Comparative Study of a Fixed-Focus Fresnel Lens Solar Concentrator/Conical Cavity Receiver System with and without Glass Cover Installed in a Solar Cooker

Abstract

1. Introduction

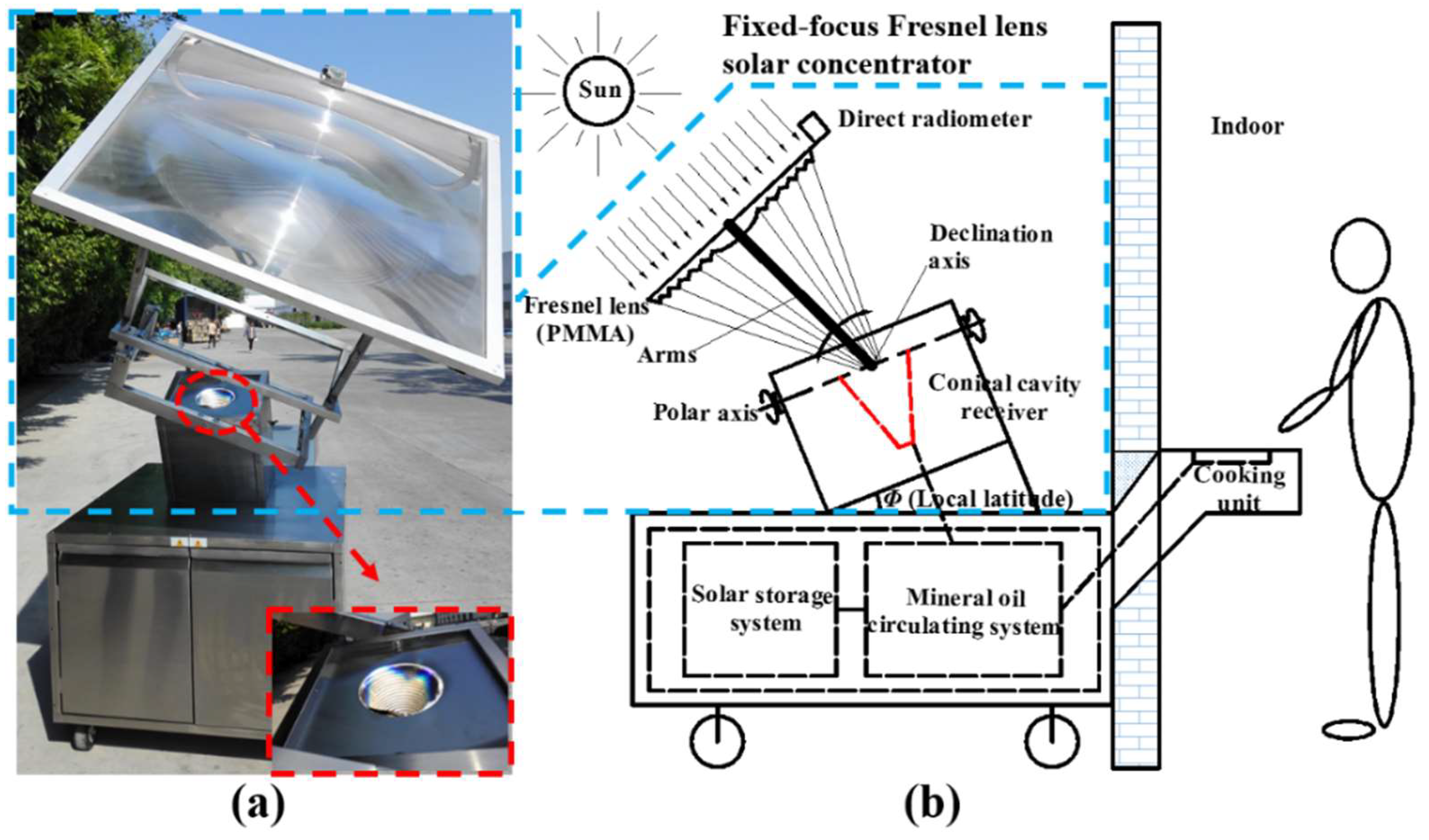

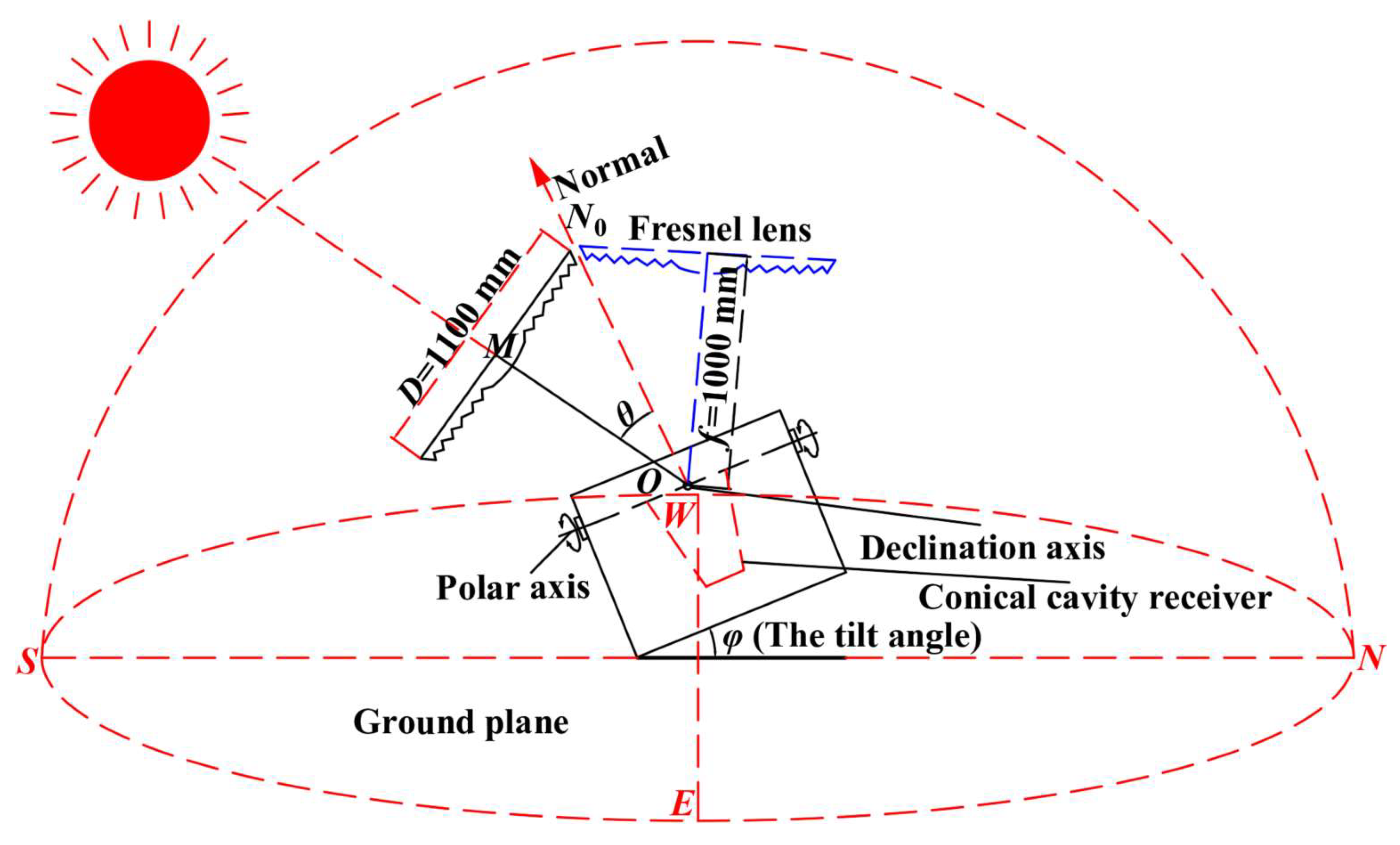

2. System Description

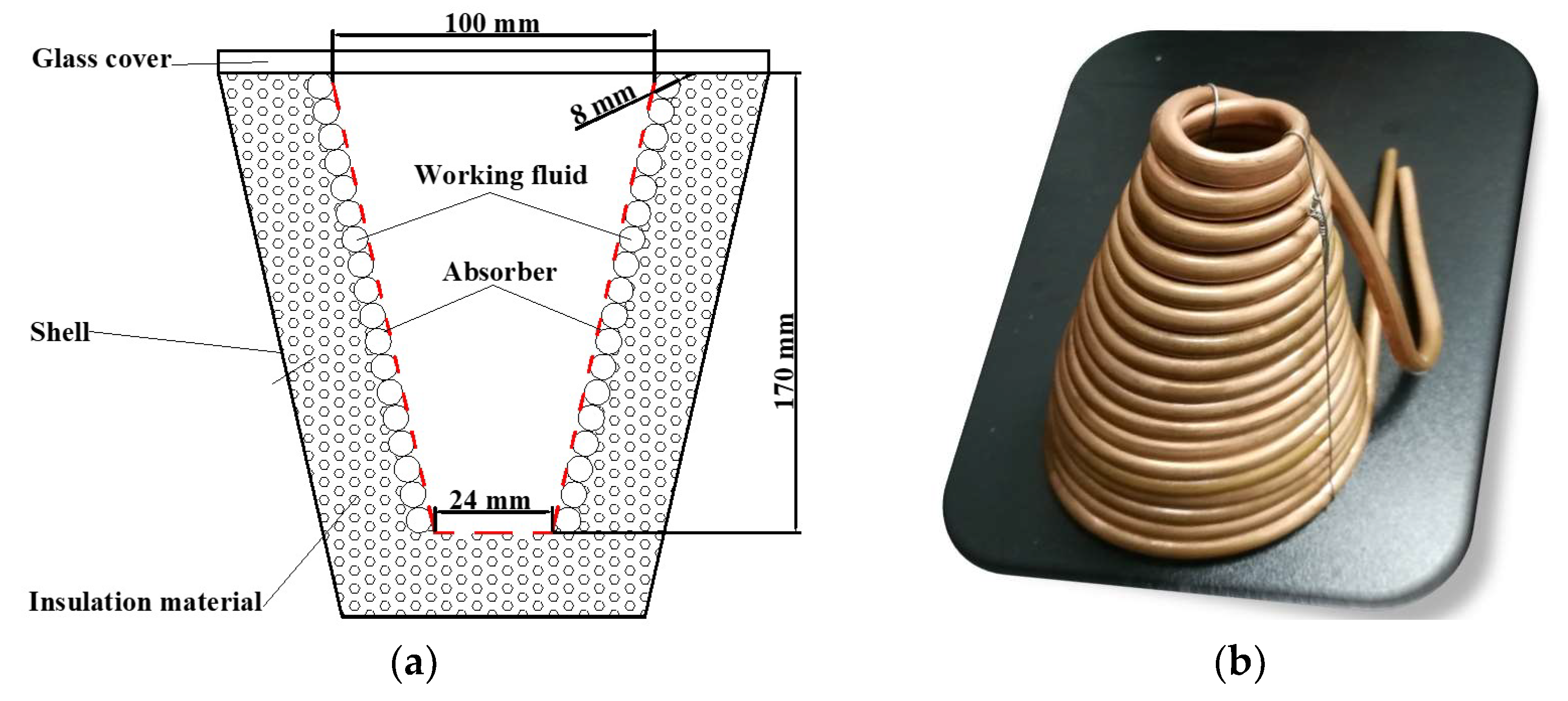

2.1. FSC-C System

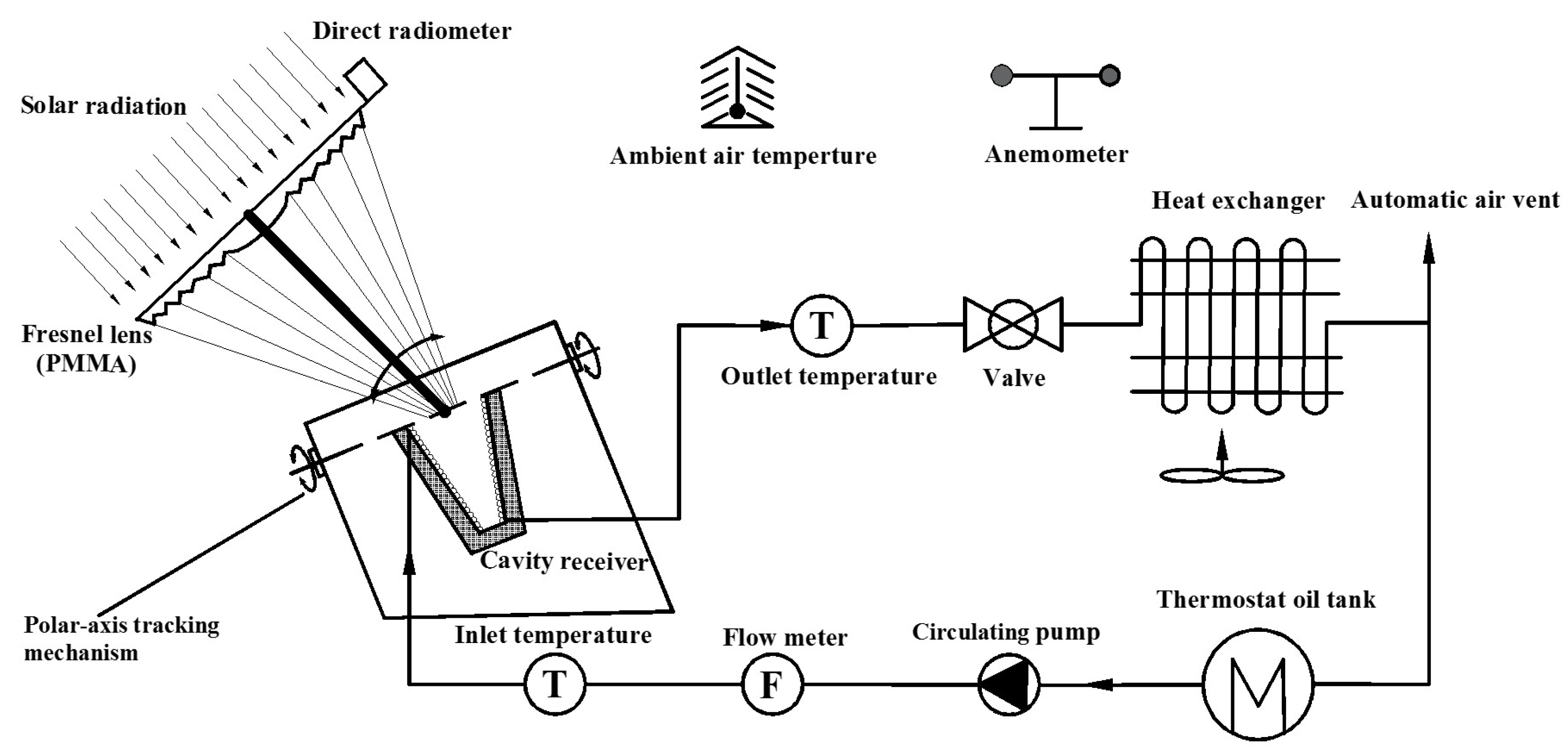

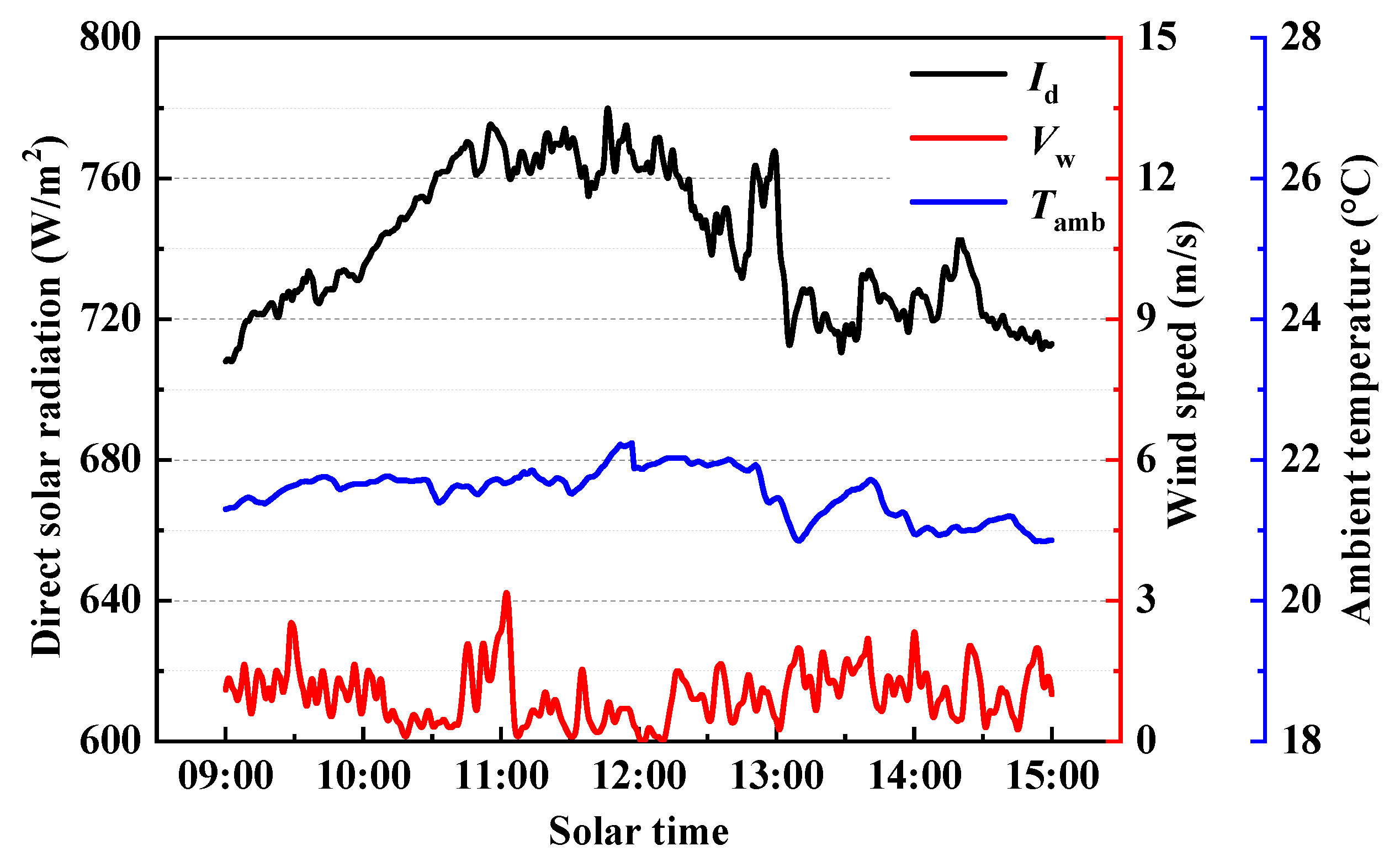

2.2. Testing System

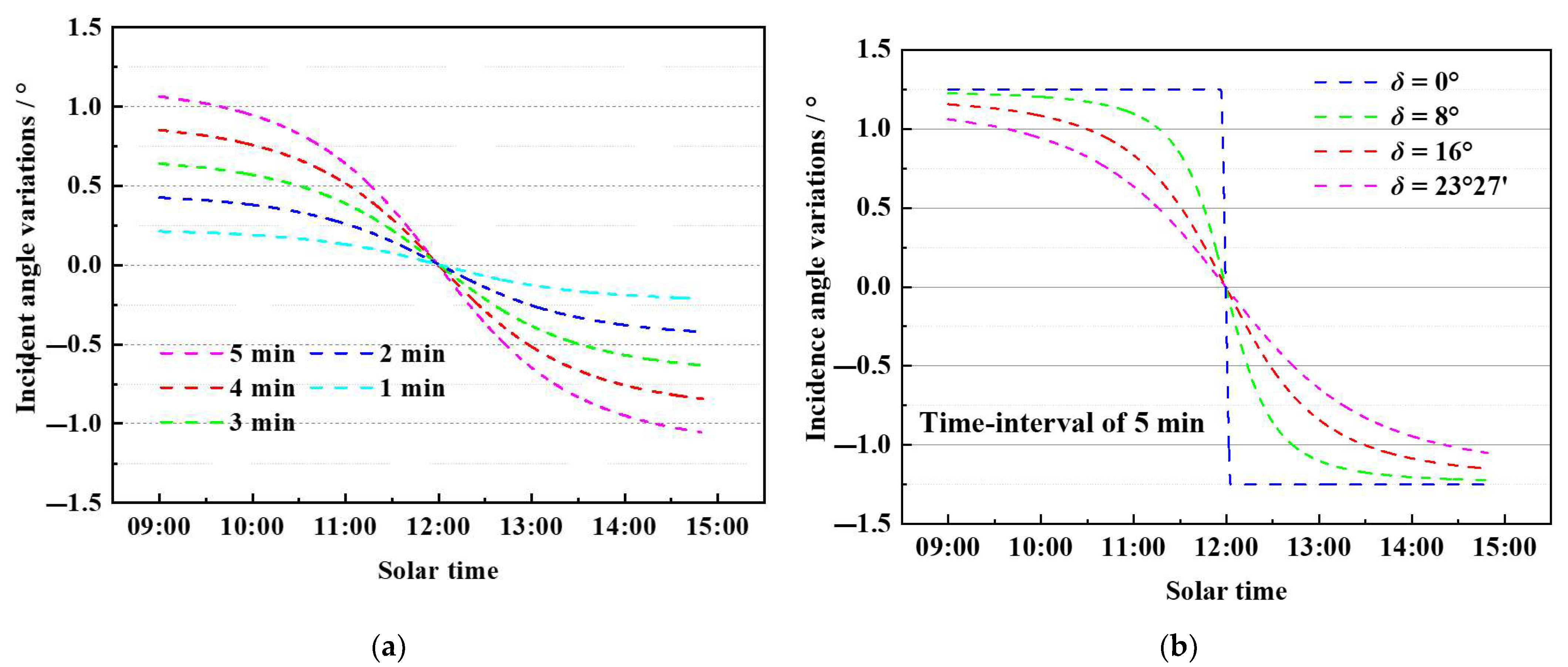

3. Optical Characteristics

3.1. Definition of Optical Efficiency, Incidence Angle Modifier and Uniformity Factor

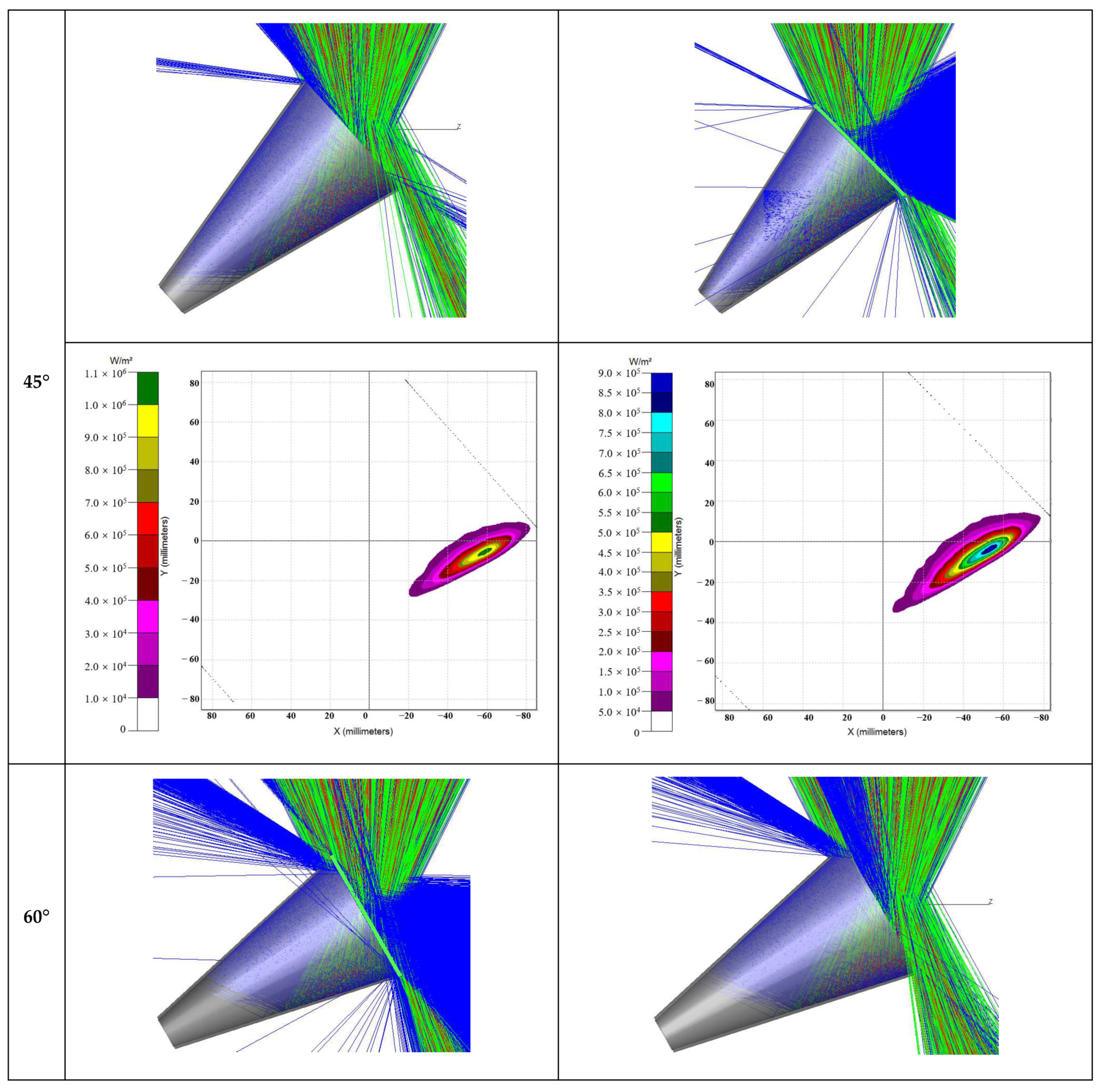

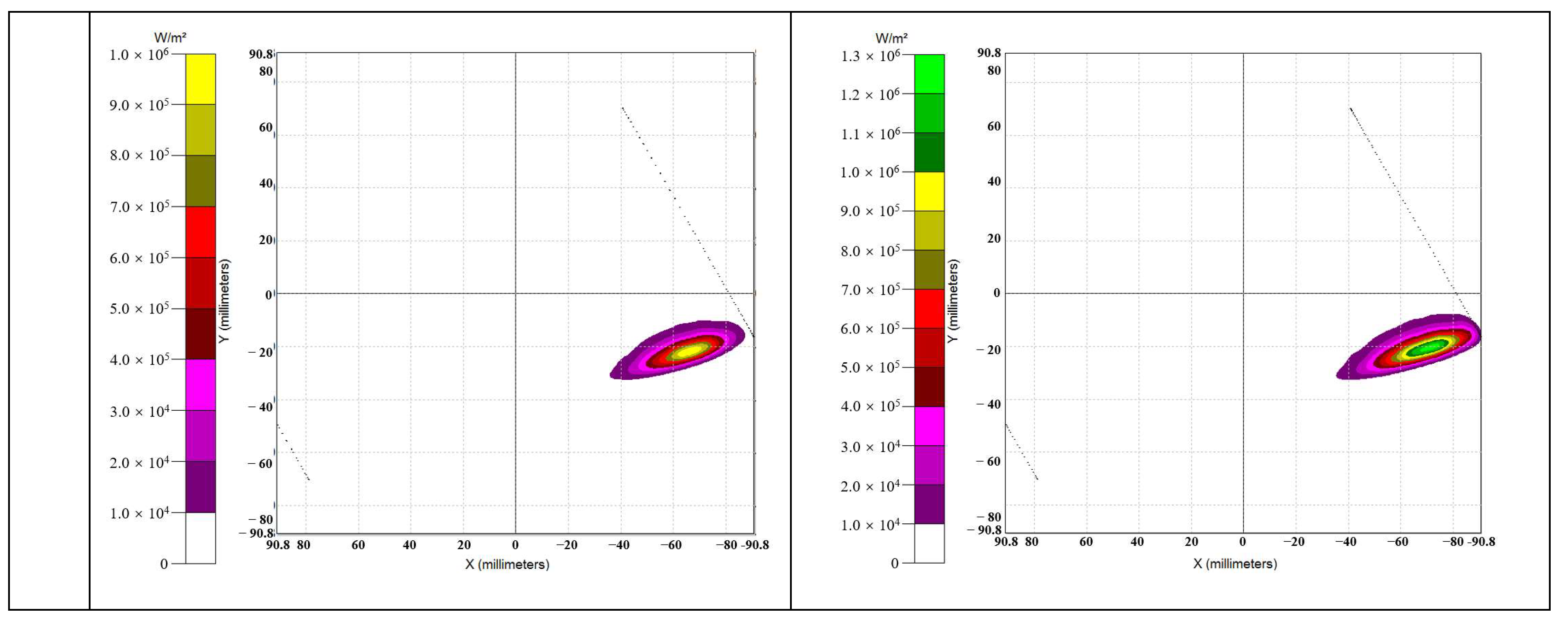

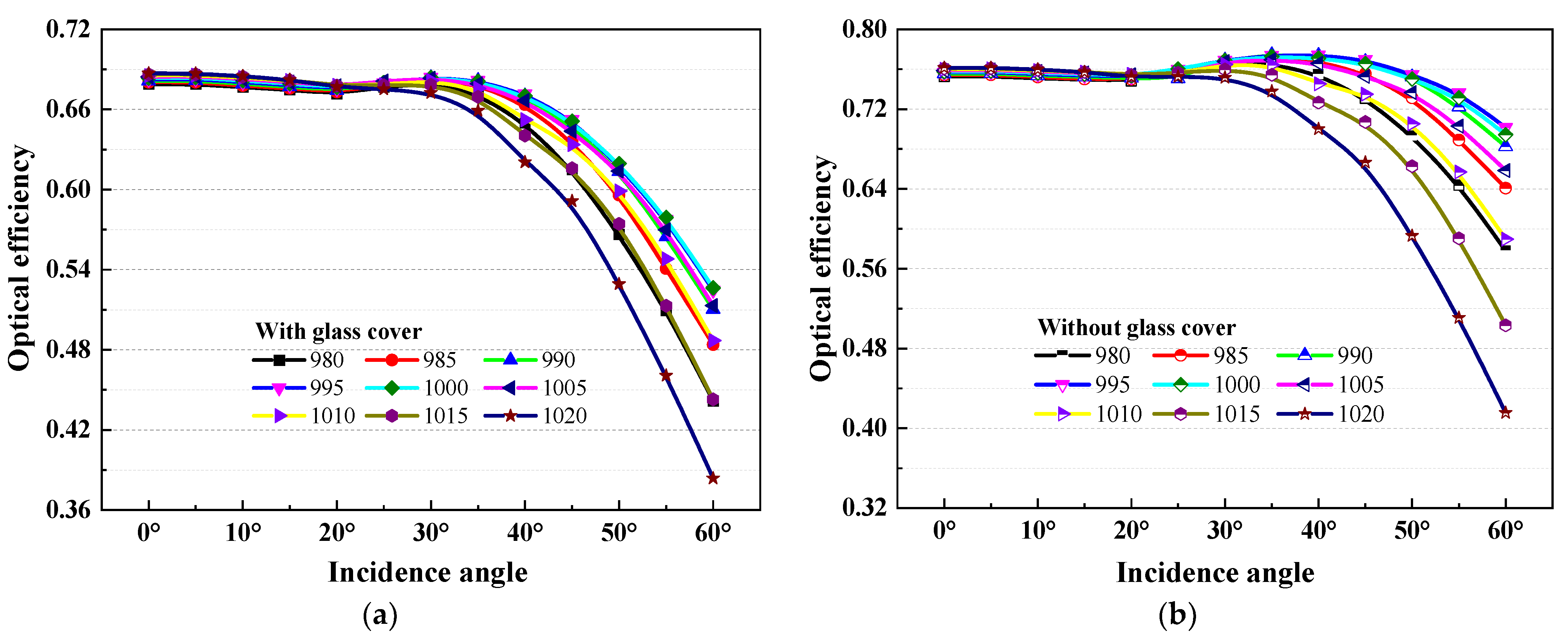

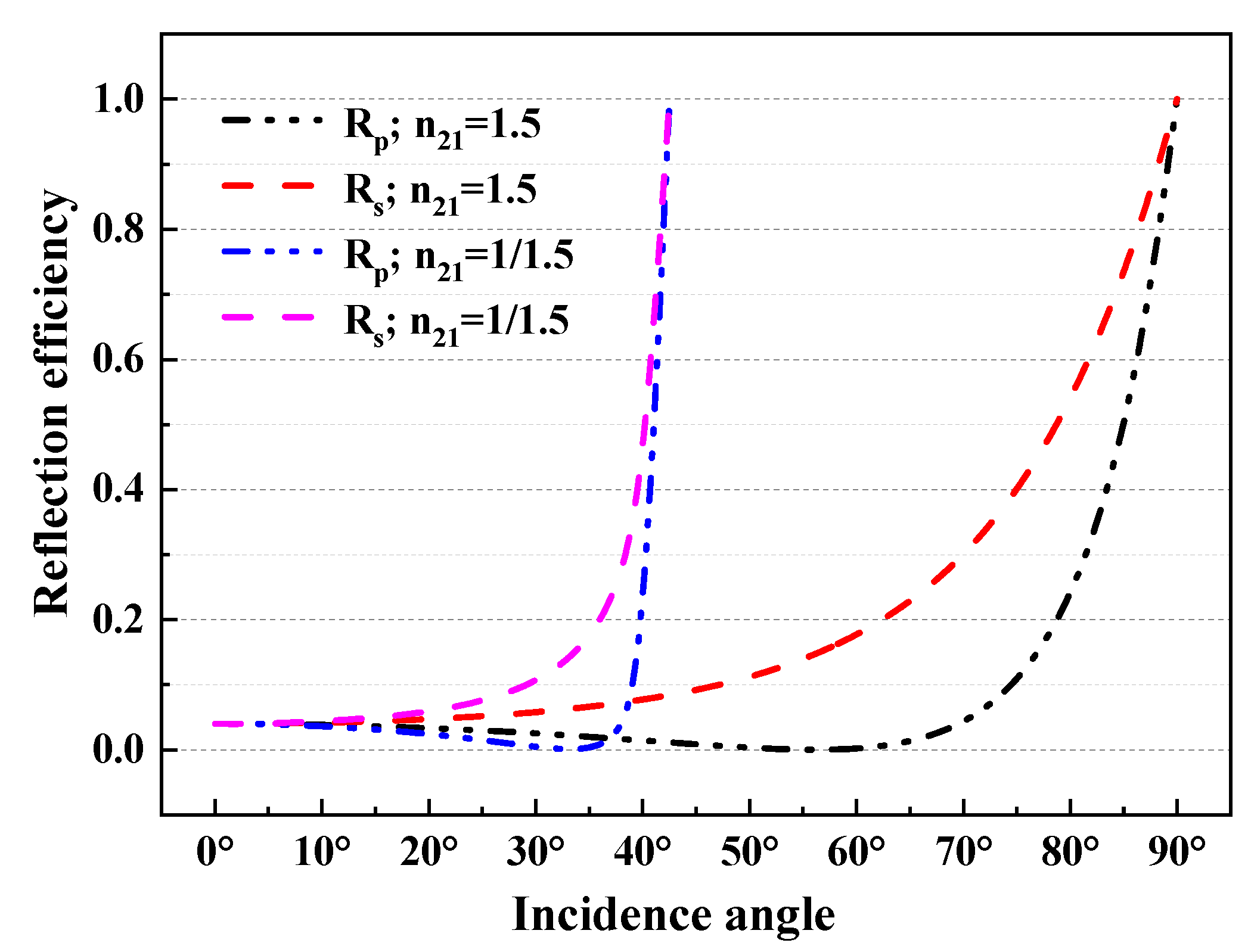

3.2. The Radiation Flux Profile of the Absorbing Surface and the Optical Efficiency of the System

4. Thermal Performance

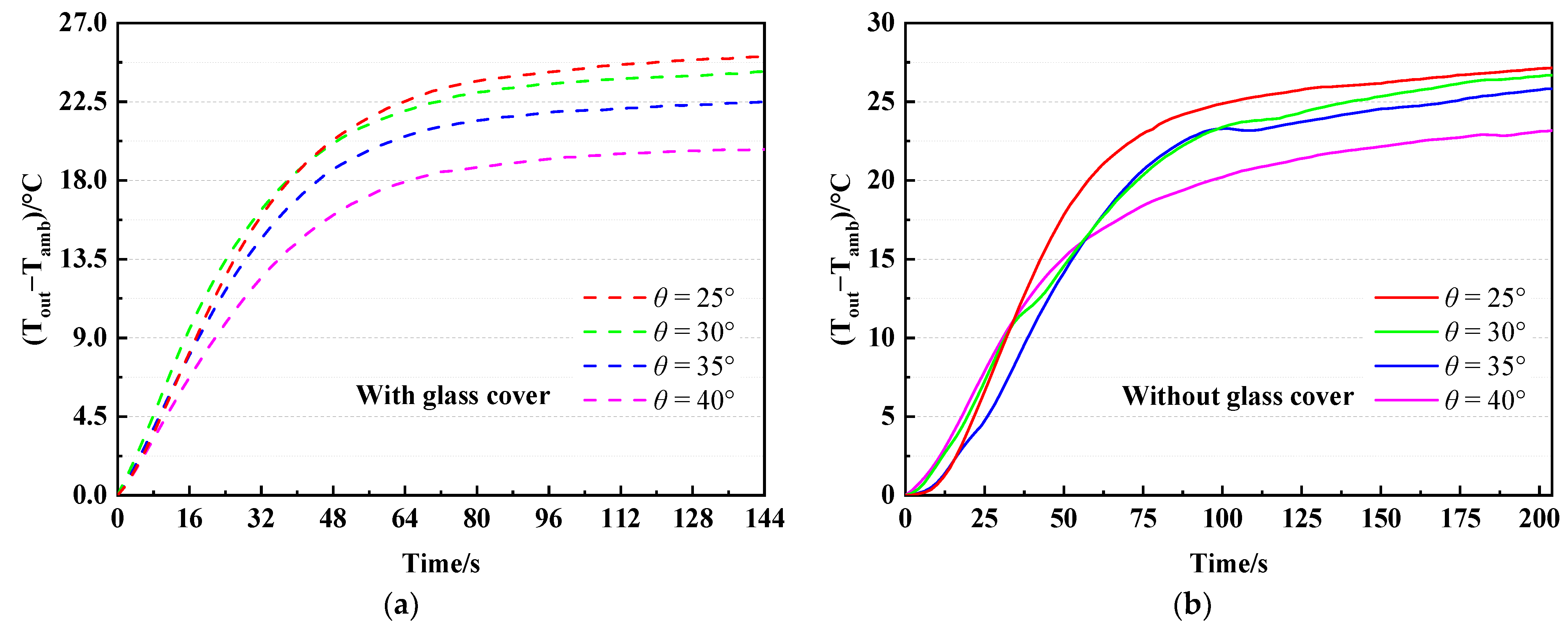

4.1. Time Constant of the FSC-C System

