Carbon Footprint Accounting and Influencing Factors Analysis for Forestry Enterprises in the Key State-Owned Forest Region of the Greater Khingan Range, Northeast China

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area

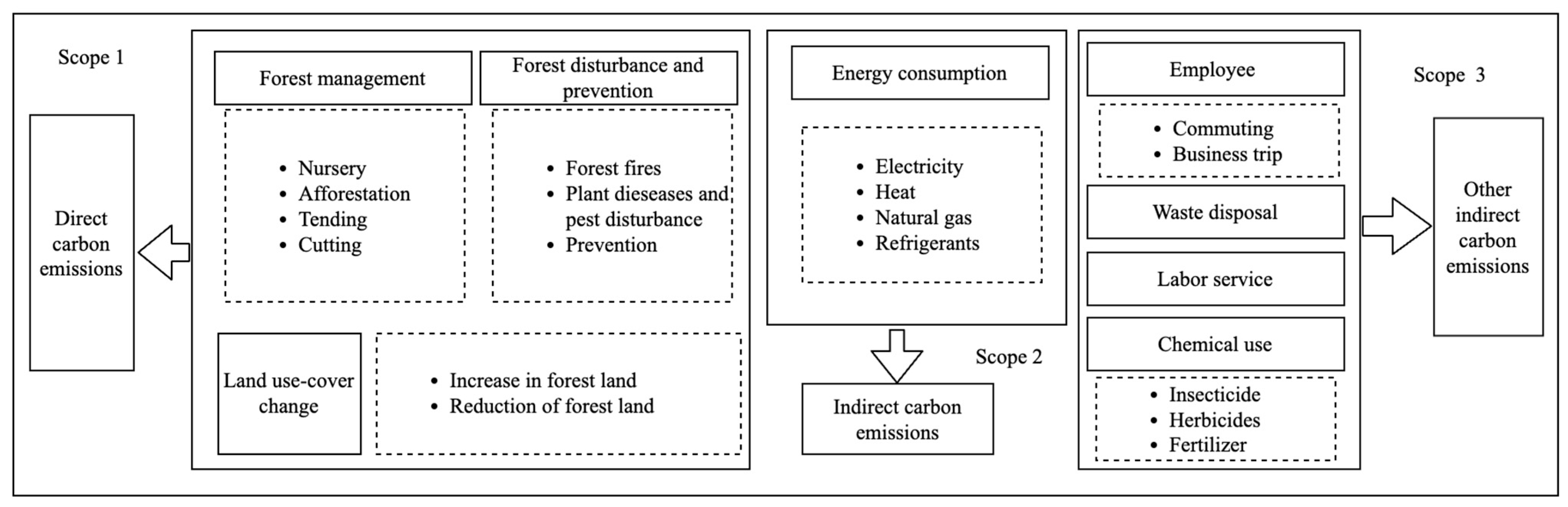

2.2. Constructing Carbon Footprint Accounting System for Forestry Enterprises

2.3. Methods for Accounting the Carbon Footprint of Forestry Enterprises

2.3.1. Accounting for the Carbon Footprint of Forestry Enterprises in Scope 1

2.3.2. Accounting for the Carbon Footprint of Forestry Enterprises in Scope 2

2.3.3. Accounting for the Carbon Footprint of Forestry Enterprises in Scope 3

2.4. Influencing Factors Analysis on the Carbon Footprint of Forestry Enterprises

2.4.1. Panel Data Model

2.4.2. Ridge Regression

2.5. Data Investigation

3. Results

3.1. Characteristics of Carbon Footprint of the Greater Khingan Forestry Group

3.1.1. Results of Annual Carbon Footprints and Carbon Footprint Intensity

3.1.2. Results of Carbon Footprint of Different Processes in Different Scopes

3.2. Characteristics of Carbon Footprint of Individual Forestry Enterprises

3.2.1. Results of the Annual Carbon Footprint of Different Forestry Enterprises

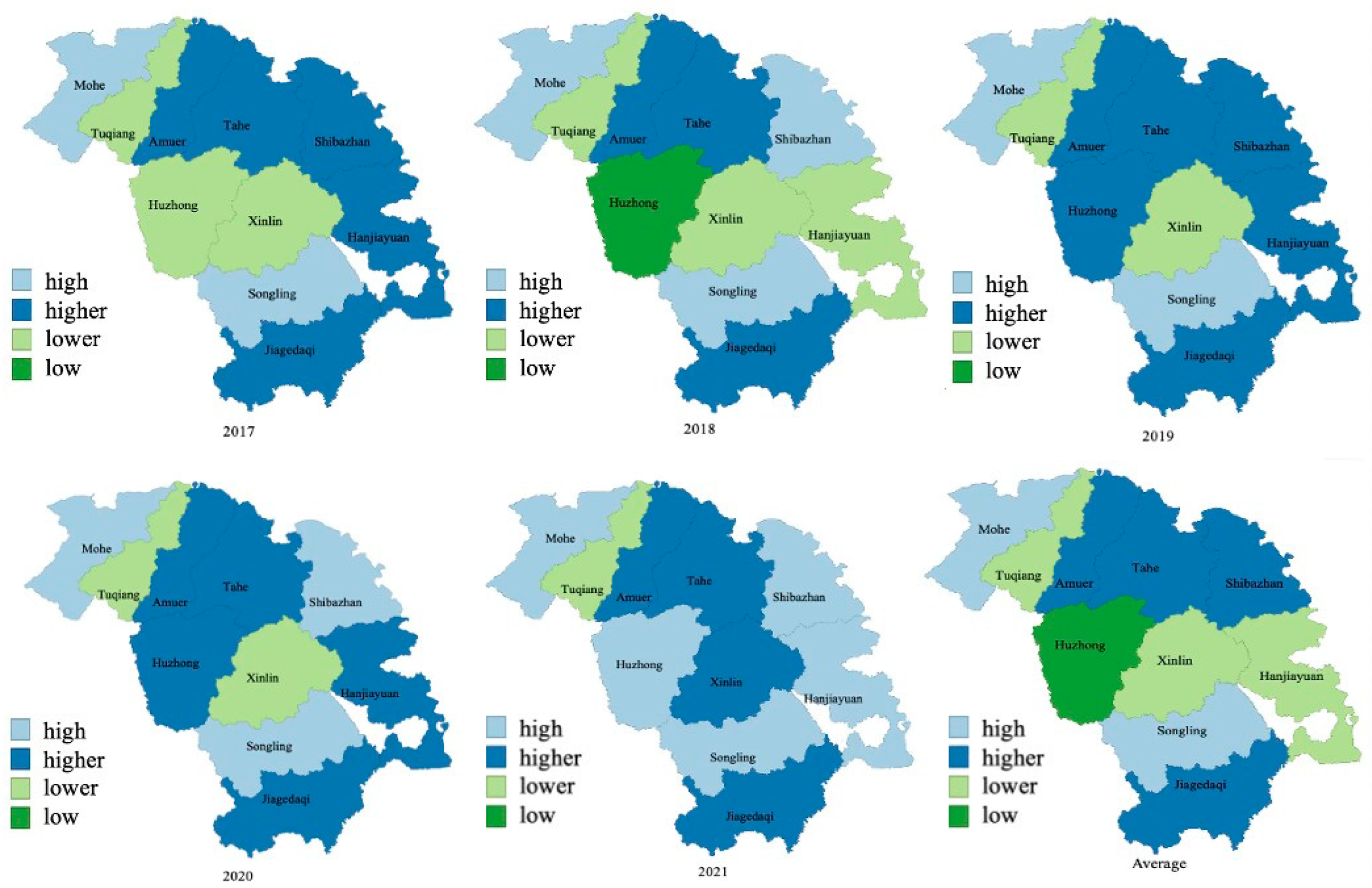

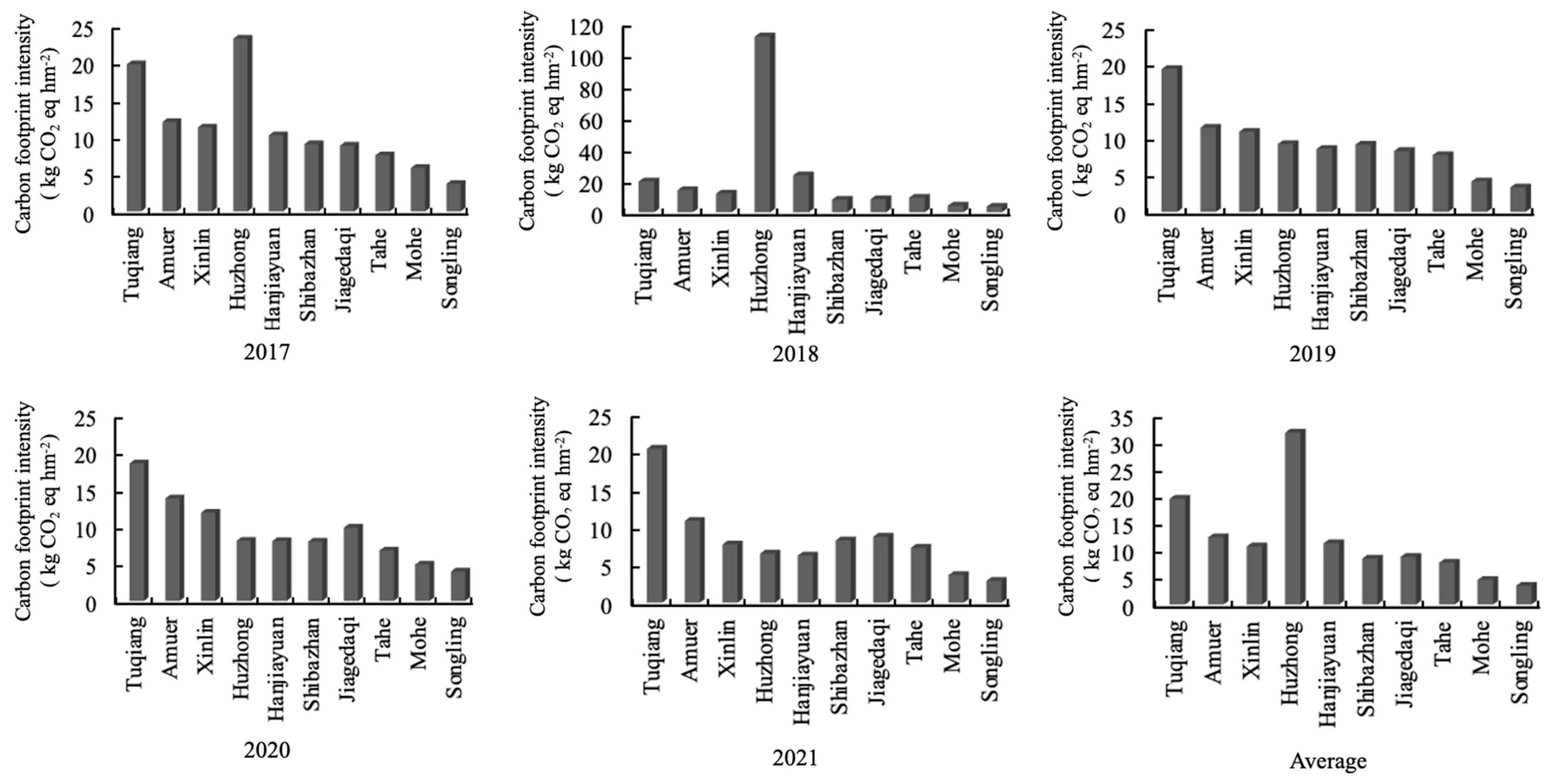

3.2.2. Results of the Annual Carbon Footprint Intensity of Different Forestry Enterprises

