The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation

Abstract

1. Introduction

2. Experimental

2.1. Materials

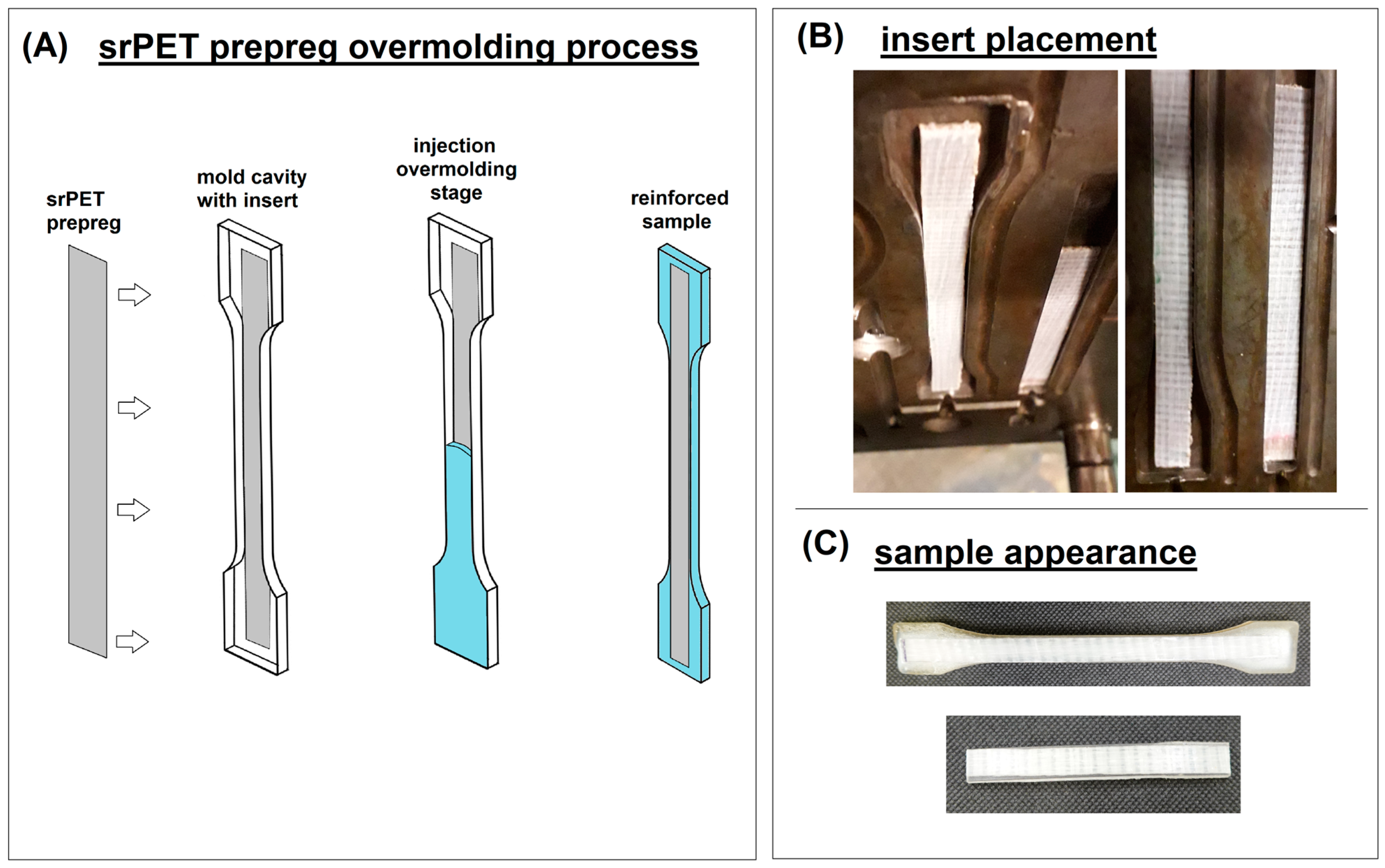

2.2. Sample Preparation

2.3. Methods

3. Results and Discussion

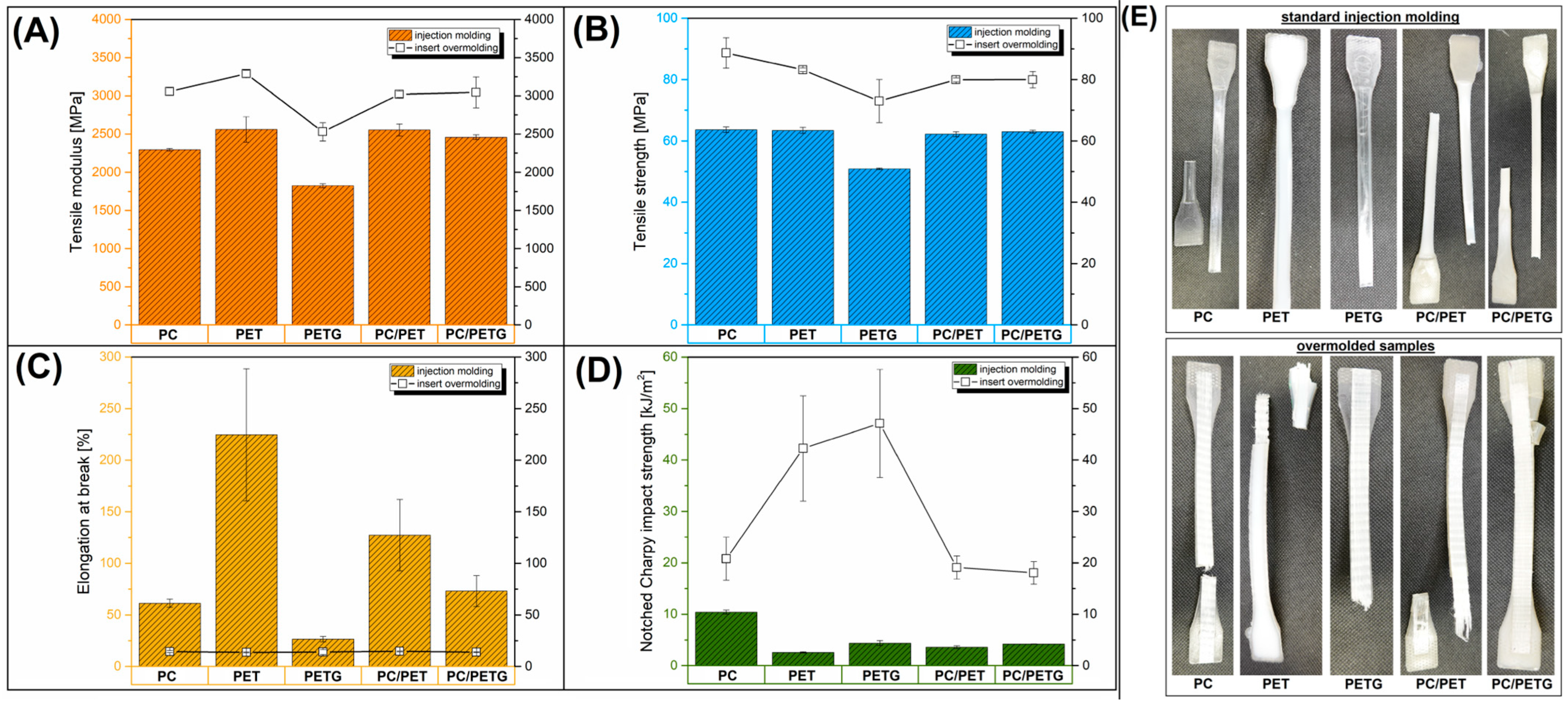

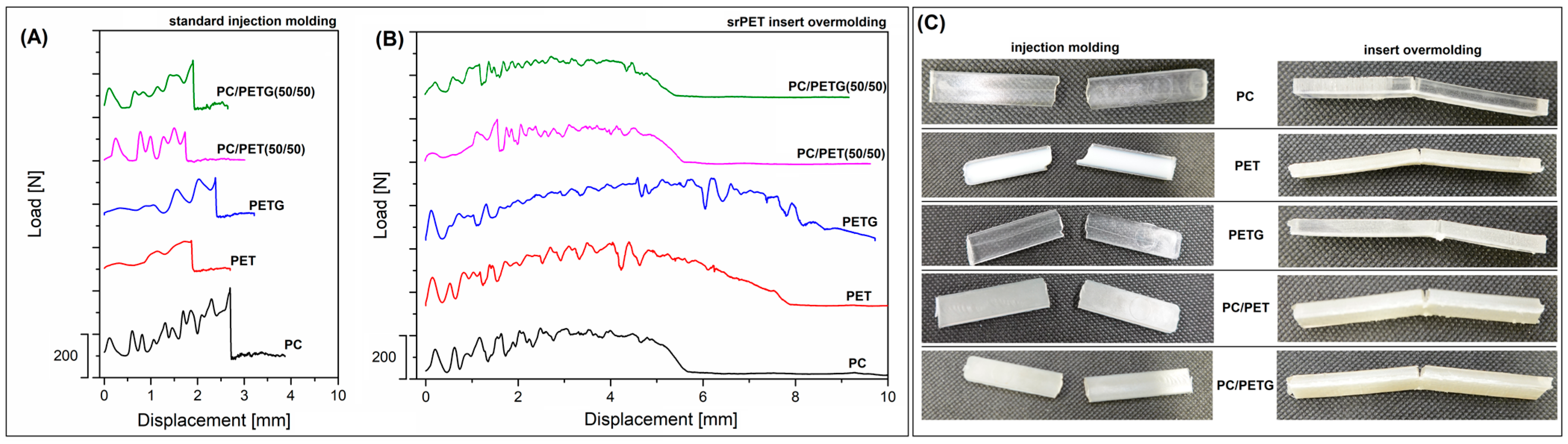

3.1. Mechanical Performance—Static Tensile Measurements and Notched Charpy Impact Tests

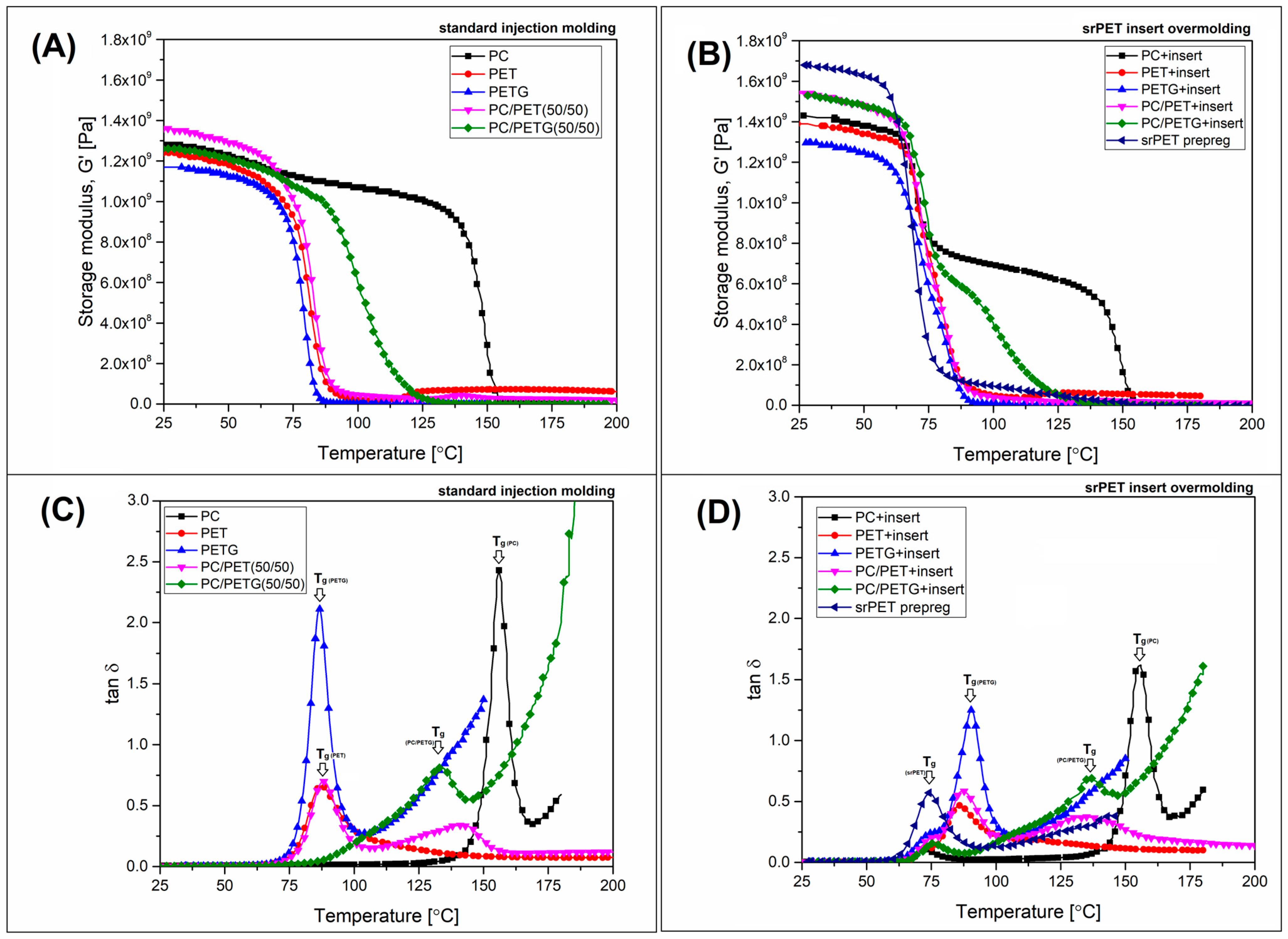

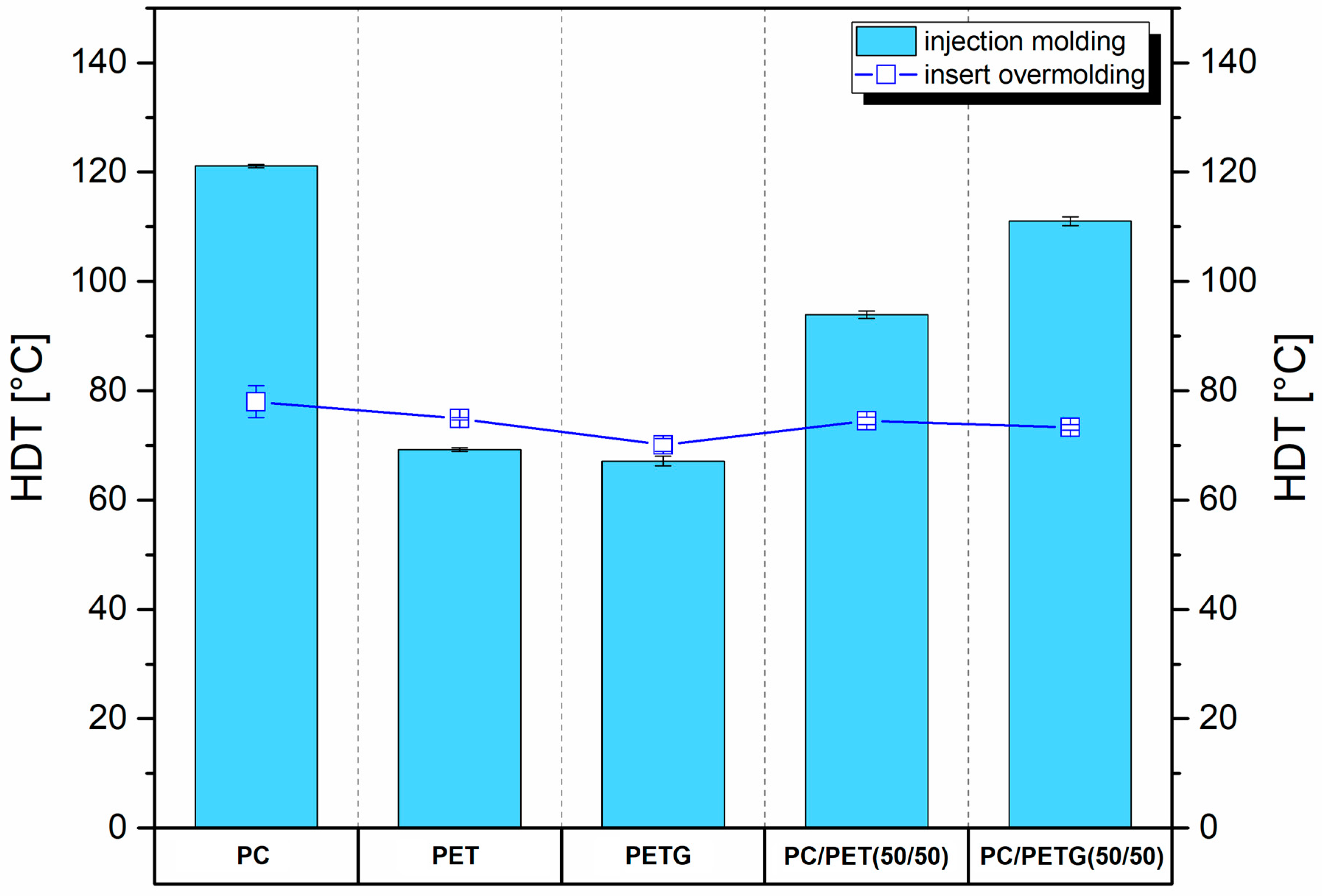

