The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review

Abstract

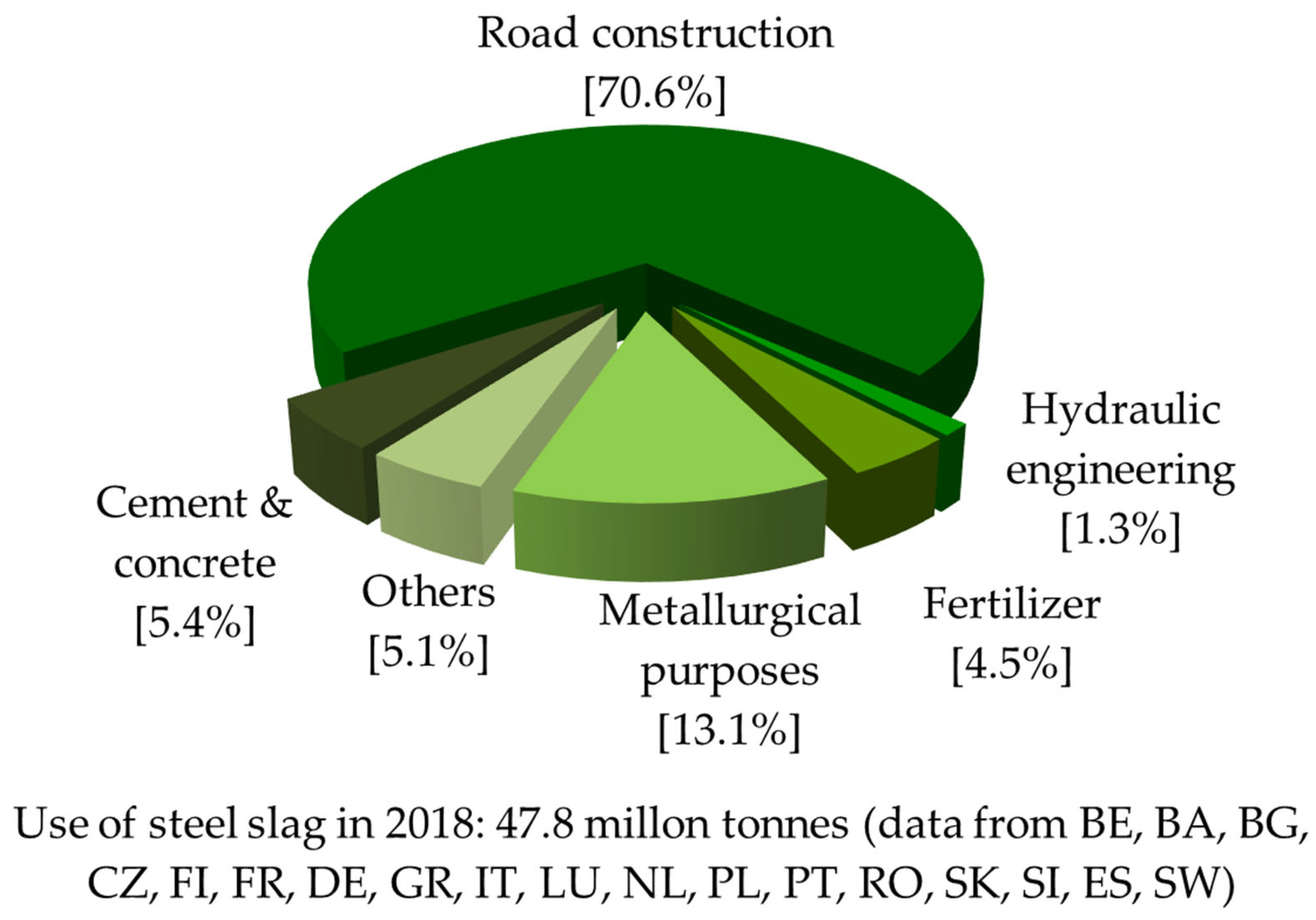

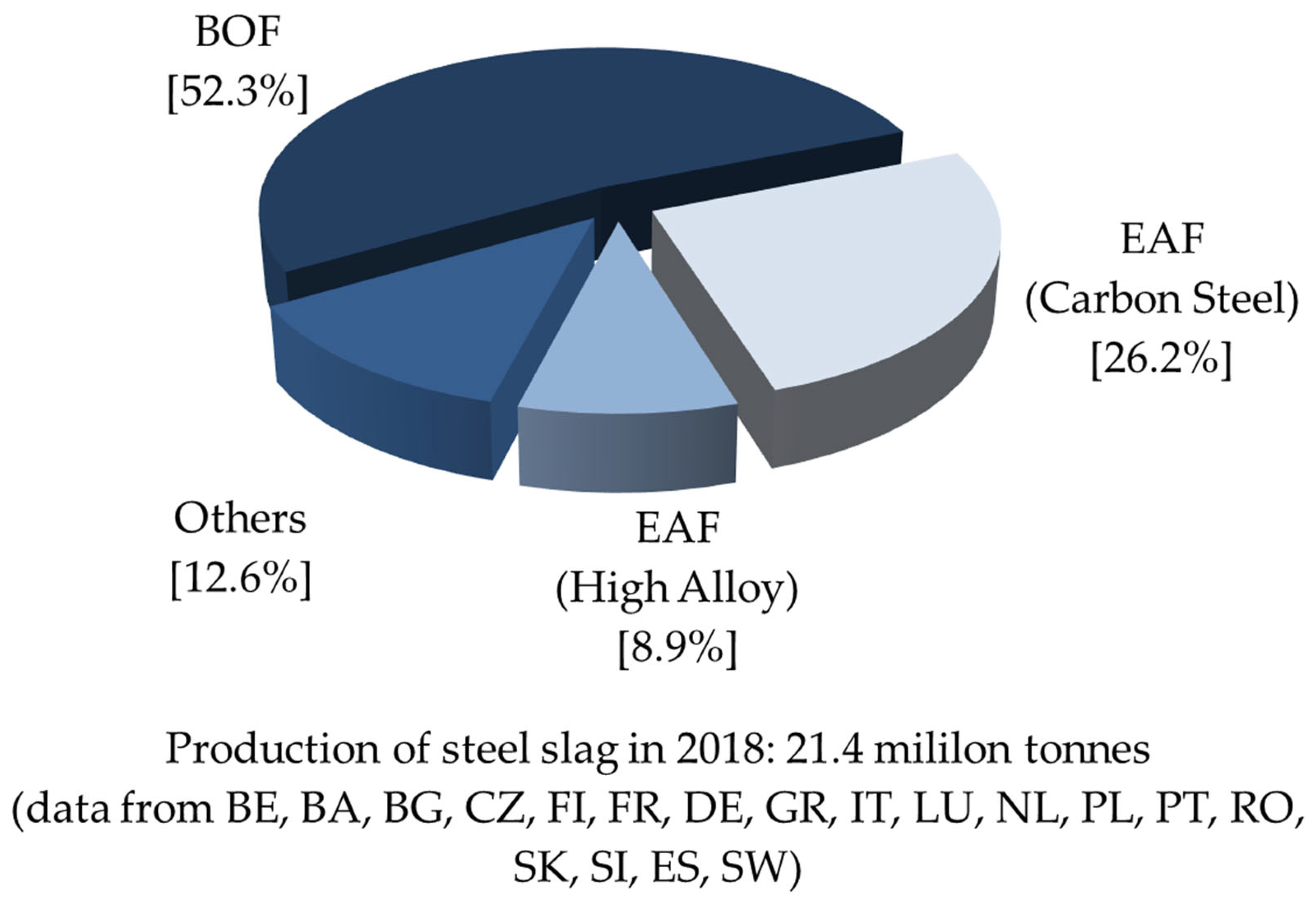

1. Introduction

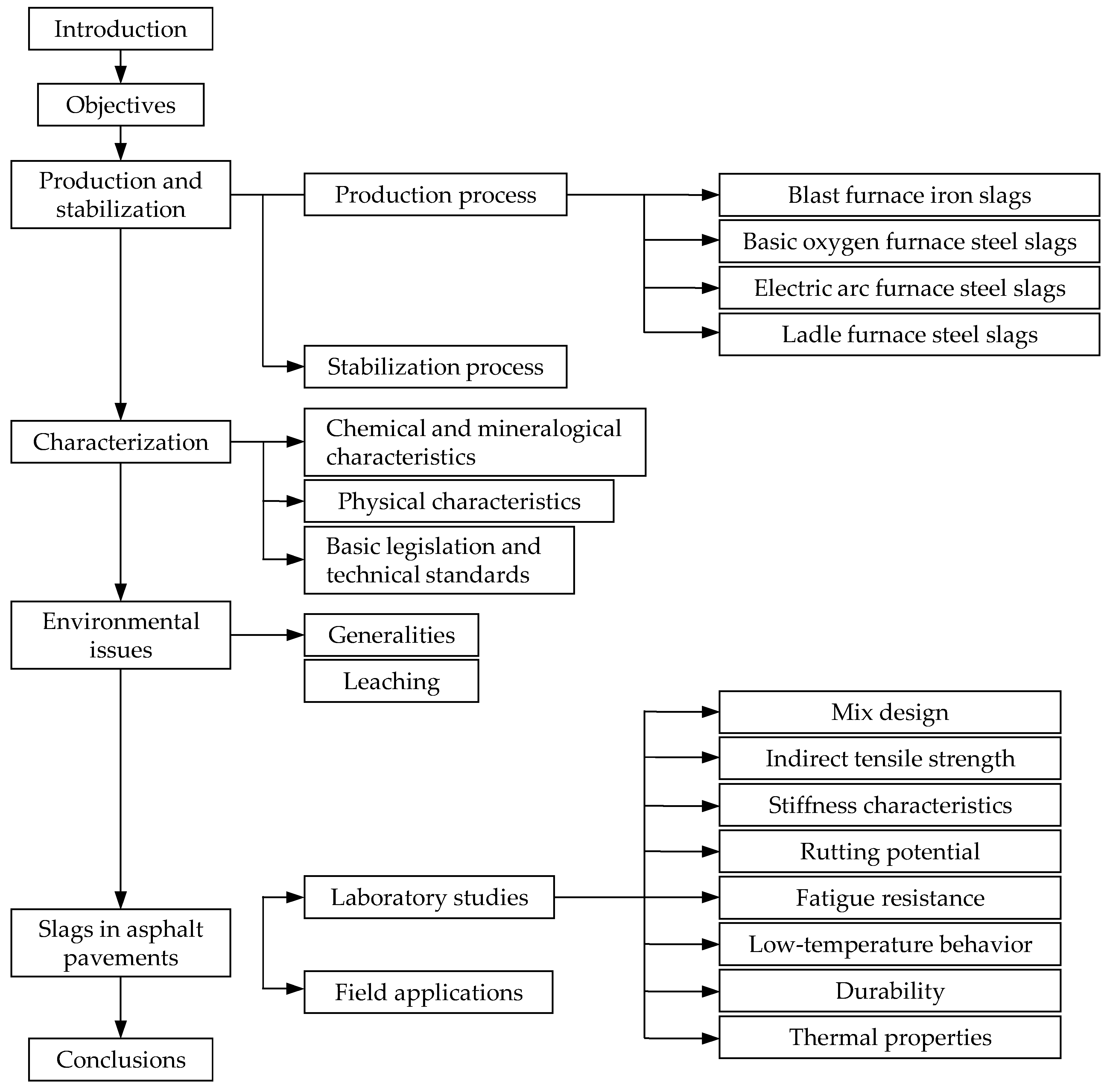

2. State-of-the-Art Objectives

3. Steel Slag Production and Stabilization

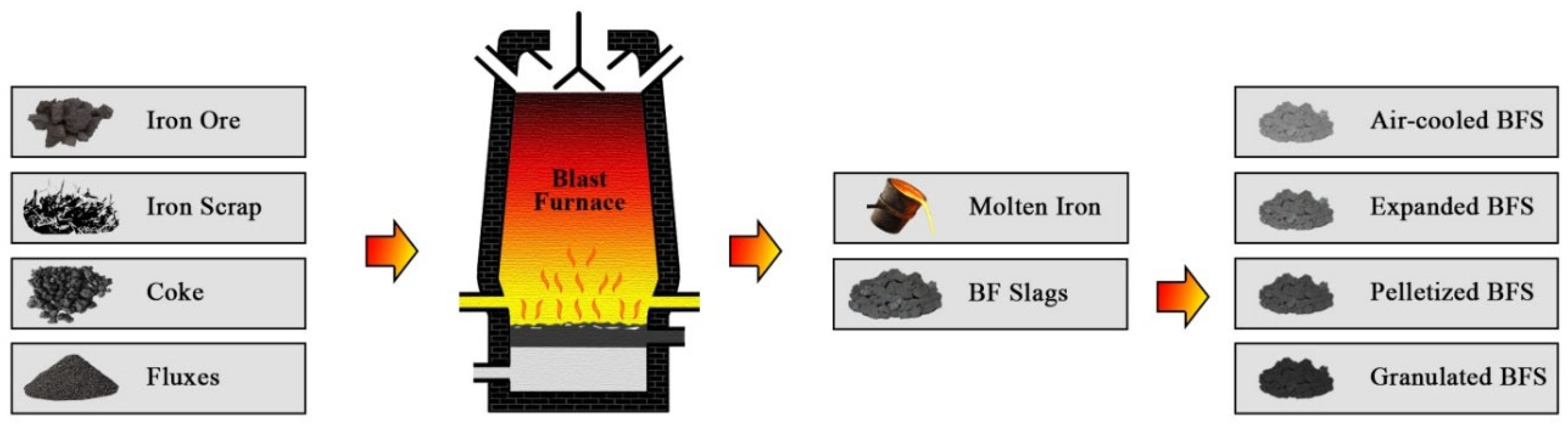

3.1. Production Process

3.1.1. Blast Furnace Iron Slags

3.1.2. Basic Oxygen Furnace Steel Slags

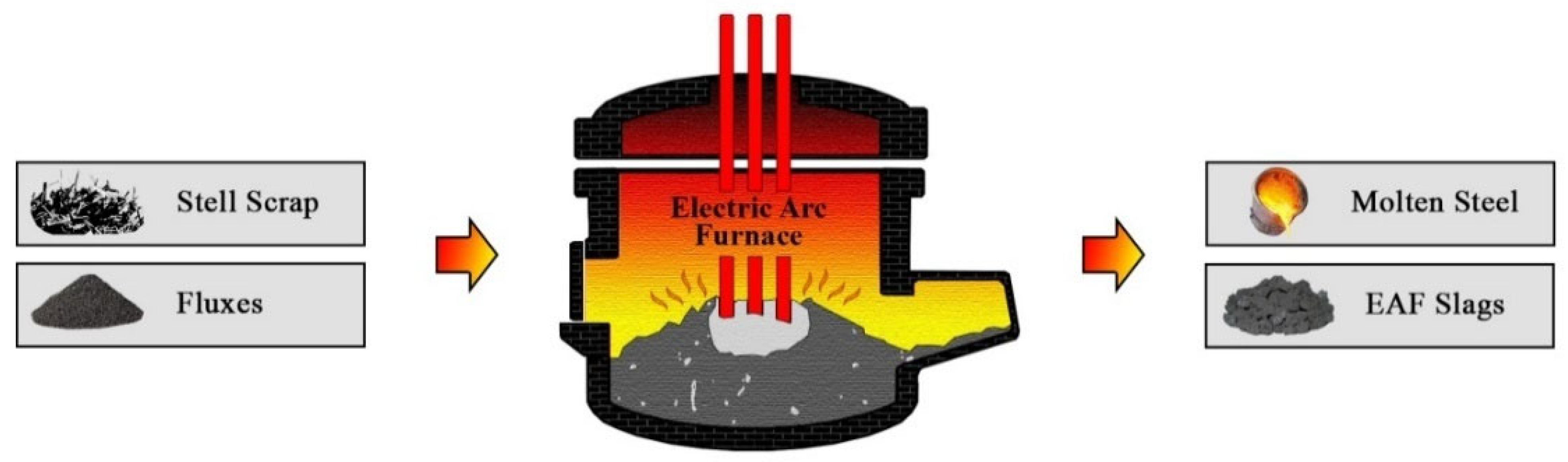

3.1.3. Electric Arc Furnace Steel Slags

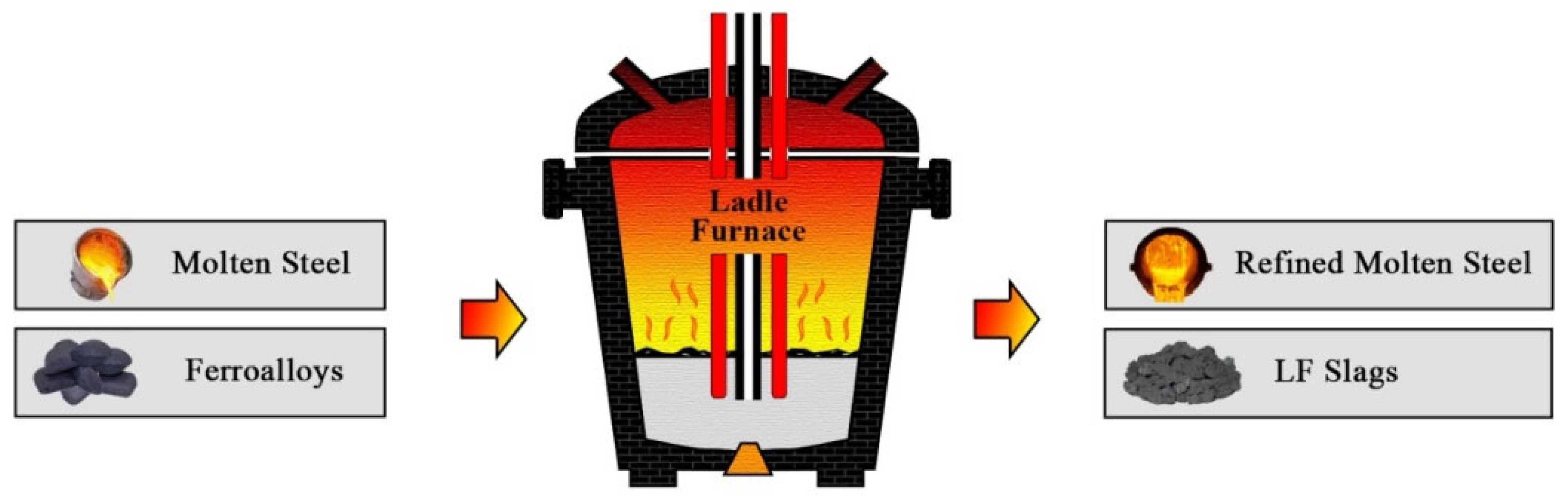

3.1.4. Ladle Furnace Steel Slags

3.2. Steel Slag Stabilization Process

4. Steel Slag Characterization

4.1. Chemical and Mineralogical Characteristics

4.2. Physiscal Characteristics

4.3. Basic Legislation and Technical Standards

5. Environmental Issues

5.1. Generalities

5.2. Leaching

6. Steel Slags in Asphalt Pavements

6.1. Laboratory Studies

6.1.1. Mix Design

6.1.2. Indirect Tensile Strength

6.1.3. Stiffness Characteristics

6.1.4. Rutting Potential

6.1.5. Fatigue Resistance

6.1.6. Low-Temperature Behavior

6.1.7. Durability

| Performance | Ref. | Slag Type | Control 1 | Trend 2 |

|---|---|---|---|---|

| ITS | [67,149,150] | n.a. | {L}{L}{L} | ▲ |

| [35] | EAFS | {L} | ▲ | |

| [151] | BOFS | {L} | ▲ | |

| [137] | EAFS | {L} | ▼ | |

| Stiffness | [77,106,143,149,167,170,172,173] | n.a. | {n.a.}{GA}{D}{L}{GR}{L}{L}{L} | ▲ |