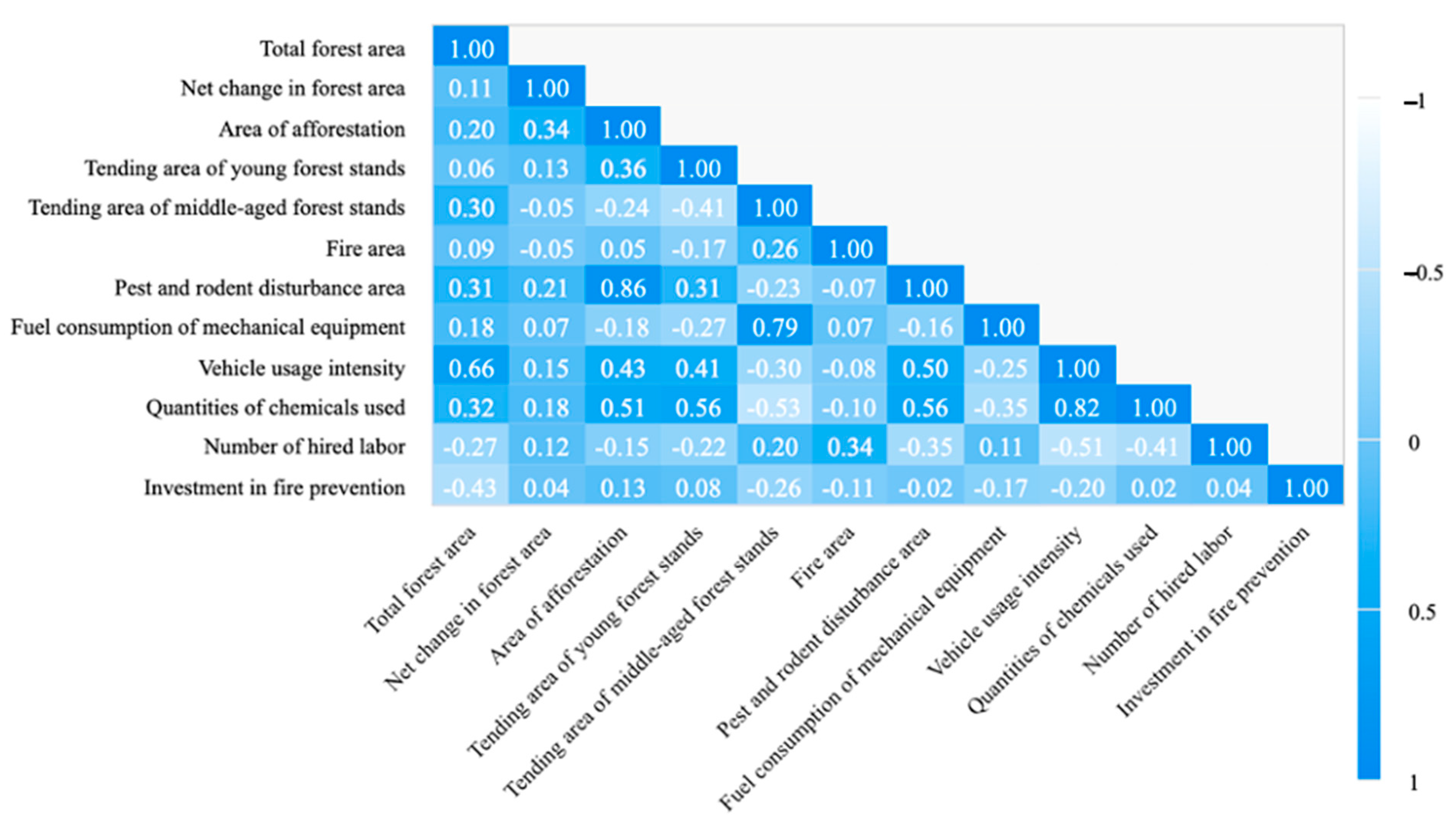

3.3. Analysis on the Influencing Factors of the Carbon Footprint of Forestry Enterprises

4. Discussions

4.1. Comparisons of Total Carbon Footprint and Carbon Footprint Intensity for the Forestry Enterprises in the Greater Khinggan Range

4.2. Comparisons of the Key Aspects of the Carbon Footprint of Forestry Enterprises in the Greater Khinggan Range

4.3. Comparison of the Factors Influencing the Carbon Footprint of Forestry Enterprises in the Greater Hinggan Mountains

4.4. Limitations and Future Research

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yoro, K.O.; Daramola, M.O. CO2 emission sources, greenhouse gases, and the global warming effect. In Advances in Carbon Capture; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28. [Google Scholar]

- Hui, D.F.; Deng, Q.; Tian, H.Q.; Luo, Y.Q. Global climate change and greenhouse gases emissions in terrestrial ecosystems. In Handbook of Climate Change Mitigation and Adaptation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 23–76. [Google Scholar]

- Ye, H.Y.; Zhang, Q.; Pan, X.Z.; Lv, L. Carbon leakage for voluntary emission reduction projects: Concept, classification, and measures. Chin. J. Environ. Manag. 2020, 12, 98–106. [Google Scholar]

