1. Introduction

As a derivative of the petrochemical industry polyester (the fibre form of PET polyethylene terephthalate) is never far from criticism. During the 15 months of this research, from November 2019 to February 2021, polyester was in the media for controversies relating to fibre pollution [

1], Higg Index scoring [

2] and claims of fraudulent financing [

3]. There is no escaping that our treatment of materials in textile production has been damaging to people and planet. This is true of many fibre sources if incorrectly managed during their life cycle, whether during the growing or extraction phase as highlighted in the case of cotton [

4]; in the manufacturing phase, such as the viscose process for transforming cellulosic raw materials including bamboo, wood pulp and waste cotton [

5]; or in the use phase, where textiles made from polyester staple fibres are criticised for being designed and made with low-quality specifications meaning that the clothing quickly becomes unwearable preventing longevity through multiple use phases [

6]. Currently, at the end of the life cycle, all textiles are a problem because there isn’t an effective and economic route to recover their value and prevent them being ‘lost’ from the system. There are many variables that will affect the impact of a material during its life cycle and few relate to the material type. Life Cycle research conducted by Research Institutes of Sweden (RISE) revealed:

“Interestingly, the data suggests the common separation into “good” and “bad” fibres, based on generic classifications of fibre types, is too simplified. A much more nuanced view is warranted, in which the separation rather is done between producers with or without appropriate environmental management, and poor or better uses of the fibre, accounting for the environmental performance throughout the life cycle of the final textile product.”

A further challenge relates to the current practice of mechanically recycling PET bottles into polyester fibres which is marketed as ‘recycled polyester’. Although this is not a false statement, there is perhaps a misunderstanding that ‘recycled polyester’ is a solution to polyester waste. Bottle-to-fibre recycling doesn’t address the multiple challenges of textile waste and also disrupts the closed loop packaging system. Anecdotally, there seems to be an assumption that because the market for ‘recycled polyester’ from bottles has grown exponentially, that circular polyester has been achieved. Therefore, there is a need to take a step back and provide a fresh perspective on the current state and future possibilities of ‘circular polyester’. This paper presents findings from a Systemic Material Innovation (SMI) study which aims to establish a macro view of the circular polyester eco-system as experienced by the stakeholders dealing with polyester in their everyday practice to understand what interventions in the current system might support the transition to circular polyester in the near future. The authors first describe the background and the methodology before presenting the interview coding metrics and a comparison between the NOW and FUTURE systems, incorporating a summary and two visual maps. A discussion of the synthesized data is presented to address the research question and illuminate the intervention points in the system, presented as SIX Actions for Circular Polyester. Finally, the limitations and recommendations resulting from the research are considered.

1.1. Attitudes to Polyester

Recognising the unique properties that make it indispensable to modern life, Professor Mark Miodownik describes plastic as ‘an everyday miracle’ [

7]. There are some applications where it would be very difficult to replace synthetic fibres, such as in highly durable, long-lasting and safe textiles. Functional applications such as in medicine (i.e., medical sutures or durable Personal Protective Equipment), in sports and extreme conditions (i.e., quick-drying or water-repellent garments that keep skin warm and dry), climbing and rescue ropes, school and corporate uniforms (due to frequency of wear they need to be highly durable), rely on synthetic fibres such as polyester to ensure safety and durability. However, in other contexts polyester has been applied inappropriately causing challenges for circularity and ultimately wasting valuable resources. One example given by recyclers participating in this study is a fleece ‘onesie’—a garment favoured as a warm alternative to pyjamas:

There is no second-hand market for fleece either in the UK or globally—it’s difficult to sell in the UK and it’s too warm for export to second-hand markets, which are mostly hot countries

The pile doesn’t perform well on repeated washes, becoming pilled/matted and unattractive for re-use

The fluffy staple fibres fragment and cause fibre loss to waterways during manufacture, use and disposal

The zip makes it difficult for existing machinery to shred

The tightly knitted fleece is difficult for the pins in the mechanical recycling process to penetrate and disassemble into usable fibre lengths for respinning or felting.

The ‘onesie’, along with the more recent trend in adult loungewear the ‘Oodie’, is perhaps most notable because from a functional perspective it seems relatively unnecessary. These examples demonstrate how materials become ‘unsustainable’ through the ways they are applied, used and discarded. However, if this can be changed, then polyester can be a valuable material. Textile design researcher Holly McQuillan comments:

‘By treating polyester as though it is cheap, we place it into the very context where it will cause the most damage. Perhaps, since polyester is literally here to stay, we need to use only what we already have and value it more.’ Holly McQuillan, researcher and co-author of Zero Waste Fashion Design.

Many of the problems with polyester therefore lie in the systems, processes, products and textiles where it has been applied, and a systemic approach to addressing the challenges of polyester is essential.

1.2. Circular Systemic Change

Much of the conceptual work around circular materials relates to cradle-to-cradle thinking, which proposes that biological materials can cascade through loops of diminishing value towards reabsorption into the biosphere [

9], whereas synthetic materials can cascade through multiple phases of value retention with some diminishing value but cannot be reabsorbed into the biosphere [

10]. As a ‘technical material’ derived from a finite natural resource, polyester must be recovered to retain the embodied value and prevent it from polluting the biosphere. There needs to be a pathway to renewing polyester fibres once their current garment manifestation is no longer valued, so that they can become feedstock for new fibres and replace conventional non-renewable polyester (

Figure 1). The Ellen MacArthur Foundation have built a strong case outlining the potential positive impacts of moving to a circular system for textiles, including synthetics [

11].

