Digitalization, Carbon Productivity and Technological Innovation in Manufacturing—Evidence from China

Abstract

1. Introduction

2. Literature Review

2.1. Digitalization of Manufacturing

2.2. Carbon Productivity of Manufacturing

2.3. The Relationship between Digitalization and Carbon Productivity

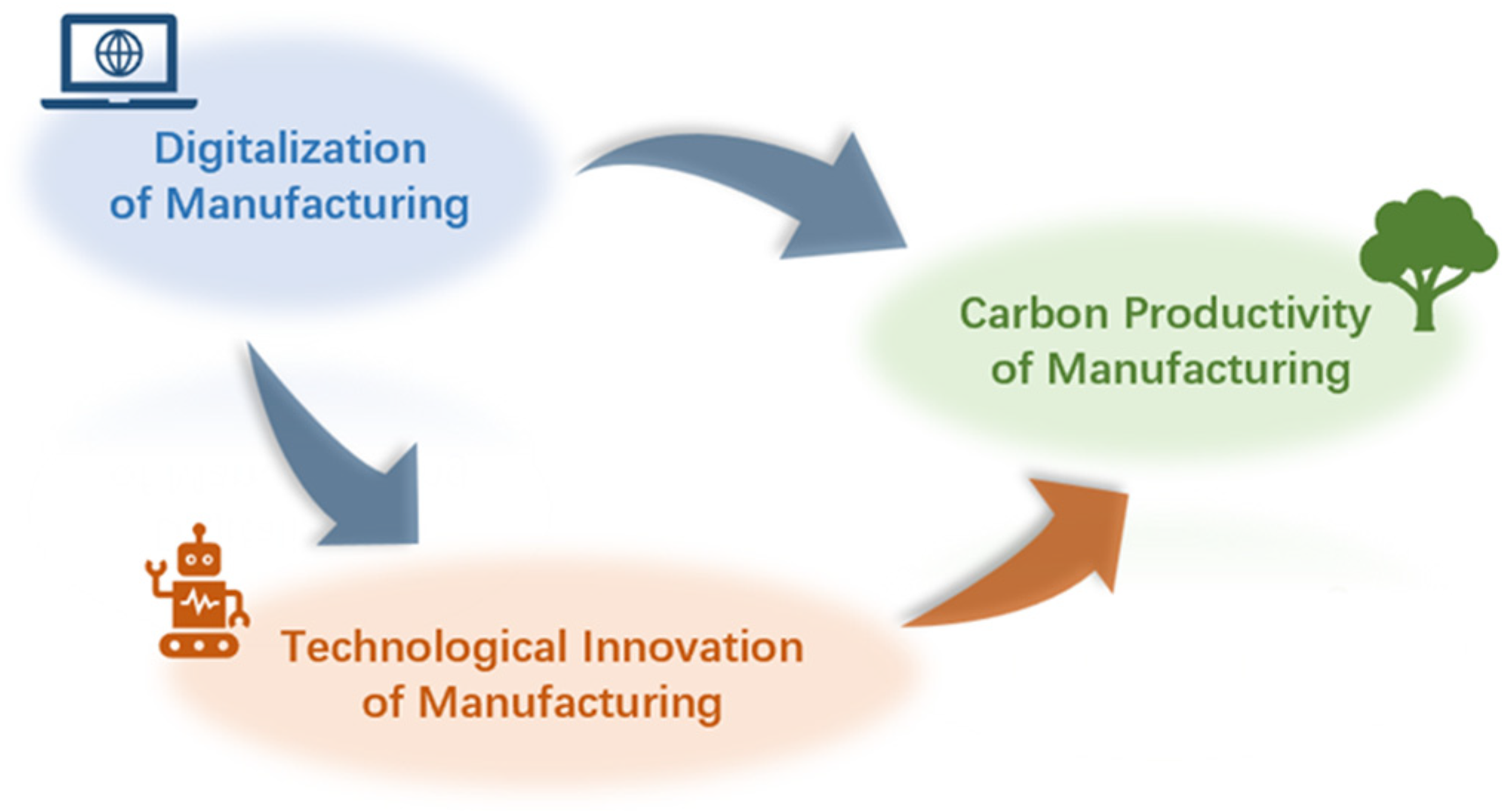

3. Research Hypotheses

3.1. Direct Effect of Manufacturing Digitalization on Carbon Productivity

3.2. Direct Effect of Manufacturing Technological Innovation on Carbon Productivity

3.3. The Mediating Role of Technological Innovation between Digitalization and Carbon Productivity for Manufacturing

4. Methodology and Data

4.1. Test Method for Mediation Effects

- I.

- If β and γ are significant, then test coefficient α′; if α′ is not significant, this indicates that the direct effect is not significant and there is a full mediation effect.

- II.

- If β and γ are significant, then test coefficient α′; if α′ is significant, this indicates a significant direct effect. Compare the sign of βγ with α′; if the signs are the same, this indicates the existence of partial mediation, and if the signs are different, this indicates a possible masking effect.

- III.

- If at least one of β and γ is not significant, observe the significance of βγ. If βγ is not significant, this indicates that there is no mediating effect.

- IV.

- If at least one of β and γ is not significant, observe the significance of βγ. If βγ is significant, observe the significance of α′; if α′ is significant, compare the signs of βγ and α′. If the signs are the same, this indicates a partial mediation effect; if the signs are different, this indicates a possible masking effect.

- V.

- If at least one of β and γ is not significant, observe the significance of βγ. If βγ is significant, observe the significance of α′; if α′ is not significant, this indicates that the direct effect is not significant and there is a full mediation effect.

