Abstract

Wax deposits related to flow assurance are a costly problem in oil production in many fields around the world. Modeling of this process is the main tool for creating and optimizing methods to deal with this problem. This paper considers a new empirical model for the formation of these deposits, based on the results of an array of laboratory studies, theoretical data and technological calculations are presented. The created technique takes into account the conditions of oil flow, data from laboratory studies, and the water cut of the product. The experience of the industrial operation of the technique showed a high convergence of the calculated and actual deposit profiles. Based on a comparison of the calculated and actual deposit profiles, it was concluded that the standard deviation of maximum wax thickness is 6.0%, and the depth with the greatest wax thickness is 3.5%, which is a fairly high result. The use of this technique makes it possible to optimize the depth of mechanical cleaning of the well, the installation of heating cables, as well as the parameters of hot flushing, which increases their efficiency and reduces the cost of combating the formation of wax deposition.

1. Introduction

The formation of wax deposits is one of the most common complications in oil production in the territory of many oil fields around the world [1].

At present, this problem is becoming more and more urgent in the context of a decline in hydrocarbon reserves and an increase in the distance of fields that are moving to the later stages of development [2,3]. As a result of these processes, there is a change in the technological parameters of oil production, namely: an increase in the water cut of the product, a decrease in bottomhole and reservoir pressure, and a change in the component composition of the produced product [4,5,6]. Such dynamics of indicators contribute to the earlier formation of organic deposits [7] and often lead to a shift in the place where paraffin formation begins from the lift pipes to the pore space of productive formations.

1.1. Preventing and Removing of Wax Deposits

The fight against the formation of deposits is carried out in two ways: the removal or prevention of the formation of these deposits. Methods for removing deposits include mechanical cleaning, flushing with hot agents (oil, water, and steam) or hydrocarbon solvents [8,9]. Methods for preventing the formation of deposits include the use of heating cable lines, track heaters, dosing of chemical reagents, the use of smooth coatings, physical fields (magnetic, acoustic) [10,11,12]. Deposit prevention methods are preferable because they allow valuable high molecular weight components to be retained in the oil composition. At the same time, scientific works [13,14] have proven that for the effective application of various methods to combat the formation of wax deposition, a correct assessment of the depth and profile of deposits is required. Next, the main aspects of wax deposit education are considered. Thus, for the use of well flushing with hot agents, it is necessary to assess the profile of wax deposits in an oil-producing well, since this type of treatment is effective only at shallow depths [15]. A similar disadvantage is the use of a heating cable, since in the absence of information about the interval of the formation of wax deposition, it is not possible to determine the installation interval of the heating cable.

1.2. Digitalization of the Oil Industry

A lot of research in this area is aimed at developing a methodology for assessing the spatiotemporal distribution of these deposits [16,17]. However, at the moment there is no universal technique [18]. At the same time, in the context of intensive digitalization of the oil field, work is underway to create digital twins of oil fields [19,20]. To accomplish this task, it is necessary to be able to simulate all technological processes in an oil field, including the formation of wax deposits, since their accumulation leads to a change in pressure and temperature in the oil collection and transportation system [21,22].

1.3. Mechanisms for the Formation of Wax Deposition

The scientific literature considers several main approaches to modeling the formation of deposits: mass transfer and phase transition [23,24]. At the same time, most scientific works describe the first approach. Mass transfer models are based on the concentration difference between the bulk and the interface, usually assuming Fick’s first law [25,26]. Phase transition models, on the other hand, assume cooling and transition from a liquid to a solid state, by analogy with the formation of ice [27]. The main mechanisms used in mass transfer models are molecular diffusion and shear dispersion [28]. A detailed description of these mechanisms is provided in [29] based on which it can be concluded that these mechanisms make little contribution to modeling the formation of wax deposition. The phase transition model is based on the assumption of a constant interfacial temperature, so the process of deposit formation is related to the phase transition problem. At the same time, in the published work [30], it is indicated that a similar system of equations can be applied to simulate the formation of wax deposition as for modeling the formation of ice. A detailed review of phase transition models is provided in [31]. In favor of the validity of the application of the phase transition mechanism, the results of studies pointing to a constant temperature of the phase interface [32,33] are in favor. Moreover, this mechanism makes it possible to explain the phenomenon of a decrease in the rate of formation of wax deposition with an increase in the Reynolds number [34].

