1. Introduction

The term “geosynthetics” is normally used to imply synthetic products for geotechnical purposes, for example, prefabricated vertical drains (PVDs) are used widely nowadays for accelerating soil consolidation, while geogrids are commonly used to reinforce soil structures such as retaining walls and foundations [

1,

2,

3]. The majority of geosynthetics are made from synthetic (artificial) polymers such as PVCs, PE, PP, etc., which are sub-products of the petroleum industry. For example, PP (polypropylene), which is the second-most widely produced plastic and is commonly used for geogrids and cores of PVDs, is made by polymerization of propylene extracted from petroleum. Despite an increasing role of these materials in the development of infrastructures, they are now seen as a considerable factor causing deteriorations to our sustainable living and natural environment. Firstly, the wider use of fossil-based materials means more exploration of oil and thus the associated oil processing industry that leads to a huge emission of greenhouse gases (i.e., approximately 40% of the total greenhouse gases from production of rubber and cement, according to [

4]). Secondly, most geosynthetics take a long time, e.g., several hundreds of years, to decompose. Further, once they are decomposed, they generate nano- and micro-plastics which can cause serious disturbances to the ecosystem and also pose significant risks to human health [

5]. Plastic wastes including geosynthetics have thus been listed as one of the most serious issues that the human race is facing in the 21st century.

The use of green materials and technologies has received greater attention in recent decades across various engineering sectors including geotechnical matters. Many sustainable approaches such as using recycled and biodegradable materials for ground improvement have been investigated extensively in recent years with considerable outcomes that have successfully been transferred into practice [

6]. Among those, natural fibres such as jute and coconuts have shown their unique and excellent engineering characteristics that can be used effectively to not only improve soil conditions but also to bring immense benefits to the natural environment. For example, coir (coconut fibre), which is abundant in many countries, especially Southeast Asia, has a large content of lignin (35–45%), making these fibres resist biodegradation very well [

7,

8]. The tensile strengths of jute and coconut fibres are relatively high (i.e., 100 to 860 MPa), which enable them to be highly valuable in enhancing soil resistance to tension-induced failures such as cracks and liquefaction. In addition, there are various natural fibres that can be employed for geotechnical purposes; they are listed in

Table 1 with their major biochemical and engineering features.

Although past studies [

9,

13,

14,

15] have provided reviews on the engineering applications of natural fibres, there is still a lack of thorough assessment on the use of natural fibres for multiple contexts of geotechnical engineering. In fact, previous review papers only look into specific applications such as soil reinforcement [

13,

14], soil consolidation [

16], erosion and filtration [

17,

18], while none of them have assessed the role of natural fibres in a wider context with their multiple functions. For example, when functioning as an erosion controller, natural fibres can also contribute significantly to reinforcing soil, which requires a more thorough consideration of multiple aspects of how natural fibres can influence the applied soil environment. Further, many past investigations heavily concentrate on biochemical, physical and manufacturing properties such as the size and sources of natural fibres, but the mechanism and real applications in geotechnical engineering have not received proper attention. This paper is hence developed to overcome those limitations by giving a critical review into the existing findings and applications of natural fibres in broader geotechnical contexts. Specifically, three major distinct applications are addressed in this paper, while noting that they can be combined or co-exist for multiple purposes, i.e.:

- (i)

Reinforcement of soil fabric for enhanced shear resistance and stability,

- (ii)

Acceleration of drainage for soil consolidation;

- (iii)

Erosion/filtration controls with vegetation promotion.

The key concept and mechanism of the above well-recognized applications in geotechnical practices will be presented, followed by successful laboratory and field studies. It is also important to emphasise that while natural fibres can significantly improve drainage capacity, it is not considered as an independent application as it normally serves as a facilitating factor to the genuine purposes such as soil consolidation and erosion controls. Combinations of natural fibres with other soil stabilization techniques such as lime and cement are not also covered in this paper due to their overly broad scope [

19,

20]. Major challenges that are currently hampering this approach from wider success will also be discussed in this paper for future research consideration.

2. Reinforcement of Soil for Enhanced Shear Resistance and Stability

2.1. Concepts and Mechanism

Natural fibres can be used to enhance the stability of soil via reinforcement and/or drainage effects.

