Improving Energy Consumption and Order Tardiness in Picker-to-Part Warehouses with Electric Forklifts: A Comparison of Four Evolutionary Algorithms

Abstract

1. Introduction

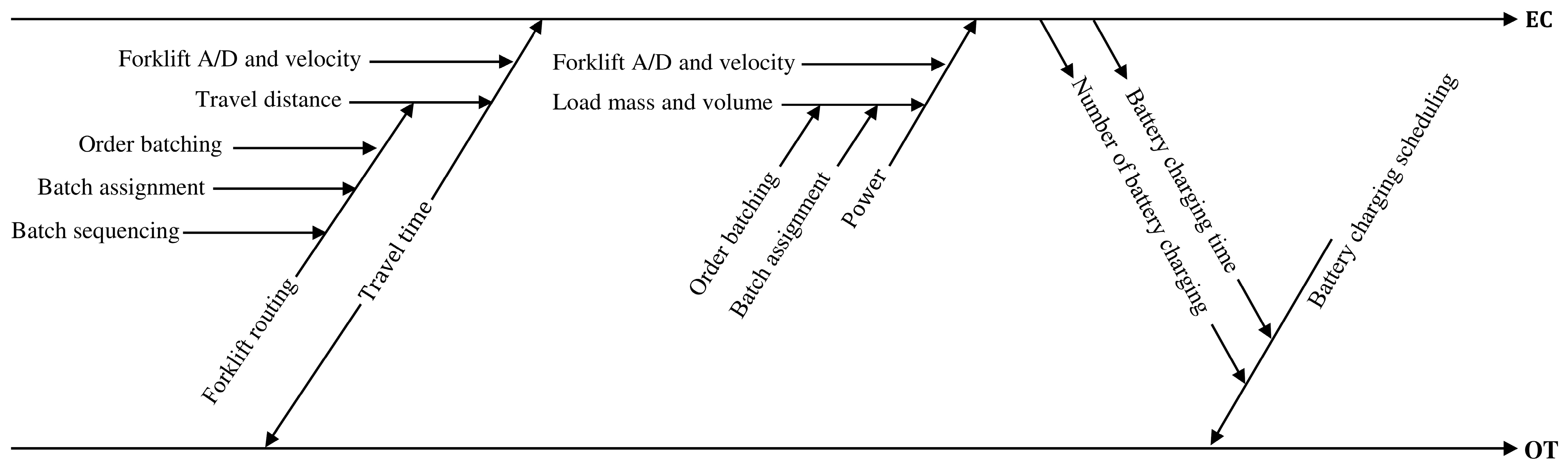

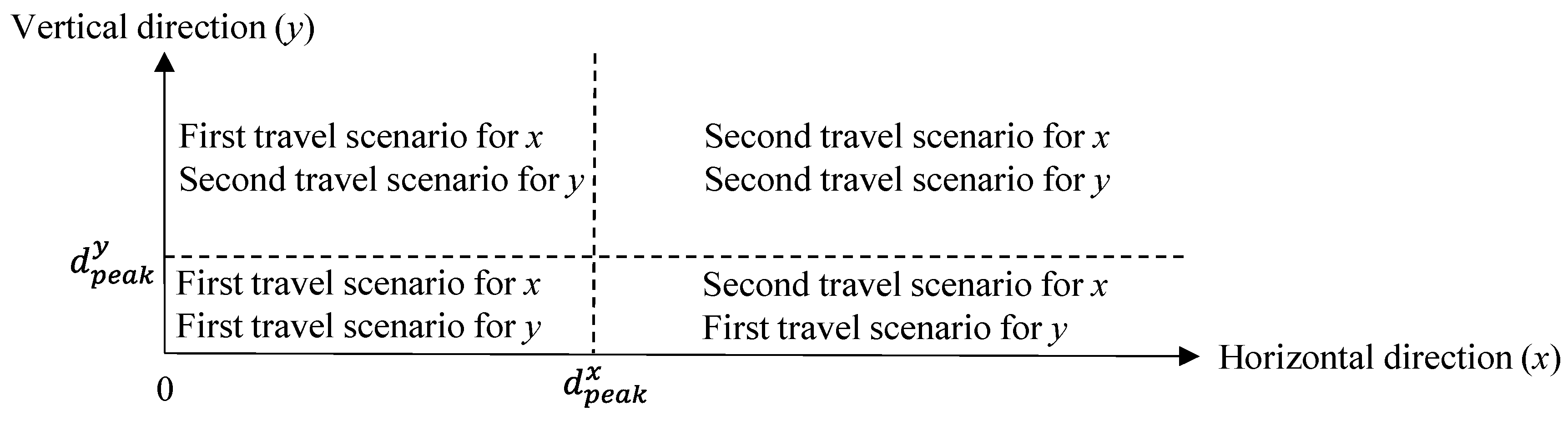

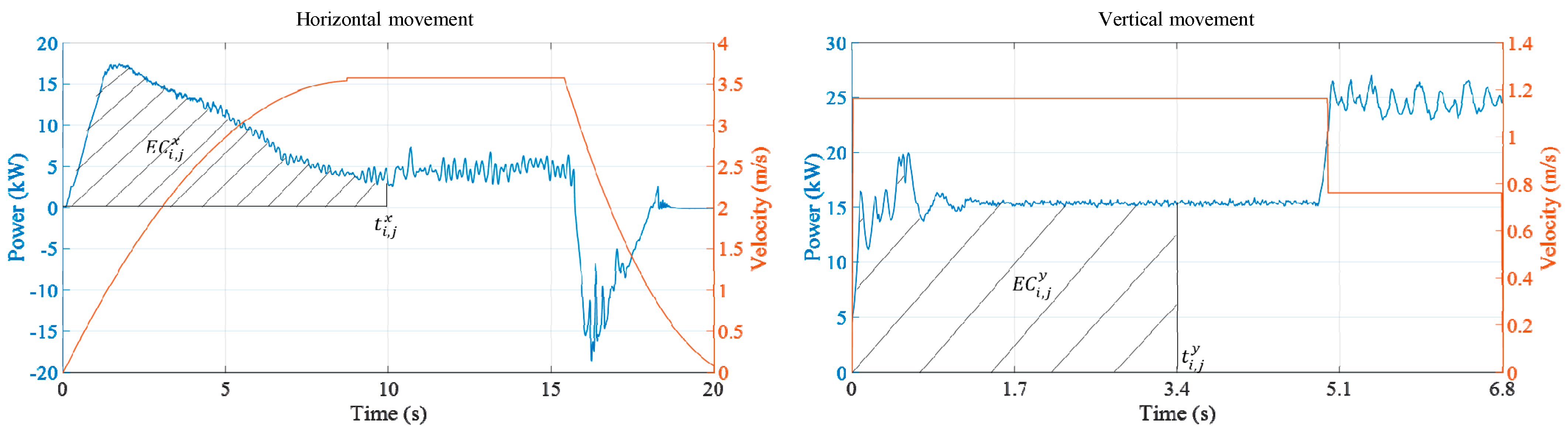

2. Problem Description

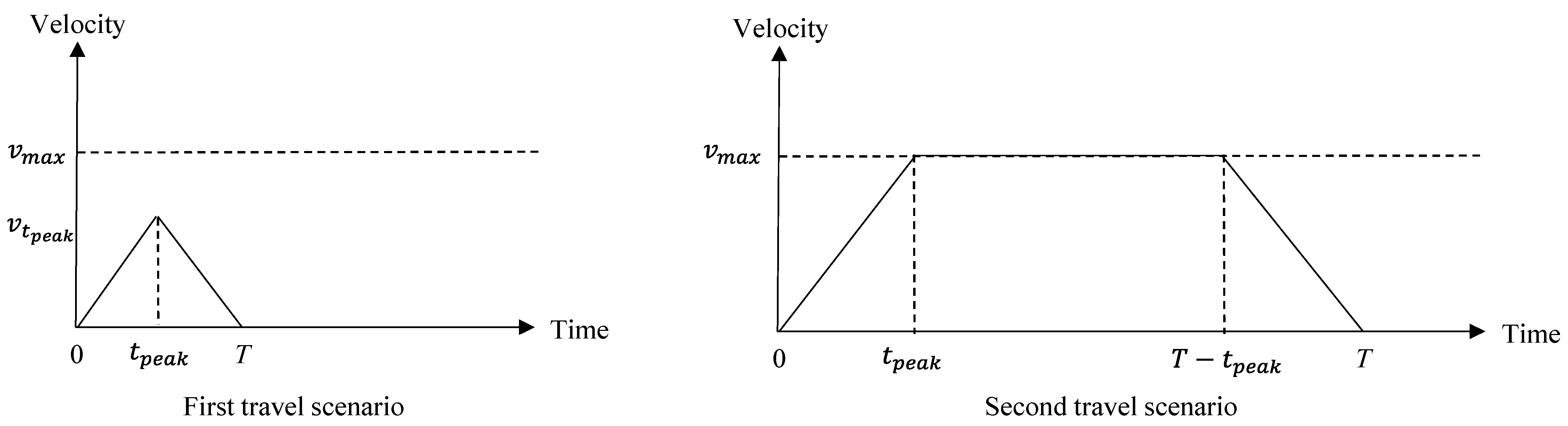

2.1. Definitions and Assumptions

2.2. Mathematical Model

| Index of forklifts | |

| Index of batches | |

| Index of orders | |

| Index of SKUs and depots |

| Maximum number of SKUs allowed being assigned to forklift f | |

| Maximum mass forklift f can handle (kg) | |

| Mass of SKU i (kg) | |

| Number of SKU i in order o | |

| Due date of order o (h) | |

| Travel time between SKU i and j by forklift f (h) | |

| EC of forklift f traveling from SKU i to j (kWh) | |

| Maximum EC of a forklift between two consecutive fast charging (kWh) | |

| Average time of a battery fast charging (h) | |

| M | A big number |

| 1 if order o is assigned to batch b of forklift f (otherwise, it is 0) | |

| 1 if SKU j is immediately picked after SKU i by forklift f in batch b (otherwise, it is 0) | |

