Bibliometric Mapping of Research on Life Cycle Assessment of Olive Oil Supply Chain

Abstract

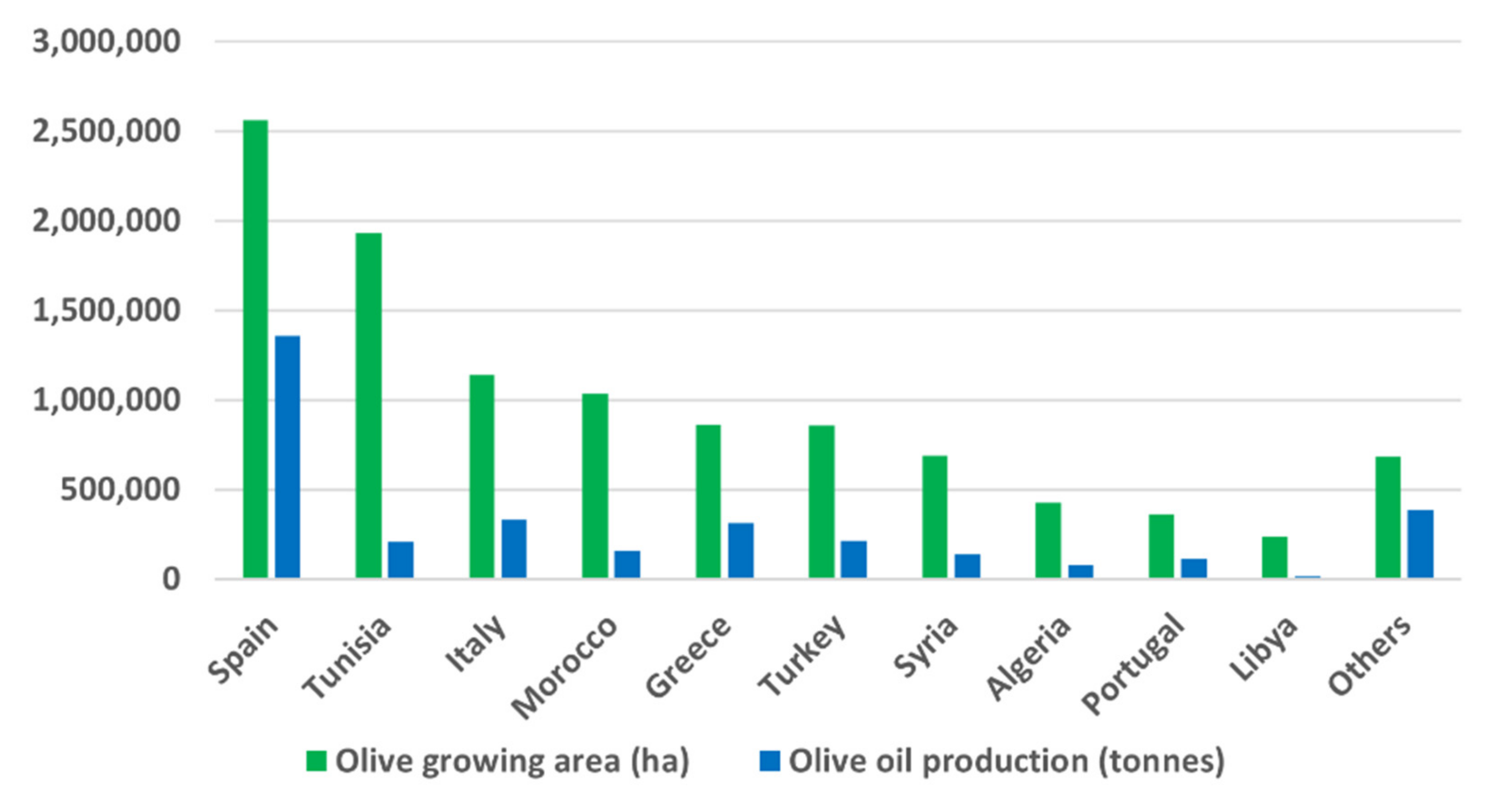

:1. Introduction

2. Materials and Methods

3. Results

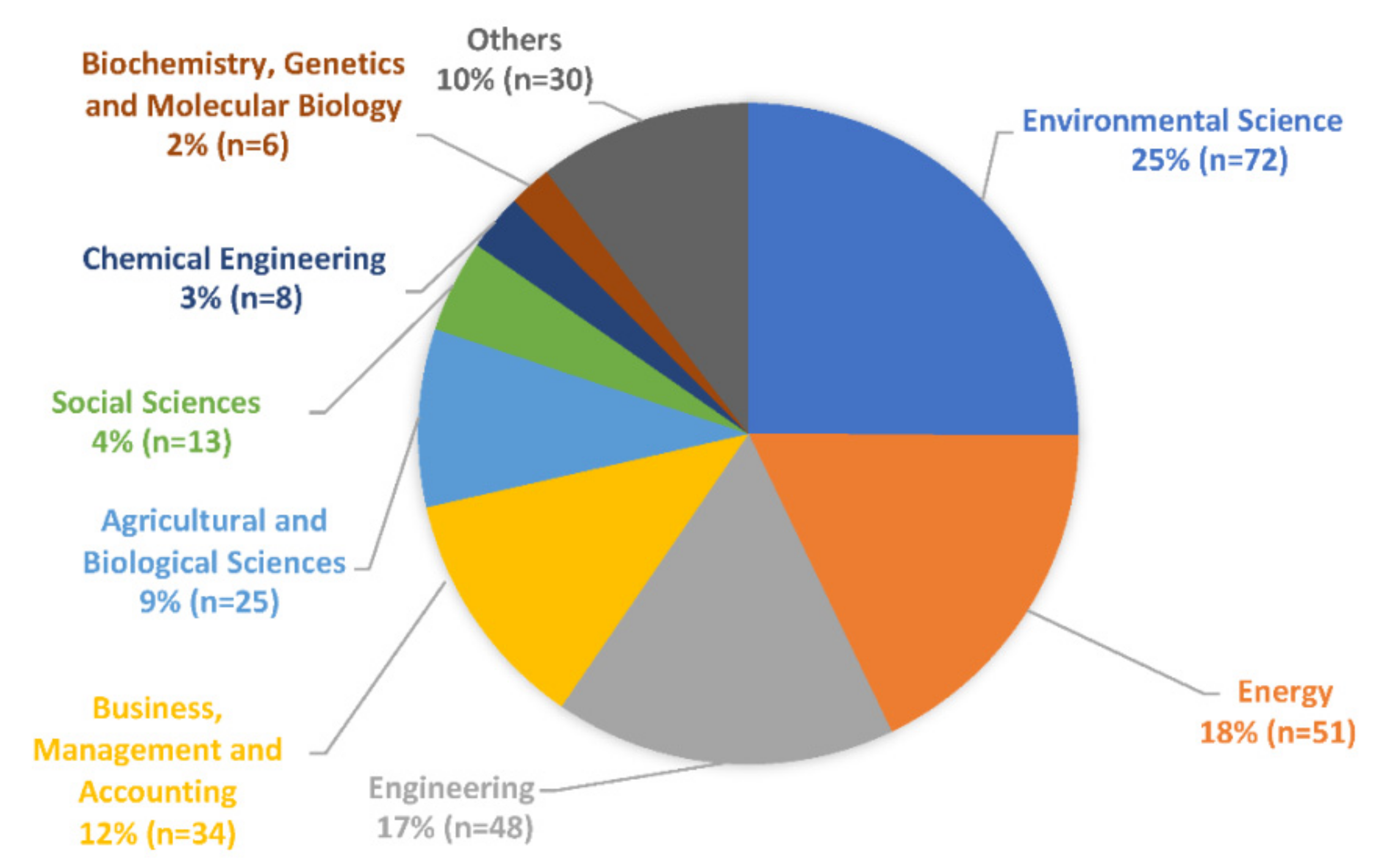

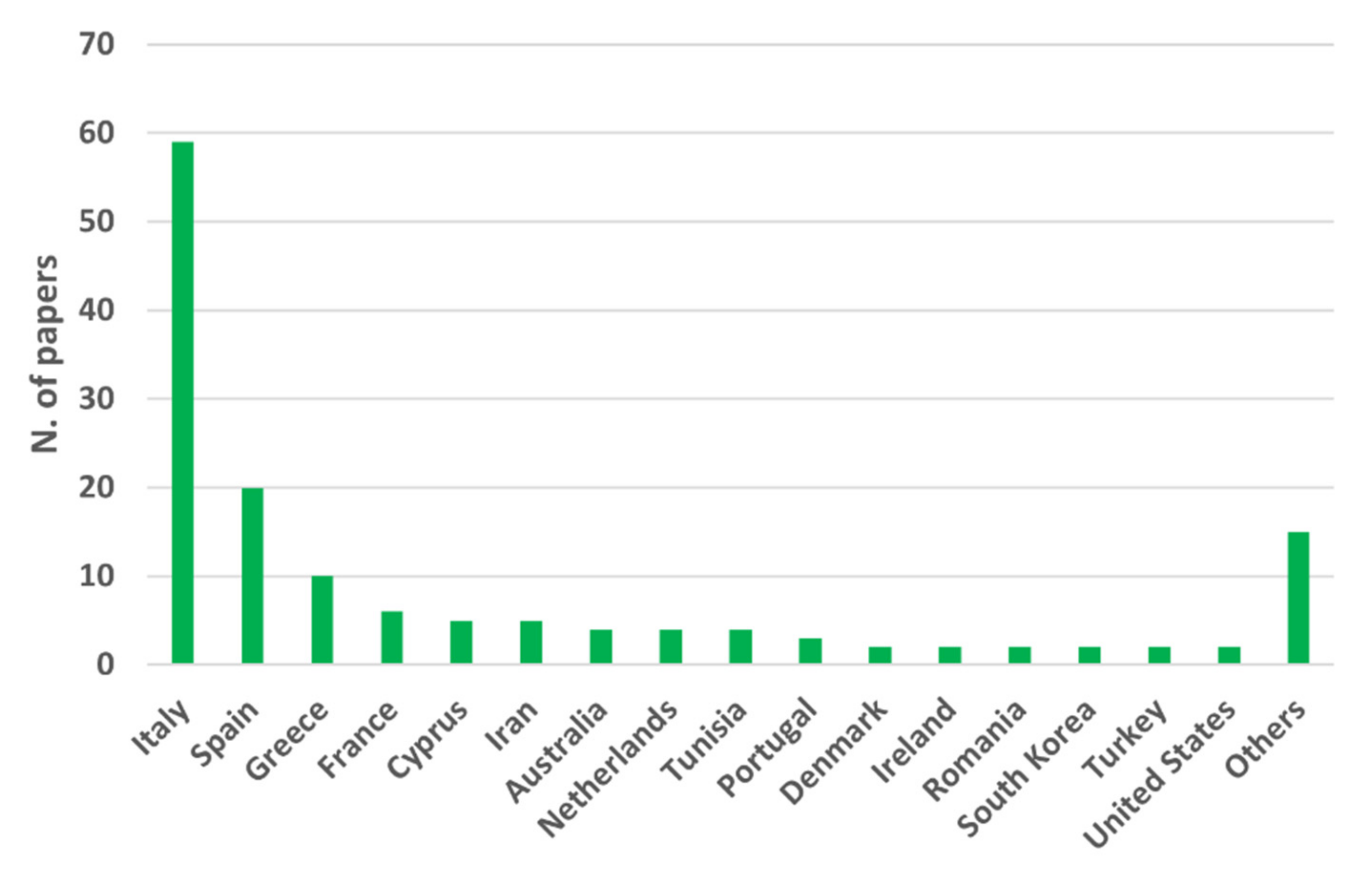

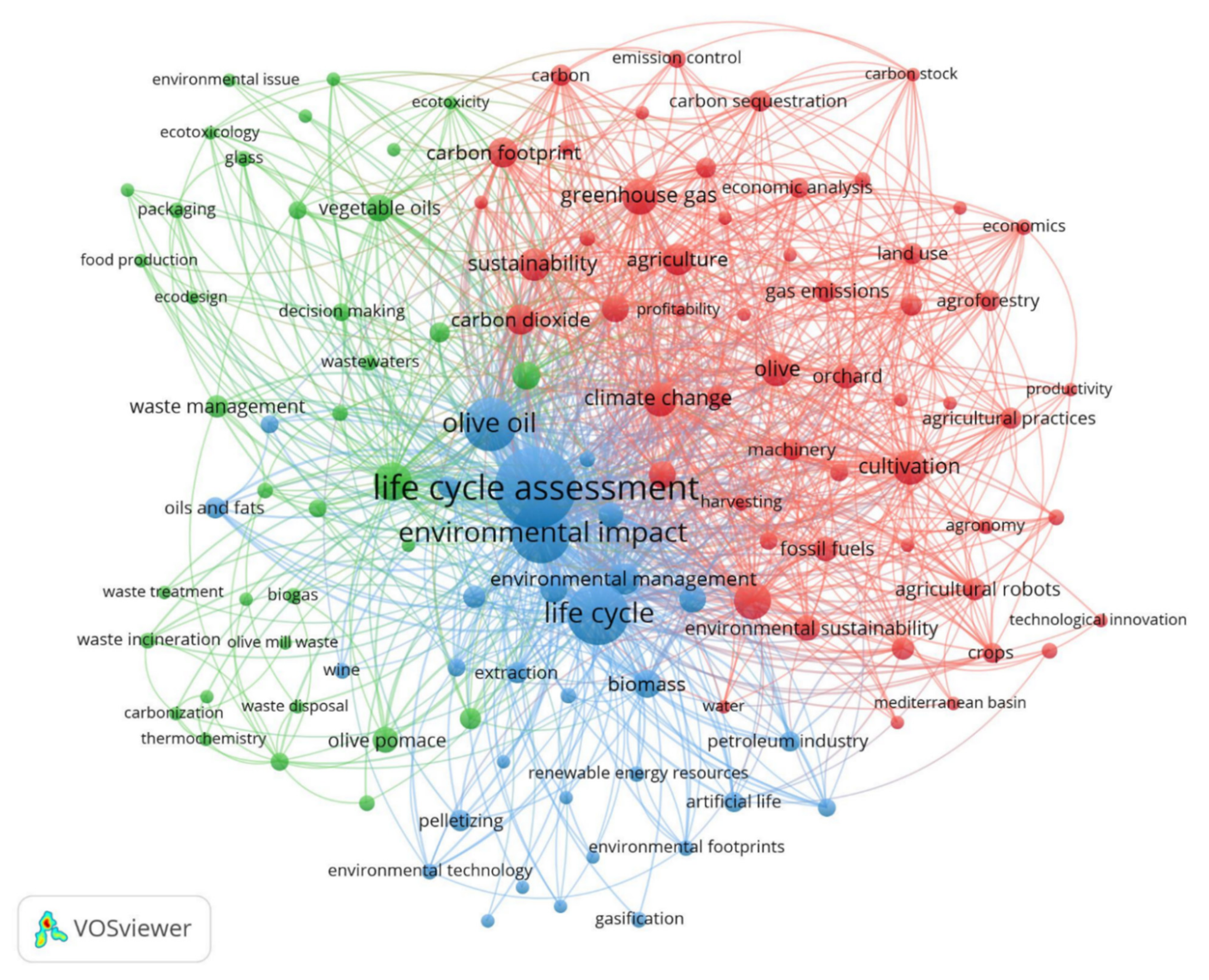

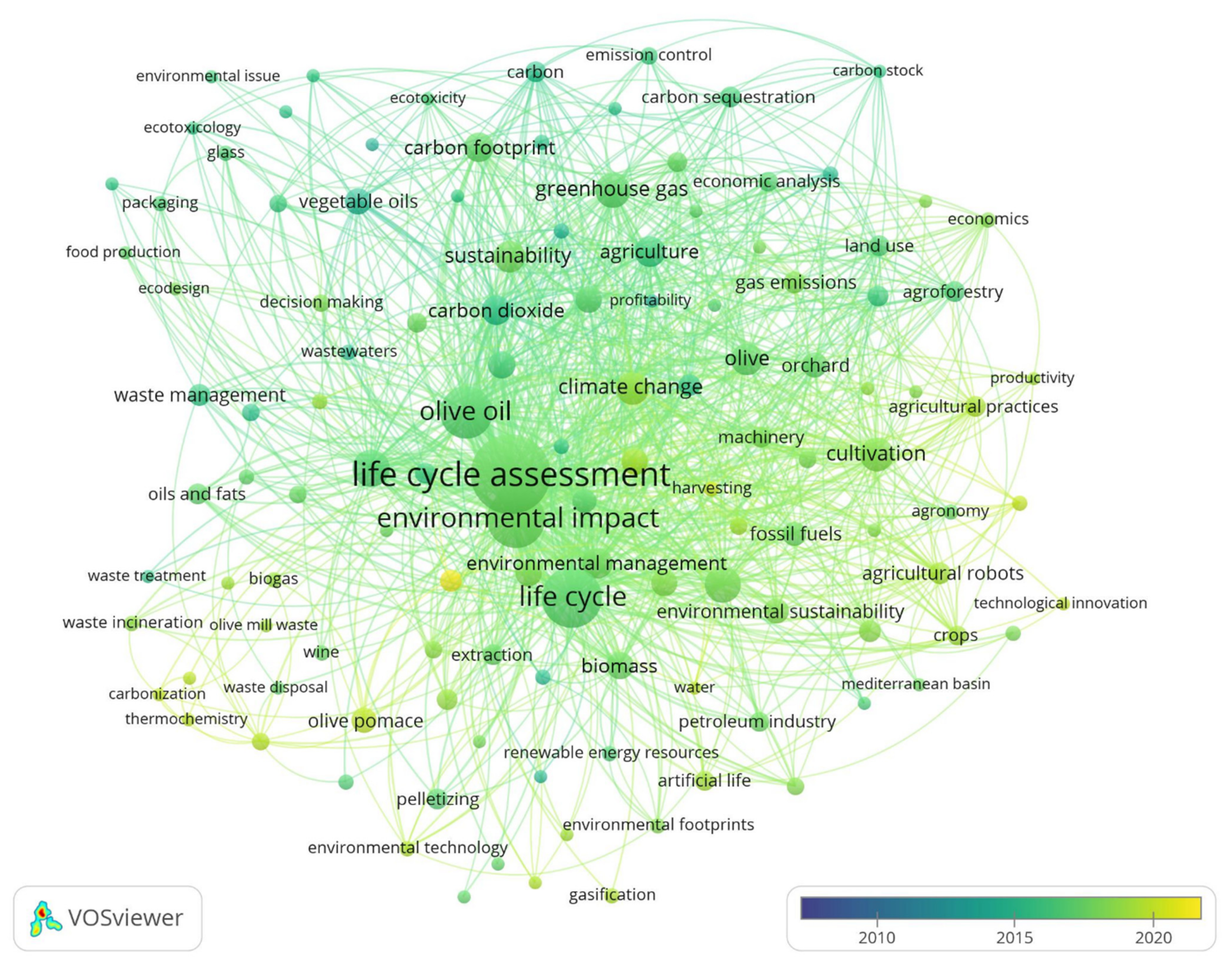

Performance Analysis

4. Principal Topics and Trends of LCA of Olive Oil Production Research

4.1. Agricultural Phase

4.1.1. Growing Systems

4.1.2. Plant Protection

4.1.3. Harvest

4.2. Oil Extraction

4.3. Waste Management and By-Product Valorization

4.3.1. Renewable Energy

4.3.2. Other Studies on by-Product Valorization

4.3.3. Packaging and Distribution

5. Research Trends

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Country | Olive Oil Production | Olive Oil Consumption | Scientific Documents | |||

|---|---|---|---|---|---|---|

| Tons | % | Tons | (%) | N. | % | |

| Spain | 1,371,400 | 44.2 | 495,120 | 16.0 | 20 | 13.7 |

| Italy | 284,960 | 9.2 | 471,000 | 15.2 | 59 | 4.1 |

| Greece | 255,200 | 8.2 | 116,460 | 3.8 | 10 | 6.8 |

| Tunisia | 229,000 | 7.4 | 33,800 | 1.1 | 4 | 2.7 |

| Turkey | 214,900 | 6.9 | 163,900 | 5.3 | 2 | 1.4 |

| Morocco | 151,000 | 4.9 | 134,000 | 4.3 | ||

| Syria | 119,400 | 3.8 | 100,700 | 3.2 | ||

| Portugal | 109,000 | 3.5 | 65,340 | 2.1 | 3 | 2.5 |

| Algeria | 87,800 | 2.8 | 87,300 | 2.8 | ||

| Egypt | 36,100 | 1.2 | 36,000 | 1.2 | ||

| Argentina | 31,400 | 1.0 | 7600 | 0.2 | ||

| Jordan | 24,200 | 0.8 | 23,500 | 0.8 | 1 | 0.7 |

| Palestine | 21,700 | 0.7 | 15,100 | 0.5 | 1 | 0.7 |

| Chile | 20,200 | 0.7 | 8000 | 0.3 | ||

| Lebanon | 19,900 | 0.6 | 15,700 | 0.5 | 1 | 0.7 |

| Australia | 18,700 | 0.6 | 47,700 | 1.5 | 4 | 2.7 |

| Libya | 16,700 | 0.5 | 16,800 | 0.5 | ||