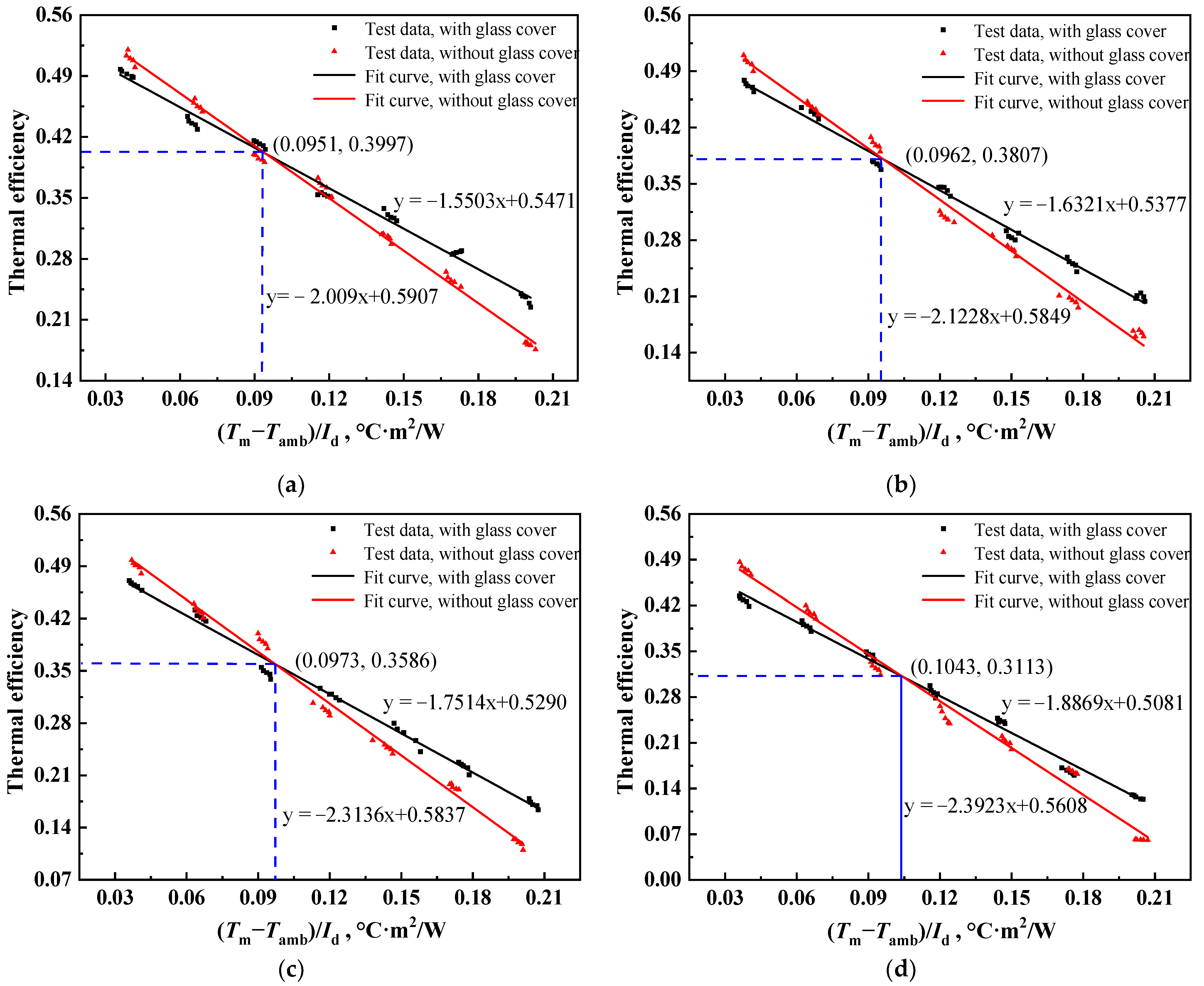

4.2. Thermal Efficiency of the FSC-C System

5. Results and Discussion

5.1. Time Constant of Different Incidence Angle

5.2. Thermal Efficiencies of Different Incidence Angles

6. Conclusions

- (1)

- The optical efficiency of the FSC-C system without a glass cover is higher than that with a glass cover. The difference between them is more significant at incidence angles of 20–60°. The increase in differences is faster with the decrease in the focal length, while it is slower or even decreasing when increasing the focal length;

- (2)

- The incidence angle has a significant influence on optical efficiency. Two models were proposed to predict the effect of incidence angle on the optical performance of conical cavity receiver coupled fixed-focus Fresnel lens solar concentrator;

- (3)

- The time constant of the FSC-C system with a glass cover is less than that without a glass cover. The time constant for incidence angles 25°, 30°, 35°, and 40° with and