| 1 if the battery of forklift f needs to be charged in batch b instead of picking up SKUs (batch b is identified as a charging batch, in which the forklift f is idle and will return to work in batch b+1) (otherwise, it is 0) | |

| Time of picking SKU i by forklift f in batch b (h) | |

| Completion time of batch b by forklift f (h) |

| Accumulation of EC from when the battery of forklift f is charged until the forklifts begin batch b (kWh) | |

| Tardiness of order o (h) |

| Total EC | |

| Total OT |

3. Multi-Objective Evolutionary Algorithms (MOEAs)

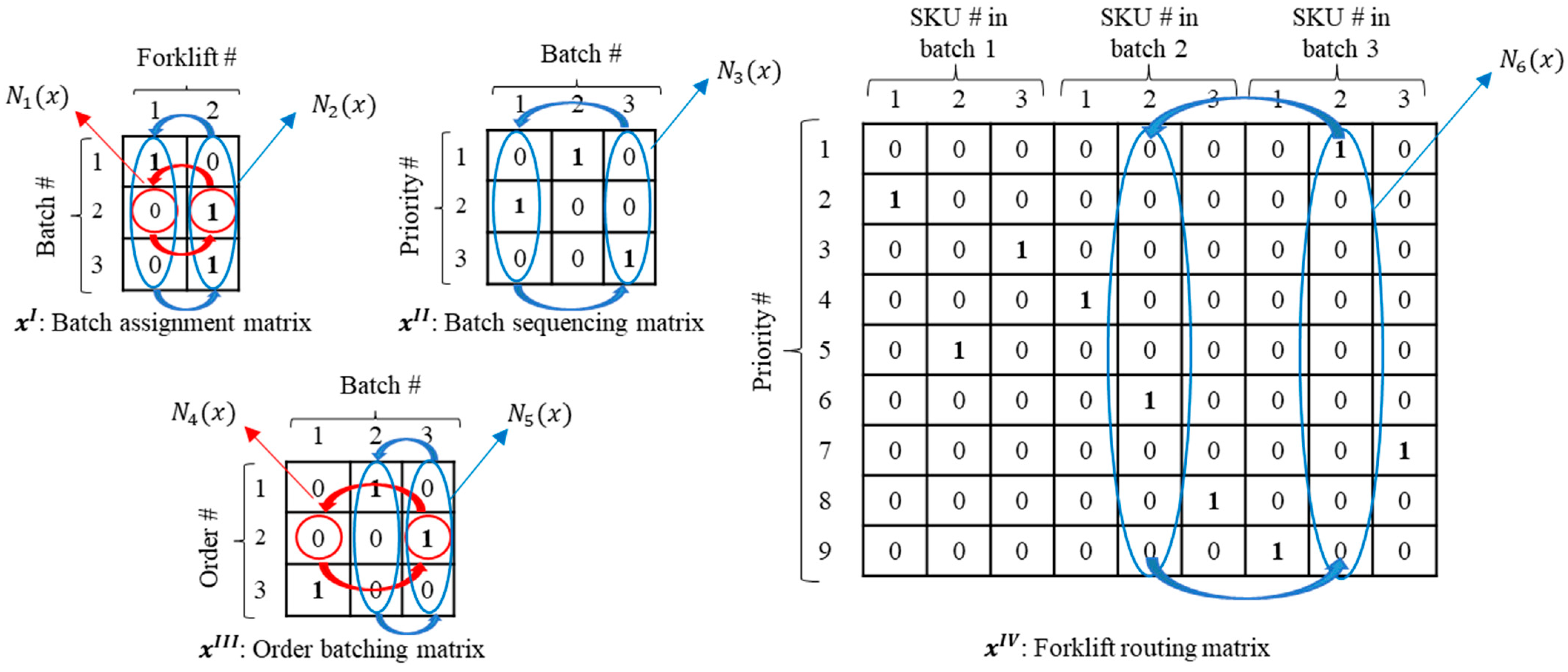

3.1. Solution Representation and Neighborhood Structures

3.2. MOEA Operators

| Algorithm 1. Pseudocode of FNS. |

|

| Algorithm 2. Pseudocode of CDM. |

|

| Algorithm 3. Pseudocode of SCS. |

|

| Algorithm 4. Pseudocode of GC. |

|

| Algorithm 5. Pseudocode of GM. |

|

| Algorithm 6. Pseudocode of MOVNS. |

|

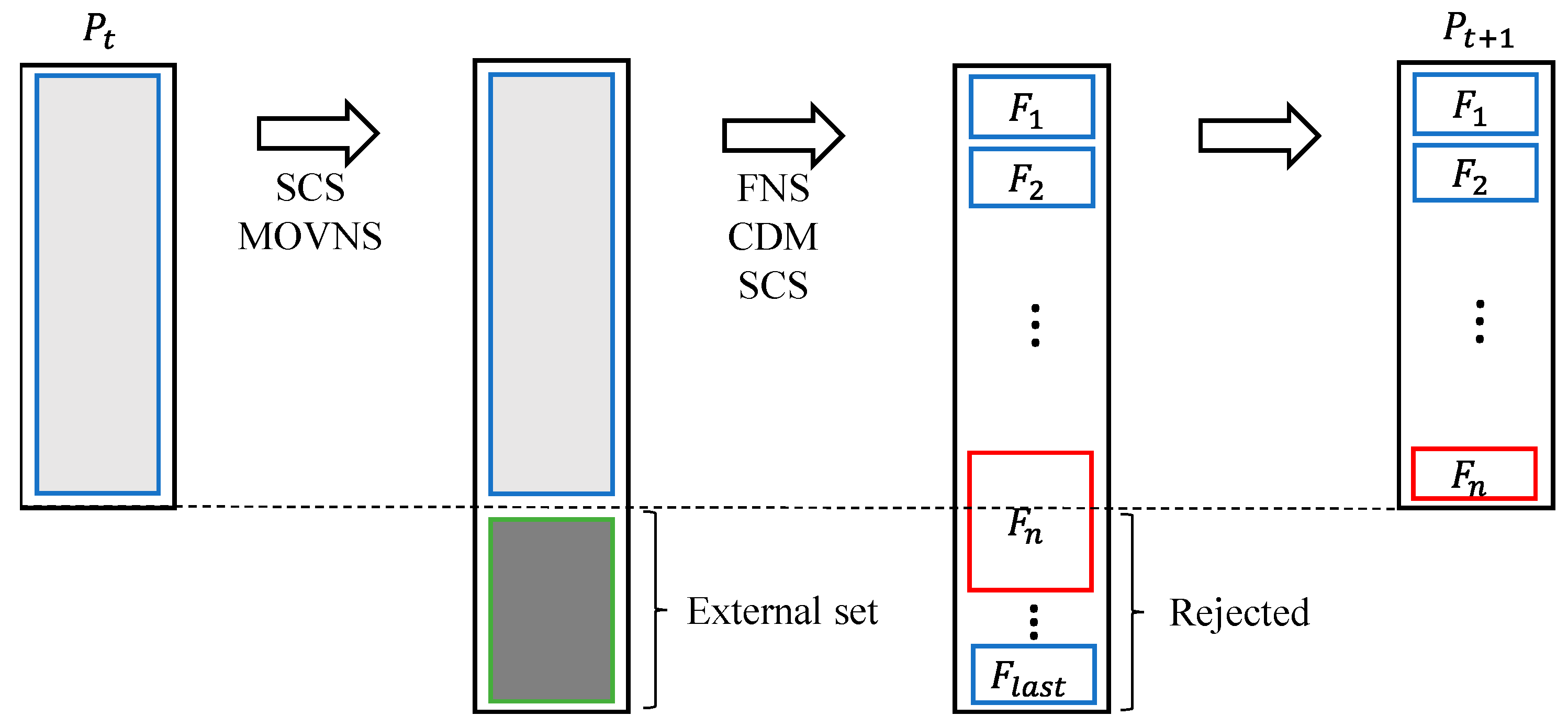

3.3. New MOEA-1: NSVNS

| Algorithm 7. Pseudocode of NSVNS. |

|

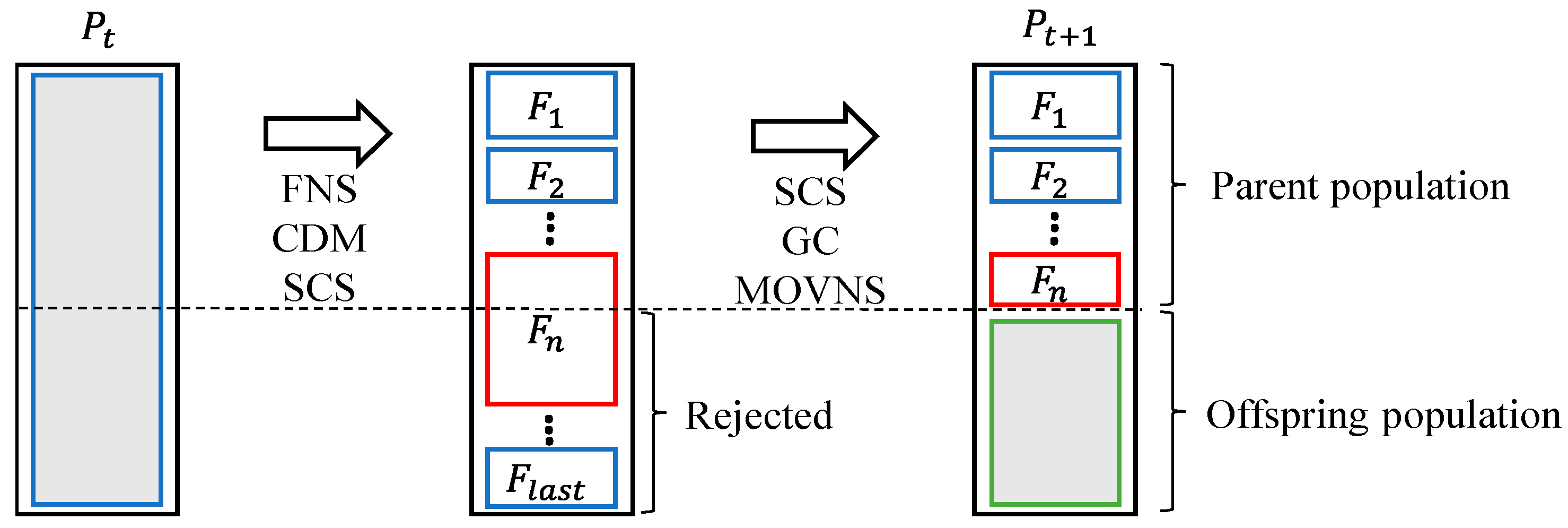

3.4. New MOEA-2: NSGA-MOVNS

| Algorithm 8. Pseudocode of NSGA-MOVNS. |

