1. Introduction

Gas catastrophes, such as overruns, explosion, coal and outburst of gas, are the main types of disasters that threaten the secure operation of coal mines [

1,

2]. Disaster prevention and control are extremely difficult [

3,

4,

5]. Diagonal connections significantly affect the stability of gas, explosion safety and air supply in coal mines. Changing the connections between devices (controllers–switches) can help improve system security [

6]. In regard to aerological risk, most explosions caused by dust–methane–air mixtures occur in the development areas, and 63.8% of these explosions occur due to CH

4 gassing linked to ventilation issues [

7]. As mining depth increases, stope structure complexity and mining intensity increase, leading to new challenges in gas damage avoidance and management [

8,

9]. To prevent spontaneous burning in coal rakes spontaneously burned due to factors such as residual coal in goafs, air leaks and extraction, the allocation and evolution characteristics of heat points, the mechanism of fire and gas interaction and the coupling disaster-causing process are more complicated [

10,

11,

12]. The in situ stress allocation of steeply inclined coal seams and low-inclination seams is relatively distinct. Support stress in the mining process during the mining evolution procedure is complicated due to the influence of roof movement direction, mining method, coal seam thickness and other factors [

13]. In steeply inclined coal seams, gas can easily exceed the limit due to large-scale coal/roof fall, thus threatening the secure production of the operating face. Therefore, studying the development of the gas and coal spontaneously burned compound disaster in steeply inclined coal seams is crucial for improving the intrinsic safety level of these mines.

The strata above the working face periodically caved and broke throughout the mining process, forming complex deposits with distinct compaction degrees in the goaf. The gas flow shows strong anisotropy due to the interactions of coal seam deformation and fracture in roof/coal, affected by the roof fissure structures and caving deposits [

14]. In contrast to relatively open spaces such as roadways and mining faces, gas explosion and transmission characteristics in goafs are significantly affected by a roof leak, which cause air disclosure and the void structure of accumulated coal bodies. Studies on the combined catastrophes of coal and gas spontaneously burned in goafs have been conducted productively both domestically and internationally. In terms of the catastrophe-causing system of compound catastrophes, Xu et al. [

15] and Gao et al. [

16] researched the internal correlation and catastrophe-causing mechanism of coal and gas spontaneously burned coexisting. The allocation and evolution processes of the crack, temperature, CH

4 and O

2 concentration spheres were investigated. It was determined, using mathematical theorems, that the intersection of the above four spheres is an essential and adequate condition for the disasters’ occurrence, and catastrophe-causing mechanism of multi-sphere intersections is proposed. A three-dimensional gas removal system is a significant means to control gas disasters [

17]. However, during the drainage event, air disclosure can alter the relative allocation of the three zones and affect the spontaneously burning process of floating coal. As the floating coal spontaneously burns, the division of the spontaneously burned zone and the prevention of compound disasters become more challenging due to the internal fire wind pressure created by gas drainage and the self-fevering of the floated coal, which intensifies air disclosure in the goaf [

18].

Sun et al. [

19] and Li et al. [

20] analyzed the results of wind speed and air flow in the tail lane on spontaneously burned in goafs. Reducing the negative pressure of the tail roadway during the air capacity, when the working face is high, may help prevent gas in the return air roadway from exceeding the limit and significantly lower the hazard of spontaneous combustion of floated coal [

21,

22,

23,

24] The explosive density range and explosion danger of CH

4 and CO mixtures—the primary gases of coal spontaneous combustion—were experimentally explored. After a large amount of CO is mixed into the CH

4, the explosive focus of the mixed gas’s top and lower limit range is significantly expanded. The continuous sufficient mixing with fresh air and the fever-transfer convection process with all zones caused gas explosion accidents to occur. Numerical simulation methods such as computational fluid dynamics (CFD) and particle flow code (PFC) are the main means to study growth course of the combined catastrophe of GCSC [

25,

26,

27]. Based on the simulation results combined with practical experience, a comprehensive prevention and control system for the compound catastrophe of GCSC in mines can be established. Coupled models of gas and coal spontaneously burned in goaf were established by Zhang et al. [

28], Shan et al. [

29], Hao et al. [

30] and Wei et al. [

31] to solve the allocation of O

2 level and heat of goaf under common environment of coal oxygen consumption and gas gushing. Zhu et al. [

32] also established three-dimensional goaf geometric models with tailgates. The distance between the connecting lanes of the tail lane grows, and the goaf’s spontaneously burned zone, also becomes wider. As it gets closer to the wind return side, the zone grows broader at a faster rate, and there is a greater distinct pressure differential between the tail lane and the return air lanes. However, these results show that it has only a little effect on the spontaneously burned zone [

33].

The allocation of spontaneously burned zone is an essential factor affecting the calamity of GCSC. This paper takes the completely automated mining face of a 11,800 steeply inclined mine as its background and uses numerical models to research the allocation and growth of O2 and CH4 levels in the goaf under distinct conditions of extraction, N2 injection and air supply. The research results help reveal the evolution process, mechanism and prevention of GCSC in the goaf of the working face. This technology has significant engineering application significance.