- Nabuurs, G.J.; Thürig, E.; Heidema, N.; Armolaitis, K.; Biber, P.; Cienciala, E.; Kaufmann, E.; Mäkipää, R.; Nilsen, P.; Petritsch, R.; et al. Hotspots of the European forests carbon cycle. For. Ecol. Manag. 2008, 256, 194–200. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, S.F.; Wang, P. Key areas and pathways for carbon emissions reduction in Beijing for the “Dual Carbon” targets. Energy Policy 2022, 164, 112873. [Google Scholar] [CrossRef]

- Richards, K.R.; Stokes, C. A review of forest carbon sequestration cost studies: A dozen years of research. Clim. Chang. 2004, 63, 1–48. [Google Scholar] [CrossRef]

- Liu, L.W.; Chen, C.X.; Zhao, Y.F.; Zhao, E.D. China’s carbon-emissions trading: Overview, challenges and future. Renew. Sustain. Energy Rev. 2015, 49, 254–266. [Google Scholar] [CrossRef]

- Ba, F.; Liu, J.L.; Zhu, T.; Liu, Y.G.; Zhao, J.C. CDM forest carbon sequestration projects in western China: An analysis using actor-centered power theory. For. Policy Econ. 2020, 115, 102139. [Google Scholar] [CrossRef]

- Lin, B.T.; Li, X.L.; Luo, D. Study on forestry enterprise carbon footprint. South China For. Sci. 2013, 3, 33–36+41. [Google Scholar]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef]

- Dooley, E.E. EHPnet: World resources institute: Climate, energy, and transport program. Environ. Health Perspect. 2007, 115, A537. [Google Scholar] [CrossRef]