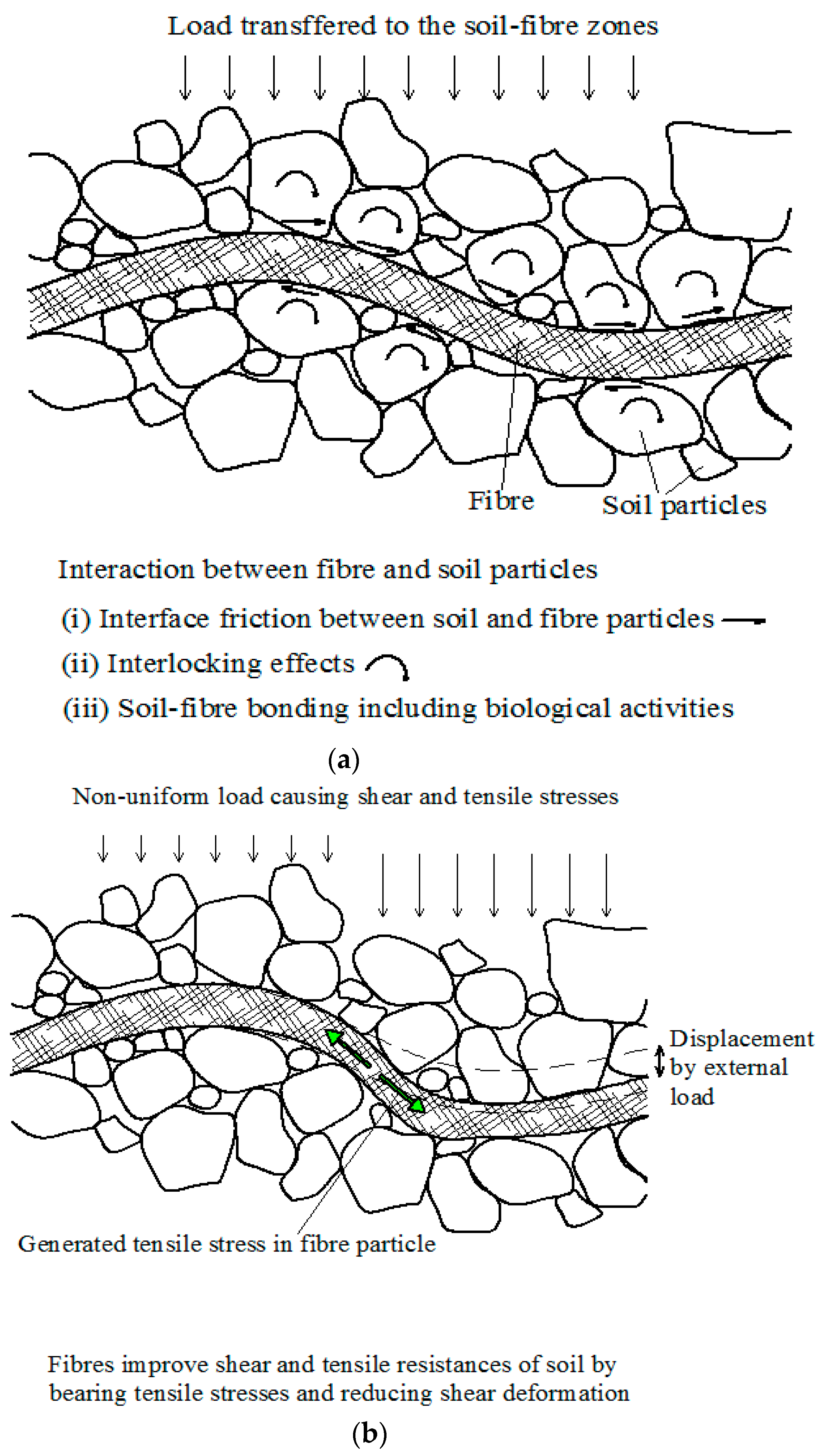

Figure 1 represents the principal concept of this application, where fibres are combined with soil elements to form a new soil–fibre composite for greater shear strength and tensile resistance. In this application, fibres alter soil structure (fabric) so that the external load will be borne by both soil skeleton and fibre networks. There are three major positive effects that natural fibres can bring to the soil matrix, i.e.:

- (i)

Enhancing internal friction by adding soil–fibre interlocking and interface resistance (

Figure 1a);

- (ii)

Bearing tensile stress while reducing the load distribution to the soil skeleton, thereby mitigating soil deformation under non-uniform loading such as earthquakes and transportation (

Figure 1b);

- (iii)

Generating biological bonding (via microorganism activities) between soil and fibre elements in the long run (both

Figure 1a,b).

In the mechanism (i), the inclusion of fibre elements can significantly prevent soil particles from displacement under loading, thus reducing soil deformation and promoting its bearing capacity. Furthermore, as soil is normally a composite of individual particles with relatively poor tensile resistance, natural fibres with significantly larger tensile strength can compensate for this weakness of soil.

Figure 1b demonstrates an example where the tensile zone near the ground surface induced by cyclic traffic loads (e.g., heavy trains) can be reinforced effectively by the inclusion of fibres. The tensile stresses are likely to be transferred and borne by fibres, thereby reducing their distribution to soil particles as well as tension-induced failures such as cracks and liquefaction, which is similar to other synthetic fibre (e.g., polypropylene)-reinforced soils [

21]. In the long run, organic bonding between soil and natural fibres can be established due to the metabolism of microorganisms around soil–fibre zones that further strengthen soil–fibre matrix.