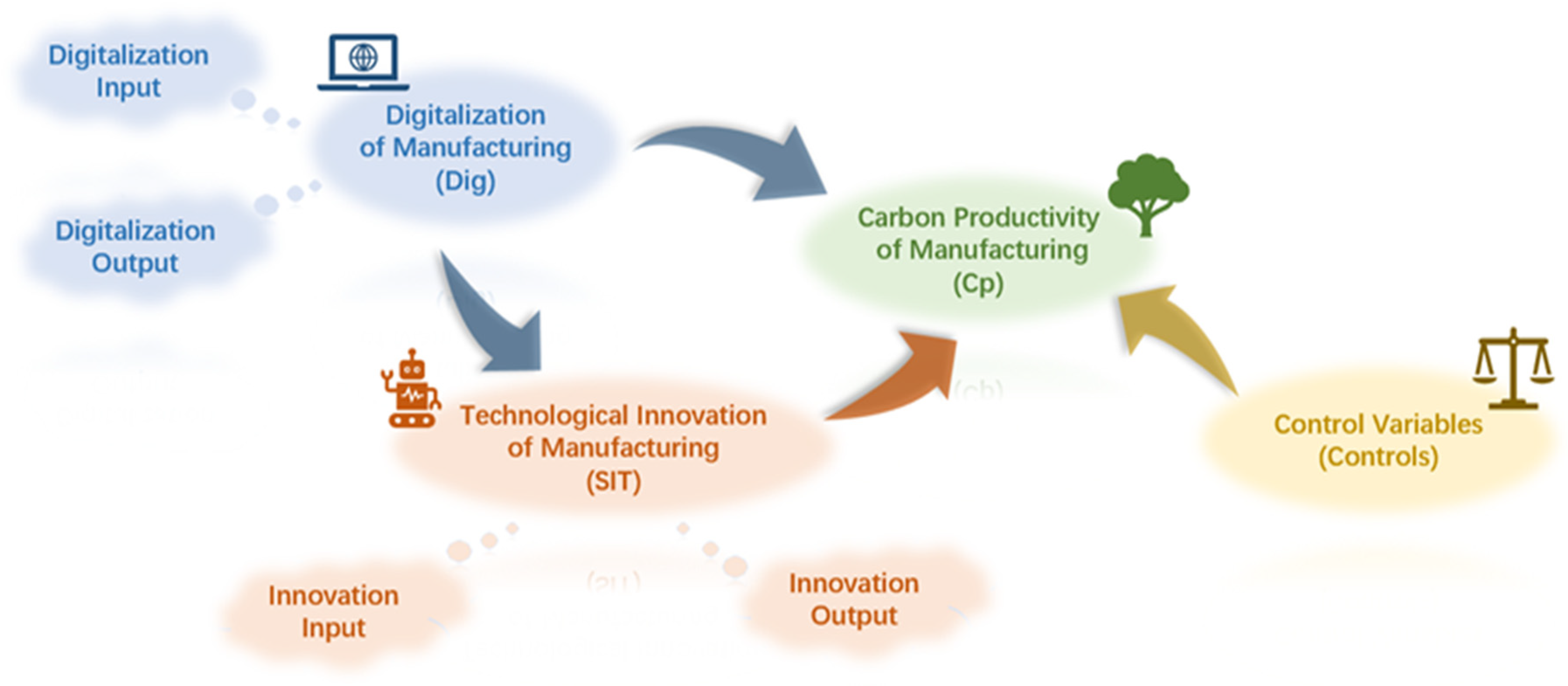

4.2. Econometric Model Building

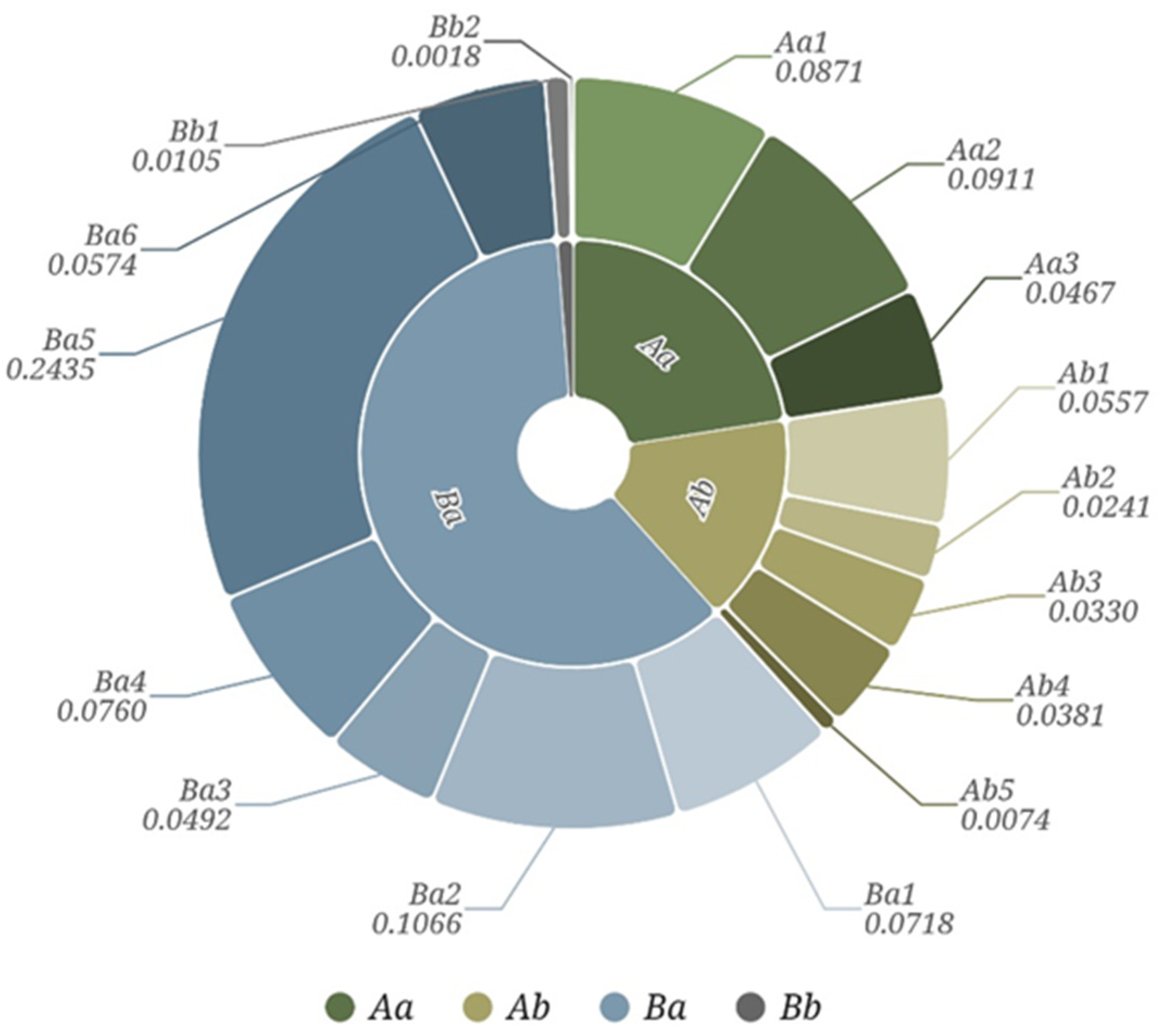

4.3. Variables Definition

4.4. Sample Selection and Data Source

5. Results and Discussion

5.1. Correlation Analysis

5.2. Regression Analysis

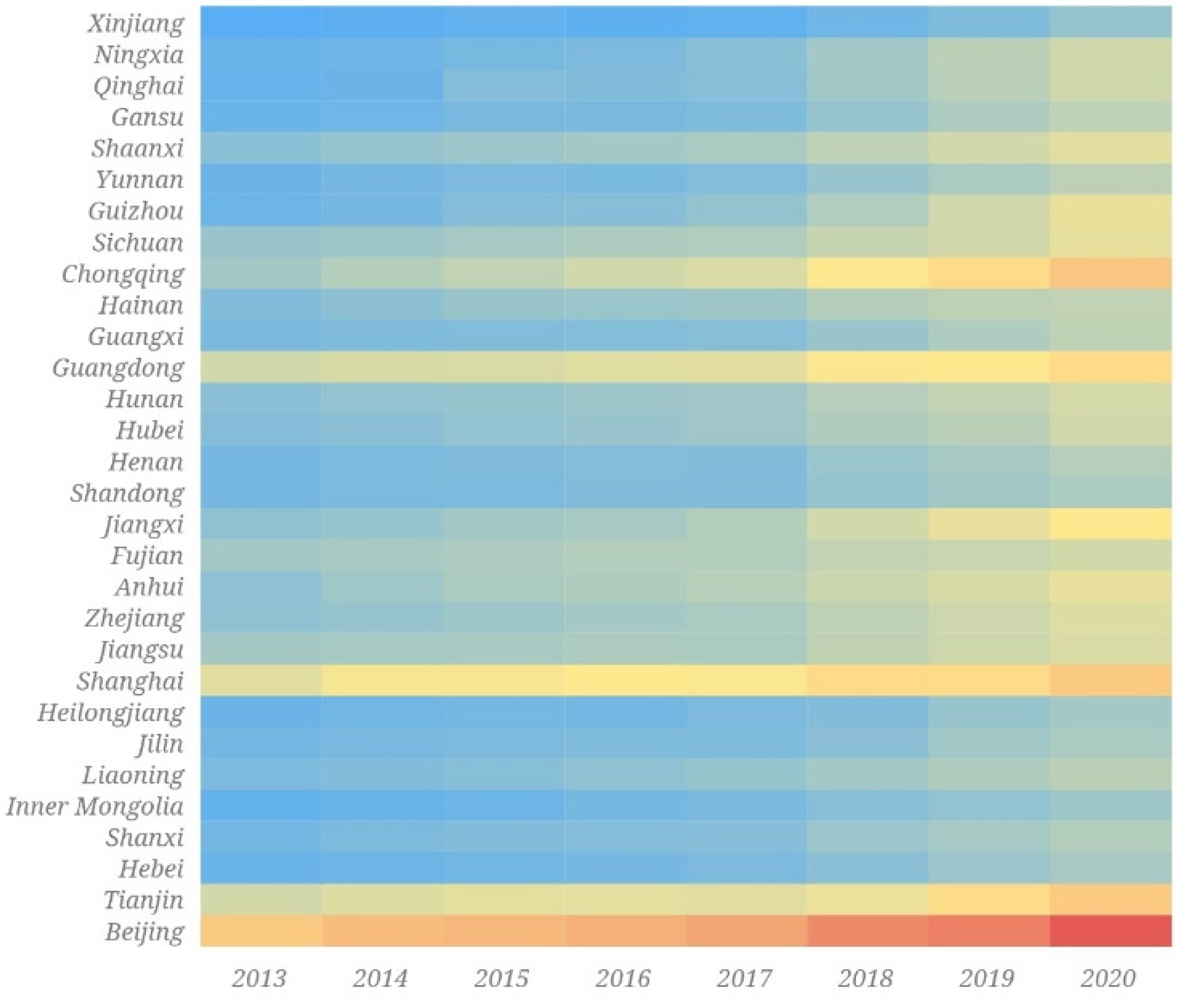

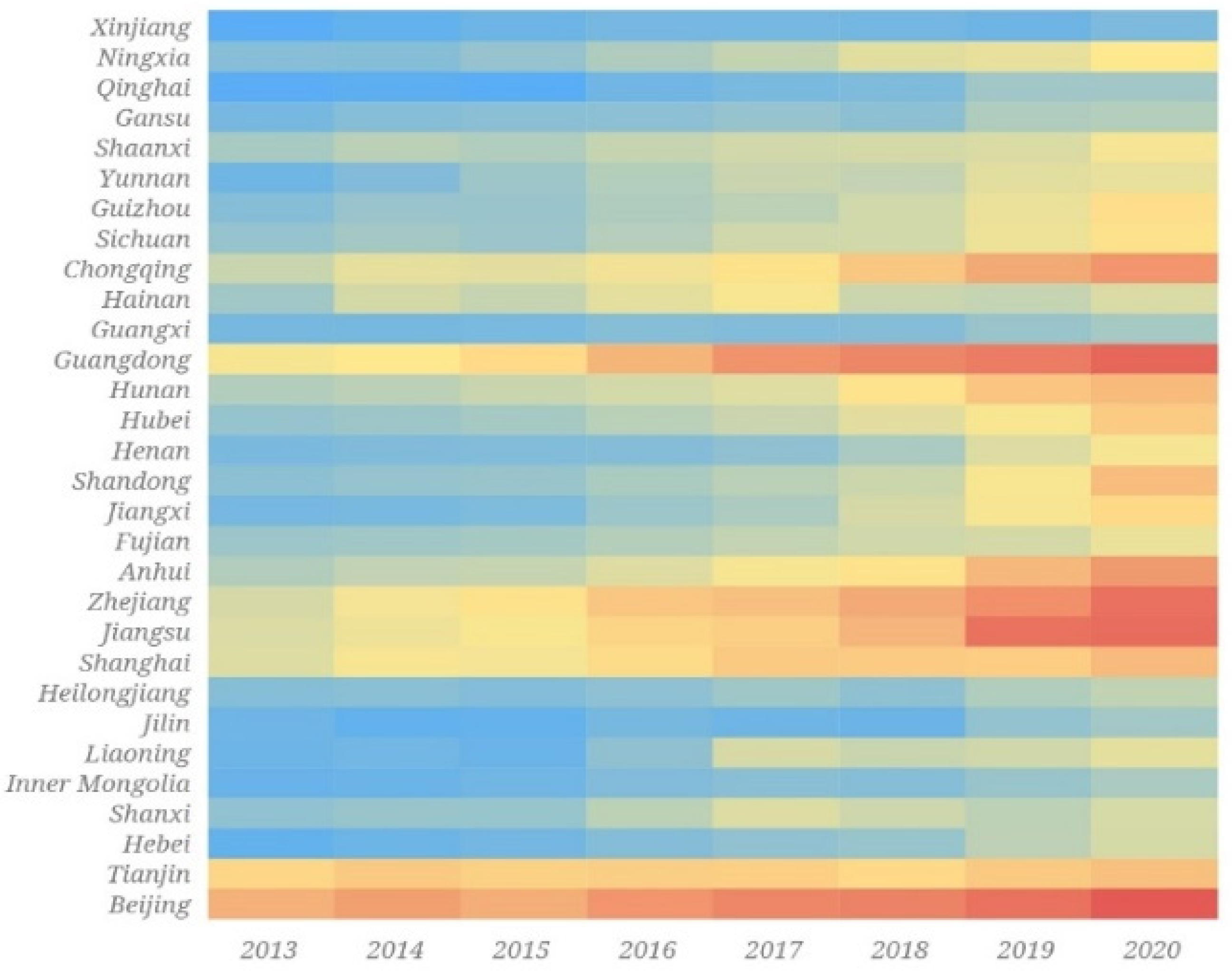

5.3. Heterogeneity Analysis

5.4. Robustness Analysis

5.5. Discussion

6. Conclusions and Implications

6.1. Conclusions

- (1)

- This paper identified the relationship between digitalization and carbon productivity in manufacturing. Unlike previous studies on carbon emissions, this paper has been concerned more with the effects of digitalization on the production efficiency of the manufacturing as a whole and entire districts, especially on the effects of carbon emission reduction brought by the direct improvement of carbon productivity. Therefore, we shifted the research object from single carbon emission to carbon productivity. On the one hand, this view is consistent with the research needs of digitalization on the production efficiency improvement of manufacturing. On the other hand, the view is also consistent with the green development demand for “carbon peaking and carbon neutrality”. It is one of the important research innovation points of this paper. Compared with previous studies that simply study carbon emissions [37,38,40,41,42,43,44,45,46], the results obtained in this paper are similar. We combined economic development and environmental protection effectively, and used carbon productivity to precisely measure the degree of decoupling between economic development and carbon emission. We also revealed the role of digitalization in improving carbon productivity for each link of manufacturing.

- (2)

- This paper is concerned more with the effects of technological innovation on the relationship between digitalization and carbon productivity. In contrast to previous studies that select innovation indicators, involving various aspects such as green innovation, technological innovation, and management innovation [40,44,53,54,55], we identified technological innovation indicators closely related to digitalization and examined the effects on carbon productivity. We have demonstrated the mediating role of technological innovation between digitalization and carbon productivity in the previous. The results indicated that technological innovation driven by digitalization development is a critical factor in carbon productivity improvement. Technological innovation is a vital link between digitalization and carbon productivity, and also a critical point to productivity improvement in manufacturing.