- Weng, C.K.; Boehmer, K. Launching of ISO 14064 for greenhouse gas accounting and verification. ISO Manag. Syst. 2006, 15, 14–16. [Google Scholar]

- Chen, L.; Chen, J.H.; Bao, W.; Guo, H.T.; Sun, L. Development progress review and policy suggestion on greenhouse gas emission quantification standards for enterprise. China Popul. Resour. Environ. 2016, 26, 20–22. [Google Scholar]

- Hammar, T.; Hansson, P.A.; Seleborg, M.; Stendahl, J. Climate Effects of a Forestry Company—Including Biogenic Carbon Fluxes and Substitution Effects; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2020. [Google Scholar]

- Zhao, Q.J.; Ding, S.; Wen, Z.M.; Toppinen, A. Energy flows and carbon footprint in the forestry-pulp and paper industry. Forests 2019, 10, 725. [Google Scholar] [CrossRef]

- Zhou, J.; Yin, Z.C.; Yue, P.P. The impact of access to credit on energy efficiency. Financ. Res. Lett. 2023, 51, 103472. [Google Scholar] [CrossRef]

- Ye, X.; Yue, P.P. Financial literacy and household energy efficiency: An analysis of credit market and supply chain. Financ. Res. Lett. 2023, 52, 103563. [Google Scholar] [CrossRef]

- Chen, K.Y.; He, Y.J.; Xie, H.S.; Li, Y.J.; Zhao, Y.X. Evaluation and prediction of coupling coordinated development of compound system of key state-owned forest region in Daxing ‘anling, Heilongjiang province. J. Ecol. Rural. Environ. 2022, 38, 578–586. [Google Scholar]

