Revolutionizing IC Genset Operations with IIoT and AI: A Study on Fuel Savings and Predictive Maintenance

Abstract

1. Introduction

2. Literature Review

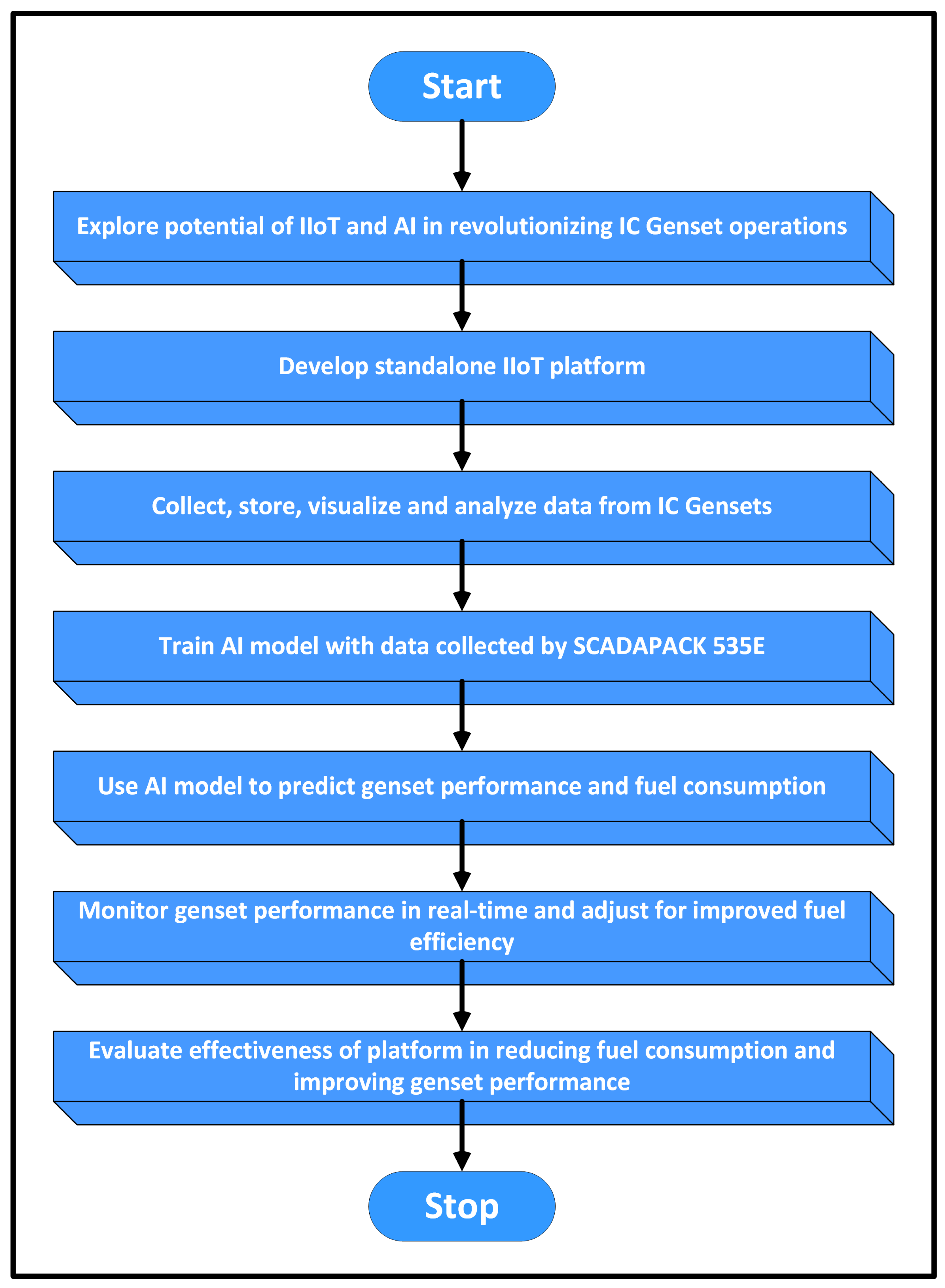