1.4. Mathematical Models of the Formation of Wax Deposition

To date, three models of wax deposition formation are widely used in commercial multiphase flow simulators: Rygg, Rydahl, and Rønningsen (RRR), and Matzain and Thermal Analogy (Heat Analogy). A detailed description of these models is provided in [35]. In [36], a review of the existing models for the formation of wax deposition was carried out. As a result, it was found that models based on correlations and physical laws have insufficient accuracy and cannot be used in various conditions. An example of an empirical model of the formation of wax deposition is the work [37]; however, the applied model did not take into account a number of important factors, as a result of which its industrial application was difficult.

1.5. Oil Flow Modes

When oil flows, two modes of oil flow are observed: “hot” and “cold” (Figure 1). The “hot” flow regime implies the oil flow at a temperature exceeding the wax appearance temperature (WAT), and in the “cold” flow regime, the oil temperature is below WAT [38,39]. In the “hot” flow regime, wax deposits are formed from the near-wall oil layer, which cools below WAT [40,41]. In the “cold flow” mode, the formation of deposits occurs in the volume of oil, creating a suspension of “oil-wax deposits” [42,43].

Figure 1.

“Hot” and “cold” flow during oil flow.

Practical confirmation of the correctness of this model of sediment distribution is presented in several scientific works, for example, in [44,45]. As part of this work, the authors combined the results of laboratory studies and the experience of past studies of authors from various countries to create a comprehensive empirical system for predicting the distribution of wax deposits in linear pipelines and lift wells.

2. Materials and Methods

2.1. “Wax Flow Loop” Installation

Laboratory studies in the framework of this work were carried out on the laboratory stand “Wax Flow Loop” (DIUS-LAB LLC). Research on this stand consists of the circulation of the studied oil at a given temperature along a closed circuit. Oil is heated by a circulation thermostat. To start the test, the temperature of the test section is reduced to create a temperature gradient and start the formation of deposits. The pressure in the system is controlled by supplying gaseous nitrogen to the raw material tank. The inner diameter of the test section is 5.5 mm, the length is 1.3 m, and the wall thickness is 0.89 mm. The thickness of the deposits is estimated based on the dynamics of the increase in the pressure drop between the inlet and outlet of the test section according to the Poiseuille equation (Equation (1)).

where is the pressure drop in the test section, MPa; is the volume flow rate of oil, m3/s; is the oil viscosity, mPa·s; is the length of the test section, m; and is the inner diameter of the test section, m.

Determination of the dynamic viscosity of oil takes place before the study when the oil is circulating in the absence of a temperature gradient. However, ref. [46] describes a method for determining the dynamics of changes in the rheological properties of oil during the formation of paraffin deposits in installations of the “Wax Flow Loop” type, used in this work.

As a result of the execution and processing of the study, a wax deposition formation curve is obtained, a graph of the dependence of the thickness of deposits on time.

2.2. Definition of WAT

For a detailed analysis of studies and further development of a methodology for predicting the formation of deposits, it is necessary to evaluate one of the most important values, wax appearance temperature (WAT). This parameter is also evaluated on the Wax Flow Loop. To do this, the oil and the test section are heated to a temperature above WAT. Then, the wall temperature is gradually reduced and then held for 2 h. If, after this time, no increase in the temperature gradient is registered, then the temperature of the oil is again reduced until a layer of deposits appears. According to the manufacturer’s data, the error of the differential pressure gauge is ±0.075 kPa, which corresponds to the error in the determined thickness of the wax deposition ± 0.006 mm.

2.3. Fluid Properties and Operational Parameters of Oil Wells

To develop a model for the formation of paraffin deposits, studies performed on oil samples “A” and “B” were used. The viscosity of oil under surface conditions was determined using a Rheotest RN 4.1 rotary viscometer, and the density was determined using an Anton Paar laboratory density meter.

Their physical and chemical properties are presented in Table 1.

Table 1.

Physicochemical properties of the studied fluids.

Within the framework of this work, the results of field studies for 10 oil-producing wells are also presented. The parameters of the operation of these wells and the properties of the extracted fluids are presented in Table 2.

Table 2.

Operating parameters of oil wells and fluid properties.

3. Intermediate Results of Creating a Wax Deposition Formation Model

Due to the considerable duration and complexity of creating a wax deposition formation model, this process is presented in stages. For ease of perception of the graphs, the research parameters are encrypted in the signature according to the following template “XX/YY–ZZ”: XX: oil temperature during the study, °C; YY: wall temperature during the study, °C; ZZ: mass flow rate of oil during the study, kg/h. As part of the development of the methodology, more than 100 studies were conducted on the Wax Flow Loop installation. The most representative variants are presented in the text of the work.