- (3)

- This paper took into account multiple synergistic aspects and considered overall integrated development rather than just concentrating on one specific issue. Another important conclusion of this paper is the necessity of synergy technological innovation and digitalization development as approaches to the issue of carbon reduction. In comparison to previous studies on carbon reduction from a single perspective [42,45,47,48,49,50,51,52], this perspective can more effectively integrate resource advantages, increase industrial value addition, enhance production efficiency, and optimize the production chain, all of which are significant for improving carbon productivity in manufacturing.

6.2. Implications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, W.; Ming; Nie, M. A Study of Regional Differences in the Efficiency of Industrial Carbon Emissions in China—An Empirical Analysis Based on a Non-Parametric Frontier. J. Quant. Tech. Econ. 2012, 29, 14. [Google Scholar]

- Xi, Y.; LI, X.; Zhou, D. A Study of the Variance and Convergence of Carbon Productivity in China’s Manufacturing Industry. J. Quant. Tech. Econ. 2015, 32, 18. [Google Scholar] [CrossRef]

- Beinhocker, E.; Oppenheim, J.; Irons, B.; Lahti, M.; Farrell, D.; Nyquist, S.; Remes, J.; Nauclér, T.; Enkvist, P.E. The Carbon Productivity Challenge: Curbing Climate Change and Sustaining Economic Growth; Mckinsey Global Institute: New York, NY, USA, 2008. [Google Scholar]

- Zhang, M.; Yu, D. Carbon emission reduction paths and industrial choices for “Made in China 2025” in the context of the new industrial revolution. Mod. Econ. Res. 2016, 1, 12–16. [Google Scholar] [CrossRef]

- Li, Z. Digital new industry to promote the transformation and upgrading of traditional industries. Chinas Foreign Trade 2021, 4, 24–26. [Google Scholar]

- Zhao, Q.; Wu, J.; Xia, P.; Liu, D.; Liu, Y.; Dong, H. Optimization and evaluation of the evaluation index system of strong manufacturing country. China Eng. Sci. 2017, 19, 13–19. [Google Scholar]

- Tan, X.; Guo, W.; Fan, J.; Guo, J.; Wang, M.; Zeng, A.; Su, L.; Sun, Y. Policy framework and technology innovation policy of carbon peak and carbon neutrality. Bull. Chin. Acad. Sci. 2022, 37, 435–443. [Google Scholar]

- Dong, L.; Miao, G.; Wen, W. China’s Carbon Neutrality Policy: Objectives, Impacts and Paths. East Asian Policy 2021, 13, 5–18. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, D.; Yan, H.; Cao, Y. Research on China’s policy instruments of carbon emission mitigation through policy content analysis method. Stud. Sci. Sci. 2023, 41, 435–443. [Google Scholar]

- Dubash, N.K.; Valiathan, P.A.; Flachsland, C.; Harrison, K.; Hochstetler, K.; Lockwood, M.; Macneil, R.; Mildenberger, M.; Paterson, M.; Teng, F.; et al. National climate institutions complement targets and policies. Science 2021, 374, 690–693. [Google Scholar] [CrossRef]

- Newel, R.G.; Pizer, W.A.; Raimi, D. Environmental economics. Carbon market lessons and global policy outlook. Science 2014, 343, 1316–1317. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, Z.; Liang, S. Digital Economy, Entrepreneurial Activity and High Quality Development—Empirical Evidence from Chinese Cities. Manag. World 2020, 36, 11. [Google Scholar] [CrossRef]

- Yoo, Y.; Boland, R.J.; Lyytinen, K.; Majchrzak, A. Organizing for Innovation in the Digitized World. Organ. Sci. 2012, 23, 1398–1408. [Google Scholar] [CrossRef]

- Xiao, X.; Qi, Y. The value dimension and theoretical logic of industrial digital transformation. Reform 2019, 61–70. [Google Scholar]

- Ji, Z. Manufacturing Digital Intelligence. China Mech. Eng. 2012, 23, 2395–2400. [Google Scholar] [CrossRef]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Hess, T.; Matt, C.; Benlian, A. Options for Formulating a Digital Transformation Strategy; Darmstadt Technical University Institute for Business Studies: Darmstadt, Germany, 2016. [Google Scholar]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reiig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes—A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Bueno, A.F.; Filho, M.G.; Frank, A.G. Smart Production Planning and Control in the Industry 4.0 context: A systematic literature review. Comput. Ind. Eng. 2020, 149, 106774. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231. [Google Scholar] [CrossRef]

- Bonvillian, W.B. Advanced Manufacturing Policies and Paradigms for Innovation. Science 2013, 342, 1173–1175. [Google Scholar] [CrossRef]

- Cai, Y.; Gong, X.; Jin, M. Digital Economy, Innovation Environment and Manufacturing Transformation and Upgrading. Stat. Decis. 2021, 17, 20–24. [Google Scholar] [CrossRef]

- Liu, X.; Hui, N. A Study on the Impact of Digital Economy on the High Quality Development of China’s Manufacturing Industry. Reform Econ. Syst. 2021, 7. [Google Scholar]

- Chen, N.; Cai, Y. The Impact of Digital Technology on the Growth Rate and Quality of China’s Manufacturing Industry—An Empirical Analysis Based on Patent Application Classification and Industry Heterogeneity. Rev. Ind. Econ. 2021, 6, 46–67. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2017, 142, 626–641. [Google Scholar] [CrossRef]

- Xie, K.; Xia, Z.; Xiao, J. Enterprise Realization Mechanism of Big Data as a Real Factor of Production: A Product Innovation Perspective. China Ind. Econ. 2020, 19, 42–60. [Google Scholar] [CrossRef]

- Ying, X.; Li, L. Development and Outlook of Big Data in Manufacturing. Inf. Control 2018, 47, 7. [Google Scholar] [CrossRef]

- Zhao, W. Research on corporate sustainable development strategy in the context of low carbon economy. Charming China 2011, 7, 1. [Google Scholar]

- Xie, X.; Zhu, Q. How to solve the problem of “harmonious coexistence” in the green innovation practice of enterprises? Manag. World 2021, 37, 23. [Google Scholar] [CrossRef]

- Kaya, Y.; Yokobori, K. Environment, Energy, and Economy: Strategies for Sustainability; United Nations University Press: Tokyo, Japan, 1997. [Google Scholar]

- Jiang, Y.; Zhou, D. Analysis of provincial carbon productivity and its convergence in China. Hubei Soc. Sci. 2016, 7, 96–102. [Google Scholar] [CrossRef]

- Sun, H.; Xiang, X. Resource-based Industry Transfer, Technology Spillover and Carbon Productivity—An Analysis Based on Dynamic Spatial Durbin Model. Areal Res. Dev. 2021, 40, 6. [Google Scholar] [CrossRef]

- Long, R.; Zhou, Y. A Study on the Impact of OFDI Reverse Technology Spillover on Regional Carbon Productivity. Ecol. Econ. 2017, 33, 5. [Google Scholar]

- Xu, D.; Wang, Y. Regional differences in carbon productivity of coastal fisheries in China and the factors influencing them. J. China Agric. Univ. 2015, 20, 284–290. [Google Scholar]

- Liu, C.; Hu, W.; Wu, H. Environmental Regulation, Economic Growth and Regional Carbon Productivity—An Empirical Examination Based on Provincial Data in China. Res. Financ. Econ. Issues 2015, 10, 31–37. [Google Scholar] [CrossRef]

