A Review of Sustainability Standards and Ecolabeling in the Textile Industry

Abstract

:1. Introduction

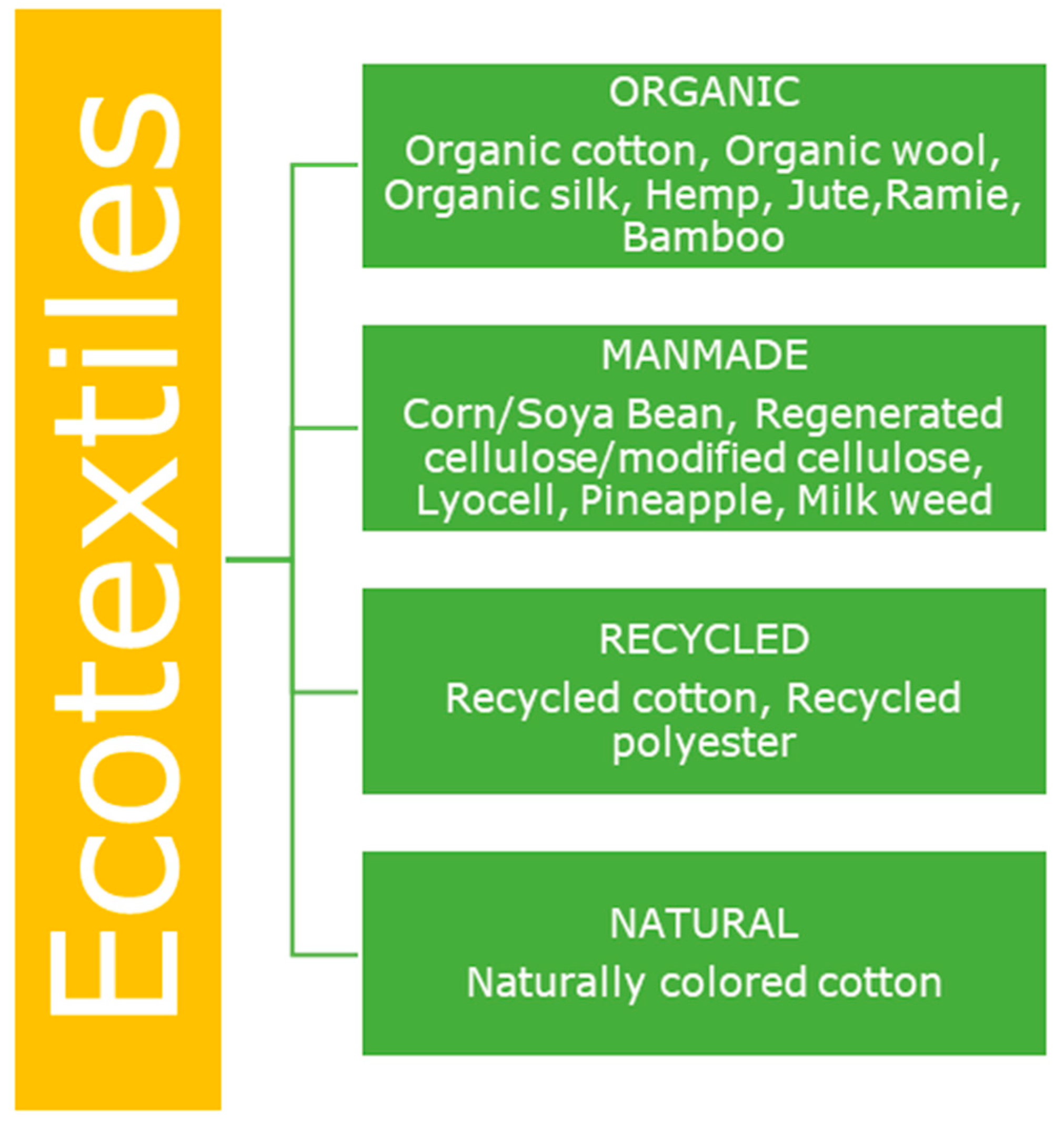

2. Sustainable Product Design and Manufacturing—Ecological Requirements

3. Ecofriendly Textile Fibers—Classification and Ecofiber Market

- Minimal chemical consumption;

- Minimal use of energy and water;

- Minimal pollution production;

- Removal of hazardous chemicals from the supply chain.

4. Restricted Substances in Textiles

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): REACH is a European Union law that was created in 2006 to govern the impact of chemical substances on society and the environment [57].

- The United Nations Basel Convention Treaty: This was signed in 1989 and bans the movement of hazardous waste between countries. It was designed to reduce the total toxicity of waste produced for environmental management purposes [58].

- The MRSL (Manufactures Restricted Substance List): This list contains forbidden textile and fashion materials such as leather, rubber, foam, adhesives, and trim elements in textiles, garments, and footwear. It is significant because it restricts ingredients not just in the completed product but also throughout the supply chain. The Zero Discharge of Hazardous Chemicals (ZDHC) initiative created the list [59].

