Study on Surrounding Rock Failure Law of Gob-Side Entry Based on the Second Invariant of Deviatoric Stress

Abstract

:1. Introduction

2. Simulation Model and Parameters

2.1. Theory of Second Deviator Stress Invariant

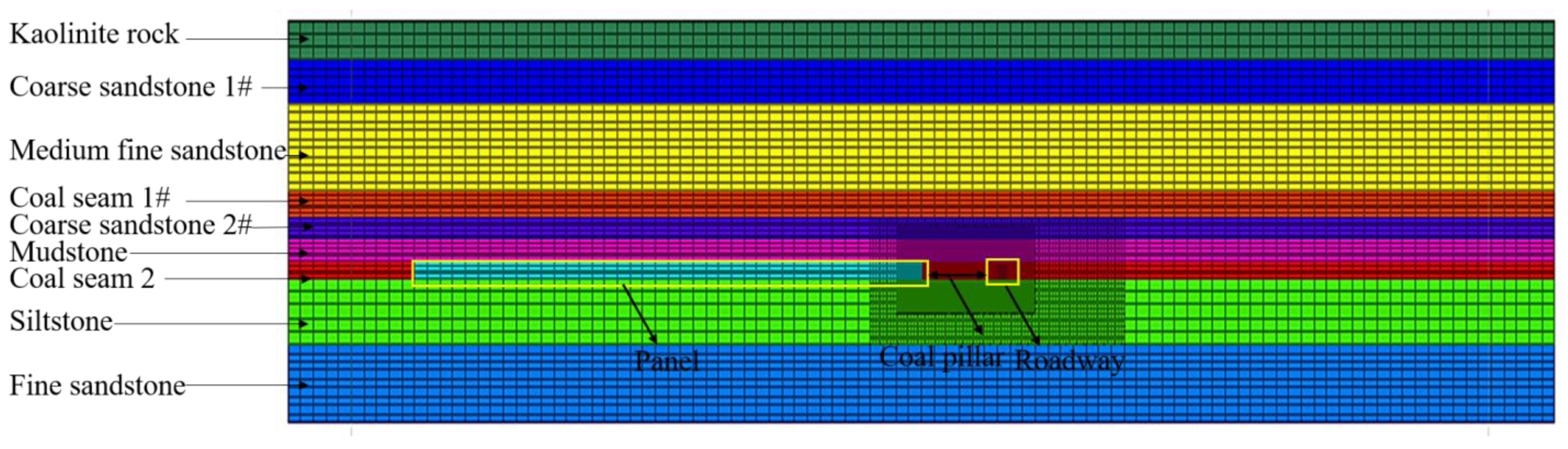

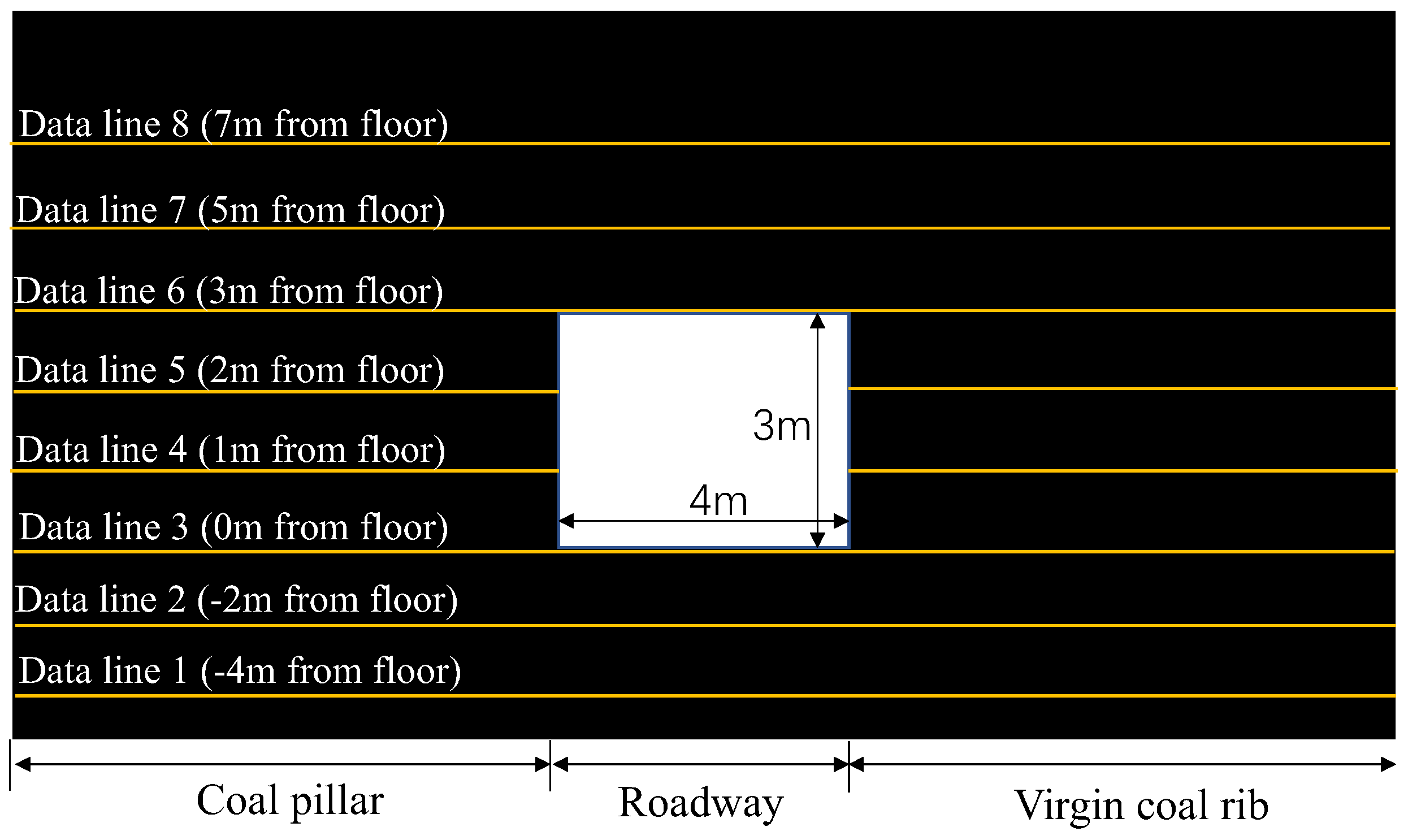

2.2. Global Model for Pillar Width

