Bridge Performance Recovery Test after Strengthening with a Prestressed CFRP Laminate

Abstract

1. Introduction

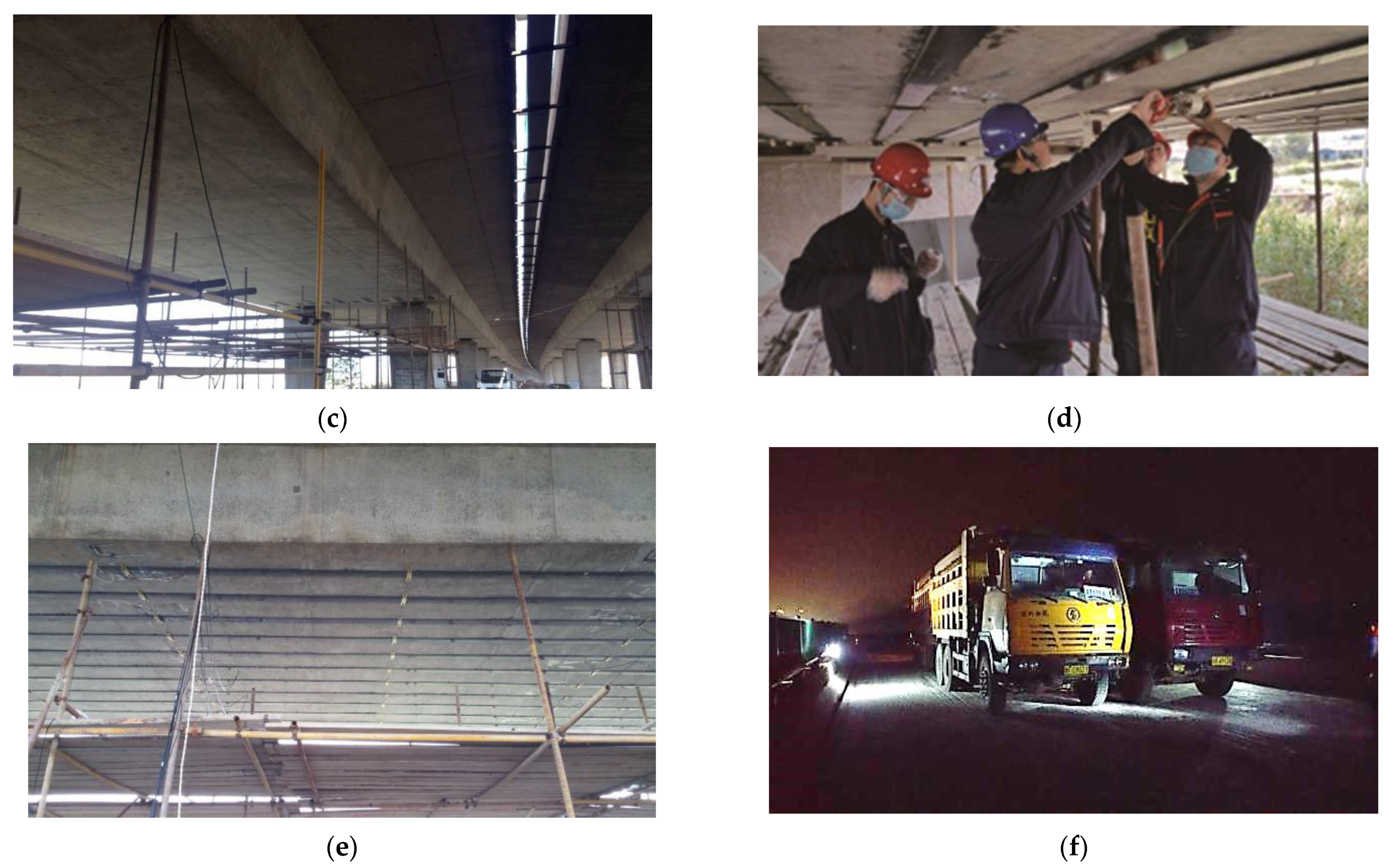

2. Reinforcement Application of the Prestressing CFRP Laminate

2.1. Prestressing CFRP Laminate Anchorage System

- (1)

- The system has a unique anchorage mode that has been proven to have an anchorage efficiency coefficient greater than 0.95, giving full play to the high-strength advantage of carbon fiber plates and greatly improving the utilization rate of carbon fiber materials.

- (2)

- This product system size is small, light, and thin, and it almost does not increase the weight of the original structure. It will not affect the original structure space and it leaves no traces after reinforcement.

- (3)

- It has good durability and corrosion resistance and it can reduce dependence on adhesives. It can also be constructed in winter without the need for large construction machinery or wet operations, making it convenient for construction and installation at small sites.