| Israel | 16,000 | 0.5 | 24,000 | 0.8 | ||

| USA | 15,800 | 0.5 | 354,500 | 11.4 | 2 | 1.4 |

| Albania | 11,900 | 0.4 | 13,300 | 0.4 | ||

| Iran | 8300 | 0.3 | 11,300 | 0.4 | 5 | 3.4 |

| China | 6200 | 0.2 | 50,000 | 1.6 | 1 | 0.7 |

| Cyprus | 5220 | 0.2 | 6140 | 0.2 | 5 | 3.4 |

| France | 4640 | 0.1 | 121,280 | 3.9 | 6 | 4.8 |

| Croatia | 4020 | 0.1 | 7840 | 0.3 | ||

| Saudi Arabia | 3000 | 0.1 | 34,700 | 1.1 | ||

| Uruguay | 1000 | 0.0 | 1700 | 0.1 | ||

| Slovenia | 580 | 0.0 | 2360 | 0.1 | ||

| Montenegro | 500 | 0.0 | 500 | 0.0 | ||

| Austria | 8340 | 0.3 | ||||

| Belgium | 15,380 | 0.5 | 1 | 0.7 | ||

| Brazil | 86,500 | 2.8 | 1 | 0.7 | ||

| Bulgaria | 3700 | 0.1 | ||||

| Canada | 49,700 | 1.6 | ||||

| Czech. Rep. | 4860 | 0.2 | ||||

| Denmark | 6000 | 0.2 | 2 | 1.4 | ||

| Estonia | 860 | 0.0 | ||||

| Finland | 2840 | 0.1 | ||||

| Georgia | 500 | 0.0 | ||||

| Germany | 65,260 | 2.1 | ||||

| Hungary | 2940 | 0.1 | ||||

| Iraq | 1500 | 0.0 | ||||

| Ireland | 4280 | 0.1 | 2 | 1.4 | ||

| Japan | 61,500 | 2.0 | ||||

| Latvia | 1380 | 0.0 | ||||

| Lithuania | 940 | 0.0 | ||||

| Luxembourg | 1520 | 0.0 | ||||

| Malta | 740 | 0.0 | ||||

| Mexico | 15,700 | 0.5 | ||||

| Netherlands | 15,660 | 0.5 | 4 | 2.7 | ||

| Norway | 4100 | 0.1 | ||||

| Poland | 9580 | 0.3 | 1 | 0.7 | ||

| Romania | 4060 | 0.1 | 2 | 1.4 | ||

| Russia | 24,600 | 0.8 | ||||

| Slovakia | 1880 | 0.1 | ||||

| Sweden | 10,420 | 0.3 | 1 | 0.7 | ||

| Switzerland | 15,500 | 0.5 | 1 | 0.7 | ||

| Taiwan | 7900 | 0.3 | ||||

| United King. | 67,825 | 2.2 | ||||

| Uzbekistan | 500 | 0.0 | ||||

| Other countries | 15,480 | 0.5 | 142,095 | 4.6 | 8 | 5.4 |

| TOTAL WORLD | 3,104,200 | 100.0 | 3,104,200 | 100.0 | ||

| Institution | Country | N. of Publications | Total Number of Citations | Average Number of Citations * | ||