2.3. Simulation Parameters and Constitutive Relation of the Rock and Coal Seam

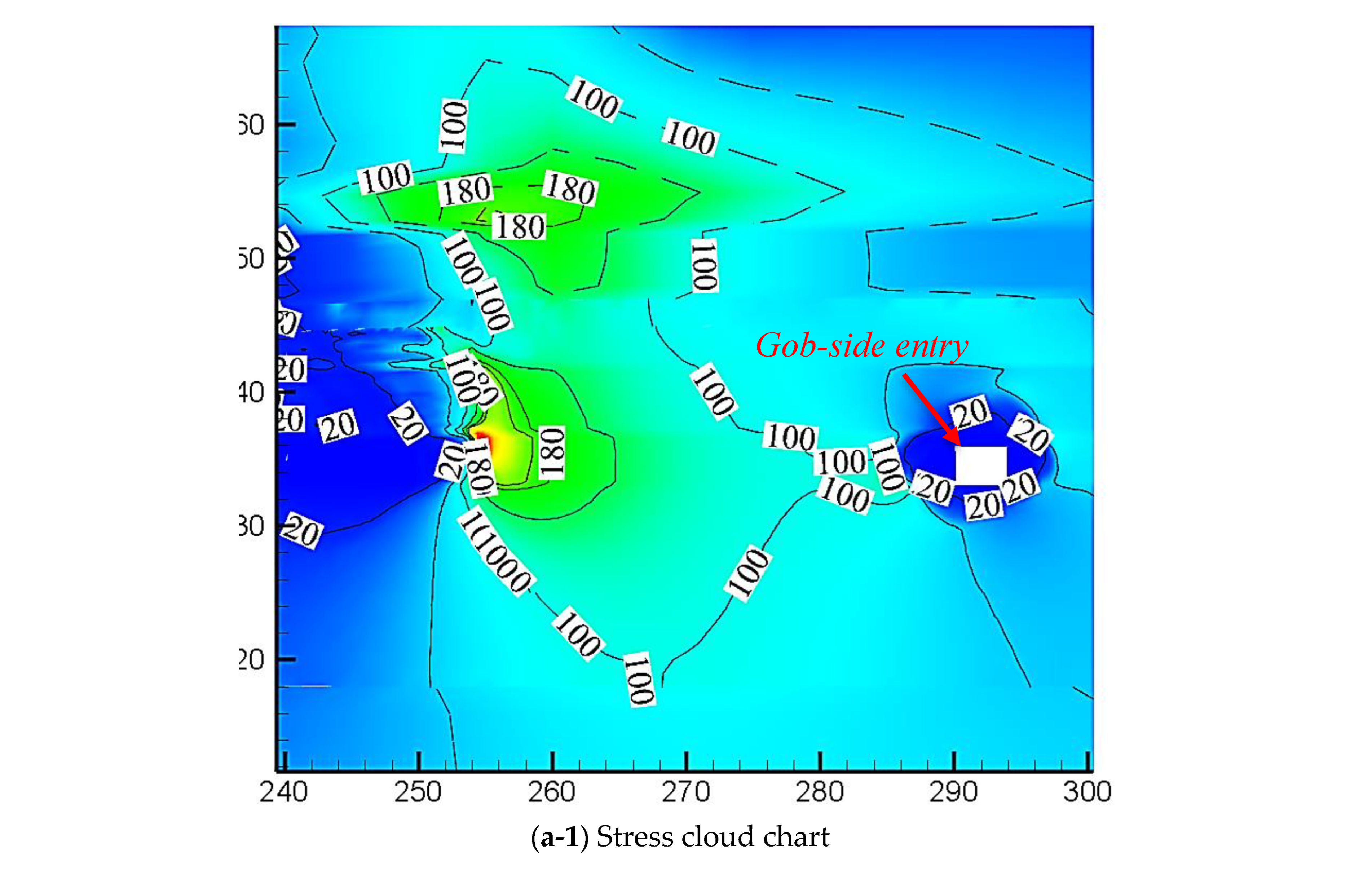

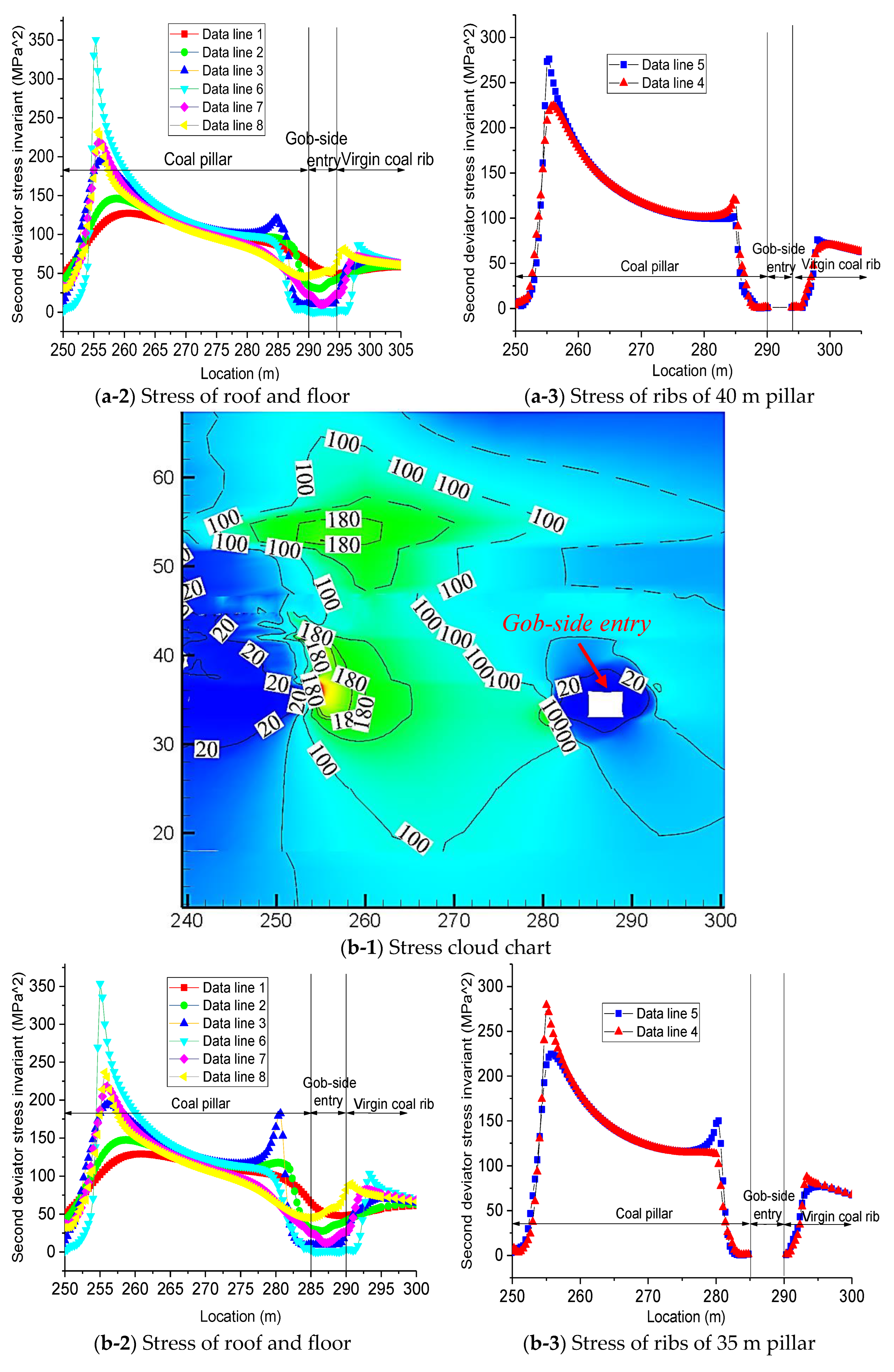