3. Methodology

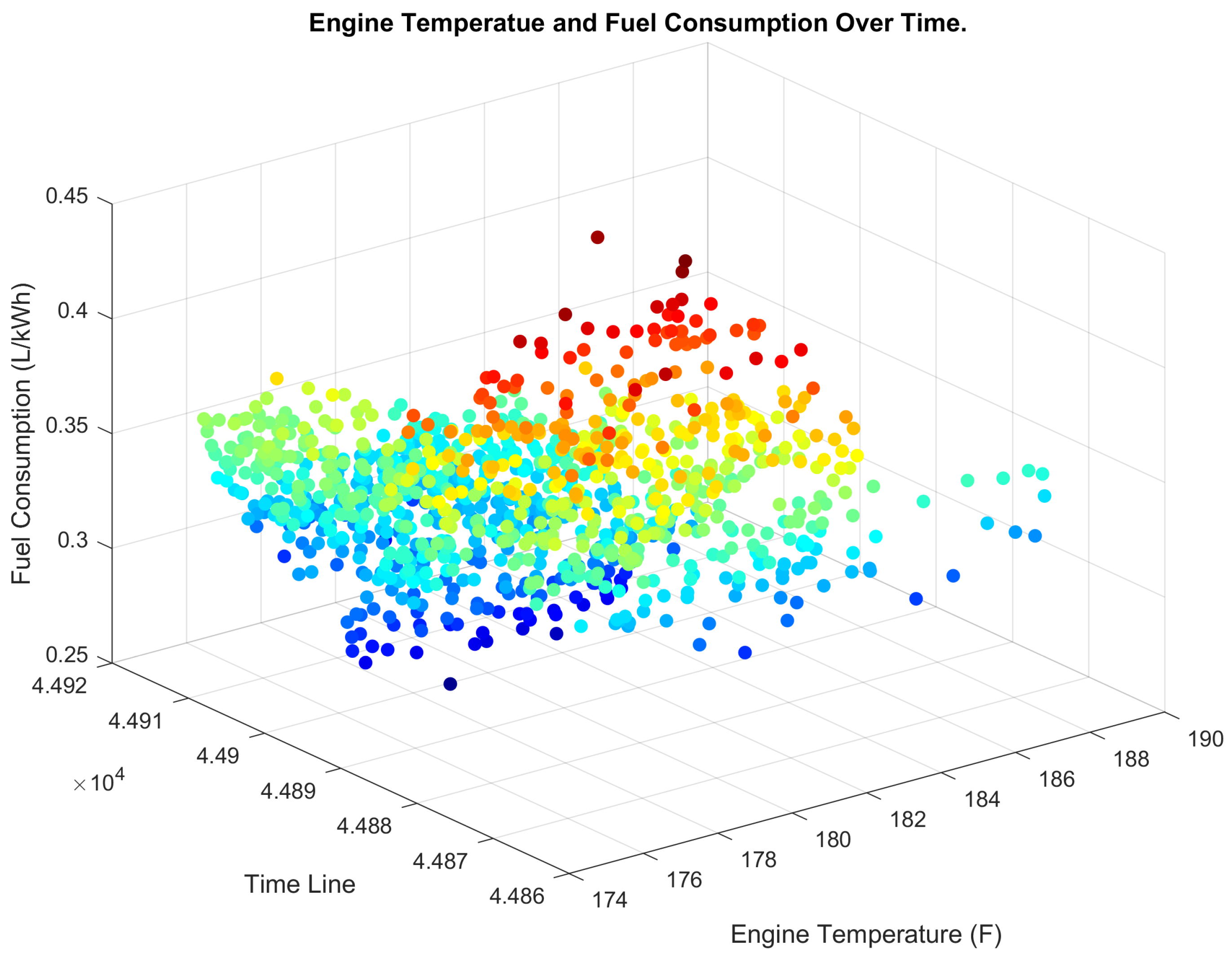

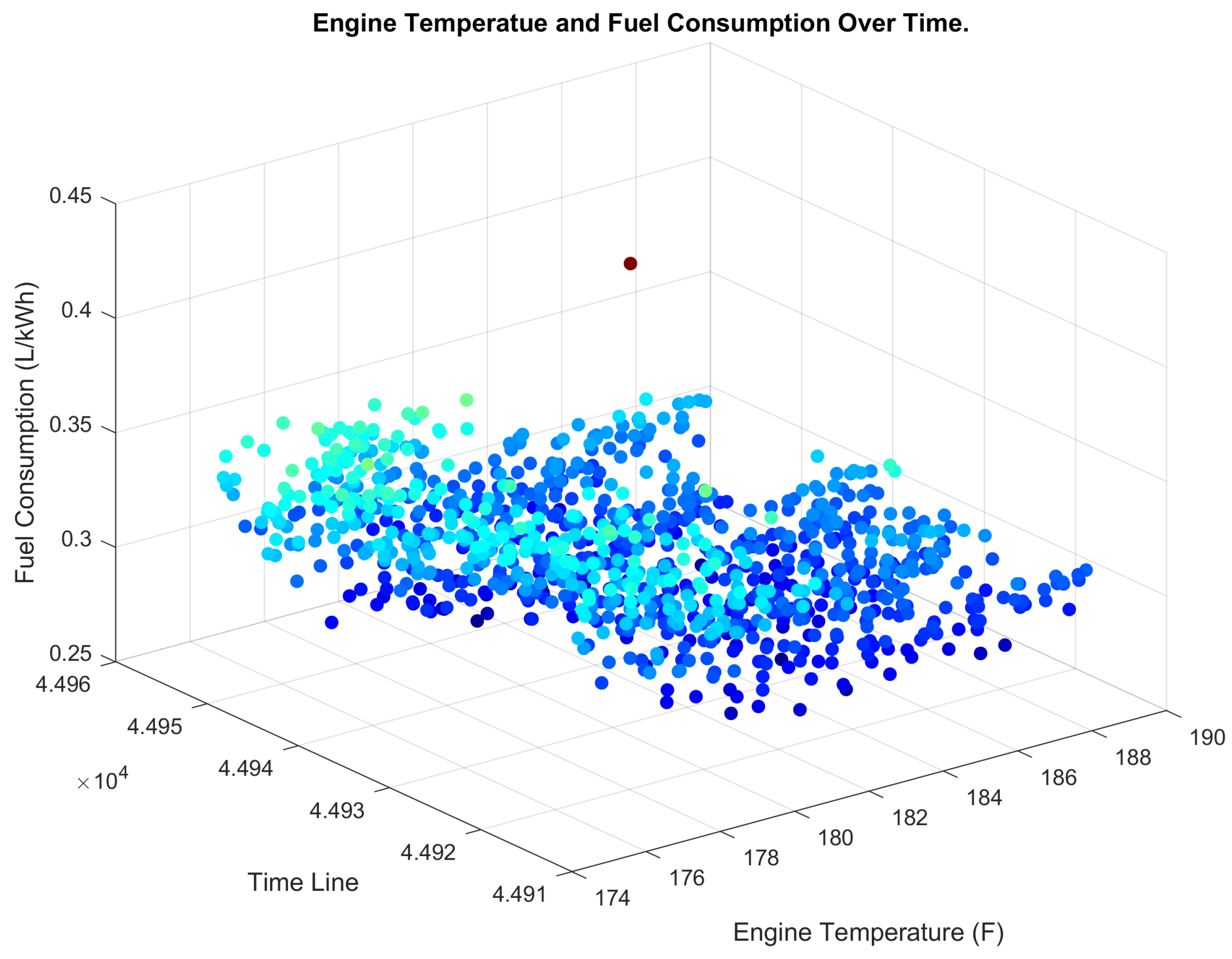

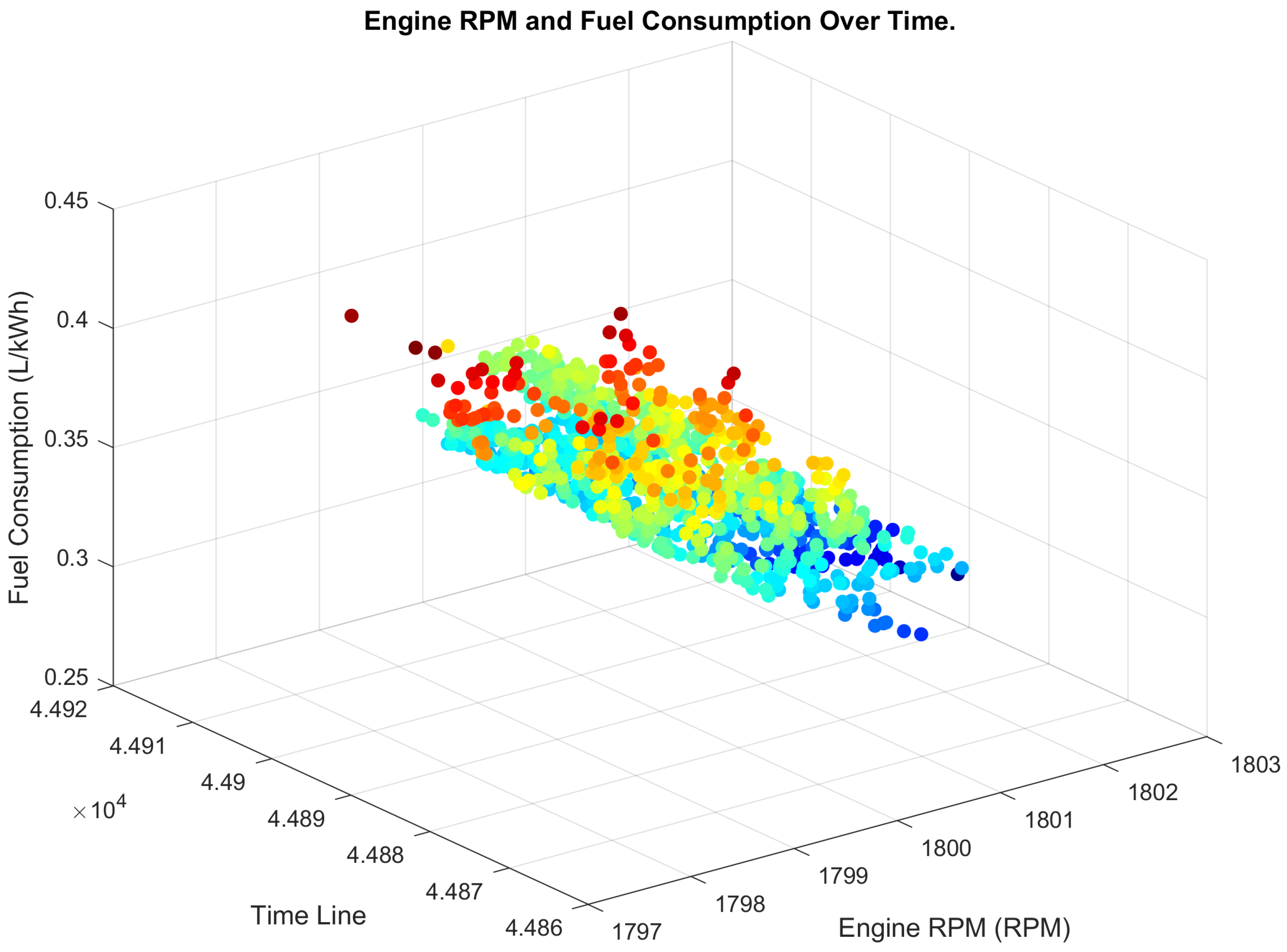

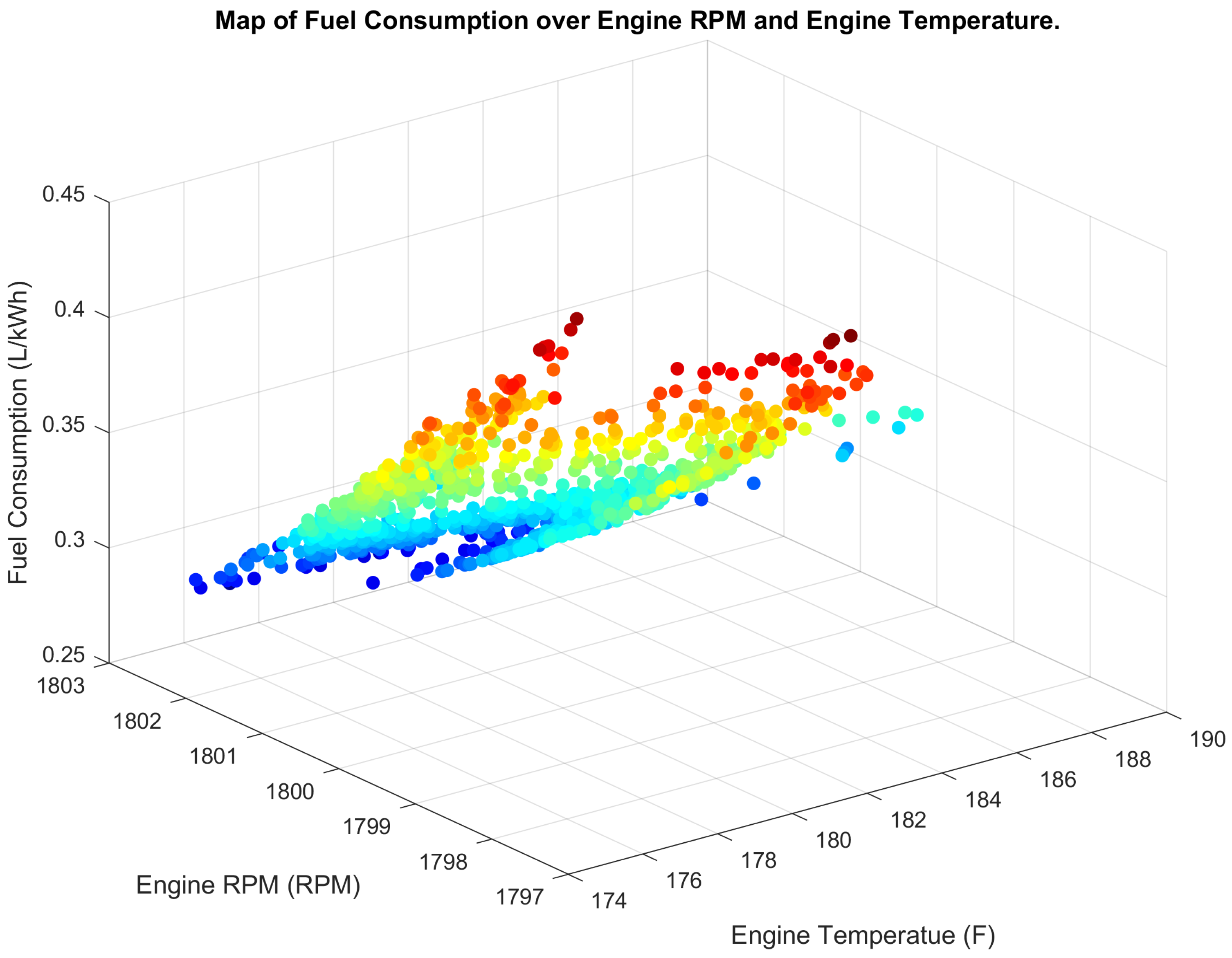