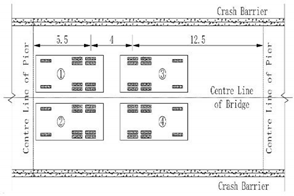

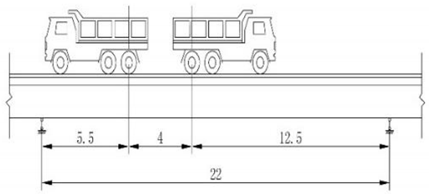

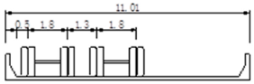

2.2. Introduction of the Strengthened Bridge for Test

- (1)

- To determine the mechanical performance to meet the design and the specifications after being strengthened.

- (2)

- (3)

- To inspect the construction method and technological process for strengthening a prestressed concrete bridge structure to improve the method.

- (4)

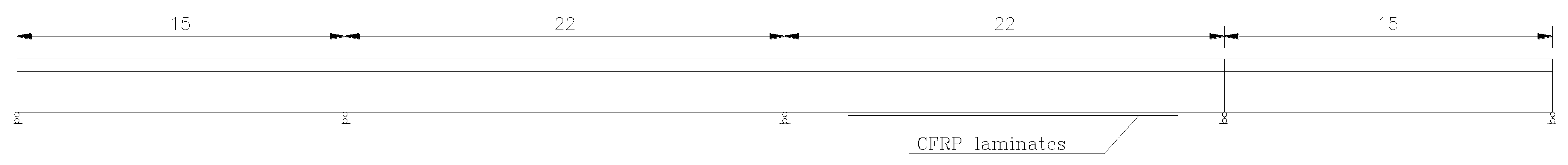

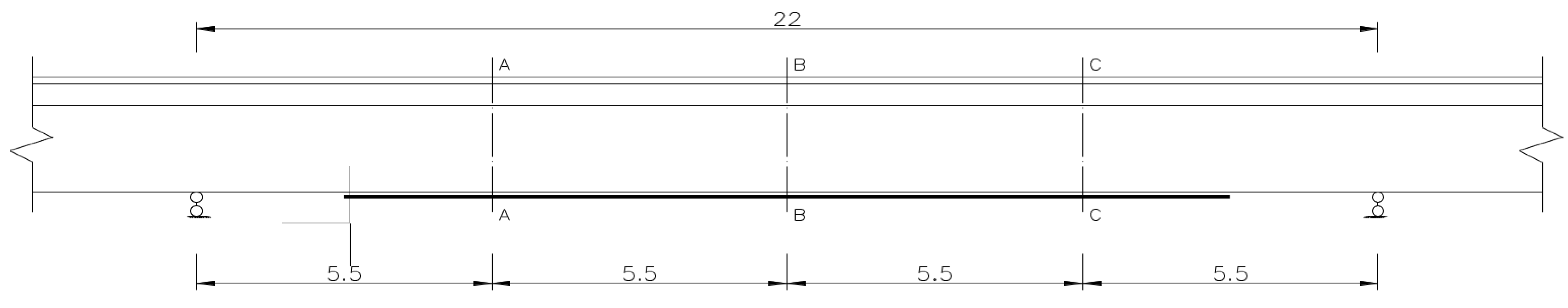

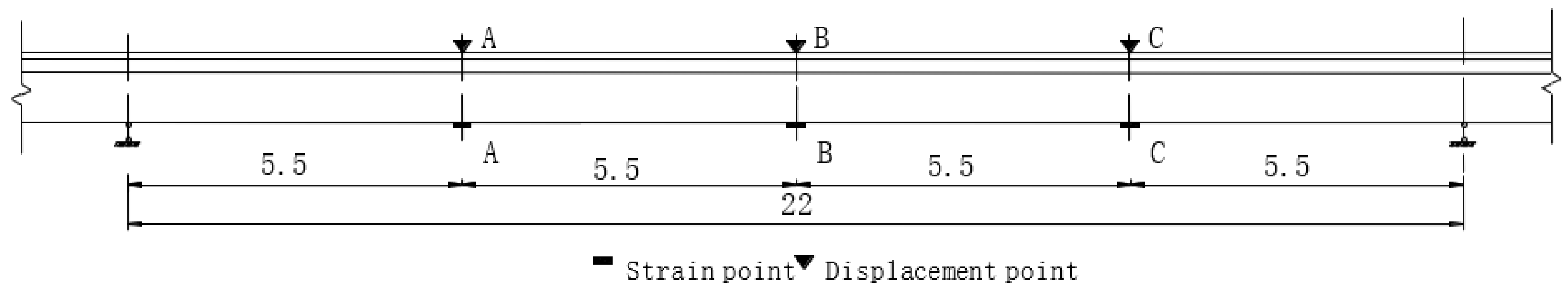

3. Test Design

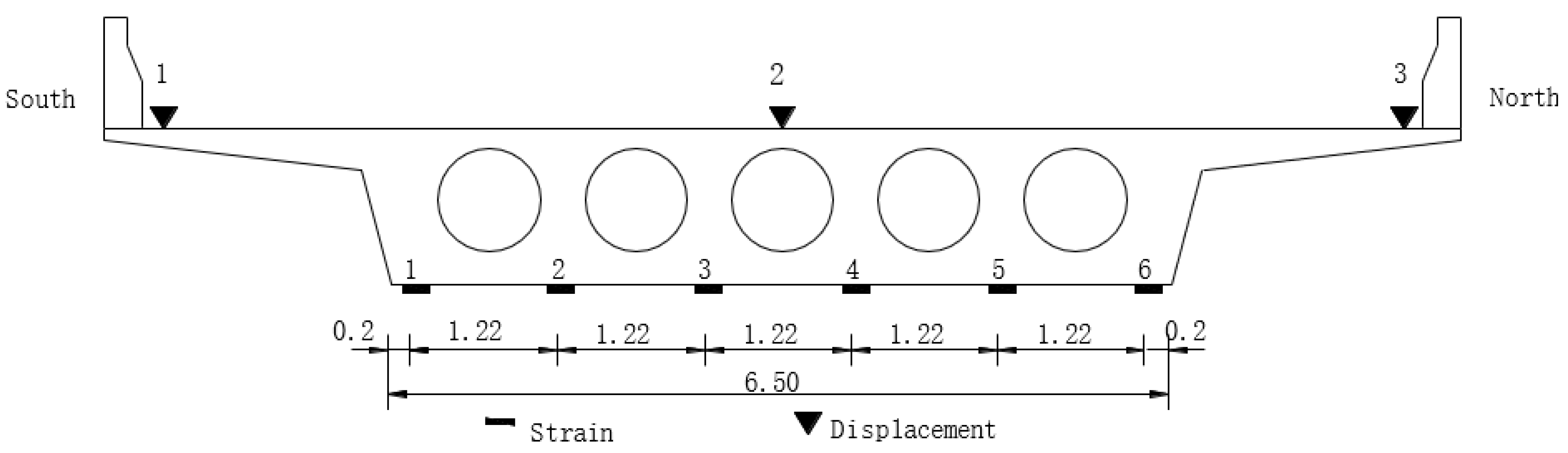

3.1. Static Test Scheme

- (1)

- The load was applied according to the abovementioned sequence during the loading test. The load gradually increased. Strain and displacement were monitored after each column of vehicles was driven to its designated position.

- (2)

