Abstract

Beer brewing is a complex process that comprises many fundamental unit operations. Over the last few years, craft brewing has become very popular, and the number of small-scale commercial brewers has drastically increased. However, due to the use of traditional beer-making methods, energy utilization in craft breweries tends to be inefficient, resulting in poor sustainability. Therefore, there is a necessity for a holistic analysis on the energy profile of craft beer brewing to evaluate its environmental performance on a unit operation basis. In this study, a gate-to-gate life cycle assessment was conducted to analyze and compare the environmental profiles of craft beer brewing, including ale and lager, at commercial (microbrewery) and pilot scales. A process simulation model was developed to estimate the electricity and/or natural gas uses of each unit operation, including heating, mashing, boiling, whirlpool, cooling, fermentation, and maturation. The model accurately predicted the steam use for pilot-scale brewing and the electricity and gas bills of a microbrewery. The beers brewed at the microbrewery scale (21.5-barrel brewhouse) had 2–11-fold lower environmental impacts than those brewed at the pilot scale (1-barrel brewhouse), and lager beer generally produced 11–32% higher impacts than ale. The fermentation and maturation steps in brewing were the major contributors to global warming and terrestrial acidification, whereas the mashing step was predominantly responsible for marine eutrophication. This study provides craft brewers with a useful tool for identifying the hotspots of energy use in their processes and developing potential improvement strategies.

Keywords:

ale; lager; microbrewery; mashing; fermentation; energy intensity; global warming potential; malt 1. Introduction

Beer is the most widely consumed alcoholic beverage in the world [1]. The United States and Germany are the countries that produce the largest quantities of beer, equal to approximately 80% of the world production [2]. In 2022, the overall beer market in the United States was valued at USD 115.4 billion, of which USD 28.4 billion corresponded to the craft brewing industry for a 13.2% market share. A craft brewery is a brewery that is often independently owned and produces relatively small quantities of beer, typically less than 6 million beer barrels (bbl) per year, using typical ingredients and traditional brewing methods. Consumption of craft beer has become very popular in the U.S. in recent years, and while the overall U.S. beer sales declined by 3.1% in 2022 compared to the previous year, sales of craft beer remained practically unchanged. In 2022, the craft beer industry produced 24 million bbl, compared to the 117.5 million bbl produced by larger breweries [3]. Craft breweries can be categorized according to their production capacity (number of barrels brewed annually) and depending on whether beer is consumed on- or off-site as: microbreweries (less than 15,000 bbl and selling more than 75% off-site), brewpubs (selling 25% or more beer on-site and operating food services), taproom breweries (selling 25% or more on-site without operating food services), and regional breweries (production between 15,000 and 6 million bbl) [3]. Furthermore, for recipe development and testing, most craft breweries use a pilot brewing system, with a size ranging from 5 gallons to a few barrels.

Craft beer brewing comprises multiple unit operations in the brewhouse, including malt milling, mashing, lautering, boiling, whirlpooling, and cooling, all of which convert raw materials into chilled wort for subsequent fermentation and maturation into finished beer [4]. Depending on the type of yeast used and the fermentation process, beer can be classified into two main styles [5]: top-fermenting beer, commonly known as ale, and bottom-fermenting, known as lager beer. In top-fermentation, ale yeasts (Saccharomyces cerevisiae) ferment maltose produced during mashing and can only ferment a third of the raffinose, but no melibiose. Ale yeasts tend to form clumps of buds that break up after fermentation starts; therefore, the yeasts can be carried up by the CO2 bubbles produced to the top of the fermenting vessel and can then be harvested. In contrast, bottom-fermentation uses lager yeasts (Saccharomyces pasteuranius) to ferment maltose, which, however, can completely ferment melibiose and raffinose. The aggregates of cells tend to fall to the bottom of the vessel or remain suspended in wort instead of rising to the surface [6]. With respect to the fermentation temperature, according to Testa et al. [7], ales are generally fermented at warm temperatures of 15–25 °C for 3–5 weeks, while lagers take much longer to ferment (up to 6–8 weeks) because their normal fermentation temperatures are lower, ranging from 7 to 14 °C [8].