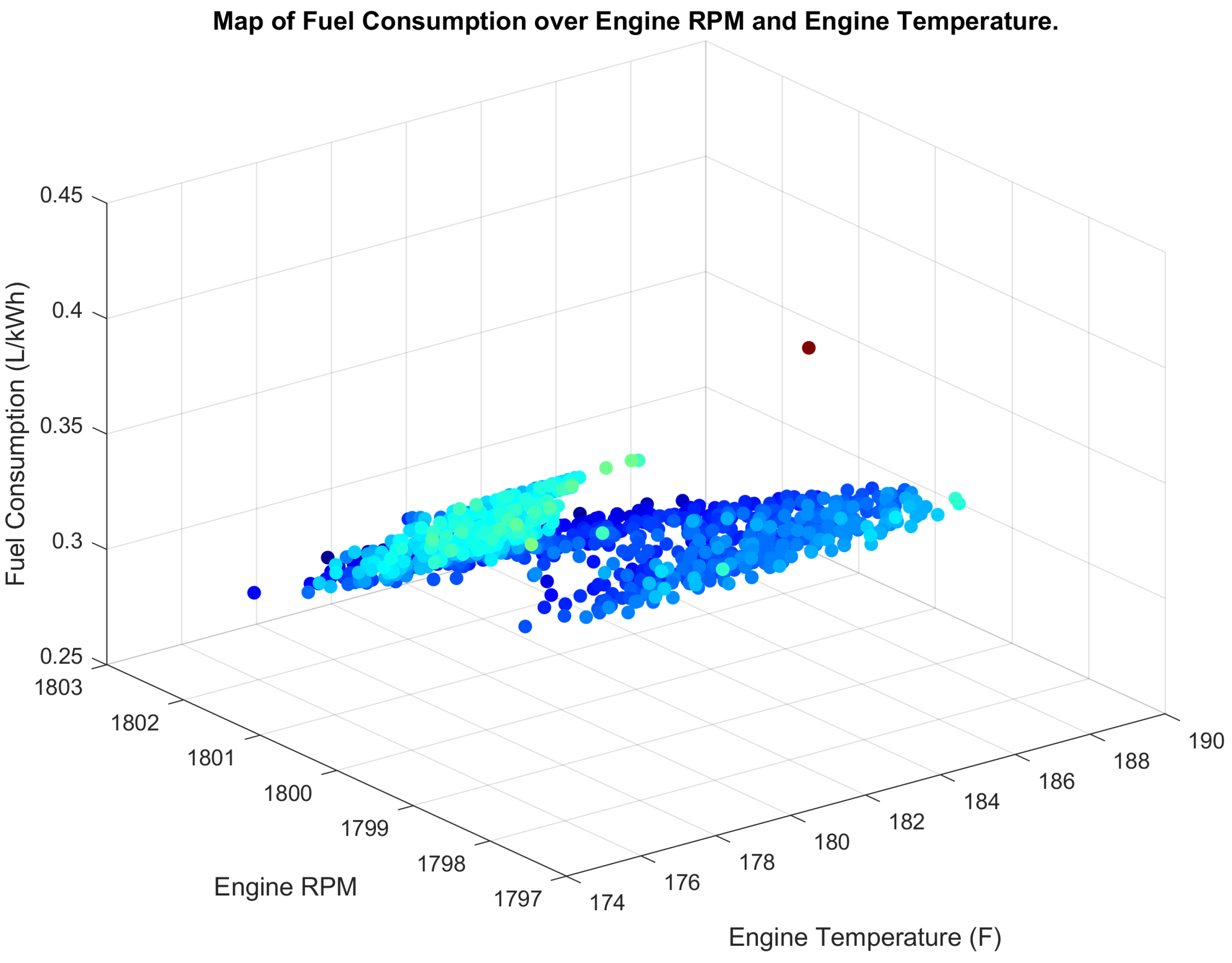

- Sensors: A set of sensors was installed on the genset to collect real-time data on engine parameters, such as fuel consumption rate, engine RPM, and temperature;