5. Ecolabeling in the Textile Industry

6. Discussion

7. Conclusions

8. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kalkanis, K.; Alexakis, D.E.; Kyriakis, E.; Kiskira, K.; Lorenzo-Llanes, J.; Themelis, N.J.; Psomopoulos, C.S. Transforming Waste to Wealth, Achieving Circular Economy. Circ. Econ. Sustain. 2022, 2, 1541–1559. [Google Scholar] [CrossRef]

- Hatzilyberis, K.; Tsakanika, L.A.; Lymperopoulou, T.; Georgiou, P.; Kiskira, K.; Tsopelas, F.; Ochsenkühn, K.M.; Ochsenkühn-Petropoulou, M. Design of an advanced hydrometallurgy process for the intensified and optimized industrial recovery of scandium from bauxite residue. Chem. Eng. Process. Process Intensif. 2020, 155, 108015. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Kiskira, K.; Kalkanis, K.; Leligou, H.C.; Themelis, N.J. The role of energy recovery from wastes in the decarbonization efforts of the EU power sector. IET Renew. Power Gener. 2022, 16, 48–64. [Google Scholar] [CrossRef]

- Kiskira, K.; Papirio, S.; Pechaud, Y.; Matassa, S.; van Hullebusch, E.D.; Esposito, G. Evaluation of Fe (II)-driven autotrophic denitrification in packed-bed reactors at different nitrate loading rates. Process Saf. Environ. Prot. 2020, 142, 317–324. [Google Scholar] [CrossRef]

- Vercalsteren, A.; Nicolau, M.; Lafond, E. Textiles and the Environment in a Circular Economy. Eionet Report 2019- ETC/WMGE 2019/6. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/textiles-and-the-environment-in-a-circular-economy (accessed on 10 January 2023).

- Sivaramakrishnan, C.N. Pollution in textile industry. Colourage 2009, 16, 66–68. [Google Scholar]

- Huang, B.; Zhao, J.; Geng, Y.; Tian, Y.; Jiang, P. Energy-related GHG emissions of the textile industry in China. Resour. Conserv. Recycl. 2017, 119, 69–77. [Google Scholar] [CrossRef]

- WWF. Cotton Facts. Available online: https://www.worldwildlife.org/industries/cotton (accessed on 15 December 2022).

- ten Wolde, A.; Korneeva, P. Circular Fashion Advocacy, A Strategy towards a Circular Fashion Industry in Europe. Report 2019, Ecopreneur.eu. Available online: https://ecopreneur.eu/wp-content/uploads/2019/03/EcoP-Circular-Fashion-Advocacy-Report-28-3-19.pdf (accessed on 15 January 2023).

- Plakantonaki, S.; Stergiou, M.; Panagiotatos, G.; Kiskira, K.; Priniotakis, G. Regenerated cellulosic fibers from agricultural waste. AIP Conf. Proc. 2022, 2430, 080006. [Google Scholar]

- Choudhury, R.A.K. Development of eco-labels for sustainable textiles. In Roadmap to Sustainable Textile and Clothing: Regulatory Aspects and Sustainability Standards of Textiles and the Clothing Supply Chain, 1st ed.; Muthu, S.S., Ed.; Springer: Cham, Switzerland, 2015; pp. 137–174. [Google Scholar]

- Periyasamy, A.P.; Militky, J. Sustainability in Regenerated Textile Fibers. In Sustainability in the Textile and Apparel Industries, 1st ed.; Muthu, S.S., Gardetti, M.A., Eds.; Springer: Cham, Switzerland, 2020; pp. 63–95. [Google Scholar]

- Pepper, L.R.; Truscott, L. Preferred Fiber & Materials Market Report 2021. Textile Exchange. Available online: https://textileexchange.org/app/uploads/2021/08/Textile-Exchange_Preferred-Fiber-and-Materials-Market-Report_2021.pdf (accessed on 11 November 2022).

- Buchel, S.; Roorda, C.; Schipper, K.; Loorbach, D.; Janssen, R. The Transition to Good Fashion. DRIFT Report 2018. Rotterdam: Erasmus University Rotterdam. Available online: https://drift.eur.nl/wp-content/uploads/2018/11/FINAL_report.pdf (accessed on 8 October 2022).

- UNECE. Fashion Is an Environmental and Social Emergency, But Can also Drive Progress towards the Sustainable Development Goals. Available online: https://unece.org/forestry/news/fashion-environmental-and-social-emergency-can-also-drive-progress-towards (accessed on 18 December 2022).

- Baaka, N.; Khiari, R.; Haji, A. Ecofriendly Dyeing of Textile Materials with Natural Colorants from Date Palm Fiber Fibrillium. Sustainability 2023, 15, 1688. [Google Scholar] [CrossRef]

- EUR-Lex. Access to European Law. Regulation 1007/2011 on Fibre Names and Related Marking of the Fibre Composition of Textile Products. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R1007&from=EN (accessed on 11 January 2023).

- Shirvanimoghaddam, K.; Motamed, B.; Ramakrishna, S.; Naebe, M. Death by waste: Fashion and textile circular economy case. Sci. Total Environ. 2020, 718, 137317. [Google Scholar] [CrossRef]

- Ben-Eli, M.U. Sustainability: Definition and five core principles, a systems perspective. Sustain. Sci. 2018, 13, 1337–1343. [Google Scholar] [CrossRef]

- Thiry, M.C. Following the Fabric lifecycle. AATCC Rev. 2009, 9, 22–29. [Google Scholar]

- Ecolabel Index. Available online: https://www.ecolabelindex.com/ecolabels/?st=category,textiles (accessed on 25 February 2023).