|

3.5. New MOEA-3: NSGA-VNS-DLS

| Algorithm 9. Pseudocode of NSGA-VNS-DLS. |

|

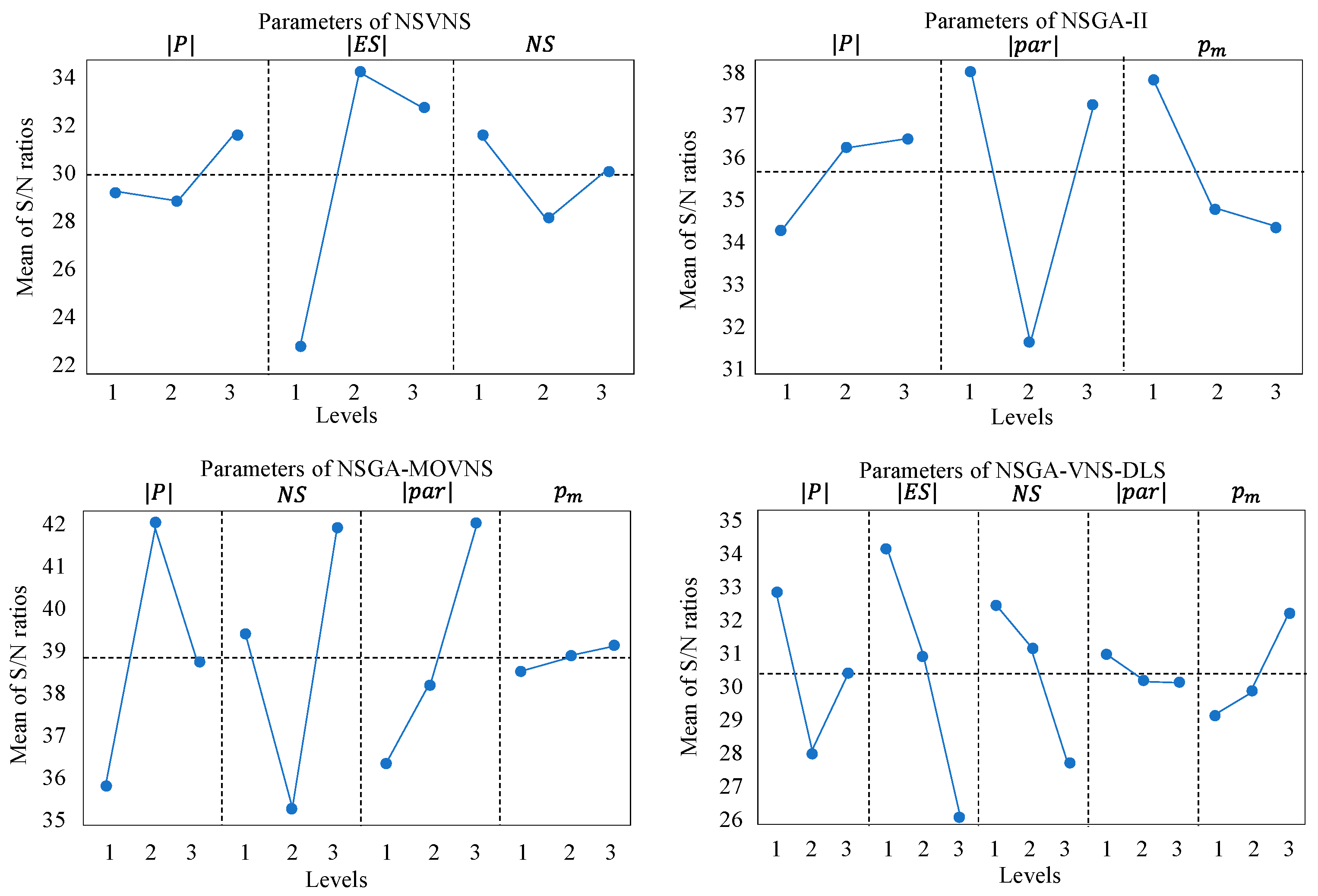

3.6. Parameter Tuning of MOEAs

4. Numerical Experiments

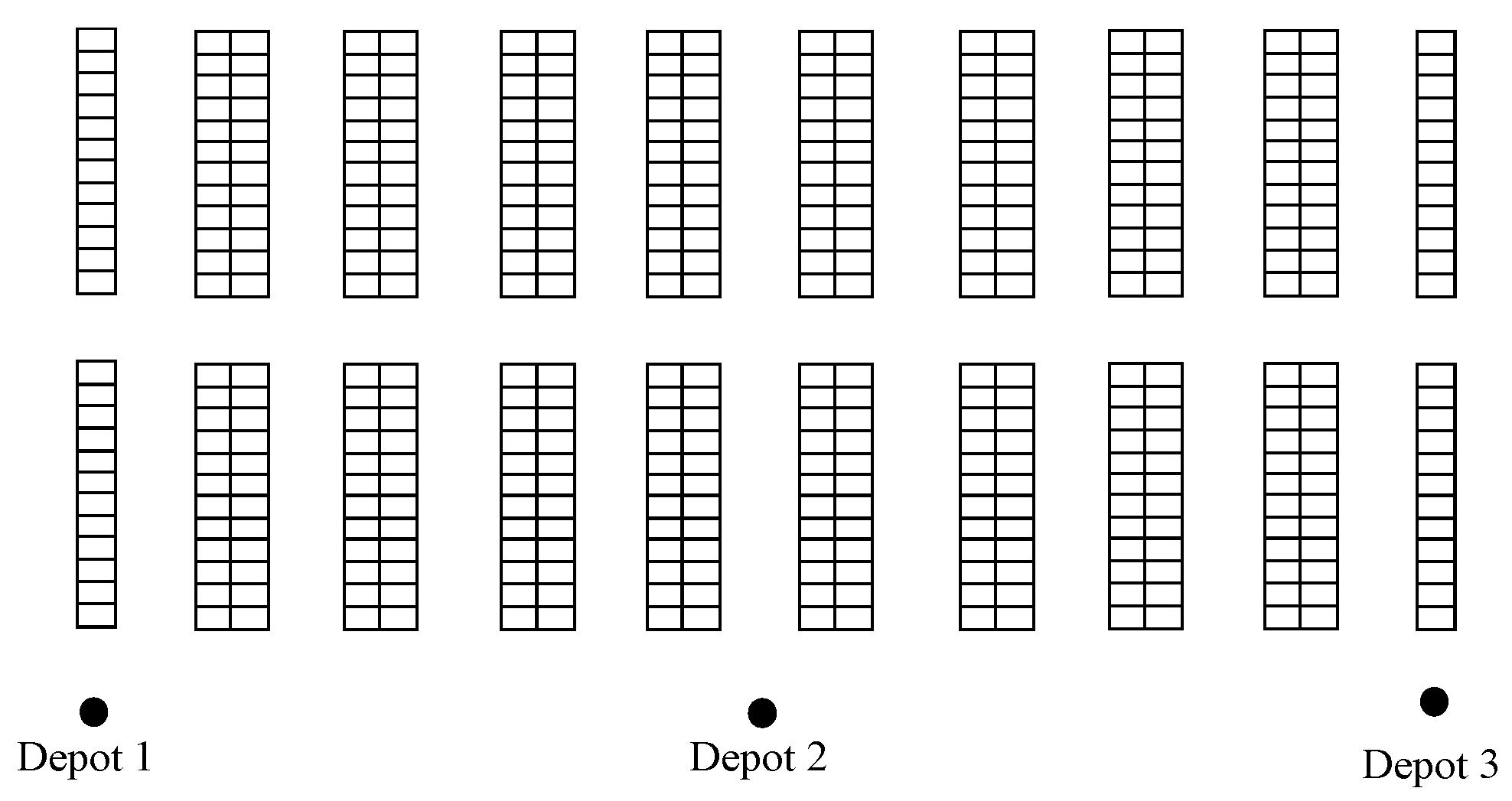

4.1. Problem Parameters

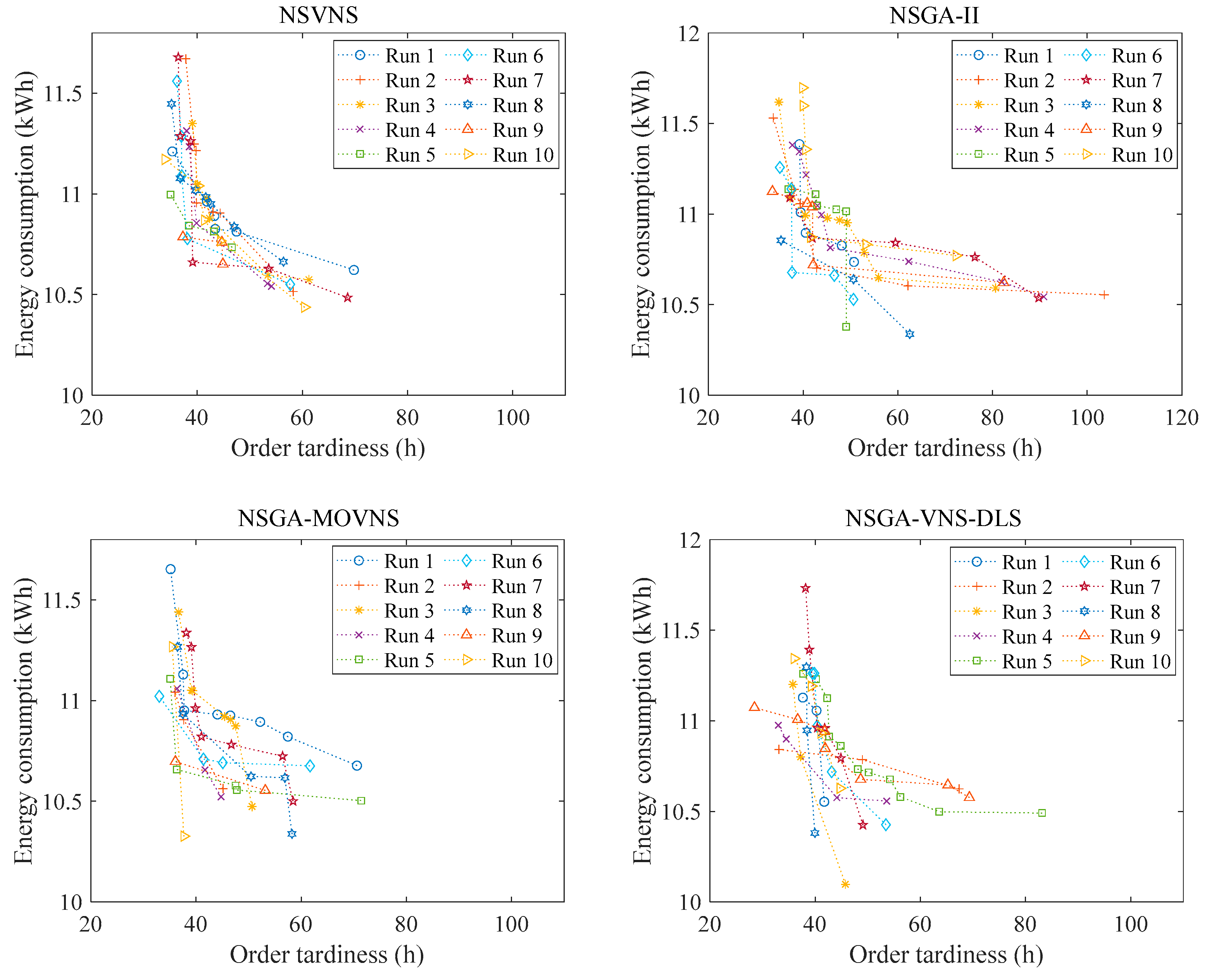

4.2. Validation and Comparison of Algorithms

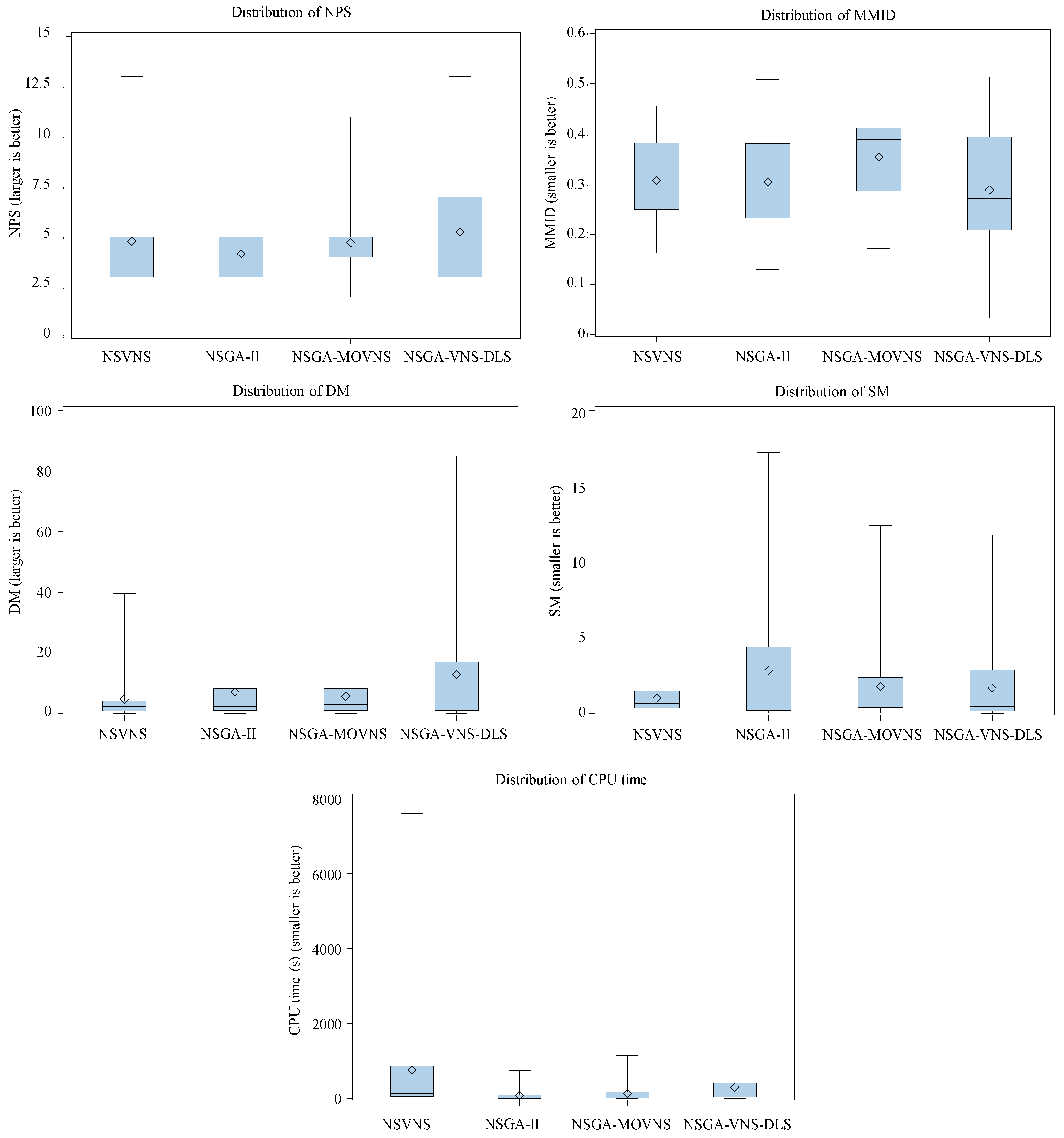

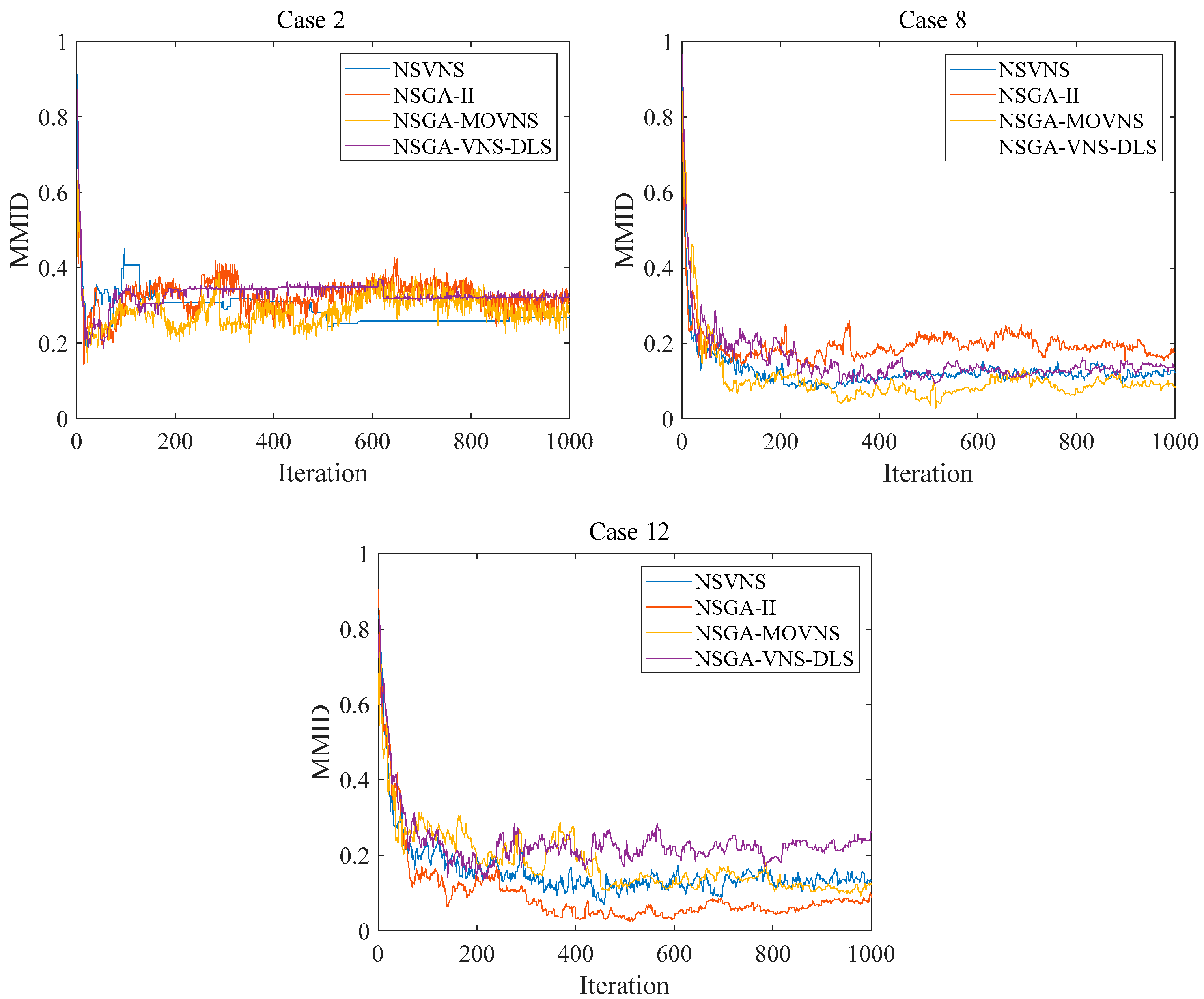

4.3. Performance Comparison of MOEAs

4.4. Managerial Insights

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| A/D | Acceleration/deceleration |

| ABHC | Attribute-based hill climber |

| ACO | Ant colony optimization |

| AGV | Automated guided vehicle |

| ALNS | Adaptive large neighborhood search |

| ANOVA | Analysis of variance |

| AUGMECON | Augmented ε-constraint method |

| CDM | Crowding distance measurement |

| CRD | Completely randomized design |

| DLS | Dynamic learning strategy |

| DM | Diversity metric |

| EC | Energy consumption |

| FNS | Fast non-dominated sorting |

| GA | Genetic algorithm |

| GALNS | General adaptive ALNS |

| GC | Genetic crossover |