- Preloading was performed prior to the actual loading process to eliminate the effect of inelastic deformation.

- (3)

- The load was applied strictly according to the sequence. A loading vehicle was used to apply a load only after its weight was measured and if it met the requirement.

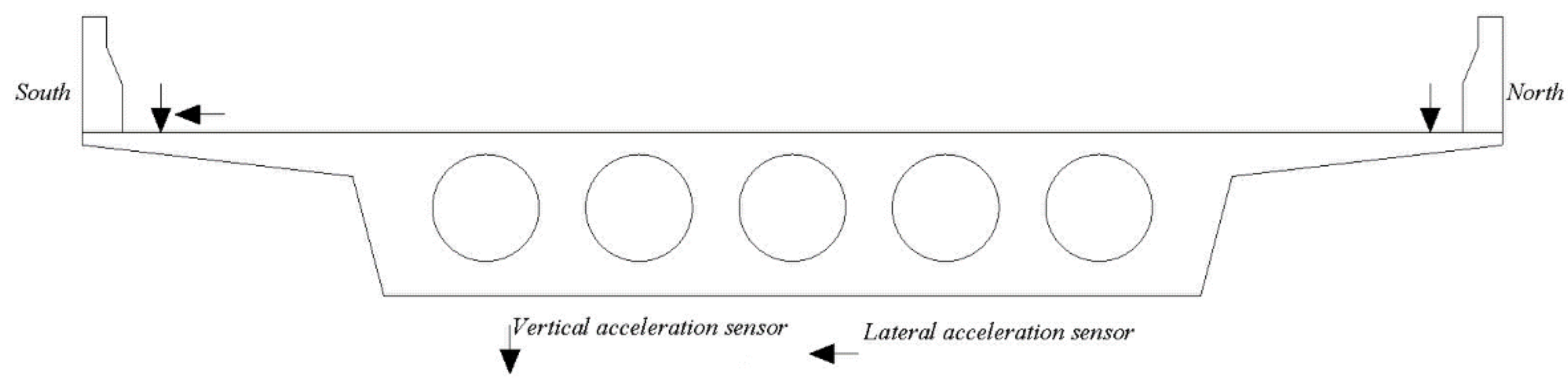

3.2. Dynamic Loading Test

3.2.1. Test Scheme

3.2.2. Loading Test

4. Results Analysis

4.1. Comparison of the Static Strain Measurements

4.2. Comparison of Deflection Measurements

4.3. Test Results concerning the Prestressed CFRP Laminates

- For the same CFRP laminate (regardless of tension), the stresses under different load cases were relatively uniform, and the range of change was relatively consistent;

- Regarding the final uniform stress of each CFRP laminate at the A-A, B-B, and C-C sections, the adhesive performance between the prestressed CFRP and the concrete was proven with a small prestress loss.