Craft brewing refers to the use of traditional methods for beer production as opposed to industrial breweries, which tend to be highly automated. Therefore, craft breweries are facing challenges of low production efficiency that result in high energy costs and poor environmental performance. Moreover, production costs in a brewery largely depend on its scale. Galitsky et al. [9] reported that the utility bills of breweries producing < 1700 bbl/year approximately double those producing > 427,350 bbl/year. Moreover, our previous study [10] monitored the monthly energy intensity (i.e., energy use per bbl produced) of a microbrewery by collecting data on its utility bills and beer sales and found that increasing the monthly barrelage decreased the electricity intensity. However, our previous study focused on the microbrewery’s total energy use, and the energy performance of each unit operation in the brewing process is still unclear. Since energy use can account for up to 94% of the utility bills of a craft brewery [10], it is necessary to thoroughly monitor and analyze the energy performance of all the unit operations for identifying improvement opportunities.

Life cycle assessment (LCA) is an ISO (International Organization for Standardization)-standardized methodology that can comprehensively quantify the environmental impacts of a product throughout its entire life cycle and identify the hotspots [11]. An LCA study involves a thorough inventory of the energy and materials that are required for a product, from its raw materials’ acquisition through production, use, and disposal, and calculates the corresponding emissions to the environment. LCA thus assesses cumulative potential environmental impacts, which are generally categorized into resource use, human health, and ecological consequences [11]. Although LCA has been applied to evaluate the environmental performance of beer production [12,13,14,15,16], most of the studies focused on large-scale breweries and reported aggregated environmental impacts of the whole brewing process instead of the impacts of each unit operation included, hence, the environmental hotspot of craft beer brewing is still not well-identified.

In this paper, we expanded our previous LCA study on craft beer production [10] to further assess and compare the environmental impacts of ale and lager produced at commercial and pilot scales on a unit operation basis. A process simulation model was developed to estimate the utility demand of each unit operation included in the brewing process. This study can provide craft brewers with a useful tool for diagnosing the energy efficiency of their processes and identifying the energy-saving potential.

2. Materials and Methods

2.1. Brewing Process

2.1.1. Microbrewery

We studied the brewing process of a microbrewery (3000 bbl/year) in Indiana, USA, for ale and lager production using a 21.5 bbl brewhouse. The process started by heating mashing water (995–1404 L) in a hot liquor tank from room temperature to 75 °C using saturated steam at 6 psi, generated by a 32 hp boiler. Then, the mashing water, malts, and adjuncts (all the commercial recipes are confidential information) were mixed in a mash tun and agitation was applied by an internal rake to ensure a homogeneous mixture of grains and water and to prevent filtration problems. The grain-to-water ratios were approximately 1:3 for ale and 1:4–5 for lager. The grains and water mixture, i.e., mash, underwent a saccharification step at 65 °C for 30 min before the “vourlauf” step, at which the mash was recirculated through the grain bed for 15 min to clarify the extract. A lautering step was used to separate the sweet wort, which in turn was transferred to a boil kettle, while the grain bed was sparged using hot water (76 °C) to maximize the recovery of fermentable sugars from the spent grains. The sparge water was added at a flow rate to maintain the water level approximately 5 cm above the grain bed. The lautering finished when the “run-off” volume (i.e., target wort volume) was achieved and the wort was brought to boiling temperature using saturated steam (6 psi) in the jacket of the boil kettle for boiling for 90 min. Hops were added during the boiling step for the extraction of bitter compounds. Then, the boiled wort was pumped into a whirlpool tank, where it rested for 60 min for the hot-break (“trub”) separation step, at which point all the larger particles and coagulated proteins sedimented to the bottom of the tank. The clear wort was cooled-down from 92–94 °C to 18–20 °C by chilled water through a plate heat exchanger before being transferred to a fermentation vessel. The wort was further cooled by glycol recirculation in the jacket of the fermentation vessel to the fermentation temperatures of 18–19 °C and 14–15 °C for ale and lager yeast strains, respectively. The yeast was pitched in, and the wort was fermented for approximately 19–20 days until the desired final specific gravity was reached. Then, the “green beer” was transferred to maturation tanks and kept at 1–5 °C for 4–7 days to obtain the final beer product. Table 1 lists the parameters of all the unit operations measured in the microbrewery for brewing one batch (21.5 bbl brewhouse) of representative ale and lager beers.

Table 1.

Process parameters of ale and lager beer brewing at the microbrewery scale (21.5 bbl brewhouse).