|---|---|---|---|---|---|---|

| Total | Articles on a Journal | Book Chapter— Conference Paper | ||||

| Mediterranean University of Reggio Calabria | Italy | 12 | 11 | 1 | 170 | 14 |

| University of Perugia | Italy | 7 | 7 | 199 | 28 | |

| University of Bari Aldo Moro | Italy | 6 | 6 | 420 | 70 | |

| University of Basilicata | Italy | 6 | 4 | 2 | 107 | 18 |

| University of Milano | Italy | 6 | 6 | 63 | 11 | |

| Frederick University | Cyprus | 4 | 2 | 2 | 94 | 24 |

| University of Toulouse | France | 4 | 4 | 61 | 15 | |

| INRAE Occitanie-Toulouse | France | 4 | 4 | 61 | 15 | |

| University of Messina | Italy | 4 | 3 | 1 | 188 | 47 |

| University of Catania | Italy | 4 | 4 | 29 | 7 | |

| University of Foggia | Italy | 4 | 4 | 58 | 15 | |

| University of Sassari | Italy | 4 | 4 | 32 | 8 | |

| University of Jaén | Spain | 4 | 4 | 11 | 3 | |

References

- Gaforio, J.J.; Visioli, F.; Alarcón-De-la-lastra, C.; Castañer, O.; Delgado-Rodríguez, M.; Fitó, M.; Hernández, A.F.; Huertas, J.R.; Martínez-González, M.A.; Menendez, J.A.; et al. Virgin Olive Oil and Health: Summary of the Iii International Conference on Virgin Olive Oil and Health Consensus Report, JAEN (Spain) 2018. Nutrients 2019, 11, 2039. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gavahian, M.; Mousavi Khaneghah, A.; Lorenzo, J.M.; Munekata, P.E.S.; Garcia-Mantrana, I.; Collado, M.C.; Meléndez-Martínez, A.J.; Barba, F.J. Health Benefits of Olive Oil and Its Components: Impacts on Gut Microbiota Antioxidant Activities, and Prevention of Noncommunicable Diseases. Trends Food Sci. Technol. 2019, 88, 220–227. [Google Scholar] [CrossRef]

- FAO. FAOSTAT Statistical Database. License: CC BY-NC-SA 3.0 IGO. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 7 March 2022).