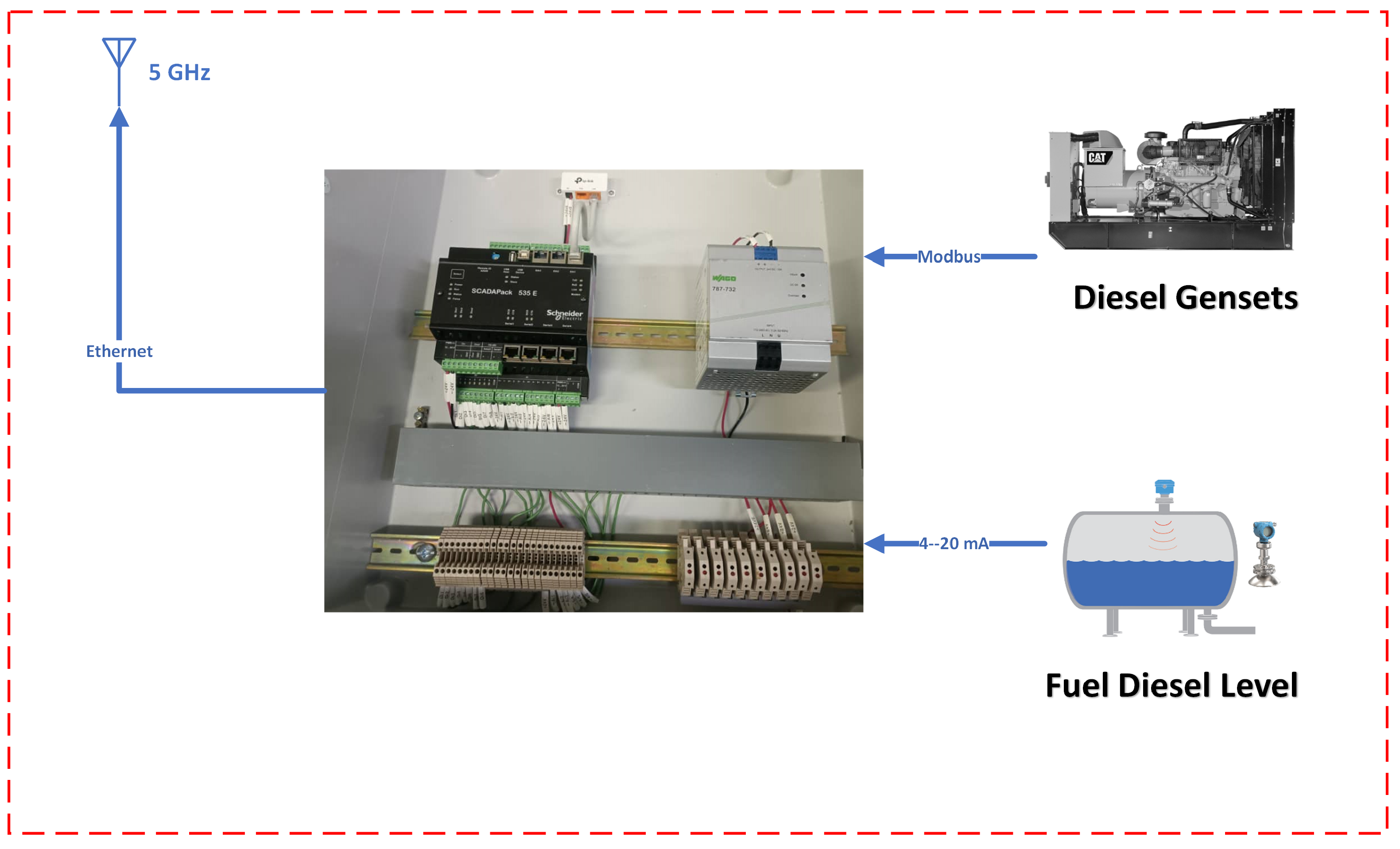

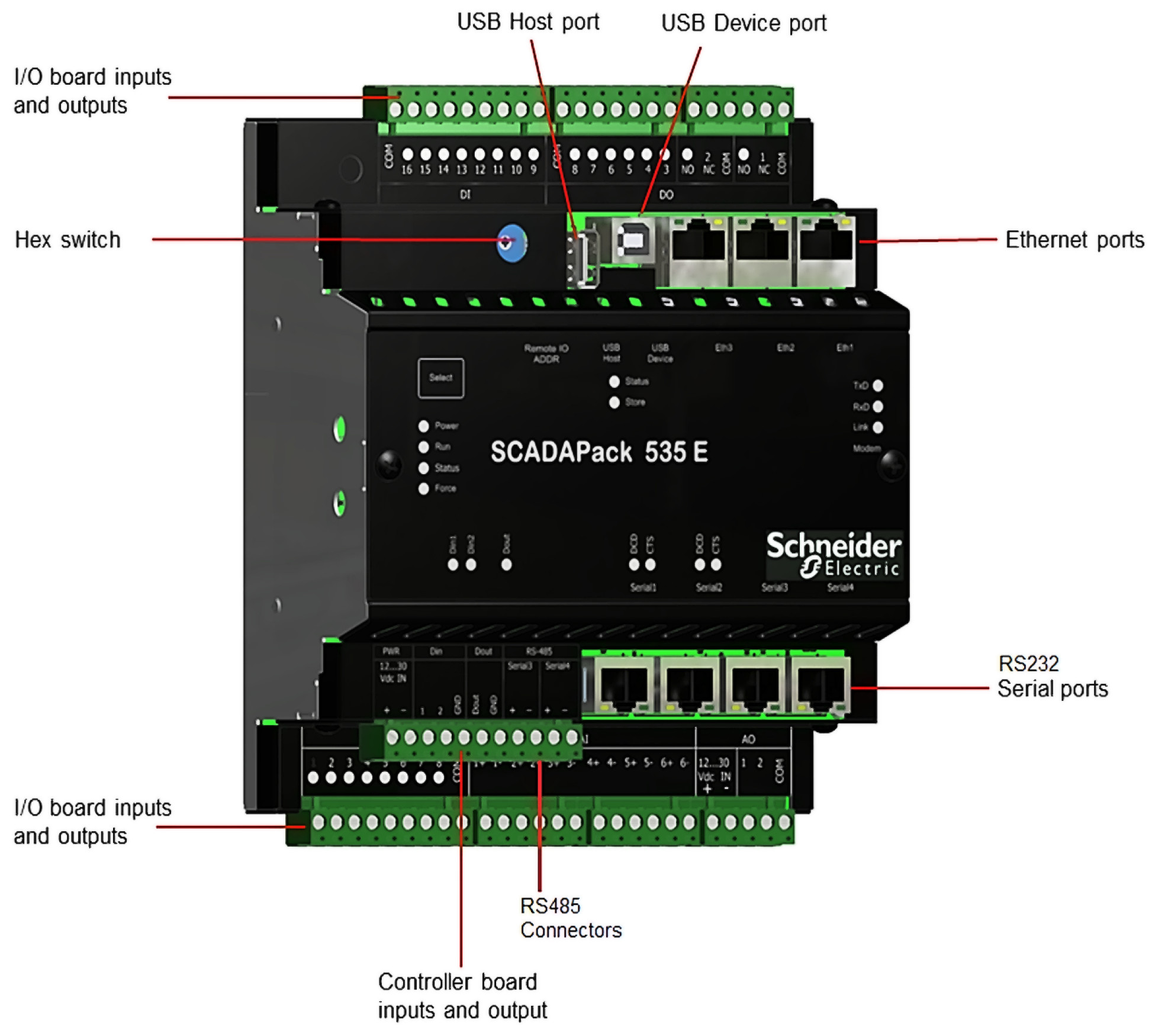

- Data Acquisition and Communication: An IIoT gateway was employed to acquire data from the sensors and transmit them to a cloud-based server for storage and analysis;

- Data Analysis and AI Algorithms: The collected data were analyzed using machine learning algorithms to identify patterns and correlations between engine parameters and fuel consumption. The AI algorithms were trained to predict fuel consumption rates and maintenance requirements based on the analyzed data;

- Control and Optimization: Based on the insights derived from the AI algorithms, the system was designed to automatically adjust engine settings to optimize fuel consumption and schedule predictive maintenance tasks.

3.1. Experimental Setup

3.2. Data Collection

3.3. Data Analysis

3.4. Evaluation and Validation

4. Sustainable Design and Configuration

- Identifying the research objectives and research questions to be answered by the study, considering the sustainability benefits, such as reduced emissions, resource conservation, and cost savings;

- Selecting the appropriate industrial devices and equipment to be used in the study, such as an energy-efficient CAT genset, sensors, and other necessary hardware, prioritizing eco-friendly and energy-saving options;

- Installing and configuring the IIoT platform, including the KEPware OPC server and the necessary drivers and libraries, ensuring the platform’s energy efficiency and minimal environmental impact;

- Configuring the wireless Ethernet connection between the industrial devices and the IIoT platform, including setting IP addresses, network settings, and security settings, while minimizing the energy consumption of the communication infrastructure;

- Setting up the data collection and storage system, including the use of databases and cloud storage, prioritizing energy-efficient and environmentally friendly options for data centers;

- Designing the user interface for the platform, including the real-time data display, device control, alarm and event monitoring, historical data, configuration and settings, security and access control, and help and documentation, with a focus on promoting sustainable practices and energy conservation;

- Implementing the AI and machine learning algorithms for predictive maintenance and fuel savings analysis, contributing to resource conservation and emissions reduction;

- Testing and evaluating the performance of the system, including monitoring the fuel savings, predictive maintenance capabilities, and sustainability benefits, such as reduced emissions and resource conservation;

- Deploying the system on a standalone machine or in a cloud-based environment, ensuring proper configuration, connectivity to the industrial devices, and alignment with sustainability objectives.