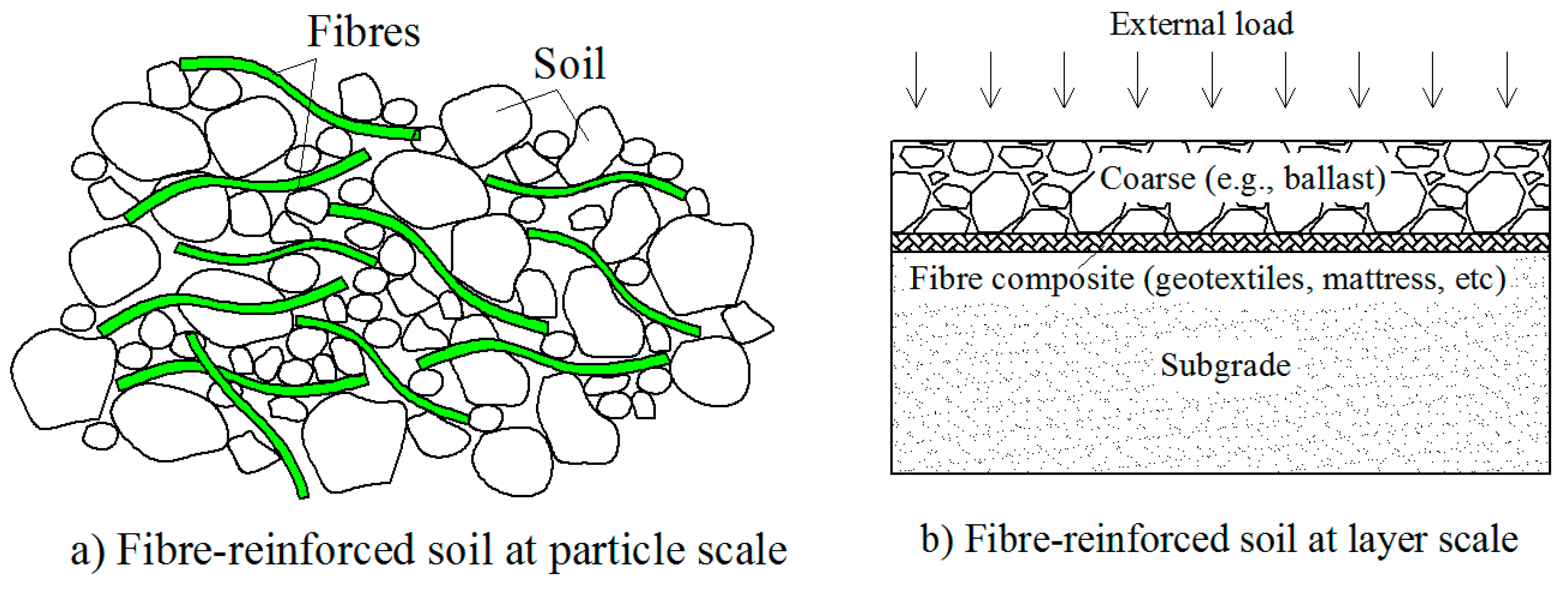

It is important to note that there are basically two different ways to reinforce the soil foundation using fibres. The initial task is mixing individual fibres with soil particles to form a new soil–fibre matrix, and second is separately placing layers of fibre composites such as geotextiles, meshes and mattresses to improve performance of the entire foundation (

Figure 2). In the first of these two approaches, fibre and soil elements work together at a particle scale to resist loading, whereas the second context is where fibre and soil layers are often separated and resist loading individually at a layer scale. For example, the vertical loads induced by trains propagate over the depth of the track foundation, and they are borne by different layers, e.g., subgrade and jute/coir geotextiles. In addition to load bearing, the fibres in the second case usually act as filters for separation and erosion controls, which will be elucidated later in this paper.

2.2. Successful Research Findings and Field Applications

Natural fibres have been used to reinforce soils since ancient times; for example, rice straws were commonly mixed with clay soil for foundation and walls of buildings thousands of years ago in Asian countries such as China, India and Vietnam, among others. However, considerable investigations were only documented around 100 years ago, and most of them were mainly carried out in laboratory and pilot field scales. One of the very first applications of natural fibres for geotechnical purposes was using cotton fibres to reinforce road foundations [

22]. On the other hand, jute burlaps were employed for road subgrade in Dundee (UK) in the 1920s [

23]. While there might have been applications in practice since then, the attention to using natural fibres for soil stabilization has truly happened in the recent 2 decades. The following are common issues that have received great efforts:

- (i)

How can fibre help improve engineering characteristics of soil, including shear strength, tensile strength, bearing capacity, internal erosion, filtration capacity, stability and liquefaction resistance?

- (ii)

What is the optimum fibre content?

- (iii)

How can fibre be combined with other techniques such as lime, cement and polymer synthetics to enhance soil stabilization?

- (iv)

How does treated soil fibre behave with enhanced durability?

Extensive laboratory tests have been carried out in the past decade to clarify the above questions; however, only representative investigations, which address different aspects of fibre-reinforced soils, are included in this paper (

Table 2). Basically, most studies agree well that the inclusion of natural fibres can improve engineering features of soil significantly, especially shear and tensile strengths. For example, Wang et al. (2019) [

20] used large-scale triaxial tests to examine shear strength of (wheat) straw fibre-reinforced clayey soil. They found that when 0.4% by mass of straw fibres was added, the cohesion and friction angle of soil increased by 13% and 17%, respectively, resulting in about a 38% increase in shear strength. Sujatha et al. [

24] adopted an unconfined compression strength test (UCS) to investigate the influence of coconut fibres on a highly compressive clay. The results showed that the shear strength increased by 51% when 0.75% by mass of fibres was used. In the failure mechanism, they found that the size of cracks under shearing decreased significantly as fibres took the majority of tensile stresses. Quantitatively, Tran et al. (2019) [

25] reported a 52.5% improvement in tensile strength, while Paul and Sarkar (2022) [

17] showed a 23.71% increase in CBR values when the optimum fibre content was used.

In addition to those fibres which are intendedly mixed with soil, the use of tree roots via vegetation can be classified into soil reinforcement using natural fibres [

27,

30]. This is because of the similar structure and mechanism that tree roots can create and work with soil under loading, for example, they are usually long and thin elements with high tensile strength. The major difference between tree roots and normal fibres is the generation of suction by trees that will significantly influence the total matrix suction of soil and improve soil–root fibre bonding. Because of this distinct mechanism, this paper does not further describe tree-root-reinforced soil, however, more details can be found in previous studies in this regard [

31]. Also, the combination of fibre with other soil stabilization methods such as lime, cement and biopolymers has received greater attention as it can significantly improve the limitations of the conventional methods such as low tensile strength and brittleness [

25,

32].