without glass cover was determined as 31 s, 29 s, 31 s, 33 s and 49 s, 59 s, 57 s, 48 s, respectively. The incident angle variations during the experiment were small, with a maximum of 1.064° over a 5-min interval;

- (4)

- Comparing the thermal efficiencies of the FSC-C system with and without glass cover under different incidence angles, it is found that the thermal efficiency with glass cover is higher for a wide range of higher temperature differences. The parameters F′η0(θ) and F′UL/C dominate at lower and higher temperature differences, respectively.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| δ | Sun declination angle (degree) |

| η0 | Optical efficiency |

| ηt | Instantaneous thermal efficiency |

| θ | Concentrated sunlight incidence angle (degree) |

| τ | Time constant (s) |

| Φ | Local latitude angle (degree) |

| φ | Tilt angle of cavity receiver with the horizontal (degree) |

| ω | Solar hour angle (degree) |

| Ac | Area of Fresnel lens (m2) |

| Ar | Area of conical cavity receiver (m2) |

| C | Geometric concentrating ratio |

| cp | Heat capacity of working fluid (kJ/kg/°C) |

| D | Aperture diameter of Fresnel lens (mm) |

| f | Focal length of Fresnel lens (mm) |

| F′ | Collector efficiency factor |

| Id | Direct solar radiation (W/m2) |

| K | Global incidence angle modifier |

| Mass flow rate of fluid flow (kg/s) | |

| Qab | Radiation energy received by the cavity receiver surface (W) |

| Tamb | Ambient temperature (°C) |

| Tin | Collector inlet fluid temperature (°C) |

| Tm | Average temperature of conical cavity receiver (°C) |

| To | Collector outlet fluid temperature (°C) |

| To,ss | Steady-state working fluid outlet temperature (°C) |

| Tr | Average inner surface temperature of cavity receiver (°C) |

| Ua | Overall heat loss coefficient base on Tr (W/m2/°C) |

| UL | Overall heat loss coefficient base on Tm (W/m2/°C) |

| Acronyms | |

| FSC-C | Fixed-focus Fresnel lens solar concentrator/conical cavity receiver |