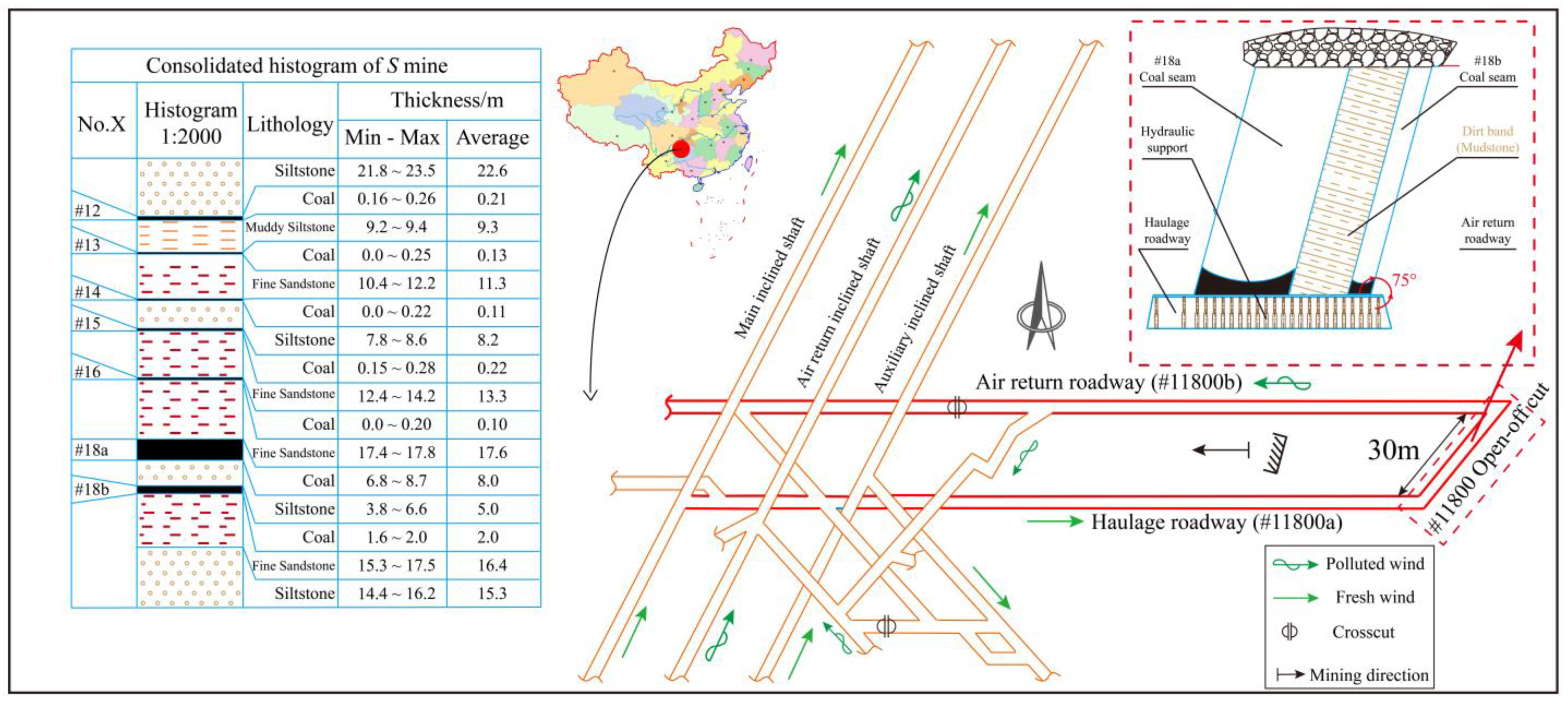

2. Geological and Engineering Background

The mining area is situated on the north wing of the eastern section of the Gemudi syncline. It is a typical deep-cut plateau corrosion landform, with the terrain generally distributed in an east–west belt shape. High mountains are present on both edges, and there is a deep river valley in the middle. The highest elevation of the area is +1926 m, the lowest is +1350 m, resulting in a relative elevation difference of about 576 m. The slope of the terrain ranges between 20 and 75°, with an average slope angle of more than 45°. The overall terrain is relatively vast. The Tongzhong River flows through the middle of the mining area, which is the lowest erosion surface of the mining area, at an altitude of +1350 m.

The design strike length of the 11,800 fully mechanized mining face is approximately 300 m, while the inclined length is 30 m (

Figure 1). The coal rake has a dip point of view ranging from 69° to 78°, with an average of 75°, and the mining height on average is 3 m. Depth of the working face that is buried is about 200 m, and the face mines the 18a and 18b coal seams. The mine employs the central parallel ventilation method. The ventilation method utilized in the mine is mechanical extraction. Mine on the measured maximum original gas pressure of the 18a coal seam is 0.92 MPa and the 18b is 1.10 MPa. The most initial gas quantity measured in 18a coal rake is 10.80 m

3/t, while in 18b, coal seam is 10.30 m

3/t. Both 18a and 18b coal seams exhibit a type II spontaneously burned tendency.

3. Numerical Model and Methods

Based on field-measured data, the working face is mined through horizontal section fully mechanized caving method. Taking the entry and return roadways as level, an initial model is established as a 3D physical model with a strike length of 134 m and a dip length of 30 m. Among them, the dimensions of the air inlet lane and the air return lane are both 30 × 4 × 3 m, the size of the working face is 4 × 30 × 3 m, the size of the goaf is 100 × 30 × 30 m, the dip angle of the coal seam is 75°, the model is shown in

Figure 2. The initial model includes the open-off cut, air entrance roadway, ventilation roadway, goaf (cave, fracture zone). The grid division method used is the hex dominant (hexahedron), with a 0.2 m grid node size for the fracture zone and a 0.1 m grid node size for the working face, air entrance and ventilation roadway and caving zone. The average grid node quality value is 0.9765.