| GM | Genetic mutation |

| ILS | Iterated local search |

| LD | Lagrangian decomposition |

| MILP | Mixed-integer linear programming |

| MLR | Multiple linear regressions |

| MMID | Modified mean ideal distance |

| MOEA | Multi-objective evolutionary algorithm |

| MOVNS | Multi-objective variable neighborhood search |

| NPS | Number of Pareto solutions |

| NSGA-II | Non-dominated sorting genetic algorithm |

| NSGA-MOVNS | Hybrid NSGA-II and MOVNS |

| NSGA-VNS-DLS | Hybrid NSGA-II and NSVNS with dynamic learning strategy |

| NSVNS | Non-dominated sorting variable neighborhood search |

| OT | Order tardiness |

| PESA-II | Pareto envelope-based selection |

| PSO | Particle swarm optimization |

| RBD | Randomized block design |

| SA | Simulated annealing |

| SAW | Simple additive weighting |

| SCS | Solution comparison and sorting |

| SKU | Stock-keeping unit |

| SM | Spacing metric |

| SPEA-II | Pareto evolutionary |

| TS | Tabu search |

| VND | Variable neighbor descent |

| VNS | Variable neighborhood search |

References

- Petersen, C.G.; Schmenner, R.W. An Evaluation of Routing and Volume-Based Storage Policies in an Order Picking Operation. Decis. Sci. 1999, 30, 481–501. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Kia, R.; Komijan, A.R. Solving a Mathematical Model Integrating Unequal-Area Facilities Layout and Part Scheduling in a Cellular Manufacturing System by a Genetic Algorithm. SpringerPlus 2016, 5, 1254. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, A.; Jeon, H.W.; Lee, S.; Wang, C. Minimizing Total Energy Cost and Tardiness Penalty for a Scheduling-Layout Problem in a Flexible Job Shop System: A Comparison of Four Metaheuristic Algorithms. Comput. Ind. Eng. 2020, 141, 106295. [Google Scholar] [CrossRef]

- Wäscher, G. Order Picking: A Survey of Planning Problems and Methods. In Supply Chain Management and Reverse Logistics; Dyckhoff, H., Lackes, R., Reese, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 323–347. ISBN 978-3-540-24815-6. [Google Scholar]

- Kutkut, N. Is Fast Charging for You? Mater. Handl. Manag. 2005, 62. Available online: https://www.mhlnews.com/powered-vehicles-and-forklifts/article/22040185/is-fast-charging-for-you (accessed on 10 March 2023).

