Development of Sustainable Concrete from Hypo Sludge Combined with Basalt Fibre and Latex

Abstract

1. Introduction

2. Experimental Methodology

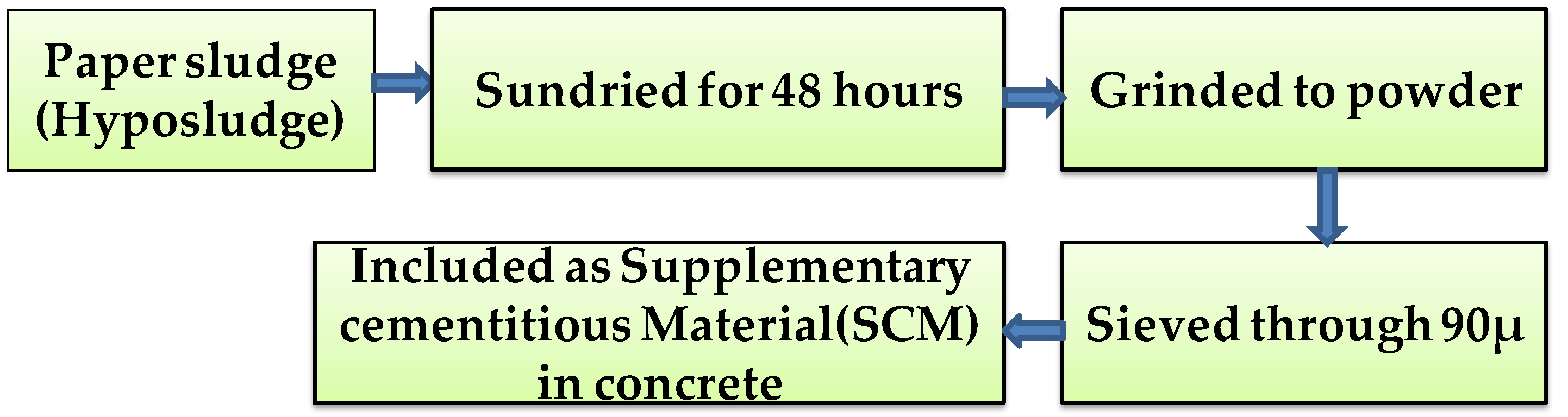

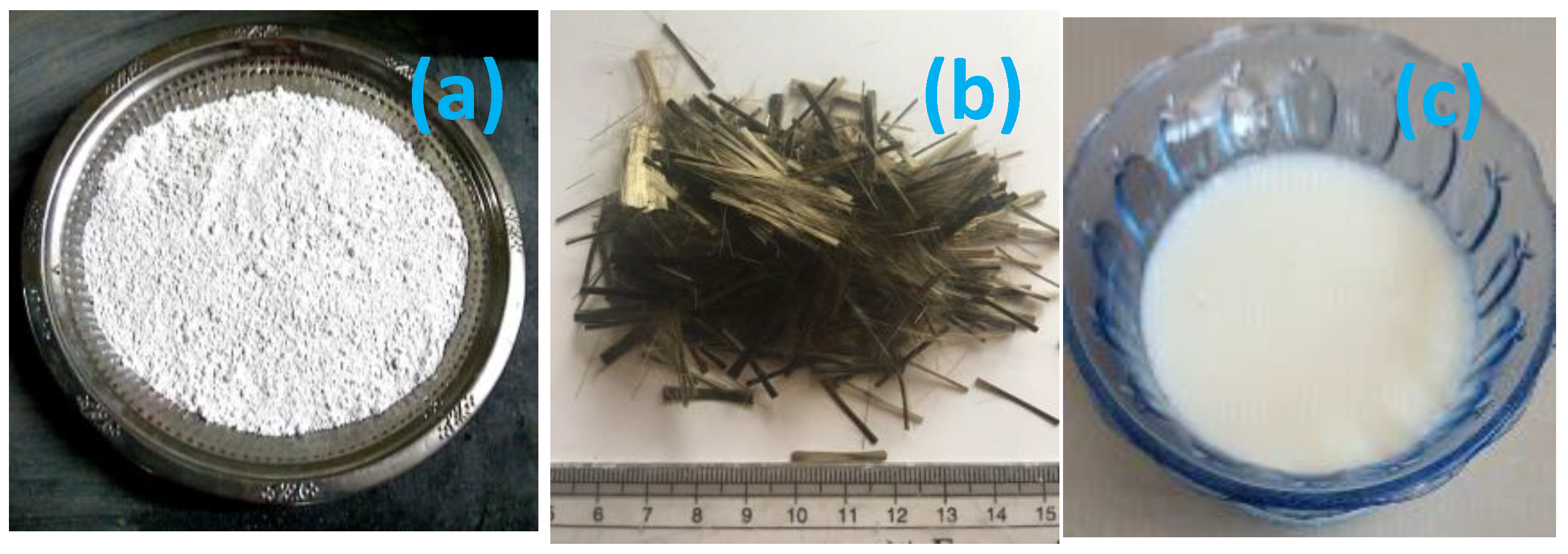

2.1. Materials

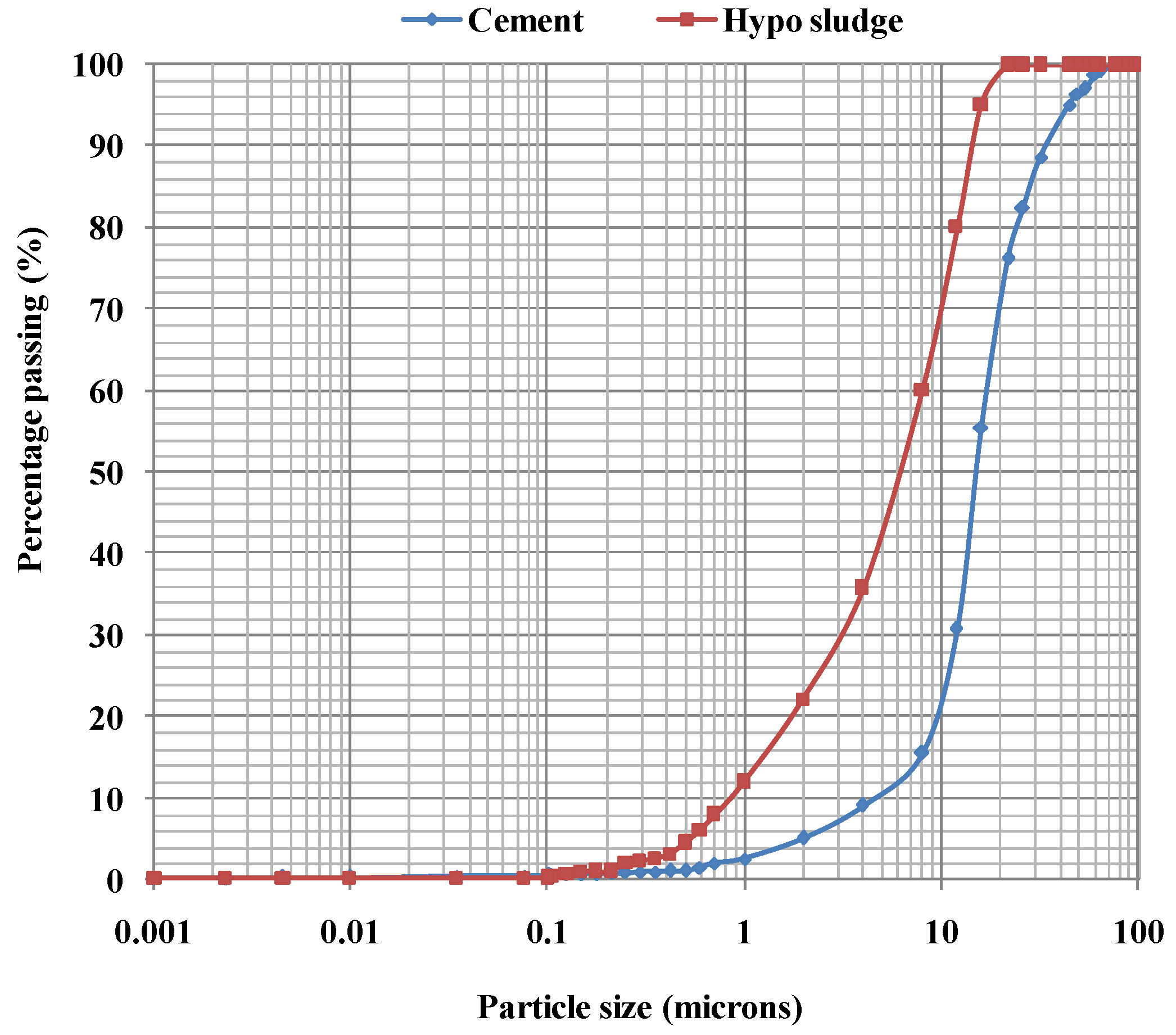

2.2. Preliminary Investigations

2.3. Mix Proportions and Testing Methods

3. Experimental Program

3.1. Mechanical Testing

3.2. Durability Testing

3.3. Microstructural Testing

4. Results and Discussions

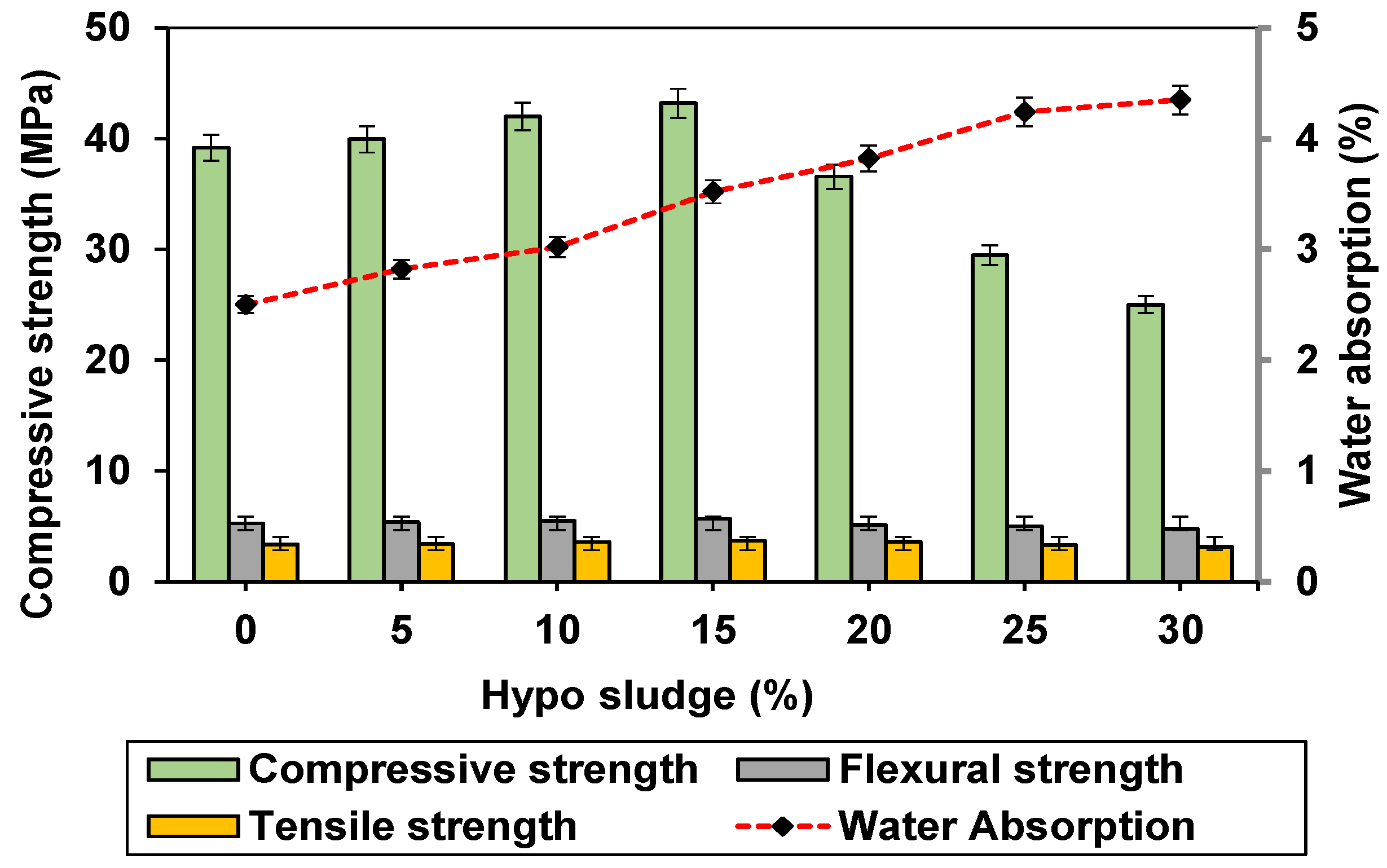

4.1. Mechanical Properties

4.1.1. Compressive Strength