4.1. Standalone IIoT Platform

4.1.1. Implementation of Standalone IIoT Platform

4.1.2. IIoT Platform User Interface

5. Data Collection and Analysis

5.1. Genset Data Collection

5.2. Fuel Consumption Data

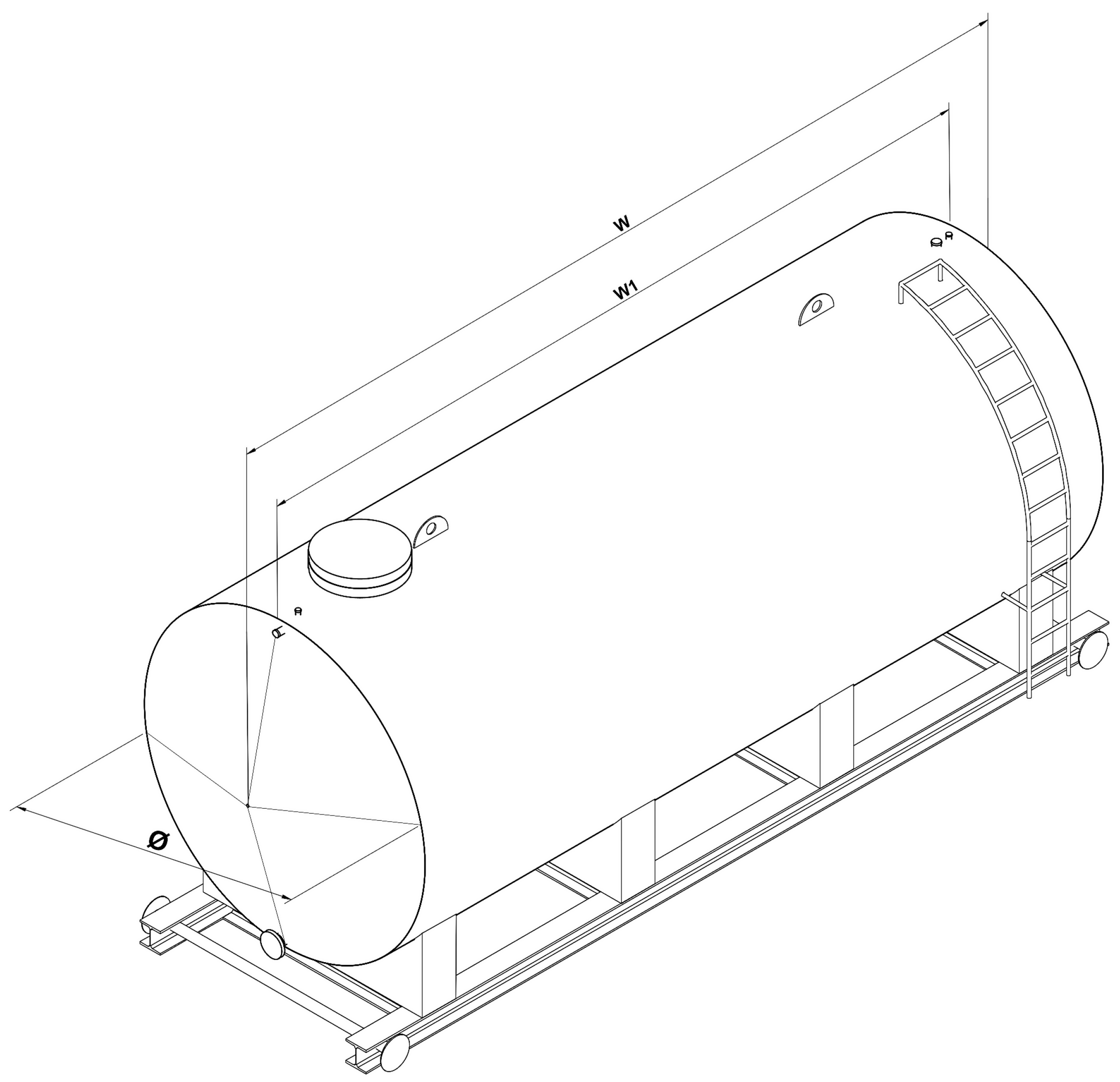

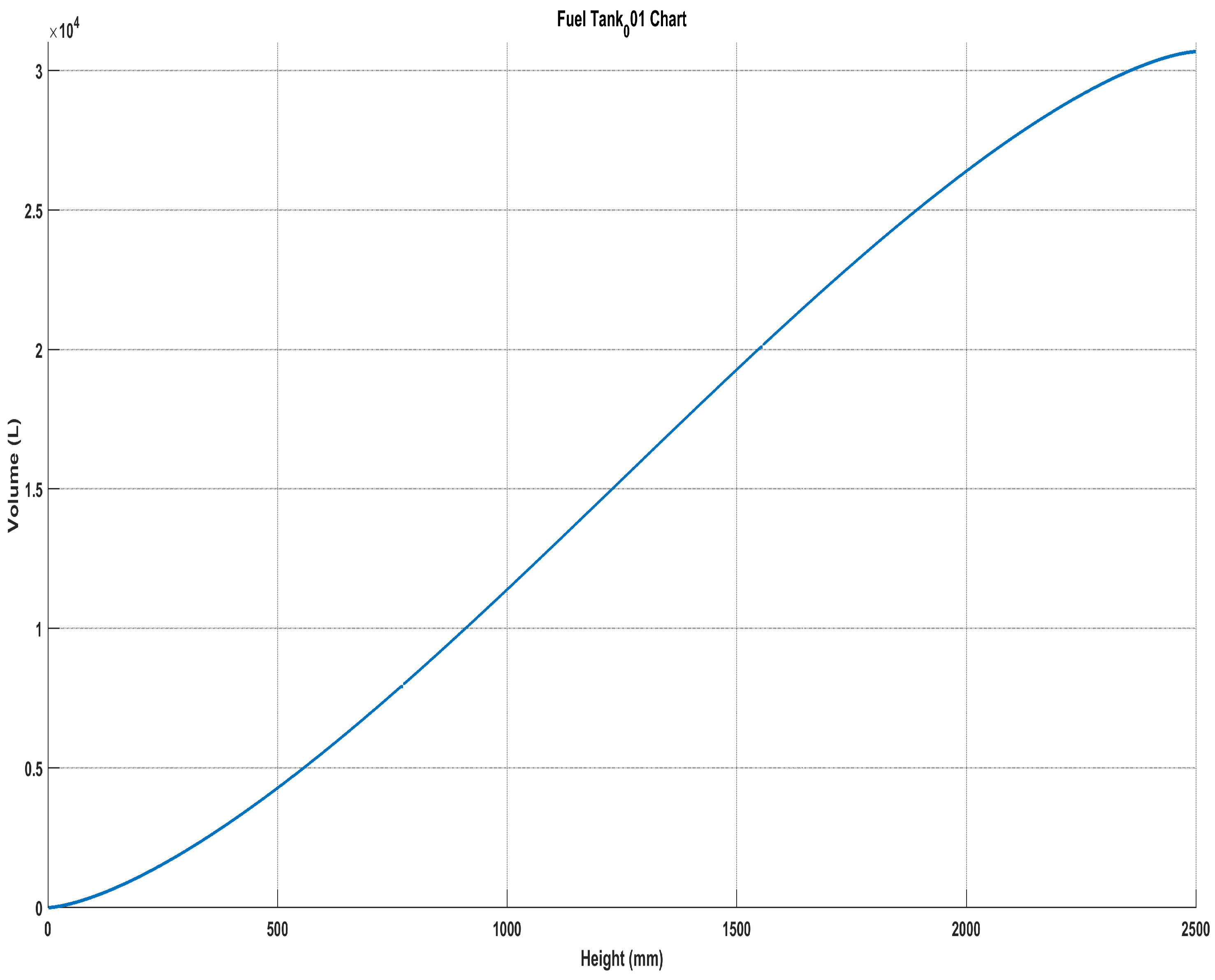

- Define the variables you will be using in the problem. In this case, you will need to define the volume of the liquid in the tank (V), the radius of the cylindrical portion of the tank (r), the height of the liquid in the tank (h), the radius of the cones at either end of the tank (the same as the tank radius ) (r), the flow rate of the liquid being added to the tank (F), and the rate at which liquid is being removed from the tank (L);

- Calculate the volume of the liquid in the tank at time t using the following equation to generate the volume chart shown in Figure 5:where ;

- Calculate the volume of the liquid in the tank at time using the same equation;

- Calculate the change in volume of the liquid in the tank over the time interval using the following equation:

- Use the following equations to calculate and at each time interval:

- To calculate the total volume of liquid added to and removed from the tank over a given period of time, sum the values of and over each time interval in the period using the following equations:

- Repeat the calculations for each time interval in the period to estimate the total volume of liquid added to and removed from the tank over the time period.