4.4. Comparison of Dynamic Behaviors

4.4.1. Moving Load Test

- (1)

- Dynamic Deflection in MidspanTable 8 lists the maximum deflection in the midspan under different vehicle speeds.The following conclusions can be drawn from the comparison of the midspan maximum dynamic deflection:

- ▪

- At different speeds, the maximum dynamic deflection in the middle span after reinforcement decreases by 25.73% compared with that before reinforcement;

- ▪

- With the increase in the vehicle speed, the change rate of the dynamic deflection in the middle span before and after reinforcement increases gradually;

- ▪

- The use of prestressed CFRP laminate for reinforcement can obviously improve the bridge’s dynamic response.

- (2)

- Dynamic strain in midspanIn Table 9, the change in dynamic strain in the midspan is listed.The following conclusions can be drawn from the maximum dynamic strain in the midspan:

- ▪

- Compared with before reinforcement, the maximum dynamic strain in the middle span after reinforcement decreases by 18.00% compared with that before reinforcement, and the change rate increases gradually with increasing vehicle speed.

- ▪

- Similar to the dynamic deflection, it was proven again that the reinforcement obviously improved the bridge’s dynamic response.

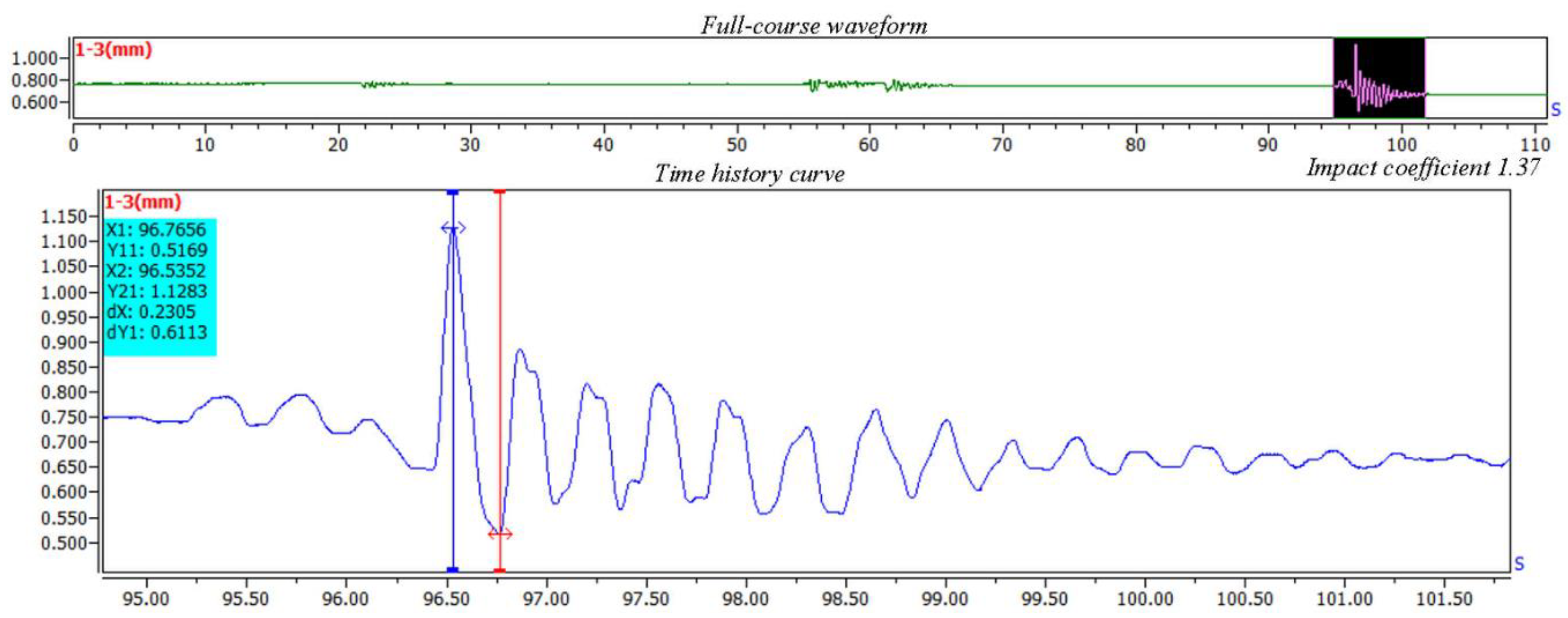

- (3)

- Impact coefficient comparisonTable 10 shows the change in the impact coefficient. The reinforcement of the bridge resulted in a reduction in the rate of vertical force generated on the bridge when a vehicle passed through it. This improvement in dynamic performance suggests that the quality of the new pavement reconstruction should be well-controlled to ensure the flatness of the bridge deck and to reduce the impact effect of the bridge. Figure 13 presents the time–history curve when the vehicle runs at 40 km/h after reinforcement.