3.2. Thermomechanical Properties—DMTA Analysis/HDT Tests

3.3. Phase Transition Measurements—DSC Analysis

4. Conclusions

- -

- the research confirmed the possibility of permanent connection of srPET composites with polymer blends of several types,

- -

- the use of recycled origin materials was proven to be possible,

- -

- the developed method does not require a complicated prepreg plasticizing procedure.

Supplementary Materials

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Capiati, N.J.; Porter, R.S. The Concept of One Polymer Composites Modelled with High Density Polyethylene. J. Mater. Sci. 1975, 10, 1671–1677. [Google Scholar] [CrossRef]

- Kmetty, Á.; Bárány, T.; Karger-Kocsis, J. Self-Reinforced Polymeric Materials: A Review. Prog. Polym. Sci. 2010, 35, 1288–1310. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Bárány, T. Single-Polymer Composites (SPCs): Status and Future Trends. Compos. Sci. Technol. 2014, 92, 77–94. [Google Scholar] [CrossRef]

- Ward, I.M.; Hine, P.J. The Science and Technology of Hot Compaction. Polymer 2004, 45, 1413–1427. [Google Scholar] [CrossRef]

- Santos, R.A.M.; Gorbatikh, L.; Swolfs, Y. Commercial Self-Reinforced Composites: A Comparative Study. Compos. Part B Eng. 2021, 223, 109108. [Google Scholar] [CrossRef]

- Romhány, G.; Bárány, T.; Czigány, T.; Karger-Kocsis, J. Fracture and Failure Behavior of Fabric-Reinforced All-Poly(Propylene) Composite (Curv®). Polym. Adv. Technol. 2007, 18, 90–96. [Google Scholar] [CrossRef]

- Izer, A.; Bárány, T.; Varga, J. Development of Woven Fabric Reinforced All-Polypropylene Composites with Beta Nucleated Homo- and Copolymer Matrices. Compos. Sci. Technol. 2009, 69, 2185–2192. [Google Scholar] [CrossRef]

- Deng, H.; Reynolds, C.T.; Cabrera, N.O.; Barkoula, N.-M.; Alcock, B.; Peijs, T. The Water Absorption Behaviour of All-Polypropylene Composites and Its Effect on Mechanical Properties. Compos. Part B Eng. 2010, 41, 268–275. [Google Scholar] [CrossRef]