Before presenting analysis of research results, an important remark should be made. The oil sample entering the test section is intensively cooled. Moreover, according to studies [47], cooling in the initial part of the test section is very intense. As a result, it must be considered that the actual oil temperature in the test section is lower than at the inlet. During the analysis of the performed studies, it was determined that in the absence of sediment breakdown, the effect of velocity is limited by changes in the parameters of heat and mass transfer.

3.1. A series of Laboratory Studies on Fluid Sample “A”

Figure 2 shows a series of studies performed on one oil sample.

Figure 2.

Results of laboratory tests on oil “A” at constant wall temperature (5 °C): (a) tests at oil temperature 30 °C and different flow rates; (b) studies at 25 °C oil temperature and different flow rates; (c) studies at a mass flow rate of 4 kg/h and various oil temperatures; (d) studies at a mass flow rate of 1 kg/h and different oil temperatures.

Analyzing these graphs, a number of important dependencies can be noted.

- Analysis of Figure 2a indicates a decrease in the rate of wax formation with an increase in the oil flow rate. At high oil temperature and movement speed, the liquid does not have time to cool down to achieve WAT and the highest intensity of wax deposition formation. As a result, a decrease in the flow rate leads to its cooling and the flow reaches WAT with an increase in the intensity of wax formation.

- At the same time, the opposite dependence is observed in Figure 2b, an increase in the flow rate leads to an increase in the intensity of wax deposition formation. This is due to the fact that the oil temperature during the study is equal to WAT. This means that with an increase in the speed of oil movement, the oil temperature in the test section remains higher, respectively, the intensity of the sediment formation process increases.

- When considering Figure 2c, it can be noted that at an oil velocity of 4 kg/h, the greatest intensity of wax deposition formation, is observed at a temperature corresponding to WAT. At the same time, Figure 2d shows studies at a lower speed (1 kg/h), at which the greatest intensity of wax deposition formation is achieved at a temperature exceeding WAT (30 °C). This dependence can also be explained by oil cooling. In the study of oil with a temperature above WAT (30 °C) at high speed, this temperature is maintained, as a result of which the formation of deposits is not so intense. At a low temperature of the oil flow, it cools, reaching the highest intensity at a temperature of 25 °C. At the same time, studies at 25 °C and a flow rate of 1 kg/h lead to rapid cooling of oil and a sharp decrease in the intensity of the sediment formation process.

The results obtained allow us to assert that when creating a model, it is extremely important to take into account the oil flow regimes.

3.2. Application of the Theory of “Hot” and “Cold” Flow

The change in the rate of deposit formation in the performed studies is similar to the theoretical curve presented in Figure 1. To compare the theoretical and practical curve for oil sample “A”, several additional studies were carried out at a constant wall temperature and a flow rate of 4 and 5 kg/h. These velocities were chosen because they correlate with the speed of oil movement along the 62 mm tubing at a flow rate of 13.6–16.9 m3/day, which is the average well flow rate in the target fields. To construct Figure 3 values, the values of the thickness of the deposits were obtained at one time during the study of one oil sample under different temperature conditions. The obtained thicknesses are recorded as relative values with respect to the thickness of deposits at an oil temperature equal to WAT. For ease of perception, the graphs are shown in reverse order of temperature, similar to Figure 1.

Figure 3.

The results of laboratory studies to study the effect of oil temperature on changes in the wax deposition formation temperature.

3.3. Studies with a Change in Wall Temperature

The next series of studies is provided at a constant oil temperature and flow rate, but with a change in wall temperature. The studies were carried out on sample “B”, the properties of which are also presented in Table 1. The results of the studies are shown in Figure 4.

Figure 4.

Laboratory results on oil “B” at constant oil temperature and mass flow, and varying wall temperature.

Considering the obtained results, it can be seen that the rate of formation of deposits decreases sharply when the wall is heated above 10 °C. At a temperature of 20 °C, the formation of deposits practically stops (at a wall temperature of 25 °C no change in pressure was recorded). By processing the obtained curves, by dividing the value of the deposit thickness for all curves by the value for the curve 35/5–4, it is possible to obtain curves of the relative intensity of deposit formation. Moreover, the site is accepted for consideration after 20 h. Based on the results of this assessment, it is possible to determine the coefficients for recalculating the wax deposition formation curves. For wall temperature 5 °C: 1; for 10 °C: 0.63; for 15 °C: 0.15; and for 20 °C: 0.04.