The goaf of the working face is a dynamic and complicated system in the actual coal mining process. It needs to be simplified in the modeling process to make the simulation less complex, ease the load on the computer, and shorten the simulation cycle. The interface between the open-off cut and the goaf is established as the internal interface, air intake lane as the air flow entrance and the return air outlet as free flow. All limits are set as non-slip static walls and the intersecting surface with the goaf is set as the jumping surface of porous media. Using the second-order upwind discretization approach, the scheme–SIM–PLE algorithm and pressure–velocity coupling to solve, the calculation needs about 3500~5000 iterations, and the convergence tolerance of all variables is 10−6. A methane–air model is used for the composition of the gas mixture in the goaf, and the porosity is defined by UDF with a value range of 0–0.32 based on the “O” ring theory.

In the process of numerical simulation, constant variables such as O2 consumption rate, heat source item, permeability and porosity are the key parameters of the simulation, and the following formulas are used to customize the settings in the simulation software.

- (1)

O2 consumption rate

While there are physical changes inside the goaf, there are also chemical changes. The factors affecting the O

2 concentration include not only the gas gushing and migration, but also the coal–O

2 recombination reaction between the residual coal and O

2 in the goaf, which is also the main reason for the decrease of the O

2 concentration in the goaf. The O

2 consumption rate is described by the following Equation (1):

—Preexponential factor;

—Thermodynamic temperature;

α—Constant between 0.5~1;

E—Activation energy.

- (2)

Heat source item

The heat release of residual coal oxidation has a heat source item and a volume ratio of the heat source. Two basic heat transfer equations, Newton’s law of cooling and Fourier’s law of heat conduction, are considered for the research on spontaneous combustion and temperature rise of leftover coal in the goaf. To obtain a mathematical model of the heat source term of the fluid that is applicable for this research, the relationship between the actual flow velocity and the average seepage flow velocity (for porosity) and the volume fraction of the fluid are taken into consideration. The resulting mathematical model of the heat source term of the fluid is as follows (2):

In the formula:

—Heat release of residual coal oxidation;

—geometric factor of the flow field;

—The ratio of CO oxygen consumption to the total coal oxygen consumption;

—The heat of oxidation when coal is oxidized to CO, KJ/mol;

—The heat of oxidation when coal is oxidized to CO2, KJ/mol;

—Oxygen consumption rate per unit volume of coal.

- (3)

Expansion coefficient ()

According to the empirical formula and the division of the third horizontal area and the third vertical area of the goaf, the calculation formula of the rock fragmentation coefficient is as follows (Equation (3)):

m—is the thickness of coal seam;

x, y, z—is the coordinate of goaf.

- (4)

Porosity

The porosity (

x,

y,

z) at any point in the goaf space has the following relationship with the coefficient of disintegration (Equation (4)).

- (5)

Permeability

The permeability is affected by the average particle size and porosity. According to the Carman formula, the goaf permeability can be calculated from the average particle size and porosity of the goaf (Equation (5)):

In the formula:

—Goaf permeability coefficient, 10−8 m2;

—Average particle diameter, m;

—Porosity of porous media.

The goaf of the working face is simplified as follows [

28,

29]: (1) air and gas flowing through the stope are treated as ideal gases. (2) the gas mixture is composed entirely of CH

4, while the air entrance contains 21% O

2 and N

2. (3) gas emissions from the coal rake, neighboring strata and working face are analyzed, with all gas assumed to originate from the goaf. This assumption is applied by setting the UDF-based goaf gas source item. (4) non-uniform porous media are assumed for the caving and fracture zones in the goaf, with the filling body at the goaf entry considered as a film-type porous medium (see

Table 1).

Boundary conditions are set as follows: the wind speed in the goaf is low, indicating a turbulent flow with low Reynolds number. Air in flow in large gaps of the gangue are also calculated using a turbulent flow model. The airflow undergoes major curvatures due to rockfall on the goaf. To describe real gas flow more accurately, these regions are treated as porous media domains following the RNG k-ε model. Based on the actual on-site conditions and previous simulation experience, the inlet of the air inlet is set as velocity-inlet while the return air outlet is set as outflow. The interface between the working face and the goaf is set as interior, and all wall boundaries are set as non-slip static walls. The intersection surface with the goaf is set as a porous jump.

4. Influence of Drainage Conditions on CH4 and O2 Focus Allocation

In the model, a section at z = 1 m was analyzed, and the allocation of O2 and CH4 levels were determined at different horizons under various drilling locations, drilling spacings and negative pressures of gas drainage. The demarcation line between the spontaneous combustion zone is divided by an O2 concentration ranging from 18% to 10%.