- Zhang, L.Y.; Dong, L.B.; Liu, Q.; Liu, Z.G. Spatial patterns and interspecific associations during natural regeneration in three types of secondary forest in the central part of the Greater Khingan Mountains, Heilongjiang Province, China. Forests 2020, 11, 152. [Google Scholar] [CrossRef]

- Forestry and Grassland Administration. China’s Forest and Grassland Resources and Ecological Status State in 2021; China Forestry Publishing House: Beijing, China, 2021. [Google Scholar]

- Kubová, P.; Hájek, M.; Třebický, V. Carbon footprint measurement and management: Case study of the school forest enterprise. Bioresources 2018, 13, 4521–4535. [Google Scholar] [CrossRef]

- Parigiani, J.; Desai, A.; Mariki, R.; Miner, R. The carbon footprint of an east African forestry enterprise. J. Sustain. Dev. 2011, 4, 152–162. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, C.Z.; Zhang, D.Y.; Zang, S.Y. Environmental influences on forest fire regime in the Greater Hinggan Mountains, northeast China. Forests 2017, 8, 372. [Google Scholar] [CrossRef]

- Wu, Z.W.; He, H.S.; Yang, J.; Liu, Z.H.; Liang, Y. Relative effects of climatic and local factors on fire occurrence in boreal forest landscapes of northeastern China. Sci. Total Environ. 2014, 493, 472–480. [Google Scholar] [CrossRef]

- Chen, K.Y.; Wang, J.J.; He, Y.J.; Zhang, L.W. Estimations of forest carbon storage and carbon sequestration potential of key state-owned forest region in Daxing’ anling, Heilongjiang province. Ecol. Environ. Sci. 2022, 31, 1725–1734. [Google Scholar]

- Zhang, L.C.; Zhang, Y.F.; Dong, L.B. Spatial pattern and correlation of forest landscape in Daxing’ an Mountains based on Landsat TM data. For. Eng. 2021, 37, 1–9. [Google Scholar]

- Choudhary, P.; Srivastava, R.K.; De, S. Integrating Greenhouse gases (GHG) assessment for low carbon economy path: Live case study of Indian national oil company. J. Clean. Prod. 2018, 198, 351–363. [Google Scholar] [CrossRef]

- Liu, X.B. Mitigating China’s Greenhouse Gas Emissions in the Last Decade: Clear Target or Blurred Path? J. WTO China 2022, 12, 73. [Google Scholar]

- Radonjic, G.; Tompa, S. Carbon footprint calculation in telecommunications companies—The importance and relevance of scope 3 greenhouse gases emissions. Renew. Sustain. Energy Rev. 2018, 98, 361–375. [Google Scholar] [CrossRef]

- Ji, J.P.; Ma, X.M. Review of carbon footprint: Definitions and accounting methods. Ecol. Econ. 2011, 4, 76–80. [Google Scholar]

- Nian, V.; Chou, S.; Su, B.; Bauly, J. Life cycle analysis on carbon emissions from power generation–The nuclear energy example. Appl. Energy 2014, 118, 68–82. [Google Scholar] [CrossRef]

- Sonne, E. Greenhouse gas emissions from forestry operations: A life cycle assessment. J. Environ. Qual. 2006, 35, 1439–1450. [Google Scholar] [CrossRef]

- Timmermann, V.; Dibdiakova, J. Greenhouse gas emissions from forestry in East Norway. Int. J. Life Cycle Assess. 2014, 19, 1593–1606. [Google Scholar] [CrossRef]

- Isaev, A.; Korovin, G.; Bartalev, S.; Ershov, D.; Janetos, A.; Kasischke, E.; Shugart, H.; French, N.; Orlick, B.; Murphy, T. Using remote sensing to assess Russian forest fire carbon emissions. Clim. Chang. 2002, 55, 235–249. [Google Scholar] [CrossRef]

- Cyr, H.; Pace, M.L. Magnitude and patterns of herbivory in aquatic and terrestrial ecosystems. Nature 1993, 361, 148–150. [Google Scholar] [CrossRef]

- Iqbal, J.; Hu, R.G.; Lin, S.; Ahamadou, B.; Feng, M.L. Carbon dioxide emissions from Ultisol under different land uses in mid–subtropical China. Geoderma 2009, 152, 63–73. [Google Scholar] [CrossRef]

- Lin, Q.W.; Zhang, L.; Qiu, B.K.; Zhao, Y.; Wei, C. Spatiotemporal analysis of land use patterns on carbon emissions in China. Land 2021, 10, 141. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, L.F.; Zhou, X.N.; Wu, Z.L.; Zhou, C.J.; Luo, W.; Lin, Y.F. Eco-benefit evaluation of biomass solid fuel based on forest cutting residues. For. Eng. 2018, 34, 24–29. [Google Scholar]

- Zhou, Y.; Li, D.; Wu, Z.L.; Zhou, C.J.; Zheng, L.F. Carbon emission in forest logging operation process. For. Eng. 2014, 30, 1–5. [Google Scholar]