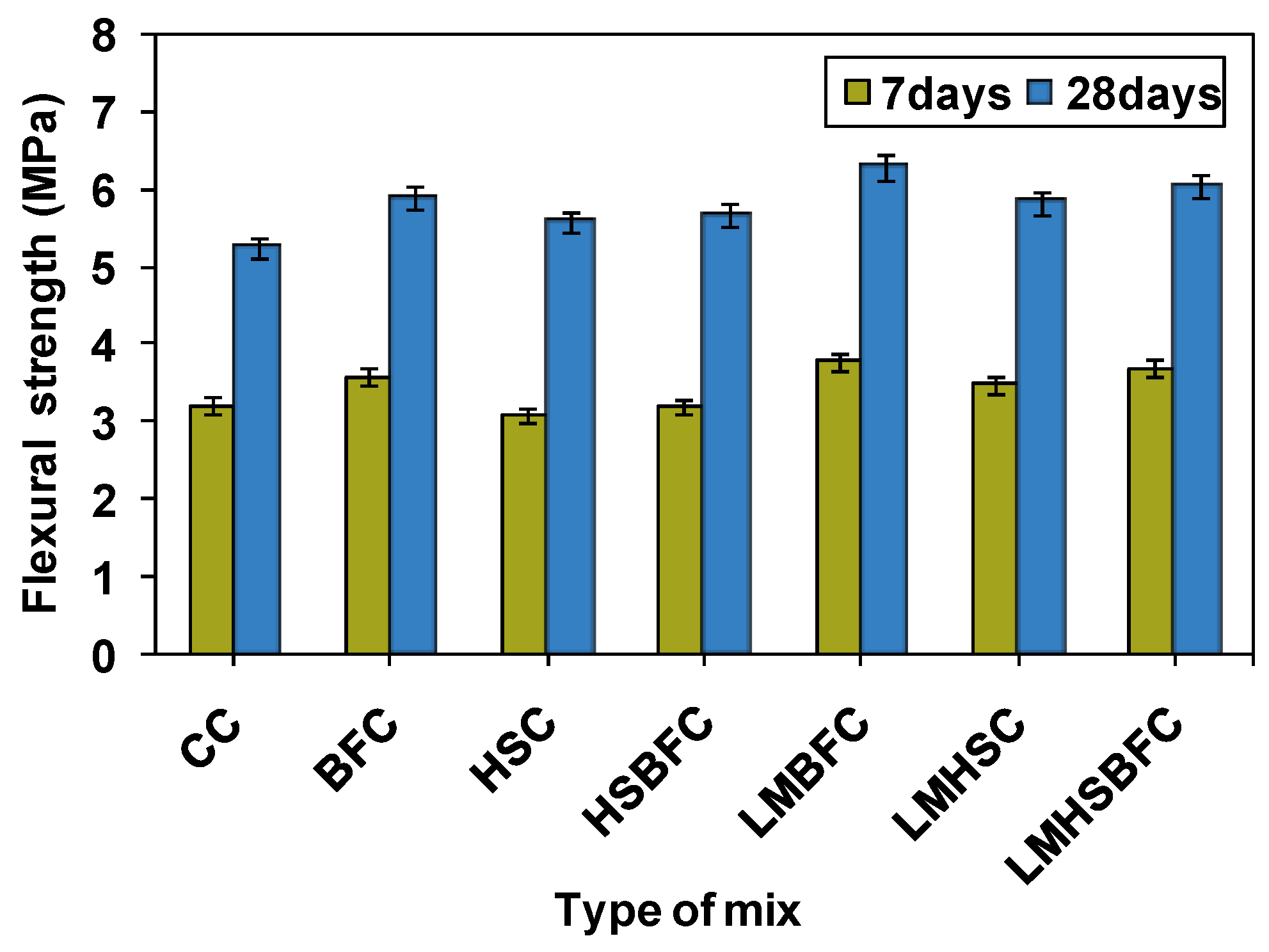

4.1.2. Flexural Strength

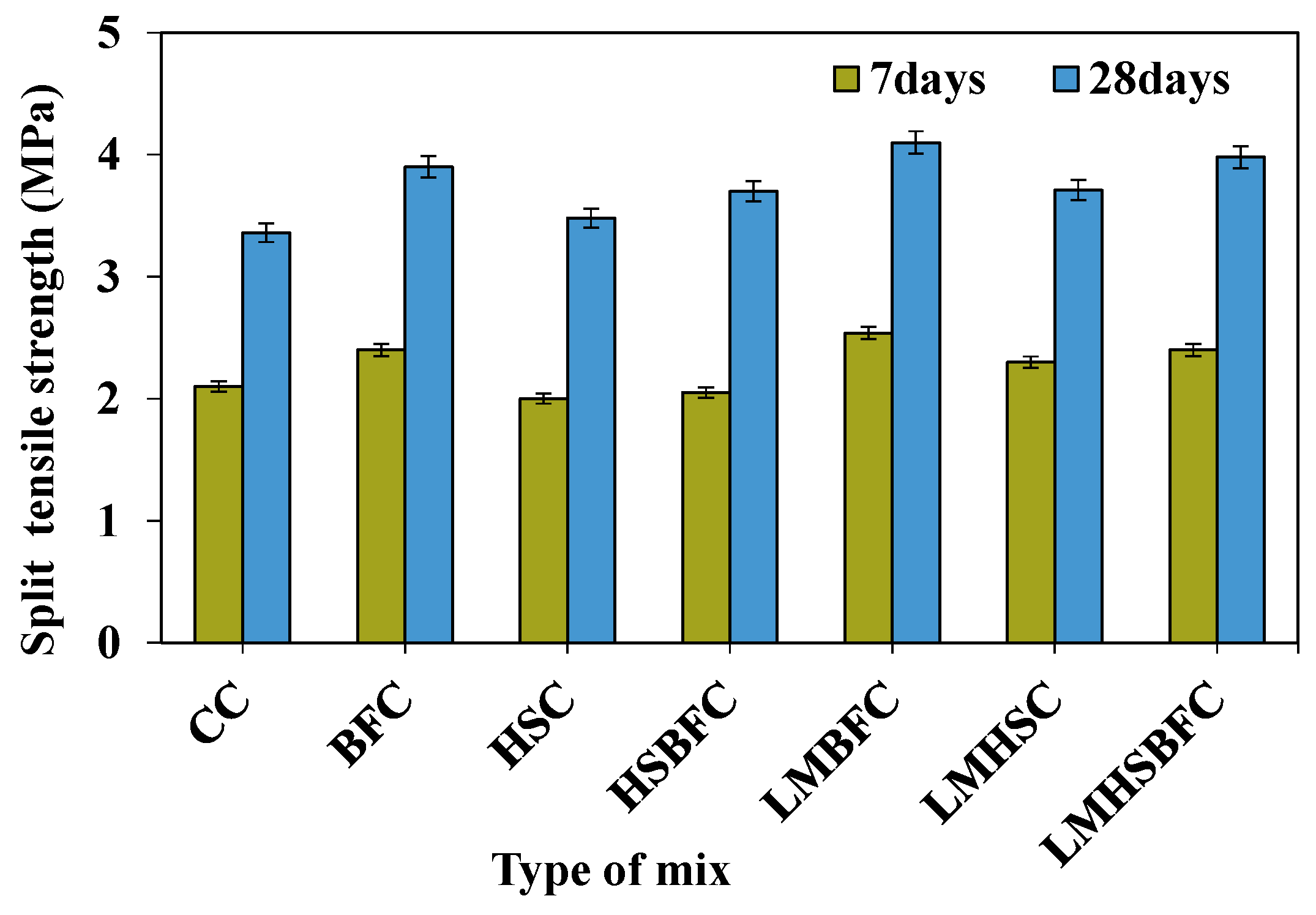

4.1.3. Split Tensile Strength

4.2. Durability Properties

4.2.1. Water Properties

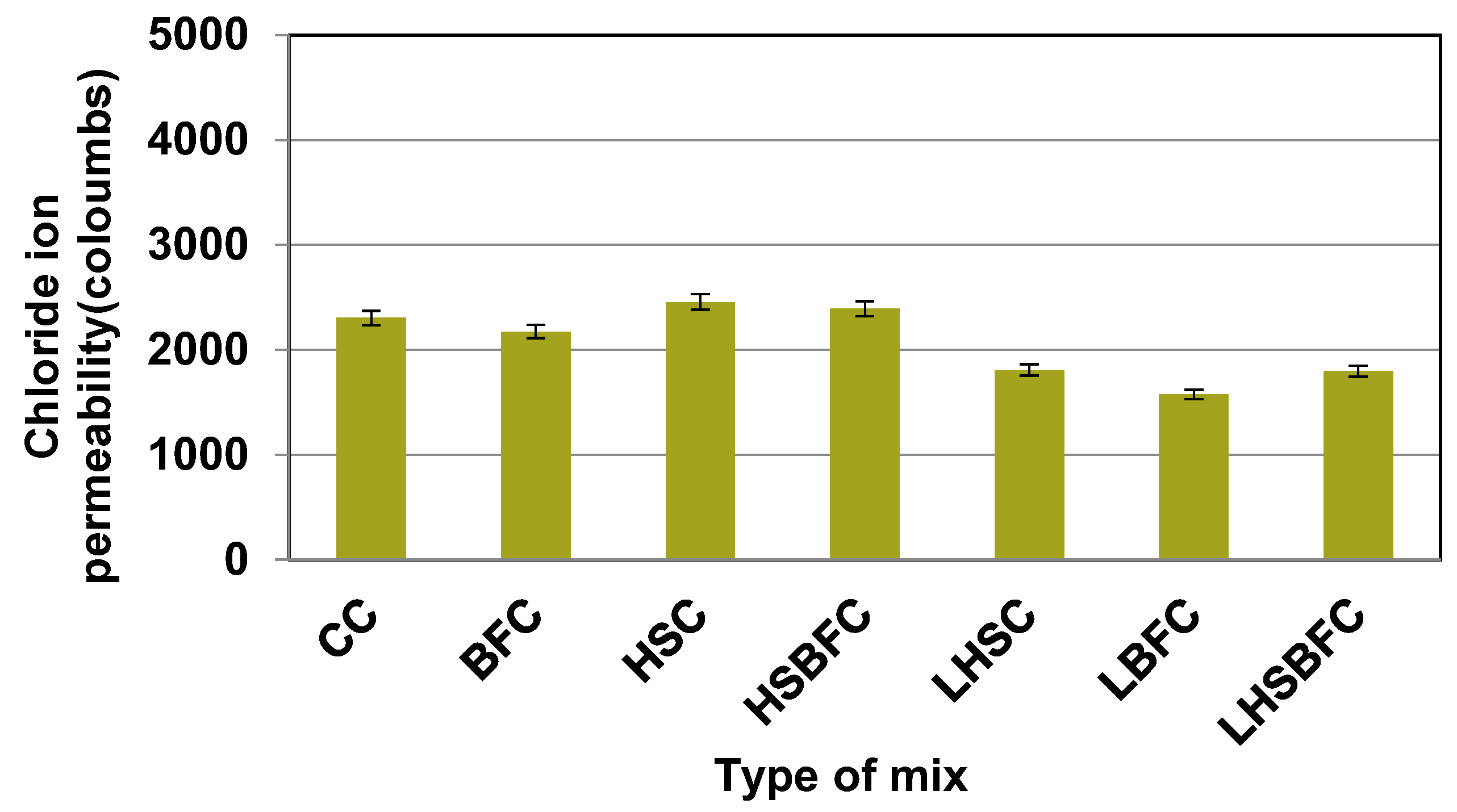

4.2.2. Rapid Chloride Ion Penetration Test

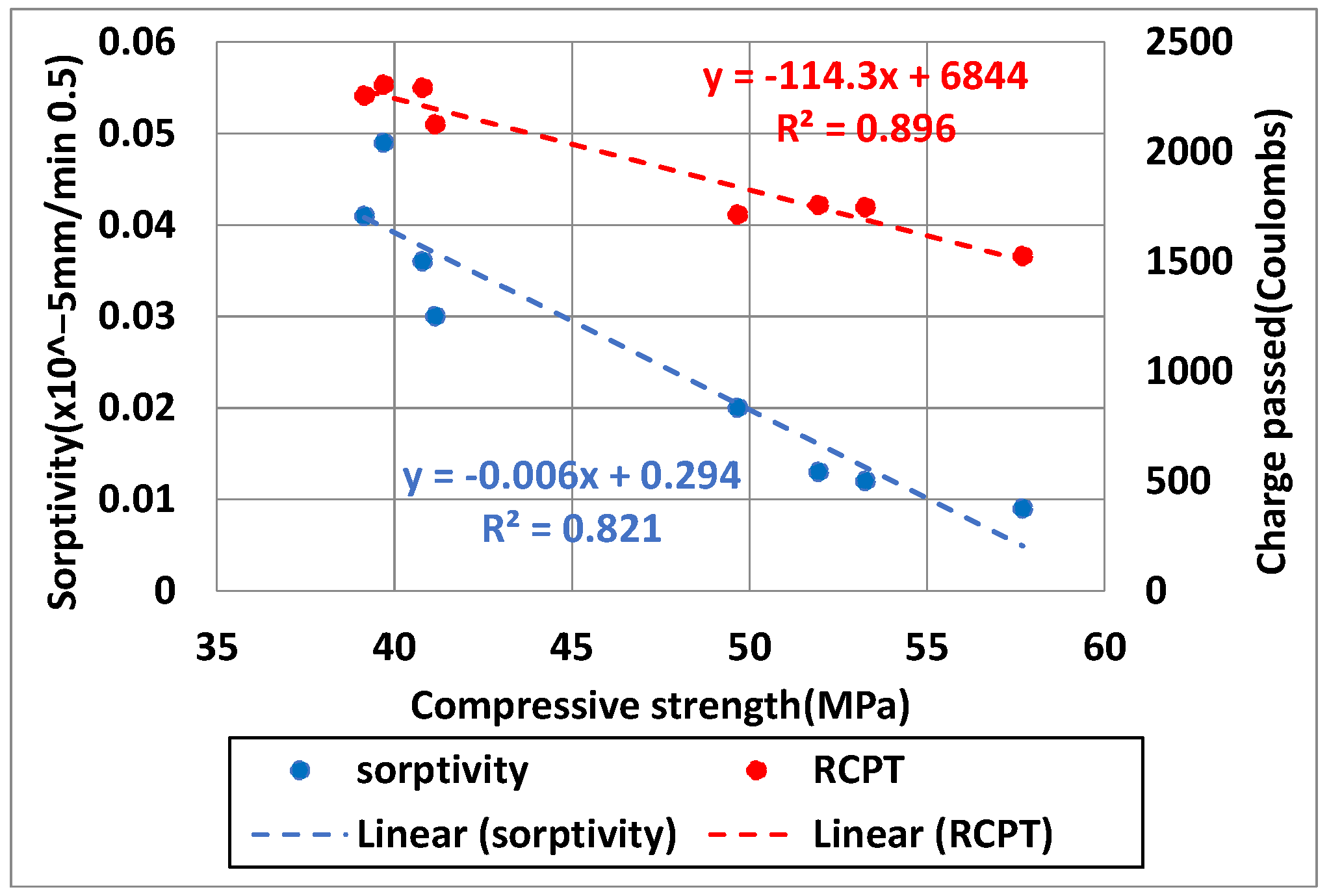

4.3. Correlation between Compressive Strength and Durability Properties

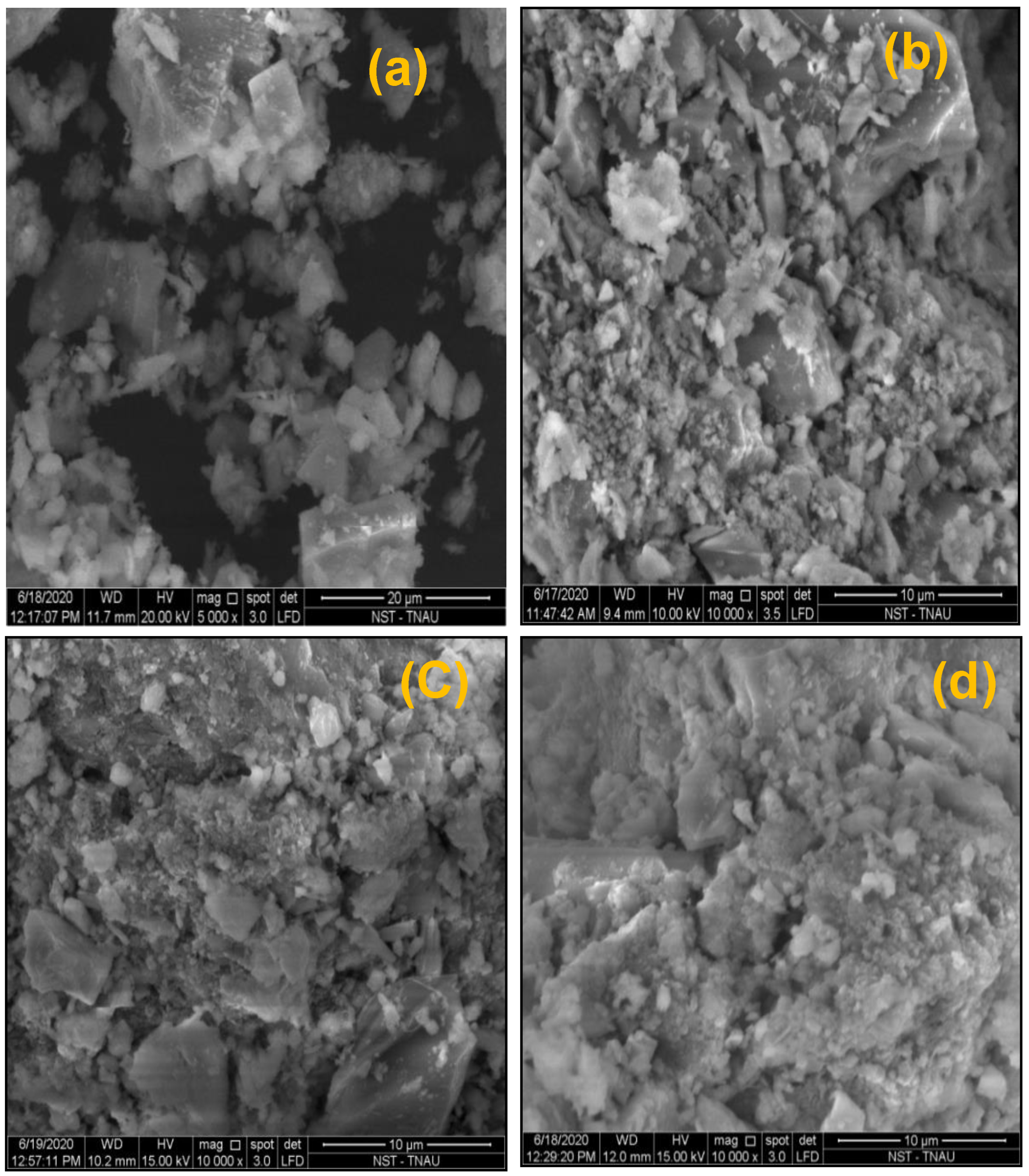

4.4. Microstructural Studies

SEM Analysis

5. Conclusions

- The waste from paper industry can be used as partial replacement for cement for making ecofriendly