4.4.2. Vehicle Braking Test

4.4.3. Jumping Vehicle Test

5. Conclusions

- (1)

- The anchorage system for CFRP laminates was effective in enhancing the anchorage efficiency of CFRP laminates, and the strengthening results demonstrated that the stress distribution at the midspan section after strengthening was reasonable. Additionally, the distribution trend of the longitudinal displacement at each measurement point was consistent with the theoretical calculations, and the measurements were lower than the theoretical values.

- (2)

- The loading test proved that the prestressed CFRP laminates showed excellent operating performance and established bonding performance between CFRP laminates and concrete. The anchorage did not undergo any retraction deformation, with only a small loss in prestress.

- (3)

- The prestressed CFRP laminates and bridge structure experienced stress and deformed together as a composite. The CFRP laminates and the bridge structure exhibited excellent operating performance together.

- (4)

- For each loading condition, the maximum measurement of the deflection at the midspan cross-section was smaller than the allowable value specified in the design specification. Therefore, the stiffness of the bridge met the requirements of the specification.

- (5)

- The small residual deformation and strain after removing the vehicles demonstrated that the bridge was in the elastic stage, indicating the efficiency of the CFRP prestressing.

- (6)

- The dynamic results under moving, braking, and jumping vehicles proved that the reinforcement with the prestressing CFRP laminate satisfied the original expectation and verified that the strengthening recovered the performance of the bridge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Shen, Y.; Jiang, X.; Qiang, X.; Chen, L. Experimental Study on Steel‒Concrete Composite Beams Strengthened by Externally Prestressed CFRP Strips. Prestress. Technol. 2023, 27, 39–52. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, H.; Guan, Z.; Yang, K. Evaluation of the properties and applications of FRP bars and anchors: A review. Rev. Adv. Mater. Sci. 2023, 62, 20220287. [Google Scholar] [CrossRef]

- El-Sayed, A.K. Effect of longitudinal CFRP strengthening on the shear resistance of reinforced concrete beams. Compos. Part B Eng. 2014, 58, 422–429. [Google Scholar] [CrossRef]

- Jokubaitis, A.; Valivonis, J. An Analysis of the Transfer Lengths of Different Types of Prestressed Fiber-Reinforced Polymer Reinforcement. Polymers 2022, 14, 3931. [Google Scholar] [CrossRef]

- Burningham, C.A.; Pantelides, C.P.; Reaveley, L.D. Repair of reinforced concrete deep beams using post-tensioned CFRP rods. Compos. Struct. 2015, 125, 256–265. [Google Scholar] [CrossRef]

- Garden, H.N.; Hollaway, L.C. An experimental study of the influence of plate end anchorage of carbon fibre composite plates used to strengthen reinforced concrete beams. Compos. Struct. 1998, 42, 175–188. [Google Scholar] [CrossRef]

- Schmidt, J.W.; Bennitz, A.; Taljsten, B.; Goltermann, P.; Pedersen, H. Mechanical anchorage of FRP tendons—A literature review. Constr. Build. Mater. 2012, 32, 110–121. [Google Scholar] [CrossRef]

- Jayaprakash, J.; Pournasiri, E.; Choong, K.K.; Tan, C.G.; De’nan, F. External CFRP repairing of pretested beams reinforced using prestress rebars. J. Reinf. Plast. Compos. 2011, 30, 1753–1768. [Google Scholar] [CrossRef]

- Mostafa, A.; Razaqpur, A.G. CFRP Anchor for Preventing Premature Debonding of Externally Bonded FRP Laminates from Concrete. J. Compos. Constr. 2013, 17, 641–650. [Google Scholar] [CrossRef]

- Mostafa, A.A.B.; Razaqpur, A.G. A new CFRP anchor for preventing separation of externally bonded laminates from concrete. J. Reinf. Plast. Compos. 2013, 32, 1895–1906. [Google Scholar] [CrossRef]

- Mosavi, S.M.; Nik, A.S. Strengthening of steel-concrete composite girders using carbon fibre reinforced polymer (CFRP) plates. Sadhana Acad. Sci. 2015, 40, 249–261. [Google Scholar] [CrossRef]

- Sun, W.; Ghannoum, W.M. Modeling of anchored CFRP strips bonded to concrete. Constr. Build. Mater. 2015, 85, 144–156. [Google Scholar] [CrossRef]

- Xu, Y.; Dong, Y.; Luo, Y.; Lin, B. Experimental study on shear behavior of reinforced concrete beams strengthened with CFRP sheet after fire. J. Build. Struct. 2015, 36, 123–132. [Google Scholar]