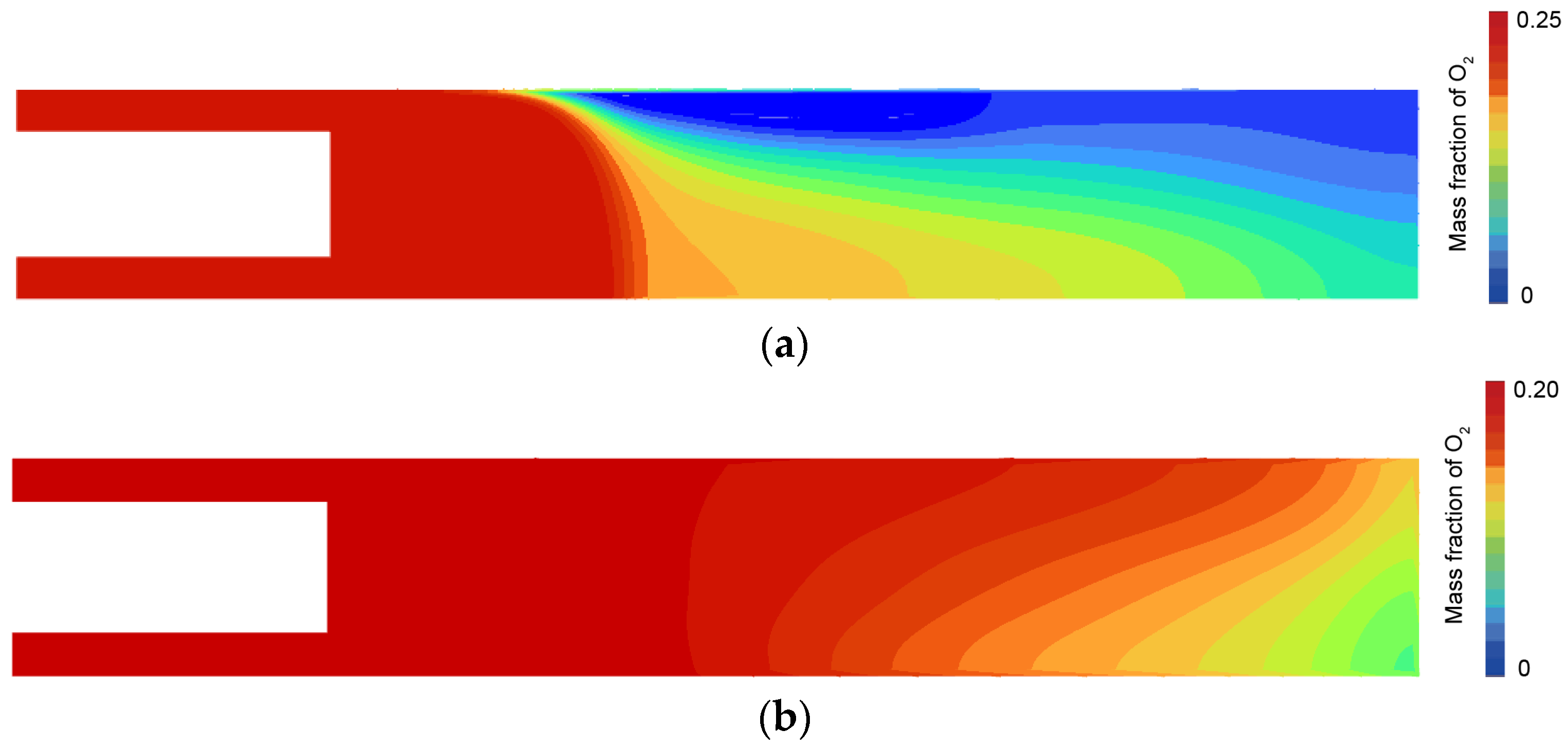

4.1. With or without Gas Drainage

Comparing the “three zones” allocation of goaf burned spontaneously before and after gas removal, it was found that the zone of O

2 spontaneously burned on the air entrance edge of the goaf under gas drainage conditions showed a relatively small increase compared to the condition without gas drainage. As shown in

Figure 3, the width of the O

2 temperature rise zones in the core region of the goaf significantly increased, reaching 70 m, and the width of the zones on the ventilation roadway also increased by approximately 20 m. Because of the borehole’s limited drainage range, the influence of the borehole on the air entrance edge of the goaf was relatively small, leading to a less significant increase in the breadth of the O

2 spontaneously burned zone. The goaf’s central part is closer to the borehole, and the wind flow constantly replenishes this region, making the borehole more effective. Consequently, the increase in the breadth of the spontaneously burned zone in the central part of the goaf is more significant.

Using large-diameter and long-hole drainage system causes the fever consumption zone on the air entrance edge of the goaf to expand, but it does not reach the O2 fevering zone until 70 m, while the cooling strip on the return air edge is shortened in the middle of the goaf. This is mainly due to the increased airflow power from the open-off cut to the goaf resulting from the negative pressure, which expands the goaf’s fever consumption zone on the air entrance edge. When the airflow reaches the middle of the goaf, a portion enters the borehole along the air disclosure channel, causing the airflow speed to decrease into the profound part of the gob on the return air edge as well. This shortens the width of the fever consumption zone in the central part of the goaf and return air edge goaf, and results in an increase in the O2 spontaneously burned zone.

Without gas extraction, air disclosure in the goaf will leak in from the lower corner and outflow from the upper corner, resulting in a two-dimensional plane of air disclosure in the goaf. Physical adsorption and low-temperature O2 reactions continue to consume O2, and the gas released from the goaf also dilutes the O2 levels. However, due to negative pressure, the airflow in the superficial part of the goaf replenishes the profound part, resulting in an increased range of air disclosure suitable for residual coal O2 and an a wider spontaneously burned zone in the goaf. This airflow replenishment delays the time it takes to enter the suffocation zone.