- Vilar, J.; Pereira, J.E.; Urieta, D.; Menor, A.; Caño, S.; Barreal, J.; del Mar Velasco Gámez, M.; Puentes Poyatos, R. International Olive Growing Worldwide Analysis and Summary; Fundación Caja Rural de Jaén: La Carolina, Spain, 2018; ISBN 9788494639494. Available online: https://www.juanvilar.com/project/international-olive-growing/ (accessed on 20 January 2022).

- Pienkowski, M.; Beaufoy, G. The Environmental Impact of Olive Oil Production in the European Union: Practical Options for Improving the Environmental Impact; European Forum on Nature Conservation and Pastoralism (EFNCP): Peterborough, UK, 2002; pp. 1–73. [Google Scholar]

- Mahmood, I.; Imadi, S.R.; Shazadi, K.; Gul, A.; Hakeem, K.R. Effects of Pesticides on Environment. In Plant, Soil and Microbes; Springer: Cham, Switzerland, 2016; pp. 253–269. [Google Scholar]

- Choudri, B.S.; Charabi, Y.; Ahmed, M. Pesticides and Herbicides. Water Environ. Res. 2018, 90, 1663–1678. [Google Scholar] [CrossRef] [Green Version]

- Paredes, C.; Cegarra, J.; Roig, A.; Sánchez-Monedero, M.A.; Bernal, M.P. Characterization of Olive Mill Wastewater (Alpechin) and Its Sludge for Agricultural Purposes. Bioresour. Technol. 1999, 67, 111–115. [Google Scholar] [CrossRef]

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An Overview on Olive Mill Wastes and Their Valorisation Methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef] [PubMed]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Stefanou, M. Environmental Impacts in the Life Cycle of Olive Oil: A Literature Review. J. Sci. Food Agric. 2017, 97, 1686–1697. [Google Scholar] [CrossRef]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Environmental Impact Assessment of Agricultural Production Systems Using the Life Cycle Assessment Methodology I. Theoretical Concept of a LCA Method Tailored to Crop Production. Eur. J. Agron. 2004, 20, 247–264. [Google Scholar] [CrossRef]

- Hauschild, M.Z. Introduction to LCA Methodology. In Life Cycle Assessment; Springer: Cham, Switzerland, 2018; pp. 59–66. [Google Scholar]

- Sarigiannis, D.A.; Triacchini, G. Meso-Scale Life-Cycle Impact Assessment of Novel Technology Policies: The Case of Renewable Energy. J. Hazard. Mater. 2000, 78, 145–171. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneve, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneve, Switzerland, 2006.

- EPD. Product Category Rules Virgin Olive Oil and Its Fractions, PCR 2010:07 Version 1.0 2010-04-27; The International EPD® System: Stockholm, Sweden, 2010. [Google Scholar]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A Review of Life Cycle Assessment (LCA) on Some Food Products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Dijkman, T.J.; Basset-Mens, C.; Antón, A.; Núñez, M. LCA of Food and Agriculture. In Life Cycle Assessment; Springer: Cham, Switzerland, 2018; pp. 723–754. [Google Scholar]

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.J.-P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and Trends for Life Cycle Assessment of Olive Oil Production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef] [Green Version]

- Avraamides, M.; Fatta, D. Resource Consumption and Emissions from Olive Oil Production: A Life Cycle Inventory Case Study in Cyprus. J. Clean. Prod. 2008, 16, 809–821. [Google Scholar] [CrossRef]

- Salomone, R.; Cappelletti, G.M.; Malandrino, O.; Mistretta, M.; Neri, E.; Nicoletti, G.M.; Notarnicola, B.; Pattara, C.; Russo, C.; Saija, G. Life Cycle Assessment in the Olive Oil Sector. Life Cycle Assess. In Life Cycle Assessment in the Agri-Food Sector; Springer: Cham, Switzerland, 2015; pp. 57–121. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Noyons, E.; Van Raan, A. Advanced Mapping of Science and Technology. Scientometrics 1998, 41, 61–67. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science Mapping Software Tools: Review, Analysis, and Cooperative Study among Tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Chen, C. Science Mapping: A Systematic Review of the Literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef] [Green Version]

- Garfield, E.; Pudovkin, A.I.; Istomin, V.S. Why Do We Need Algorithmic Historiography? J. Am. Soc. Inf. Sci. Technol. 2003, 54, 400–412. [Google Scholar] [CrossRef] [Green Version]

- Chen, C. CiteSpace II: Detecting and Visualizing Emerging Trends and Transient Patterns in Scientific Literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Glänzel, W.; Veugelers, R. Science for Wine: A Bibliometric Assessment of Wine and Grape Research for Wine-Producing and Consuming Countries. Am. J. Enol. Vitic. 2006, 57, 23–32. [Google Scholar]

- Bartol, T.; Mackiewicz-Talarczyk, M. Bibliometric Analysis of Publishing Trends in Fiber Crops in Google Scholar, Scopus, and Web of Science. J. Nat. Fibers 2015, 12, 531–541. [Google Scholar] [CrossRef]

- Stopar, K.; Mackiewicz-Talarczyk, M.; Bartol, T. Cotton Fiber in Web of Science and Scopus: Mapping and Visualization of Research Topics and Publishing Patterns. J. Nat. Fibers 2021, 18, 547–558. [Google Scholar] [CrossRef]

- Figueroa-Rodríguez, K.A.; Hernández-Rosas, F.; Figueroa-Sandoval, B.; Velasco-Velasco, J.; Aguilar Rivera, N. What Has Been the Focus of Sugarcane Research? A Bibliometric Overview. Int. J. Environ. Res. Public Health 2019, 16, 3326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, A.; Mallick, S.; Swarnakar, P. Mapping Scientific Collaboration: A Bibliometric Study of Rice Crop Research in India. J. Scientometr. Res. 2020, 9, 29–39. [Google Scholar] [CrossRef]

- Yuan, B.Z.; Sun, J. Mapping the Scientific Research on Maize or Corn: A Bibliometric Analysis of Top Papers during 2008–2018. Maydica 2020, 65, 9. [Google Scholar]

- Raparelli, E.; Lolletti, D. Research, Innovation and Development on Corylus Avellana through the Bibliometric Approach. Int. J. Fruit Sci. 2020, 20, S1280–S1296. [Google Scholar] [CrossRef]

- Cecchini, C.; Menesatti, P.; Antonucci, F.; Costa, C. Trends in Research on Durum Wheat and Pasta, a Bibliometric Mapping Approach. Cereal Chem. 2020, 97, 581–588. [Google Scholar] [CrossRef]

- Yuan, B.-Z.; Sun, J. Bibliometric Analysis of Potato Research Publications from Agronomy Category Based on Web of Science from 2000 to 2021. Potato Res. 2021, 1–21. [Google Scholar] [CrossRef]

- Yuan, B.-Z.; Sun, J. Research Trends and Status of Wheat (Triticum aestivum L.) Based on the Essential Science Indicators during 2010–2020: A Bibliometric Analysis. Cereal Res. Commun. 2021, 1–12. [Google Scholar] [CrossRef]

- Yuan, B.-Z.; Bie, Z.-L.; Sun, J. Bibliometric Analysis of Global Research on Muskmelon (Cucumis melo L.) Based on Web of Science. HortScience 2021, 56, 867–874. [Google Scholar] [CrossRef]

- Singh, V.K.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P. The Journal Coverage of Web of Science, Scopus and Dimensions: A Comparative Analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSViewer: Visualizing Scientific Landscapes [Software]; v. 1.6.16; Univeristeit Leiden: Leiden, The Netherlands, 2010; Available online: https://www.vosviewer.com (accessed on 21 April 2021).