| [44,137,165,166,175] | EAFS | {L}{L}{L}{L}{L} | ▲ | |

| [72,151] | BOFS | {n.a.}{L} | ▲ | |

| [171] | BFS | {n.a.} | ▲ | |

| Rutting resistance | [138,150,186,189,191] | n.a. | {B}{L}{L}{L}{L} | ▲ |

| [42,75,76,175,197] | EAFS | {L}{L}{L}{L}{L}{GR} | ▲ | |

| [190,195] | BOFS | {n.a.}{n.a.} | ▲ | |

| [171] | BFS | {L} | ▲ | |

| [137] | EAFS | {L} | ▼ | |

| Fatigue resistance | [143,208] | n.a. | {D}{L} | ▲ |

| [24,37,75,76,80,207] | EAFS | {L}{n.a.}{L}{L}{L}{L}{L} | ▲ | |

| [190,195,207] | BOFS | {n.a.}{n.a.}{L} | ▲ | |

| [105] | n.a. | {L} | ▼ | |

| [166,175] | EAFS | {L}{GA} | ▼ | |

| [207] | BOFS | {L} | ▼ | |

| Low-temperature resistance | [25,138,208] | n.a. | {B}{B}{L} | ▲ |

| [215] | BOFS | {L} | ▲ | |

| [214] | EAFS | {L} | ▼ | |

| Moisture resistance | [149,220,227] | n.a. | {L}{L}{n.a.} | ▲ |

| [35,137,145] | EAFS | {L}{L}{GR} | ▲ | |

| [151,190,228] | BOFS | {L}{n.a.}{B} | ▲ | |

| [171] | BFS | {L} | ▲ |

6.1.8. Thermal Properties

6.2. Field Applications

7. Conclusions

- the main slag types (blast furnace slag, basic oxygen furnace slag, electric arc furnace slag, and ladle furnace slag), the characteristics of which depend on the original scraps, production furnace type, and cooling method applied to the molten mass, differ in properties and, consequently, in the performance conferred to asphalt mixtures;

- the rough texture, high angularity, and superior mechanical properties commonly owned by steel slag aggregates generally contribute to improving the performance of bituminous mixes;

- steel slags can result in good interlocking properties of the asphalt mixtures thanks to improved adhesion forces at binder–particle contacts (improvement of bituminous film thickness around the aggregate);

- a proper stabilization (stockpiling for some months in an outdoor environment) is a crucial aspect of yielding slags suitable for recycling in asphalt pavements, in order to avoid expansion problems caused by the hydration of the calcium and magnesium oxide components;

- leaching of heavy metals and pollutants included in steel slags are typically experienced in low percentages, within the prescribed legal limit of various local environmental regulations.

- a correct mix design, with adequate granulometric distributions and bitumen contents, in accordance with the volumetric proportions and physical characteristics of the constituent materials, is mandatory since slag aggregates are heavier than natural ones;

- the high particle density of steel slag could restrict its use in road pavement construction, mainly due to the consequently higher transportation costs, above all, in the finer fractions;

- influenced by the aggregate surface texture, the indirect tensile strength is often reported to be higher with respect to conventional mixes;

- a wide collection of literature found that the progressive steel slag introduction, as a replacement for natural aggregate, leads to stiffer asphalt concrete;

- improved rutting and fatigue resistance of steel slag-based asphalt mixtures is often measured, ascribing this to steel slag high angularity, rough texture, and polyhedral shapes;

- steel slag mixtures are generally reported to be characterized by lower moisture susceptibility than the corresponding traditional mixes;

- steel slag asphalt pavements exhibit excellent skid resistance, surface texture depth, abrasion, and friction coefficients.

8. Research Gaps and Future Efforts

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Euroslag—History. Available online: https://www.euroslag.com/products/history (accessed on 20 January 2023).

- Arribas, I.; Santamaria, A.; Ruiz, E.; Ortega-Lopez, V.; Manso, J.M. Electric arc furnace slag and its use in hydraulic concrete. Constr. Build. Mater. 2015, 90, 68–79. [Google Scholar] [CrossRef]

- Faleschini, F.; Brunelli, K.; Zanini, M.A.; Dabalà, M.; Pellegrino, C. Electric arc furnace slag as coarse recycled aggregate for concrete production. J. Sustain. Metall. 2016, 1, 44–50. [Google Scholar] [CrossRef]

- Juckes, L.M. The volume stability of modern steel making slag. Int. J. Miner. Process. 2003, 112, 177–197. [Google Scholar]

- Shi, C.; Qian, J. High performance cementing materials from industrial slag—A review. Resour. Conserv. Recycl. 2000, 29, 195–207. [Google Scholar] [CrossRef]

- Pramukh, N.; Jayadeva, M.N.; Rahul Sona, H.R.; Shashank, S.; Anand, S. Replacement of coarse aggregate with steel slag in hot mix asphalt. Int. J. Res. Eng. Technol. 2018, 7, 128–131. [Google Scholar]

- Autelitano, F.; Giuliani, F. Swelling behavior of electric arc furnace aggregates for unbound granular mixtures in road construction. Int. J. Pavement Res. Technol. 2015, 8, 103–111. [Google Scholar]

- Mahieux, P.Y.; Aubert, J.E.; Escadeillas, G. Utilization of weathered basic oxygen furnace slag in the production of hydraulic road binders. Constr. Build. Mater. 2009, 23, 742–747. [Google Scholar] [CrossRef]

- Rohde, L.; Núñez, W.P.; Ceratti, J.A.P. Electric arc furnace steel slag: Base material for low-volume roads. Transp. Res. Rec. 2003, 1819, 201–207. [Google Scholar] [CrossRef]

- Euroslag—Statistics 2018. Available online: https://www.euroslag.com/products/statistics/statistics-2018 (accessed on 20 January 2023).

- Proctor, D.M.; Fehling, K.A.; Shay, E.C.; Wittenborn, J.L.; Green, J.J.; Avent, C.; Bigham, R.D.; Connolly, M.; Lee, B.; Shepker, T.O.; et al. Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ. Sci. Technol. 2000, 34, 1576–1582. [Google Scholar] [CrossRef]

- US Geological Survey. Mineral Commodity Summaries; USGS: Reston, VA, USA, 1998. [Google Scholar]

- Yildirim, I.Z.; Prezzi, M. Chemical, mineralogical, and morphological properties of steel slag. Adv. Civ. Eng. 2011, 2011, 463638. [Google Scholar] [CrossRef]

- Setién, J.; Hernández, D.; González, J.J. Characterization of ladle furnace basic slag for use as a construction material. Constr. Build. Mater. 2009, 23, 1788–1794. [Google Scholar] [CrossRef]

- Bureau of Mines. Mineral Commodity Summaries; U.S. Department of the Interior: Washington, DC, USA, 1993. [Google Scholar]

- US Geological Survey. Slag-iron and steel mineral industry surveys. In Annual Review; USGS: Reston, VA, USA, 1997. [Google Scholar]

- Jullien, A.; Denis, F.; Lumière, L.; De Larrard, F.; Chateau, L. Alternative materials for roads. Road Mater. Pavement Des. 2010, 11, 203–212. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China 2016. Available online: http://www.stats.gov.cn/english/ (accessed on 17 June 2020).

- UK Office of the Deputy Prime Minister. Summary Sheet Covering Individual Materials; ODPM: London, UK, 2022. [Google Scholar]

- Motz, H.; Geiseler, J. Products of steel slags an opportunity to save natural resources. J. Waste Manag. 2001, 21, 285–293. [Google Scholar] [CrossRef] [PubMed]

- Manso, J.M.; Polanco, J.A.; Losanez, M.; Gonzalez, J.J. Durability of concrete made with EAF slag as aggregate. Cem. Concr. Compos. 2006, 28, 528–534. [Google Scholar] [CrossRef]

- Luciano, A.; Reale, P.; Cutaia, L.; Carletti, R.; Pentassuglia, R.; Elmo, G.; Mancini, G. Resources optimization and sustainable waste management in construction chain in Italy: Toward a resource efficiency plan. Waste Biomass Valor. 2020, 11, 5405–5417. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Jin, W.; Meiling, Z.; Mingwei, Y.; Jiuming, W. Utilization of gneiss coarse aggregate and steel slag fine aggregate in asphalt mixture. Constr. Build. Mater. 2015, 93, 911–918. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J. Fatigue characterization of asphalt mixes containing electric arc furnace (EAF) steel slag subjected to long term aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- Bai, X.; Wamg, L. Study on mesoscopic model of low-temperature cracking of steel slag asphalt mixture based on random aggregate. Constr. Build. Mater. 2023, 364, 129974. [Google Scholar] [CrossRef]

- Humbert, P.S.; Castro-Gomes, J. CO2 activated steel slag-based materials: A review. J. Clean. Prod. 2019, 208, 448–457. [Google Scholar] [CrossRef]

- Dang, D.T.; Nguyen, M.T.; Nguyen, T.P.; Isawa, T.; Ta, Y.; Sato, R. Mechanical properties of steel slag replaced mineral aggregate for road base/sub-base application based Vietnam and Japan standard. Environ. Sci. Pollut. Res. 2022, 29, 42067–42073. [Google Scholar] [CrossRef]

- Gu, X.; Yu, B.; Dong, Q.; Deng, Y. Application of secondary steel slag in subgrade: Performance evaluation and enhancement. J. Clean. Prod. 2018, 181, 102–108. [Google Scholar] [CrossRef]

- Akbarnejad, S.; Houben, L.J.M.; Molenaar, A.A.A. Application of aging methods to evaluate the longterm performance of road bases containing blast furnace slag materials. Road Mater. Pavement Des. 2014, 15, 488–506. [Google Scholar] [CrossRef]

- Manso, J.M.; Ortega-Lopez, V.; Polanco, J.A.; Setién, J. The use of ladle furnace slag in soil stabilization. Constr. Build. Mater. 2013, 40, 126–134. [Google Scholar] [CrossRef]

- Akbarnejad, S.; Copuroglu, O.; Houben, L.J.M.; Molenaar, A.A.A. Characterization of blast furnace slag to be used as road base material. In Proceedings of the 7th International Conference on Maintenance and Rehabilitation of Pavements and Technological Control, Auckland, New Zealand, 28–30 August 2012. [Google Scholar]

- Yildirim, I.Z.; Prezzi, M. Subgrade stabilisation mixtures with EAF steel slag: An experimental study followed by field implementation. Int. J. Pavement Eng. 2020, 23, 1754–1767. [Google Scholar] [CrossRef]