- Carli, R.; Dotoli, M.; Digiesi, S.; Facchini, F.; Mossa, G. Sustainable Scheduling of Material Handling Activities in Labor-Intensive Warehouses: A Decision and Control Model. Sustainability 2020, 12, 3111. [Google Scholar] [CrossRef]

- Henn, S.; Wäscher, G. Tabu Search Heuristics for the Order Batching Problem in Manual Order Picking Systems. Eur. J. Oper. Res. 2012, 222, 484–494. [Google Scholar] [CrossRef]

- Henn, S.; Schmid, V. Metaheuristics for Order Batching and Sequencing in Manual Order Picking Systems. Comput. Ind. Eng. 2013, 66, 338–351. [Google Scholar] [CrossRef]

- Chen, T.-L.; Cheng, C.-Y.; Chen, Y.-Y.; Chan, L.-K. An Efficient Hybrid Algorithm for Integrated Order Batching, Sequencing and Routing Problem. Int. J. Prod. Econ. 2015, 159, 158–167. [Google Scholar] [CrossRef]

- Cheng, C.-Y.; Chen, Y.-Y.; Chen, T.-L.; Yoo, J.J.-W. Using a Hybrid Approach Based on the Particle Swarm Optimization and Ant Colony Optimization to Solve a Joint Order Batching and Picker Routing Problem. Int. J. Prod. Econ. 2015, 170, 805–814. [Google Scholar] [CrossRef]

- Henn, S. Order Batching and Sequencing for the Minimization of the Total Tardiness in Picker-to-Part Warehouses. Flex. Serv. Manuf. J. 2015, 27, 86–114. [Google Scholar] [CrossRef]

- Muter, İ.; Öncan, T. An Exact Solution Approach for the Order Batching Problem. IIE Trans. 2015, 47, 728–738. [Google Scholar] [CrossRef]

- Fekete, P.; Lim, S.; Martin, S.; Kuhn, K.; Wright, N. Improved Energy Supply for Non-Road Electric Vehicles by Occasional Charging Station Location Modelling. Energy 2016, 114, 1033–1040. [Google Scholar] [CrossRef]

- Ardjmand, E.; Huh, D.W. Coordinated Warehouse Order Picking and Production Scheduling: A NSGA-II Approach. In Proceedings of the 2017 IEEE Symposium Series on Computational Intelligence (SSCI), Honolulu, HI, USA, 27 November–1 December 2017; pp. 1–8. [Google Scholar]

- Li, J.; Huang, R.; Dai, J.B. Joint Optimisation of Order Batching and Picker Routing in the Online Retailer’s Warehouse in China. Int. J. Prod. Res. 2017, 55, 447–461. [Google Scholar] [CrossRef]

- Scholz, A.; Schubert, D.; Wäscher, G. Order Picking with Multiple Pickers and Due Dates–Simultaneous Solution of Order Batching, Batch Assignment and Sequencing, and Picker Routing Problems. Eur. J. Oper. Res. 2017, 263, 461–478. [Google Scholar] [CrossRef]

- Menéndez, B.; Bustillo, M.; Pardo, E.G.; Duarte, A. General Variable Neighborhood Search for the Order Batching and Sequencing Problem. Eur. J. Oper. Res. 2017, 263, 82–93. [Google Scholar] [CrossRef]

- Ardjmand, E.; Shakeri, H.; Singh, M.; Bajgiran, O.S. Minimizing Order Picking Makespan with Multiple Pickers in a Wave Picking Warehouse. Int. J. Prod. Econ. 2018, 206, 169–183. [Google Scholar] [CrossRef]

- Žulj, I.; Kramer, S.; Schneider, M. A Hybrid of Adaptive Large Neighborhood Search and Tabu Search for the Order-Batching Problem. Eur. J. Oper. Res. 2018, 264, 653–664. [Google Scholar] [CrossRef]

- Pinto, A.R.F.; Nagano, M.S. An Approach for the Solution to Order Batching and Sequencing in Picking Systems. Prod. Eng. 2019, 13, 325–341. [Google Scholar] [CrossRef]

- Kuhn, H.; Schubert, D.; Holzapfel, A. Integrated Order Batching and Vehicle Routing Operations in Grocery Retail—A General Adaptive Large Neighborhood Search Algorithm. Eur. J. Oper. Res. 2020, 294, 1003–1021. [Google Scholar] [CrossRef]

- Lee, I.G.; Chung, S.H.; Yoon, S.W. Two-Stage Storage Assignment to Minimize Travel Time and Congestion for Warehouse Order Picking Operations. Comput. Ind. Eng. 2020, 139, 106129. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, Z.; Guo, H. Order Batch Picking Optimization under Different Storage Scenarios for E-Commerce Warehouses. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101897. [Google Scholar] [CrossRef]

- Cano, J.A.; Cortés, P.; Campo, E.A.; Correa-Espinal, A.A. Multi-objective grouping genetic algorithm for the joint order batching, batch assignment, and sequencing problem. Int. J. Manag. Sci. Eng. Manag. 2021, 17, 188–204. [Google Scholar] [CrossRef]

- Dauod, H.; Won, D. Real-Time Order Picking Planning Framework for Warehouses and Distribution Centres. Int. J. Prod. Res. 2021, 60, 5468–5487. [Google Scholar] [CrossRef]

- Karimi-Mamaghan, M.; Mohammadi, M.; Pasdeloup, B.; Meyer, P. Learning to Select Operators in Meta-Heuristics: An Integration of Q-Learning into the Iterated Greedy Algorithm for the Permutation Flowshop Scheduling Problem. Eur. J. Oper. Res. 2023, 304, 1296–1330. [Google Scholar] [CrossRef]

- Mavrotas, G. Effective Implementation of the ε-Constraint Method in Multi-Objective Mathematical Programming Problems. Appl. Math. Comput. 2009, 213, 455–465. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, N.; Tian, L.; Zhou, Z.; Wang, P. Robots’ Picking Efficiency and Pickers’ Energy Expenditure: The Item Storage Assignment Policy in Robotic Mobile Fulfillment System. Comput. Ind. Eng. 2023, 176, 108918. [Google Scholar] [CrossRef]

- Yusoff, Y.; Ngadiman, M.S.; Zain, A.M. Overview of NSGA-II for Optimizing Machining Process Parameters. Procedia Eng. 2011, 15, 3978–3983. [Google Scholar] [CrossRef]

- Lv, L.; Shen, W. An Improved NSGA-II with Local Search for Multi-Objective Integrated Production and Inventory Scheduling Problem. J. Manuf. Syst. 2023, 68, 99–116. [Google Scholar] [CrossRef]

- Lesch, V.; Müller, P.B.; Krämer, M.; Hadry, M.; Kounev, S.; Krupitzer, C. Optimizing Storage Assignment, Order Picking, and Their Interaction in Mezzanine Warehouses. Appl. Intell. 2023, 1–25. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; Wang, D.; Cheng, T.C.E.; Yin, Y. Bi-Objective Perishable Product Delivery Routing Problem with Stochastic Demand. Comput. Ind. Eng. 2023, 175, 108837. [Google Scholar] [CrossRef]

- Min, C.; Pan, Y.; Dai, W.; Kawsar, I.; Li, Z.; Wang, G. Trajectory Optimization of an Electric Vehicle with Minimum Energy Consumption Using Inverse Dynamics Model and Servo Constraints. Mech. Mach. Theory 2023, 181, 105185. [Google Scholar] [CrossRef]

- Yao, Z.; Yoon, H.-S.; Hong, Y.-K. Control of Hybrid Electric Vehicle Powertrain Using Offline-Online Hybrid Reinforcement Learning. Energies 2023, 16, 652. [Google Scholar] [CrossRef]

- Cao, B.; Yan, Y.; Wang, Y.; Liu, X.; Lin, J.C.-W.; Sangaiah, A.K.; Lv, Z. A Multiobjective Intelligent Decision-Making Method for Multistage Placement of PMU in Power Grid Enterprises. IEEE Trans. Ind. Inform. 2023, 19, 7636–7644. [Google Scholar] [CrossRef]

- TMHNA. Available online: https://www.tmhna.com/ (accessed on 19 March 2023).

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Mladenović, N.; Hansen, P. Variable Neighborhood Search. Comput. Oper. Res. 1997, 24, 1097–1100. [Google Scholar] [CrossRef]

- Taguchi, G. Introduction to Quality Engineering: Designing Quality into Products and Processes; Asian Productivity Organization: Tokyo, Japan, 1986. [Google Scholar]

- Maghsoudlou, H.; Kahag, M.R.; Niaki, S.T.A.; Pourvaziri, H. Bi-Objective Optimization of a Three-Echelon Multi-Server Supply-Chain Problem in Congested Systems: Modeling and Solution. Comput. Ind. Eng. 2016, 99, 41–62. [Google Scholar] [CrossRef]

- Rahmati, S.H.A.; Hajipour, V.; Niaki, S.T.A. A Soft-Computing Pareto-Based Meta-Heuristic Algorithm for a Multi-Objective Multi-Server Facility Location Problem. Appl. Soft Comput. 2013, 13, 1728–1740. [Google Scholar] [CrossRef]

- Karimi, N.; Zandieh, M.; Karamooz, H.R. Bi-Objective Group Scheduling in Hybrid Flexible Flowshop: A Multi-Phase Approach. Expert Syst. Appl. 2010, 37, 4024–4032. [Google Scholar] [CrossRef]

- Zitzler, E. Evolutionary Algorithms for Multiobjective Optimization: Methods and Applications. Ph.D. Thesis, Swiss Federal Institute of Technology Zurich, Zurich, Switzerland, 1999. [Google Scholar]

- Elsayed, E.A.; Lee, M.-K. Order Processing in Automated Storage/Retrieval Systems with Due Dates. IIE Trans. 1996, 28, 567–577. [Google Scholar] [CrossRef]

- Parks, B. Forklift Batteries: Conventional vs. Fast vs. Opportunity Charging. Available online: https://www.tmhnc.com/blog/forklift-battery-charging-fast-opportunity-conventional (accessed on 24 November 2020).