Figure 4 shows that the CH

4 level on the air entrance edge of the goaf is low, while the CH

4 level on the air return edge is relatively high. The CH

4 levels in the goaf gradually increases from the air entrance edge to the air return edge. At the upper corner, the CH

4 level reaches its maximum. This is because the goaf flow sphere operates under the negative pressure effect, and the pressure gradient in the goaf causes the CH

4 to flow in the gob in a Darcy seepage manner. The CH

4 fluxion is proportional to the pressure gradient, and the greater air disclosure intensity per unit length on the wind edge indicates that the air disclosure’s CH

4 dilution capacity is higher than that on the return air edge.

Gas drainage by drilling significantly reduces the CH4 level in the goaf and ascending corner. This is due to the pressure difference inside the goaf increasing due to gas drainage in boreholes, resulting in an increase in the intensity of air disclosure. Most of the airflow is exhausted from the borehole, and a large amount of CH4 inside the goaf is discharged. The gas levels on the air entrance edge enters the CH4 explosion zone with a certain delay due to CH4 elimination from air disclosure, resulting in a decrease in CH4 level. On the side of return air, the CH4 level is significantly reduced due to the obvious effect of CH4 extraction, with a delay in the CH4 concentration entering the explosive zone. The goaf has a reduced CH4 content, indicating that the CH4 in the ascending corner and goaf can be effectively reduced by the gas drainage technique.

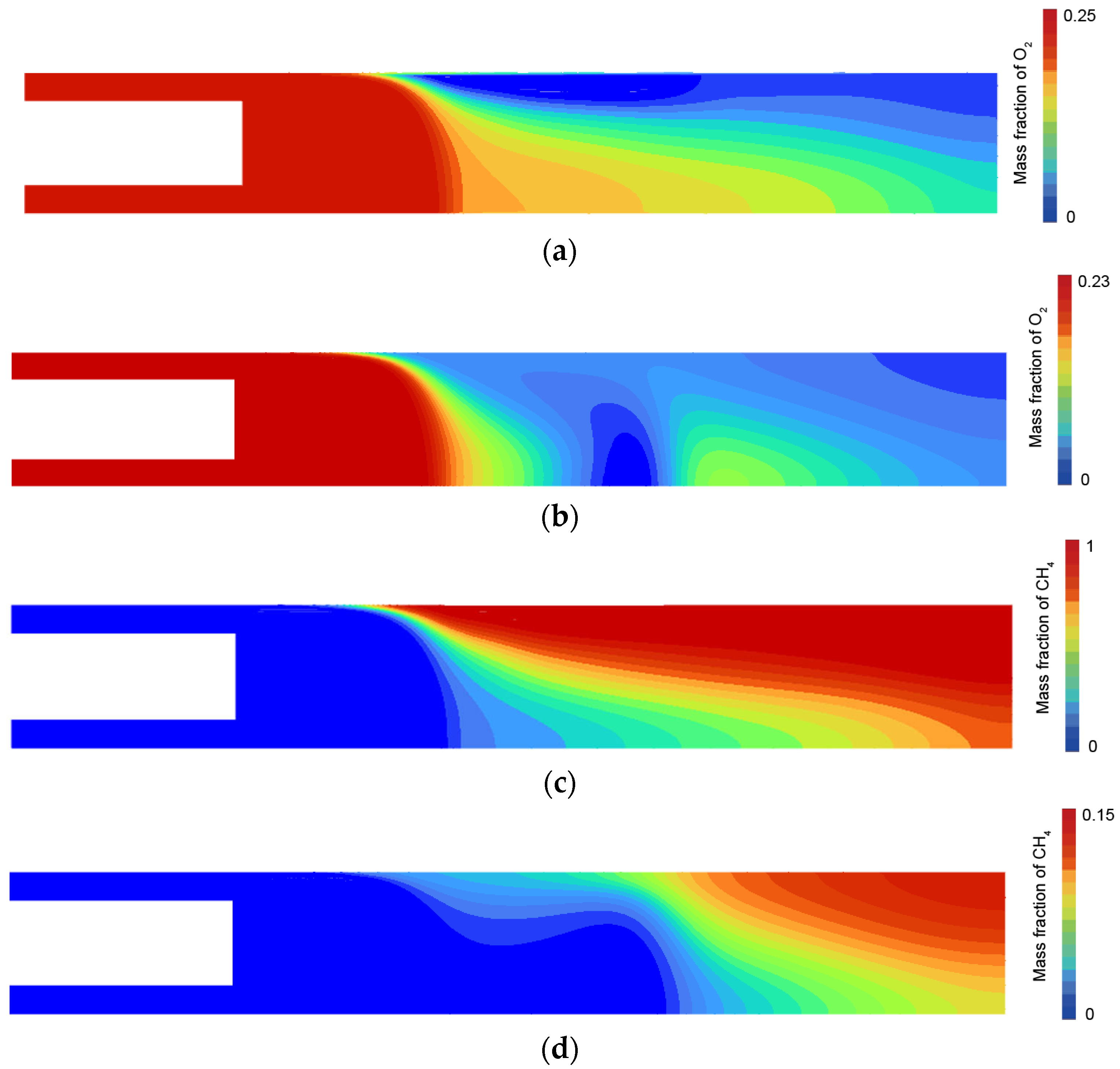

4.2. Negative Pressure

With the arrangement of drainage boreholes, the goaf is greatly impacted, and the width of the three-dimensional drainage expands as the vertical height of the boreholes increases. This study focuses on analyzing the allocation of O2 and CH4 levels under the state of P = −10 kPa and −20 kPa. The final drainage borehole is located in the roof caving area at a depth of 22 m (z = 22 m).