- Nguyen, V.L.; Nguyen, D.S.; Nguyen, T.H.; Le, T.L. Evaluation of the possibility of application of porous asphalt concrete containing steel slag to road construction. In Advances in Research on Water Resources and Environmental Systems 2022; Vo, P.L., Tran, D.A., Pham, T.L., Le, T.T., Nguyen, N., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 661–669. [Google Scholar]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Hosseinzadeh, N.; Rezaei, M.J.; Hosseini, S.M. Investigation and performance improvement of hot mix asphalt concrete containing EAF slag. Int. J. Civ. Eng. Tech. 2016, 8, 260–264. [Google Scholar] [CrossRef]

- Emery, J.J. Steel Slag Utilization in Asphalt Mixes; Report MF 186-1; National Slag Association: Pleasant Grove, UT, USA, 1984; pp. 63–66. [Google Scholar]

- Aziz, M.M.A.; Shokri1, M.; Ahsan, A.; Liu, H.Y.; Tay, L.; Muslim, N.H. An overview on performance of steel slag in highway industry. J. Adv. Res. Mater. Sci. 2020, 67, 1–10. [Google Scholar] [CrossRef]

- Ramzi, T.; Okan, S.; Husam, S. Recycling of local Qatar’s steel slag and gravel deposits in road construction. Int. J. Waste Resour. 2014, 4, 4. [Google Scholar]

- Pasetto, M.; Baldo, N. Laboratory investigation on foamed bitumen bound mixtures made with steel slag, foundry sand, bottom ash and reclaimed asphalt pavement. Road Mater. Pavement Des. 2012, 13, 691–712. [Google Scholar] [CrossRef]

- Goli, H.; Hasemi, S.; Ameri, M. Laboratory evaluation of damage behavior of warm mix asphalt containing steel slag aggregates. J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Maoudi, S.; Abtahi, S.M.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Pasetto, M.; Giacomello, G.; Pasquini, E.; Canestrari, F. Effect of warm mix chemical additives on the binder-aggregate bond strength and high-service temperature performance of asphalt mixes containing electric arc furnace steel slag. In Proceedings of the 8th RILEM International Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015. [Google Scholar]

- Skaf, M.; Ortega-López, V.; Revilla-Cuesta, V.; Manso, J.M. Bituminous pavement overlay of a porous asphalt mixture with ladle furnace slag: A pilot project. Road Mater. Pavement Des. 2022, 1–14. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Technical feasibility for the replacement of high rates of natural aggregates in asphalt mixtures. Int. J. Pavement Eng. 2019, 22, 940–949. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahamadi, A. Recycling of RAP and steel slag aggregates into the warm mix asphalt: A performance evaluation. Constr. Build. Mater. 2017, 147, 630–638. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; He, Z.; Liu, H. Evaluation of the adhesion property and moisture stability of rubber modified asphalt mixture incorporating waste steel slag. J. Adhesion Sci. Technol. 2023, 37, 296–318. [Google Scholar] [CrossRef]

- Li, S.; Xiong, R.; Zhai, J.; Zhang, K.; Jiang, W.; Yang, F.; Yang, X.; Zhao, H. Research progress on skid resistance of basic oxygen furnace (BOF) slag asphalt mixtures. Materials 2020, 13, 2169. [Google Scholar] [CrossRef]

- Euroslag—Products. Available online: https://www.euroslag.com/products (accessed on 20 January 2023).

- Chegenizadeh, A.; Hanson, S.W.; Nikraz, H.; Kress, C.S. Effects of ground-granulated blast-furnace slag used as filler in dense graded asphalt. Appl. Sci. 2022, 12, 2769. [Google Scholar] [CrossRef]

- Collins, R.J.; Ciesielski, S.K. Recycling and Use of Waste Materials and By-Products in Highway Construction; Synthesis of Highway Practice 199; National Cooperative Highway Research Program: Washington, DC, USA, 1994; pp. 78–85. [Google Scholar]

- National Slag Association. Processed Blast Furnace Slag, the All-Purpose Construction Aggregate; Alexandria: Virginia, VA, USA, 1998. [Google Scholar]

- Emery, J.J. Pelletized lightweight slag aggregate. In Proceedings of the Concrete International, London, UK, 13–18 April 1980. [Google Scholar]

- Brandt, D.; Warner, J.C. Metallurgy Fundamentals, 3rd ed.; Goodheart-Willcox: Illinois, IL, USA, 2005; pp. 1027–1033. [Google Scholar]

- Reddy, A.S.; Pradhan, R.K.; Chandra, S. Utilization of basic oxygen furnace (BOF) slag in the production of a hydraulic cement binder. Int. J. Miner. Proc. 2006, 79, 98–105. [Google Scholar] [CrossRef]

- Remus, R.; Agualdo-Monsonet, M.A.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for Iron and Steel Production; European Commission, Joint. Research Centre: Brussels, Belgium, 2013. [Google Scholar]

- Energy Manager Training. Iron and Steel Process; Council Decision of 19 December 2002; Department of Energy: Washington, DC, USA, 2008. [Google Scholar]

- Branca, T.A.; Colla, V.; Valentini, R. A way to reduce environmental impact of ladle furnace slag. Ironmak Steelmak 2009, 36, 597–602. [Google Scholar] [CrossRef]

- Lee, T.S.; Choi, I.S.; Song, W.Y. The technology of recycling ladle slag. Stahl Eisen 2003, 123, 113–117. [Google Scholar]

- Dahlin, A.; Tilliander, A.; Eriksson, J.; Jönsson, P. Influence of ladle slag additions on BOF process performance. Ironmak Steelmak 2012, 39, 378–385. [Google Scholar] [CrossRef]

- Tsubone, A. Direct recycling of the reducing slag in EAF. Seaisi Q. 2006, 35, 32–38. [Google Scholar]

- Porisiensi, S. Recycling of ladle slag and spent refractories by injection into an EAF. Iron Steel Technol. 2004, 1, 63–66. [Google Scholar]

- Cavallotti, P.L.; Mapelli, C.; Memoli, F.; Pustorino, M. Recycling of LF-white slag. Metall. Ital. 2007, 99, 41–48. [Google Scholar]

- Guzzon, M.; Mapelli, C.; Memoli, F.; Marcozzi, N. Recycling of ladle slag in the EAF: Improvement of the foaming behaviour and decrease of the environmental impact. Rev. Métall. 2007, 104, 171–178. [Google Scholar] [CrossRef]

- Skaf, M.; Ortega-Lopez, V.; Fuente-Alonso, J.A.; Santamaria, A.; Manso, J.M. Ladle furnace slag in asphalt mixes. Constr. Build. Mater. 2016, 122, 488–495. [Google Scholar] [CrossRef]

- Chen, Z.; Gong, Z.; Jiao, Y.; Wang, Y.; Shi, K.; Wua, J. Moisture stability improvement of asphalt mixture considering the surface characteristics of steel slag coarse aggregate. Constr. Build. Mater. 2020, 251, 118987. [Google Scholar] [CrossRef]

- Krayushkina, K.; Prentkovskis, O.; Bieliatynskyi, A.; Junevieius, R. Use of steel slags in automobile road construction. Trans. J. 2012, 27, 129–137. [Google Scholar] [CrossRef]

- Noureldin, A.S.; MacDaniel, R.S. Evaluation of surface mixtures of steel slag and asphalt. Transp. Res. Rec. 1990, 1269, 133–149. [Google Scholar]

- Sun, J.; Bieliatynskyi, A.; Krayushkina, K.; Akmaldinova, O. Research progress of steel slag asphalt concrete. E3S Web Conf. 2020, 175, 11014. [Google Scholar] [CrossRef]

- Tseng, Y.H.; Lee, Y.C.; Sheu, B.L. The application and breakthrough of BOF slag modification: Technique. China Steel Rep. 2015, 28, 46–51. [Google Scholar]

- Sichien, J. Slag-stabilisation-process at Arcelor Gent. In Proceedings of the 5th European Slag Conference, Luxembourg, 19–21 September 2007. [Google Scholar]

- Kühn, M.; Behmenburg, H. Decreasing the scorification of chrome. In Primary Steelmaking; Report EUR 19382; European Commission: Brussels, Belgium, 2000; pp. 793–804. [Google Scholar]

- Kühn, M.; Drissen, P.; Geiseler, J.; Schrey, H.J. A new BOF slag treatment technology. In Proceedings of the 2nd European Oxygen Steel Making Congress, Taranto, Italy, 13–15 October 1997. [Google Scholar]

- DePree, P.; Ferry, C. Mitigation of expansive electric arc furnace slag in brownfield redevelopment. In Proceedings of the Geo Congress 2008, New Orleans, LA, USA, 9–12 March 2008. [Google Scholar]

- Shi, C.; Hu, S. Cementitious properties of ladle slag fines under autoclave curing conditions. Cement Concr. Res. 2003, 33, 1851–1856. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Performance comparative analysis of stone mastic asphalts with electric arc furnace steel slag: A laboratory evaluation. Mater. Struct 2012, 45, 411–424. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Experimental evaluation of high performance base course and road base asphalt concrete with electric arc furnace steel slags. J. Hazard. Mater. 2010, 181, 938–948. [Google Scholar] [CrossRef] [PubMed]

- Akinmusuru, J.O. Potential beneficial uses of steel slag wastes for civil engineering purposes. Resour. Conserv. Recycl. 1991, 5, 73–80. [Google Scholar] [CrossRef]

- EN 1744-1; Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis. European Committee for Standardization: Bruxelles, Belgium, 2009.

- ASTM D4792M-13; Standard Test Method for Potential Expansion of Aggregates from Hydration Reactions. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019.