- Xiaoli, F. A Study on the Factors Influencing Carbon Productivity in China from the Perspective of New Urbanization—A Dynamic Relationship Analysis Based on VEC Model. Mod. Manag. 2015, 35, 3. [Google Scholar]

- Shao, G.; Chang, Y.; Li, C. Study on the threshold effect of export commodity structure on carbon productivity. Resour. Sci. 2019, 41, 10. [Google Scholar]

- Tang, Z.; Liu, W.; Song, T. Analysis of factors influencing provincial carbon productivity in China based on mixed geographical weighted regression. Resour. Sci. 2017, 39, 2223–2232. [Google Scholar] [CrossRef]

- Zhang, K. The Two-way Influence Mechanism of Industrial Agglomeration and Regional Innovation and the Examination Based on the Perspective of Industry Heterogeneity. J. Audit Econ. 2019, 34, 94–105. [Google Scholar]

- Li, X.; Lu, X.; Zhu, Z. International trade, technological progress and productivity growth in China’s industrial sector. China Econ. Q. 2008, 16. [Google Scholar]

- Pan, J.; Zhang, L. A study on the regional variability of carbon productivity in China. China Ind. Econ. 2011, 11, 47–57. [Google Scholar] [CrossRef]

- Deng, R.; Zhang, A. Impacts and Mechanisms of Digital Financial Development on Carbon Emission Performance in Chinese Cities. Resour. Sci. 2021, 43, 15. [Google Scholar] [CrossRef]

- Yi, M.; Liu, Y.; Sheng, S.M.; Wen, L. Effects of digital economy on carbon emission reduction: New evidence from China. Energy Policy 2022, 171, 113271. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, G. Can Environmental Regulation Improve High-Quality Economic Development in China? The Mediating Effects of Digital Economy. Sustainability 2022, 14, 12143. [Google Scholar] [CrossRef]

- Xie, Y. The effect of digital economy on regional carbon emission intensity and its mechanism of action. Contemp. Econ. Manag. 2022, 44, 68–78. [Google Scholar] [CrossRef]

- Peng, Y.; Zhou, J.; Lin, M.; Feng, D. The Impact of IT Capability on Corporate Green Technological Innovation: Evidence from Manufacturing Companies in China. J. Inf. Knowl. Manag. 2023, 22. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, C. The impact of ICT industry on CO2 emissions: A regional analysis in China. Glob. Warm. Focus 2015, 44, 12–19. [Google Scholar] [CrossRef]

- Padmaja, B.; Narayan, S.; Chandra, P.P. ICT, foreign direct investment and environmental pollution in major Asia Pacific countries. Environ. Sci. Pollut. Res. 2021, 28, 1–21. [Google Scholar] [CrossRef]

- Asongu, S.A. ICT, Openness and CO2 emissions in Africa. Environ. Sci. Pollut. Res. 2018, 25, 9351–9359. [Google Scholar] [CrossRef] [PubMed]

- Danish; Khan, N.; Baloch, M.A.; Saud, S.; Fatima, T. The effect of ICT on CO2 emissions in emerging economies: Does the level of income matters? Environ. Sci. Pollut. Res. 2018, 25, 22850–22860. [Google Scholar] [CrossRef]

- Kunofiwa, T.; Bester, C. The Impact of Information and Communication Technology on Carbon Emissions in Emerging Markets. Int. J. Energy Econ. Policy 2019, 9, 320–326. [Google Scholar] [CrossRef]

- Salahuddin, M.; Alam, K.; Ozturk, I. The effects of Internet usage and economic growth on CO2 emissions in OECD countries: A panel investigation. Renew. Sustain. Energy Rev. 2016, 62, 1226–1235. [Google Scholar] [CrossRef]

- Xu, W.; Zhou, J.; Liu, C. Spatial effects of digital economy development on urban carbon emissions. Geogr. Res. 2022, 41, 111–129. [Google Scholar]

- Wu, C.; Gao, Y. Study on the mechanism and effect of digital economy-driven low-carbon industry development. Guizhou Soc. Sci. 2020, 7. [Google Scholar] [CrossRef]

- Gao, Y. Unleashing the mechanism among environmental regulation, artificial intelligence, and global value chain leaps: A roadmap toward digital revolution and environmental sustainability. Environ. Sci. Pollut. Res. 2022, 30, 28107–28117. [Google Scholar] [CrossRef]

- Ali, M.A.; Hoque, M.R.; Alam, K. An empirical investigation of the relationship between e-government development and the digital economy: The case of Asian countries. J. Knowl. Manag. 2018, 22, 1176–1200. [Google Scholar] [CrossRef]

- Ding, Z. A study on the mechanism of digital economy driving high quality economic development: A theoretical analysis framework. Mod. Econ. Res. 2020, 457, 85–92. [Google Scholar] [CrossRef]

- Yang, H. Research on the Growth Effectiveness of the Digital Economy and the High Quality Development of China’s Economy. Stud. Social. Chin. Charact. 2020, 153, 21–32. [Google Scholar]

- Hsiao, S.H. PTE, innovation capital and firm value interactions in the biotech medical industry. J. Bus. Res. 2014, 67, 2636–2644. [Google Scholar] [CrossRef]

- Bukht, R.; Heeks, R. Defining, Conceptualising and Measuring the Digital Economy. Int. Organ. Res. J. 2018, 13, 143–172. [Google Scholar] [CrossRef]

- Curran, D. Risk, innovation, and democracy in the digital economy. Eur. J. Soc. Theory 2018, 21, 207–226. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Collis, A. How Should We Measure the Digital Economy? Harv. Bus. Rev. 2019, 97, 140–148. [Google Scholar]

- Zhu, X.; Ma, Y. A Study of the Impact of the Digital Economy on Green Total Factor Productivity Changes. Econ. Probl. 2022, 11, 1–11. [Google Scholar] [CrossRef]

- Han, C.; Chen, Z.; Wang, Z. Research on the mechanism of pollution reduction effect of enterprises under energy saving target constraint. China Ind. Econ. 2020, 19, 43–61. [Google Scholar] [CrossRef]

- Su, X.; Zhou, S. The Impact of Dual Environmental Regulation, Government Subsidies on Firms’ Innovation Output and Moderation. China Popul. Resour. Environ. 2019, 29, 9. [Google Scholar]

- Zhang, C.; Lu, Y.; Guo, L.; Yu, T. Environmental regulation intensity and production technology progress. Econ. Res. J. 2011, 46, 113–124. [Google Scholar]

- Li, B.; Peng, X.; Ouyang, M. Environmental Regulation, Green Total Factor Productivity and the Transformation of China’s Industrial Development—An Empirical Study Based on Data from 36 Industrial Industries. China Ind. Econ. 2013, 13, 56–68. [Google Scholar] [CrossRef]

- Han, X.; Hui, N.; Song, W. Can informatization improve the efficiency of technological innovation in China’s industrial sector? China Ind. Econ. 2014, 13, 70–82. [Google Scholar] [CrossRef]

- Cai, S.; Chen, X.; Bose, I. Exploring the role of IT for environmental sustainability in China: An empirical analysis. Int. J. Prod. Econ. 2013, 146, 491–500. [Google Scholar] [CrossRef]

- Higón, D.; Gholami, R.; Shirazi, F. ICT and environmental sustainability: A global perspective. Telemat. Inform. 2017, 34, 85–95. [Google Scholar] [CrossRef]

- Shi, D. Green Development and the New Stage of Global Industrialization: China’s Progress and Comparison. China Ind. Econ. 2018, 10, 5–18. [Google Scholar] [CrossRef]