Figure 5 shows that at a negative pressure of −10 kPa, the O

2 level around the return air edge decreases to 18% at 20 m from the open-off cut, entering the range of the O

2 temperature rise zone. As the distance from the open-off cut increases, the O

2 levels quickly drops. At around 30 m from the open-off cut, the O

2 level drops to about 10%. When the negative pressure is −20 kPa, the fever consume zone is relatively wide due to the large air disclosure at the air entrance edge. Even at about 35 m from the open-off cut, it is still around 18%. However, as the distance from the open-off cut increases, the O

2 level drops rapidly, reaching 10% at about 45 m from the open-off cut.

Figure 6 reveals that under various negative pressure conditions, the CH

4 level in the front part of the goaf is almost zero, indicating that the drilling effect of drainage is significant. CH

4 generally accumulates in the deep area of the goaf, and as the negative pressure of gas drainage increases, CH

4 on the return air edge consistently flows out until it is almost completely extracted. On the entrance edge, the extraction effect decreases significantly due to gangue separation, resulting in a high concentration of CH

4.

4.3. Drill Hole Spacing

When a negative pressure of −20 kPa is selected, the drainage borehole layout spacing is set to 1.5 m and 4.5 m. The simulation graphics are presented in

Figure 7. The CH

4 concentration cloud map is shown at the cross-section positions of z = 3 m (above the goaf) and z = 9 m (in the middle of the caving zone).

As shown in

Figure 7, the effect of gas drainage is more pronounced when the borehole spacing is smaller, resulting in a significant reduction in CH

4 level in the superficial part of the goaf and ascending corner area. When the borehole spacing is larger, the time when the CH

4 level on the return air edge enters the gas explosion zone is earlier compared to the drainage results under the condition of a 1.5 m borehole spacing. This is because the gas drainage effect on the air return edge and ascending corner is less pronounced with a wider range of borehole distribution. Under the condition of centralized borehole arrangement, gas drainage will have a greater impact on the air return edge of the borehole, delaying the moment when the CH

4 levels enter the gas explosion area to a certain extent.

4.4. Influence of Air Supply Conditions on O2 Distribution

Referring to the actual variation range of air volume in the 11,800 working face, simulated air speeds that are too large or too small have no practical significance. In order to investigate how the range of spontaneous combustion in the goaf changes with respect to various air volumes and to simulate the space of the goaf flow field, the air supply volume is set to 0.9 times, 1 time, 1.1 times and 1.2 times the original air supply volume. The cloud diagrams of the horizontal O

2 concentration distribution for air volumes of 972, 1188 and 1286 m

3/min are shown in

Figure 8, respectively.

Figure 8 shows that the air inlet side of the working face has a relatively high O

2 level, reaching 21%. The O

2 levels on the return air edge of the operating face gradually decreases, and the allocation of O

2 level on the air entrance edge is wider compared to the narrow allocation range of 110 m in the middle of the operating face. On the air input and return sides of the open-off cut, the O

2 levels in the goaf is higher, and they are lower in the middle. This is mainly due to the lower air permeability in the middle of the goaf.

Moreover, as the air supply volume increases from 972 m3/min to 1286 m3/min, the contour line of 18% O2 level in the entrance and return air moves further from the open-off cut. This is because the increase in air capacity results in an increase in tunnel air disclosure. With increasing air volume, the degree of O2 level dilution increases, and the distance from 21% to 18% of the O2 levels gradually widens. In the goaf, the tunnel air disclosure is more pronounced near the air entrance and return lanes, and the O2 levels gradually decreases with increasing goaf depth. The allocation range of O2 levels in the goaf are wider.