- Van Eck, N.J.; Waltman, L. VOSviewer Manual. Available online: https://www.vosviewer.com (accessed on 21 April 2021).

- Scopus Sources. Available online: https://www.scopus.com/sources.uri (accessed on 30 December 2021).

- Aguilera, E.; Guzmán, G.; Alonso, A. Greenhouse Gas Emissions from Conventional and Organic Cropping Systems in Spain. II. Fruit Tree Orchards. Agron. Sustain. Dev. 2015, 35, 725–737. [Google Scholar] [CrossRef] [Green Version]

- Mohamad, R.S.; Verrastro, V.; Cardone, G.; Bteich, M.R.; Favia, M.; Moretti, M.; Roma, R. Optimization of Organic and Conventional Olive Agricultural Practices from a Life Cycle Assessment and Life Cycle Costing Perspectives. J. Clean. Prod. 2014, 70, 78–89. [Google Scholar] [CrossRef]

- De Gennaro, B.; Notarnicola, B.; Roselli, L.; Tassielli, G. Innovative Olive-Growing Models: An Environmental and Economic Assessment. J. Clean. Prod. 2012, 28, 70–80. [Google Scholar] [CrossRef]

- Pellegrini, G.; Ingrao, C.; Camposeo, S.; Tricase, C.; Contò, F.; Huisingh, D. Application of Water Footprint to Olive Growing Systems in the Apulia Region: A Comparative Assessment. J. Clean. Prod. 2016, 112, 2407–2418. [Google Scholar] [CrossRef]

- Romero-Gámez, M.; Castro-Rodríguez, J.; Suárez-Rey, E.M. Optimization of Olive Growing Practices in Spain from a Life Cycle Assessment Perspective. J. Clean. Prod. 2017, 149, 25–37. [Google Scholar] [CrossRef]

- Ben Abdallah, S.; Elfkih, S.; Suárez-Rey, E.M.; Parra-López, C.; Romero-Gámez, M. Evaluation of the Environmental Sustainability in the Olive Growing Systems in Tunisia. J. Clean. Prod. 2021, 282, 124526. [Google Scholar] [CrossRef]

- Fernández-Lobato, L.; García-Ruiz, R.; Jurado, F.; Vera, D. Life Cycle Assessment, C Footprint and Carbon Balance of Virgin Olive Oils Production from Traditional and Intensive Olive Groves in Southern Spain. J. Environ. Manag. 2021, 293, 112951. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, A.Y. Water Footprint Assessment: Evolvement of a New Research Field. Water Resour. Manag. 2017, 31, 3061–3081. [Google Scholar] [CrossRef] [Green Version]

- Fernández, J.E.; Alcon, F.; Diaz-Espejo, A.; Hernandez-Santana, V.; Cuevas, M.V. Water Use Indicators and Economic Analysis for On-Farm Irrigation Decision: A Case Study of a Super High Density Olive Tree Orchard. Agric. Water Manag. 2020, 237, 106074. [Google Scholar] [CrossRef]

- Maesano, G.; Chinnici, G.; Falcone, G.; Bellia, C.; Raimondo, M.; D’amico, M. Economic and Environmental Sustainability of Olive Production: A Case Study. Agronomy 2021, 11, 1753. [Google Scholar] [CrossRef]

- Fereres, E.; Soriano, M.A. Deficit Irrigation for Reducing Agricultural Water Use. J. Exp. Bot. 2007, 58, 147–159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mesa-Jurado, M.A.; Berbel, J.; Orgaz, F. Estimating Marginal Value of Water for Irrigated Olive Grove with the Production Function Method. Span. J. Agric. Res. 1970, 8, 197–206. [Google Scholar] [CrossRef] [Green Version]

- European Commission. The European Green Deal. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; COM/2019/640 Final; European Union: Brussels, Belgium, 2019. [Google Scholar]

- Fotia, K.; Mehmeti, A.; Tsirogiannis, I.; Nanos, G.; Mamolos, A.P.; Malamos, N.; Barouchas, P.; Todorovic, M. Lca-Based Environmental Performance of Olive Cultivation in Northwestern Greece: From Rainfed to Irrigated through Conventional and Smart Crop Management Practices. Water 2021, 13, 1954. [Google Scholar] [CrossRef]

- Pergola, M.; Favia, M.; Palese, A.M.; Perretti, B.; Xiloyannis, C.; Celano, G. Alternative Management for Olive Orchards Grown in Semi-Arid Environments: An Energy, Economic and Environmental Analysis. Sci. Hortic. 2013, 162, 380–386. [Google Scholar] [CrossRef]

- Todde, G.; Murgia, L.; Deligios, P.A.; Hogan, R.; Carrelo, I.; Moreira, M.; Pazzona, A.; Ledda, L.; Narvarte, L. Energy and Environmental Performances of Hybrid Photovoltaic Irrigation Systems in Mediterranean Intensive and Super-Intensive Olive Orchards. Sci. Total Environ. 2019, 651, 2514–2523. [Google Scholar] [CrossRef]

- Salomone, R.; Ioppolo, G. Environmental Impacts of Olive Oil Production: A Life Cycle Assessment Case Study in the Province of Messina (Sicily). J. Clean. Prod. 2012, 28, 88–100. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heidari, M.D. Energy-Economic Life Cycle Assessment (LCA) and Greenhouse Gas Emissions Analysis of Olive Oil Production in Iran. Energy 2014, 66, 139–149. [Google Scholar] [CrossRef]

- Tsarouhas, P.; Achillas, C.; Aidonis, D.; Folinas, D.; Maslis, V. Life Cycle Assessment of Olive Oil Production in Greece. J. Clean. Prod. 2015, 93, 75–83. [Google Scholar] [CrossRef]

- Pattara, C.; Salomone, R.; Cichelli, A. Carbon Footprint of Extra Virgin Olive Oil: A Comparative and Driver Analysis of Different Production Processes in Centre Italy. J. Clean. Prod. 2016, 127, 533–547. [Google Scholar] [CrossRef]

- Guarino, F.; Falcone, G.; Stillitano, T.; De Luca, A.I.; Gulisano, G.; Mistretta, M.; Strano, A. Life Cycle Assessment of Olive Oil: A Case Study in Southern Italy. J. Environ. Manag. 2019, 238, 396–407. [Google Scholar] [CrossRef]

- Fernández-Lobato, L.; López-Sánchez, Y.; Blejman, G.; Jurado, F.; Moyano-Fuentes, J.; Vera, D. Life Cycle Assessment of the Spanish Virgin Olive Oil Production: A Case Study for Andalusian Region. J. Clean. Prod. 2021, 290, 125677. [Google Scholar] [CrossRef]

- De Luca, A.I.; Falcone, G.; Stillitano, T.; Iofrida, N.; Strano, A.; Gulisano, G. Evaluation of Sustainable Innovations in Olive Growing Systems: A Life Cycle Sustainability Assessment Case Study in Southern Italy. J. Clean. Prod. 2018, 171, 1187–1202. [Google Scholar] [CrossRef]

- Bernardi, B.; Falcone, G.; Stillitano, T.; Benalia, S.; Strano, A.; Bacenetti, J.; De Luca, A.I. Harvesting System Sustainability in Mediterranean Olive Cultivation. Sci. Total Environ. 2018, 625, 1446–1458. [Google Scholar] [CrossRef]

- Bernardi, B.; Falcone, G.; Stillitano, T.; Benalia, S.; Bacenetti, J.; De Luca, A.I. Harvesting System Sustainability in Mediterranean Olive Cultivation: Other Principal Cultivar. Sci. Total Environ. 2021, 766, 142508. [Google Scholar] [CrossRef] [PubMed]

- Fantozzi, F.; Bartocci, P.; D’Alessandro, B.; Testarmata, F.; Fantozzi, P. Carbon Footprint of Truffle Sauce in Central Italy by Direct Measurement of Energy Consumption of Different Olive Harvesting Techniques. J. Clean. Prod. 2015, 87, 188–196. [Google Scholar] [CrossRef]

- Amirante, P.; Clodoveo, M.L.; Leone, A.; Tamborrino, A.; Patel, V.B. Chapter 10—Influence of Different Centrifugal Extraction Systems on Antioxidant Content and Stability of Virgin Olive Oil; Preedy, V.R., Watson, R.R., Eds.; Academic Press: San Diego, CA, USA, 2010; pp. 85–93. [Google Scholar] [CrossRef]

- Duman, A.K.; Özgen, G.Ö.; Üçtuğ, F.G. Environmental Life Cycle Assessment of Olive Pomace Utilization in Turkey. Sustain. Prod. Consum. 2020, 22, 126–137. [Google Scholar] [CrossRef]