2.1.2. Pilot-Scale Brewery

The pilot-scale (1 bbl brewhouse) brewing process was performed in the Pilot Plant of the Department of Food Science at Purdue University, which consisted of the same unit operations described in the previous section except the maturation step, which was not included due to the beer recipes selected. Since the full malt recipes used by the microbrewery studied were not available, we used alternative recipes for pilot-scale brewing which were the best approximates based our personal communications with the brewer. One lager recipe and one ale recipe with similar parameters (original gravity = 1.045 and 1.047, final gravity = 1.010 and 1.012, international bitterness unit = 21 and 32, standard reference method scale = 4 and 4, and alcohol by volume = 4.6% and 4.8% for ale and lager beers, respectively) were chosen, and the fermentation temperature was the most important difference between the two beer styles. The operating conditions were modified due to the scale differences and the heat transfer agents available. All the parameters were collected through measurements and are summarized in Table 2.

Table 2.

Process parameters of ale and lager beer brewing at the pilot scale (1 bbl brewhouse).

2.2. Process Simulation

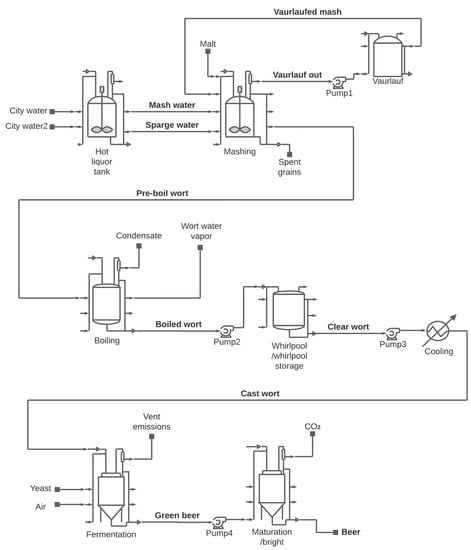

Process simulation is a useful tool when measurements are not feasible, especially to estimate the utility demand of each unit operation included in a process. A model was built using the SuperPro Designer software v9.0 (Intelligen Inc., Scotch Plains, NJ, USA) to simulate the brewing process at both the microbrewery and the pilot-scale brewery. Figure 1 shows the flows of the brewing process modeled. Due to the differences between ale and lager brewing, including the grain-to-water ratio, temperature, and time required for fermentation and maturation, the energy uses in both scenarios were estimated using the model for comparison. The unit operation data listed in Table 1 and Table 2 were used for model development. The data on heating and cooling agents were adapted from the database of SuperPro Designer. The mass and energy balance in each unit operation, amounts of heat transfer agents required, and power demands were calculated.

Figure 1.

Process flow diagram of craft beer brewing. Maturation was excluded in the pilot-scale brewing.

To validate the model, the simulated total energy uses for ale and lager brewing at the microbrewery scale were compared with the average monthly utility bills from June 2018 to May 2019 provided by the brewer. For pilot-scale brewing, the model was validated by comparing the simulated and measured steam uses for water heating, mashing, and wort boiling. The measurement was performed by collecting the steam condensate from the jackets of both the hot liquor tank and the boil kettle after each brewing experiment.

2.3. Life Cycle Assessment

2.3.1. Goal and Scope

The goal of the life cycle assessment (LCA) was to analyze the environmental profile of the brewing process of craft beer and compare the environmental performance of ale and lager brewing in a microbrewing facility and a pilot plant in Indiana, USA. The functional unit (FU) was defined as 1 bbl of beer brewed. The system boundary of the LCA was from gate to gate, with a particular focus on the eight unit operations listed in Table 1 and Table 2. The environmental impacts associated with spent grains were calculated using the “cut-off” approach, by which all the impacts generated beyond the system boundary were not considered. The intended applications of the LCA were to identify the environmental hotspots in craft beer brewing and the opportunities to reduce the environmental footprint of the beers produced. The intended audience included U.S. microbrewers interested in improving the environmental performance of their brewing processes and consumers who want to purchase more sustainable beer products.