- Wang, H.-T.; Bian, Z.-N.; Xu, G.-W.; Chen, M.-S.; Xiong, H.; Liu, S.-S. Flexural Strengthening of Large-Scale RC Beams with Nonprestressed and Prestressed CFRP Using Different Anchorages. Polymers 2022, 14, 5498. [Google Scholar] [CrossRef]

- Rogowski, J.; Kotynia, R. Comparison of Prestressing Methods with CFRP and SMA Materials in Flexurally Strengthened RC Members. Materials 2022, 15, 1231. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Harries, K.A.; Zhang, L. Prediction of prestress losses in RC beams externally strengthened with prestressed CFRP sheets/plates. J. Reinf. Plast. Compos. 2014, 33, 699–713. [Google Scholar] [CrossRef]

- Yapa, H.D.; Lees, J.M. Rectangular Reinforced Concrete Beams Strengthened with CFRP Straps. J. Compos. Constr. 2014, 18, 04013032. [Google Scholar] [CrossRef]

- Trentin, C.; Casas, J.R. Safety factors for CFRP strengthening in bending of reinforced concrete bridges. Compos. Struct. 2015, 128, 188–198. [Google Scholar] [CrossRef]

- Li, F.; Li, W.; Lu, S.; Shen, Y. Development of a Prestressing CFRP Laminate Anchorage System and Bridge Strengthening Application. Adv. Mater. Sci. Eng. 2019, 2019, 3503898. [Google Scholar] [CrossRef]

- Richardson, T.; Fam, A. Modulus Effect of Bonded CFRP Laminates Used for Repairing Preyield and Postyield Cracked Concrete Beams. J. Compos. Constr. 2014, 18, 04013054. [Google Scholar] [CrossRef]

- Sakar, G.; Tanarslan, H.M. Prestressed CFRP Fabrics for Flexural Strengthening of Concrete Beams with an Easy Prestressing Technique. Mech. Compos. Mater. 2014, 50, 537–542. [Google Scholar] [CrossRef]

- Verbruggen, S.; Tysmans, T.; Wastiels, J. TRC or CFRP strengthening for reinforced concrete beams: An experimental study of the cracking behaviour. Eng. Struct. 2014, 77, 49–56. [Google Scholar] [CrossRef]

- Xie, J.H.; Guo, Y.C.; Liu, Y.F.; Chen, G.F. Experimental Study on Flexural Behaviour of Pre-Damaged Reinforced Concrete Beams Strengthened with CFRP. Mater. Plast. 2014, 51, 370–375. [Google Scholar]

- JTG/T J22-2008; Specifications for Strengthening Design of Highway Bridge. CCCC First Highway Consultants Co., Ltd., China Communications Press: Beijing, China, 2008.

- JTG/T J23-2008; Technical Specifications for Strengthening Construction of Highway Bridges. CCCC First Highway Consultants Co., Ltd., China Communications Press: Beijing, China, 2008.

- JTGD62-2004; Code for Design of Highway Reinforced Concrete and Prestressed Concrete Rridge and Culverts. CCCC Highway Consultants Co., Ltd., China Communications Press: Beijing, China, 2004.

- JTG D60-2015; General Specifications for Design of Highway Bridges and Culverts. CCCC Highway Consultants Co., Ltd., China Communications Press: Beijing, China, 2015.

- GB 50010-2010; Code for Design of Concrete Structure. CCCC Highway Consultants Co., Ltd., China Architecture & Building Press: Beijing, China, 2015.

- Volume JTG/T J21-2011; Specification for Inspection and Evaluation of Load-Bearing Capacity of Highway Bridges. Academy of Highway Science, Ministry of Transport, China Communications Press: Beijing, China, 2011.

- Saadatmanesh, H.; Ehsani, M.R. RC beams strengthened with GFRP plates. I: Experimental study. J. Struct. Eng. ASCE 1991, 11, 3417–3433. [Google Scholar] [CrossRef]

- Boukhezar, M.; Samai, M.L.; Mesbah, H.A.; Houari, H. Flexural behaviour of reinforced low-strength concrete beams strengthened with CFRP plates. Struct. Eng. Mech. 2013, 47, 819–838. [Google Scholar] [CrossRef]

| Type | Width × Thickness/mm | Tensile Strength/ MPa | Ultimate Strength/ kN | Tensile Modulus/ GPa | Extensibility/ % |

|---|---|---|---|---|---|

| OVM.CFP100-1.4 | 100 × 1.4 | ≥2600 | 364 | ≥160 | ≥1.6 |

| Technical parameters of anchorage device | |||||

| Type | C’ × D’ × H (thickness) | A’ × B’ | K × J | K’ × J’ | ΦG × h (depth) |

| OVM.CFP100-1.2 | 150 × 150 × 55 | 100 × 1.2 | 210 × 260 | 260 × 210 | 24 × 300 |

| Installation Space for Anchorage | Groove Dimensions for Fixed Anchorage End E × F × H | Groove Dimensions for Tension Anchorage End E’ × F’ × H | Chemical Bolt Hole Size |

