liu Z, Zhu L. CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines—A Case of Coal Shed. Sustainability. 2023; 15(15):11651. https://doi.org/10.3390/su151511651

Chicago/Turabian StyleAo, Zhongchen, Zhiming Wang, Wei Zhou, Yanzhen Qiao, Abdoul Wahab, Zexuan Yang, Shouhu Nie, Zhichao Liu, and Lixia Zhu. 2023. "CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines—A Case of Coal Shed" Sustainability 15, no. 15: 11651. https://doi.org/10.3390/su151511651

APA StyleAo, Z., Wang, Z., Zhou, W., Qiao, Y., Wahab, A., Yang, Z., Nie, S., Liu, Z., & Zhu, L. (2023). CFD Simulation Based Ventilation and Dust Reduction Strategy for Large Scale Enclosed Spaces in Open Pit Coal Mines—A Case of Coal Shed. Sustainability, 15(15), 11651. https://doi.org/10.3390/su151511651