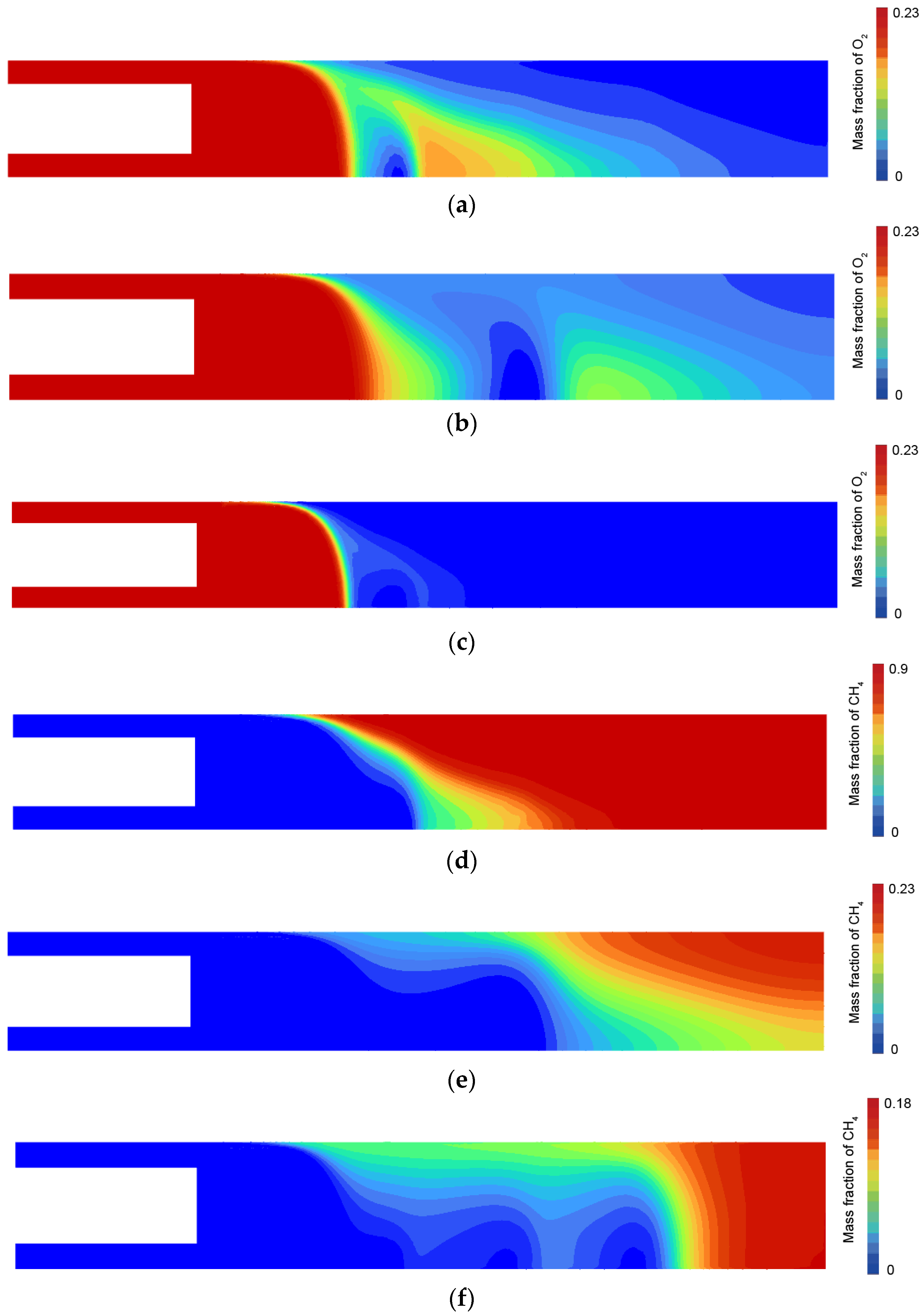

5. Effect of N2 Injection on Allocation of CH4 and O2 Levels

5.1. CH4 and O2 Levels before and after N2 Injection

Figure 9 demonstrates that without N

2 injection, the O

2 concentration on the air entrance edge is higher than on the air return edge. In the goaf, the O

2 seepage ranges are more active at the air input side than they are in the middle and on the air return side. As air returns to the return air edge, it undergoes O

2 consumption and momentum loss along the way, resulting in a significant reduction of the O

2 concentration.

Due to the influence of the gangue in the middle of coal seams 18a and 18b, there is an obvious dividing line in the goaf interspace. The O2 level on the return air edge shows a decreasing trend as it extends to the depth of the goaf. The O2 belts with higher concentration are distributed non-equidistantly in the air entrance and return air lanes. According to the standard of 3 O2 level zones, 10–18% is the O2 zone, greater than 18% is the fever consume zone and less than 10% is the suffocation zone. It is evident that the width of the O2 zone on the return air side is greater than that on the air intake side. From a trend perspective, the width of the O2 zone initially grows from the air entrance edge to the air outlet edge, before decreasing. Prior to N2 injection, low levels of O2 are present in the goaf subsequently gangue. The maximum width of the O2 zone on the air entrance side is about 30–80 m behind the open-off cut, and the width of the O2 zone can reach up to 50 m at its widest point.

5.2. N2 Injection Location

The position of the N

2 injection port is an important parameter in preventing coal spontaneous combustion [

30,

31], referring to the distance between the N

2 injection port and the open-off cut. If the open-off cut and N

2 injection port are too close to one another, the effect of reducing the O

2 levels in the middle and rear of the goaf is not significant. If the N

2 injection port is too far away from the open-off cut, it will not be able to effectively inert the O

2 zone in the goaf.

To determine a reasonable N

2 injection position and study the effect of different N

2 injection locations on the N

2 injection effect, different N

2 injection locations are selected, the coordinate X value represents the distance between the open-off cut and the N

2 injection port, namely X = 25 m, X = 50 m, X = 75 m in

Figure 10. In the simulation, the flow rate of N

2 injection is set to 2000 m

3/h. The following figures illustrate the effects of moving the N

2 injection port and display multiple sets of simulations with different configurations while analyzing the change of the “three zones” of spontaneous combustion.

N2 injection at various locations can reduce the extent of the O2 zone, but the extent of the shortened O2 zone varies depending on the injection location. However, it is found that the boundaries between the fire consumption zone and the O2 zone does not change significantly—that is, the isoline with an O2 levels of 18% does not change much. The boundary line between the O2 zone and the suffocation zone changes significantly, and the isoline with an O2 levels of 10% moves back significantly.

The O2 concentration is greatly reduced by N2 injection, especially near the N2 injection port on the air inflow side. N2 injection has a significant diluting effect. When X = 25 m, due to the N2 injection position being too close to the open-off cut, the injected N2 is mainly concentrated in the fire consumption zone, and it is difficult to diffuse to the deeper part of the goaf. However, it can effectively block the entry of O2 and dilute the CH4 concentration. Although there is some wastage, it can ensure the safety of mining.