|---|---|---|---|

| 250 × 500 × 25 | 300 × 1100 × 25 | d28 × 210 |

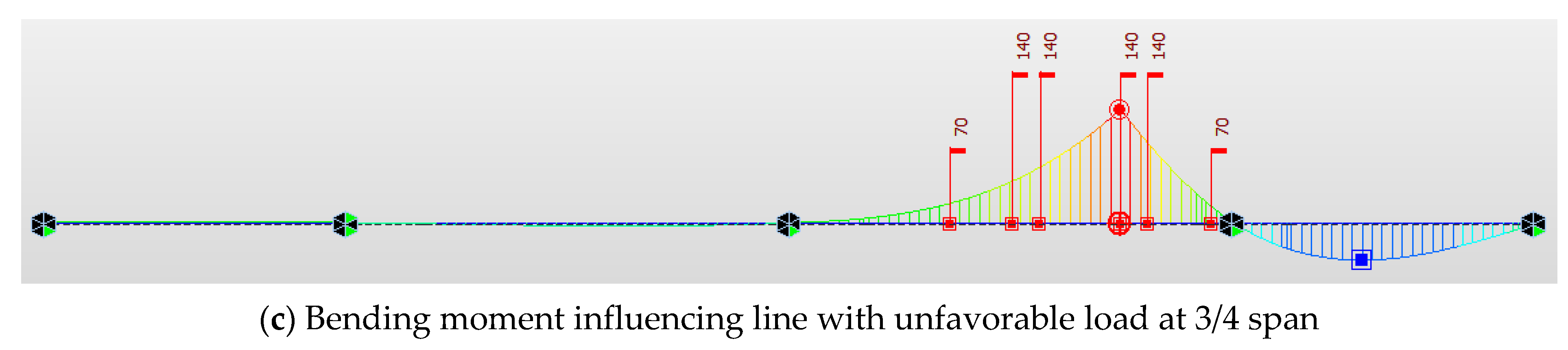

| Location | Under Design Load Action (Truck-Load over 20, Including ) | Under Test Vehicle Load (70 + 140 + 140 = 350 kN) | Loading Efficiency |

|---|---|---|---|

| 1/4 span | 2269.7 | 2070.6 | 0.912 |

| 1/2 span | 3152 | 3176.7 | 1.008 |

| 3/4 span | 2034.4 | 1931.7 | 0.950 |

| Arrangement | Central Loading | Eccentric Loading |

|---|---|---|

| (a) | East |  West West |

| (b) | East West West | |

| (c) | South |  North North |

| Section Location | Point ID | Load Case 1 | Load Case 2 | Load Case 3 | Load Case 4 | Load Case 5 | Load Case 6 |

|---|---|---|---|---|---|---|---|

| 1/4 span | A-1 | −10.48 | −17.60 | −12.48 | −9.48 | −11.48 | −11.48 |

| A-2 | −10.52 | −17.94 | −11.52 | −11.52 | −11.52 | −11.52 | |

| A-3 | −11.33 | −17.43 | −9.33 | −11.33 | −12.33 | −13.33 | |

| A-4 | −10.08 | −12.16 | −10.08 | −10.08 | −10.08 | −11.08 | |

| A-5 | −7.65 | −4.69 | −7.65 | −6.65 | −8.65 | −10.65 | |

| A-6 | −10.56 | −5.69 | −9.56 | −9.56 | −11.56 | −11.56 | |

| 1/2 span | B-1 | −11.00 | −17.07 | −11.00 | −10.00 | −11.00 | −10.00 |

| B-2 | −11.25 | −19.35 | −12.25 | −11.25 | −12.25 | −13.25 | |

| B-3 | −10.83 | −14.88 | −11.83 | −10.83 | −10.83 | −8.83 | |

| B-4 | −6.70 | −6.73 | −5.70 | −3.70 | −7.70 | −5.70 | |

| B-5 | −10.85 | −11.90 | −11.85 | −10.85 | −11.85 | −11.85 | |

| B-6 | −14.40 | −10.41 | −10.40 | −8.40 | −13.40 | −13.40 | |

| 3/4 span | C-1 | −11.96 | −13.03 | −11.96 | −12.96 | −10.96 | −10.96 |

| C-2 | −7.17 | −8.25 | −12.17 | −12.17 | −13.17 | −7.17 | |

| C-3 | −10.83 | −14.88 | −11.83 | −12.83 | −12.83 | −11.83 | |

| C-4 | −20.66 | −21.70 | −36.66 | −25.66 | −6.66 | −2.66 | |

| C-5 | −11.55 | −11.57 | −10.55 | −10.55 | −11.55 | −9.55 | |

| C-6 | −11.07 | −10.04 | −11.07 | −10.07 | −12.07 | −8.07 |

| Section Location | Point ID | Load Case | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| A-A | 1 | −0.320 | −0.330 | −0.300 | −0.330 | −0.320 | −0.300 |