- Pasetto, M.; Baldo, N. Fatigue performance of asphalt concretes made with steel slags and modified bituminous binders. Int. J. Pavement Res. Technol. 2013, 6, 294–303. [Google Scholar]

- Wang, G.; Wang, Y.; Gao, Z. Use of steel slag as a granular material: Volume expansion prediction and usability criteria. J. Hazard. Mater. 2010, 184, 555–560. [Google Scholar] [CrossRef]

- Kandhal, S.P.; Hoffman, L.G. Evaluation of steel slag fine aggregate in Hot-Mix Asphalt mixtures. Transp. Res. Rec. 1997, 1583, 28–36. [Google Scholar] [CrossRef]

- Sorlini, S.; Sanzeni, A.; Rondi, L. Reuse of steel slag in bituminous paving mixtures. J. Hazard. Mater. 2012, 209, 84–91. [Google Scholar] [CrossRef]

- Bian, L.; Gao, Y. Influence of Al2O3, CaO/SiO2, and B2O3 on viscous behavior of high alumina and medium titania blast furnace slag. J. Chem. 2017, 2017, 3261520. [Google Scholar] [CrossRef]

- Harada, A.; Matsui, A.; Nabeshima, S.; Kikuchi, N.; Miki, Y. Effect of slag composition on MgO-Al2O3 spinel-type inclusions in molten steel. Iron Steel Inst. Jpn. Int. 2017, 57, 1546–1552. [Google Scholar] [CrossRef]

- Liu, J.; Yu, B.; Hong, Q. Molecular dynamics simulation of distribution and adhesion of asphalt components on steel slag. Constr. Build. Mater. 2020, 255, 119332. [Google Scholar] [CrossRef]

- Navarro, C.; Diaz, M.; Villa-Garcia, M.A. Physico-chemical characterization of steel slag. Study of its behavior under simulated environmental conditions. Environ. Sci. Technol. 2010, 44, 5383–5388. [Google Scholar] [CrossRef]

- Papayianni, I.; Anastasiou, E. Concrete incorporating high calcium fly ash and EAF slag aggregates. Mag. Concr. Res. 2011, 63, 597–604. [Google Scholar] [CrossRef]

- Dunster, A.M. The use of blast furnace slag and steel slag as aggregates. In Proceedings of the 4th European Symposium on Performance of Bituminous and Hydraulic Materials in Pavements, Nottingham, UK, 11–12 April 2002. [Google Scholar]

- Sherwood, P. Alternative Materials in Road Construction, 2nd ed.; Thomas Telford: London, UK, 2011; pp. 1–7. [Google Scholar]

- Liu, J.; Yu, B.; Wang, S.; Li, L.; Zhang, J. Use of tricalcium silicate to evaluate asphalt absorption on steel slag: Atomic simulation and micro-scale characterization. Measurement 2021, 177, 109224. [Google Scholar] [CrossRef]

- Euroslag—Properties. Available online: https://www.euroslag.com/products/properties/ (accessed on 20 January 2023).

- Tossavainen, M.; Engstrom, F.; Yang, Q.; Menad, N.; Larsson, M.L.; Bjorkman, B. Characteristics of steel slag under different cooling conditions. J. Waste Manag. 2007, 27, 1335–1344. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Sharif, A.M.; Shameem, M.; Ibrahim, M.; Barry, M. Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr. Build. Mater. 2003, 17, 105–112. [Google Scholar] [CrossRef]

- Bessa, S.I.; Branco, V.T.F.C.; Barbosa, J. Evaluation of polishing and degradation resistance of natural aggregates and steel slag using the aggregate image measurement system. Road Mater. Pavement Des. 2014, 15, 385–405. [Google Scholar] [CrossRef]

- Masad, E.; Luce, A.; Mahmoud, E. Implementation of AIMS in Measuring Aggregate Resistance to Polishing, Abrasion and Breakage; Report FHWA/TX-06/5-1707-03-1; Texas A&M University: College Station, TX, USA, 2006; pp. 155–165. [Google Scholar]

- Al Rousan, T.M. Characterization of Aggregate Shape Properties Using a Computer Automated System; Texas A&M University, College Station: Texas, TX, USA, 2004; pp. 73–80. [Google Scholar]

- O’Connor, J.; Hguyen, T.B.T.; Hanoeyands, T.; Monaghan, B.; O’Dea, D.; Rinklebe, J.; Vinu, A.; Hoang, S.A.; Singh, G.; Kirkham, M.B.; et al. Production, characterisation, utilisation, and beneficial soil application of steel slag: A review. J. Hazard. Mater. 2021, 419, 126478. [Google Scholar] [CrossRef]

- Sasamoto, H.; Tsubone, A.; Kamiya, Y.; Sano, K. Development of fishing block using EAF refining slag. J. Iron Steel Inst. Japan 2003, 89, 461–465. [Google Scholar] [CrossRef]

- Cao, L.; Shen, W.; Huang, J.; Yang, Y.; Zhang, D.; Huang, X.; Lv, Z.; Ji, X. Process to utilize crushed steel slag in cement industry directly: Multi-phased clinker sintering technology. J. Clean. Prod. 2019, 217, 520–529. [Google Scholar] [CrossRef]

- Dippenaar, R. Industrial uses of slag (the use and re-use of iron and steelmaking slags). Ironmak 2005, 32, 35–46. [Google Scholar] [CrossRef]

- Manso, J.M.; Losáñez, M.; Polanco, J.A.; González, J.J. Ladle furnace slag in construction. J. Mater. Civ. Eng. 2005, 17, 513–518. [Google Scholar] [CrossRef]

- Kanagawa, A.; Kuwayama, T. The improvement of soft clayey soil utilizing reducing slag produced from electric arc furnace. Denki Seiko 1997, 68, 261–267. [Google Scholar] [CrossRef]

- Chen, X.; Wen, W.; Zhou, J.; Zhou, X.; Ning, Y.; Liang, Z.; Ma, Z. Research on the interaction capability and microscopic interfacial mechanism between asphalt-binder and steel slag aggregate-filler. Coatings 2022, 12, 1871. [Google Scholar] [CrossRef]

- Tao, G.; Xiao, Y.; Yang, L.; Cui, P.; Kong, D.; Xue, Y. Characteristics of steel slag filler and its influence on rheological properties of asphalt mortar. Constr. Build. Mater. 2019, 201, 439–446. [Google Scholar] [CrossRef]

- Hassan, K.E.; Attia, M.I.E.; Reid, M.; Al-Kuwari, M.B.S. Performance of steel slag aggregate in asphalt mixtures in a hot desert climate. Case Stud. Constr. Mater. 2021, 14, e00534. [Google Scholar] [CrossRef]

- Liu, J.; Chen, S.; Liu, Q.; Wang, Y.; Yu, B. Influence of steel slag incorporation on internal skeletal contact characteristics within asphalt mixture. Constr. Build. Mater. 2022, 352, 129073. [Google Scholar] [CrossRef]

- Jiang, S.; Yu, H.; Mo, L. Crushing characteristics of coarse aggregates for asphalt mixtures under simulated laboratory compaction loads and repeated traffic loads. Materials 2022, 15, 5865. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.; Wang, J.; Zhou, X.; Wang, S.; Liu, Q.; Yu, B. Towards the sustainable utilization of steel slag in asphalt pavements: A case study of moisture resistance and life cycle assessment. Case Stud. Constr. Mater. 2023, 18, e01722. [Google Scholar] [CrossRef]

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. European Committee for Standardization: Bruxelles, Belgium, 2022.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee for Standardization: Bruxelles, Belgium, 2022.

- EN 1097-8; Tests for Mechanical and Physical Properties of Aggregates—Part 8: Determination of the Polished Stone Value. European Committee for Standardization: Bruxelles, Belgium, 2020.

- EN 1367-5; Tests for Thermal and Weathering Properties of Aggregates—Part 5: Determination of Resistance to Thermal Shock. European Committee for Standardization: Bruxelles, Belgium, 2011.

- Directive 2008/98/EC of the European Parliament and the Council of 19 November 2008 on Waste and Repealing Certain Directives; Eurepean Parilamnt: Bruxelles, Belgium, 2008.

- EN 14227-12; Hydraulically Bound Mixtures—Specifications—Part 12: Soil Treated by Slag. European Committee for Standardization: Bruxelles, Belgium, 2006.

- EN 14227-2; Hydraulically Bound Mixtures—Specifications—Part 2: Slag Bound Granular Mixtures. European Committee for Standardization: Bruxelles, Belgium, 2013.

- EN13043; Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas. European Committee for Standardization: Bruxelles, Belgium, 2002.

- EN 13242; Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction. European Committee for Standardization: Bruxelles, Belgium, 2002.

- ASTM D5106-15; Standard Specification for Steel Slag Aggregates for Bituminous Paving Mixtures. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015.

- Gao, J.; Sha, A.; Wang, Z.; Tong, Z.; Liu, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. J. Clean. Prod. 2017, 152, 429–442. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Vilaplana, A.; García-Armingol, T.; Aranda-Usón, A.; Lausín-González, C.; López-Sabirón, A.M.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2015, 130, 175–186. [Google Scholar] [CrossRef]

- Khasreen, M.; Banfill, P.F.; Menzies, G. Life-cycle assessment and the environmental impact of buildings: A review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Udo de Haes, H.A.; Heijungs, R. Life-cycle assessment for energy analysis and management. Appl. Energy 2007, 84, 817–827. [Google Scholar] [CrossRef]

- ISO 14004; Environmental Management Systems—General Guidelines on Implementation. European Committee for Standardization: Bruxelles, Belgium, 2016.

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Life-cycle assessment of road pavements containing marginal materials: Comparative analysis based on a real case study. In Pavement Life-Cycle Assessment, 1st ed.; Al-Qadi, I.L., Ozer, H., Harvey, J., Eds.; CRC Press: London, UK, 2017; pp. 189–198. [Google Scholar]

- Mladenovič, A.; Turk, J.; Kovač, J.; Mauko, A.; Cotič, Z. Environmental evaluation of two scenarios for the selection of materials for asphalt wearing courses. J. Clean. Prod. 2015, 87, 683–691. [Google Scholar] [CrossRef]

- Loi, S.S.; Subramaniam, S.K.; Xusheng, H. Carbon footprint assessment of steel slag asphalt pavement in Singapore. Lect. Notes Civ. Eng. 2021, 193, 771–779. [Google Scholar]

- Gomes, H.I.; Mayes, W.M.; Baxter, H.A.; Jarvis, A.P.; Burke, I.T.; Stewart, D.I.; Rogerson, M. Options for managing alkaline steel slag leachate: A life cycle assessment. J. Clean. Prod. 2018, 202, 401–412. [Google Scholar] [CrossRef]

- Miraoui, M.; Zentar, R.; Abriak, N.E. Road material basis in dredged sediment and basic oxygen furnace steel slag. Constr. Build. Mater. 2012, 30, 309–319. [Google Scholar] [CrossRef]

- Cirilli, F.; Di Donato, A.; Di Sante, L.; Martini, U.; Miceli, P. V leaching in EAF slags. In Proceedings of the 8th Euroslag Conference, Linz, Austria, 21–23 October 2015. [Google Scholar]

- European Communities. Establishing Criteria and Procedures for Acceptance of Waste at Landfills; Official Journal of the European Communities; European Communities: Brussels, Belgium, 2003. [Google Scholar]

- Suer, P.; Lindqvist, J.E.; Arm, M.; Fronger-Kockum, P. Reproducing ten years of road ageing—Accelerated carbonation and leaching of EAF steel slag. Sci. Total Environ. 2009, 407, 5110–5118. [Google Scholar] [CrossRef]

- EN 12457-2; Characterization of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 4 mm (without or with Size Reduction). European Committee for Standardization: Bruxelles, Belgium, 2002.