sustainable concrete and it will reduce the emission of CO2 and landfill problems. Utilising the waste material can reduce the amount of cement used in concrete construction.

- In comparison to the control concrete, the addition of hypo sludge at 15% for replacement of cement with 0.3% BF and 10% SBR latex significantly increased compressive strength by 17.08%, and the LMHSBFC mix significantly increased flexural strength by 14.55% at 28 days.

- Compared with the control concrete, the mix LMHSBFC significantly increased split tensile strength by 14.29%. In order to increase the splitting tensile strength of concrete, hypo sludge containing basalt fibres and SBR latex was used. In the LMBFC mix, the greatest improvement in tensile strength of 20.95% was noted.

- The mechanical qualities of hypo sludge concrete significantly improved with the addition of basalt fibres and SBR latex.

- In comparison with control concrete, the mix LMHSBFC exhibits decreased water absorption, permeability, and chloride ion penetration, as well as better concrete durability.

- Micro-structural research showed that adding hypo sludge to the concrete enhanced its interfacial interactions. Due to the creation of a film layer by SBR latex in the cement matrix and a decrease in the ITZ of the concrete, the mix LMHSBFC demonstrated a homogeneous and denser microstructure when compared with the control concrete.

Author Contributions

Funding

Institutional review board statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tripathi, J.G. Study of India’s Paper Industry-Potential and Growth in 21st Century. Indian J. Appl. Res. 2011, 4, 112–115. [Google Scholar] [CrossRef]

- Pokhrel, D.; Viraraghavan, T. Treatment of Pulp and Paper Mill Wastewater—A Review. Sci. Total Environ. 2004, 333, 37–58. [Google Scholar] [CrossRef]

- Sumathi, S.; Hung, Y.T. Treatment of Pulp and Paper Mill Wastes. Waste Treat. Process Ind. 2005, 495–542. [Google Scholar]

- Letelier, V.; Tarela, E.; Osses, R.; Cárdenas, J.P.; Moriconi, G. Mechanical Properties of Concrete with Recycled Aggregates and Waste Glass. Struct. Concr. 2017, 18, 40–53. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ghaderi, A. Experimental Investigation of Waste Glass Powder, Basalt Fibre, and Carbon Nanotube on the Mechanical Properties of Concrete. Constr. Build. Mater. 2020, 252, 119115. [Google Scholar] [CrossRef]