2.3.2. Life Cycle Inventory

The life cycle inventory (LCI) data included the raw materials (malt and hops), cooling agent (glycol), and utilities (natural gas and electricity) required for brewing one barrel of beer. The data on malting were collected from Kløverpris et al. [17], which included the water, electricity, and natural gas uses for production of 1 ton of malt. The data on hop and glycol uses were measured in the microbrewery and at the Purdue Food Science Pilot Plant. The utilities for each unit operation of brewing were obtained with process simulations, as described in Section 2.2. End-of-pipe wastewater emissions were also considered. The emissions from the microbrewery were estimated according to the typical ranges of the U.S. breweries [18], and those from the pilot plant were measured by collecting and analyzing the wastewater generated from mashing and trub. All the background inventory data, including productions of grains, glycol, and energy, were adapted from the ecoinvent database v3.0 developed by Wernet et al. [19]. All the brewing equipment was not included in this study because it is rigid and considered as long-term infrastructure.

2.3.3. Life Cycle Impact Assessment

The environmental impacts of one barrel of beer brewed were determined using the ReCiPe 2016 Midpoint (E) v1.02 method. The impact category indicators presented included global warming potential (GWP; kg CO2 eq), terrestrial acidification potential (AP; kg SO2 eq), freshwater eutrophication potential (FWEP; kg P eq), marine eutrophication potential (MEP; kg N eq), and water use (WU; m3). These impact categories were selected because they have been found to be the most significant impacts of beer production in the literature [16,20,21]. All data were analyzed using the SimaPro software v8.5.2 (PRé Consultants, Amersfoort, The Netherlands).

3. Results and Discussion

3.1. Model Validation

Table 3 compares the total steam use for the heating and boiling steps of pilot-scale brewing (1 bbl) determined by the developed model and experimental measurements. Very good agreements were observed between the simulation and the experimental results, regardless of the unit operation and beer type.

Table 3.

Steam use for brewing one barrel of beer in the pilot-scale brewery.

Table 4 compares the simulated electricity and natural gas use for brewing one barrel of beer at the microbrewery scale (21.5 bbl), with the microbrewery’s average monthly bills collected over a one-year production. All the simulated values were well-aligned with the microbrewery’s data for both types of beers. The variation in the electricity intensity of beer (i.e., electricity use per barrel of beer produced) was because the monthly beer production of the microbrewery studied greatly varied with market demand over a year, and a higher monthly barrelage resulted in a lower electricity intensity [10]. The slight discrepancies between the simulated gas use and the average gas bill can be attributed to the additional gas use for heating the brewery facility during the winter season and heating the water for cleaning brewing equipment. The results proved that the developed model can reliably estimate the energy use for craft beer brewing at both pilot and microbrewery scales. Therefore, the model is an important tool for brewers to predict production costs and potentially improve their profitability.

Table 4.

Electricity and natural gas use for brewing one barrel of beer in the microbrewery.

3.2. Inventory Analysis

Table 5 presents the LCI of the brewing process for ale and lager at the microbrewery and pilot scales. The ale brewed by the microbrewery used 6 kg more malt than the lager for production of one barrel because of the higher final extract concentration (specific gravity = 1.0539) required. Consequently, the ale used approximately 27% more natural gas for boiling. The fermentation and maturation stages were the hotspots of electricity use in the microbrewery, respectively accounting for approximately 61.3% and 38.6% for the ale and 49.7% and 50.2% for the lager of their total electricity uses. Due to the differences between the physiological requirements of ale and lager yeast strains, the lower temperatures and prolonged periods required for lager fermentation and maturation resulted in its 24% higher total electricity use compared to the ale. Similarly, De Marco et al. [13] reported that lager beer consumed 36% more electricity than ale. The sugar assimilation efficiency of a yeast strain during fermentation is determined by the expression of its specific genes that transport α-glucosides (e.g., maltose and maltrotriose) across the yeast cell plasma, which can be delimited by the temperature of the environment [22,23]. For instance, lager yeast strains have been reported to show a five-fold reaction rate at 0 °C compared to those at 20 °C [24]. However, a lower fermentation temperature consumes more energy. Therefore, from the cost perspective, it is necessary to determine the optimal combination of fermentation temperature and time for the specific yeast strain used in order to minimize the energy use for fermentation.

Table 5.

Inventory of brewing one barrel of ale and lager beers at the microbrewery and pilot scales.