- De Luca, A.I.; Stillitano, T.; Falcone, G.; Squeo, G.; Caponio, F.; Strano, A.; Gulisano, G. Economic and Environmental Assessment of Extra Virgin Olive Oil Processing Innovations. Chem. Eng. Trans. 2018, 67, 133–138. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Arnal, Á.J.; Royo, P.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Energy and Resource Efficiency of Electroporation-Assisted Extraction as an Emerging Technology towards a Sustainable Bio-Economy in the Agri-Food Sector. J. Clean. Prod. 2019, 233, 1123–1132. [Google Scholar] [CrossRef]

- Stillitano, T.; Falcone, G.; De Luca, A.I.; Piga, A.; Conte, P.; Strano, A.; Gulisano, G. Innovative Technologies in Evo Oil Extraction: An Economic and Environmental Impact Analysis. Riv. Ital. Sostanze Grasse 2019, 96, 223–230. [Google Scholar]

- Casson, A.; Beghi, R.; Giovenzana, V.; Fiorindo, I.; Tugnolo, A.; Guidetti, R. Visible near Infrared Spectroscopy as a Green Technology: An Environmental Impact Comparative Study on Olive Oil Analyses. Sustainability 2019, 11, 2611. [Google Scholar] [CrossRef] [Green Version]

- El Hanandeh, A. Carbon Abatement via Treating the Solid Waste from the Australian Olive Industry in Mobile Pyrolysis Units: LCA with Uncertainty Analysis. Waste Manag. Res. 2013, 31, 341–352. [Google Scholar] [CrossRef] [PubMed]

- Torquati, B.; Venanzi, S.; Ciani, A.; Diotallevi, F.; Tamburi, V. Environmental Sustainability and Economic Benefits of Dairy Farm Biogas Energy Production: A Case Study in Umbria. Sustainability 2014, 6, 6696–6713. [Google Scholar] [CrossRef] [Green Version]

- Benavente, V.; Fullana, A.; Berge, N.D. Life Cycle Analysis of Hydrothermal Carbonization of Olive Mill Waste: Comparison with Current Management Approaches. J. Clean. Prod. 2017, 142, 2637–2648. [Google Scholar] [CrossRef] [Green Version]

- Batuecas, E.; Tommasi, T.; Battista, F.; Negro, V.; Sonetti, G.; Viotti, P.; Fino, D.; Mancini, G. Life Cycle Assessment of Waste Disposal from Olive Oil Production: Anaerobic Digestion and Conventional Disposal on Soil. J. Environ. Manag. 2019, 237, 94–102. [Google Scholar] [CrossRef]

- Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.F.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F.G. Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion versus Olive Pomace Oil Extraction. Processes 2020, 8, 626. [Google Scholar] [CrossRef]

- Khoshgoftar Manesh, M.H.; Jadidi, E. Conventional and Advanced Exergy, Exergoeconomic and Exergoenvironmental Analysis of a Biomass Integrated Gasification Combined Cycle Plant. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–22. [Google Scholar] [CrossRef]

- Mendecka, B.; Lombardi, L.; Micali, F.; De Risi, A. Energy Recovery from Olive Pomace by Hydrothermal Carbonization on Hypothetical Industrial Scale: A LCA Perspective. Waste Biomass Valoriz. 2020, 11, 5503–5519. [Google Scholar] [CrossRef]

- Valenti, F.; Liao, W.; Porto, S.M.C. Life Cycle Assessment of Agro-Industrial by-Product Reuse: A Comparison between Anaerobic Digestion and Conventional Disposal Treatments. Green Chem. 2020, 22, 7119–7139. [Google Scholar] [CrossRef]

- Khounani, Z.; Hosseinzadeh-Bandbafha, H.; Moustakas, K.; Talebi, A.F.; Goli, S.A.H.; Rajaeifar, M.A.; Khoshnevisan, B.; Salehi Jouzani, G.; Peng, W.; Kim, K.-H.; et al. Environmental Life Cycle Assessment of Different Biorefinery Platforms Valorizing Olive Wastes to Biofuel, Phosphate Salts, Natural Antioxidant, and an Oxygenated Fuel Additive (Triacetin). J. Clean. Prod. 2021, 278, 123916. [Google Scholar] [CrossRef]

- Puig-Gamero, M.; Parascanu, M.M.; Sánchez, P.; Sanchez-Silva, L. Olive Pomace versus Natural Gas for Methanol Production: A Life Cycle Assessment. Environ. Sci. Pollut. Res. 2021, 28, 30335–30350. [Google Scholar] [CrossRef]

- Benalia, S.; Falcone, G.; Stillitano, T.; De Luca, A.I.; Strano, A.; Gulisano, G.; Zimbalatti, G.; Bernardi, B. Increasing the Content of Olive Mill Wastewater in Biogas Reactors for a Sustainable Recovery: Methane Productivity and Life Cycle Analyses of the Process. Foods 2021, 10, 1029. [Google Scholar] [CrossRef] [PubMed]

- Cusenza, M.A.; Longo, S.; Cellura, M.; Guarino, F.; Messineo, A.; Mistretta, M.; Volpe, M. Environmental Assessment of a Waste-to-Energy Practice: The Pyrolysis of Agro-Industrial Biomass Residues. Sustain. Prod. Consum. 2021, 28, 866–876. [Google Scholar] [CrossRef]

- El Hanandeh, A. Energy Recovery Alternatives for the Sustainable Management of Olive Oil Industry Waste in Australia: Life Cycle Assessment. J. Clean. Prod. 2015, 91, 78–88. [Google Scholar] [CrossRef] [Green Version]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental Evaluation of Biomass Pelleting Using Life Cycle Assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Tziolas, E.; Bournaris, T. Economic and Environmental Assessment of Agro-Energy Districts in Northern Greece: A Life Cycle Assessment Approach. Bioenergy Res. 2019, 12, 1145–1162. [Google Scholar] [CrossRef]

- Rajabi Hamedani, S.; Colantoni, A.; Gallucci, F.; Salerno, M.; Silvestri, C.; Villarini, M. Comparative Energy and Environmental Analysis of Agro-Pellet Production from Orchard Woody Biomass. Biomass Bioenergy 2019, 129, 105334. [Google Scholar] [CrossRef]

- Saba, S.; El Bachawati, M.; Malek, M. Cradle to Grave Life Cycle Assessment of Lebanese Biomass Briquettes. J. Clean. Prod. 2020, 253, 119851. [Google Scholar] [CrossRef]

- Uceda-Rodríguez, M.; López-García, A.B.; Moreno-Maroto, J.M.; Cobo-Ceacero, C.J.; Cotes-Palomino, M.T.; García, C.M. Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates. Materials 2020, 13, 2351. [Google Scholar] [CrossRef]

- López-garcía, A.B.; Cotes-palomino, T.; Uceda-rodríguez, M.; Moreno-maroto, J.M.; Cobo-ceacero, C.J.; Fernanda Andreola, N.M.; Martínez-garcía, C. Application of Life Cycle Assessment in the Environmental Study of Sustainable Ceramic Bricks Made with ‘Alperujo’ (Olive Pomace). Appl. Sci. 2021, 11, 2278. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Di Bona, G.; Silvestri, C. Circular Economy Strategy of Reusing Olive Mill Wastewater in the Ceramic Industry: How the Plant Location Can Benefit Environmental and Economic Performance. J. Clean. Prod. 2021, 326, 129388. [Google Scholar] [CrossRef]

- Russo, G.; Vivaldi, G.A.; De Gennaro, B.; Camposeo, S. Environmental Sustainability of Different Soil Management Techniques in a High-Density Olive Orchard. J. Clean. Prod. 2015, 107, 498–508. [Google Scholar] [CrossRef]

- Castellani, F.; Esposito, A.; Geldermann, J.; Altieri, R. Life Cycle Assessment of Passively Aerated Composting in Gas-Permeable Bags of Olive Mill Waste. Int. J. Life Cycle Assess. 2019, 24, 281–296. [Google Scholar] [CrossRef]

- Pardo, G.; Martin-Garcia, I.; Arco, A.; Yañez-Ruiz, D.R.; Moral, R.; Del Prado, A. Greenhouse-Gas Mitigation Potential of Agro-Industrial by-Products in the Diet of Dairy Goats in Spain: A Life-Cycle Perspective. Anim. Prod. Sci. 2016, 56, 646–654. [Google Scholar] [CrossRef]

- Frascari, D.; Molina Bacca, A.E.; Wardenaar, T.; Oertlé, E.; Pinelli, D. Continuous Flow Adsorption of Phenolic Compounds from Olive Mill Wastewater with Resin XAD16N: Life Cycle Assessment, Cost–Benefit Analysis and Process Optimization. J. Chem. Technol. Biotechnol. 2019, 94, 1968–1981. [Google Scholar] [CrossRef]