3. Enhance Drainage for Soil Consolidation

3.1. Concepts and Mechanism

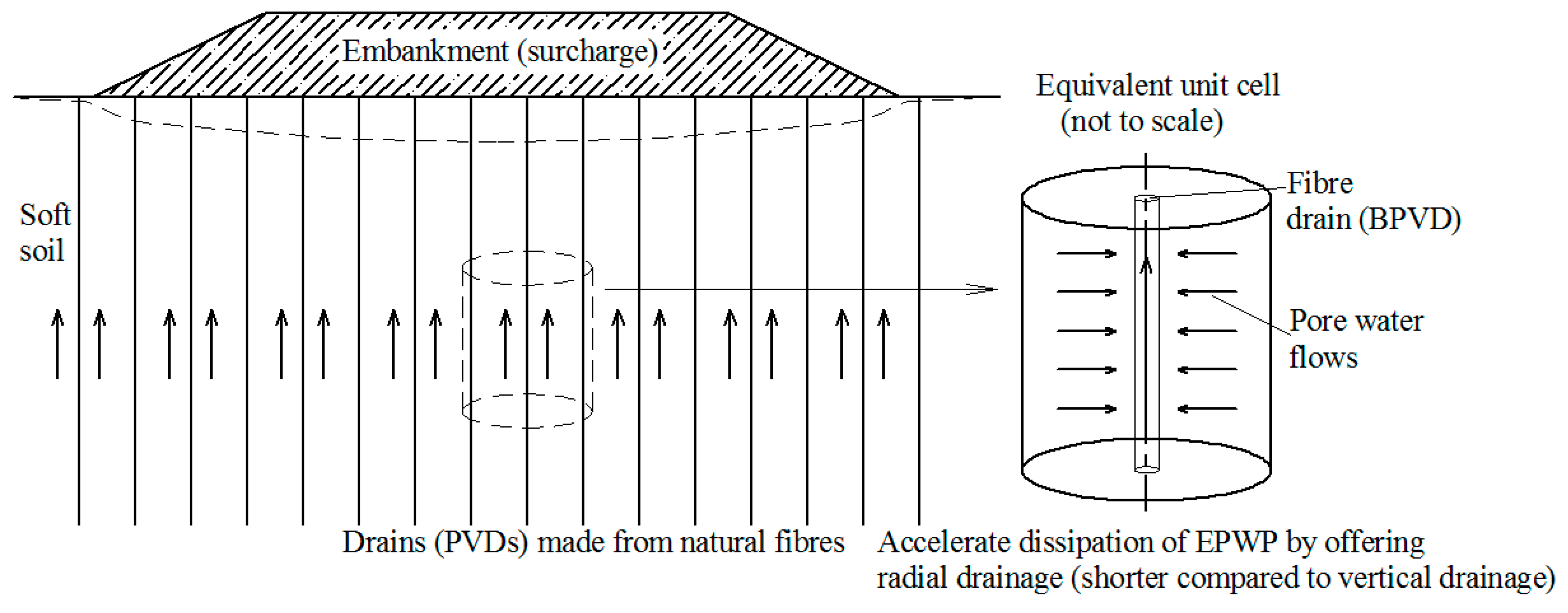

A composite of natural fibres such as fibre bundles and bands can have a significantly large porosity with relatively strong resistance to compression, making them effectively deliver pore water [

33,

34]. This is why the use of natural fibres to create fibre drains (also known as biodegradable BPVDs) has attracted significant interest with considerable success in practice. In this application, fibre drains are driven into the soft soil, similarly to the conventional polymeric PVDs, by which the built-up excess pore water pressure (EPWP) induced by external loads can dissipate through the radial flows to the drain (

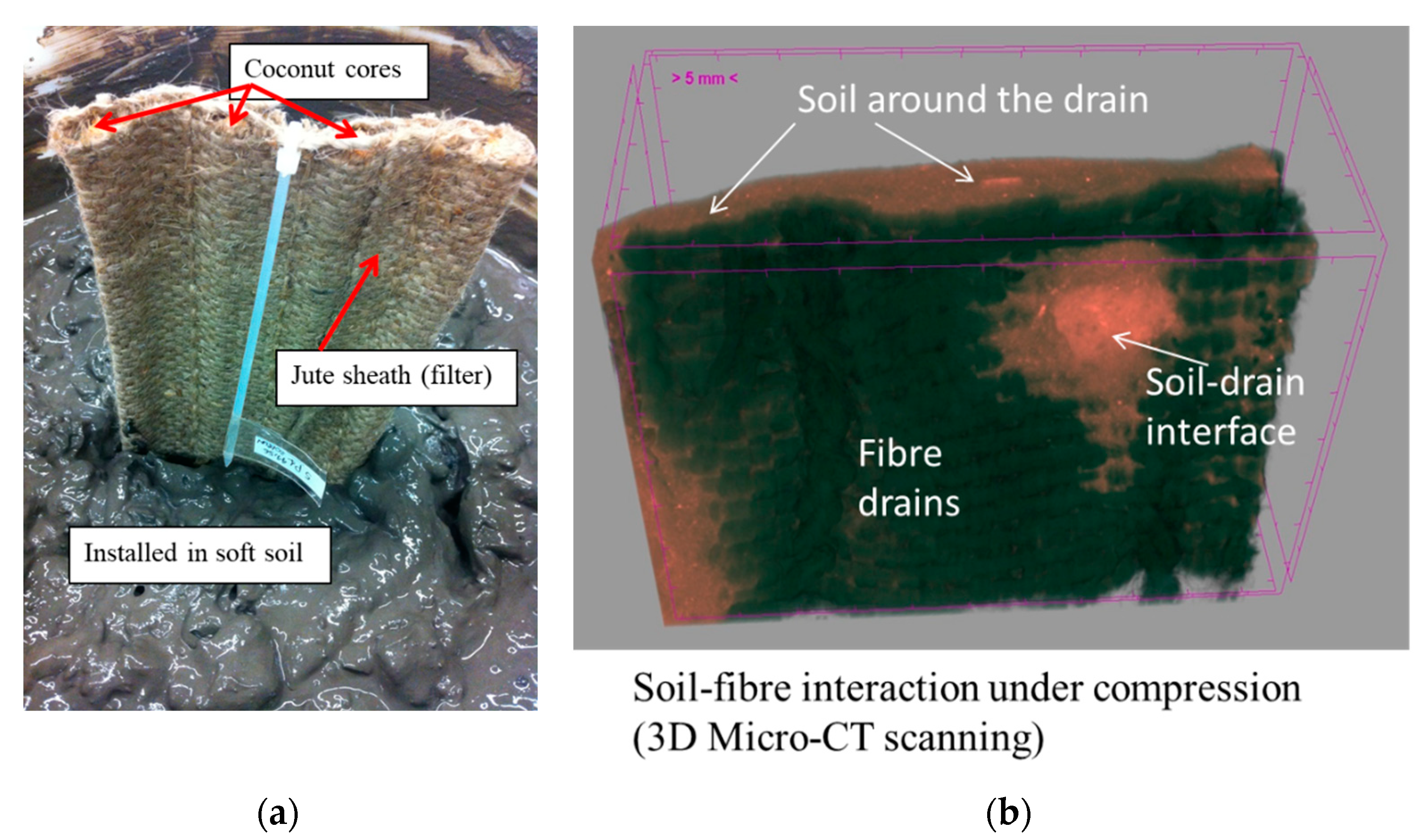

Figure 3). A typical fibre drain usually includes several stiff fibre cores such as coconut strands that help form and maintain the shape (normally band or circle) of the drain. These cores are then wrapped by a layer of fibre geotextiles such as a jute sheath which functions as a filter preventing soil clogging (