| 2 | −0.339 | −0.309 | −0.319 | −0.299 | −0.319 | −0.309 | |

| 3 | −0.314 | −0.314 | −0.314 | −0.304 | −0.314 | −0.324 | |

| B-B | 1 | −0.455 | −0.445 | −0.345 | −0.395 | −0.385 | −0.395 |

| 2 | −0.461 | −0.451 | −0.411 | −0.401 | −0.501 | −0.391 | |

| 3 | −0.428 | −0.438 | −0.418 | −0.398 | −0.398 | −0.398 | |

| C-C | 1 | −0.334 | −0.324 | −0.344 | −0.364 | −0.314 | −0.254 |

| 2 | −0.343 | −0.303 | −0.343 | −0.303 | −0.313 | −0.313 | |

| 3 | −0.329 | −0.339 | −0.329 | −0.359 | −0.349 | −0.359 |

| Number of CFRP | 1 | 3 | 2 | 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Location | B-B | B-B | A-A | B-B | C-C | A-A | B-B | C-C |

| Load Case | Point 1 | Point 2 | Point 3 | Point 1 | Point 2 | Point 3 | ||

| Preload | 11.205 | 3.113 | 3.914 | 4.202 | 3.716 | 4.058 | 4.328 | 3.734 |

| 1 | 10.917 | 3.315 | 3.680 | 4.202 | 3.986 | 3.770 | 4.310 | 3.950 |

| 2 | 10.953 | 3.260 | 3.698 | 4.220 | 4.022 | 3.734 | 4.202 | 3.878 |

| 3 | 10.989 | 3.334 | 3.788 | 4.256 | 4.040 | 3.842 | 4.436 | 3.950 |

| 4 | 11.007 | 3.242 | 3.734 | 4.220 | 4.004 | 3.752 | 4.256 | 3.806 |

| 5 | 11.133 | 3.058 | 3.896 | 4.184 | 3.680 | 3.968 | 4.310 | 3.680 |

| 6 | 11.205 | 2.984 | 3.860 | 4.148 | 3.626 | 3.806 | 4.094 | 3.572 |

| No. | Vehicle Speed/km/h | Before Reinforcement/mm | After Reinforcement/mm | Rate of Change/% |

|---|---|---|---|---|

| 1 | 20 | 0.8828 | 0.8232 | −6.75 |

| 2 | 30 | 0.9807 | 0.7748 | −21.00 |

| 3 | 40 | 0.9254 | 0.6873 | −25.73 |

| No. | Vehicle Speed/km/h | Before Reinforcement/με | After Reinforcement/με | Rate of Change/% |

|---|---|---|---|---|

| 1 | 20 | 9.0020 | 8.6495 | −3.92% |

| 2 | 30 | 9.7081 | 8.6495 | −10.90% |

| 3 | 40 | 8.8255 | 7.2369 | −18.00% |

| No. | Vehicle Speed/km/h | Before Reinforcement | After Reinforcement | Rate of Change/% |

|---|---|---|---|---|

| 1 | 20 | 1.24 | 1.12 | −9.68 |

| 2 | 30 | 1.22 | 1.21 | −0.82 |

| 3 | 40 | 1.12 | 1.28 | 14.29 |

| No. | Item | Before Reinforcement | After Reinforcement | Rate of Change/% |

|---|---|---|---|---|

| 1 | Dynamic deflection at midspan/mm | 0.8541 | 0.8047 | −5.78% |

| 2 | Dynamic strain of concrete at midspan/με | 6.5309 | 10.4141 | 59.46% |

| 3 | Dynamic strain of CFRP laminate at midspan/με | — | 21.4265 | — |

| Item | Before Reinforcement | After Reinforcement | Rate of Change/% |

|---|---|---|---|

| Impact coefficient | 1.40 | 1.37 | −2.14% |

| Damping ratio | 2.93% | 1.65% | −43.69% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Li, F. Bridge Performance Recovery Test after Strengthening with a Prestressed CFRP Laminate. Sustainability 2023, 15, 11197. https://doi.org/10.3390/su151411197

Li Y, Li F. Bridge Performance Recovery Test after Strengthening with a Prestressed CFRP Laminate. Sustainability. 2023; 15(14):11197. https://doi.org/10.3390/su151411197

Chicago/Turabian StyleLi, Yang, and Fangyuan Li. 2023. "Bridge Performance Recovery Test after Strengthening with a Prestressed CFRP Laminate" Sustainability 15, no. 14: 11197. https://doi.org/10.3390/su151411197

APA StyleLi, Y., & Li, F. (2023). Bridge Performance Recovery Test after Strengthening with a Prestressed CFRP Laminate. Sustainability, 15(14), 11197. https://doi.org/10.3390/su151411197