3.4. Transfer of Laboratory Research to Field Conditions

To perform modeling of the formation of wax deposits on real oil field facilities, it is necessary to conduct studies on a sample of the target fluid. Samples are examined on the “Wax Flow Loop” installation, and the wax deposition formation curve is approximated by one or more laws (Figure 5).

Figure 5.

The results of the study of an oil sample from well No. 9.

4. Wax Deposit Formation Prediction Model

On the basis of the studies performed, the authors formed a model for the formation of organic deposits. Its step-by-step application is described in this chapter. As an example, we simulate the formation of deposits in well No. 8.

- Performing a “basic” study on the “Wax Flow Loop” installation, it is necessary to determine the shape of the curve for the formation of organic deposits. After the study, it must be approximated for use as a mathematical function. Let us provide, as an example, the result of a laboratory study of an oil sample taken from well No. 8. The properties of the oil sample from the target oil well and parameters of this well are shown in Table 2. Figure 5 shows the result of the study of this sample on the “Wax Flow Loop” installation.

- In addition, a study to estimate the WAT of this oil is necessary. For this sample this value is 16 °C.

- The study performed on the Wax Flow Loop installation is valid only for the conditions in the test section. However, during the movement of oil through the lift column or a linear oil pipeline, it cools and the conditions for wax deposition formation change significantly. It is important to consider that the constancy of the temperature gradient does not mean the constancy of the intensity of wax deposition formation. As described earlier, oil cooling can lead to wax crystallization inside the stream, as a result of which the intensity of wax deposition formation is significantly reduced. To take into account the conditions of oil movement in the developed model, two coefficients are used.

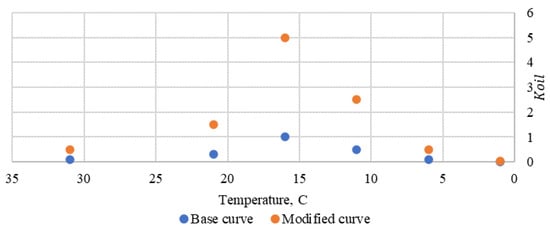

- A coefficient is needed that considers the change in oil temperature (). To determine the value of this coefficient at each moment of time, it is necessary to construct a curve (basic curve), the shape of which was obtained in Section 3.2. This curve is plotted against the WAT value of each oil. At the same time, it is necessary to consider the conditions for performing the study. So, in this example, the study on the Wax Flow Loop installation was performed at an oil temperature of 25 °C. In this regard, the curve must be modified by dividing all values by the value of the base curve at the temperature of the study. This process is shown in Figure 6.

Figure 6. Building the curve.

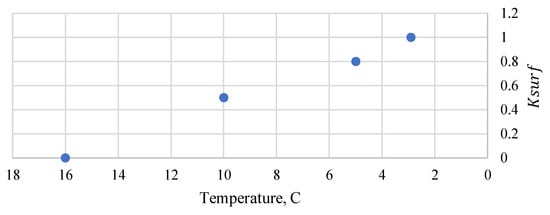

Figure 6. Building the curve. - The coefficient for the wall temperature ( is built based on the coefficients presented after the analysis of Figure 4. It is obvious that above WAT, the formation of deposits does not occur, and as the temperature decreases, the dynamics of the increase in intensity is also assumed to be identical for all the considered oils. An example of the curve is shown in Figure 7.

Figure 7. Building the curve.

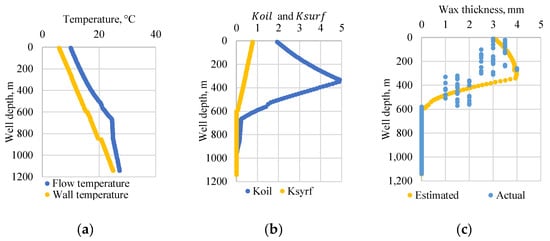

Figure 7. Building the curve. - The simulation time is set, the temperature profile along the oil wellbore is calculated (Figure 8a). Based on the simulation time, the approximation law is determined and, by supplying the simulation time to it, the base thickness of the deposits is determined. For example, when performing simulation for a period of 936 h using the logarithmic according to the law described in Figure 5, the base deposit thickness is 2.93 mm.

Figure 8. Distribution along the length of well No. 1: (a) flow and wall temperatures; (b) coefficients and ; (c) results of comparison of the calculated and actual thickness of deposits in well No. 8 (see Supplementary Materials).