- Schneider, C.; Velea, M.N.; Kazemahvazi, S.; Zenkert, D. Compression Properties of Novel Thermoplastic Carbon Fibre and Poly-Ethylene Terephthalate Fibre Composite Lattice Structures. Mater. Des. 2015, 65, 1110–1120. [Google Scholar] [CrossRef]

- Poulikidou, S.; Schneider, C.; Björklund, A.; Kazemahvazi, S.; Wennhage, P.; Zenkert, D. A Material Selection Approach to Evaluate Material Substitution for Minimizing the Life Cycle Environmental Impact of Vehicles. Mater. Des. 2015, 83, 704–712. [Google Scholar] [CrossRef]

- Jerpdal, L.; Åkermo, M. Influence of Fibre Shrinkage and Stretching on the Mechanical Properties of Self-Reinforced Poly(Ethylene Terephthalate) Composite. J. Reinf. Plast. Compos. 2014, 33, 1644–1655. [Google Scholar] [CrossRef]

- Rojanapitayakorn, P.; Mather, P.T.; Goldberg, A.J.; Weiss, R.A. Optically Transparent Self-Reinforced Poly(Ethylene Terephthalate) Composites: Molecular Orientation and Mechanical Properties. Polymer 2005, 46, 761–773. [Google Scholar] [CrossRef]

- Beauson, J.; Schillani, G.; Van der Schueren, L.; Goutianos, S. The Effect of Processing Conditions and Polymer Crystallinity on the Mechanical Properties of Unidirectional Self-Reinforced PLA Composites. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106668. [Google Scholar] [CrossRef]

- Goutianos, S.; Van der Schueren, L.; Beauson, J. Failure Mechanisms in Unidirectional Self-Reinforced Biobased Composites Based on High Stiffness PLA Fibres. Compos. Part A Appl. Sci. Manuf. 2019, 117, 169–179. [Google Scholar] [CrossRef]

- Salahuddin, B.; Mutlu, R.; Baigh, T.A.; Alghamdi, M.N.; Aziz, S. Self-Reinforced Nylon 6 Composite for Smart Vibration Damping. Polymers 2021, 13, 1235. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, A.; Yang, G. Polyamide Single Polymer Composites Prepared via in Situ Anionic Polymerization of ε-Caprolactam. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1006–1011. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Maitrot, P.; Fakirov, S. Polyamide 6 Single Polymer Composites. Express Polym. Lett. 2009, 3, 525–532. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Przyszczypkowski, P.; Szostak, M. Development and Characterization of Poly(Ethylene Terephthalate) Based Injection Molded Self-Reinforced Composites. Direct Reinforcement by Overmolding the Composite Inserts. Mater. Des. 2018, 153, 273–286. [Google Scholar] [CrossRef]

- Poulikidou, S.; Jerpdal, L.; Björklund, A.; Åkermo, M. Environmental Performance of Self-Reinforced Composites in Automotive Applications—Case Study on a Heavy Truck Component. Mater. Des. 2016, 103, 321–329. [Google Scholar] [CrossRef]

- Begum, S.A.; Rane, A.V.; Kanny, K. Applications of Compatibilized Polymer Blends in Automobile Industry; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128160060. [Google Scholar]

- Evstatiev, M.; Nicolov, N.; Fakirov, S. Morphology of Microfibrillar Reinforced Composites PET/PA 6 Blend. Polymer 1996, 37, 4455–4463. [Google Scholar] [CrossRef]

- Yan, Y.; Huang, Y.H.; Wang, Y.; Xiao, Z.C.; Yang, M.B. Polyamide 6 (PA6) /Polyethylene Terephthalate (PET) Blends with Gradient and Encapsulation Structure Developed by Injection Molding. Polymer 2019, 180, 121679. [Google Scholar] [CrossRef]

- Tanaka, F.H.; Cruz, S.A.; Canto, L.B. Morphological, Thermal and Mechanical Behavior of Sepiolite-Based Poly(Ethylene Terephthalate)/Polyamide 66 Blend Nanocomposites. Polym. Test. 2018, 72, 298–307. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Bechtold, G.; Friedrich, K. Structure-Property Relationships of Injection- and Compression-Molded Microfibrillar-Reinforced PET/PA-6 Composites. Adv. Polym. Technol. 2000, 19, 249–259. [Google Scholar] [CrossRef]