However, other systemic factors create barriers to achieving these technical loops. For example, in 2005, the performance-wear brand Patagonia reported that they had created a closed-loop circular system for polyester fleece in collaboration with Japanese fabric manufacturer Teijin [

12]. Many regarded Eco-Cycle as the ‘holy grail’ of circular textiles, but in 2009 Patagonia reported that shipping material for regeneration wasn’t economically viable or sustainable [

13]. Today, globally less than 1% of discarded clothing is recycled back into ‘same or similar quality applications [

11]’, with the majority still incinerated or landfilled.

Fibre regeneration technologies are one potential solution to recovering value from unwearable discarded textiles. In the last five years there has been a huge increase in the number of fibre regeneration technologies being developed and scaled-up to commercialisation, which has reignited the hope that there will be a solution for unwearable polyester textiles. For those who have been involved in the evolving conversations around regenerative recycling technologies the concept of ‘renewable polyester’ is becoming a real possibility [

14]. These technologies can transform unwearable ‘bottom-of-the-pile’ garments into new fibres for textiles as well as raw materials for other high-value applications. The main criticism of these types of recovery processes is the high energy needed when compared to thermomechanical or shredding technologies. However, LCA experts claim that the energy use can be justified if the resulting fibres can replace more impactful materials that are currently used and also prevent the loss of material from the system [

15].

Material quantities and collection systems for materials also impact the ability of technologies to create real change in the system. For example, regenerative recycling technologies have been developed for dominant material types. This is for two connected reasons:

Despite the upscaling of these technologies, it will be challenging for regenerated synthetics to compete with the price of conventional synthetics. The success of the circular system relies on the value of the end-product to justify the cost of processing, and the quality of the end-product to ensure that it can replace more impactful materials. The fibre regeneration industry relies on the assumption that as demand increases, this will drive investment in the infrastructure to effectively collect, sort and prepare unwearable textiles for their process.

Policy also impacts the ability of systems to transition. In March 2020, the European Commission launched the new Circular Economy Action Plan within the framework of the European Green Deal [

17]. The action sets out new measures that focus on “strengthening industrial competitiveness and innovation in the sector, boosting the EU market for sustainable and circular textiles, including the market for textiles reuse, addressing fast fashion and driving new business models.” In 2025, it will be mandatory for all members of the European Union to collect textiles waste separately from household waste. Extended producer responsibility (EPR) for textiles products will also be a priority—already operational in France [

18], it is also being developed in several other member countries including Sweden [

19]. In January 2021, the publication of the EU Strategy for Sustainable Textiles [

20] reinforced this action and underlined the Commission’s long-term commitment to EPR, textiles collections, the development and use of secondary materials through funding, and other indirect initiatives, for example, around circular business models and sustainable behaviour [

17]. In the UK, the Environmental Audit Committee (EAC) consulted on the topic of textiles and clothing production in 2018 and produced the Fixing Fashion: Clothing Consumption and Sustainability report in 2019 [

21]. The EAC launched a second consultation in 2020 and the authors submitted evidence from this research to the UK government [

22]. Although there was no direct action following the EAC recommendations, in March 2021 the Department for Environment, Food & Rural Affairs (DEFRA) stated that it would ‘seek to review and consult on’ EPR for textiles by 2022 [

23]. However, that has now been shelved by the UK government [

24]. It is hoped that the UK government will fall in-line with Europe and commit to mandatory textiles collections, which will help to drive the feedstock preparation and scaling-up of regenerative recycling technologies. However, the industry recognises that circular polyester is still some years away from realisation. World Circular Textiles Day has set 2050 [

25] as a realistic goal for achieving mainstream circularity in textiles. WRAP has set out interim goals in its Textiles 2030 initiative, which aims to cut emissions from its signatories’ operations by 50% while ‘circular fashion is business as usual [

26]’ by 2030. Regenerative recycling technologies propose a future where polyester can be well-managed with low impacts and represent an opportunity to change the course set by previous generations of polyester production, which has been mishandled, without limits or guidance about the possible impacts, causing untold damage. Yet there are differing opinions on whether a technological approach is most appropriate for reducing impacts. Regenerative recycling has environmental costs too, and should be seen as a last resort for recovering value from unwanted clothes as one participant commented:

‘There’s almost a myth around the idea that if we create a more circular system and more circular way of doing things, that we are necessarily achieving sustainability. How do we make sure that circular synthetics are still mindful of sustainability?’

(Participant 5)

Referring to the waste hierarchy, systemic approaches are necessary before resorting solely to technological solutions:

Eliminating material loss (including through fibre fragmentation)

Replacing more impactful materials, such as conventional synthetics or conventional cotton

Longevity and repair (including rental)

Establishing second-/third-/fourth-use markets

Effective collection, sorting and preparation into valuable feedstocks

Low-energy processing into economically viable products, for example remanufacture, or mechanical disassembly

Regeneration into circular polyester fibres.

Therefore, the factors that could impact the transition to circular polyester are complex and systemic in nature. A simplistic, single perspective approach is not appropriate for understanding how to realise circular polyester; the possibility is becoming more imaginable, yet for most the route is still unclear. This research study was initiated to signpost a way forward for researchers, policy makers, and the wider stakeholder community whose action is needed to support the transition to circular polyester.

1.3. Research Question

The main research question explored in this study is therefore: what interventions in the current system might help to achieve circular polyester in the future?