Figure 8. Distribution along the length of well No. 1: (a) flow and wall temperatures; (b) coefficients and ; (c) results of comparison of the calculated and actual thickness of deposits in well No. 8 (see Supplementary Materials). - Based on the calculated wall temperature and the oil flow temperature, the coefficients and are determined. An example is shown in Figure 8b.

- The influence of water cut is assumed to be linear, since only the initial and final points of the influence of water cut are reliably known, and it is obvious that with its increase, the intensity of wax deposition formation decreases.

As a result, the equation for determining the thickness of deposits in a particular section of the test section contains several multipliers and is presented in Equation (2).

where is the coefficient considering changes in oil temperature; is the coefficient considering the change in wall temperature; is the approximation law constant, mm/h; is the approximation law constant, mm; is the simulation time, c; and is the water cut, unit fraction.

As a result of the above studies, a model was created that makes it possible to predict the intensity of wax deposition formation in the production string of an oil well (Figure 8c).

5. Results of Application of the Developed Model

As can be seen, the result of applying the developed technique made it possible to reproduce with high accuracy the results of direct measurements of the thickness of wax deposits. To confirm the work of the above method, it is necessary to carry out several such comparisons. Using the above algorithm, a comparison was made between the calculated and actual profiles for 10 oil wells. To assess the correctness of the model, two parameters were used: the deviation of the maximum thickness and the deviation of the depth at which the largest layer of sediments is formed. The evaluation results are shown in Table 3.

Table 3.

The results of modeling the formation of wax deposition.

The results of applying this technique on 10 oil wells allow us to speak about the high accuracy of this technique. However, the authors consider it important to discuss emerging deviations (wells 1 and 5), as well as technological limitations of the applied technique.

6. Discussion

So, despite the positive result of applying the developed methodology, it is important to discuss the limitations of this methodology. Next, we describe the main limitations of the technique point by point.

- At present, the technique has not been explored in batch wells. The reason for this is the peculiarities of the operating mode of these wells;

- The technique considers the effect of the water cut as a linear one since it is not possible to correctly assess the effect of the water phase on the Wax Flow Loop installation;

- The methodology does not consider the change in oil properties when associated petroleum gas is dissolved in it, which is a technological limitation of the installation;

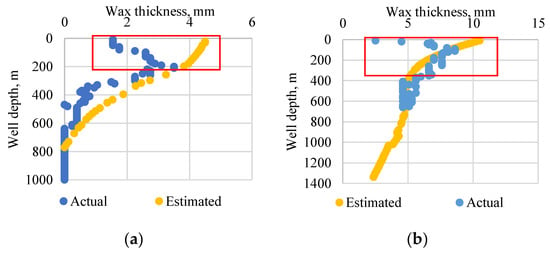

- It is also important to consider in detail the results with the largest deviation. As an example, in Figure 9, we present the results of comparing the wax profiles for wells No. 1 and 5.

Figure 9. Results of comparing the calculated and actual thickness of deposits in the well (a) No. 1; (b) No. 5.

Figure 9. Results of comparing the calculated and actual thickness of deposits in the well (a) No. 1; (b) No. 5.

Based on the presented results, the main reason for the deviation of the values of the maximum thickness and depth of the formation of the wax deposition is a deviation in the wellhead part. Similar patterns occur in several other simulated wells operated with sucker rod pumps (No. 2, 7), but in these wells they are the most obvious. There can be several reasons for this phenomenon, but the most likely cause is crushing and removal of deposits when lifting the tubing rods. In wells operated with electrical submersible pumps, there is no such specific feature.

7. Conclusions

- Based on laboratory studies, the authors developed a new empirical model of the formation of paraffin deposits. The developed model is based on the results of laboratory studies, water cut in the product, temperature of the oil flow and the internal surface of the tubing. The model considers the phenomena of hot and cold flow, as well as oil WAT.

- As a result of the application of the developed methodology on several oil wells, it was obtained that the standard deviation of maximum wax thickness is 6.0%, and the depth with the greatest wax thickness is 3.5%, which is a fairly high result. The paper also provides examples of simulation results, where there is a significant deviation of the calculated thickness from the actual one. After analyzing these examples, the possible reasons for the deviation are described, which are the technological features of the well repair.

- The developed model makes it possible to simulate the spatial and temporal distribution of organ deposits along the length of the elevator column to assess dangerous areas and periods of well cleaning from the formed deposits.