- Pan, B.B.; Zhang, Y.L. Impact of affluence, nuclear and alternative energy on US carbon emissions from 1960 to 2014. Energy Strategy Rev. 2020, 32, 100581. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, L.Q.; Wang, R.; Wang, B.Y.; Liu, Y.Q.; Liu, W.Q.; Wang, J.; Wen, M.X. The influencing factors of industrial carbon emissions in the context of undertaking industrial transfer in Anhui Province, China. Appl. Ecol. Environ. Res. 2019, 17, 4205–4227. [Google Scholar] [CrossRef]

- Fu, W.; Luo, M.C.; Cheng, C.J. Research progress and prospects of carbon footprint and Its influencing factors. For. Econ. 2021, 43, 39–49. [Google Scholar]

- Wang, F.; Ni, J. Study on the influencing factors of enterprises’ carbon emission—An empirical analysis of Zhejiang enterprises. J. Bus. Econ. 2016, 1, 71–80. [Google Scholar]

- Chinnakum, W.; Sriboonchitta, S.; Pastpipatkul, P. Factors affecting economic output in developed countries: A copula approach to sample selection with panel data. Int. J. Approx. Reason. 2013, 54, 809–824. [Google Scholar] [CrossRef]

- Al-Mulali, U. Investigating the impact of nuclear energy consumption on GDP growth and CO2 emission: A panel data analysis. Prog. Nucl. Energy 2014, 73, 172–178. [Google Scholar] [CrossRef]

- Wang, S.J.; Fang, C.L.; Wang, Y. Spatiotemporal variations of energy-related CO2 emissions in China and its influencing factors: An empirical analysis based on provincial panel data. Renew. Sustain. Energy Rev. 2016, 55, 505–515. [Google Scholar] [CrossRef]

- Al-mulali, U. Factors affecting CO2 emission in the Middle East: A panel data analysis. Energy 2012, 44, 564–569. [Google Scholar] [CrossRef]

- Holtz-eakin, D.; Newey, W.; Rosen, H. Estimating vector autoregressions with panel data. Econom. J. Econom. Soc. 1988, 56, 1371–1395. [Google Scholar] [CrossRef]

- Wang, Z.G. Panel Data Model and Its Application in the Economic Analysis; Economic Science Press: Beijing, China, 2008. [Google Scholar]

- Hoerl, A.E.; Kennard, R.W. Ridge regression: Biased estimation for nonorthogonal problems. Technometrics 1970, 12, 55–67. [Google Scholar] [CrossRef]

- Wang, P.; Cheng, W.S. Research on intensive utilization and driving factors of cultivated land in Jiuquan city based on ridge regression model. Territ. Nat. Resour. Study 2022, 4, 1–5. [Google Scholar]

- Zhao, S.W.; Liao, J.; Yu, D.L. Model averaging estimator in ridge regression and its large sample properties. Stat. Pap. 2020, 61, 1719–1739. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, C.; Li, Y.; Zhang, X.H.; Wei, G.W. Can CBOE gold and silver implied volatility help to forecast gold futures volatility in China? Evidence based on HAR and Ridge regression models. Financ. Res. Lett. 2020, 35, 101287. [Google Scholar] [CrossRef]

- Park, S.-J.; Kim, D.C. Analysis on Determinant Factors of Local Government Expenditure with Panel Data Ridge Regression (in Korean). Econ. Anal. 2018, 24, 67–98. [Google Scholar]

- Zhao, S.N.; Liu, R.Q.; Shang, Z.F. Statistical inference on panel data models: A kernel ridge regression method. J. Bus. Econ. Stat. 2021, 39, 325–337. [Google Scholar] [CrossRef]

- Hoerl, A.E.; Kannard, R.W.; Baldwin, K.F. Ridge regression: Some simulations. Commun. Stat. Theory Methods 1975, 4, 105–123. [Google Scholar] [CrossRef]

- National Bureau of Statistics. China Statistical Yearbook-2021; China Statistical Publishing House: Beijing, China, 2021.

- Xiao, X.D. Study on Life Cycle Carbon Emission and Life Cycle Cost of Green Buildings. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2021. [Google Scholar]

- Ke, S.F.; Li, B.; Yang, Y.H.; Ma, C.G.; Jia, Y.S. The evaluation of carbon footprint from the operation of forest farm and carbon storage by forest resources-based on the Wangyedian forest farm in Chifeng of inner Mongolia. For. Econ. 2013, 35, 93–101. [Google Scholar]

- Wu, Y.; Wang, X.K.; Lu, F. The carbon footprint of food consumption in Beijing. Acta Ecol. Sin. 2012, 32, 1570–1577. [Google Scholar]

- Song, X.Y.; Dong, X.B. Effects of tending and thinning on undergrowth vegetation biomass and carbon density in natural coniferous and broad-leaved mixed forest. J. Northeast. For. Univ. 2020, 48, 32–35+41. [Google Scholar]