- Cook, W.D.; Zhang, T.; Moad, G.; Van Deipen, G.; Cser, F.; Fox, B.; O’Shea, M. Morphology-Property Relationships in ABS/PET Blends. I. Compositional Effects. J. Appl. Polym. Sci. 1996, 62, 1699–1708. [Google Scholar] [CrossRef]

- Rivas, B.L.; Pereira, E.D. Blends of Acrylonitrile-Butadiene-Styrene/Waste Poly(Ethylene Terephthalate) Compatibilized by Styrene Maleic Anhydride. J. Appl. Polym. Sci. 2001, 80, 2593–2599. [Google Scholar] [CrossRef]

- Oral, M.A.; Ersoy, O.G.; Serhatli, E. Effect of Acrylonitrile–Butadiene–Styrene/Polyethylene Terephthalate Blends on Dimensional Stability, Morphological, Physical and Mechanical Properties and after Aging at Elevated Temperature. J. Plast. Film Sheeting 2018, 34, 394–417. [Google Scholar] [CrossRef]

- Wu, Y.H.; Wang, C.C.; Chen, C.Y. Nucleation Effect of Aliphatic Polycarbonate in Its Blends with Poly(Ethylene Terephthalate). Mater. Chem. Phys. 2020, 248, 122920. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, S.; Hou, J.; Zhang, K.; Wang, X.; Li, Q.; Liu, G. Effect of Injection Velocity on the Structure and Mechanical Properties of Micro Injection Molded Polycarbonate/Poly(Ethylene Terephthalate) Blends. Mater. Des. 2018, 141, 132–141. [Google Scholar] [CrossRef]

- Marchese, P.; Celli, A.; Fiorini, M. Influence of the Activity of Transesterification Catalysts on the Phase Behavior of PC-PET Blends. Macromol. Chem. Phys. 2002, 203, 695–704. [Google Scholar] [CrossRef]

- Luo, F.; Liu, X.; Liu, C.; Ma, J.; Wang, X.; Shen, C. Dynamic Viscoelasticity and Molecular Orientation in Uniaxially Drawn PC/PET Blends. J. Appl. Polym. Sci. 2019, 136, 47514. [Google Scholar] [CrossRef]

- Montaudo, G.; Puglisi, C.; Samperi, F. Mechanism of Exchange in PBT/PC and PET/PC Blends. Composition of the Copolymer Formed in the Melt Mixing Process. Macromolecules 1998, 31, 650–661. [Google Scholar] [CrossRef]

- Ishigami, A.; Kodama, Y.; Wagatsuma, T.; Ito, H. Evaluation of Structures and Morphologies of Recycled PC/PET Blends Fabricated by High-Shear Kneading Processing. Int. Polym. Process. 2017, 32, 568–573. [Google Scholar] [CrossRef]

- Nassar, T.R.; Paul, D.R.; Barlow, J.W. Polyester–Polycarbonate Blends. II. Poly(Ethylene Terephthalate). J. Appl. Polym. Sci. 1979, 23, 85–99. [Google Scholar] [CrossRef]

- Srithep, Y.; Pholharn, D.; Dassakorn, A.; Morris, J. Effect of Chain Extenders on Mechanical and Thermal Properties of Recycled Poly (Ethylene Terephthalate) and Polycarbonate Blends. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 012008. [Google Scholar] [CrossRef]

- Jerpal, L.; Schuette, P.; Ståhlberg, D.; Åkermo, M. Influence of temperature during overmolding on the tensile modulus of self-reinforced poly(ethylene terephthalate) insert. J. Appl. Polym. Sci. 2020, 137, 48334. [Google Scholar] [CrossRef]