- The use of this technique for predicting the formation of deposits in an oil well in industrial conditions has shown that it allows: optimizing existing methods of sediment control, choosing optimal methods, and preventing emergencies. These results are obtained due to the possibility of evaluating the optimal intervals for installing heating cables, mechanical cleaning of the well, and conditions for hot flushing.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su15129616/s1.

Author Contributions

Conceptualization, P.I. and A.K.; methodology, A.K. and K.V.; software, K.V.; validation, K.V. and P.I.; formal analysis, K.V.; investigation, A.K.; resources, P.I.; data curation, P.I.; writing—original draft preparation, A.K. and K.V.; writing—review and editing, P.I.; visualization, A.K.; supervision, P.I.; project administration, P.I.; funding acquisition, P.I. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out at the expense of the Russian Science Foundation grant No. 21-79-10403, https://rscf.ru/project/21-79-10403/.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are unavailable due to privacy or ethical restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nurgalieva, K.S.; Saychenko, L.A.; Riazi, M. Improving the Efficiency of Oil and Gas Wells Complicated by the Formation of Asphalt–Resin–Paraffin Deposits. Energies 2021, 14, 6673. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Pham, T.V.; Rogachev, M.K.; Korobov, G.Y.; Parfenov, D.V.; Zhurkevich, A.O.; Islamov, S.R. A comprehensive method for determining the dewaxing interval period in gas lift wells. J. Pet. Explor. Prod. Technol. 2023, 13, 1163–1179. [Google Scholar] [CrossRef]

- Lekomtsev, A.V. Development of an asphalt-resin-paraffin deposits inhibitor and substantiation of the technological parameters of its injection into the bottom-hole formation zone. Periódico Tchê Química 2020, 17, 769–781. [Google Scholar]

- Kayumov, M.S.; Tronov, V.P.; Guskova, I.A.; Lipaev, A.A. Taking into account the peculiarities of the formation of asphalt-resin-paraffin deposits at the late stage of oil field development. Oil Ind. 2006, 3, 48–49. [Google Scholar]

- Sandyga, M.S.; Struchkov, I.A.; Rogachev, M.K. Formation damage induced by wax deposition: Laboratory investigations and modeling. J. Pet. Explor. Prod. Technol. 2020, 10, 2541–2558. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Q.; Chen, W.; Zhang, Y.; Gao, X.; Liu, Y.; Wang, Y. Field Pigging Modeling for Predicting Wax Breaking Force and Wax Removal Efficiency of Disk Pig. SPE J. 2022, 27, 3864–3883. [Google Scholar] [CrossRef]

- Nebogina, N.A.; Prozorova, I.V.; Yudina, N.V. Features of formation and sedimentation of water-oil emulsions. Oil Refin. Petrochem. 2008, 1, 21–23. [Google Scholar]

- Struchkov, I.A.; Rogachev, M.K. Risk of wax precipitation in oil well. Nat. Resour. Res. 2017, 26, 67–73. [Google Scholar] [CrossRef]

- Sousa, A.L.; Matos, H.A.; Guerreiro, L.P. Preventing and removing wax deposition inside vertical wells: A review. J. Pet. Explor. Prod. Technol. 2019, 9, 2091–2107. [Google Scholar] [CrossRef]

- Revel-Muroz, P.A.; Bakhtizin, R.N.; Karimov, R.M.; Mastobaev, B.N. Joint use of thermal and chemical methods of exposure during transportation of high–viscosity and solidifying oils. Sci. Work. NIPI Neft. SOCAR 2017, 2, 49–55. [Google Scholar]

- Lei, Y.; Han, S.; Zhang, J. Effect of the dispersion degree of asphaltene on wax deposition in crude oil under static conditions. Fuel Process. Technol. 2016, 146, 20–28. [Google Scholar] [CrossRef]

- Bai, J.; Jin, X.; Wu, J.T. Multifunctional anti-wax coatings for paraffin control in oil pipelines. Pet. Sci. 2019, 16, 619–631. [Google Scholar] [CrossRef]

- Ilushin, P.; Vyatkin, K.; Kozlov, A. Development of an approach for determining the effectiveness of inhibition of paraffin deposition on the wax flow loop laboratory installation. Inventions 2021, 7, 3. [Google Scholar] [CrossRef]