- Wu, J.H. Research on Emission Reduction Management of Forestry Enterprises Based on the Dual Perspective of Carbon Sink and Carbon Source; Beijing University of Chemical Technology: Beijing, China, 2020. [Google Scholar]

- Zhang, R.N.; Yang, J. Study on carbon emission and carbon footprint of land use in Shaanxi Province. Agric. Technol. 2020, 40, 126–130. [Google Scholar]

- Wang, Y.F.; Mao, B.N.; Liang, T.N.; Guo, L.S.; Du, S.P.; Liao, D.Q.; Chen, C.C.; Zhang, J.; Fan, Z.L.; Liu, G.Y. Analysis of household carbon emission change characteristics and influencing factors in post-epidemic period. Nat. Resour. Inf. 2022, 4, 51–59. [Google Scholar]

- Li, Z.; Li, G.P.; Hu, Z. Xi’an household carbon emission characteristics. Resour. Sci. 2017, 39, 1394–1405. [Google Scholar]

- Dai, L.D.; Zhou, R.; Zhang, F.E.; Wang, X.J. A study on the impact of urban land use on carbon emissions from residential commuting. Resour. Environ. Yangtze Basin 2016, 25, 68–77. [Google Scholar]

- Chen, W.X. A study on the influencing factors and measurement of college students’ personal carbon footprint. Mod. Bus. Trade Ind. 2011, 23, 220–221. [Google Scholar]

- Bai, Y.F.; Zhang, W.R.; Liu, J.P.; Yu, Y. Study on forecasting method of per capita carbon emissions in urban demonstration area based on environmental Kuznets curve. Ecol. Econ. 2022, 38, 35–42+84. [Google Scholar]

- Smith, T.M.; Cramer, W.P.; Dixon, R.K.; Leemans, R.; Neilson, R.P.; Solomon, A.M. The global terrestrial carbon cycle. Water Air Soil Pollut. 1993, 70, 19–37. [Google Scholar] [CrossRef]

- Guo, C.L.; Xu, W.L. Research on influencing factors of carbon dioxide emission in forest industry. For. Econ. 2020, 42, 3–14. [Google Scholar]

- Chang, F.C.; Ko, C.H.; Tsai, M.J. Afforestation and tending operations affecting the carbon footprint and renewable resources at an artificial forest in Taiwan. BioResources 2020, 15, 641–653. [Google Scholar] [CrossRef]

| Symbol | Interpretation | Value | Unit |

|---|---|---|---|

| Rf | The carbon emission factor of gasoline | 2.26 | kg CO2-eq L−1 |

| The carbon emission factor of diesel | 2.73 | kg CO2-eq L−1 | |

| The average carbon content of woody biomass | 0.5 | kg C·kg−1 | |

| H | The electricity consumption per capita | 1.3 | kWh d−1 |

| Re | The carbon emission factor of electricity in Northeast China | 0.6613 | kg CO2-eq kWh−1 |

| N | Burning efficiency of wood | 0.25 | kg CO2-eq kg−1 |

| The carbon absorption coefficient of forest land | 0.644 | t·hm−2 | |

| The carbon emission coefficient of arable land | 0.422 | t·hm−2 | |

| The carbon emission coefficient of garden land | 0.210 | t·hm−2 | |

| The carbon absorption coefficient of grassland | 0.021 | t·hm−2 | |

| The carbon absorption coefficients of water facilities land | 0.218 | t·hm−2 | |

| The carbon absorption coefficient of other lands | 0.005 | t·hm−2 | |

| The carbon emission factor of natural gas | 43.21 | kg CO2 eq tank−1 | |

| The carbon emission factor of thermal energy | 12.1 | kg CO2 eq m−2 | |

| Rk | The carbon emission factor for buses | 0.035 | kg CO2 eq km−1 |

| The carbon emission factor for private cars | 0.135 | kg CO2 eq km−1 | |

| The carbon emission factor for motorcycles | 0.048 | kg CO2 eq km−1 | |

| The carbon emission factor for electric cars | 0.008 | kg CO2 eq km−1 | |

| Rm | The carbon emission factor for planes | 0.135 | kg CO2 eq km−1 |

| The carbon emission factor for trains | 0.0236 | kg CO2 eq km−1 | |

| δ | The rate of solid waste generation per capita | 270 | kg year−1 |

| r1 | The carbon emission factor of landfill | 2.1 | t CO2 eq t−1 |

| r2 | The carbon emission factor of incineration | 0.56 | t CO2 eq t−1 |

| Year | Carbon Footprint in Scope 1 (kg CO2-eq) | Carbon Footprint in Scope 2 (kg CO2-eq) | Carbon Footprint in Scope 3 (kg CO2-eq) | Total Carbon Footprint (kg CO2-eq) | Forest Land Area (hm2) | Carbon Footprint Intensity (kg CO2-eq hm−2) |

|---|---|---|---|---|---|---|

| 2017 | 36,288,256 | 20,225,486 | 19,308,939 | 75,822,681 | 6,884,908 | 11.01 |

| 2018 | 112,500,909 | 20,189,849 | 21,386,425 | 154,077,183 | 6,867,027 | 22.44 |