- da Silva, A.M.G.; de Barcelos, K.A.; da Silva, M.C.; Morelli, C.L. Blend of Recycled Poly(Ethylene Terephthalate) and Polycarbonate with Polyaniline for Antistatic Packaging. Polym. Polym. Compos. 2020, 28, 331–337. [Google Scholar] [CrossRef]

- Nofar, M.; Oğuz, H. Development of PBT/Recycled-PET Blends and the Influence of Using Chain Extender. J. Polym. Environ. 2019, 27, 1404–1417. [Google Scholar] [CrossRef]

- Celik, Y.; Shamsuyeva, M.; Endres, H.J. Thermal and Mechanical Properties of the Recycled and Virgin PET—Part I. Polymers 2022, 14, 1326. [Google Scholar] [CrossRef]

- Szymczak, P.; Dziadowiec, D.; Andrzejewski, J.; Szostak, M. The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements. Appl. Sci. 2023, 13, 3434. [Google Scholar] [CrossRef]

- Zicans, J.; MerijsMeri, R.; Ivanova, T.; Berzina, R.; Kalkis, V.; Maksimov, R. Recycled Polycarbonate Blend as Matrix for Development of Polymer Nanocomposite. Macromol. Symp. 2012, 321–322, 221–224. [Google Scholar] [CrossRef]

- Khan, M.M.K.; Hilado, C.J.; Agarwal, S.; Gupta, R.K. Flammability Properties of Virgin and Recycled Polycarbonate (PC) and Acrylonitrile-Butadiene-Styrene (ABS) Recovered from End-of-Life Electronics. J. Polym. Environ. 2007, 15, 188–194. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M. Preparation of Hybrid Poly(Lactic Acid)/Flax Composites by the Insert Overmolding Process: Evaluation of Mechanical Performance and Thermomechanical Properties. J. Appl. Polym. Sci. 2020, 138, 49646. [Google Scholar] [CrossRef]

- ISO 527-1; ISO-Committee Plastics—Determination of Tensile Properties. ISO-Committee: Geneva, Switzerland, 2012.

- ISO 179-1; ISO-Committee Plastics—Determination of Charpy Impact Properties. ISO-Committee: Geneva, Switzerland, 2010.

- ISO 75; ISO-Committee Plastics—Determination of Temperature of Deflection under Load. ISO-Committee: Geneva, Switzerland, 2013.

- Chen, L.; Zhang, X.; Li, H.; Li, B.; Wang, K.; Zhang, Q.; Fu, Q. Superior Tensile Extensibility of PETG/PC Amorphous Blends Induced via Uniaxial Stretching. Chin. J. Polym. Sci. 2011, 29, 125–132. [Google Scholar] [CrossRef]

- Monnier, X.; Cavallo, D.; Righetti, M.C.; Di Lorenzo, M.L.; Marina, S.; Martin, J.; Cangialosi, D. Physical Aging and Glass Transition of the Rigid Amorphous Fraction in Poly(l-Lactic Acid). Macromolecules 2020, 53, 8741–8750. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. The Role of Crystalline, Mobile Amorphous and Rigid Amorphous Fractions in the Performance of Recycled Poly (Ethylene Terephthalate) (PET). Polym. Degrad. Stab. 2012, 97, 98–107. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D.; Pfaendner, R. Reactive-Extrusion Route for the Closed-Loop Recycling of Poly(Ethylene Terephthalate). J. Appl. Polym. Sci. 2007, 104, 1671–1678. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Savi, S.; Bianchi, S.; Castelvetro, V. Chain Extension and Branching of Poly(Ethylene Terephthalate) (PET) with Di- and Multifunctional Epoxy or Isocyanate Additives: An Experimental and Modelling Study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrzejewski, J. The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability 2023, 15, 11318. https://doi.org/10.3390/su151411318

Andrzejewski J. The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability. 2023; 15(14):11318. https://doi.org/10.3390/su151411318

Chicago/Turabian StyleAndrzejewski, Jacek. 2023. "The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation" Sustainability 15, no. 14: 11318. https://doi.org/10.3390/su151411318

APA StyleAndrzejewski, J. (2023). The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability, 15(14), 11318. https://doi.org/10.3390/su151411318