- Angelova, R.A.; Sofronova, D. Sustainable Textiles: Design of New Weave Patterns Based on Texts. Sustainability 2023, 15, 1614. [Google Scholar] [CrossRef]

- Kalkanis, K.; Kiskira, K.; Papageorgas, P.; Kaminaris, S.D.; Piromalis, D.; Banis, G.; Mpelesis, D.; Batagiannis, A. Advanced Manufacturing Design of an Emergency Mechanical Ventilator via 3D Printing—Effective Crisis Response. Sustainability 2023, 15, 2857. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Kalkanis, K.; Chatzistamou, E.D.; Kiskira, K.; Ioannidis, G.C.; Kaminaris, S.D. End of life treatment of photovoltaic panels. Expected volumes up to 2045 in EU. AIP Conf. Proc. 2022, 2437, 20084–20098. [Google Scholar]

- Fernández, V.; Laborda, E.; Del-Busto, F.; Bartolomé, C. Social Perspectives towards Biobased Products and Textiles. Sustainability 2023, 15, 2284. [Google Scholar] [CrossRef]

- Toghyani, A.E.; Matthews, S.; Varis, J. Feasibility assessment of a wood-plastic composite post-production process: Cuttability. Procedia Manuf. 2018, 25, 271–278. [Google Scholar] [CrossRef]

- Lee, H.W. Development of Sustainable Creative Three-Dimensional Virtual Woven Textiles Using Clothing Waste. Sustainability 2023, 15, 2263. [Google Scholar] [CrossRef]

- Bourtsalas, A.C.; Papadatos, P.E.; Kiskira, K.; Kalkanis, K.; Psomopoulos, C.S. Ecodesign for Industrial Furnaces and Ovens: A Review of the Current Environmental Legislation. Sustainability 2023, 15, 9436. [Google Scholar] [CrossRef]

- Patra, A.K.; Pariti, S.R.K. Restricted substances for textiles. Text. Prog. 2022, 54, 1–101. [Google Scholar] [CrossRef]

- Dulo, B.; De Somer, T.; Phan, K.; Roosen, M.; Githaiga, J.; Raes, K.; De Meester, S. Evaluating the potential of natural dyes from nutshell wastes: Sustainable colouration and functional finishing of wool fabric. Sustain. Mater. Technol. 2022, 34, 518–531. [Google Scholar]

- Lant, N.J.; Hayward, A.S.; Peththawadu, M.M.; Sheridan, K.J.; Dean, J.R. Microfiber release from real soiled consumer laundry and the impact of fabric care products and washing conditions. PLoS ONE 2020, 15, 233332–233350. [Google Scholar] [CrossRef]

- Yun, C.; Patwary, S.; LeHew, M.L.; Kim, J. Sustainable care of textile products and its environmental impact: Tumble-drying and ironing processes. Fibers Polym. 2017, 18, 590–596. [Google Scholar]

- Rotzler, S.; Krshiwoblozki, M.V.; Schneider-Ramelow, M. Washability of e-textiles: Current testing practices and the need for standardization. Text. Res. J. 2021, 91, 2401–2417. [Google Scholar] [CrossRef]

- Iqbal, S.; Ansari, T.N. Extraction and application of natural dyes. In Sustainable Practices in the Textile Industry, 1st ed.; Rather, L.J., Shabbir, M., Haji, A., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 1–40. [Google Scholar]

- Uddin, F. Environmental hazard in textile dyeing wastewater from local textile industry. Cellulose 2021, 28, 10715–10739. [Google Scholar] [CrossRef]

- Mandal, S.; Venkatramani, J. A review of plant-based natural dyes in leather application with a special focus on color fastness characteristics. Environ. Sci. Pollut. Res. 2023, 30, 48769–48777. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Eco-friendly dyes and dyeing. Adv. Mater. Technol. Environ. 2018, 2, 145–176. [Google Scholar]

- Gross, M. Oceans of plastic waste. Curr. Biol. 2015, 25, 93–96. [Google Scholar] [CrossRef] [Green Version]

- Rochman, C.M.; Tahir, A.; Williams, S.L.; Baxa, D.V.; Lam, R.; Miller, J.T.; Teh, F.C.; Werorilangi, S.; Teh, S.J. Anthropogenic debris in seafood: Plastic debris and fibers from textiles in fish and bivalves sold for human consumption. Sci. Rep. 2015, 5, 14340. [Google Scholar]

- De Falco, F.; Gullo, M.P.; Gentile, G.; Di Pace, E.; Cocca, M.; Gelabert, L.; Brouta-Agnésa, M.; Rovira, A.; Escudero, R.; Villalba, R.; et al. Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ. Pollut. 2018, 236, 916–925. [Google Scholar] [CrossRef]

- Byrd, K.; Su, J. Investigating consumer behaviour for environmental, sustainable and social apparel. Int. J. Cloth. Sci. Technol. 2021, 33, 336–352. [Google Scholar] [CrossRef]