- Liu, R.; Wang, G.; Huang, N.; Ding, M. Research on the pathway of carbon neutrality supported by science and technology innovation in China. Soc. Sci. Guangxi 2021, 314, 1–7. [Google Scholar]

- Jiang, L.; Lin, C.; Lin, P. The determinants of pollution levels: Firm-level evidence from Chinese manufacturing. J. Comp. Econ. 2014, 42, 118–142. [Google Scholar] [CrossRef]

- Xing, X.; Liang, D.; Liu, T.; Gan, Y. Impact of Sustainable Exploration of Innovation and Sustainable Use of Innovation on Environmental Performance—A Moderated Mediation Model. Soft Sci. 2019, 33, 99–105. [Google Scholar] [CrossRef]

- Zhang, Z.; Chang, Y.; Cao, D.; Zhang, C. An Empirical Study on Executive Tenure, Corporate Technological Innovation and Environmental Performance: The Implementation of the New Environmental Protection Law as an Event Window. Sci. Technol. Prog. Policy 2020, 37, 9. [Google Scholar]

- Chen, Y.; Lu, J.; Yu, P. Has technological innovation reduced environmental pollution?—Empirical evidence from 285 cities in China. J. Xian Jiaotong Univ. Soc. Sci. 2019, 39, 79–90. [Google Scholar] [CrossRef]

- Ma, Q.; Murshed, M.; Khan, Z. The nexuses between energy investments, technological innovations, emission taxes, and carbon emissions in China. Energy Policy 2021, 155, 112345. [Google Scholar] [CrossRef]

- Aragon-Correa, J.A.; Hurtado-Torres, N.; Sharma, S.; Garcia-Morales, V.J. Environmental strategy and performance in small firms: A resource-based perspective. J. Environ. Manag. 2008, 86, 88–103. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Atif, M.; Chien-Chi, C.; Soytas, U. Does corporate R&D investment affect firm environmental performance? Evidence from G-6 countries. Energy Econ. 2019, 78, 401–411. [Google Scholar] [CrossRef]

- Berkhout, F.; Hertin, J. De-materialising and re-materialising: Digital technologies and the environment. Futures 2004, 36, 903–920. [Google Scholar] [CrossRef]

- Grabot, B.; Schlegel, T. ICT for sustainability in industry. Comput. Ind. 2014, 65, 383–385. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schoensleben, P.; Brulhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management—Gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy management in manufacturing: From literature review to a conceptual framework. J. Clean. Prod. 2016, 1464–1489. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Xie, K.; Zhang, D. Deep Integration of Information Technology and Real Economy: A Spellbinding Mechanism for the Chinese Context. China Ind. Econ. 2020, 392, 80–98. [Google Scholar] [CrossRef]

- Guo, J.; Luo, P. Has the Internet contributed to total factor productivity in China? Manag. World 2016, 277, 34–49. [Google Scholar] [CrossRef]

- Baron, R.M.; Kenny, D.A. The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Personal. Soc. Psychol. 1999, 51, 1173. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Ye, B. Intermediary effects analysis: Methodology and model develop. Adv. Psychol. Sci. 2014, 22, 731–745. [Google Scholar] [CrossRef]

- Sun, H.; Du, X. The impact of the degree of embeddedness and status of global value chains on the carbon productivity of industries. China Popul. Resour. Environ. 2020, 30, 11. [Google Scholar]

- Jin, J. Theoretical system of integration of industrialization and informatization. Informatiz. Constr. 2009, 128, 9–12. [Google Scholar]

- Luo, X.; Huang, L. Measuring the Level of High Quality Transformation and Upgrading of China’s Manufacturing Industry and Inter-provincial Comparison: Based on the Perspective of “Four Transformations” and Progress. Econ. Probl. 2020, 10, 43–52. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, C.; Wang, L.; Yang, Z. Study on the Evaluation of Transformation and Upgrading Capability of Chinese Manufacturing Enterprises in the Context of New Old Dynamic Energy Conversion. J. Ind. Technol. Econ. 2020, 39, 78–88. [Google Scholar] [CrossRef]

- Li, X.; Li, M. Green investment and corporate environmental governance under carbon neutrality target—A test of the mediating effect based on technological innovation. Forum Sci. Technol. China 2022, 9, 118–127. [Google Scholar] [CrossRef]

- Porter, M. America’s green strategy. Sci. Am. 1991, 8, 168. [Google Scholar] [CrossRef]

- Yin, B. Environmental Regulation and Green Total Factor Productivity in China’s Manufacturing Industry—Empirical Evidence Based on International Vertical Specialization Perspective. China Popul. Resour. Environ. 2012, 22, 60–66. [Google Scholar] [CrossRef]

- Zha, J.; Fan, L.; Gao, M. Study on the Economic Performance of China’s Industrial Carbon Emissions and its Influencing Factors. Soft Sci. 2014, 28, 30–34. [Google Scholar] [CrossRef]

- Tu, Z. Harmonization of environment, resources and industrial growth. Econ. Res. J. 2008, 478, 93–105. [Google Scholar]

- Chen, C. Green Total Factor Productivity of Chinese Industries and its Influencing Factors—An Empirical Study Based on ML Productivity Index and Dynamic Panel Model. Stat. Res. 2016, 33, 10. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhong, W. A Study on Regional Total Factor Carbon Emission Performance and Influencing Factors in China. J. Bus. Econ. 2012, 1, 85–96. [Google Scholar] [CrossRef]

- Wang, B.; Wu, Y.; Yan, P. Regional Environmental Efficiency and Environmental Total Factor Productivity Growth in China. Econ. Res. J. 2010, 45, 95–109. [Google Scholar]

- Hoffmann, R.; Lee, C.G.; Ramasamy, B.; Yeung, M. FDI and pollution: A granger causality test using panel data. J. Int. Dev. 2005, 17, 311–317. [Google Scholar] [CrossRef]

- Perkins, R.; Neumayer, E. Transnational linkages and the spillover of environment-efficiency into developing countries. SSRN Electron. J. 2009, 19, 375–383. [Google Scholar] [CrossRef]

- He, X.; Zhang, Y. Factors Influencing Industrial Carbon Emissions and CKC Restructuring Effects in China—An Empirical Study of Dynamic Panel Data by Industry Based on STIRPAT Model. China Ind. Econ. 2012, 10. [Google Scholar]

- Stiglitz, J. Capitalism, Socialism and Democracy; Harper Torchbooks; Routledge: London, UK, 1942. [Google Scholar] [CrossRef]

- Cong, J.; Liu, X.; Zhu, J.; Tang, Z. Industrial Carbon Emissions in Small and Medium-sized Cities: Accounting Methods and Influencing Factors—Jiyuan City, Henan Province as an Example. Resour. Sci. 2013, 35, 8. [Google Scholar]

- Mansfield, E. Industrial Innovation in Japan and the United States. Science 1988, 241, 1769–1774. [Google Scholar] [CrossRef] [PubMed]