| UF | Uniformity factor |

Appendix A

| Temperature (°C) | 20 | 50 | 80 | 110 | 140 | 170 | 200 |

| Heat capacity (kJ/kg/°C) | 1.625 | 1.730 | 1.850 | 1.945 | 2.045 | 2.150 | 2.255 |

References

- Zhang, J.; Raufer, R.; Liu, L. Solar home systems for clean cooking: A cost–health benefit analysis of lower-middle-income countries in Southeast Asia. Sustainability 2020, 12, 3909. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental impact assessment of food waste management using two composting techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef]

- Zahedi, R.; Zahedi, A.; Ahmadi, A. Strategic study for renewable energy policy, optimizations and sustainability in Iran. Sustainability 2022, 14, 2418. [Google Scholar] [CrossRef]

- Gorjian, A.; Rahmati, E.; Gorjian, S.; Anand, A.; Jathar, L.D. A comprehensive study of research and development in concentrating solar cookers (CSCs): Design considerations, recent advancements, and economics. Sol. Energy 2022, 245, 80–107. [Google Scholar] [CrossRef]

- Bhave, A.G.; Kale, C.K. Development of a thermal storage type solar cooker for high temperature cooking using solar salt. Sol. Energy Mater. Sol. Cells 2020, 208, 110394. [Google Scholar] [CrossRef]

- Lentswe, K.; Mawire, A.; Owusu, P.; Shobo, A. A review of parabolic solar cookers with thermal energy storage. Heliyon 2021, 7, e08226. [Google Scholar] [CrossRef] [PubMed]

- Munir, A.; Hensel, O.; Scheffler, W. Design principle and calculations of a Scheffler fixed focus concentrator for medium temperature applications. Sol. Energy 2010, 84, 1490–1502. [Google Scholar] [CrossRef]

- Chandrashekara, M.; Yadav, A. An experimental study of the effect of exfoliated graphite solar coating with a sensible heat storage and Scheffler dish for desalination. Appl. Therm. Eng. 2017, 123, 111–122. [Google Scholar] [CrossRef]

- Ruelas, J.; Velázquez, N.; Beltrán, R. Opto–geometric performance of fixed-focus solar concentrators. Sol. Energy 2017, 141, 303–310. [Google Scholar] [CrossRef]

- Valmiki, M.M.; Li, P.; Heyer, J.; Morgan, M.; Albinali, A.; Alhamidi, K.; Wagoner, J. A novel application of a Fresnel lens for a solar stove and solar heating. Renew. Energy 2011, 36, 1614–1620. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Song, M.; Yan, J. Effects of receiver parameters on the optical performance of a fixed-focus Fresnel lens solar concentrator/cavity receiver system in solar cooker. Appl. Energy 2019, 237, 70–82. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Song, M.; Hu, Y.; Wang, Y.; Lu, Z. Simulation and experimental study on the optical performance of a fixed-focus Fresnel lens solar concentrator using polar-axis tracking. Energies 2018, 11, 887. [Google Scholar] [CrossRef]

- Renzi, M.; Cioccolanti, L.; Barazza, G.; Egidi, L.; Comodi, G. Design and experimental test of refractive secondary optics on the electrical performance of a 3-junction cell used in CPV systems. Appl. Energy 2017, 185, 233–243. [Google Scholar] [CrossRef]