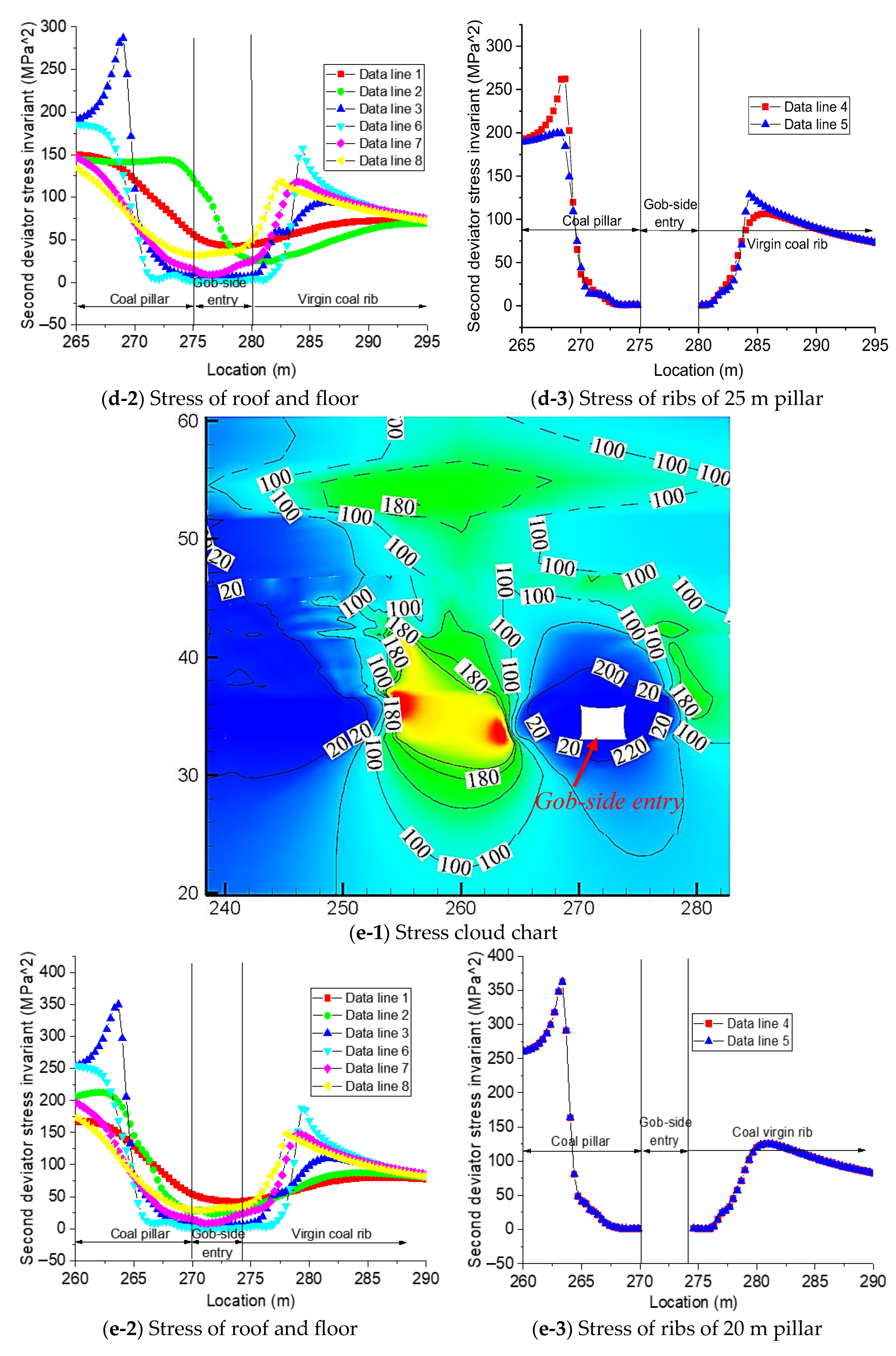

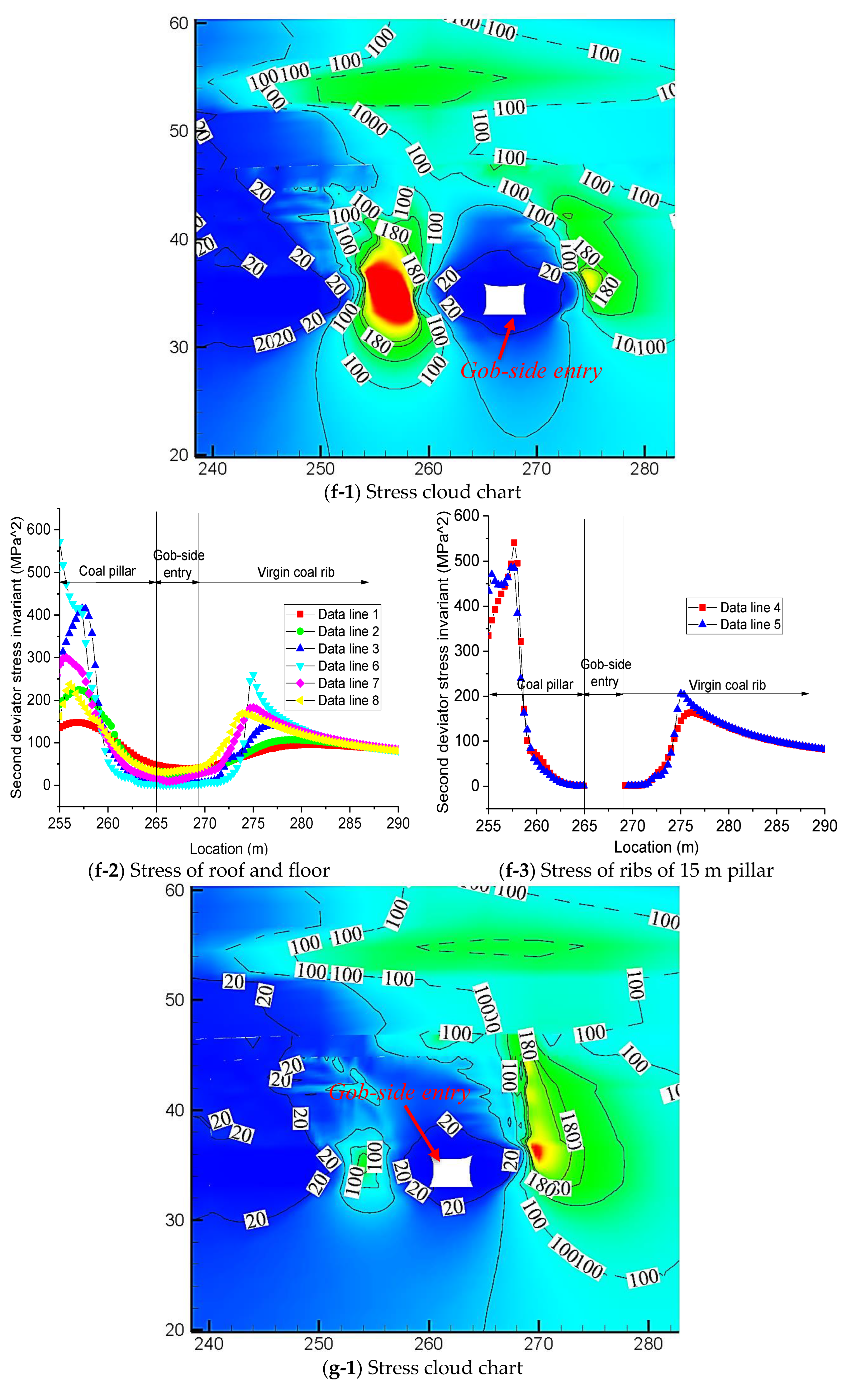

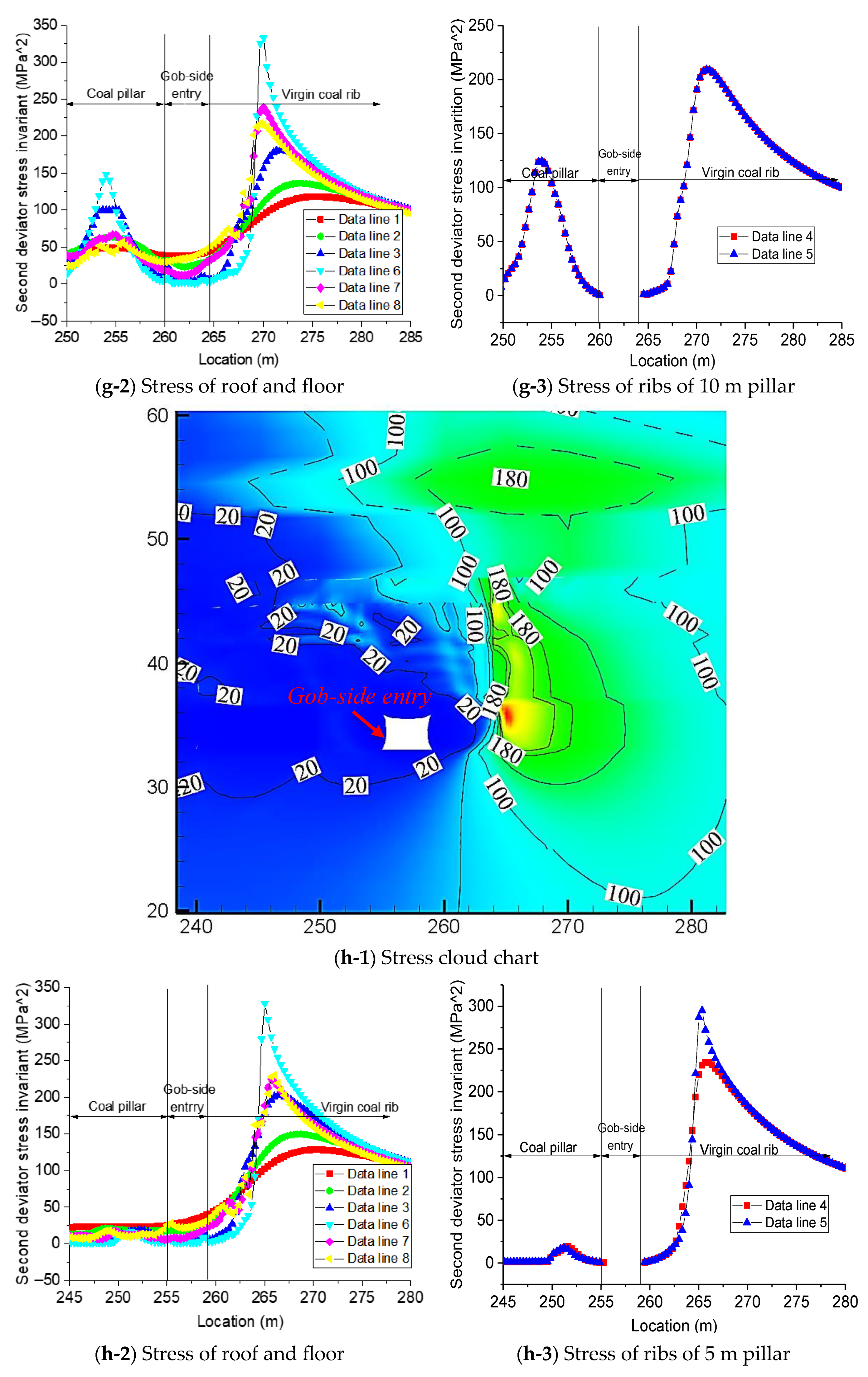

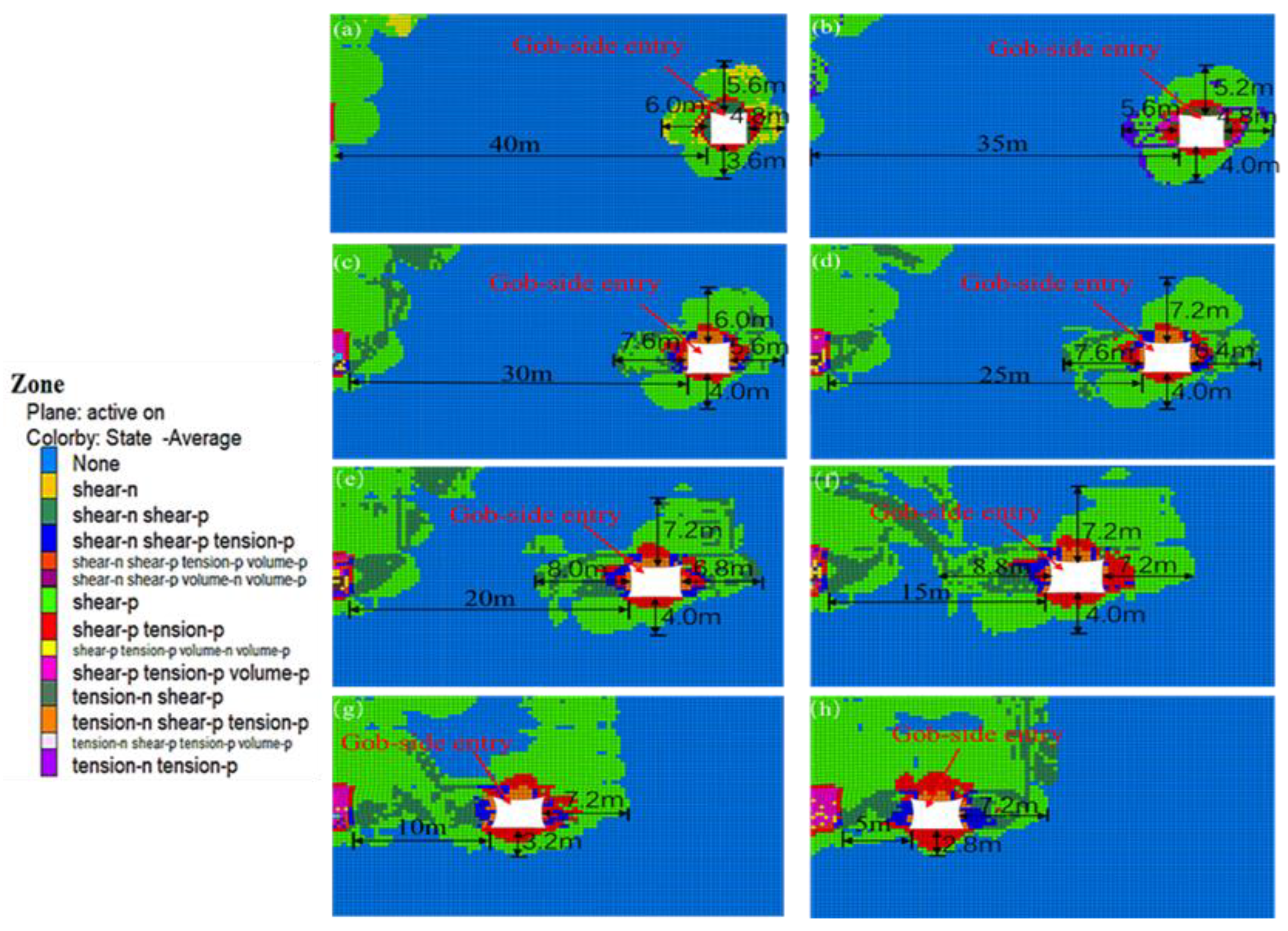