- Kalogerakis, N.; Politi, M.; Foteinis, S.; Chatzisymeon, E.; Mantzavinos, D. Recovery of Antioxidants from Olive Mill Wastewaters: A Viable Solution That Promotes Their Overall Sustainable Management. J. Environ. Manag. 2013, 128, 749–758. [Google Scholar] [CrossRef] [Green Version]

- Pampuri, A.; Casson, A.; Alamprese, C.; Di Mattia, C.D.; Piscopo, A.; Difonzo, G.; Conte, P.; Paciulli, M.; Tugnolo, A.; Beghi, R.; et al. Environmental Impact of Food Preparations Enriched with Phenolic Extracts from Olive Oil Mill Waste. Foods 2021, 10, 980. [Google Scholar] [CrossRef]

- Hjaila, K.; Baccar, R.; Sarrà, M.; Gasol, C.M.; Blánquez, P. Environmental Impact Associated with Activated Carbon Preparation from Olive-Waste Cake via Life Cycle Assessment. J. Environ. Manag. 2013, 130, 242–247. [Google Scholar] [CrossRef]

- Nebili, F.; Bouachir, F. Syntheses and Modelling of the Activated Carbon Made by Olive Cake Residues by Pyrolysis and Actived by a Water Vapour Current at One Process. J. Eng. Appl. Sci. 2013, 8, 235–240. [Google Scholar] [CrossRef]

- Guermazi, Z.; Gharsallaoui, M.; Perri, E.; Gabsi, S.; Benincasa, C. Integrated Approach for the Eco Design of a New Process through the Life Cycle Analysis of Olive Oil: Total Use of Olive by-Products. Eur. J. Lipid Sci. Technol. 2017, 119, 1700009. [Google Scholar] [CrossRef]

- De Benedetti, B.; Barbera, A.C.; Freni, P.; Tecchio, P. Wastewater Valorization Adopting the Microalgae Accelerated Growth. Desalin. Water Treat. 2015, 53, 1001–1011. [Google Scholar] [CrossRef]

- Chatzisymeon, E.; Foteinis, S.; Mantzavinos, D.; Tsoutsos, T. Life Cycle Assessment of Advanced Oxidation Processes for Olive Mill Wastewater Treatment. J. Clean. Prod. 2013, 54, 229–234. [Google Scholar] [CrossRef] [Green Version]

- Accorsi, R.; Versari, L.; Manzini, R. Glass vs. Plastic: Life Cycle Assessment of Extra-Virgin Olive Oil Bottles across Global Supply Chains. Sustainability 2015, 7, 2818–2840. [Google Scholar] [CrossRef] [Green Version]

- Bertoluci, G.; Leroy, Y.; Olsson, A. Exploring the Environmental Impacts of Olive Packaging Solutions for the European Food Market. J. Clean. Prod. 2014, 64, 234–243. [Google Scholar] [CrossRef]

- Guiso, A.; Parenti, A.; Masella, P.; Guerrini, L.; Baldi, F.; Spugnoli, P. Environmental Impact Assessment of Three Packages for High-Quality Extra-Virgin Olive Oil. J. Agric. Eng. 2016, 47, 191–196. [Google Scholar] [CrossRef] [Green Version]

- Navarro, A.; Puig, R.; Martí, E.; Bala, A.; Fullana i Palmer, P. Tackling the Relevance of Packaging in Life Cycle Assessment of Virgin Olive Oil and the Environmental Consequences of Regulation. Environ. Manag. 2018, 62, 277–294. [Google Scholar] [CrossRef]

- Rinaldi, S.; Barbanera, M.; Lascaro, E. Assessment of Carbon Footprint and Energy Performance of the Extra Virgin Olive Oil Chain in Umbria, Italy. Sci. Total Environ. 2014, 482–483, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Boesen, S.; Bey, N.; Niero, M. Environmental Sustainability of Liquid Food Packaging: Is There a Gap between Danish Consumers’ Perception and Learnings from Life Cycle Assessment? J. Clean. Prod. 2019, 210, 1193–1206. [Google Scholar] [CrossRef]

- Giovenzana, V.; Casson, A.; Beghi, R.; Tugnolo, A.; Grassi, S.; Alamprese, C.; Casiraghi, E.; Farris, S.; Fiorindo, I.; Guidetti, R. Environmental Benefits: Traditional vs Innovative Packaging for Olive Oil. Chem. Eng. Trans. 2019, 75, 193–198. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental Impacts of Food Consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- Salomone, R.; Cappelletti, G.M.; Ioppolo, G.; Nicoletti, G.M. Italian Experiences in Life Cycle Assessment of Olive Oil: A Survey and Critical Review. In Proceedings of the VII International Conference on Life Cycle Assessment in the Agri-Food Sector, Bari, Italy, 22–24 September 2010. [Google Scholar]

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental Impact Assessment of Olive Pomace Oil Biodiesel Production and Consumption: A Comparative Lifecycle Assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Paolotti, L.; Boggia, A.; Castellini, C.; Rocchi, L.; Rosati, A. Combining Livestock and Tree Crops to Improve Sustainability in Agriculture: A Case Study Using the Life Cycle Assessment (LCA) Approach. J. Clean. Prod. 2016, 131, 351–363. [Google Scholar] [CrossRef]

- Intini, F.; Rospi, G.; Kuhtz, S.; Ranieri, L.; Dassisti, M. Model-Based LCA for Sustainable Energy-Production from Olive-Oil Production: An Italian Agricultural-District Case. In Proceedings of the OTM Confederated International Conferences “On the Move to Meaningful Internet Systems”, Amantea, Italy, 27–30 October 2014; Springer: Berlin/Heidelberg, Germany, 2014; pp. 70–79. [Google Scholar] [CrossRef]

- Proietti, S.; Sdringola, P.; Regni, L.; Evangelisti, N.; Brunori, A.; Ilarioni, L.; Nasini, L.; Proietti, P. Extra Virgin Olive Oil as Carbon Negative Product: Experimental Analysis and Validation of Results. J. Clean. Prod. 2017, 166, 550–562. [Google Scholar] [CrossRef]

- Lehmann, L.M.; Borzęcka, M.; Żyłowska, K.; Pisanelli, A.; Russo, G.; Ghaley, B.B. Environmental Impact Assessments of Integrated Food and Non-Food Production Systems in Italy and Denmark. Energies 2020, 13, 849. [Google Scholar] [CrossRef] [Green Version]

- European Commission. European Commission Implementing Regulation (EU) No 1348/2013 of 16 December 2013 Amending Regulation (EEC) No 2568/91 on the Characteristics of Olive Oil and Olive-Residue Oil and on the Relevant Methods of Analysis; European Commission: Luxembourg, 2013; pp. 31–67. [Google Scholar]

- European Commission. Commission Recommendation of 9 April 2013 on the Use of Common Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission: Luxembourg, 2013; pp. 1–210. [Google Scholar]

- European Commission. Guidance for the Implementation of the EU Product Environmental Footprint (PEF) during the Environmental Footprint (EF) Pilot Phase, Guidance for the Implementation of the EU PEF during the EF Pilot Phase—Version 5.2—February 2016; European Commission: Luxembourg, 2016. [Google Scholar]

- Lardo, E.; Fiore, A.; Quinto, G.A.; Dichio, B.; Xiloyannis, C. Climate Change Mitigation Role of Orchard Agroecosystems: Case Studies in Southern Italy. Acta Hortic. 2018, 1216, 13–17. [Google Scholar] [CrossRef]

- Olive4climate. Olive4climate—Life: A Project Co-Funded by the European Commission that Focuses on Climate Change Mitigation through a Sustainable Supply Chain for the Olive Oil Sector. Available online: https://olive4climate.eu/en/ (accessed on 27 January 2022).

- Olive4climate. Introduction of New oLIVE Crop Management Practices Focused on Climate Change Mitigation and Adaptation. Available online: http://www.oliveclima.eu/en/ (accessed on 27 January 2022).

- Movilla-Pateiro, L.; Mahou-Lago, X.M.; Doval, M.I.; Simal-Gandara, J. Toward a Sustainable Metric and Indicators for the Goal of Sustainability in Agricultural and Food Production. Crit. Rev. Food Sci. Nutr. 2021, 61, 1108–1129. [Google Scholar] [CrossRef] [PubMed]

- IOC (International Olive Council). Olive Oil Production and Consumption Up by 1 Million Tonnes in the Last 25 Years. IOC News. Available online: https://www.internationaloliveoil.org/1071-olive-oil-production-and-consumption-up-by-1-million-tonnes-in-the-last-25-years/ (accessed on 30 December 2021).