- Hasita, S.; Hoy, M.; Suddeepong, A.; Horpibulsuk, S.; Yeanyong, C.; Arulrajah, A.; Mohammadinia, A. Performance and toxic leaching evaluation of dense-graded asphalt concrete using steel slag as aggregate. J. Mater. Civ. Eng. 2021, 33, 04020432. [Google Scholar] [CrossRef]

- Gan, Y.; Li, C.; Zou, J.; Wang, W.; Yu, T. Evaluation of the impact factors on the leaching risk of steel slag and its asphalt mixture. Case Stud. Constr. Mater. 2022, 16, e01067. [Google Scholar] [CrossRef]

- Federal Highway Administration, Research and Technology Coordinating. User Guidelines for Waste and By-Product Materials in Pavement Construction; Publication FHWA-RD-97-148; Federal Highway Administration: Washington, DC, USA, 2008. [Google Scholar]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as an aggregate for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Jones, J.A.T.; Bowman, B.; Lefrank, P.A. Electric furnace steelmaking. In The Making, Shaping and Treating of Steel, 525–660; The AISE Steel Foundation: Pittsburgh, PA, USA, 1998; pp. 122–132. [Google Scholar]

- Preston, R. American Steel; Avon Books: New York, NY, USA, 1991; pp. 817–827. [Google Scholar]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Moreno-Navarro, M.; Tauste-Martinez, R.; Cannone Falchetto, A.; Vaillancourt, M.; Carter, A.; Viscione, N.; Russo, F.; et al. An interlaboratory test program on the extensive use of waste aggregates in asphalt mixtures: Preliminary steps. In Proceedings of the RILEM International Symposium on Bituminous Materials, Lyon, France, 14–16 December 2020. [Google Scholar]

- Xie, J.; Wu, S.; Lin, J.; Cai, J.; Chen, Z.; Wei, W. Recycling of basic oxygen furnace slag in asphalt mixture: Material characterization & moisture damage investigation. Constr. Build. Mater. 2012, 36, 467–474. [Google Scholar]

- Arabani, M.; Azarhoosh, A.R. The effect of recycled concrete aggregate and steel slag on the dynamic properties of asphalt mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

- Taha, R.; Sirin, O.; Sadek, H. Beneficial use of Qatar’s steel slag and gravel deposits in road construction. In Proceedings of the 13th Annual International Conference on Asphalt, Pavement Engineering and Infrastructure, Liverpool, UK, 26–27 February 2014. [Google Scholar]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Trans. Geotech 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Zumrawi, M.E.; Khalill, O.A. Experimental study of steel slag used as aggregate in asphalt mixture. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2015, 9, 683–688. [Google Scholar]

- Khodary, F. Comparative study of using steel slag aggregate and crushed limestone in asphalt concrete mixtures. Int. J. Civ. Eng. Tech. 2015, 6, 73–82. [Google Scholar]

- Pasetto, M.; Baldo, N. Mix design and performance analysis of asphalt concretes with electric arc furnace slag. Constr. Build. Mater. 2011, 25, 3458–3468. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Behnood, A.; Ameri, M. Experimental investigation of stone matrix asphalt mixtures containing steel slag. Sci. Iran Sharif Univ. Tech. 2012, 19, 1214–1219. [Google Scholar] [CrossRef]

- Lin, D.F.; Chou, L.H.; Wang, Y.K.; Luo, H.L. Performance evaluation of asphalt concrete test road partially paved with industrial waste—Basic oxygen furnace slag. Constr. Build. Mater. 2015, 78, 315–323. [Google Scholar] [CrossRef]

- Chen, S.H.; Lin, J.D.; Huang, D.; Hung, C.T. Effect of film thickness and voids in mineral aggregate in basic oxygen furnace slag dense-graded asphalt concrete. J. Test. Eval. 2015, 43, 229–236. [Google Scholar] [CrossRef]

- Huang, L.S.; Lin, D.F.; Luo, H.L.; Lin, P.C. Effect of field compaction mode on asphalt mixture concrete with basic oxygen furnace slag. Constr. Build. Mater. 2012, 34, 16–17. [Google Scholar] [CrossRef]

- Luan, Y.; Zhang, W.; Zhao, Y.; Pan, Z.; Niu, Z.; Zeng, K.; Chen, X.; Mohammad, L.M. Mechanical property evaluation for steel slag in asphalt mixture with different skeleton structures using modified Marshall mix design methodology. J. Mater. Civ. Eng. 2022, 34, 04021382. [Google Scholar] [CrossRef]

- Cominsky, R.J.; Huber, G.A.; Kennedy, T.W.; Anderson, M. The Superpave Mix Design Manual for New Construction and Overlays; SHRP-A-407; Strategic Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- Wang, R.; Xiong, Y.; Ma, X.; Guo, Y.; Yue, M.; Yue, J. Investigating the differences between steel slag and natural limestone in asphalt mixes in terms of microscopic mechanism, fatigue behavior and microwave-induced healing performance. Constr. Build. Mater. 2022, 328, 127107. [Google Scholar] [CrossRef]

- Shaker, H.; Ameri, M.; Aliha, M.R.M.; Rooholamini, H. Evaluating low-temperature fracture toughness of steel slag aggregate-included asphalt mixture using response surface method. Constr. Build. Mater. 2023, 370, 130647. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Liu, Z.; Dong, Q.; Zhao, X. T emperature analyses of porous asphalt mixture using steel slag aggregates heated by microwave through laboratory tests and numerical simulations. J. Clean. Prod. 2022, 338, 130614. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Piao, Z.; Poulikakos, L.D. Electric arc furnace slag as aggregates in semi-dense asphalt. Case Stud. Constr. Mater. 2023, 18, e02049. [Google Scholar] [CrossRef]

- Vavrik, W.R.; Pine, W.J.; Carpenter, S.H. Aggregate blending for asphalt mix design: Bailey method. Transp. Res. Rec. 2002, 1789, 146–153. [Google Scholar] [CrossRef]

- Swathi, M.; Andiyappan, T.; Guduru, G.; Reddy, M.A.; Kuna, K.K. Design of asphalt mixes with steel slag aggregates using the Bailey method of gradation selection. Constr. Build. Mater. 2021, 279, 122426. [Google Scholar] [CrossRef]

- EN 12697-23; Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. European Committee for Standardization: Bruxelles, Belgium, 2017.

- Anagnos, J.N.; Kennedy, T.W. Practical Method of Conducting the Indirect Tensile Test; Report 98-10; Center of Highway Research, University of Texas at Austin: Austin, TX, USA, 1972; pp. 1214–1219. [Google Scholar]

- EN 12697-26; Bituminous Mixtures—Test Methods—Part 26: Stiffness. European Committee for Standardization: Bruxelles, Belgium, 2022.

- Preti, F.; Noto, S.; Accardo, C.; Romeo, E.; Montepara, A.; Tebaldi, G. Effect of hyper-modified asphalt binder and steel slags on cracking and rutting behaviour of wearing course mixtures. Road Mater. Pavement Des. 2019, 20 (Suppl. S2), S678–S694. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- Kim, K.; Jo, S.H.; Kim, N.; Kim, H. Characteristics of hot mix asphalt containing steel slag aggregate according to temperature and void percentage. Constr. Build. Mater. 2012, 188, 1128–1136. [Google Scholar] [CrossRef]

- ASTM D7369-11; Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Test. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2011.

- Huang, Y.H. Pavement Analysis and Design; Prentice Hall: Hoboken, NJ, USA, 1993; pp. 32–38. [Google Scholar]

- Hainin, M.R.; Rusbintardjo, G.; Hameed, M.A.S.; Hassan, N.A.; Yusoff, N.I.M. Utilisation of steel slag as an aggregate replacement in porous asphalt mixtures. J. Teknol 2014, 69, 67–73. [Google Scholar] [CrossRef]

- Jain, P.K.; Swami, R.K.; Sengupta, J.B.; Kar, S.S.; Singh, G. Studies on use of air-cooled blast furnace slag as aggregate in road construction. In Proceedings of the 14th Annual International Conference on Asphalt, Pavement Engineering and Infrastructure, Liverpool, UK, 11–12 February 2015. [Google Scholar]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of steel slag aggregate in asphalt concrete mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Farrand, B.; Emery, J.J. Recent improvements in quality of steel slag aggregates. Transp. Res. Rec. 2005, 1486, 137–141. [Google Scholar]

- Groenniger, J.; Cannone Falchetto, A.; Isailovic, I.; Wang, D.; Wistuba, M.P. Experimental investigation of asphalt mixture containing Linz-Donawitz steel slag. J. Traffic Transp. Eng. (Engl. Ed.) 2017, 4, 372–379. [Google Scholar] [CrossRef]

- Abulkhair, M.; Zeiada, W.; Al-Khateeb, G.; Shanableh, A.; Dabous, S.A. Stiffness and rutting assessment of asphalt mixtures using steel slag aggregates. In Proceedings of the 5th World Congress on Civil, Structural, and Environmental Engineering, Lisbon, Portugal, 18–20 October 2020. [Google Scholar]

- Awed, A.M.; Tarbay, E.W.; El-Badawy, S.M.; Azam, A.M. Performance characteristics of asphalt mixtures with industrial waste/by-product materials as mineral fillers under static and cyclic loading. Road Mater. Pavement Des. 2020, 23, 335–357. [Google Scholar] [CrossRef]