Figure 4a). Previous studies [

35,

36] have proved that fibre drains can resist soil clogging very well due to their intra-bundle pores that can remain under confinement very well. Compared to polymer PPVDs, fibre drains can have excellent discharge capacity (>6 × 10

−6 m

3/s) and adequate tensile strength (>1.5 kN) for field installation. Further, fibre drains are found to be more flexible, which makes them perform very well even under high degrees of displacement (i.e., thus no issue with bending and kinking).

3.2. Successful Research Findings and Field Applications

3.2.1. Laboratory Studies

Many laboratory tests have been carried out since the first study of fibre drains in 1987 by Le et al. [

37]. Basically, there are four different aspects of fibre drains that have been investigated in the past 3 decades, and they are:

- (i)

Discharge capacity;

- (ii)

Soil consolidation in a unit cell;

- (iii)

The interaction between soil and fibre (clogging and infiltration);

- (iv)

Biodegradation of fibre drains (BPVDs).

Most previous investigations agreed that the fibre drains have sufficient discharge capacity, even in extreme bending and kinking conditions. For example, Nguyen et al. (2018) [

8] by carrying out unit-cell discharge capacity tests at various compression degrees reported a discharge capacity for jute fibre drains of about 6 × 10

−6 m

3/s, which is in a similar range (i.e., 2–14 × 10

−6 m

3/s for a confining pressure up to 200 kPa) to that given by Asha and Mandal (2012) [

33] using in-plane compression tests. In comparison with polymeric PPVDs, these values are smaller, but can certainly satisfy the requirement for accelerating soil consolidation [

36]. In order to examine the performance of fibre drains when being installed in soft soil, utilising unit-cell apparatus where the drain is positioned in the middle of the soil under varying confining pressures is commonly adopted. Jang et al. (2001) [

36] carried out cylindrical consolidation tests to compare the consolidation behaviour of soft soil treated by band-shaped PPVDs and natural fibre drains (both band- and circle-shaped). They proved the similar performance of these two types of PVDs; however, when subjected to higher confining pressure (e.g., 250 kPa), natural fibre drains became more effective as they were less affected by deformation and compression.

Unlike conventional synthetic PPVDs, BPDVs are made by the combination of individual fibres in a specific structure, and, as a result, soil clogging induced by soil infiltration through the fibre geotextiles (e.g., jute sheath) under confinement has received significant concern. Fine particles such as silt and clay are relatively smaller compared to the normal opening size (e.g., 0.075 to 0.2 mm) of the jute filter, and they can penetrate the porous system and significantly reduce the hydraulic conductivity (thus discharge capacity) of fibre drains. Several efforts have been made to clarify this issue, for instance, Nguyen and Indraratna (2019) [

35] compressed clay soil and a jute drain under different pressures (i.e., up to 200 kPa) and used Micro-CT scanning to examine the clogging behaviour.

Figure 4b shows an example of how soil clogging into jute fibre drains can be captured by Micro-CT scanning (data obtained by the current Authors). The results indicated that, despite the penetration of the soil, the porosity of the entire drain can resist against the ingression of fine soil particles well, i.e., approximately 76% of the initial porosity before soil clogging. The major reasons were that (i) the used soil (i.e., Ballina high-plasticity clay) had very high viscosity, preventing them from deep penetration; and (ii) the complex twisted structure of fibre bundles could resist particle migration very well, thereby making the intra-bundle porosity (i.e., internal pores of bundles) almost unchanged. It is important to note that soil penetration mainly occurs at the initial stages of soil consolidation due to the large degree of EPWP, and it becomes stable when EPWP dissipates considerably. Asha and Mandal (2015) [

38] also investigated the performance of different fibre drains (woven and nonwoven jute geotextiles) confined by a marine clay; the results confirmed the insignificant influence of soil clogging on consolidation behaviour.

The major unique feature that makes fibre drains advantageous over polymeric PPVDs is their biodegradability. As they are made from natural fibres, they can decompose biologically over time, i.e., forming organic components of the treated soil. However, this feature can also cause an adverse impact on soil consolidation when the fibre drains decay too fast. For example, most clayey soils take more than 1 year to reach 90 to 95% of the required consolidation degree, but if the fibre drains decay earlier when subjected to adverse environmental factors, it will result in insufficient discharge capacity of the fibre drain for soil consolidation, causing considerable residual EPWP. There are very limited efforts in this regard up to date, probably due to the complexity in capturing microorganism activities in the geotechnical investigations. One of the significant attempts that has been made recently was the use of genomic analysis techniques to identify bacteria in the decayed jute fibres installed in saturated soft soil [

8]. Although this investigation has successfully detected several cellulose-degrading strains such as species of the genera Clostridium and Bacillus which can accelerate the biodegradation of natural fibres, most other studies including laboratory and field investigations often do not find any significant impact of biodegradation on the consolidation behaviour.

3.2.2. Field Investigations and Implications

Field applications have been carried out across many countries around the world, including pilot tests to real projects, and some well-known projects are summarized in

Table 3.