For the brewing in the pilot plant, both beers had similar natural gas uses but the lager had a 32% higher electricity use than the ale because of its longer fermentation period and the lower temperature used. Compared to the brewing in the microbrewery, the pilot-scale brewing was much more energy-intensive, using approximately a 2-fold amount of natural gas and a 13-fold amount of electricity per barrel of beer. Majority of the gas and electricity were used by boiling (63.6%) and fermentation (99.9%), respectively. Sturm et al. [25] indicated that brewing at a smaller scale generally has a lower mashing efficiency, and thus requires more malted barley to achieve the target concentration of wort extract. This trend was not observed in this study because the malts used for brewing at the microbrewery and pilot scales were not identical. This study provides the first unit operation-based LCI of U.S. craft beers, and the data are valuable for future LCA studies.

3.3. Midpoint Environmental Impacts

Table 6 compares the environmental impacts of ale and lager brewed at the microbrewery and the pilot plant. Lager produced higher environmental impacts, except that ale brewed at the microbrewery had higher MEP and WU values because more malt was used. These results were, in general, aligned with those reported by De Marco et al. [13]. Lager had a 21% (microbrewery) and 28% (pilot plant) higher GWP, mainly because it used more electricity for fermentation and maturation at lower temperatures, as described in the previous section. The GWP of the lager brewed by the microbrewery studied (126 kg CO2 eq) was of the same magnitude as the GWP reported by Cimini and Moresi [12] for lager produced by a Latvian brewery, with an annual production of approximately 511 bbl. The U.S. electricity mix mainly comprises fossil fuels, with natural gas (34.1%) and coal (28.6%) as the major sources in 2018, which caused higher greenhouse gas emissions than the countries that use more renewable energy in their electricity mixes, e.g., 52.0% for Latvia [26].

Table 6.

Midpoint environmental impacts of ale and lager brewed at different scales.

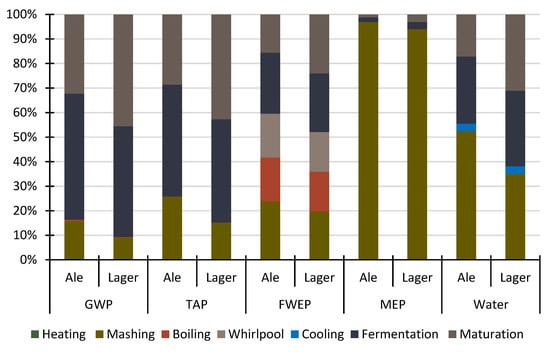

The environmental profiles of the brewing in the microbrewery (Figure 2) showed that fermentation and maturation were the GWP hotspots, respectively contributing 45.1% and 45.6% for the lager and 51.4% and 32.3% for the ale to their total GWP. Electricity generation, required for fermentation and maturation, accounted for the largest share of the total WU, of 30.8% and 31.1% for the lager, and 27.3% and 17.2% for the ale, respectively. The mashing step also played an important role due to the environmental impacts associated with malt production, which predominated the total MEP, by 98.5% for the ale and 89.3% for the lager. Since ale features 8.5–14% higher original gravity than lager [27], its production requires a larger ratio of grains to water, and hence produces a higher grain bill. Therefore, the mashing step including malt use represented 15.5% of the ale’s GWP, but only 10% for the lager. The TAP of both beers showed similar profiles to the GWP, demonstrating that fermentation and maturation were the main contributors, followed by mashing. The boiling and whirlpool steps only had significant contributions to the FWEP, of 16.2–17.9%, which can be associated with the protein precipitated at a high temperature during boiling, that was then released as “trub” into the wastewater. Other major organic components in brewing wastewater include cellulose, sugars, and amino acids [18], which are highly biodegradable [28], with BOD and COD values of 600–5000 and 1800–5500 ppm, respectively [18].

Figure 2.

Environmental profiles of ale and lager brewed in a microbrewery.

As for the effect of the brewing scale, the beer brewed at the pilot scale caused 2–11-fold higher environmental impacts than that at the microbrewery scale, for both types of beers and all the impact categories (Table 6). Moreover, similar to the environmental profile at the microbrewery scale, fermentation and maturation were identified as the environmental hotspots of pilot-scale brewing (data not reported).