- Lou, L.; Yu, W.; Ramkumar, S. Wearable and smart responsive textiles. In High Performance Technical Textiles, 1st ed.; Paul, P., Ed.; John Wiley & Sons, Ltd.: West Sussex, UK, 2019; pp. 439–473. [Google Scholar]

- Pandit, P.; Nadathur, G.T.; Jose, S. Upcycled and low-cost sustainable business for value-added textiles and fashion. In Circular Economy in Textiles and Apparel, 1st ed.; Muthu, S.S., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; pp. 95–122. [Google Scholar]

- Pandey, R.; Pandit, P.; Pandey, S.; Mishra, S. Solutions for sustainable fashion and textile industry. In Recycling from Waste in Fashion and Textiles: A Sustainable and Circular Economic Approach, 1st ed.; Pandit, P., Ahmed, S., Singha, K., Shrivastava, S., Eds.; John Wiley & Sons, Ltd.: West Sussex, UK, 2020; pp. 33–72. [Google Scholar]

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods. Environ. Qual. Manag. 2018, 27, 31–41. [Google Scholar] [CrossRef]

- Dissanayake, D.G.K.; Weerasinghe, D. Towards circular economy in fashion: Review of strategies, barriers and enablers. Circ. Econ. Sustain. 2021, 2, 25–45. [Google Scholar] [CrossRef]

- Durham, T.C.; Mizik, T. Comparative economics of conventional, organic, and alternative agricultural production systems. Economies 2021, 9, 64–84. [Google Scholar] [CrossRef]

- Srijita, D. Biopesticides: An ecofriendly approach for pest control. World J. Pharm. Pharm. Sci. 2015, 4, 250–265. [Google Scholar]

- Beyond Pesticides. Defining a Strong IPM or EPM Program. Available online: https://www.beyondpesticides.org/resources/safety-source-on-pesticide-providers/what-is-integrated-pest-management (accessed on 26 June 2023).

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549. [Google Scholar] [CrossRef]

- Grand View Research. Market Analysis Report 2021. Available online: https://www.grandviewresearch.com/industry-analysis/eco-fiber-market# (accessed on 10 April 2023).

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728–120748. [Google Scholar] [CrossRef]

- Kiskira, K.; Lymperopoulou, T.; Lourentzatos, I.; Tsakanika, L.A.; Pavlopoulos, C.; Papadopoulou, K.; Ochsenkühn, K.M.; Tsopelas, F.; Chatzitheodoridis, E.; Lyberatos, G.; et al. Bioleaching of Scandium from Bauxite Residue using Fungus Aspergillus Niger. Waste Biomass Valorization 2023, 1, 1–14. [Google Scholar] [CrossRef]

- Nabil, I.; Chaudhery, M. Green Chemistry for Sustainable Textiles: Modern Design and Approaches, 1st ed.; Woodhead Publishing: Duxford, UK, 2021; pp. 1–491. [Google Scholar]

- Rovira, J.; Domingo, J.L. Human health risks due to exposure to inorganic and organic chemicals from textiles: A review. Environ. Res. 2019, 168, 62–69. [Google Scholar] [CrossRef]

- de Oliveira Neto, G.C.; Correia, J.M.F.; Silva, P.C.; de Oliveira Sanches, A.G.; Lucato, W.C. Cleaner Production in the textile industry and its relationship to sustainable development goals. J. Clean. Prod. 2019, 228, 1514–1525. [Google Scholar] [CrossRef]

- ECHA, EU. Available online: https://echa.europa.eu/regulations/reach/understanding-reach (accessed on 15 January 2023).

- UN, Environmnet Programme. Available online: http://www.basel.int/TheConvention/Overview/tabid/1271/Default.aspx (accessed on 15 March 2023).

- ZDHC Manufacturing Restricted Substance List. Available online: https://www.roadmaptozero.com/?locale=en (accessed on 20 April 2023).

- Henninger, C.E. Traceability the new eco-label in the slow-fashion industry?—Consumer perceptions and micro-organisations responses. Sustainability 2015, 7, 6011–6032. [Google Scholar] [CrossRef] [Green Version]

- Diekel, F.; Mikosch, N.; Bach, V.; Finkbeiner, M. Life cycle based comparison of textile ecolabels. Sustainability 2021, 13, 1751. [Google Scholar] [CrossRef]

- Wojnarowska, M.; Sołtysik, M.; Prusak, A. Impact of eco-labelling on the implementation of sustainable production and consumption. Environ. Impact Assess. Rev. 2021, 86, 106505. [Google Scholar] [CrossRef]

- Singer, A.A.; van der Ven, H. Beyond market, firm, and state: Mapping the ethics of global value chains. Bus. Soc. Rev. 2019, 124, 325–343. [Google Scholar] [CrossRef]

- Ranasinghe, L.; Jayasooriya, V. Ecolabelling in textile industry: A review. Resour. Environ. Sustain. 2021, 6, 100037. [Google Scholar] [CrossRef]

- ISO 14020:2022. Environmental Statements and Programmes for Products—Principles and General Requirements. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14020:ed-3:v1:en (accessed on 20 April 2023).