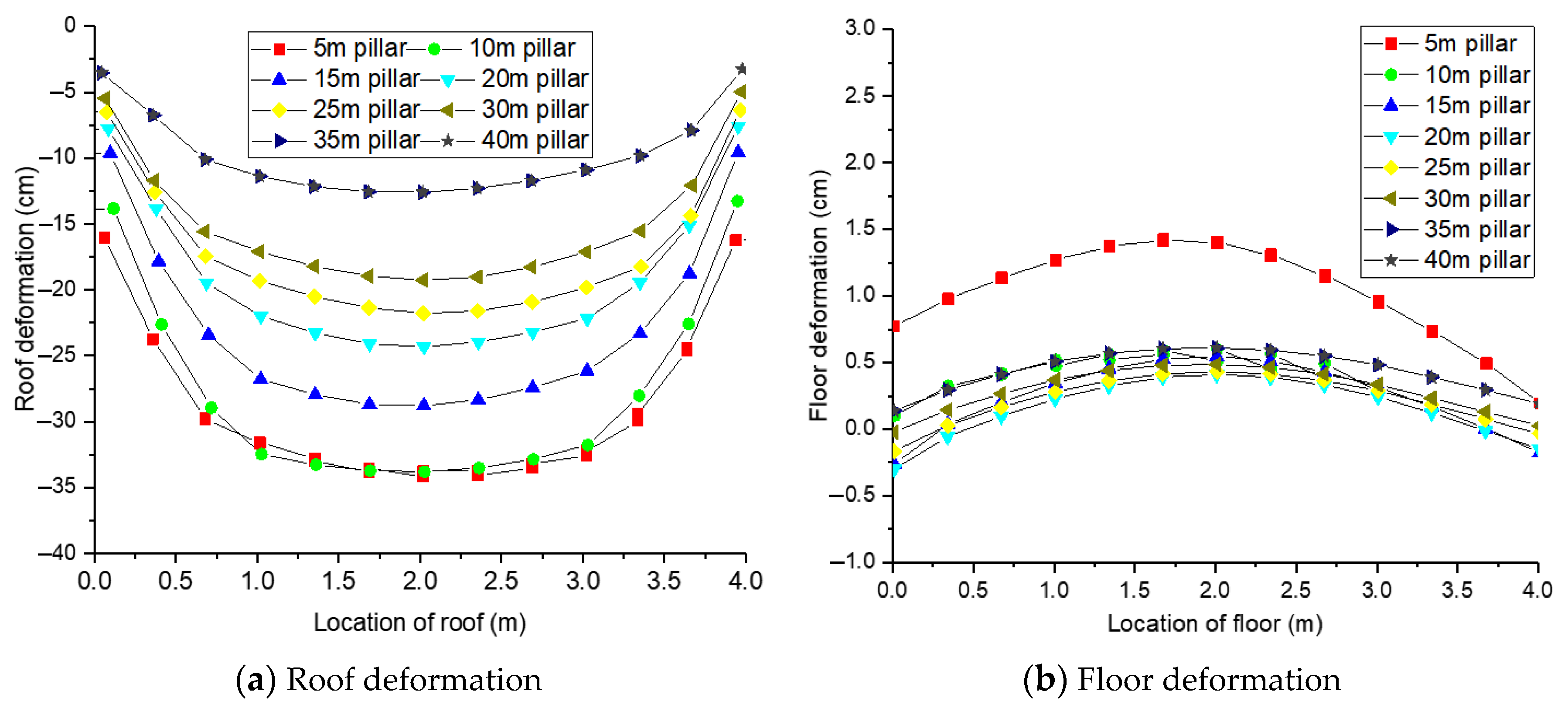

3. Results Analyses

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, S.; Xu, L.; Zhang, G.; Li, S.; Gong, S.; Yang, S. Subsidence broken of deep gob-side entry retaining surrounding rock structure with large mining height and its control. Rock Soil Mech. 2015, 36, 569–583. (In Chinese) [Google Scholar]