- Ofuyatan, O.M.; Adeniyi, A.G.; Ijie, D.; Ighalo, J.O.; Oluwafemi, J. Development of High-Performance Self Compacting Concrete Using Eggshell Powder and Blast Furnace Slag as Partial Cement Replacement. Constr. Build. Mater. 2020, 256, 119403. [Google Scholar] [CrossRef]

- Chithambaram, S.J.; Kumar, S.; Prasad, M.M.; Adak, D. Effect of Parameters on the Compressive Strength of Fly Ash Based Geopolymer Concrete. Struct. Concr. 2018, 19, 1202–1209. [Google Scholar] [CrossRef]

- Molaei Raisi, E.; Vaseghi Amiri, J.; Davoodi, M.R. Mechanical Performance of Self-Compacting Concrete Incorporating Rice Husk Ash. Constr. Build. Mater. 2018, 177, 148–157. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Fava, G.; Ruello, M.L. Paper Mill Sludge Ash as Supplementary Cementitious Material. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancone, Italy, 28–30 June 2010; pp. 85–94. [Google Scholar]

- Sundaresan, S.; Ramamurthy, V.; Meyappan, N. Improving Mechanical and Durability Properties of Hypo Sludge Concrete with Basalt Fibres and SBR Latex. Adv. Concr. Constr. 2021, 12, 327–337. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S. An Investigation on Use of Paper Mill Sludge in Brick Manufacturing. Constr. Build. Mater. 2017, 148, 334–343. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Alexandre, J.; Margem, J.I.; Sánchez, R.; Vieira, C.M.F. Incorporation of Sludge Waste from Water Treatment Plant into Red Ceramic. Constr. Build. Mater. 2008, 22, 1281–1287. [Google Scholar] [CrossRef]

- Solanki, J.; Pitroda, J. Flexural Strength of Beams by Partial Replacement of Cement with Fly Ash and Hypo Sludge in Concrete. Int. J. Eng. Sci. Innov. Technol. 2013, 2, 173–179. [Google Scholar]

- Mohammed, B.S.; Fang, O.C. Mechanical and Durability Properties of Concretes Containing Paper-Mill Residuals and Fly Ash. Constr. Build. Mater. 2011, 25, 717–725. [Google Scholar] [CrossRef]

- Segui, P.; Aubert, J.E.; Husson, B.; Measson, M. Characterization of Wastepaper Sludge Ash for Its Valorization as a Component of Hydraulic Binders. Appl. Clay Sci. 2012, 57, 79–85. [Google Scholar] [CrossRef]

- Wong, H.S.; Barakat, R.; Alhilali, A.; Saleh, M.; Cheeseman, C.R. Hydrophobic Concrete Using Waste Paper Sludge Ash. Cem. Concr. Res. 2015, 70, 9–20. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. SBR Latex Modified Mortar Rheology and Mechanical Behaviour. Cem. Concr. Res. 2004, 34, 527–535. [Google Scholar] [CrossRef]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory Evaluation of Permeability and Strength of Polymer-Modified Pervious Concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Kim, W.; Oh, R.O.; Lee, J.H.; Kim, M.S.; Jeon, S.M.; Park, C.G. Mechanical and Durability Characteristics of Latex-Modified Fiber-Reinforced Segment Concrete as a Function of Microsilica Content. Adv. Civ. Eng. 2019, 2019, 3658125. [Google Scholar] [CrossRef]

- Siddiqi, Z.A.; Hameed, R.; Saleem, M.; Khan, Q.S. Determination of compressive strength and water absorption of styrene butadiene rubber (SBR) latex modified concrete. Pak. J. Sci. 2013, 65, 124. [Google Scholar]

- Rossignolo, J.A. Interfacial Interactions in Concretes with Silica Fume and SBR Latex. Constr. Build. Mater. 2009, 23, 817–821. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural Behavior Evaluation and Energy Dissipation Mechanisms of Modified Iron Tailings Powder Incorporating Cement and Fibers Subjected to Freeze-Thaw Cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental Study on the Mechanical Properties and Microstructure of Chopped Basalt Fibre Reinforced Concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical Behaviour of Basalt Fibre Reinforced Concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Fenu, L.; Forni, D.; Cadoni, E. Dynamic Behaviour of Cement Mortars Reinforced with Glass and Basalt Fibres. Compos. Part B Eng. 2016, 92, 142–150. [Google Scholar] [CrossRef]

- Shaker, F.A.; El-Dieb, A.S.; Reda, M.M. Durability of styrene-butadiene latex modified concrete. Cem. Concr. Res. 1997, 27, 711–720. [Google Scholar] [CrossRef]

- IS:12269-1987; Specification for 53 Grade Ordinary Portland Cement. Bureau of Indian Standards: New Delhi, India, 1987.

- IS:383-1970; Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau of Indian Standards: New Delhi, India, 1970; pp. 1–24.

- IS:9103-2008; I. Specification for Concrete Admixtures. Bureau of Indian Standards: New Delhi, India, 1999; pp. 1–22.

- Vigil de la Villa, R.; Frías, M.; Sánchez de Rojas, M.I.; Vegas, I.; García, R. Mineralogical and Morphological Changes of Calcined Paper Sludge at Different Temperatures and Retention in Furnace. Appl. Clay Sci. 2007, 36, 279–286. [Google Scholar] [CrossRef]

- BIS:10262; Indian Standard Guidelines for Concrete Mix Design Proportioning. Bureau of Indian Standards: New Delhi, India, 2009.

- IS 516:2014; Method of Tests for Strength of Concrete. IS 516-1959 (Reaffirmed 2004); Bureau of Indian Standards: New Delhi, India, 2004. [CrossRef]

- BIS:5816; Indian Standard Splitting Tensile Strength of Concrete—Method of Test. Bureau of Indian Standards: New Delhi, India, 1999; pp. 1–14.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008; pp. 11–13.