2. Materials and Methods

This research was conducted by design researchers as part of the Business of Fashion, Textiles and Technology Creative Research & Development Partnership UK (BFTT), funded through the Creative Industries Clusters Programme (CICP) by UK Research & Innovation (UKRI). The broader aim of the research funding was to support industry in the adoption of technology for economic development, which included ‘green growth’ or sustainability. The focus of this ‘work package’ within the broader project was to explore the role of regenerative technologies in achieving circularity in synthetic fashion and textiles. The methodology is grounded in Systemic Design which is an emerging field of design research and practice that aims for a systemic view of a problem area to identify leverage points or ‘hotspots’ where design intervention may bring about a systemic change [

27]. The research process for Systemic Design involves defining the actors within a system, exploring their experiences of the system and emphasises co-design, participation and data visualisation as core methods of knowledge co-creation about the system, its actors and their interdependencies. The methodology is qualitative in nature and has its roots in Grounded Theory [

28]. The methodology applied to this research therefore adapts these frameworks to a problem of circularity and a specific material [

29]. The authors describe this novel research approach as a Systemic Material Innovation (SMI) study where the outcome is defined areas in the system where further intervention might bring about systemic change. These areas are articulated as questions and actions (see

Section 5) that may be taken up by industry or academic stakeholders who want to intervene in the system to bring about change [

30]. The supporting research about the system is presented visually to enable a wide range of stakeholders to act on the research, without needing technical knowledge. In an SMI study therefore, the translation of the research is integrated into the research process.

The phases of the SMI study are outlined in

Table 1. In Phase 1 a review of the academic and grey literature revealed the state-of-the-art in circular polyester textiles and helped define the design of the survey instrument. In Phase 2, to achieve a systemic perspective on the area of investigation the authors co-created an eco-system map from three different perspectives: a sportwear brand (SME), a textile recycling trade organisation, and a regenerative recycler. This provided a techno-economic view of the circular polyester eco-system in the UK, which was needed to meet the overarching goal of supporting SMEs in their transition. A critique of this system framing is provided elsewhere [

31].

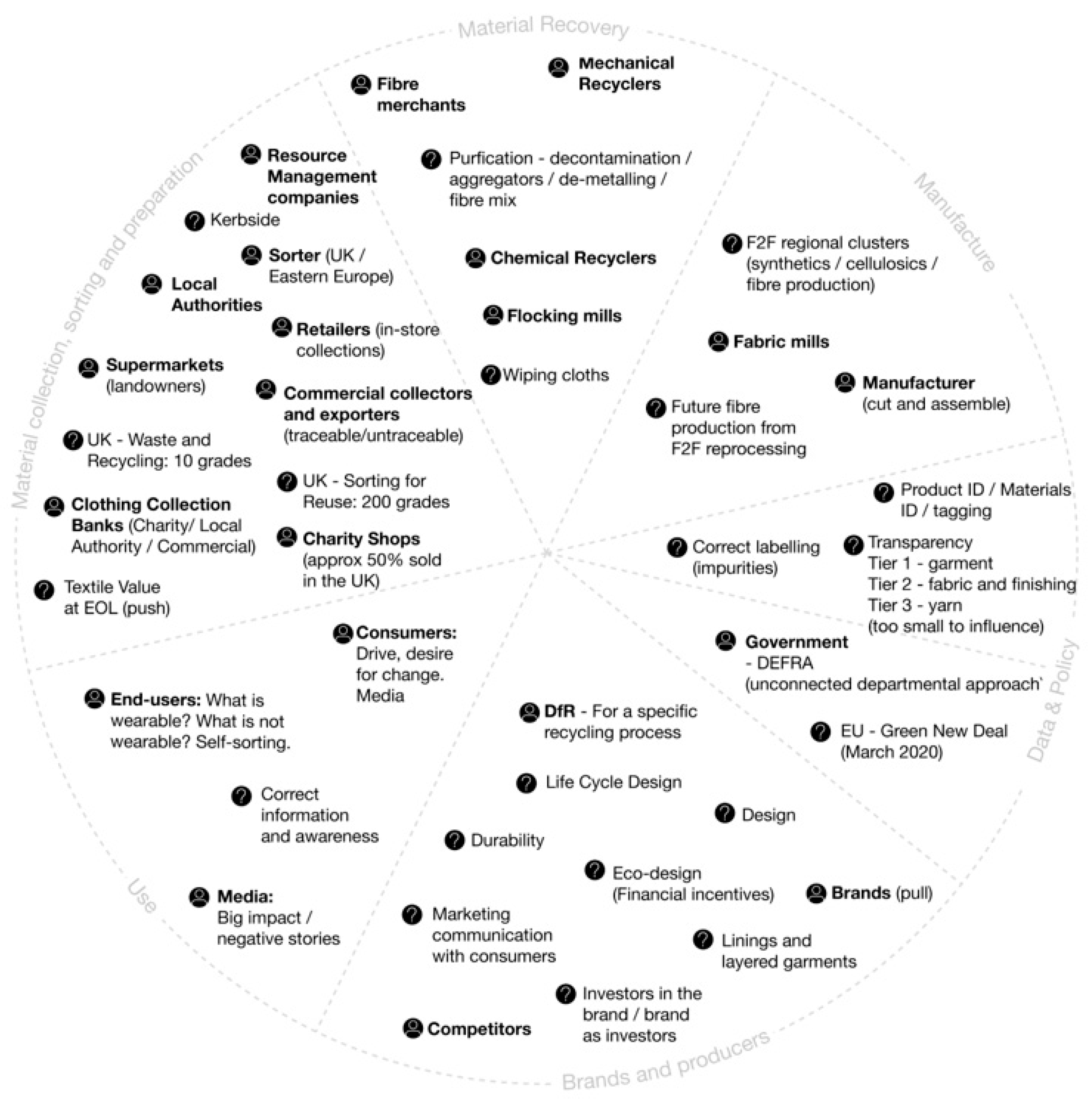

Figure 2 shows the eco-system map synthesised from these three perspectives, which was then visualised. This map was used to identify potential research participants and assist in representing a systemic perspective in Phase 3 of the research. Based on this map participants were selected from the researchers’ own networks and those of the participants in Phase 2. This initial selection ‘snowballed’ into a final selection of 20 ‘industry experts’ who each participated in a semi-structured interview around one hour in length. In addition to questions, the interviewer used three canvases to take notes as a way of probing and guiding reflection. The aim was to explore participants’ day-to-day encounters with polyester textiles while pursing circular systems, processes, materials and products. This was an important feature of the research, that the real situation being observed by people working in close proximity to polyester would be revealed and challenge common assumptions: by uncovering the finer detail, system leverage points [