- Zhang, G. Asymmetric Failure Mechanism and Regulation System of Gob-Side Entry Roof with Fully-Mechanized Caving Mining and a Loose and Weak Coal Pillar. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Shen, B.T. Coal Mine Roadway Stability in Soft Rock: A Case Study. Rock Mech. Rock Eng. 2013, 47, 2225–2238. [Google Scholar] [CrossRef]

- Li, H.; Lin, B.Q.; Hong, Y.D.; Gao, Y.B.; Yang, W.; Liu, T.; Wang, R.; Huang, Z.B. Effects of in-situ stress on the stability of a roadway excavated through a coal seam. Int. J. Min. Sci. Technol. 2017, 27, 917–927. [Google Scholar] [CrossRef]

- Xiong, X.Y.; Dai, J.; Chen, X.N. Analysis of Stress Asym metric Distribution Law of Surrounding Rock of Roadway in Inclined Coal Seam: A Case Study of Shitanjing No.2 Coal Seam. Adv. Civ. Eng. 2020, 2020, 8877172. [Google Scholar] [CrossRef]

- Wu, X.Y.; Jiang, L.S.; Xu, X.G.; Guo, T.; Zhang, P.P.; Huang, W.P. Numerical analysis of deformation and failure characteristics of deep roadway surrounding rock under static-dynamic coupling stress. J. Cent. South Univ. 2021, 28, 543–555. [Google Scholar] [CrossRef]

- Wang, X.H.; Zhao, Z.Q.; Wu, Z.; Zhang, H.H.; Wang, J.; Sui, Y.; Ren, Z.C. Deformation and Failure Mechanism of the Lower Roadway in a Close-Range Residual Coal Pillar Area. J. Hypothesis Theory 2022, 10, 937276. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhang, Y.Y.; Zhang, Q.; Wei, Y.Y.; Liu, W.G.; Jiang, T. Space-Time Evolution Characteristics of Deformation and Failure of Surrounding Rock in Deep Soft Rock Roadway. Sustainability 2022, 14, 12587. [Google Scholar] [CrossRef]

- Xia, Z.; Yao, Q.; Meng, G.; Xu, Q.; Tang, C.; Zhu, L.; Wang, W.; Shen, Q. Numerical Study of Stability of Mining Roadways with 6.0-m Section Coal Pillars under Influence of Repeated Mining. J. Int. J. Rock Mech. Min. Sci. 2021, 138, 104641. [Google Scholar] [CrossRef]

- Li, S.C.; Wang, Q.; Wang, H.T.; Jiang, B.; Wang, D.C.; Zhang, B.; Li, Y.; Ruan, G.Q. Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. J. Entryling Undergr. Space Technol. 2015, 47, 52–63. [Google Scholar] [CrossRef]

- Ma, C.Q.; Li·, H.Z.; Niu, Y. Experimental study on damage failure mechanical characteristics and crack evolution of water-bearing surrounding rock. Environ. Earth Sci. 2018, 77, 23. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Wang, H.; Liu, S.M.; Mu, Z.L.; Lu, Z.G. Dynamic failure risk of coal pillar formed by irregular shape longwall face: A case study. Int. J. Min. Sci. Technol. 2018, 28, 775–781. [Google Scholar] [CrossRef]

- He, H.; Dou, L.M.; Gong, S.Y.; He, J.; Zheng, Y.L.; Zhang, X. Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 2019, 114, 30–39. [Google Scholar] [CrossRef]

- He, M.C.; Ma, X.G.; Niu, F.L.; Wang, J.; Liu, Y.X. Adaptability research and application of rapid gob- side entry retaining formed by roof cutting and pressure releasing with composite roof and medium thick coal seam. Chin. J. Rock Mech. Eng. 2018, 37, 2641–2654. [Google Scholar]

- He, M.C.; Ma, Z.M.; Guo, Z.B.; Chen, S.Y. Key parameters of the gob-side entry retaining formed by roof cutting and pressure release in deep medium thickness coal seams. J. China Univ. Min. Technol. 2018, 47, 468–477. [Google Scholar]

- He, M.C.; Wang, Y.J.; Yang, J.; Gao, Y.B.; Gao, Q.; Wang, S.B. Zonal characteristics and its influence factors of working face pressure using roof cutting and pressure relief mining method with no pillar and roadway formed automaticly. J. China Univ. Min. Technol. 2018, 47, 1157–1165. [Google Scholar]

- He, M.C. Research on deep shaft hoisting dynamics. Adv. Mech. 2021, 51, 702–728. [Google Scholar]

- He, M.C.; Wang, B.; Tao, Z.G.; Qiao, Y.F.; Xiao, Y.M. Axial compression behavior of adaptive steel arch joint for large-deformation entrys. Chi. J. Highw. Transp. 2021, 34, 1–10. [Google Scholar]

- Chen, X.J.; Li, L.Y.; Wang, L.; Qi, L.L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in china. Saf. Sci. 2019, 115, 229–236. [Google Scholar] [CrossRef]

- Yuan, Y.; Yuan, C.f.; Zhu, C.; Wang, P. Mechanical model and application of the deformation cylinder of the surrounding rock in the deep large section chamber. J. Min. Saf. Eng. 2020, 37, 338–348. [Google Scholar]

- Ma, N.J.; Zhao, X.D.; Zhao, Z.Q.; Guo, X.; Liu, H.; Jiahou, P. Conjecture about Mechanism of Butterfly-Shape Coal and Gas Outburst in Excavation Roadway. Chin. J. J. Min. Sci. Technol. 2017, 2, 137–149. [Google Scholar]