- Ibanez, L. Ecolabels: Are They Environmental-Friendly? In Encyclopedia of Law and Economics, 1st ed.; Marciano, A., Ramello, G., Eds.; Springer: New York, NY, USA, 2016; pp. 1–9. [Google Scholar]

- de Freitas Netto, S.V.; Sobral, M.F.F.; Ribeiro, A.R.B.; Soares, G.R.D.L. Concepts and forms of greenwashing: A systematic review. Environ. Sci. Eur. 2020, 32, 19. [Google Scholar] [CrossRef] [Green Version]

- Nemes, N.; Scanlan, S.J.; Smith, P.; Smith, T.; Aronczyk, M.; Hill, S.; Lewis, S.L.; Montgomery, A.W.; Tubiello, F.N.; Stabinsky, D. An integrated framework to assess greenwashing. Sustainability 2022, 14, 4431. [Google Scholar] [CrossRef]

- Horne, R.E. Limits to labels: The role of eco-labels in the assessment of product sustainability and routes to sustainable consumption. Int. J. Consum. Stud. 2009, 33, 175–182. [Google Scholar] [CrossRef]

- Riskos, K.; Dekoulou, P.; Mylonas, N.; Tsourvakas, G. Ecolabels and the attitude–behavior relationship towards green product purchase: A multiple mediation model. Sustainability 2021, 13, 6867. [Google Scholar] [CrossRef]

- Grolleau, G.; Ibanez, L.; Mzoughi, N.; Teisl, M. Helping eco-labels to fulfil their promises. Clim. Policy 2016, 16, 792–802. [Google Scholar] [CrossRef]

- Yenipazarli, A. The economics of eco-labeling: Standards, costs and prices. Int. J. Prod. Econ. 2015, 170, 275–286. [Google Scholar] [CrossRef]

| Chemicals | Details | Manufacturing Process |

|---|---|---|

| Heavy metals, especially nickel | Natural allergen nickel has the potential to cause contact dermatitis and is thought to be carcinogenic. Metal components have a release point for nickel. Impurities in dyes or catalytic agents may contain heavy metals with various health risks. Heavy metals such as arsenic, lead, cadmium, mercury, nickel, copper, chromium, cobalt, and zinc are present in traces in certain dyes. | Dyeing and printing: dyes containing traces of heavy metals |

| Azo Dyes | Most commonly used in textile and clothing manufacturing. They are most highly concentrated in black and brown colors and contain concentrations of p-Phenylenediamine (PPD), a chemical that can cause skin allergies and dermatitis. | Dyeing and printing: azo dyes containing/releasing banned amines 1 |

| Chlorinated Phenols | Chlorinated phenols (for example, pentachlorophenol (PCP) and tetrachlorophenol (TeCP)) have been employed as wood preservatives, textile impregnation agents, tanning bactericides, and in the paper and pulp industries. They are extremely dangerous to both humans and the environment. | Sizing—pentachlorophenol as a preservative |

| Brominated Flame Retardants (BFRs) | These substances are likely to accumulate in biological tissues, remain in the environment and food chain, and pose a risk to animals. The usage of pentabromodiphenyl ether (pentaPBDE) and octabromodiphenyl ether (octaPBDE) has been outlawed by the European Parliament, while risk assessments for decabromodiphenyl ether (decaPBDB) are now being conducted. | Production—BFRs are mixtures of man-made chemicals that are added to textiles to make them less flammable |

| Formaldehyde | With its strong odor, formaldehyde can be utilized as a cross-linking agent. It is employed as an anti-greasing and anti-shrinking agent, as well as a preservative. Formaldehyde is a known carcinogen that is also irritating to the eyes, nose, and other tissues. | Dyeing and printing: formaldehyde-based auxiliaries Finishing: formaldehyde-based finishes |

| Organotin Compounds | Plastic stabilizers, catalytic agents, industrial biocides, and antifouling paints are all examples of organotin compounds in use. They are pollutants that are especially detrimental to the aquatic environment. Even at low concentrations, organotins are extremely poisonous to marine and freshwater creatures. | Production |

| Banned pesticides/biocides such as DDT, Dieldrin, Aldrin, etc. | Because of their particularly hazardous nature, pesticides and biocides present major health issues. | Cotton growing Packing—wooden boxes treated with insecticides |

| Chlorinated Organic Dye Carriers | These compounds are prohibited in buyer goods because they can affect the neurological system and may be irritating to the skin and mucous membranes. Trichloro benzene, biphenyl phenol, orthophenyl phenol, and halogenated aromatic hydrocarbons can all be used as dye carriers. | In the dyeing process of polyester or wool/polyester fibers, they are used as carriers |

| Chlorinated products | Chlorine easily combines with natural organic matter brought into the water, resulting in the development of potentially hazardous chlorination byproducts (CBPs). The establishment of CBPs is of special relevance because some have been linked to the development of various clinical symptoms. | Scouring: chlorinated products Bleaching: sodium and calcium hypochlorite Finishing: stain removers containing chlorinated products |

| Phthalate | Phthalates are a class of phthalic acid ester compounds that are utilized as plasticizers. Phthalate compounds are commonly used in the textile industry to create motifs, plastisol patterns, coated fabrics, buttons, and so on. These substances have the potential to cause endocrine (hormonal) and reproductive system disruption. In animal studies, phthalates can induce liver, kidney, lung, and testicular damage at high dosages. | Production |