Affected by the gangue in the middle of the goaf, the influence of N

2 injection is more significant as it extends deeper into the goaf, but it is also influenced by the amount of N

2 injected, and the compound disaster area is likely to recur between the open-off cut and the N

2 injection port. According to the analysis of multiple N

2 injection ports, it can be found that the arrangement of N

2 injection ports every 25 m from the open-off cut can completely fill this blank area (as shown in

Figure 10).

6. Application

The faster the advancing speed of the mining face, the longer the time that the change of coal spontaneous combustion in the goaf lags behind the change of the advancing speed of the mining face. The “favorable” zone in the goaf becomes shallower and the maximal temperature increases as the advancing rate slows down. Once the rate drops to a certain “critical” value, spontaneous heating transforms into flaming combustion [

32,

33]. Speeding up the advancing speed of working face is the most effective ways to stop coal from spontaneously burning. As the completely mechanized mining face continues to advance, the roof and surface continues to fall and compact [

34,

35], and the air flow state also changes accordingly.

The “fire consumption zone”, “O

2 fevering zone” and “suffocation zone” in the goaf can also change dynamically. When the time required for working face to advance to the “O

2 fevering zone” is less than the spontaneously burned period, the risk of coal rake ignition is very small. Since coal 18 is a type of coal with secondary spontaneous combustion, the spontaneously burned period is 47 days. From the simulation, it can be seen that the maximum width of the possible oxidation temperature rise zone under the condition of normal air supply at the working face is 50 m. When the advancing degree of the working face is equal to or greater than the width of the oxidation temperature rise zone of the working face, the normal mining of the working face can be guaranteed (Equation (6)).

In the Equation (6):

For this reason, according to the distribution characteristics of O2, CH4 and temperature, it can be determined that the recovery speed of the operating face is not less than 1.06 m/d, which can reach the necessary advance speed for active coal spontaneously burned protection.

In the calculation of the actual required air volume of operating face, the following factors need to be considered: (1) the temperature of operating surface; (2) appropriate wind speed on the operating face; (3) the outflow of CH4 and (4) the amount of oxygen required by the number of fully mechanized mining machines. Through numerical simulation and various parameters of the operating face, we can calculate that the air supply volume of the operating face should be in the range of 1030.18 m3/min~1080 m3/min to ensure the normal progress of the mining work.

In the selection of spontaneously burned and compound disaster prevention and controlling technology, the N

2 injection inerting treatment’s use in goafs can abate the scope of the zone with spontaneous combustion of coal due to O

2 in goafs, and also, greatly reduce the area of compound disasters by N

2 injection [

36,

37]. According to the analysis of multiple N

2 injection ports, it can be found that the arrangement of N

2 injection ports every 25 m from the open-off cut can completely fill this blank area when the flow rate of N

2 injection is set to 2000 m

3/h.

Optimized ventilation and drainage parameters can block the airflow and O

2 supply conditions in the goaf in time [

38,

39], and at the same time reduce the compound disaster area. The gas drainage borehole is used as the grouting hole, which can consider the dual functions of CH

4 drainage and coal spontaneously burned prevention. The above-identified goaf N

2 injection inerting treatment technology, optimized ventilation and drainage parameters, and “combined pumping and injection” high-level drilling gas controlling and coal spontaneously burned prevention and extinguishing can realize effective collaborative prevention and control of the combined catastrophe of gas and coal spontaneously burned in the goaf of working face.

Benefiting from the conclusions obtained from the numerical simulation, the working face finally adopted the technical measures of comprehensive measures of high-level drilling drainage and N

2 injection technology in the goaf to prevent and control the natural complex disasters of GCSC. In order to verify the effectiveness of this measure, sensors were arranged at the upper corner of the return air flow to monitor the characteristics of CO and CH

4 concentration changes during the advancement of the working face. It can be seen from the results that the change ranges of CO and CH

4 during the advancing process of the working face fall within the safe range, indicating that the numerical simulation conclusions provide a useful reference for the combined disaster prevention and control of GCSC in goafs (see

Figure 11).

7. Limitations and Perspectives

GCSC disasters have always been an important disaster that affects underground safety mining [

40,

41,

42]. Because of its long cycle, strong concealment and great harm, the method of pre-disaster prevention can effectively reduce the losses caused by disasters. However, the downhole conditions are complex and the scene is changeable; moreover, it is difficult to conduct experiments or the monitoring period can be long, so it is challenging to predict the occurrence of disasters in time [

43,

44]. Numerical simulation is a commonly used method both domestically and internationally. Among them, Ansys Fluent has been recognized in the industry in simulating GCSC. It can simulate and predict the occurrence of GCSC disasters in different periods based on the actual situation of the underground mine site. Based on the simulation results, the disaster prevention and control strategy can be adjusted in time on site, supplemented by on-site monitoring methods, which can effectively reduce the probability of disaster occurrence and the cost of prevention and control. Based on this, this paper uses the method of numerical simulation to study the natural gas and coal combustion disasters.

At the same time, the numerical simulation is based on the iterative calculation based on the actual situation on the spot to predict the disaster. Limited by risks such as roof caving [

45,

46,

47] in the upper goaf and increased concentration of internal gases such as CO, some specific parameters [

48,

49,

50], such as the porosity of the fracture zone, are difficult to measure in practice, and are calculated using theoretical and empirical formulas, and there are certain errors with the actual situation, which is unavoidable. However, with the advancement of downhole technology, these parameters will become more accurate in the future, and the numerical results will be more reliable.