32] might be identified for industry, for policy and for research. The systemic perspective allowed insights from multiple perspectives to provide much greater possibility for circular innovation, as others have noted [

33]. During the interviews, researchers probed participants’ perspectives on the challenges and opportunities in circular polyester [

34]. Participants also took part in mapping life cycles for polyester sports garments, identifying key points on a roadmap to circular synthetics and co-creating a definition for circular synthetics. Two typical polyester garments were selected from the sportwear brand’s product portfolio to provide a focal point for probing the participants’ perspectives in relation to real garments. Mapping the life cycle events of specific garments is an approach developed by design researchers to draw the discussion down from a conceptual level to a tangible product level, teasing out additional insights that may have otherwise remained hidden [

35,

36].

The sportswear and performance-wear sector was chosen as the focal point for this study because it provided an interesting pool of polyester-rich product cases. Although other synthetic fibres are used widely and offer opportunities for circularity, the study focused on polyester because it is the most common synthetic fibre and there are more regenerative technologies being developed for recycling polyester and polyester-rich textiles. The sports sector consistently uses more synthetic than non-synthetic textiles and is heavily reliant on the functional performance that can’t easily be achieved with animal, cellulosic or other plant-based fibres. The two sportswear garments selected for the research interviews were:

Leggings: reported by the SME to be in consistently high demand, both now and in future projections—82% polyester, 18% elastane.

Fleece hoodie: chosen to offer a contrast in materials and fastenings (zip) to provoke comparisons and new insights during the interviews—100% polyester.

These garments were positioned at the centre of the mapping canvases. During the interviews, the first map was annotated with the current barriers to circular polyester in sportswear, the second was annotated with ideas for what the future life cycle for circular polyester would ideally look like, and the third was a road map looking at the steps needed to get from the present to the future. The interviews were transcribed and thematically analysed according to Grounded Theory, with codes and subcodes emerging iteratively to build the final codes [

37] to reveal the main barriers and opportunities to realising circular polyester identified by participants.

Visualisation

Sense-making and visualisation of the data resulted in interim representations of the maps (

Figures S1 and S2) consolidating the participants’ perspectives. To sense-check these initial visualisations, the expert participants were invited to review the interim findings through an asynchronous online focus group using MIRO over the course of one week, culminating in a focus group. The focus group discussion was recorded and transcribed, and the findings were used to refine the visualisations. The data was then mapped using different visual structures to ascertain the best visual display for each data type and combination. Each infographic was then iterated collaboratively using MIRO. The visualisations aim to communicate the findings of the study to assist multi-disciplinary and multistakeholder reading of the system.

3. Results

The interview data was analysed to reveal 17 codes related to ‘barriers to realising circular polyester’ and 23 codes relating to ‘opportunities to realising circular polyester’. These are presented in

Table 2. To enable a deeper dive of the most pressing ‘barriers’ and ‘opportunities’ the sub-codes for the ‘Top 5’ most frequently occurring codes for barriers and opportunities are identified in

Table 3 and

Table 4. These are now briefly annotated to draw out the main findings, before presenting the detailed discussion.

‘Design for Recycling and Reuse’ takes a prominent position as both a barrier and an opportunity for realising circular polyester which is expected from a linear system where the impacts of decisions downstream are not taken fully into consideration at fibre, textile or garment stages. This can be linked to ‘Improved understanding of life-cycle impacts and actions’ which participants most frequently discussed as an opportunity: if impacts are understood then actions can be taken to reduce those impacts at the materials engineering, textile and garment design stages. Likewise, the improvement of data concerning material flow throughout the lifecycle was seen as an important barrier and an opportunity.

Collection systems featured as one of the main barriers and opportunities which highlights a particular area for action in central and regional policy. Meanwhile, participants recognised that for polyester in particular, regenerative recycling technologies represent an important technological opportunity give the prominence of the ‘no recycling route for polyester’ code.

Brands are seen as a clear barrier to circularity and looking to the sub-codes for the ‘inaction by brands’ code, there is clearly a feeling that Brand strategy and responsibility is currently lacking. In terms of opportunities for Brands to act, ‘design for reuse and recycling’ subcodes provide some direction as well as advocating data and transparency.

From a materials perspective, elastane explicitly features in three sub-codes relating to barriers and opportunities and fleece (as a prominent staple fibre) appears in three sub-codes. These are perhaps most interesting because they are characteristic of polyester garment design in sportswear and are associated by the participants to different types of impacts.

Transition from NOW to FUTURE Versions of the Polyester Eco-System

Figure S1 presents the synthesised findings from the mapping exercise that took place during the interviews and shows a comparison between how participants see the current polyester life cycle (NOW map) and the ideal future system (FUTURE map) for circular polyester. These points of differentiation are also described in

Table 5. Some clear differences between the current and future systems include a visible shift from a linear system to a circular one, a reduction in the material loss from the system, and the increase in ‘policy and funding’, and ‘data and transparency’ activity that participants believe is necessary for future circularity. There is more connectivity through the FUTURE map between different parts of the system, through regional industrial hubs.

The discussion in

Section 4 synthesises the interview data to reveal the key themes relating to the research question: what interventions in the current system might help to achieve circular polyester in the future?