| Ecolabel Name | Details |

|---|---|

| ABNT Ecolabel | Life cycle-based ecolabeling is a voluntary way of certifying and labeling products and services for environmental performance in Brazil. |

| Animal Welfare Approved (AWA) | Animals must be able to behave normally and be in a condition of physical and mental wellbeing in order to meet the standard for farm animal care. |

| B Corporation | B Corporations are a brand-new form of business that employs the power of the market to address social and environmental issues. |

| BMP Certified Cotton | BMP is the cotton industry’s blueprint for cultivating cotton in harmony with the natural world in Australia. |

| Better Cotton Initiative (BCI) | The BCI advocates a thorough set of production guidelines and standards for cultivating cotton in a more socially, ecologically, and commercially sustainable way. |

| Blue Angel | The German government established the Blue Angel award, which is presented to products that are more ecologically friendly than others serving the same purpose. |

| Bluesign® standard | With the help of the Bluesign® standard, the whole textile production chain can work together to lessen the environmental impact of a sustainably run textile business. |

| CRI Green Label | The Green Label was created by the Carpet and Rug Institute (CRI) in 1992 to test carpets, cushions, and adhesives to help specifiers find products with extremely low VOC emissions. |

| Carbon Reduction Label | A public statement that the carbon footprint of a good or service has been calculated and validated and that the owner has agreed to lessen it over the following two years. |

| CarbonCare | The MRO (Measuring, Reducing, and Offsetting) method of addressing climate change is encouraged and recognized by the CarbonCare® program. |

| CarbonFree® Certified | The CarbonFree® Product Certification badge serves to highlight businesses reducing their carbon footprints and raise consumer awareness of product emissions. |

| Certified Humane Raised and Handled | designed to verify the ethical treatment of animals used to produce dairy, lamb, poultry, and beef products. |

| Certified Wildlife Friendly® | If production has a good effect on the regional economy, people or communities that live beside animals engage in the production, etc., products may be certified by WFEN. |

| China Environmental Labelling | SEPA launched the China Environmental Label in 1993. It offers environmental requirements for things like building materials, clothing, automobiles, cosmetics, and electronics. |

| Climatop | The goal of Climatop is to identify the goods and services that are most friendly to the environment. |

| Clear to Wear | With the tightest product hygiene and safety regulations, the Inditex group and the University of Santiago de Compostela (Spain) established a hygiene and safety standard. |

| Compostability Mark of European Bioplastics | Allows for the identification of compostable items via a distinctive mark and the channeling of such products for the recovery of their component elements in specially devised methods. |

| Coop Naturaline: Switzerland | For cotton that has been grown under regulated biological conditions in accordance with EU or BIO Suisse criteria used to make textiles and natural cosmetics. |

| Cradle-to-Cradle Certified (CM) Products | Using the Cradle-to-Cradle-Certified (CM) Products Program, a business may show its commitment to eco-intelligent design. |

| Danish Indoor Climate Label | A tool for developing and choosing goods that are friendly to indoor air quality and for better understanding how different items and materials affect the indoor air quality of buildings. |

| Degree of Green® | By evaluating items and providing a clear explanation of those ratings, the Degree of Green® grading program seeks to assist customers. |

| Demeter Biodynamic® | A certification stating the application of biodynamic agricultural methods. |

| Ecocert | An organization for sustainable development certification. It is an organization for inspection and certification of agronomists founded in France for agriculture that is ecologically friendly. |

| Eco-INSTITUT-Label | Customers who purchase construction materials and textiles from Eco-Institut receive a trustworthy and important label free of any health risks. |

| ECOLOGO | Based on standards with several attributes and the life cycle. Before being given the mark, products that have been certified to an ECOLOGO standard must fulfill or surpass each of the specified requirements. |

| EU Ecolabel | The EU created the optional EU Ecolabel or EU Flower program in 1992. |

| Earthsure | The objective is to supply purchasers (companies and individuals) with comprehensive environmental data so that the market may steer the economy in the direction of general environmental improvement. |

| Eco-Leaf | Life cycle analysis-based environmental product declaration. |

| Eco Mark Africa (EMA) | An introductory prize that is ideal for Africa. |

| EcoMark Japan | Through prudent product selection, the Eco Mark program works to encourage environmentally sustainable (or “ecological”) lives. |

| Ecomark India | A government-run certification scheme for ecologically friendly consumer goods. |

| Ecoproof | The label is for textiles, especially textiles made from cotton. |

| Eco Safe | Label for use by businesses issued by the ICQ group (Commitment for Safety and Quality—Impegno per la Sicurezza e la Qualità established in Italy), mostly used by the Benetton group. |

| Ekologicky setrny vyrobek | The official registered label of the Czech ecolabeling scheme is “Ekologicky setrny vyrobek” (Environmentally Friendly Product). |

| Environmental Choice New Zealand | A voluntary environmental labeling program with many parameters that adhere to global norms and guidelines. |

| Environmental Product Declaration | An Environmental Product Declaration’s (EPD) main objective is to offer pertinent, verified, and comparable data to satisfy varied market and consumer objectives. |

| Etichetta ambientale (AssoSCAI) | The multi-label was created by AssoSCAI to help Italian businesses properly categorize environmental items in accordance with ISO 14021. |