| 2019 | 20,756,112 | 20,286,161 | 20,097,038 | 61,139,311 | 6,869,828 | 8.90 |

| 2020 | 22,192,201 | 20,386,635 | 20,212,960 | 62,791,796 | 6,925,611 | 9.07 |

| 2021 | 15,179,106 | 20,330,632 | 19,129,319 | 54,639,056 | 6,962,153 | 7.85 |

| Average | 41,383,317 | 20,283,753 | 20,026,936 | 81,694,006 | 6,901,905 | 11.84 |

| Scope | Process | Carbon Footprint (kg CO2-eq) | Proportion (%) | |

|---|---|---|---|---|

| Scope 1 | Forest resource management | Seedlings cultivation | 78,435 | 0.02 |

| Afforestation | 24,352,777 | 5.96 | ||

| Forest tending | 47,623,000 | 11.66 | ||

| Forest disturbance and prevention | Forest fires | 116,540,081 | 28.53 | |

| Pest disturbance | 14,688,517 | 3.60 | ||

| Disturbance prevention | 73,358,225 | 17.96 | ||

| Land use-cover change (LUCC) | 1,754,826 | 0.43 | ||

| Scope 2 | Electricity consumption | 74,323,208 | 18.20 | |

| Thermal energy consumption | 27,095,555 | 6.63 | ||

| Scope 3 | Commuting | 8,710,043 | 2.13 | |

| Business travel | 15,181,417 | 3.72 | ||

| Waste treatment (landfill and incineration) | 1,967,911 | 0.48 | ||

| Use of chemicals (fertilizer, herbicide, pesticides) | 2,474,805 | 0.61 | ||

| Labor service (patrol, afforestation, tending) | 71,800,505 | 17.58 | ||

| Total | 408,470,028 | 100.00 | ||

| Test Type | Test Purpose | Test Value | Test Result |

|---|---|---|---|

| F test | Comparing FE Model and POOL Model | F (9,30) = 189.866, p = 0.000 | FE model |

| BP test | Comparing RE model and POOL model | χ2(1) = 24.513, p = 0.000 | RE model |

| Hausman test | Comparing FE model and RE model | χ2(9) = −29.466, p = 1.000 | RE model |

| Items | Coef | Std. Err | p | VIF |

|---|---|---|---|---|

| Intercept | 6,605,605.596 | 1,944,524.929 | 0.002 ** (3.397) | - |

| Total forest area | −7.809 | 3.134 | 0.017 * (−2.491) | 4.030 |

| Net change in forest area | −233.030 | 1413.596 | 0.870 (−0.165) | 1.292 |

| Area of afforestation | −3326.909 | 999.388 | 0.002 ** (−3.329) | 5.934 |

| Tending area of young forest stands | 180.476 | 81.483 | 0.033 * (2.215) | 1.588 |

| Tending area of middle-aged forest stands | −36.731 | 69.830 | 0.602 (−0.526) | 5.314 |

| Fire area | 36,686.683 | 851.838 | 0.000 ** (43.068) | 1.396 |

| Pest and rodent disturbance area | 584.362 | 144.188 | 0.000 ** (4.053) | 5.953 |

| Fuel consumption of mechanical equipment | 6.185 | 2.400 | 0.014 * (2.577) | 3.229 |

| Vehicle usage intensity | 15.090 | 2.631 | 0.000 ** (5.736) | 8.574 |

| Quantities of chemicals used | −216.156 | 54.349 | 0.000 ** (−3.977) | 6.038 |

| Number of hired labor | 4388.223 | 645.566 | 0.000 ** (6.797) | 1.872 |

| Investment in fire prevention | 0.284 | 2.937 | 0.924 (0.097) | 1.415 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wu, J.; Lin, W.; Luan, Z. Carbon Footprint Accounting and Influencing Factors Analysis for Forestry Enterprises in the Key State-Owned Forest Region of the Greater Khingan Range, Northeast China. Sustainability 2023, 15, 8898. https://doi.org/10.3390/su15118898

Wang H, Wu J, Lin W, Luan Z. Carbon Footprint Accounting and Influencing Factors Analysis for Forestry Enterprises in the Key State-Owned Forest Region of the Greater Khingan Range, Northeast China. Sustainability. 2023; 15(11):8898. https://doi.org/10.3390/su15118898

Chicago/Turabian StyleWang, Hui, Jinzhuo Wu, Wenshu Lin, and Zhaoping Luan. 2023. "Carbon Footprint Accounting and Influencing Factors Analysis for Forestry Enterprises in the Key State-Owned Forest Region of the Greater Khingan Range, Northeast China" Sustainability 15, no. 11: 8898. https://doi.org/10.3390/su15118898

APA StyleWang, H., Wu, J., Lin, W., & Luan, Z. (2023). Carbon Footprint Accounting and Influencing Factors Analysis for Forestry Enterprises in the Key State-Owned Forest Region of the Greater Khingan Range, Northeast China. Sustainability, 15(11), 8898. https://doi.org/10.3390/su15118898