- ASTM C1585:2007; ASTM Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007; pp. 1–6.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012; pp. 1–8. [CrossRef]

- Kinuthia, J. Wastepaper Sludge Ash; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; Volume 1, ISBN 9780081021569. [Google Scholar]

- Shadmani, A.; Tahmouresi, B.; Saradar, A.; Mohseni, E. Durability and Microstructure Properties of SBR-Modified Concrete Containing Recycled Asphalt Pavement. Constr. Build. Mater. 2018, 185, 380–390. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength Properties of Nylon- and Polypropylene-Fiber-Reinforced Concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Joshi, G.; Pitroda, J.R. Evaluation of Sorptivity and Water Captivation of Concrete with Partial Replacement of Cement by Hypo Sludge. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 032010. [Google Scholar] [CrossRef]

- Hassan, M.M.; Le Guen, M.J.; Tucker, N.; Parker, K. Thermo-Mechanical, Morphological and Water Absorption Properties of Thermoplastic Starch/Cellulose Composite Foams Reinforced with PLA. Cellulose 2019, 26, 4463–4478. [Google Scholar] [CrossRef]

- Sakai, E.; Sugita, J. Composite mechanism of polymer modified cement. Cem. Concr. Res. 1995, 25, 127–135. [Google Scholar] [CrossRef]

- Patel, J.; Patil, H.; Patil, Y.; Vesmawala, G. Strength and Transport Properties of Concrete with Styrene Butadiene Rubber Latex Modified Lightweight Aggregate. Constr. Build. Mater. 2019, 195, 459–467. [Google Scholar] [CrossRef]

- Zabihi, S.M.; Tavakoli, H.; Mohseni, E. Engineering and Microstructural Properties of Fiber-Reinforced Rice Husk-Ash Based Geopolymer Concrete. J. Mater. Civ. Eng. 2018, 30, 04018183. [Google Scholar] [CrossRef]

- Lu, Z.; Kong, X.; Zhang, C.; Xing, F.; Cai, Y.; Jiang, L.; Zhang, Y.; Dong, B. Effect of Surface Modification of Colloidal Particles in Polymer Latexes on Cement Hydration. Constr. Build. Mater. 2017, 155, 1147–1157. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.; Yao, H.; Farhan, S.; Zheng, S.; Wang, Z.; Du, C.; Jiang, H. Research on the Mechanism of Polymer Latex Modified Cement. Constr. Build. Mater. 2016, 111, 710–718. [Google Scholar] [CrossRef]

| Composition | Lime | Silica | Iron Oxide | Alumina | Magnesium Oxide | Loss on Ignition |

|---|---|---|---|---|---|---|

| Hypo sludge (%) | 27.03 | 20.56 | 26.74 | 19.35 | 6.32 | 3.04 |

| Parameters | Density (kg/dm3) | Melting Point (°C) | Diameter (μm) | Length (mm) | Moisture Content (%) | Thermal Conductivity |

|---|---|---|---|---|---|---|

| Values | 2.8 | 1350 | 13 | 18 | <0.3 | Low |

| Description | Styrene Content (%) | Butadiene Content (%) | Density (g/mm3) | Colour | pH |

|---|---|---|---|---|---|

| Values | 34 ± 1.5 | 66 ± 1.5 | 1.03 | White | 11 |

| Mix Id | w/c | BF (%) | SBR (%) | HS (kg/m3) | Cement (kg/m3) | FA (kg/m3) | CA (kg/m3) | Water (kg/m3) | SP (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| CC | 0.45 | 0 | 0 | 0 | 338 | 757 | 1107 | 197 | 0 |

| BFC | 0.45 | 0.3 | 0 | 0 | 338 | 757 | 1107 | 197 | 4.8 |

| HSC | 0.45 | 0 | 0 | 51 | 287 | 757 | 1107 | 197 | 4.8 |

| HSBFC | 0.45 | 0.3 | 0 | 51 | 287 | 757 | 1107 | 197 | 4.8 |

| LMBFC | 0.45 | 0.3 | 10 | 0 | 338 | 757 | 1107 | 131 | 4.8 |

| LMHSC | 0.45 | 0 | 10 | 51 | 287 | 757 | 1107 | 131 | 4.8 |

| LMHSBFC | 0.45 | 0.3 | 10 | 51 | 287 | 757 | 1107 | 131 | 4.8 |

| Charge Passed (Coulombs) | Chloride Ion Penetrability |

|---|---|

| >4000 | High |

| 2000–4000 | Moderate |

| 1000–2000 | Low |

| 100–1000 | Very low |

| <100 | Negligible |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandra Sekar, K.; Murugesan, R.; Sivaraja, M.; Prakash, R. Development of Sustainable Concrete from Hypo Sludge Combined with Basalt Fibre and Latex. Sustainability 2023, 15, 10986. https://doi.org/10.3390/su151410986

Chandra Sekar K, Murugesan R, Sivaraja M, Prakash R. Development of Sustainable Concrete from Hypo Sludge Combined with Basalt Fibre and Latex. Sustainability. 2023; 15(14):10986. https://doi.org/10.3390/su151410986

Chicago/Turabian StyleChandra Sekar, Krishnan, Ramasamy Murugesan, Muthusamy Sivaraja, and Ramaiah Prakash. 2023. "Development of Sustainable Concrete from Hypo Sludge Combined with Basalt Fibre and Latex" Sustainability 15, no. 14: 10986. https://doi.org/10.3390/su151410986

APA StyleChandra Sekar, K., Murugesan, R., Sivaraja, M., & Prakash, R. (2023). Development of Sustainable Concrete from Hypo Sludge Combined with Basalt Fibre and Latex. Sustainability, 15(14), 10986. https://doi.org/10.3390/su151410986