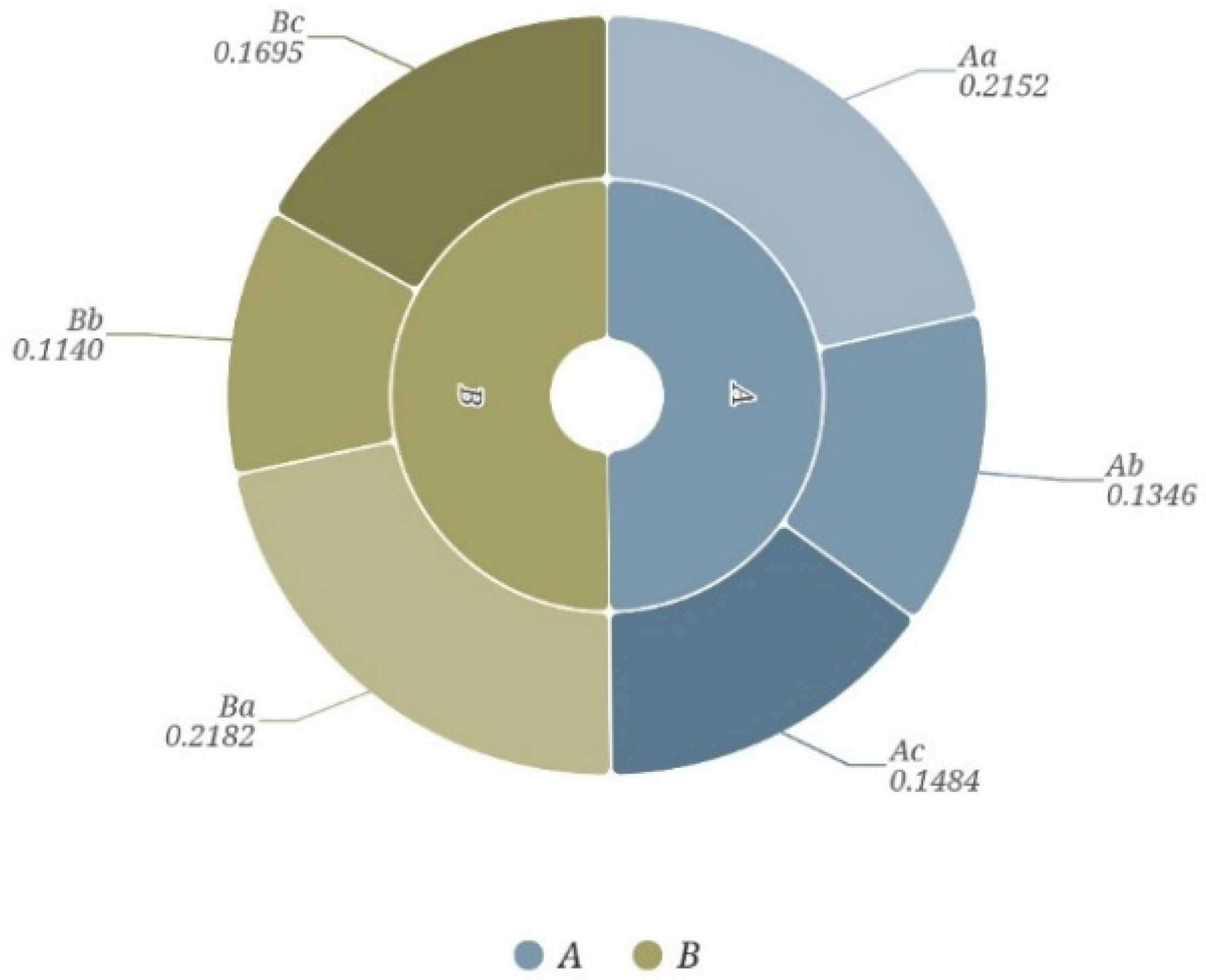

| Type | Dimension | Indicator |

|---|---|---|

| Digital Investment (A) | Talent Investment (Aa) | Number of employees in the software and information technology services industries (Aa1) |

| Number of people working in the computer, communications, and other electronic equipment manufacturing industries (Aa2) | ||

| The full-time equivalent of R&D personnel in manufacturing enterprises above the designated size (Aa3) | ||

| Digital Infrastructure Investment (Ab) | Number of manufacturing enterprises in the electronic information industry (Ab1) | |

| The proportion of enterprises with e-commerce transaction activities (Ab2) | ||

| R & D funding investment (Ab3) | ||

| Number of computers used per every hundred people (Ab4) | ||

| Every 100 enterprises have websites (Ab5) | ||

| Digital Effectiveness (B) | Technical and Economic Benefits (Ba) | The total output value of the computer, communications, and other electronic equipment manufacturing industry (Ba1) |

| Software business revenue (Ba2) | ||

| Income from the high-tech industries (Ba3) | ||

| Telecom business volume (Ba4) | ||

| Number of patent applications (Ba5) | ||

| E-commerce sales volume (Ba6) | ||

| Ecological Benefit (Bb) | Unit amount of energy consumption (Bb1) | |

| Investment in industrial pollution control was completed (Bb2) |

| Type | Indicator |

|---|---|

| Innovation Input (A) | Number of R & D active enterprises (Aa) |

| R & D funds for manufacturing enterprises above the scale (Ab) | |

| Number of R & D projects of manufacturing enterprises above the scale (Ac) | |

| Innovation Output (B) | Number of effective invention patents per unit of R&D expenditure (Ba) |

| Percentage of new product sales revenue (Bb) | |

| High-tech industry production and operation (Bc) |

| Variable | Symbol | Variable Description | |

|---|---|---|---|

| Explained Variable | Manufacturing Carbon Productivity | Cp | Manufacturing industrial output/manufacturing carbon emissions |

| Core Explanatory Variables | Digitalization of Manufacturing | Dig | Digital integration degree of manufacturing industry and regional digital level multiplier |

| Mediating Variable | Technological Innovation in Manufacturing | STI | A combined score of the entropy method for six measures |

| Control Variables | Environmental Regulation | Envir | Main business income/total energy consumption of above-scale manufacturing enterprises |

| Endowment Structure | Endow | Total assets of manufacturing enterprises above the scale/number of all employees | |

| Foreign Investment | FDI | Foreign-invested and Hong-Kong-, Macao-, and Taiwan-invested manufacturing enterprises’ main business income/above-scale manufacturing enterprises’ main business income | |

| firm scale | Scal | The main business income of manufacturing enterprises above the scale/number of enterprise units | |