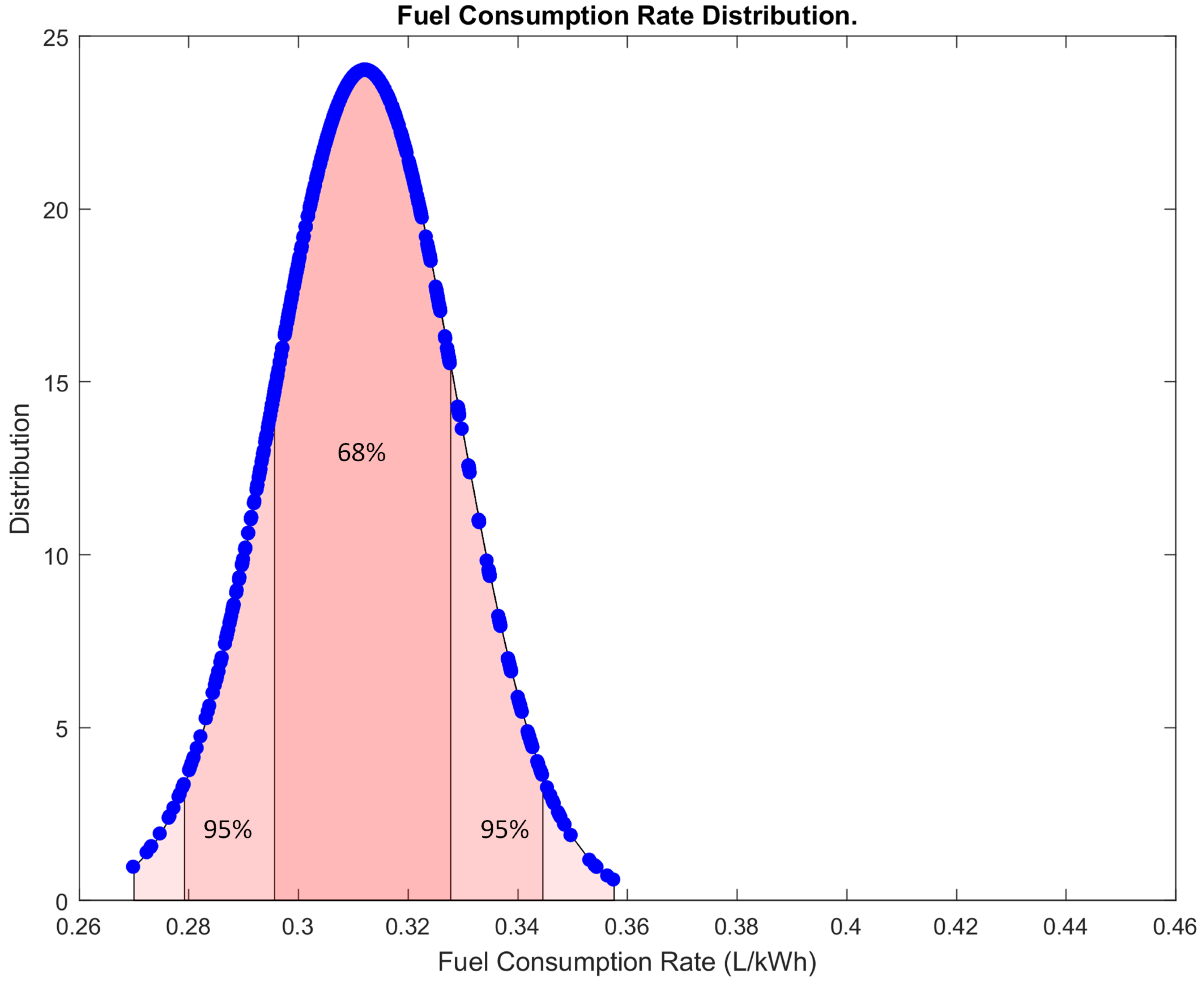

5.3. Data Analysis

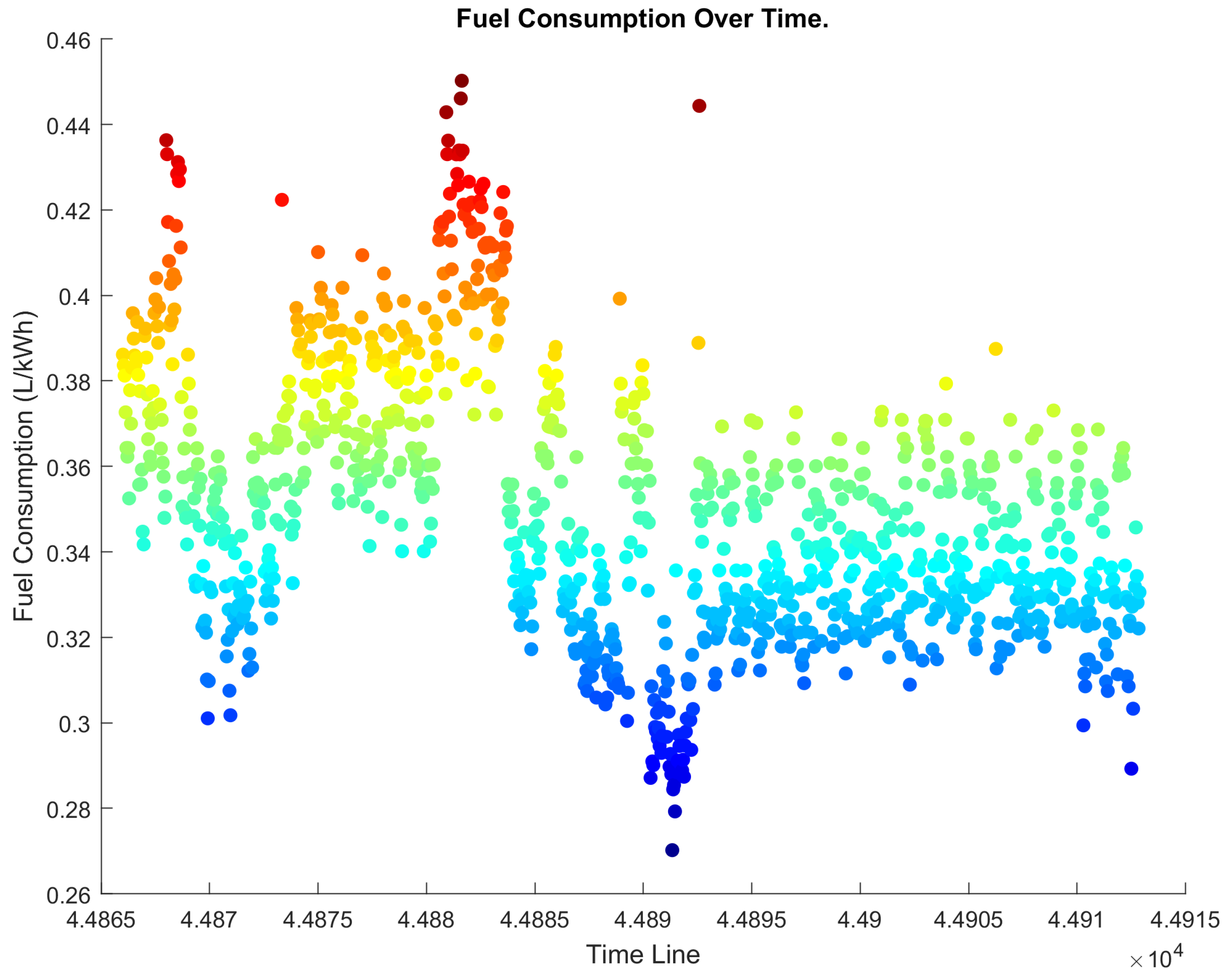

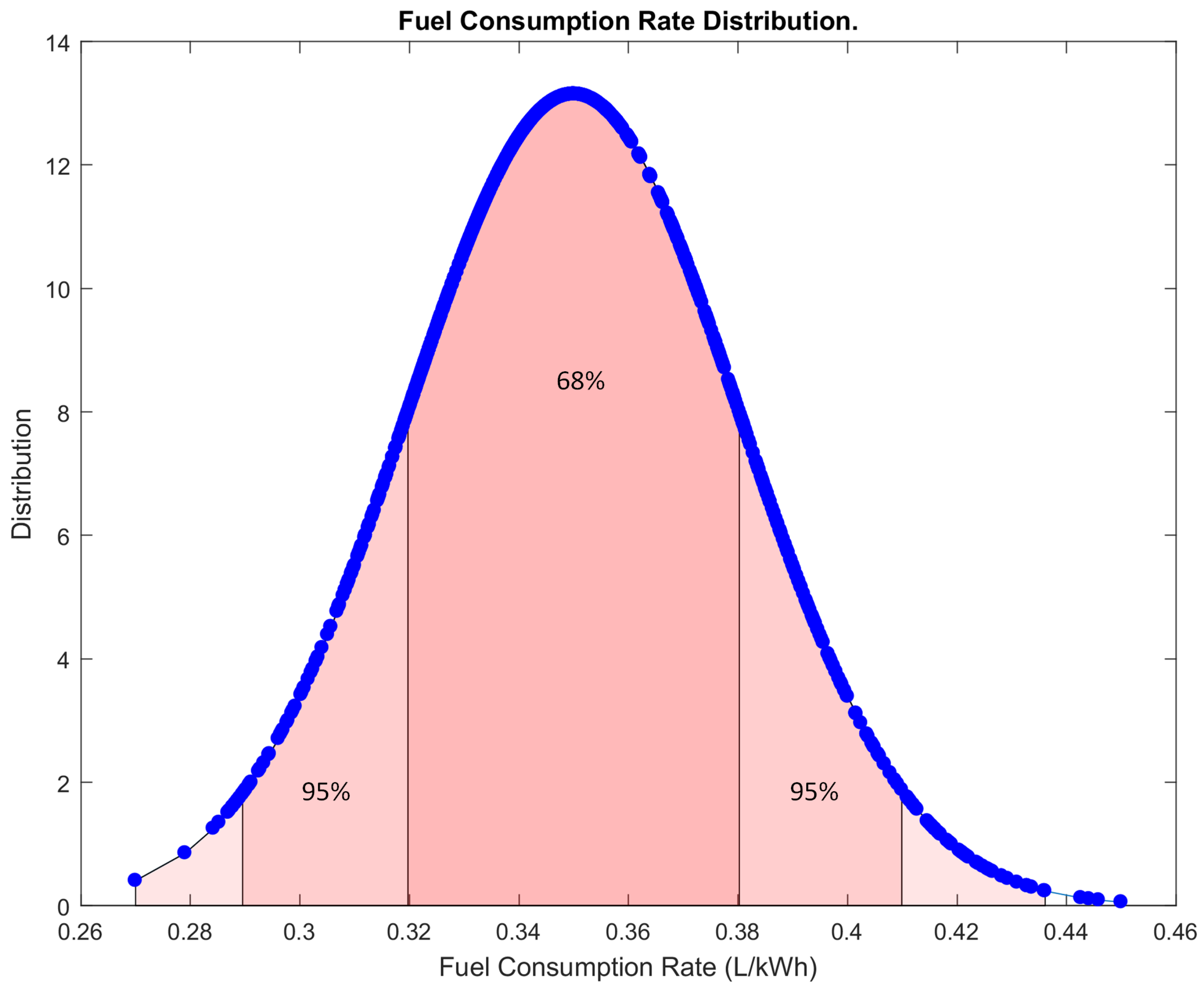

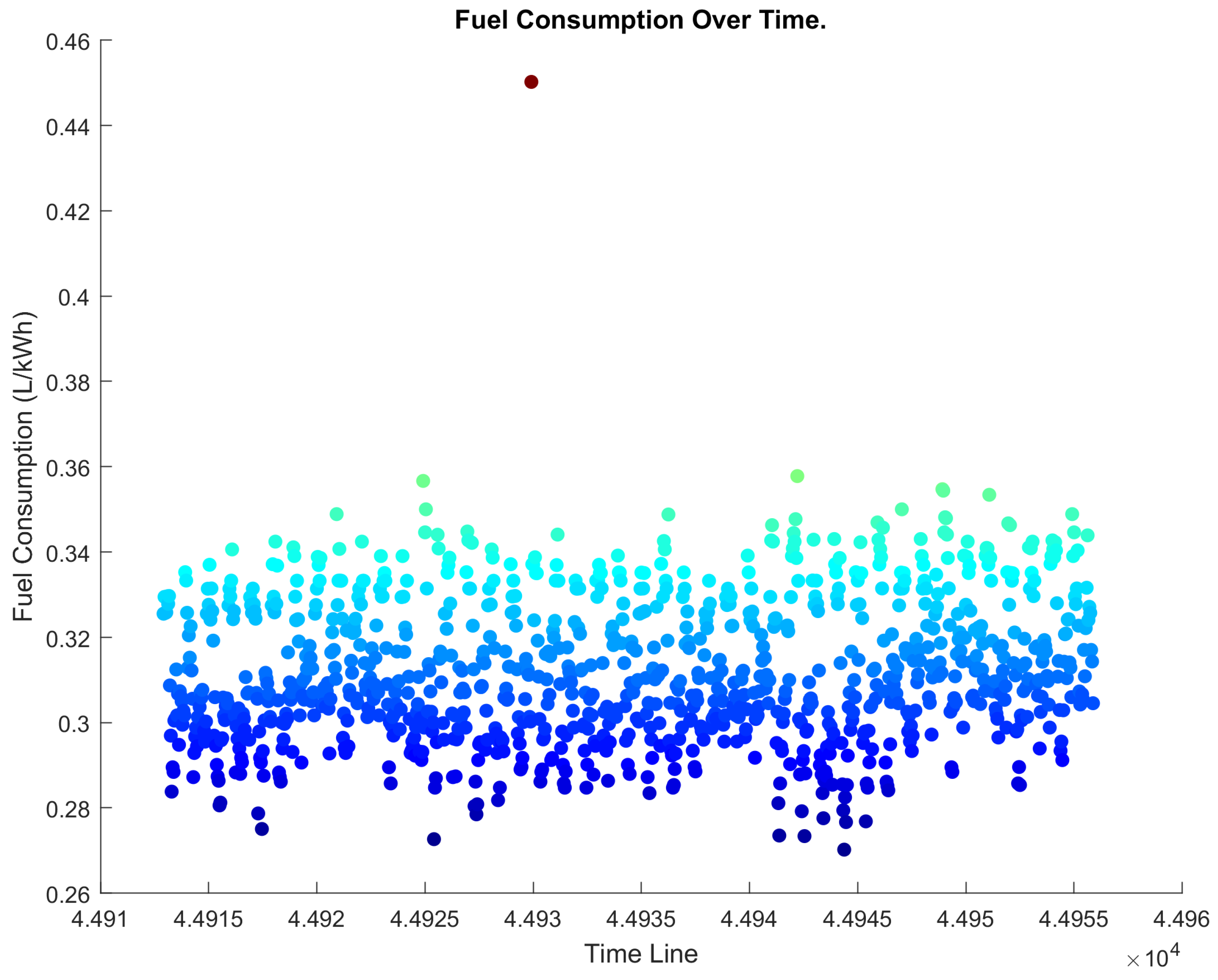

- Collect data on fuel consumption (measured in L/kWH) from the CAT genset using the IIoT system;

- Clean and preprocess the data to ensure accuracy and consistency;

- Use statistical analysis methods such as regression analysis to identify patterns and relationships in the data;

- Use machine learning algorithms such as decision trees and random forests to model the data and predict fuel consumption;

- Compare the predicted fuel consumption to actual fuel consumption to evaluate the accuracy of the model;

- Use the model to identify potential areas for improvement in terms of fuel savings and predictive maintenance;

- Implement changes and continue to monitor fuel consumption to track the effectiveness of these improvements;

- Repeat the analysis process periodically to adapt to any changes in the system and to continue to optimize fuel savings and predictive maintenance.