4. Conclusions

This study presented a gate-to-gate LCA on craft beer brewing in the U.S., in which the environmental performance of ale and lager were compared on a unit operation basis at the microbrewery and pilot scales. A simulation model was developed to estimate the utilities required for each unit operation of the brewing process, which accurately predicted the electricity and natural gas uses at both scales and is thus a very useful tool for production cost estimation. Brewing in the microbrewery produced lower environmental impacts than that at in the pilot plant, and ale was more environment-friendly than lager. In the brewing process, fermentation and maturation were the hotspots of the GWP and TAP, and mashing predominated the MEP. While LCA studies on U.S. craft beer are still limited, the results of this study not only provide valuable LCI data, but also, more importantly, are expected to facilitate craft brewers’ decision-making toward a more sustainable brewing process. For example, fermentation and maturation were the most energy-intensive unit operations due to the low temperatures required; therefore, alternative yeast strains which can ferment at higher temperatures without compromising the beer yield and quality need to be explored. Moreover, the model developed here will be applied to simulate the brewing processes of other types of beers for comprehensive analyses on the effects of the fermentation temperature and time on the beer yield and energy use, which will ultimately determine the optimum combination that minimizes the energy intensity of fermentation. However, the current model was only validated for breweries with relatively low productivity. To expand its application to larger breweries (e.g., regional breweries that produce 15,000 to 6,000,000 bbl each year), more data on their brewing operations are needed for further validation. Other approaches to reducing energy use for beer brewing include keeping evaporation during boiling at the possible minimum rate, recovering energy from vapor, installing an energy storage system, using a process automation system, equipping tanks and pipelines with proper insulation, using variable speed drives, and minimizing losses of wort and beer.

Author Contributions

Conceptualization, M.F.S.M.-G. and J.-Y.H.; methodology, M.B.S.T., M.F.S.M.-G. and J.-Y.H.; validation, M.B.S.T. and M.F.S.M.-G.; formal analysis, M.B.S.T.; investigation, M.B.S.T. and M.F.S.M.-G.; resources, M.F.S.M.-G. and J.-Y.H.; data curation, M.B.S.T. and J.-Y.H.; writing—original draft preparation, J.-Y.H.; writing—review and editing, M.F.S.M.-G. and J.-Y.H.; visualization, M.B.S.T., J.A.V.D. and J.-Y.H.; supervision, M.F.S.M.-G. and J.-Y.H.; project administration, J.-Y.H.; funding acquisition, M.F.S.M.-G. and J.-Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the USDA National Institute of Food and Agriculture, Hatch project number 1014964.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We gratefully thank Chris Johnson for providing the data on the beer brewing operations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bimbo, F.; De Meo, E.; Baiano, A.; Carlucci, D. The Value of Craft Beer Styles: Evidence from the Italian Market. Foods 2023, 12, 1328. [Google Scholar] [CrossRef] [PubMed]

- Iannone, M.; Ovidi, E.; Vitalini, S.; Laghezza Masci, V.; Marianelli, A.; Iriti, M.; Tiezzi, A.; Garzoli, S. From Hops to Craft Beers: Production Process, VOCs Profile Characterization, Total Polyphenol and Flavonoid Content Determination and Antioxidant Activity Evaluation. Processes 2022, 10, 517. [Google Scholar] [CrossRef]

- Brewers Association. National Beer Sales & Production Data. Available online: https://www.brewersassociation.org/statistics-and-data/national-beer-stats/ (accessed on 26 June 2023).

- Gil, R.L.; Amorim, C.M.P.G.; Amorim, H.G.; Montenegro, M.D.C.B.S.M.; Araújo, A.N. Influence of Brewing Process on the Profile of Biogenic Amines in Craft Beers. Sensors 2023, 23, 343. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.; Oliveira, A.I.; Cruz, A.; Oliveira, R.F.; Almeida, R.; Pinho, C. Physicochemical Properties and Antioxidant Activity of Portuguese Craft Beers and Raw Materials. Molecules 2022, 27, 8007. [Google Scholar] [CrossRef]

- Bokulich, N.A.; Bamforth, C.W. The microbiology of malting and brewing. Microbiol. Mol. Biol. Rev. 2013, 77, 157–172. [Google Scholar] [CrossRef]

- Testa, B.; Coppola, F.; Letizia, F.; Albanese, G.; Karaulli, J.; Ruci, M.; Pistillo, M.; Germinara, G.S.; Messia, M.C.; Succi, M.; et al. Versatility of Saccharomyces cerevisiae 41CM in the Brewery Sector: Use as a Starter for “Ale” and “Lager” Craft Beer Production. Processes 2022, 10, 2495. [Google Scholar] [CrossRef]