4. Discussion

The synthesis of interview findings presented in

Table 5 and

Figure S1—shows a huge gap between participants’ observations of the current state of circular polyester and the ideal future scenario they envisage for the industry. This discussion focuses on what needs to happen to transition from the current state of the system to circular polyester in the future according to the expert participants, and is organised into the key themes that emerged from the data synthesis representing the ‘interventions in the current system that might help to achieve circular polyester in the future’:

Brands and product design

Collection, sorting and preparation

Transformation technologies

Data, knowledge and behaviour

Economics, policy and regulation

4.1. Brands and Product Design

‘Inaction by brands’ and ‘not designed for reuse and recycling’ were the most frequently mentioned barriers to achieving circular polyester. As the driving force behind design decisions, Brands could make a positive contribution towards future circularity through their existing activities as this participant describes:

‘The strength and focus of the brands and retailers that really have the market pull at their fingertips, with the decisions they make in terms of their fibre portfolios, will have a lot of impact on how things develop. This shows that market pull is really important.’

(Participant 19)

‘Design for recycling’ was frequently mentioned during this research. The people who work with discarded garments offered useful insights into why some materials are not fit for circular systems, and provided guidance for designing synthetic garments, such as:

The waistband perishing in a pair of leggings can be attributed to the short life of elastane;

Using company logos or embellishments means there is no reuse market or recycling route;

Fleece cannot be reused because it is often in poor condition. There also is no export market for warm clothes, fleece cannot be easily pulled apart in mechanical recycling, and it is no good for rags;

Linings, and even care labels themselves, are seen as detrimental to the process of sorting and recycling;

Blends are seen as problematic, with those for which there are currently no technical solutions, such as poly-elastane rather than poly-cotton, causing the most concern. This also depends on the economic case for extracting polyester from different blend ratios

However, design for recycling only addresses a small part of the problem of circularity and arguably has limited potential without a more connected, collaborative and strategic approach.

One of the greatest challenges brands face in taking a truly circular perspective, is their level of understanding of different parts of the material life cycle. For example, insight into the available recycling processes might help brands develop design-for-recycling approaches. However, brands reported having very little insight or influence further up the material supply chain, towards the raw material. This suggests that an important priority for circular brands is to develop relationships with a range of circular stakeholders, for example working directly with producers of circular materials through supplier nominations. Buying into these new and evolving circular technologies is likely to mean that larger brands will need to invest more in circular materials, having a powerful advocacy role in the transition to the mainstream. Working in this way requires more material tracking and traceability throughout the supply chain. At the other end of the life cycle, once a garment has left the warehouse or store, brands reported having very little intelligence about how it is used, re-used, and disposed of, which is a huge barrier to action.

Participants identified a number of actions that brands could take to support circular polyester:

Focus on design-for-recycling approaches for specific post-use processes, which would enable easier sorting, reuse and recycling;

Be willing to pay more for materials produced using emerging technologies and at smaller scales during the scaling-up phase, therefore investing in the further development of those technologies;

Commit to circular polyester, for example by setting targets and having a strategy for meeting those targets;

Be part of the conversation around materials and product ID or tracking;

Phase out elastane, which would benefit all stages of the post-use phase;

Invest in improving understanding of the post-use phase and data;

Develop relationships with other circular stakeholders.

4.2. Collection, Sorting and Preparation

‘Limitations of current collection systems’ was one of the most frequently discussed barriers, while “More dynamic collection operations’ was seen as a significant opportunity. How clothes are collected, sorted and prepared for their next use or transformation is central to circularity, and connects to every decision in the garment life cycle as this participant explains:

‘There’s no technology where you just put in a whole garment of any material composition—a magical container where you put in a garment and then something comes out. There’s a lot of pre-processing and sorting effort necessary in order to prepare the material so that it can go into this regenerative recycling technology.’

(Participant 8)

Given how important this stage is to circularity, it receives relatively little attention from research, development or funding, and policy is still reactive rather than proactive in this area. Participants reported that one of the core problems with current collection methods, such as textile banks and kerbside bags, is that textiles are often exposed to damp, dirty conditions, which means they are contaminated when they arrive for sorting. The introduction of retailer take-back schemes is seen as a way of collecting cleaner textiles, but these are not always convenient for people to access.

Once collected, a number of sorting steps are performed, often by skilled workers, which adds cost to the process. Automated technologies are being developed to sort unwearable textiles, but the markets are not yet established, meaning they aren’t currently economically viable and are risky to invest in. Further challenges include identifying complex textile blends, sorting to a high specification of fibre type, and processing layered and laminated garments. ID technologies, to automatically identify fibre types, would enable materials to be accurately sorted for regenerative recycling processes. Data is sparse in the post-use phase so there is a huge opportunity if intelligence can be gathered here. The unwearable materials destined for mechanical or regenerative transformation often need further preparation, such as layer separation, hardware removal or shredding. All of these steps are technically feasible, but they also need to be economically viable for the specific transformation technology and the resulting end product. Therefore, designing, collecting, sorting and preparing materials for a specific transformation process is a key area for consideration and development.

While these technologies are evolving to cope with mixed post-use textiles, the routine segregation and collection of pre-use discarded textiles, such as cutting-room-floor and end-of-line fabric and garments (as a last resort after zero-waste options have been exhausted), could feed regenerative technologies and help them to transition to commercial scale. From a consumer perspective there is still much to understand about how to pass on different types of garments. Currently the solutions are not yet sufficiently in place to communicate a coherent message to users so, for now, the most important message is simply ‘don’t throw it in the bin’. In the future, communication and user participation in an effective system of collection, sorting and preparation will be important.

4.3. Data, Knowledge and Behaviour

‘Lack of material/product/process data’ was a frequently discussed barrier, while ‘Improved understanding of life-cycle impacts and actions ‘and ‘Improved data collection and provision’ were frequently discussed opportunities. This also was echoed in the mapping exercise, where data featured more prominently in the FUTURE system map. Therefore, knowledge of the whole life cycle of a synthetic fibre, textile and garment could be the key to understanding how to act at different points in the material journey, as this participant explains:

‘It would be very valuable to get inside what happens to the product after it’s sold to the consumer. How long will they use it? What route will it take? When really is end-of-life?’