One of the very first installations of natural fibre drains was in Southeast Asia, including Indonesia and Malaysia, around the 1980s [

40]. For example, fibre drains were used for soil reclamation in the Pluit area of Jakarta (Indonesia) in 1987, where the observation for 2 years showed the effective function of the fibre drains. Other field installations in Malaysia and Singapore clays also reported the same rate of consolidation induced by fibre drains and synthetic PPVDs [

16,

39]. In Japan, fibre drains have also been used for soil consolidation more than 3 decades, for example, they were used successfully in Ariake and Hiroshima clays [

41,

44]. Their further examination into kinking indicated almost no significant issue with fibre drains, whereas the synthetic PPVDs experienced serious kinking that reduced the discharge capacity significantly. In addition, pilot tests with detailed instrumentations have also been carried out to enhance understanding based on reliable field data. Kim and Cho (2008) [

42] installed fibre drains made from straw and jute fibres in comparison with PPVDs. While the measurement showed a significant drop in discharge capacity of the drains in the early stages, there was no significant difference in the settlement induced by fibre drains and PPVDs.

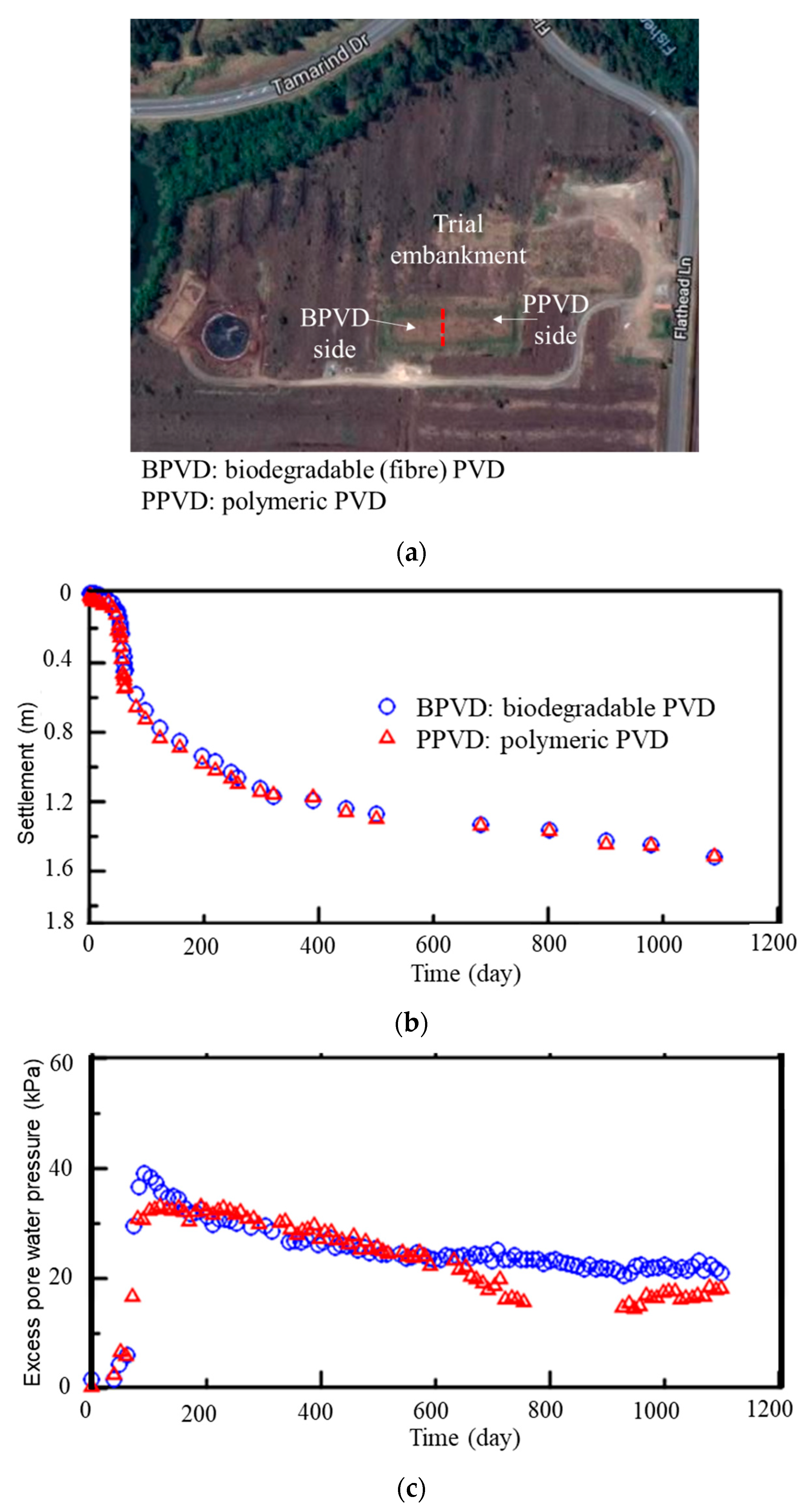

In Australia, a comprehensive embankment test, where jute fibre drains were installed in parallel to synthetic PPVDs in Ballina clay (see

Figure 5a), was carried out in 2013 to 2016 [

43]. The two types of drains were used under the same condition, including the installation method (e.g., same mandrel), penetration depth and soil properties. The monitoring of data during a period of 3 years shows almost the same settlement, EPWP and lateral deformation between the two sites treated by PPVDs and BPVDs. For example,

Figure 5b shows that both soils treated by BPVDs and PPVDs experience almost the same behaviour including primary and secondary consolidation (after 800 days). The largest settlement was recorded at around 1.6 m after 3 years, given approximately 12 m thick clay (including 10 m Holocene silt clay). On the other hand, the excess pore pressure was almost identical and only became different after 650 days, which was probably due to a clogging issue that often affects the performance of piezometers at the end of embankment tests. In short, this pilot test, in agreement with previous site studies, again confirmed the high confidence in using natural fibre drains to accelerate soil consolidation.