- Ciont, C.; Epuran, A.; Kerezsi, A.D.; Coldea, T.E.; Mudura, E.; Pasqualone, A.; Zhao, H.; Suharoschi, R.; Vriesekoop, F.; Pop, O.L. Beer Safety: New Challenges and Future Trends within Craft and Large-Scale Production. Foods 2022, 11, 2693. [Google Scholar] [CrossRef]

- Galitsky, C.; Martin, N.; Worrell, E.; Lehman, B. Energy Efficiency Improvement and Cost Saving Opportunities for Breweries: An ENERGY STAR (R) Guide for Energy and Plant Managers; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2003. [Google Scholar]

- Salazar, T.; San Martín-González, M.F.S.; Cai, H.; Huang, J.-Y. Economic and environmental performance of instantaneous water heating system for craft beer production. Food Bioprod. Process. 2021, 127, 472–481. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental management—Life cycle assessment—Requirements and guidelines. ISO: Geneva, Switzerland, 2006.

- Cimini, A.; Moresi, M. Effect of brewery size on the main process parameters and cradle-to-grave carbon footprint of lager beer. J. Ind. Ecol. 2018, 22, 1139–1155. [Google Scholar] [CrossRef]

- De Marco, I.; Miranda, S.; Riemma, S.; Iannone, R. Life cycle assessment of ale and lager beers production. Chem. Eng. Trans. 2016, 49, 337–342. [Google Scholar] [CrossRef]

- The Climate Conservancy. The Carbon Footprint of Fat Tire Amber Ale; The Climate Conservancy: Lincoln, OR, USA, 2008. [Google Scholar]

- Cordella, M.; Tugnoli, A.; Spadoni, G.; Santarelli, F.; Zangrando, T. LCA of an Italian lager beer. Int. J. Life Cycle Assess. 2008, 13, 133–139. [Google Scholar] [CrossRef]

- Koroneos, C.; Roumbas, G.; Gabari, Z.; Papagiannidou, E.; Moussiopoulos, N. Life cycle assessment of beer production in Greece. J. Clean. Prod. 2005, 13, 433–439. [Google Scholar] [CrossRef]

- Kløverpris, J.; Spillane, D. Comparative LCA of malt-based beer and 100% barley beer. Brew. Beverage Ind. Int. 2010, 2, 34–36. [Google Scholar]

- Brewers Association. Water and Wastewater: Treatment/Volume Reduction Manual; Brewers Association: Boulder, CO, USA, 2014. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Hospido, A.; Moreira, M.T.; Feijoo, G. Environmental analysis of beer production. Int. J. Agric. Resour. Gov. Ecol. 2005, 4, 152–162. [Google Scholar] [CrossRef]

- Talve, S. Life cycle assessment of a basic lager beer. Int. J. Life Cycle Assess. 2001, 6, 293–298. [Google Scholar] [CrossRef]

- Stambuk, B.U.; Alves, S.L., Jr.; Hollatz, C.; Zastrow, C.R. Improvement of maltotriose fermentation by Saccharomyces cerevisiae. Lett. Appl. Microbiol. 2006, 43, 370–376. [Google Scholar] [CrossRef]

- Rautio, J.; Londesborough, J. Maltose transport by brewer’s yeasts in brewer’s wort. J. Inst. Brew. 2003, 109, 251–261. [Google Scholar] [CrossRef]

- Vidgren, V.; Multanen, J.-P.; Ruohonen, L.; Londesborough, J. The temperature dependence of maltose transport in ale and lager strains of brewer’s yeast. FEMS Yeast Res. 2010, 10, 402–411. [Google Scholar] [CrossRef] [PubMed]

- Sturm, B.; Hugenschmidt, S.; Joyce, S.; Hofacker, W.; Roskilly, A.P. Opportunities and barriers for efficient energy use in a medium-sized brewery. Appl. Therm. Eng. 2013, 53, 397–404. [Google Scholar] [CrossRef]

- International Energy Agency. Electricity Information; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Kunze, W. Technology Brewing and Malting, revidierte Ausgabe, 5th ed; Versuchs- u. Lehranstalt f. Brauerei: Berlin, Germany, 2016; p. 968. ISBN 978-3-921690-77-2. [Google Scholar]

- Inyang, U.; Bassey, E. Characterization ofbrewery effluent fluid. J. Eng. Appl. Sci. 2021, 4, 67–76. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).