(Participant 1)

In the past few years greater emphasis has been placed on transparency in the supply chain, from manufacture to sale, with a variety of service providers now capitalising on this opportunity. However, currently these providers only collect data on a small part of the material life cycle. Participants reported that in many cases brands currently find it challenging to ‘see’ further up the supply chain, to the fibre and raw material producers. This impacts a brand’s ability to understand and influence the origin of the fibres used in its products. However, there are solutions emerging that could increasingly address this concern. Downstream, there is very little data about behaviour with polyester garments, the decisions made about garment care and what people do with their unwanted clothes. When a collector takes a garment, they need to know the material composition to sort it into appropriate streams for recovery. However, there are numerous behavioural challenges: users sometimes add materials, such as starch, patches and adhesives, that can change the way that a garment can be reused or processed, while labels are often inaccurate or have been cut away. Regenerative recycling technologies are sensitive to the types of fibres and blends that can be processed, and so this information is crucial.

Knowledge of the whole life cycle can affect behaviours and, vice versa, the more stakeholders know, the more they can understand how to act. This applies for garment owners, producers, designers and textile collectors—every stakeholder can benefit from access to data. Participants felt that a solution for attaching an ID to a fibre or garment, that also connects data through integrated data platforms from different service providers would be play a crucial role in achieving circular polyester. One of the likely reasons for current data gaps is the lack of incentives for developing data capture throughout the life cycle. Who will pay for data collection during the use and post-use phases? How will the cost of a whole systems approach be distributed between stakeholders? EPR would almost certainly help with this as brands will need to take more responsibility over the use and post-use phases, which could drive the pursuit of data, as this participant explains:

‘I have no doubt that, in the next couple of years, we may do more around post-use data, even if it’s just information such as where the garment came from or the composition of the garment that’s recorded, or where it’s gone to be recycled. Then, even if we just take it to that point, from a compliance perspective it might be quite useful for retailers.’

(Participant 15)

While data can go a long way to enabling stakeholders to act, first there needs to be a mindset shift in how we conceptualise and understand textile production and use—the concept of designing-in reuse and circular regeneration is still unfamiliar to many. Regenerative recycling will enable brands to continue, more or less, with business as usual, replacing conventional polyester with circular polyester. However, the impact of fibres and textiles could be reduced further if there was greater acceptance of different material properties than are expected of conventional materials. And it will take an even greater mindset shift to adopt business models where polyester fibres move through multiple, cascaded use and processing phases, and a general slowing down of production. Building understanding of the circular system’s mechanisms is also an opportunity to create small changes that will support long-term transition. Central to this understanding will be the development of partnerships that take stakeholders out of their linear relationships. A change in approach is needed not only for brands but also for the manufacturing, collection and sorting sectors. Fostering new mindsets among people in key positions in the circular supply chain could offer a great opportunity for driving innovation and uptake of circular practices.

4.4. Transformation Technologies

‘No recycling route for polyester’ and ‘Industrialised regenerative recycling technologies’ featured sixth in the coding frequency table, so were discussed as barriers and opportunities but not as strongly as others. However, transformation technologies became more prominent in the discussions during the FUTURE mapping exercise, where participants made this one of the key features to realising circular polyester. Participants identified three routes for the development of transformation technologies to support circular polyester: mechanical melting, mechanical disassembly, and regenerative chemistry.

Transforming polyester using a melt process is very challenging unless the material is homogenous with known contaminants, which is why this process has mainly been used for transforming PET bottles into polyester fibres. Heterogenous textile waste contains too many unknown contaminants, such as dyes, finishes, dirt and fastenings, to be transformed back into a useful material using a melt process. Transforming polyester textiles into new yarns using a disassembly method and then re-spinning the fibres into new yarns, is a low-energy process and participants viewed this as beneficial for sustainability goals if a saleable end product can be achieved that replaces a high-impact material. However, this method has traditionally been developed and used for cotton and wool, and it is not easy to adapt the existing machinery for synthetics, particularly those with stretch. Moreover, participants acknowledged that few in the fashion and textiles industry are willing (or, in some cases, able) to accept or adapt to polyester yarns and textiles that have different qualities to conventional materials. While some design applications can accept a different ‘quality’ of polyester yarn, many applications and processes demand high strength, durable or fine fibres that are difficult to achieve using mechanical processes.

Regenerative recycling is seen as a huge opportunity for regaining these properties from the ‘bottom-of-the-pile’ mixed polyester textiles, which are unsuitable for mechanical processes and are currently incinerated or landfilled. Regenerative technologies that can transform polyester textiles back into fibres of the same quality and at the same price. Participants claimed that the barriers to achieving circular synthetics, particularly with polyester, of the same quality as conventional synthetics are not technological, they are to do with feedstock supply, scalability and economics. Participants identified two main barriers to achieving commercial scale with regenerative technologies, in addition to the current low cost of conventional polyester:

Investment in commercial-scale textile biorefineries: Moving from pilot scale to commercial scale requires huge investment. This is very risky for private investors if the feedstock supply is not in place.

Feedstock development: For commercial-scale textile biorefineries to work efficiently, they need to process huge volumes of material. Each regenerative technology has a specification for the textile feedstock it can accept into the process. This varies in composition, whether it’s 100% polyester or a polyester-cotton blend, and how much polyester hardware or other contaminants it can cope with. Using feedstock from known sources, such as manufacturing clippings, ‘fallout’ or uniforms, may be a worthwhile first step in scaling up until the preparations of mixed post-use textiles become more sophisticated and mainstream.

While regenerative recycling offers a last-resort option for bottom-of-the-pile synthetics, the most appropriate feedstocks for the process need to be identified and developed. Participants involved in collections, sorting and recycling identified the feedstock archetypes in the UK that are currently suitable for regenerative transformation, these also relate to the feedstock types mentioned in the Roadmap (

Figure S2):

Pre-use 100% PES textiles, such as off-cuts and end-of-line.