| Fair Labor Practices and Community Benefits | Scientific Certification Systems (SCS) established social responsibility certification to go along with organic fair labor practices and community benefits certification. |

| FairWertung (German Fair Recycling Federation) | Network of charitable organizations and social enterprises that adhere to the standards set out by FairWertung for the ethical collection and sale of used clothing. |

| Fairtrade | A system of ethical commerce that prioritizes the needs of people and gives farmers and workers in developing nations a better bargain as well as the chance to enhance their lives and invest in the future. |

| GREENGUARD | Aids in the development of interior items and materials with minimal chemical emissions into indoor air and aids purchasers in identifying such products. |

| GUT | Throughout the whole life cycle of a textile floor covering (from manufacture through installation, usage phase, and recycling), it is the goal to enhance all environmental and consumer protection elements. |

| Global Fashion Agenda (GFA) | A leadership forum for industry collaboration on sustainability has a wide number of partners, including some of the biggest textile and fashion firms in the world. |

| Global GreenTag Certified | Global Green Tag® is a third party, green product rating and certification system underpinned by scientific and Life Cycle Assessment (LCA) processes. |

| Global Organic Textile Standard (GOTS) | Global textile processing standard for organic fibers, including independent certification of the complete textile supply chain, as well as ecological and social standards. |

| Global Recycle Standard | The Global Recycled Standard is designed for businesses that produce and/or market goods that use recycled material. |

| Good Environmental Choice “Bra Miljöval” | “Good Environmental Choice” or “Good Green Buy” in English. This category focuses on somewhat popular goods and services that have a significant environmental impact. |

| Good Environmental Choice Australia (GECA) | It is the sole Australian member of the Global Ecolabeling Network (GEN) and manages Australia’s only independent, not-for-profit, multi-sector ecolabeling program. |

| Good Shopping Guide Ethical Award | Enables businesses and brands to show an environmental, animal, and human health score that has been independently validated. |

| GoodWeave | GoodWeave works to provide children in South Asia with educational opportunities and to put a stop to child labor in the carpet business. |

| Green Crane: Ukraine | A voluntary environmental labeling program that uses several requirements and adheres to international standards and tenets is called Green Crane. |

| Green Mark | To promote the concept of recycling, pollution reduction, and resource conservation. |

| Green Mark Taiwan | Certification label issued for the production of textile materials in Taiwan. |

| Green Products Standard | Green Products Standard helps consumers better understand the growing number of green and eco-friendly products in the marketplace. |

| Green Shape | Green Shape is VAUDE’s label for products that feature special ecological manufacturing. |

| Green Tick | Independent sustainability certification of goods, services, and businesses based on an evaluation of performance in accordance with the Green Tick Sustainability Standards across the course of their lifecycles. |

| GreenCircle | GreenCircle Certified, LLC offers third-party certification of environmentally friendly features of products and production processes. |

| GreenPla | Japan’s goal is to develop the technology of biodegradable plastics (GreenPla) and to promote its widespread commercial application. |

| Healthy Child, Healthy World | Promotes goods and services that are geared toward non-toxic lifestyle changes and environmental wellness for kids and families. |

| Hong Kong Green Label (HKGLS) | The Green Council (GC) introduced the HKGLS, an independent, non-profit certification program for ecologically friendly goods, in December 2000. |

| IMO Certified | A worldwide organization for product inspection, certification, and quality control of environmentally friendly goods is the Institute for Market ecology (IMO). |

| Korean Ecolabel | The Korea Eco-Products Institute carries out various operations related to improvement in eco-products and product environmental friendliness. |

| Label STEP | Awarded to handmade carpet retailers who adhere to fair trade principles, such as paying fair pricing and preventing the exploitation of children in the labor force. |

| Max Havelaar | A quality mark is given by the Max Havelaar Foundation to goods that were manufactured in accordance with fair trade standards. |

| Migros ECO | A textile’s promise that no material likely to irritate or aggravate skin, cause allergies, or harm the environment must be labeled on the product. |

| Milieukeur: the Dutch environmental quality label | The Dutch environmental quality badge for goods and services is called Milieukeur. There are Milieukeur criteria for a number of goods and services, including consumer goods and services. |

| NATURTEXTIL Best | “Naturtextil BEST” is a holistic standard. It values environmental and social criteria along the whole textile production chain. |

| NSF Sustainability Certified Product | The NSF Sustainability Certified mark is available to products that meet conformity assessment to an NSF/ANSI or other national or international sustainable product standards. NSF/ANSI 140 Sustainability Assessment for Carpet. NSF/ANSI 336: Sustainability Assessment for Commercial Furnishings Fabric. |

| Naturland e.V. | Naturland—Association for organic agriculture is a private certification body and an organic farmers association. |

| Nike Considered Design | A sustainable footwear brand from Nike Inc. The use of materials that are mostly found within 200 miles (320 km) of the Nike facility decreases the energy required for production. |

| Nordic Ecolabel or “Swan” | Demonstrates that a product is a good environmental choice. The “Swan” symbol, as it is known in Nordic countries, is available for 65 product groups. |

| ÖkoControl | After rigorous testing conducted by independent and certified test facilities, the Label is applied to furniture, beds, or mattresses made of natural, sustainable materials. |