- Kassenova, Z.; Kozhabekov, S.; Zhubanov, A.; Galymzhan, A.; Seilkhanov, T. Synthesis of comb-like copolymers based on alkyl fumarates and their application as pour-point depressants for akshabulak crude oil. Results Eng. 2023, 17, 100820. [Google Scholar] [CrossRef]

- Lekomtsev, A.; Kozlov, A.; Kang, W.; Dengaev, A. Designing of a washing composition model to conduct the hot flushing wells producing paraffin crude oil. J. Pet. Sci. Eng. 2022, 217, 110923. [Google Scholar] [CrossRef]

- Hoteit, H.; Banki, R.; Firoozabadi, A. Wax deposition and aging in flowlines from irreversible thermodynamics. Energy Fuels 2008, 22, 2693–2706. [Google Scholar] [CrossRef]

- Mahir, L.H.A.; Fávero, C.V.B.; Ketjuntiwa, T.; Fogler, H.S.; Larson, R.G. Mechanism of wax deposition on cold surfaces: Gelation and deposit aging. Energy Fuels 2018, 33, 3776–3786. [Google Scholar] [CrossRef]

- Merino-Garcia, D.; Margarone, M.; Correra, S. Kinetics of waxy gel formation from batch experiments. Energy Fuels 2007, 21, 1287–1295. [Google Scholar] [CrossRef]

- Petrochenkov, A.; Ilyushin, P.; Mishurinskikh, S.; Kozlov, A. Development of a Method for Improving the Energy Efficiency of Oil Production with an Electrical Submersible Pump. Inventions 2023, 8, 29. [Google Scholar] [CrossRef]

- Ilyushin, P.Y.; Vyatkin, K.A.; Kozlov, A.V. Development of intelligent algorithms for controlling peripheral technological equipment of the well cluster using a single control station. Bull. Tomsk. Polytech. Univ. Geo Assets Eng. 2022, 21, 1287–1295. [Google Scholar]

- Fan, K.; Li, S.; Li, W. Experimental study on the wax deposit properties in the radial direction in crude oil pipeline: Wax precipitation, carbon number distribution. Pet. Sci. Technol. 2022, 40, 2319–2335. [Google Scholar] [CrossRef]

- Hosseinipour, A.; Japper-Jaafar, A.; Yusup, S.; Ismail, L. Application of the Avrami theory for wax crystallisation of synthetic crude oil. Int. J. Eng. 2019, 32, 18–27. [Google Scholar]

- Singh, P.; Venkatesan, R.; Fogler, H.S.; Nagarajan, N. Formation and aging of incipient thin film wax-oil gels. AIChE J. 2000, 46, 1059–1074. [Google Scholar] [CrossRef]

- Veiga, H.M.B.; e Souza, L.B.; Fleming, F.P.; Ibanez, I.; Linhares, R.C.; Nieckele, A.O.; Azevedo, L.F.A. Experimental and numerical study of wax deposition in a laboratory-scale pipe section under well-controlled conditions. Energy Fuels 2020, 34, 12182–12203. [Google Scholar] [CrossRef]

- Fan, K.; Li, S.; Li, R. Development of wax molecular diffusivity correlation suitable for crude oil in wax deposition: Experiments with a cold-finger apparatus. J. Pet. Sci. Eng. 2021, 205, 108851. [Google Scholar] [CrossRef]

- Creek, J.; Lund, H.J.; Brill, J.P.; Volk, M. Wax deposition in single phase flow. Fluid Phase Equilibria 1999, 158, 801–811. [Google Scholar] [CrossRef]

- Bhat, N.V.; Mehrotra, A.K. Modeling of deposit formation from “waxy” mixtures via moving boundary formulation: Radial heat transfer under static and laminar flow conditions. Ind. Eng. Chem. Res. 2005, 44, 6948–6962. [Google Scholar] [CrossRef]

- Soedarmo, A.A.; Daraboina, N.; Sarica, C. Validation of wax deposition models with recent laboratory scale flow loop experimental data. J. Pet. Sci. Eng. 2017, 149, 351–366. [Google Scholar] [CrossRef]

- Yang, J.; Lu, Y.; Daraboina, N.; Sarica, C. Wax deposition mechanisms: Is the current description sufficient? Fuel 2020, 275, 117937. [Google Scholar] [CrossRef]

- Ehsani, S.; Mehrotra, A.K. Validating heat-transfer-based modeling approach for wax deposition from paraffinic mixtures: An analogy with ice deposition. Energy Fuels 2019, 33, 1859–1868. [Google Scholar] [CrossRef]