Pre-use polyester-rich fall-out garments, such as over-stock and merchandise.

Post-use polyester-rich branded uniform, such as school uniform, service wear, and sports team kit.

Post-use polyester-rich home textiles, such as bulky bedding, seat coverings, and bed linen.

Mixed post-use, non-re-wearable textile with no secondary market shown to be consistently polyester-rich.

Some of these pre-use textiles could be repurposed for remanufacture if a suitable re-sale model could be established, and the search for lower-energy mechanical disassembly solutions within regional small-scale operations should continue, and perhaps receive more attention and funding than currently.

4.5. Economics, Policy and Regulation

‘Lack of appropriate central policy, regulations and incentives’ was discussed moderately as a barrier, however ‘High cost of circular polyester versus low costs of conventional polyester’ was frequently discussed. ‘More investment’ was also seen as an opportunity. Within the mapping exercise economics, policy and investment became more prominent when participants were asked to think about how to transition from NOW to the FUTURE. The low cost of conventional polyester, which is largely determined by the price of crude oil, creates volatility in the market for all materials that seek to compete with petrochemical-derived products. While demand is increasing for circular polyester fibres and PET pellets for packaging, the capacity to process and supply this material is not yet sufficient to compete with low-cost conventional sources. The processes to prepare both pre- and post-use textiles are currently prohibitively expensive, and it will take time to set up efficient systems for collection, sorting, stripping and shredding. Currently, the regional clusters described in the FUTURE map (

Figure S1), which would help with the logistical costs, are still emerging. However, the economic barriers could be greatly eased through investment and policy actions, as this participant comments:

‘Policy is what sets the direction for change—it sets out the frameworks. Where market drivers are missing, it can help to balance the market so that certain areas aren’t disadvantaged, and make sure that we’re helping with that transition to a circular economy.’

(Participant 13)

Until the risks are acceptable for private investment, participants felt that an important area for state and regional funding will be the technology-enabled infrastructure needed for sorting and preparation which they believe is currently neglected by funding policy. Regional approaches could be powerful in driving circularity; participants felt that in-use and post-use behaviours are best understood and addressed at a local level. Moreover, a strategy for reskilling within a given region towards the new vision for circular textiles could attract funding and investment from regional grants. Policies are needed to create a fairer price comparison between circular and conventional PET, for example using tax breaks and other financial incentives for buying circular materials (market ‘pull’), and for collecting unwearable textiles (supply ‘push’). Four specific legislative actions were identified by participants in the research:

Extended Producer Responsibility (EPR) is important for encouraging brands and producers to invest and take more action over design-for-recycling, take-back and alternative business models for their products. However, setting up this type of legislation is complex and requires careful consideration of the impacts. Making sure EPR reflects the waste hierarchy and broader sustainability aims will require significant regulation and standards, and could take a long time to develop.

Mandatory separate textiles collections would ensure that government and local authorities are incentivised to find solutions for regionally generated post-use textiles. For members of the EU, this will come into force in 2025.

A 1p levy on each new garment sold would provide funds to invest in the infrastructure needed for a sustainable fashion and textiles industry. Other suggestions include a weighted penalty system based on a yet-to-be-defined set of eco-design standards applied to each garment.

A ban on fibres of unknown origin would help prevent fraudulent claims of circular or sustainable origin, but would require sophisticated systems for tracking and transparency through the supply chain.

Currently there are no plans to implement these measures in the UK.

5. Conclusions and Recommendations

The research has shown that to realise circular polyester there needs to be a range of interventions in the system and in particular relating to the five themes presented in the discussion, as noted by this participant:

‘I think the challenge is to really have a systems approach. These areas [of the life cycle] are so interconnected, but to work with them [systemically] can be challenging and it takes a mindset shift.’

(Participant 5)

Creating a shared vision of fashion and textiles within a circular future can help communicate the path ahead to all stakeholders, helping them to visualise their roles. Regional and localised demonstrations can help to make the change seem feasible and relatable. Real-world contexts can hugely impact the possibilities of circular textile eco-systems, with local policy, demographics, socioeconomic factors, housing types, cultures, skills and infrastructure all impacting what circular systems can be achieved. The participants of this research see a shift to a regional focus for circular systems as both desirable for sustainability and necessary to create more resilient textile economies.

The evidence from this study builds the picture for a new circular polyester, one that is fit for circular systems, connected to data and services, and designed for multiple use phases and regeneration processes. These participants talked about the level of vision that is needed, the scale of the challenge but also the justification, if needed, for why it is worth pursuing large-scale systemic change through a whole life cycle ‘circular’ approach rather than relying solely on isolated pockets of activity and grass roots initiatives—a multi-scale systemic collaborative approach is needed as these participants describe:

‘When I started talking about this, people were saying, “Well, you could do some upcycling, you could do this, you could do that.” That’s great and, don’t get me wrong, some artisan things will help, but the scale of the problem is beyond that, and it’s massive. It needs a massive amount of funding and a massive amount of stuff thrown at it to get it up and running. Once it is up and running, I think it could change the way we are.’

(Participant 9)

‘A point solution does not solve this. You’ve got to have partnerships; you’ve got to have industry partners. I honestly think recycling is one of those things, the more I’ve learned about it, that is a really great example of, “Oh, that’s somebody else’s problem”—every single stakeholder believes it is somebody else’s problem.’