4. Natural Fibre Composites for Erosion/Filtration Controls

4.1. Concepts and Mechanism

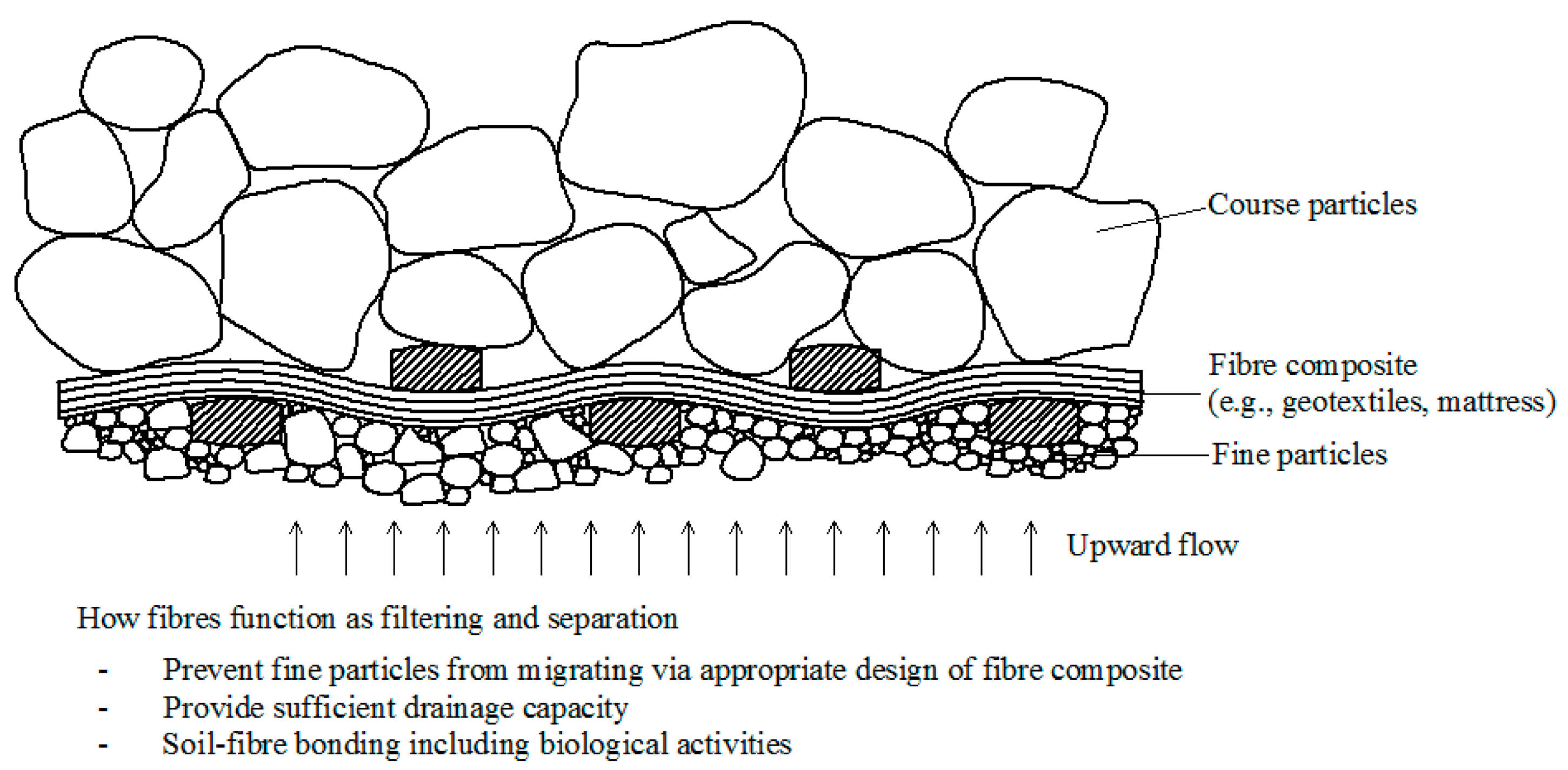

Making geotextiles, mattresses and other composites (also termed as geocomposites) for separation, filtration and erosion controls in soil foundation, slopes and retaining walls can be considered as the most common and successful applications of natural fibres in geotechnical contexts. Generally, natural fibres are used to form in-plane composites such as textiles and mattresses which have appropriate drainage and filtering capabilities to prevent migrations of soil particles.

Figure 6 presents the mechanism of how a fibre composite with proper design of opening size and fabric can prevent soil particles from migrating upward, while maintaining adequate drainage capacity. Different geomaterials/layers of foundation can be separated effectively by an intermediate layer of fibres, whereas fine particles are blocked at the soil–fibre interface, so mitigating internal erosion and/or mud pumping (soil fluidization) [

45]. In addition to these benefits, it is apparent that the existence of fibre composites can significantly improve shear strength and bearing capacity of the entire foundation, similarly to the conventional use of polymeric geogrids and geotextiles to stabilize road foundation.

In slope, embankment and retaining wall contexts, jute and coconut geotextiles/meshes have been used successfully to prevent lateral deformation and collapse. The fibre meshes and nettings provide resistance to the lateral earth pressure, and they also remediate the surface erosion of soils. Furthermore, the fibre meshes are very friendly to the surrounding environment and thus give good support for tree roots to grow that, in turn, enhances slope stability and erosion resistance sustainably.

4.2. Successful Research Findings and Field Applications

Studies on the use of natural fibres for erosion and filtration controls have been carried out extensively in the past decades. Basically, there are four different research aspects are concentrated, for instance:

- (i)

Interactions between soil particles and fibre composite under fluid flows, for example, soil clogging and filter cakes;

- (ii)

Performance of the soil foundation reinforced by fibre geotextiles/mattresses under external loading (e.g., traffic and embankment), for example, investigation into the deformation and bearing capacity of the foundation with and without fibre layers;

- (iii)

Drainage characteristics of fibre composites such as the transverse permeability considering soil clogging and the composite fabric;

- (iv)

Long-term investigations into the bio-interaction between soil and fibres and also the vegetation potential with tree root development.