- Hwang, H.; Lee, S.B. Travel-Time Models Considering the Operating Characteristics of the Storage and Retrieval Machine. Int. J. Prod. Res. 1990, 28, 1779–1789. [Google Scholar] [CrossRef]

- Schott, J.R. Fault Tolerant Design Using Single and Multicriteria Genetic Algorithm Optimization. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1995. [Google Scholar]

- Benoit, K. Linear Regression Models with Logarithmic Transformations; London School of Economics: London, UK, 2011; Volume 22, pp. 23–36. [Google Scholar]

- Zhao, H.; Zhang, C. An Online-Learning-Based Evolutionary Many-Objective Algorithm. Inf. Sci. 2020, 509, 1–21. [Google Scholar] [CrossRef]

- Dulebenets, M.A. An Adaptive Polyploid Memetic Algorithm for Scheduling Trucks at a Cross-Docking Terminal. Inf. Sci. 2021, 565, 390–421. [Google Scholar] [CrossRef]

- Dulebenets, M.A.; Kavoosi, M.; Abioye, O.; Pasha, J. A Self-Adaptive Evolutionary Algorithm for the Berth Scheduling Problem: Towards Efficient Parameter Control. Algorithms 2018, 11, 100. [Google Scholar] [CrossRef]

| Reference | Decisions | Optimization Objective(s) | Solution Method(s) | ||||

|---|---|---|---|---|---|---|---|

| (i) Order Batching | (ii) Batch Assignment | (iii) Batch Sequencing | (iv) Forklift Routing | (v) Battery Charing | |||

| [6] | O | O | Makespan, EC cost | Commercial solver | |||

| [7] | O | Travel distance | TS and ABHC | ||||

| [8] | O | O | OT | ILS and ABHC | |||

| [9] | O | O | O | OT | Hybrid GA-ACO | ||

| [10] | O | O | Travel distance | Hybrid PSO-ACO | |||

| [11] | O | O | OT | VND and VNS | |||

| [12] | O | Travel costs based on travel distance | Column generation based exact algorithm | ||||

| [13] | O | Charging time | Heuristic algorithm | ||||

| [14] | O | O | Makespan, travel time | NSGA-II | |||

| [15] | O | O | Travel distance | Heuristic algorithm, ACO | |||

| [16] | O | O | O | O | OT | VND | |

| [17] | O | O | OT | VNS | |||

| [18] | O | O | O | O | Makespan | VND, hybrid LD-PSO, hybrid SA-ACO | |

| [19] | O | Travel distance | Hybrid ALNS-TS | ||||

| [20] | O | O | Number of travels, travel time | GA | |||

| [21] | O | O | OT | GALNS | |||

| [22] | O | Travel time, OT | NSGA-II, SPEA-II, PESA-II | ||||

| [23] | O | O | Travel distance | Heuristic order batching algorithms | |||

| [24] | O | O | O | Travel time, OT | Grouping GA | ||

| [25] | O | O | OT | TS | |||

| Batch Assignment and Batch Sequencing | Order Batching | Forklift Routing among SKUs | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Forklift No. | 1 | 2 | Batch No. | 1 | 2 | 3 | Forklift No. | 1 | 2 |

| Batch No. | 1 | 2, 3 | Order No. | 3 | 1 | 2 | SKU No. | Batch 1: 1, 3, 2 | Batch 2: 1, 2, 3 Batch 3: 2, 3, 1 |

| Parameters | Levels | Values | Algorithms | |||

|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||

| 1 | 50 | ✔ | ||||

| 2 | 100 | ✔ | ||||

| 3 | 200 | ✔ | ✔ | |||

| 1 | N/A | N/A | ✔ | |||

| 2 | ✔ | N/A | N/A | |||

| 3 | N/A | N/A | ||||

| 1 | 2 | ✔ | N/A | ✔ | ||

| 2 | 3 | N/A | ||||

| 3 | 4 | N/A | ✔ | |||

| 1 | N/A | ✔ | ✔ | |||

| 2 | N/A | |||||

| 3 | N/A | ✔ | ||||

| 1 | 0.1 | N/A | ✔ | |||

| 2 | 0.2 | N/A | ||||

| 3 | 0.3 | N/A | ✔ | ✔ | ||

| Layout Information | Specification |

|---|---|

| Number of storage locations | 1296 |

| Number of depots | 3 |

| Number of bays per rack | 12 |

| Number of tiers per rack | 3 |

| Number of racks | 18 |

| Number of aisles | 18 |

| Length | 74 m |

| Width | 48 m |

| Height | 5 m |

| Length of rack | 22 m |

| Width of rack | 2 m |

| Height of rack | 5 m |

| Length of aisle | 22 m |

| Width of Aisle | 5 m |

| Case 1 (5 Orders, 3 SKUs Each, and 3 Forklifts) | |||||||||||

| Algorithms | |||||||||||

| AUGMECON | NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||||

| Solutions | |||||||||||

| 1 | 0.502 | 1.216 | 0.508 | 1.015 | 0.623 | 0.255 | 0.507 | 1.147 | 0.535 | 0.920 | |

| 2 | 0.611 | 0.366 | 0.775 | 0.182 | 0.691 | 0.046 | 0.61 | 0.704 | |||

| 3 | 0.651 | 0.342 | 0.706 | 0.073 | |||||||

| 4 | 0.77 | 0.318 | |||||||||

| 5 | 0.79 | 0.046 | |||||||||

| Case 2 (10 orders, 3 SKUs each, and 3 forklifts) | |||||||||||

| Algorithms | |||||||||||

| AUGMECON | NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||||

| Solutions | |||||||||||

| 1 | 0.962 | 3.748 | 0.974 | 1.85 | 1.009 | 3.124 | 1.007 | 0.84 | 0.993 | 1.775 | |

| 2 | 1.068 | 0.6 | 1.118 | 0.338 | 1.114 | 0.384 | 1.032 | 1.75 | |||

| 3 | 1.214 | 0.207 | 1.099 | 0.408 | |||||||

| Case 3 (15 orders, 3 SKUs each, and 3 forklifts) | |||||||||||

| Algorithms | |||||||||||

| AUGMECON | NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||||

| Solutions | |||||||||||

| 1 | 2.111 | 12.058 | 2.117 | 1.51 | 2.174 | 1.932 | 2.141 | 2.231 | 2.16 | 5.729 | |

| 2 | 2.602 | 4.318 | 2.204 | 2.074 | 2.177 | 1.801 | |||||

| 3 | 2.533 | 3.578 | 2.326 | 1.813 | 2.215 | 0.865 | |||||

| 4 | 2.673 | 0.865 | |||||||||

| Case No.: Number of Orders, Order Size (Number of SKUs), Number of Forklifts | Algorithms | |||||||

|---|---|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | |

| Case 1: 5-3-3 | 3 | A | 3.5 | A | 3.5 | A | 3.75 | A |

| Case 2: 10-3-3 | 3 | A | 3.25 | A | 4.5 | A | 4 | A |

| Case 3: 15-3-3 | 4.5 | A | 4.5 | A | 4.25 | A | 3.75 | A |

| Case 4: 20-3-3 | 3.25 | A | 3.5 | A | 5.5 | A | 3.25 | A |

| Case 5: 50-3-3 | 3.75 | A | 4.75 | A | 5.5 | A | 6.25 | A |

| Case 6: 50-5-5 | 4.75 | A | 4.75 | A | 5 | A | 4.75 | A |

| Case 7: 100-3-3 | 4 | A | 3.25 | A | 4.75 | A | 4.5 | A |

| Case 8: 100-5-5 | 4.5 | A | 5 | A | 4.5 | A | 6.25 | A |

| Case 9: 100-10-8 | 4.5 | A | 4.75 | A | 5.75 | A | 6.25 | A |

| Case 10: 200-3-3 | 6.5 | A | 3.75 | A | 4.5 | A | 5.75 | A |

| Case 11:200-5-5 | 10 | A | 5 | B | 4.5 | B | 10 | A |

| Case 12: 200-10-8 | 5.75 | A | 4 | A | 4.5 | A | 4.5 | A |

| Case No.: Number of Orders, Order Size (Number of SKUs), Number of Forklifts | Algorithms | |||||||