- Cardone, F.; Frigio, F.; Ferrotti, G.; Canestrari, F. Influence of mineral fillers on the rheological response of polymer-modified bitumens and mastics. J. Traffic Trans. Eng. 2015, 2, 373–381. [Google Scholar] [CrossRef]

- Chen, J.S.; Kuo, P.H.; Lin, P.S.; Huang, C.C.; Lin, K.Y. Experimental and theoretical characterization of the engineering behavior of bitumen mixed with mineral filler. Mater. Struct 2008, 41, 1015–1024. [Google Scholar] [CrossRef]

- Grabowski, W.; Wilanowicz, J. The structure of mineral fillers and their stiffening properties in filler-bitumen mastics. Mater. Struct. 2008, 41, 793–804. [Google Scholar] [CrossRef]

- Kim, Y.R.; Little, D.N. Linear viscoelastic analysis of asphalt mastics. J. Mater. Civ. Eng. 2004, 16, 122–132. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Rheological characterization of warm-modified asphalt mastics containing electric arc furnace steel slags. Adv. Mater. Sci. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I.L.; Faheem, A.F.; Bahia, H.U.; Yang, S.H.; Reinke, G.H. Effect of mineral filler characteristics on asphalt mastic and mixture rutting potential. Transp. Res. Rec. 2011, 2208, 33–39. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Cai, J.; Zhu, L.; Zhang, Y.; Feng, N.; et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, J.; Yang, Z.; Wang, J.; Zhao, Y.; Zhang, Y. Creep and fatigue properties of asphalt mastic with steel slag powder filler. Case Stud. Constr. Mater. 2023, 18, e01743. [Google Scholar] [CrossRef]

- Bahuguna, S. Permanent Deformation and Rate Effects in Asphalt Concrete: Constitutive Modeling and Numerical Implementation. Ph.D. Dissertation, Case Western Reserve University, Cleveland, OH, USA, 2003; pp. 35–46. [Google Scholar]

- Zhao, M.; Wu, S.; Zongwu, C.; Li, C. Production and application of steel slag coarse aggregate in asphalt mixture. Emerg. Mater. Res. 2017, 6, 1–16. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G. Improvement of Porous Pavement; Final Report to, 166; US Green Building Council: Washington, DC, USA; East Carolina University: Greenville, NC, USA, 2011. [Google Scholar]

- Ziari, H.; Khabiri, M.M. Preventive maintenance of flexible pavement and mechanical properties of steel slag asphalt. J. Environ. Eng. Landsc. Manag. 2007, 15, 188–192. [Google Scholar] [CrossRef]

- Zhou, F.J.; Scullion, T.; Sun, L.J. Verification and modeling of three-stage permanent deformation behavior of asphalt mixes. J. Trans. Eng. 2004, 130, 486–494. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, S.; Haobo, H.; Zha, J. Experimental investigation of basic oxygen furnace slag used as aggregate in asphalt mixture. J. Hazard. Mater. 2006, 138, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wei, J.; Xu, X.; Zhang, X.; Han, W.; Yan, X.; Hu, G.; Lu, Z. Study on the optimum steel slag content of SMA-13 asphalt mixes based on road performance. Coatings 2021, 11, 1436. [Google Scholar] [CrossRef]

- Loureiro, C.D.A.; Silva, H.M.R.D.; Moura, C.F.N.; Rodrigues, M.; Martinho, F.C.G.; Oliveira, J.R.M. Steel slag and recycled concrete aggregates: Replacing quarries to supply sustainable materials for the asphalt paving industry. Sustainability 2022, 14, 5022. [Google Scholar] [CrossRef]

- EN 12697-22; Bituminous Mixtures—Test methods—Part 22: Wheel Tracking. European Committee for Standardization: Bruxelles, Belgium, 2020.

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.A. Comparative evaluation of dense-graded and gap-graded asphalt mix incorporating electric arc furnace steel slag and copper mine tailings. J. Clean. Prod. 2016, 122, 315–325. [Google Scholar] [CrossRef]

- Lee, E.J.; Park, H.M.; Suh, Y.C.; Lee, J.S. Performance evaluation of asphalt mixtures with 100% EAF and BOF steel slag aggregates using laboratory tests and mechanistic analyses. KSCE J. Civ. Eng. 2022, 26, 4542–4551. [Google Scholar] [CrossRef]

- EN 16659; Bitumen and Bituminous Binders—Multiple Stress Creep and Recovery Test (MSCRT). European Committee for Standardization: Bruxelles, Belgium, 2015.

- Alandish, A.M.; Aman, M.Y.; Katman, H.Y.B.; Ibrahim, M.R. Characteristics of warm mix asphalt incorporating coarse steel slag aggregates. Appl. Sci. 2021, 11, 3708. [Google Scholar] [CrossRef]

- Bahia, H.U.; Faheem, A.; Hintz, C.; Al-Qadi, I.; Reinke, G. Test Methods and Specification Criteria for Mineral Filler Used in HMA; Report 9-45; National Cooperative Highway Research Program: Washington, DC, USA, 2010; pp. 294–303. [Google Scholar]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Mechanical feasibility of asphalt materials for pavement solar collectors: Small-scale laboratory characterization. Appl. Sci. 2023, 13, 358. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Rutting behavior of asphalt surface layers designed for solar harvesting systems. Materials 2023, 16, 277. [Google Scholar] [CrossRef]

- Medani, T.O.; Molenaar, A.A.A. Estimation of fatigue characteristics of asphalt mixes using simple tests. Heron 2000, 45, 155–165. [Google Scholar]

- EN 12697-24; Bituminous Mixtures—Test Methods—Part 24: Resistance to Fatigue. European Committee for Standardization: Bruxelles, Belgium, 2018.

- Artamendi, I.; Khalid, H. Characterization of fatigue damage for paving asphaltic materials. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 1113–1118. [Google Scholar] [CrossRef]

- Tayebali, A.A.; Rowe, G.M.; Sousa, J.B. Fatigue response of asphalt-aggregate mixtures. J. Assoc. Asph. Paving Technol. 1992, 61, 333–360. [Google Scholar]

- Di Benedetto, H.; De La Roche, C.; Baaj, H.; Pronk, A.; Lundstron, R. Fatigue of bituminous mixtures: Different approaches and RILEM group contribution. In Proceedings of the 6th International RILEM Symposium, Zurich, Switzerland, 14–16 April 2003. [Google Scholar]

- Pronk, A.C. Comparison of 2 and 4 point fatigue tests and healing in 4 point dynamic test based on the dissipated energy concept. In Proceedings of the 8th International Conference on Asphalt Pavement, Seattle, WA, USA, 10–14 August 1997. [Google Scholar]

- Qazizadeh, M.J.; Farhad, H.; Kavussi, A.; Sadeghi, A. Evaluating the fatigue behavior of asphalt mixtures containing electric arc furnace and basic oxygen furnace slags using surface free energy estimation. J. Clean. Prod. 2018, 188, 355–361. [Google Scholar] [CrossRef]

- Groenniger, J.; Wistuba, M.P. Performance properties of asphalt mixture containing Linz-Donawitz (LD) steel slag. In Proceedings of the 10th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Athens, Greece, 28 June–1 July 2017. [Google Scholar]

- Lundstrom, R.; Di Benedetto, H.; Isacsson, U. Influence of asphalt mixture stiffness on fatigue failure. J. Mater. Civ. Eng. 2004, 16, 516–525. [Google Scholar] [CrossRef]

- Ge, Z.; Huang, X. Study on effect factors of asphalt-mixtures low temperature anti cracking performance by grey relation degree theory. J. Highw. Transp. Res. Dev 2003, 20, 1–3. [Google Scholar]

- Hao, P.; Zhang, D.; Hu, X.N. Evaluation method for low temperature anti-cracking performance of asphalt mixture. J. Xi’an Highw. Univ. 2000, 20, 1–5. [Google Scholar]

- Isacsson, U.; Zeng, H. Relationships between bitumen chemistry and low temperature behaviour of asphalt. Constr. Build. Mater. 1997, 11, 83–91. [Google Scholar] [CrossRef]

- EN 12697-46; Bituminous Mixtures—Test Methods—Part 46: Low Temperature Cracking and Properties by Uniaxial Tension Tests. European Committee for Standardization: Bruxelles, Belgium, 2020.

- Pasetto, M.; Baldo, N. Moisture damage and low temperature cracking of bituminous mixtures made with recycled aggregates. In Proceedings of the 6th International Conference on Bituminous Mixtures and Pavements, Thessaloniki, Greece, 10–12 June 2015. [Google Scholar]

- Li, Q.; Qiu, Y.; Rahman, A.; Ding, H. Application of steel slag powder to enhance the low-temperature fracture properties of asphalt mastic and its corresponding mechanism. J. Clean. Prod. 2018, 184, 21–31. [Google Scholar] [CrossRef]

- Georgius, P.; Loizos, A. Characterization of sustainable asphalt mixtures containing high reclaimed asphalt and steel slag. Materials 2021, 14, 4938. [Google Scholar] [CrossRef]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D. Moisture susceptibility of asphalt mixtures—Part I: Mechanisms. Int. J. Pavement Eng. 2008, 9, 81–98. [Google Scholar] [CrossRef]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D. Moisture susceptibility of asphalt mixtures—Part II: Characterisation and modelling. Int. J. Pavement Eng. 2008, 9, 99–114. [Google Scholar] [CrossRef]

- Hesami, S.; Ameri, M.; Goli, H.; Akbari, A. Laboratory investigation of moisture susceptibility of warm-mix asphalt mixtures containing steel slag aggregates. Int. J. Pavement Eng. 2015, 16, 745–759. [Google Scholar] [CrossRef]

- Chiu, C.; Lu, L. A laboratory study in stone matrix asphalt using ground tire rubber. Constr. Build. Mater. 2007, 21, 1027–1033. [Google Scholar] [CrossRef]

- Kennedy, T.W.; Anangos, J.N. Wet-Dry Indirect Tensile Test for Evaluating Moisture Susceptibility of Asphalt Mixtures; Research Report 253-8; Center for Transportation Research, University of Texas: Austin, TX, USA, 1984; pp. 1–3. [Google Scholar]

- Birgisson, B.; Roque, R.; Page, G.C. Evaluation of water damage using hot mix asphalt fracture mechanics. J. Assoc. Asph. Paving Technol. 2003, 72, 424–462. [Google Scholar]

- Roque, R.; Birgisson, B.; Sangpetngam, B.; Zhang, Z. Hot mix asphalt fracture mechanics: A fundamental crack growth law for asphalt mixtures. J. Assoc. Asph. Pavement Technol. 2002, 71, 816–827. [Google Scholar]

- AASHTO T314-14; Standard Method of Test for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- ASTM D4867M-09; Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2014.