- Nene, A.; Suyambazhahan, S.; Ramchandran, S. Comparative analysis of performance of two Scheffler solar concentrators having different concentration ratios. Int. J. Eng. Technol. 2017, 9, 704–709. [Google Scholar] [CrossRef]

- Nene, A.A.; Ramachandran, S.; Suyambazhahan, S. Effect of wind flow on convective heat losses from Scheffler solar concentrator receivers. J. Inst. Eng. (India) Ser. C 2019, 100, 737–745. [Google Scholar] [CrossRef]

- Senthil, R.; Cheralathan, M. Effect of non-uniform temperature distribution on surface absorption receiver in parabolic dish solar concentrator. Therm. Sci. 2017, 21, 2011–2019. [Google Scholar] [CrossRef]

- Dabiri, S.; Khodabandeh, E.; Poorfar, A.K.; Mashayekhi, R.; Toghraie, D.; Zade, S.A.A. Parametric investigation of thermal characteristic in trapezoidal cavity receiver for a linear Fresnel solar collector concentrator. Energy 2018, 153, 17–26. [Google Scholar] [CrossRef]

- Liang, H.; Zhu, C.; Fan, M.; You, S.; Zhang, H.; Xia, J. Study on the thermal performance of a novel cavity receiver for parabolic trough solar collectors. Appl. Energy 2018, 222, 790–798. [Google Scholar] [CrossRef]

- Cui, F.; He, Y.; Cheng, Z.; Li, Y. Study on combined heat loss of a dish receiver with quartz glass cover. Appl. Energy 2013, 112, 690–696. [Google Scholar] [CrossRef]

- Chen, X.; Xia, X.L.; Dong, X.H.; Dai, G.L. Integrated analysis on the volumetric absorption characteristics and optical performance for a porous media receiver. Energy Convers. Manag. 2015, 105, 562–569. [Google Scholar] [CrossRef]

- Soulayman, S.; Hammoud, M. Optimum tilt angle of solar collectors for building applications in mid-latitude zone. Energy Convers. Manag. 2016, 124, 20–28. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; El-Naggar, M. Year round performance and cost analysis of a finned single basin solar still. Appl. Therm. Eng. 2017, 110, 787–794. [Google Scholar] [CrossRef]

- Pérez-Enciso, R.; Brito-Bazan, E.; Pérez-Rábago, C.A.; Arancibia-Bulnes, C.A.; Riveros-Rosas, D.; Estrada, C.A. Correction of the concentrated sunlight spot’s drift of the IER-UNAM’s solar furnace. Appl. Therm. Eng. 2015, 75, 1187–1191. [Google Scholar] [CrossRef]

- Lv, Y.; Si, P.; Rong, X.; Yan, J.; Feng, Y.; Zhu, X. Determination of optimum tilt angle and orientation for solar collectors based on effective solar heat collection. Appl. Energy 2018, 219, 11–19. [Google Scholar] [CrossRef]

- Feng, L.; Liao, H.; Wang, P.; Huang, J.; Schumacher, K.L. A technique to avoid two-phase flow in solar collector tubes of the direct steam generation system for a solar aided power generation plant. Appl. Therm. Eng. 2019, 148, 568–577. [Google Scholar] [CrossRef]

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K. The optical efficiency of three different geometries of a small scale cavity receiver for concentrated solar applications. Appl. Energy 2016, 179, 1081–1096. [Google Scholar] [CrossRef]

- Ma, X.L.; Zheng, H.F.; Tian, M. Optimize the shape of curved-Fresnel lens to maximize its transmittance. Sol. Energy 2016, 127, 285–293. [Google Scholar] [CrossRef]

- GB/T4271-2007; Test Methods for Thermal Performance of Solar Collectors. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, and China National Standardization Administration: Beijing, China, 2007.

- Subramani, J.; Nagarajan, P.K.; Mahian, O.; Sathyamurthy, R. Efficiency and heat transfer improvements in a parabolic trough solar collector using TiO2 nanofluids under turbulent flow regime. Renew. Energy 2018, 119, 19–31. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Dawood, M.M.K.; Shehata, A.I. Augmentation of thermal efficiency of the glass evacuated solar tube collector with coaxial heat pipe with different refrigerants and filling ratio. Energy Convers. Manag. 2017, 138, 286–298. [Google Scholar] [CrossRef]

- Zhu, T.T.; Diao, Y.H.; Zhao, Y.H.; Li, F.F. Thermal performance of a new CPC solar air collector with flat micro-heat pipe arrays. Appl. Therm. Eng. 2016, 98, 1201–1213. [Google Scholar] [CrossRef]

- Tchinda, R. Thermal behaviour of solar air heater with compound parabolic concentrator. Energy Convers. Manag. 2008, 49, 529–540. [Google Scholar] [CrossRef]

- Hu, M.; Zheng, R.; Pei, G.; Wang, Y.; Li, J.; Ji, J. Experimental study of the effect of inclination angle on the thermal performance of heat pipe photovoltaic/thermal (PV/T) systems with wickless heat pipe and wire-meshed heat pipe. Appl. Therm. Eng. 2016, 106, 651–660. [Google Scholar] [CrossRef]

- Singh, P.L.; Sarviya, R.M.; Bhagoria, J.L. Heat loss study of trapezoidal cavity absorbers for linear solar concentrating collector. Energy Convers. Manag. 2010, 51, 329–337. [Google Scholar] [CrossRef]

| No. | Measurements | Type | Uncertainty |

|---|---|---|---|

| 1 | Temperature | PT-100 sensor | ±0.1 °C |

| 2 | Mass flow rate | Flow meter | 0.5 lpm |

| 3 | Wind speed | Hot wire anemometer | ±0.01 m/s |

| 4 | Direct solar irradiance | TBS-2-2 | 2% |

| 5 | Tracking accuracy | Polar-axis tracking mechanism | ±0.1° |

| System Type | Incident Angle | 16° | 24° | 32° | 40° |

|---|---|---|---|---|---|

| With glass cover | F′η0(θ) | 0.5471 | 0.5377 | 0.529 | 0.5081 |

| Without glass cover | F′UL/C | 1.5503 | 1.6321 | 1.7514 | 1.8869 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H. Comparative Study of a Fixed-Focus Fresnel Lens Solar Concentrator/Conical Cavity Receiver System with and without Glass Cover Installed in a Solar Cooker. Sustainability 2023, 15, 9450. https://doi.org/10.3390/su15129450

Wang H. Comparative Study of a Fixed-Focus Fresnel Lens Solar Concentrator/Conical Cavity Receiver System with and without Glass Cover Installed in a Solar Cooker. Sustainability. 2023; 15(12):9450. https://doi.org/10.3390/su15129450

Chicago/Turabian StyleWang, Hai. 2023. "Comparative Study of a Fixed-Focus Fresnel Lens Solar Concentrator/Conical Cavity Receiver System with and without Glass Cover Installed in a Solar Cooker" Sustainability 15, no. 12: 9450. https://doi.org/10.3390/su15129450

APA StyleWang, H. (2023). Comparative Study of a Fixed-Focus Fresnel Lens Solar Concentrator/Conical Cavity Receiver System with and without Glass Cover Installed in a Solar Cooker. Sustainability, 15(12), 9450. https://doi.org/10.3390/su15129450