|---|---|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | |

| Case 1: 5-3-3 | 0.249 | A | 0.275 | A | 0.3 | A, B | 0.375 | B |

| Case 2: 10-3-3 | 0.268 | A | 0.312 | A | 0.28 | A | 0.321 | A |

| Case 3: 15-3-3 | 0.341 | A | 0.324 | A | 0.296 | A | 0.181 | A |

| Case 4: 20-3-3 | 0.164 | A | 0.361 | B | 0.356 | B | 0.235 | A |

| Case 5: 50-3-3 | 0.355 | B | 0.272 | A, B | 0.384 | B | 0.173 | A |

| Case 6: 50-5-5 | 0.374 | A | 0.393 | A | 0.406 | A | 0.317 | A |

| Case 7: 100-3-3 | 0.323 | A | 0.239 | A | 0.399 | A | 0.302 | A |

| Case 8: 100-5-5 | 0.122 | A | 0.177 | A | 0.085 | A | 0.137 | A |

| Case 9: 100-10-8 | 0.423 | A | 0.232 | A | 0.34 | A | 0.328 | A |

| Case 10: 200-3-3 | 0.227 | A | 0.386 | A | 0.405 | A | 0.41 | A |

| Case 11:200-5-5 | 0.276 | A, B | 0.378 | B | 0.252 | A, B | 0.203 | A |

| Case 12: 200-10-8 | 0.133 | A | 0.089 | A | 0.121 | A | 0.263 | A |

| Case No.: Number of Orders, Order Size (Number of SKUs), Number of Forklifts | Algorithms | |||||||

|---|---|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | |

| Case 1: 5-3-3 | 0.887 | A | 0.72 | A | 0.677 | A | 0.734 | A |

| Case 2: 10-3-3 | 0.753 | A | 2.317 | A | 1.613 | A | 0.78 | A |

| Case 3: 15-3-3 | 2.073 | A | 3.505 | A | 1.648 | A | 1.397 | A |

| Case 4: 20-3-3 | 2.11 | A | 1.46 | A | 3.12 | A | 1.219 | A |

| Case 5: 50-3-3 | 1.726 | A | 3.54 | A | 3.347 | A | 6.352 | A |

| Case 6: 50-5-5 | 1.331 | B | 3.062 | A, B | 2.106 | B | 8.152 | A |

| Case 7: 100-3-3 | 1.586 | B | 3.031 | A, B | 2.788 | A, B | 11.656 | A |

| Case 8: 100-5-5 | 5.493 | B | 22.181 | A | 3.555 | B | 5.234 | B |

| Case 9: 100-10-8 | 1.785 | B | 3.34 | B | 9.615 | A, B | 16.955 | A |

| Case 10: 200-3-3 | 13.939 | A | 15.406 | A | 15.384 | A | 24.89 | A |

| Case 11:200-5-5 | 19.521 | B | 8.263 | B | 12.977 | B | 56.456 | A |

| Case 12: 200-10-8 | 5.193 | A | 16.802 | A | 10.705 | A | 20.825 | A |

| Case No.: Number of Orders, Order Size (Number of SKUs), Number of Forklifts | Algorithms | |||||||

|---|---|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | |

| Case 1: 5-3-3 | 0.374 | A, B | 0.07 | A | 0.884 | B | 0.391 | A, B |

| Case 2: 10-3-3 | 0.374 | A | 0.096 | A | 0.581 | A | 0.465 | A |

| Case 3: 15-3-3 | 0.317 | A | 0.536 | A | 0.197 | A | 0.485 | A |

| Case 4: 20-3-3 | 2.142 | C | 0.273 | A | 0.779 | B | 0.193 | A |

| Case 5: 50-3-3 | 0.14 | A | 1.684 | A | 0.889 | A | 0.916 | A |

| Case 6: 50-5-5 | 0.451 | A | 2.803 | A | 0.623 | A | 1.344 | A |

| Case 7: 100-3-3 | 0.965 | A | 1.358 | A | 0.743 | A | 2.95 | A |

| Case 8: 100-5-5 | 2.449 | A, B | 0.914 | A | 1.04 | A | 3.791 | B |

| Case 9: 100-10-8 | 0.341 | A, B | 3.55 | B | 2.774 | A, B | 0.136 | A |

| Case 10: 200-3-3 | 2.029 | A | 5.612 | A | 5.322 | A | 0.915 | A |

| Case 11:200-5-5 | 0.961 | A | 8.679 | B | 3.749 | A, B | 2.255 | A, B |

| Case 12: 200-10-8 | 1.416 | A | 11.085 | B | 3.51 | A, B | 6.122 | A, B |

| Case No.: Number of Orders, Order Size (Number of SKUs), Number of Forklifts | Algorithms | |||||||

|---|---|---|---|---|---|---|---|---|

| NSVNS | NSGA-II | NSGA-MOVNS | NSGA-VNS-DLS | |||||

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | |

| Case 1: 5-3-3 | 502.66 | B | 41.094 | A | 162.42 | A | 329.92 | A, B |

| Case 2: 10-3-3 | 517.66 | A | 36.875 | A | 116.09 | A | 155 | A |

| Case 3: 15-3-3 | 299.84 | A | 38.75 | A | 150.39 | A | 509.14 | A |

| Case 4: 20-3-3 | 663.75 | B | 103.13 | A | 217.73 | A | 652.03 | B |

| Case 5: 50-3-3 | 653.44 | B | 112.27 | A | 204.22 | A | 403.98 | A, B |

| Case 6: 50-5-5 | 701.56 | B | 165.16 | A | 206.17 | A | 414.06 | A, B |

| Case 7: 100-3-3 | 3975.16 | B | 352.42 | A | 864.77 | A | 2020.47 | A, B |

| Case 8: 100-5-5 | 3963.25 | B | 391.725 | A | 826.257 | A | 2415.5 | A, B |

| Case 9: 100-10-8 | 4310.47 | B | 391.41 | A | 850.47 | A | 2441.56 | A, B |

| Case 10: 200-3-3 | 10933 | B | 1182.97 | A | 2179.84 | A | 5633.83 | A, B |

| Case 11:200-5-5 | 10932 | B | 1260.47 | A | 2188.67 | A | 5574.3 | A, B |

| Case 12: 200-10-8 | 11306 | B | 1444.06 | A | 2443.75 | A | 3943.05 | A |

| Algorithms | NPS (Larger Is Better) | MMID (Smaller Is Better) | DM (Larger Is Better) | SM (Smaller Is Better) | CPU Time (s) (Smaller Is Better) | SAW Score (Larger Is Better) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | Estimate | Group | ||

| NSVNS | 4.792 | A | 0.307 | A | 4.700 | B | 0.997 | A | 7696.2 | B | 3.667 |

| NSGA-II | 4.167 | A | 0.304 | A | 6.969 | A, B | 2.772 | B | 819.11 | A | 4 |

| NSGA-MOVNS | 4.708 | A | 0.354 | A | 5.628 | B | 1.757 | A, B | 1324.97 | A | 4 |

| NSGA-VNS-DLS | 5.299 | A | 0.288 | A | 13.013 | A | 1.663 | A, B | 2945.43 | A, B | 4.333 |

| Final Model | |||

|---|---|---|---|

| Terms | Coefficient | p-Value | VIF |

| Constant | −6.97391 | 0.0011 | 0 |

| 4.02317 | <0.0001 | 2.78592 | |

| - | - | - | |

| 3.31685 | 0.0066 | 1.78024 | |

| 0.45979 | <0.0001 | 2.15809 | |

| 0.8742 | |||

| Final Model | |||

|---|---|---|---|

| Terms | Coefficient | p-Value | VIF |

| Constant | 3.27696 | 0.8486 | 0 |

| 18.50963 | <0.0001 | 1.57369 | |

| - | - | - | |

| - | - | - | |

| 3.92938 | <0.0001 | 1.57369 | |

| 0.7741 | |||

| 1% Increase in Parameters | (kWH) | (h) |

|---|---|---|

| 0.04003 | 0.18418 | |

| 0.033 | - | |

| 0.00457 | 0.0391 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, A.; Jeon, H.-w.; Jung, S.-y. Improving Energy Consumption and Order Tardiness in Picker-to-Part Warehouses with Electric Forklifts: A Comparison of Four Evolutionary Algorithms. Sustainability 2023, 15, 10551. https://doi.org/10.3390/su151310551

Ebrahimi A, Jeon H-w, Jung S-y. Improving Energy Consumption and Order Tardiness in Picker-to-Part Warehouses with Electric Forklifts: A Comparison of Four Evolutionary Algorithms. Sustainability. 2023; 15(13):10551. https://doi.org/10.3390/su151310551

Chicago/Turabian StyleEbrahimi, Ahmad, Hyun-woo Jeon, and Sang-yeop Jung. 2023. "Improving Energy Consumption and Order Tardiness in Picker-to-Part Warehouses with Electric Forklifts: A Comparison of Four Evolutionary Algorithms" Sustainability 15, no. 13: 10551. https://doi.org/10.3390/su151310551

APA StyleEbrahimi, A., Jeon, H.-w., & Jung, S.-y. (2023). Improving Energy Consumption and Order Tardiness in Picker-to-Part Warehouses with Electric Forklifts: A Comparison of Four Evolutionary Algorithms. Sustainability, 15(13), 10551. https://doi.org/10.3390/su151310551