| Ø-label: Norway | Aims to protect Norway’s future organic production. Debio’s inspection program, which covers all operations from farm to table, encompasses all suppliers of organic goods in Norway. |

| Organic Content Standard (OCS) | An optional chain of custody requirement that provides companies with a way to have a third party confirm that a completed product includes the right amount of an organically produced ingredient. To guarantee the authenticity and integrity of the organic material input, each organization in the supply chain must take the necessary steps. |

| Oeko-Tex Standard 100 | A global testing and certification system for textile raw materials, intermediate products, and finished goods at all stages of manufacturing. |

| Oregon Tilth | Organic certification confirms compliance with the USDA National Organic Program requirements and verifies that the agreed-upon norms of organic agriculture systems are being followed. |

| Organic Farmers and Growers Certification | The UK Department for Environment, Food, and Rural Affairs (Defra) standards for organic production and processing are met by products bearing the Organic Farmers and Growers mark. |

| Processed Chlorine Free | Processed Chlorine-Free (PCF) audits assess the environmental effect of a manufacturing process and need a chain of custody for all raw ingredients. |

| SCS Sustainable Choice | Carpet goods must fulfill quantifiable environmental performance and social responsibility standards in order to receive the Sustainable Choice certification. |

| SEE What You Are Buying Into | A labeling program called SEE What You Are Buying Into is for companies that are upfront and truthful about their Social, Environmental, and Ethical (SEE) policies and practices. |

| SMaRT Consensus Sustainable Product Standards | Sustainable products standard and label for building products, fabric, apparel, textile, and flooring, covering 80% of the world’s products with environmental, social, and economic criteria. |

| Singapore Green Label Scheme (SGLS) | Aims to help the public identify environment-friendly products that meet certain ecostandards in Singapore. |

| Skal Eko Symbol | A certification program for agricultural goods made using organic production techniques. |

| Soil Association Organic Standard | Organic certification is available to UK-based farmers, growers, food processors and packers, retailers, caterers, textile manufacturers, and importers of health and beauty products. |

| Sourcemap (Sourcemap.com) | Making decisions that are sustainable by using a platform for supply chain transparency that allows producers to communicate in-depth details about their operations to customers and buyers. |

| Sustainable Apparel Coalition (SAC) | The creation of the Higg Index, which is used by more than 10,000 enterprises globally to evaluate numerous characteristics to determine how sustainable they are. |

| SustentaX | An ecolabel from Brazil called SustentaX helps customers find environmentally friendly goods and services based on the evaluation of both human safety and product quality. |

| TerraCycle | Carries out nationwide garbage collecting initiatives in ten nations, where non-recyclable post-consumer waste (among many other categories) is gathered and transformed into fresh goods and resources. |

| Texas Certified Organically Produced | Under the Organic Certification Program, TDA inspects and certifies organic farms as well as processors, distributors, and retailers of organic food and fiber. |

| Thai Green Label | A certification is given to certain items that, compared to other products performing the same function, have the least negative environmental effect. |

| Timberland Green Index | The “Green Index” by Timberland rates the environmental effect of their offerings. Consumers are given access to information on the environmental impact Timberland has. |

| Totally Chlorine Free | The Totally Chlorine Free standard uses a Sustainability Index to assess environmental effects. |

| Tunisia Ecolabel | In 1997, a national ecolabel was established by order. It was established to make it easier for Tunisian goods and services to reach European and global markets. |

| USDA Certified BioBased | A label that is managed and operated by the federal government and is based on the BioPreferred program, which was established by the US Farm Bill in 2002 to promote the use of biobased goods. |

| Zque | Natural performance wool is combined with a program of accreditation that protects the sustainability of the environment, the social and economic system, the welfare of animals, and the capacity to track products. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plakantonaki, S.; Kiskira, K.; Zacharopoulos, N.; Chronis, I.; Coelho, F.; Togiani, A.; Kalkanis, K.; Priniotakis, G. A Review of Sustainability Standards and Ecolabeling in the Textile Industry. Sustainability 2023, 15, 11589. https://doi.org/10.3390/su151511589

Plakantonaki S, Kiskira K, Zacharopoulos N, Chronis I, Coelho F, Togiani A, Kalkanis K, Priniotakis G. A Review of Sustainability Standards and Ecolabeling in the Textile Industry. Sustainability. 2023; 15(15):11589. https://doi.org/10.3390/su151511589

Chicago/Turabian StylePlakantonaki, Sofia, Kyriaki Kiskira, Nikolaos Zacharopoulos, Ioannis Chronis, Fernando Coelho, Amir Togiani, Konstantinos Kalkanis, and Georgios Priniotakis. 2023. "A Review of Sustainability Standards and Ecolabeling in the Textile Industry" Sustainability 15, no. 15: 11589. https://doi.org/10.3390/su151511589

APA StylePlakantonaki, S., Kiskira, K., Zacharopoulos, N., Chronis, I., Coelho, F., Togiani, A., Kalkanis, K., & Priniotakis, G. (2023). A Review of Sustainability Standards and Ecolabeling in the Textile Industry. Sustainability, 15(15), 11589. https://doi.org/10.3390/su151511589