- Ma, N.J.; Ma, J.; Zhao, Z.Q.; Guo, X.F.; Shi, H.Y.; Qiao, J.Y. Mechanical Mechanism and Evolution of X-Shaped Conjugate Shear Fractures-Seism. J. China Coal Soc. 2019, 44, 1647–1653. [Google Scholar]

- Guo, X.; Zhao, Z.; Gao, X.; Wu, X.; Ma, N. Analytical Solutions for Characteristic Radii of Circular Roadway Surrounding Rock Plastic Zone and Their Application. Int. J. Min. Sci. Technol. 2019, 29, 263–272. [Google Scholar] [CrossRef]

- Hao, Z.; Guo, L.F.; Zhao, X.D.; Chen, G.X.; Zhang, G.H. Analysis of Burst Failure Energy Characteristics of Mining Roadway Surrounding Rock. J. China Coal Soc. 2020, 45, 3995–4005. [Google Scholar]

- Kong, X.Z. Research and Application of Gob-Side Roadway Support Parameters for Extra-thick COAL Seams in Tashan Mine. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. [Google Scholar]

- Tao, M.; Zhao, H.T.; Li, X.B.; Li, X.; Du, K. Failure characteristics and stress distribution of pre-stressed rock specimen with circular cavity subjected to dynamic loading. Entryling Undergr. Space Technol. 2018, 81, 1–15. [Google Scholar] [CrossRef]

- Weng, L.; Li, X.B.; Taheri, A.; Wu, Q.H.; Xie, X.F. Fracture evolution around a cavity in brittle rock under uniaxial compression and coupled static–dynamic loads. Rock Mech. Rock Eng. 2018, 51, 531–545. [Google Scholar] [CrossRef]

- Wu, Q.H.; Chen, L.; Shen, B.T.; Li, S.Q.; Zhu, Y.J. Experimental investigation on rock bolt performance under the tension load. Rock Mech. Rock Eng. 2019, 52, 4605–4618. [Google Scholar] [CrossRef]

- Li, D.Y.; Xiao, P.; Han, Z.Y.; Zhu, Q.Q. Mechanical and failure properties of rocks with a cavity under coupled static and dynamic loads. Eng. Fract. Mech. 2020, 225, 106195. [Google Scholar] [CrossRef]

- Wu, Q.H.; Li, X.B.; Weng, L.; Li, Q.F.; Zhu, Y.J.; Luo, R. Experimental investigation of the dynamic response of prestressed rock bolt by using an SHPB-based rock bolt test system. Entryling Undergr. Space Technol. 2019, 93, 103088. [Google Scholar] [CrossRef]

- Cai, M.F. Rock Mechanics and Engineering; Science Press: Beijing, China, 2022. [Google Scholar]

| Lithology | Density D (kg/m3) | Bulk K (GPa) | Shear G (GPa) | Friction Angle φ (°) | Cohesive c (MPa) |

|---|---|---|---|---|---|

| Kaolinite rock | 2550 | 3.5 | 2.7 | 32 | 1.7 |

| Coarse sandstone 1# | 2500 | 6.0 | 5.1 | 34 | 1.8 |

| Medium fine sandstone | 2800 | 7.2 | 6.1 | 36 | 2.5 |

| Coal seam 1# | 1450 | 1.5 | 0.8 | 25 | 1.0 |

| Coarse sandstone 2# | 2500 | 6.0 | 5.1 | 34 | 1.8 |

| Mudstone | 1900 | 3.3 | 2.5 | 31 | 1.2 |

| Coal seam 2# | 1450 | 1.8 | 1.0 | 28.0 | 1.2 |

| Siltstone | 2540 | 5.5 | 3.5 | 32.0 | 1.6 |

| Fine sandstone | 2850 | 7.4 | 6.3 | 37.0 | 2.0 |

| Lithology | Density D (kg/m3) | Bulk K (GPa) | Shear G (GPa) | Friction Angle φ (°) | Cohesive C (MPa) | Tensile T (MPa) | Dilation d (°) |

|---|---|---|---|---|---|---|---|

| Gob rock | 1000 | 3.2 | 1.0 | 10 | 5.0 | 0.03 | 2 |

| Strain | Pressure (KPa) | Strain | Pressure (KPa) |

|---|---|---|---|

| 0.01 | 150 | 0.10 | 3500 |

| 0.02 | 350 | 0.15 | 12,000 |

| 0.05 | 1250 | 0.18 | 18,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Xu, H.; Li, B.; He, W.; Liang, X.; Xia, H. Study on Surrounding Rock Failure Law of Gob-Side Entry Based on the Second Invariant of Deviatoric Stress. Sustainability 2023, 15, 10569. https://doi.org/10.3390/su151310569

Liu X, Xu H, Li B, He W, Liang X, Xia H. Study on Surrounding Rock Failure Law of Gob-Side Entry Based on the Second Invariant of Deviatoric Stress. Sustainability. 2023; 15(13):10569. https://doi.org/10.3390/su151310569

Chicago/Turabian StyleLiu, Xiaozhou, Hu Xu, Ben Li, Wenrui He, Xian Liang, and Hongchun Xia. 2023. "Study on Surrounding Rock Failure Law of Gob-Side Entry Based on the Second Invariant of Deviatoric Stress" Sustainability 15, no. 13: 10569. https://doi.org/10.3390/su151310569

APA StyleLiu, X., Xu, H., Li, B., He, W., Liang, X., & Xia, H. (2023). Study on Surrounding Rock Failure Law of Gob-Side Entry Based on the Second Invariant of Deviatoric Stress. Sustainability, 15(13), 10569. https://doi.org/10.3390/su151310569