(Participant 16)

5.1. Systemic Interventions for Circular Polyester

As part of the mapping exercise, participants were asked to identify points in a roadmap to realising circular polyester. These were synthesised with the interview findings to create one visual roadmap that includes the key points, in particular relating to ‘policy and economics’, ‘transparency, tracking and economics’, and ‘materials and transformations’ (

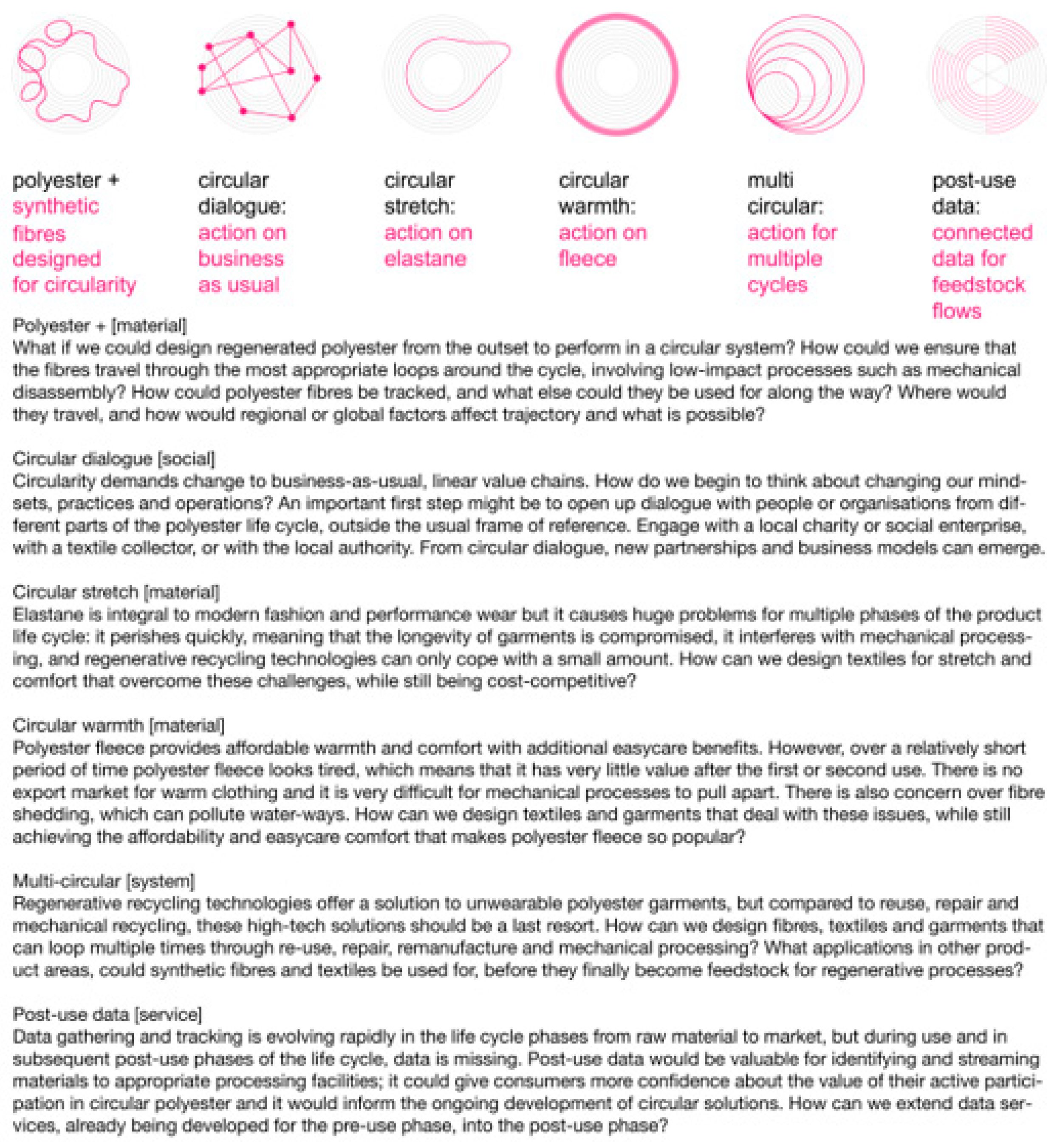

Figure S2). Interventions for research and industry were also identified and articulated as SIX ACTIONS (

Figure 3).

These are not meant to fully represent the work that needs to be done, but to present some tangible interventions that the participants confirmed would be beneficial to pursue and investigate further. Each of these actions relates to a different level or area of action [material/social/system/service] and will be appropriate for different stakeholders, depending on the skills, expertise, scale and activities of the organisation or individual interested in working towards circular polyester. These maps were presented to the participants in an asynchronous workshop and focus group for feedback and expert evaluation of their appropriateness.

5.2. Closing Remarks

By taking a systemic approach to this investigation and gathering the perspectives of the people who are striving to develop circular practices for polyester, this research has demonstrated the complexity of transitioning the current system from linear to circular. While the high level of marketing around the use of rPET fibres in sportswear and performance textiles would lead most to believe the ‘work’ of circular textiles is ‘done’, the accounts of these participants shows that there are still great challenges to achieving circularity for polyester textiles. The research has identified some of the key barriers and opportunities to realising circular polyester and the data has been analysed and synthesised to reveal promising systemic interventions. Action is needed at multiple levels and across the whole stakeholder eco-system, involving policy change, economic leverage, and behaviour change, as well as investment in new and emerging technologies, infrastructure, materials and services. However, the recent emergence of regenerative recycling technologies is encouraging and the varied work of the stakeholders working in different areas of the polyester textile life cycle shows that these systemic challenges are beginning to be addressed. The FUTURE map, the roadmap and the six ACTIONS provide a guide for what needs to happen from the perspective of these industry experts.

This research has a particular focus on the UK and through a technoeconomic lens, so an additional recommendation is that more research is needed to understand the perspectives of social stakeholders in the circular polyester system, such as the users of polyester garments, the workers in the current polyester textiles value chain, and the communities outside of Europe who are impacted by any changes to the current system in the ‘consuming’ countries.