6. AI Model

6.1. Decision Trees

6.2. Random Forests

6.3. Gradient Boosting Machines

6.4. Best Algorithm Selection

6.5. ML.Net

6.5.1. Testing and Validation of AI/ML Methods with ML.Net

6.5.2. Data Splitting

6.5.3. Model Evaluation Metrics

6.5.4. Cross Validation

6.5.5. Algorithm Selection and Hyperparameter Tuning

6.5.6. Model Validation

7. Results

7.1. Fuel Consumption Rate

7.2. Engine Parameters

7.3. Future Research Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- WCED; Special Working Session. World commission on environment and development. Our Common Future 1987, 17, 1–91. [Google Scholar]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Cazañas-Gordón, A.; Parra-Mora, E. The Internet of Things in Healthcare. An Overview. Lat.-Am. J. Comput. 2020, 7, 86–99. [Google Scholar]

- Ali, Z.H.; Ali, H.A.; Badawy, M.M. Internet of Things (IoT): Definitions, challenges and recent research directions. Int. J. Comput. Appl. 2015, 128, 37–47. [Google Scholar]

- Singh, P.; Elmi, Z.; Meriga, V.K.; Pasha, J.; Dulebenets, M.A. Internet of Things for sustainable railway transportation: Past, present, and future. Clean. Logist. Supply Chain 2022, 4, 100065. [Google Scholar] [CrossRef]

- Singh, P.; Elmi, Z.; Lau, Y.y.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Blockchain and AI technology convergence: Applications in transportation systems. Veh. Commun. 2022, 38, 100521. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, C. An online-learning-based evolutionary many-objective algorithm. Inf. Sci. 2020, 509, 1–21. [Google Scholar] [CrossRef]

- Dulebenets, M.A. An Adaptive Polyploid Memetic Algorithm for scheduling trucks at a cross-docking terminal. Inf. Sci. 2021, 565, 390–421. [Google Scholar] [CrossRef]

- Kavoosi, M.; Dulebenets, M.A.; Abioye, O.; Pasha, J.; Theophilus, O.; Wang, H.; Kampmann, R.; Mikijeljević, M. Berth scheduling at marine container terminals: A universal island-based metaheuristic approach. Marit. Bus. Rev. 2019, 5, 30–66. [Google Scholar] [CrossRef]

- Pasha, J.; Nwodu, A.L.; Fathollahi-Fard, A.M.; Tian, G.; Li, Z.; Wang, H.; Dulebenets, M.A. Exact and metaheuristic algorithms for the vehicle routing problem with a factory-in-a-box in multi-objective settings. Adv. Eng. Inform. 2022, 52, 101623. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Fazlollahtabar, H.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Preventive maintenance for the flexible flowshop scheduling under uncertainty: A waste-to-energy system. Environ. Sci. Pollut. Res. 2021, 14, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Rabbani, M.; Oladzad-Abbasabady, N.; Akbarian-Saravi, N. Ambulance routing in disaster response considering variable patient condition: NSGA-II and MOPSO algorithms. J. Ind. Manag. Optim. 2022, 18, 1035–1062. [Google Scholar] [CrossRef]

- Garralaga Rojas, E.; Sadri, H.; Krueger, W. Case study of MW-sized power generation at St. Eustatius island combining photovoltaics, battery storage, and gensets. Prog. Photovoltaics Res. Appl. 2020, 28, 562–568. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Oszczypała, M.; Małachowski, J.; Szkutnik-Rogoż, J. Use of artificial neural networks to predict fuel consumption on the basis of technical parameters of vehicles. Energies 2021, 14, 2639. [Google Scholar] [CrossRef]

- Sharma, P. Gene expression programming-based model prediction of performance and emission characteristics of a diesel engine fueled with linseed oil biodiesel/diesel blends: An artificial intelligence approach. Energy Sour. Part A Recover. Util. Environ. Eff. 2020, 12, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Jia, M.; Han, X.; Bai, X.S. Towards a comprehensive optimization of engine efficiency and emissions by coupling artificial neural network (ANN) with genetic algorithm (GA). Energy 2021, 225, 120331. [Google Scholar] [CrossRef]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive maintenance in the automotive sector: A literature review. Math. Comput. Appl. 2022, 27, 2. [Google Scholar] [CrossRef]

- Thakur, V.; Mogha, A. IIOT in Utility Operations Paper. In ISUW 2021, Proceedings of the 7th International Conference and Exhibition on Smart Energy and Smart Mobility for Smart Cities; Springer: Singapore, 2022; pp. 45–59. [Google Scholar]

- Björklöf, C.; Castro, D.A. Implementation of Industrial Internet of Things to improve Overall Equipment Effectiveness. Master’s Thesis, Mälardalen University, Västerås, Sweden, 2022. [Google Scholar]

- Kalsoom, T.; Ahmed, S.; Rafi-ul Shan, P.M.; Azmat, M.; Akhtar, P.; Pervez, Z.; Imran, M.A.; Ur-Rehman, M. Impact of IOT on Manufacturing Industry 4.0: A new triangular systematic review. Sustainability 2021, 13, 12506. [Google Scholar] [CrossRef]

- Sasikumar, A.; Ravi, L.; Kotecha, K.; Saini, J.R.; Varadarajan, V.; Subramaniyaswamy, V. Sustainable Smart Industry: A Secure and Energy Efficient Consensus Mechanism for Artificial Intelligence Enabled Industrial Internet of Things. Comput. Intell. Neurosci. 2022, 2022, 1419360. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Paiva, A.R.; Gurciullo, C.S. Advancing from predictive maintenance to intelligent maintenance with ai and iiot. arXiv 2020, arXiv:2009.00351. [Google Scholar]

- Ramesh, P.; Dutta, S.J.; Neog, S.S.; Baishya, P.; Bezbaruah, I. Implementation of predictive maintenance systems in remotely located process plants under industry 4.0 scenario. Adv. Rams Eng. 2020, 293–326. [Google Scholar] [CrossRef]

- Katreddi, S.; Kasani, S.; Thiruvengadam, A. A Review of Applications of Artificial Intelligence in Heavy Duty Trucks. Energies 2022, 15, 7457. [Google Scholar] [CrossRef]

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; Elger, G. Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliab. Eng. Syst. Saf. 2021, 215, 107864. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On predictive maintenance in industry 4.0: Overview, models, and challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Fu, J.; Yang, R.; Li, X.; Sun, X.; Li, Y.; Liu, Z.; Zhang, Y.; Sunden, B. Application of artificial neural network to forecast engine performance and emissions of a spark ignition engine. Appl. Therm. Eng. 2022, 201, 117749. [Google Scholar] [CrossRef]

- Castresana, J.; Gabina, G.; Martin, L.; Uriondo, Z. Comparative performance and emissions assessments of a single-cylinder diesel engine using artificial neural network and thermodynamic simulation. Appl. Therm. Eng. 2021, 185, 116343. [Google Scholar] [CrossRef]

- Ahmad, T.; Chen, H.; Shah, W.A. Effective bulk energy consumption control and management for power utilities using artificial intelligence techniques under conventional and renewable energy resources. Int. J. Electr. Power Energy Syst. 2019, 109, 242–258. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allahloh, A.S.; Sarfraz, M.; Ghaleb, A.M.; Al-Shamma’a, A.A.; Hussein Farh, H.M.; Al-Shaalan, A.M. Revolutionizing IC Genset Operations with IIoT and AI: A Study on Fuel Savings and Predictive Maintenance. Sustainability 2023, 15, 8808. https://doi.org/10.3390/su15118808

Allahloh AS, Sarfraz M, Ghaleb AM, Al-Shamma’a AA, Hussein Farh HM, Al-Shaalan AM. Revolutionizing IC Genset Operations with IIoT and AI: A Study on Fuel Savings and Predictive Maintenance. Sustainability. 2023; 15(11):8808. https://doi.org/10.3390/su15118808

Chicago/Turabian StyleAllahloh, Ali S., Mohammad Sarfraz, Atef M. Ghaleb, Abdullrahman A. Al-Shamma’a, Hassan M. Hussein Farh, and Abdullah M. Al-Shaalan. 2023. "Revolutionizing IC Genset Operations with IIoT and AI: A Study on Fuel Savings and Predictive Maintenance" Sustainability 15, no. 11: 8808. https://doi.org/10.3390/su15118808

APA StyleAllahloh, A. S., Sarfraz, M., Ghaleb, A. M., Al-Shamma’a, A. A., Hussein Farh, H. M., & Al-Shaalan, A. M. (2023). Revolutionizing IC Genset Operations with IIoT and AI: A Study on Fuel Savings and Predictive Maintenance. Sustainability, 15(11), 8808. https://doi.org/10.3390/su15118808