- Mehrotra, A.K.; Ehsani, S.; Haj-Shafiei, S.; Kasumu, A.S. A review of heat-transfer mechanism for solid deposition from “waxy” or paraffinic mixtures. Can. J. Chem. Eng. 2020, 98, 2463–2488. [Google Scholar] [CrossRef]

- Veiga, H.M.B.; Fleming, F.P.; Azevedo, L.F.A. Wax deposit thermal conductivity measurements under flowing conditions. Energy Fuels 2017, 31, 11532–11547. [Google Scholar] [CrossRef]

- Kasumu, A.S.; Mehrotra, A.K. Solids deposition from two-phase wax–solvent–water “waxy” mixtures under turbulent flow. Energy Fuels 2013, 27, 1914–1925. [Google Scholar] [CrossRef]

- van der Geest, C.; Melchuna, A.; Bizarre, L.; Bannwart, A.C.; Guersoni, V.C. Critical review on wax deposition in single-phase flow. Fuel 2021, 293, 120358. [Google Scholar] [CrossRef]

- Giacchetta, G.; Marchetti, B.; Leporini, M.; Terenzi, A.; Dall’acqua, D.; Capece, L.; Grifoni, R.C. Pipeline wax deposition modeling: A sensitivity study on two commercial software. Petroleum 2019, 5, 206–213. [Google Scholar] [CrossRef]

- Theyab, M.A. Wax deposition process: Mechanisms, affecting factors and mitigation methods. Open Access J. Sci. 2018, 2, 112–118. [Google Scholar] [CrossRef]

- Ilyushin, P.Y.; Vyatkin, K.A.; Kozlov, A.V. Development and verification of a software module for predicting the distribution of wax deposition in an oil well based on laboratory studies. Results Eng. 2022, 16, 100697. [Google Scholar] [CrossRef]

- Wang, W.; Huang, Q.; Wang, C.; Li, S.; Qu, W.; Zhao, J.; He, M. Effect of operating conditions on wax deposition in a laboratory flow loop characterized with DSC technique. J. Therm. Anal. Calorim. 2015, 119, 471–485. [Google Scholar] [CrossRef]

- Bidmus, H.O.; Mehrotra, A.K. Heat-transfer analogy for wax deposition from paraffinic mixtures. Ind. Eng. Chem. Res. 2004, 43, 791–803. [Google Scholar] [CrossRef]

- Merino-Garcia, D.; Correra, S. Cold flow: A review of a technology to avoid wax deposition. Pet. Sci. Technol. 2008, 26, 446–459. [Google Scholar] [CrossRef]

- Bidmus, H.O.; Mehrotra, A.K. Solids deposition during “cold flow” of wax− solvent mixtures in a flow-loop apparatus with heat transfer. Energy Fuels 2009, 23, 3184–3194. [Google Scholar] [CrossRef]

- Arumugam, S.; Kasumu, A.S.; Mehrotra, A.K. Modeling of solids deposition from “waxy” mixtures in “hot flow” and “cold flow” regimes in a pipeline operating under turbulent flow. Energy Fuels 2013, 27, 6477–6490. [Google Scholar] [CrossRef]

- Ehsani, S.; Haj-Shafiei, S.; Mehrotra, A.K. Experiments and modeling for investigating the effect of suspended wax crystals on deposition from’waxy’mixtures under cold flow conditions. Fuel 2019, 243, 610–621. [Google Scholar] [CrossRef]

- Aslanov, H.; Novruzov, A.; Harun, A. En pipelines by integrating wax modeling and pigging performance. SPE Prod. Oper. 2019, 34, 625–634. [Google Scholar]

- Ehsani, S.; Haj-Shafiei, S.; Mehrotra, A.K. Deposition from waxy mixtures in a flow-loop apparatus under turbulent conditions: Investigating the effect of suspended wax crystals in cold flow regime. Can. J. Chem. Eng. 2019, 97, 2740–2751. [Google Scholar] [CrossRef]

- Ilyushin, P.Y.; Vyatkin, K.A.; Kozlov, A.V. Investigation of rheological properties of oil during the formation of wax deposits. Results Eng. 2022, 14, 100434. [Google Scholar] [CrossRef]

- Ilyushin, P.Y.; Vyatkin, K.A.; Kozlov, A.V. Development of a Method for Estimating Thermal Conductivity of Organic Deposits on the Wax Flow Loop Laboratory Installation. Int. J. Eng. 2022, 35, 1178–1185. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).