- Wu, S.; Yang, W.F.; Xue, Y.J.; Lin, Z.H. Design and preparation of steel slag SMA. J. Wuhan Univ. Technol. 2003, 18, 86–88. [Google Scholar]

- Chen, Z.; Xie, J.; Xiao, Y.; Chen, J.; Wu, S. Characteristics of bonding behavior between basic oxygen furnace slag and asphalt binder. Constr. Build. Mater. 2014, 64, 60–66. [Google Scholar] [CrossRef]

- Goli, H.; Latifi, M.; Sadeghian, M. Moisture characteristics of warm mix asphalt containing reclaimed asphalt pavement (RAP) or steel slag. Mater. Struct 2022, 55, 53. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C. Deformation of steel slag asphalt mixtures under normal temperature water immersion. Front. Mater. 2021, 8, 718516. [Google Scholar] [CrossRef]

- Pathak, S.; Choudhary, R.; Kumar, A. Investigation of moisture damage in open graded asphalt friction course mixtures with basic oxygen furnace steel slag as coarse aggregate under acidic and neutral pH environments. Transp. Res. Rec. 2020, 2674, 887–901. [Google Scholar] [CrossRef]

- Bell, C.A.; Sosnovske, D. Aging: Binder Validation; Report SHRP-A-384; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1994; pp. 1–6. [Google Scholar]

- Bai, B.C.; Park, D.W.; Vo, H.V.; Dessouky, S.; Im, J.S. Thermal properties of asphalt mixtures modified with conductive fillers. J. Nanomat. 2015, 2015, 926809. [Google Scholar] [CrossRef]

- Jiao, W.; Sha, A.; Liu, Z.; Li, W.; Jiang, W.; Qin, W.; Hu, Y. Study on thermal properties of steel slag asphalt concrete for snowmelting pavement. J. Clean. Prod. 2020, 277, 123574. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Pasquini, E.; Giacomello, G. High albedo pavement materials. In Eco-Efficient Materials for Reducing Cooling Needs in Buildings and Construction: Design, Properties and Applications, 1st ed.; Pacheco-Torgal, F., Czarnecki, L., Pisello, A.L., Cabeza, L.F., Granqvist, C.G., Eds.; Elsevier: Amsterdam, The Netherland, 2021; pp. 15–32. [Google Scholar]

- Luo, W.; Huang, S.; Liu, Y.; Peng, H.; Ye, Y. Three-dimensional mesostructure model of coupled electromagnetic and heat transfer for microwave heating on steel slag asphalt mixtures. Constr. Build. Mater. 2022, 330, 127235. [Google Scholar] [CrossRef]

- Jiao, W.; Sha, A.; Liu, Z.; Jiang, W.; Hu, L.; Li, X. Utilization of steel slags to produce thermal conductive asphalt concretes for snow melting pavements. J. Clean. Prod. 2020, 261, 121197. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Galgaro, A.; Mogentale, E.; Sandalo, A. Preliminary study of an energy harvesting system for road pavements made with marginal aggregate. Lec Notes Civ. Eng. 2020, 48, 101–113. [Google Scholar]

- Mirzanamadi, R.; Johansson, P.; Grammatikos, S.A. Thermal properties of asphalt concrete: A numerical and experimental. Constr. Build. Mater. 2018, 158, 774–785. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Schlangen, E.; Sun, Y.; Wu, S. Research on the mechanical, thermal, induction heating and healing properties of steel slag/steel fibers composite asphalt mixture. Appl. Sci. 2017, 7, 1008. [Google Scholar] [CrossRef]

- Barra, M.; Aponte, D.; Vazquez, E.; Mendez, B.; Miro, R.; Valls, S. Experimental study of the effect of the thermal conductivity of EAF slag aggregates used in asphaltic concrete of wearing courses on the durability of road pavements. In Proceedings of the 4th International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Cao, Y.; Sha, A.; Liu, Z.; Zhang, F.; Li, J.; Liu, H. Thermal conductivity evaluation and road performance test of steel slag asphalt mixture. Sustainability 2022, 14, 7288. [Google Scholar] [CrossRef]

- EN 13036-4; Road and Airfield Surface Characteristics—Test Methods—Part 4: Method for Measurement of Slip/Skid Resistance of a Surface: The Pendulum Test. European Committee for Standardization: Bruxelles, Belgium, 2011.

- Akbari, A.; Babagoli, R. Laboratory evaluation of the effect of temperature on skid resistance of different asphalt mixtures. Mater. Res. Innov. 2020, 25, 83–89. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Lu, D.X.; Le, S.D. Investigation of using steel slag in hot mix asphalt for the surface course of flexible pavements. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 143, pp. 1–10. [Google Scholar]

- Stock, A.F.; Ibberson, M.; Taylor, I.F. Skidding characteristics of pavement surfaces incorporating steel slag aggregates. Transp. Res. Rec. 1996, 1545, 35–40. [Google Scholar] [CrossRef]

- Sofilić, T.; Rastovčan-Mioč, A.; Ćosić, M.; Merle, V.; Mioč, B.; Sofilić, U. EAF steel slag application possibilities in Croatian asphalt mixture production. Chem Eng. Transact. 2010, 19, 109–116. [Google Scholar]

| Constituent | Iron Slag 1 | Steel Slag 1 |

|---|---|---|

| CaO | 35–42% | 35–45% |

| SiO2 | 33–38% | 11–17% |

| Al2O3 | 10–15% | 1–6% |

| MgO | 7–12% | 2–9% |

| FeO | ≤1.0% | 16–26% |

| MnO | ≤1.0% | 2–6% |

| P2O5 | not available | 1–2% |

| S | 1–1.5% | ≤0.2% |

| Cr2O3 | ≤0.1% | 0.5–2% |

| Property | Standard | Unit | Iron Slag | Steel Slag | Basalt | Greywacke |

|---|---|---|---|---|---|---|

| Impact value | EN 1097-2 [110] | % | 27 | 17 | 17 | 20 |

| Particle density | EN 1097-6 [111] | g/cm3 | 2.4 | 3.6 | 3.0 | 2.7 |

| Water absorption | EN 1097-6 [111] | % | 2 | 1 | <0.5 | <0.5 |

| Polishing resistance | EN 1097-8 [112] | PSV | 50 | 57 | 50 | 56 |

| Freeze/thaw resistance | EN 1367-5 [113] | % | <0.5 | <0.5 | <0.5 | <0.5 |

| Property | Potential Hazard | Environmental Risk |

|---|---|---|

| Leachable (or soluble) trace metals | Presence of As, Cd, Cu, Cr, Hg, Pb, Zn | Groundwater and surface water pollution |

| Soluble solids | Presence of soluble and mobile salts | Contamination of groundwater and sensitive freshwater ecosystems |

| Total and respirable dust | Presence of fine particulate matter | Respiratory diseases (particles also susceptible to airborne migration) |

| Volatile metals | Presence of volatile metals such as As, Hg, Cd, Pb, and Zn | Worker health issues (particles released at high temperatures) |

| Ref. | Slag Type {Content} | Method | OBC 1 | MQ | Flow | Voids |

|---|---|---|---|---|---|---|

| [24] | EAFS {≅90%} | Marshall | ≅+1% {L} | ≅+50% | ≅−5% | Fixed |

| [35] | EAFS {≅90%} | Marshall | n.a. {L} | ≅+25% | ≅−20% | ≅−10% |

| [76] | EAFS {≅50%} | Marshall | ≅+0.1% {L} | n.a. | n.a. | ≅−15% |

| [137] | EAFS {≅50%} | Marshall | ≅+0.05% {L} | ≅+5% | +14% | ≅−20% |

| [141] | EAFS {≅90%} | Marshall | ≅+0.5% {L} | n.a. | n.a. | ≅−30% |

| [142] | BOFS {≅70%} | Marshall | ≅+0.2% {L} | n.a. | n.a. | n.a. |

| [143] | n.a. {≅50%} | Marshall | ≅+0.4% {D} | ≅+40% | ≅−15% | ≅+15% |

| [144] | n.a. {≅50%} | Marshall | ≅+1% {GA} | ≅+35% | ≅−10% | ≅−20% |

| [145] | EAFS {≅70%} | Marshall | ≅0% {GR} | ≅+30% | ≅−25% | ≅−15% |

| [146] | EAFS {≅90%} | Marshall | ≅+0.2% {GR} | ≅+30% | ≅−25% | ≅−30% |

| [147] | n.a. {n.a.} | Marshall | ≅+0.5% {L} | ≅+50% | ≅−30% | ≅+20% |

| [148] | EAFS {≅90%} | Marshall | ≅+0.35% {L} | ≅+50% | ≅−20% | Fixed |

| [149] | n.a. {≅90%} | Marshall | ≅+0.8% {L} | ≅+20% | ≅−25% | ≅−15% |

| [159] | EAFS {≅20%} | Superpave | ≅+0.4% {S} | n.a. | n.a. | ≅+5% |

| [151] | BOFS {≅60%} | Marshall | ≅−0.4% {L} | ≅+45% | ≅−15% | ≅−20% |

| [152] | BOFS {≅90%} | Marshall | ≅−0.4% {L} | ≅0% | ≅−5% | Fixed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review. Sustainability 2023, 15, 8817. https://doi.org/10.3390/su15118817

Pasetto M, Baliello A, Giacomello G, Pasquini E. The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review. Sustainability. 2023; 15(11):8817. https://doi.org/10.3390/su15118817

Chicago/Turabian StylePasetto, Marco, Andrea Baliello, Giovanni Giacomello, and Emiliano Pasquini. 2023. "The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review" Sustainability 15, no. 11: 8817. https://doi.org/10.3390/su15118817

APA StylePasetto, M., Baliello, A., Giacomello, G., & Pasquini, E. (2023). The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review. Sustainability, 15(11), 8817. https://doi.org/10.3390/su15118817