- IOC (International Olive Council). World Olive Oil and Table Olive Figures. Available online: https://www.internationaloliveoil.org/what-we-do/economic-affairs-promotion-unit/#figures (accessed on 20 January 2022).

| Year | Number of Documents | Number of Authors | Number of Journals | Number of Countries | Number of Citations | |||

|---|---|---|---|---|---|---|---|---|

| Total | Articles on a Journal | Book Chapter—Conference Paper | Total | Average * | ||||

| 2008 | 1 | 1 | 0 | 2 | 1 | 1 | 96 | 96 |

| 2011 | 1 | 1 | 0 | 6 | 1 | 1 | 1 | 1 |

| 2012 | 3 | 3 | 0 | 11 | 2 | 3 | 201 | 67 |

| 2013 | 9 | 6 | 3 | 33 | 8 | 7 | 351 | 39 |

| 2014 | 10 | 8 | 2 | 44 | 9 | 5 | 349 | 35 |

| 2015 | 8 | 8 | 0 | 30 | 5 | 5 | 282 | 35 |

| 2016 | 14 | 13 | 1 | 61 | 11 | 10 | 424 | 30 |

| 2017 | 10 | 9 | 1 | 40 | 5 | 8 | 429 | 43 |

| 2018 | 9 | 6 | 3 | 28 | 7 | 4 | 175 | 19 |

| 2019 | 14 | 14 | 0 | 67 | 12 | 9 | 214 | 15 |

| 2020 | 13 | 12 | 1 | 56 | 12 | 13 | 78 | 6 |

| 2021 | 18 | 18 | 0 | 105 | 12 | 12 | 40 | 2 |

| Journal a | Publisher | N. b | CS c | SJR d | HP e |

|---|---|---|---|---|---|

| Journal of Cleaner Production | Elsevier | 30 | 13.1 | 1.937 | 98 |

| Journal of Environmental Management | Elsevier | 5 | 9.8 | 1.441 | 95 |

| Sustainability (Switzerland) | Multidisciplinary Digital Publishing Institute (MDPI) | 5 | 3.9 | 0.612 | 84 |

| Science of the Total Environment | Elsevier | 4 | 10.5 | 1.795 | 96 |

| International Journal of Life Cycle Assessment | Springer | 4 | 7.8 | 1.093 | 90 |

| Foods | Multidisciplinary Digital Publishing Institute (MDPI) | 4 | 3.0 | 0.774 | 93 |

| Sustainable Production and Consumption | Elsevier | 3 | 6.7 | 1.019 | 88 |

| Chemical Engineering Transactions | Ital. Ass. Chem. Eng in. (AIDIC) | 3 | 1.5 | 0.274 | 38 |

| Acta Horticulturae | Inter. Soc. Hort. Science (ISHS) | 2 | 0.5 | 0.181 | 12 |

| Biomass And Bioenergy | Elsevier | 2 | 6.7 | 1.037 | 94 |

| Renewable Energy | Elsevier | 2 | 10.8 | 1.825 | 88 |

| Agronomy | Multidisciplinary Digital Publishing Institute (MDPI) | 2 | 2.6 | 0.707 | 65 |

| Energy | Elsevier | 2 | 11.5 | 1.961 | 98 |

| Journal of the Science of Food and Agriculture | Wiley-Blackwell | 2 | 5.5 | 0.782 | 88 |

| Year | Authors | Countries a | Title | Journal | TC b | Avg. C c |

|---|---|---|---|---|---|---|

| 2017 | Notarnicola B., Tassielli G., Renzulli P.A., Castellani V., Sala S. [115] | Italy | Environmental impacts of food consumption in Europe | Journal of Cleaner Production | 219 | 44 |

| 2012 | Salomone R., Ioppolo G. [61] | Italy | Environmental impacts of olive oil production: a life cycle assessment case study in the province of Messina (Sicily) | Journal of Cleaner Production | 114 | 11 |

| 2008 | Avraamides M., Fatta D. [21] | Cyprus | Resource consumption and emissions from olive oil production: a life cycle inventory case study in Cyprus | Journal of Cleaner Production | 96 | 7 |

| 2013 | Chatzisymeon E., Foteinis S., Mantzavinos D., Tsoutsos T. [107] | Greece | Life cycle assessment of advanced oxidation processes for olive mill wastewater treatment | Journal of Cleaner Production | 86 | 10 |

| 2012 | De Gennaro B., Notarnicola B., Roselli L., Tassielli G. [47] | Italy | Innovative olive-growing models: An environmental and economic assessment | Journal of Cleaner Production | 76 | 8 |

| 2014 | Mohamad R.S., Verrastro V., Cardone G., Bteich M.R., Favia M., Moretti M., Roma R. [46] | Italy | Optimization of organic and conventional olive agricultural practices from a life cycle assessment and life cycle costing perspectives | Journal of Cleaner Production | 75 | 9 |

| 2018 | De Luca A.I., Falcone G., Stillitano T., Iofrida N., Strano A., Gulisano G. [67] | Italy | Evaluation of sustainable innovations in olive growing systems: a life cycle sustainability assessment case study in southern Italy | Journal of Cleaner Production | 72 | 18 |

| 2013 | Kalogerakis N., Politi M., Foteinis S., Chatzisymeon E., Mantzavinos D. [101] | Greece | Recovery of antioxidants from olive mill wastewaters: a viable solution that promotes their overall sustainable management | Journal of Environmental Management | 70 | 8 |

| 2015 | Aguilera E., Guzmán G., Alonso A. [45] | Spain | Greenhouse gas emissions from conventional and organic cropping systems in Spain. II. Fruit tree orchards | Agronomy for Sustainable Development | 69 | 10 |

| 2014 | Rajaeifar M.A., Akram A., Ghobadian B., Rafiee S., Heidari M.D. [62] | Iran | Energy-economic life cycle assessment (LCA) and greenhouse gas emissions analysis of olive oil production in Iran | Energy | 63 | 8 |

| 2016 | Rajaeifar M.A., Akram A., Ghobadian B., Rafiee S., Heijungs R., Tabatabaei M. [117] | Iran, Netherlands | Environmental impact assessment of olive pomace oil biodiesel production and consumption: a comparative lifecycle assessment | Energy | 60 | 10 |

| 2016 | Paolotti L., Boggia A., Castellini C., Rocchi L., Rosati A. [118] | Italy | Combining livestock and tree crops to improve sustainability in agriculture: a case study using the life cycle assessment (LCA) approach | Journal of Cleaner Production | 59 | 10 |

| 2019 | Boesen S., Bey N., Niero M. [113] | Denmark | Environmental sustainability of liquid food packaging: is there a gap between Danish consumers’ perception and learnings from life cycle assessment? | Journal of Cleaner Production | 53 | 18 |

| 2015 | Accorsi R., Versari L., Manzini R. [108] | Italy | Glass vs. plastic: life cycle assessment of extra-virgin olive oil bottles across global supply chains | Sustainability (Switzerland) | 52 | 7 |

| 2016 | Kylili A., Christoforou E., Fokaides P.A. [90] | Cyprus | Environmental evaluation of biomass pelleting using life cycle assessment | Biomass and Bioenergy | 52 | 9 |

| 2017 | Benavente V., Fullana A., Berge N.D. [79] | Spain, United States | Life cycle analysis of hydrothermal carbonization of olive mill waste: comparison with current management approaches | Journal of Cleaner Production | 50 | 10 |

| 2015 | Tsarouhas P., Achillas C., Aidonis D., Folinas D., Maslis V. [63] | Greece | Life cycle assessment of olive oil production in Greece | Journal of Cleaner Production | 50 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco, I.; De Bellis, L.; Luvisi, A. Bibliometric Mapping of Research on Life Cycle Assessment of Olive Oil Supply Chain. Sustainability 2022, 14, 3747. https://doi.org/10.3390/su14073747

Blanco I, De Bellis L, Luvisi A. Bibliometric Mapping of Research on Life Cycle Assessment of Olive Oil Supply Chain. Sustainability. 2022; 14(7):3747. https://doi.org/10.3390/su14073747

Chicago/Turabian StyleBlanco, Ileana, Luigi De Bellis, and Andrea Luvisi. 2022. "Bibliometric Mapping of Research on Life Cycle Assessment of Olive Oil Supply Chain" Sustainability 14, no. 7: 3747. https://doi.org/10.3390/su14073747

APA StyleBlanco, I., De Bellis, L., & Luvisi, A. (2022). Bibliometric Mapping of Research on Life Cycle Assessment of Olive Oil Supply Chain. Sustainability, 14(7), 3747. https://doi.org/10.3390/su14073747