| Variables | N | Mean | sd | Min | Max |

|---|---|---|---|---|---|

| Cp | 240 | 0.976 | 0.671 | 0.163 | 3.678 |

| SIT | 240 | 0.285 | 0.146 | 0.0644 | 0.710 |

| Dig | 240 | 0.110 | 0.0572 | 0.0238 | 0.373 |

| Envir | 240 | 1.847 | 1.146 | 0.216 | 4.835 |

| Endow | 240 | 5.159 | 0.610 | 3.910 | 6.606 |

| FDI | 240 | 0.180 | 0.147 | 0.0112 | 0.618 |

| Scal | 240 | 3.374 | 1.014 | 1.536 | 7.504 |

| Variable | Cp | STI | Dig | Envir | Endow | FDI | Scal |

|---|---|---|---|---|---|---|---|

| Cp | 1 | ||||||

| SIT | 0.785 *** | 1 | |||||

| Dig | 0.792 *** | 0.851 *** | 1 | ||||

| Envir | 0.726 *** | 0.508 *** | 0.436 *** | 1 | |||

| Endow | −0.272 *** | −0.0700 | 0.0470 | −0.714 *** | 1 | ||

| FDI | 0.700 *** | 0.577 *** | 0.637 *** | 0.562 *** | −0.263 *** | 1 | |

| Scal | 0.0670 | 0.0270 | 0.272 *** | −0.234 *** | 0.594 *** | 0.205 *** | 1 |

| Variable | Unit Root Test | Multiple Collinearity Test | |

|---|---|---|---|

| The Adjusted T-Statistic | p | The Coefficient of Variance Inflation | |

| Cp | −3.578 | 0.006 *** | |

| SIT | −3.994 | 0.001 *** | 4.858 |

| Dig | −4.803 | 0.000 *** | 5.115 |

| Envir | −5.309 | 0.000 *** | 4.270 |

| Endow | −2.974 | 0.021 ** | 4.828 |

| Fdi | −2.573 | 0.066 ** | 2.355 |

| Scal | −4.514 | 0.000 *** | 2.463 |

| Variable | Model (5) Cp | Model (6) Cp | Model (7) STI | Model (8) Cp |

|---|---|---|---|---|

| Dig | 5.434 *** | 1.906 *** | 3.884 *** | |

| (7.98) | (18.78) | (3.98) | ||

| SIT | 1.889 *** | 0.813 ** | ||

| (7.34) | (2.42) | |||

| Envir | 0.318 *** | 0.311 *** | 0.034 *** | 0.290 *** |

| (11.40) | (10.22) | (4.23) | (12.10) | |

| Endow | 0.196 *** | 0.178 *** | 0.070 *** | 0.139 *** |

| (3.47) | (3.17) | (4.25) | (2.84) | |

| FDI | 0.733 *** | 0.901 *** | 0.090 * | 0.660 *** |

| (3.80) | (5.55) | (1.65) | (3.68) | |

| Scal | −0.047 | 0.029 | −0.044 *** | −0.011 |

| (−1.25) | (0.73) | (−6.65) | (−0.35) | |

| Constant | −1.194 *** | −1.312 *** | −0.216 *** | −1.019 *** |

| (−4.80) | (−4.33) | (−2.75) | (−4.40) | |

| Year | Yes | Yes | Yes | Yes |

| N | 240 | 240 | 240 | 240 |

| R2 | 0.817 | 0.802 | 0.790 | 0.823 |

| F | 163.4 | 160.9 | 268.9 | 159.5 |

| Variable | Eastern | Central | Western | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model (5) Cp | Model (7) STI | Model (8) Cp | Model (5) Cp | Model (7) STI | Model (8) Cp | Model (5) Cp | Model (7) STI | Model (8) Cp | |

| Dig | 9.658 *** | 1.612 *** | 7.809 *** | 3.916 *** | 2.531 *** | −2.099 | 1.583 ** | 1.741 *** | 4.743 *** |

| (10.54) | (7.79) | (6.50) | (2.71) | (8.20) | (−0.89) | (2.20) | (8.86) | (4.34) | |

| SIT | 1.147 *** | 2.377 *** | −1.815 *** | ||||||

| (3.15) | (3.69) | (−3.86) | |||||||

| Envir | 0.317 *** | 0.059 *** | 0.249 *** | 0.108 | −0.036 *** | 0.193 ** | 0.476 *** | 0.048 ** | 0.563 *** |

| (9.08) | (5.53) | (7.87) | (1.30) | (−2.78) | (2.57) | (5.21) | (2.19) | (6.93) | |

| Endow | 0.411 *** | 0.173 *** | 0.212 * | −0.207 | 0.064 *** | −0.358 *** | 0.172 ** | 0.047 * | 0.258 *** |

| (3.71) | (4.20) | (1.96) | (−1.32) | (2.77) | (−2.70) | (2.00) | (1.92) | (3.02) | |

| FDI | −0.511 * | −0.045 | −0.459 * | 2.178 * | −0.208 | 2.674 ** | 0.338 | −0.019 | 0.303 |

| (−1.84) | (−0.56) | (−1.80) | (1.73) | (−0.95) | (2.70) | (0.80) | (−0.15) | (0.73) | |

| Scal | −0.244 *** | −0.068 *** | −0.166 *** | −0.011 | −0.071 *** | 0.158 ** | −0.036 | −0.033 *** | −0.096 *** |

| (−4.26) | (−4.98) | (−3.01) | (−0.15) | (−7.77) | (2.25) | (−1.14) | (−4.14) | (−2.93) | |

| Constant | −1.684 *** | −0.603 *** | −0.993 ** | 0.981 * | 0.029 | 0.913 * | −0.856 * | −0.128 | −1.089 ** |

| (−4.01) | (−3.33) | (−2.37) | (1.79) | (0.30) | (1.84) | (−1.91) | (−1.05) | (−2.56) | |

| Year | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| N | 80 | 80 | 80 | 48 | 48 | 48 | 88 | 88 | 88 |

| R2 | 0.875 | 0.763 | 0.885 | 0.731 | 0.893 | 0.784 | 0.712 | 0.826 | 0.760 |

| F | 121.5 | 83.75 | 114.3 | 113.4 | 77.93 | 69.11 | 94.35 | 149.5 | 54.57 |

| Variables | Model (5) Cp | Model (6) Cp | Model (7) STI | Model (8) Cp |

|---|---|---|---|---|

| Dig | 6.627 *** | 1.916 *** | 5.128 *** | |

| (8.18) | (17.23) | (4.32) | ||

| STI | 2.164*** | 0.782 * | ||

| (7.15) | (1.95) | |||

| Envir | 0.278 *** | 0.275 *** | 0.031 *** | 0.254 *** |

| (9.90) | (8.14) | (3.81) | (10.59) | |

| Endow | 0.132 ** | 0.108 * | 0.068 *** | 0.079 |

| (2.24) | (1.73) | (4.19) | (1.52) | |

| FDI | 0.699 *** | 0.984 *** | 0.091 | 0.627 *** |

| (3.34) | (5.52) | (1.62) | (3.17) | |

| Scal | −0.054 | 0.028 | −0.040 *** | −0.022 |

| (−1.35) | (0.69) | (−5.94) | (−0.68) | |

| Constant | −0.801 *** | −0.894 ** | −0.216 *** | −0.632 ** |

| (−3.04) | (−2.53) | (−2.78) | (−2.51) | |

| Year | Yes | Yes | Yes | Yes |

| N | 210 | 210 | 210 | 210 |

| R2 | 0.819 | 0.793 | 0.788 | 0.824 |

| F | 155.9 | 147.0 | 221.6 | 152.7 |

| Impact | The Direct Effect of Dig on Cp | |||

|---|---|---|---|---|

| parameter | Effect | SE | LLCI | ULCI |

| figure | 0.4495 | 0.0707 | 0.3102 | 0.5888 |

| impact | The indirect effect of Dig on Cp | |||

| parameter | Effect | BootSE | BootLLCI | BootULCI |

| figure | 0.3429 | 0.0858 | 0.1705 | 0.5093 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Lai, S.; Lu, M.; Li, Y. Digitalization, Carbon Productivity and Technological Innovation in Manufacturing—Evidence from China. Sustainability 2023, 15, 11014. https://doi.org/10.3390/su151411014

Li G, Lai S, Lu M, Li Y. Digitalization, Carbon Productivity and Technological Innovation in Manufacturing—Evidence from China. Sustainability. 2023; 15(14):11014. https://doi.org/10.3390/su151411014

Chicago/Turabian StyleLi, Gang, Sen Lai, Mengyu Lu, and Yonghong Li. 2023. "Digitalization, Carbon Productivity and Technological Innovation in Manufacturing—Evidence from China" Sustainability 15, no. 14: 11014. https://doi.org/10.3390/su151411014

APA StyleLi, G., Lai, S., Lu, M., & Li, Y. (2023). Digitalization, Carbon Productivity and Technological Innovation in Manufacturing—Evidence from China. Sustainability, 15(14), 11014. https://doi.org/10.3390/su151411014