4.2.1. Laboratory Studies

Various laboratory tests have been carried out to examine the efficiency of fibre composites including geotextiles, nettings and mattresses in filtration and erosion controls. The most common testing model is usually composed of three layers, i.e., (i) the coarse (surface) material such as gravel and ballast, (ii) the fibre composite (e.g., jute and coconut geotextiles) and (iii) the subgrade or subbase/natural soils, which mimics the field structure as demonstrated in

Figure 2b. Loading can either be applied on the surface (i.e., vertical static/cyclic load) or induced by upward seepage flows (hydraulic load) from the bottom to investigate how the fibre layer can prevent soil particles from migrating. Filtering performance of the fibre layer is usually assessed by quantifying the fines that migrate from the subgrade to coarse layers through the fibre filter, i.e., the erosion rate, which is similar to conventional investigations on polymeric geotextiles [

46]. In addition, changes in hydraulic behaviour (permeability and flow rate) and surface settlement are monitored. On the other hand, rainfall simulations on fibre-reinforced slopes can also be carried out in the laboratory to assess soil erosion [

47,

48,

49].

Most past laboratory investigations proved that natural fibre composites are excellent at enhancing filtration as well as mitigating soil erosion, provided there is appropriate fabric design. For example, Asha and Mandal [

50] carried out filtration tests on jute geotextiles having different opening sizes (OS) in contact with a marine clayey soil (approximately 50% clay content). They found that woven jute geotextiles can only retain clay particles effectively with the ratios O

95/D

85 < 4.5 and O

50/D

50 < 100, where O and D denote the opening and particle sizes of jute geotextiles and soil, respectively. Sreedhar et al. [

51] showed that using coir fibre composites can mitigate soil erosion under rainfall up to 92.6%, whereas the higher the slope angle, the larger the erosion rate. Rickson and Loveday [

52] found that jute woven products can provide great support to seedling germination, plant emergence and vegetation growth (>20% cover compared to bare soil).

4.2.2. Field Investigations and Implications

Unlike using natural fibres for accelerating soil consolidation, the use of fibre composites for the combined effects of soil filtration and reinforcement has been practiced widely for years. For example, jute geotextiles have been effectively employed for many different infrastructure projects such as roads, railways, erosion controls for riverbanks and surface soils, slope stabilization, embankments and retaining walls [

53,

54]. In fact, one of the very first applications of jute mesh for slope protection was recorded in the 1930s in the USA [

23], but well-documented studies could only be made in recent decades. Most studies confirmed the efficiency of using natural geotextiles to enhance the filtration capacity and erosion resistance of soil structures.

Figure 7 shows a recent slope stabilization using jute geotextile carried out in Vietnam (2022–2023) combined with vegetation, which has received increasing attention in recent years because of its environmental benefits. In this application, jute geotextiles are nailed to cover the soil surface before a vegetation process with selected appropriate plants (e.g., grasses and bushes) is carried out. The development of plants is well supported by jute geotextiles (e.g., mitigated erosion of surface soil), while the expansion of plant roots in the long run will facilitate the erosion resistance of the slope. This concept of green bioengineering techniques has in fact been practiced with great success for the past decades, especially among tropical and agricultural regions such as Indonesia, Thailand, India, Bangladesh, etc. Lekha (2004) [

55] describes one of the pioneering applications of coir netting combined with vegetation for erosion control in a degraded hilly terrain (Kerala, India). The results proved the substantial reduction of soil loss despite heavy rainfall (i.e., >94% in the projected plots), while the coir netting was found to promote the growth of lemongrass significantly. Furthermore, shear strength of the treated soil increased significantly (>20%), and the negative impact of fibre biodegradation could be diminished as the root systems of grasses could hold and reinforce the soil effectively. The same interaction between natural geotextiles and plants was also observed in other field studies such as Vishnudas et al. (2012) [

56] and Kalibova et al. (2016) [

48]. The efficiency of using natural geotextiles and mattresses in mitigating surface soil erosion is also confirmed through various site investigations, despite different fabrics and fibres used. The reduction rate of soil loss (or erosion rate) is usually found in the range from around 40 to 99%, depending on the soil type, rainfall and characteristics of slopes and fibre composites [

48,

57].

5. Distinct Features of Natural Fibres Compared to Synthetic Fibres

Although natural and synthetic fibres (e.g., polypropylene, polyester and glass, among others) basically share the same mechanisms in stabilizing soil, especially the way that fibrous structures physically interact with soil particles, they have some distinct differences that can be highlighted as follows (

Table 4).

Durability: The first and the most important difference is the considerable variation in durability and service capacity of natural fibres due to their biodegradability. Normally, natural fibrous geoproducts such as coir and jute geotextiles can serve for approximately 3 to 20 years, heavily depending on environmental condition, biochemical characteristics and pretreatment of natural fibres. For example, fibres such as coir or wood fibres with more than 30% lignin content can maintain their engineering properties very well for certainly longer than 10–20 years if there are no harmful microorganisms. Environmental factors such as humidity, oxygen concentration and the exposure to UV can also accelerate bio- and physical degradations significantly. On the other hand, synthetic fibres such as polypropylene and polyester with stable chemical structure are much less vulnerable to environmental conditions, especially the biological factor, making them more durable.

Energy cost for production: Undoubtedly, natural fibres with their origin from nature and agriculture require significantly less energy for production, for example, the average consumption of 4 GJ/ton is estimated for natural fibres compared 120 GJ/ton for carbon fibres [

58]. This implies immense benefits that using natural fibres can bring to the natural environment and climate change as it can save energy by a factor of approximately 30.

Physical/mechanical features: Unlike synthetic fibres, most natural fibres have a significantly smaller elongation at break (e.g., <5% compared to 10 to several hundred percent of polymer elastomers), meaning they have less ductile behaviour. Other physical parameters such as the density, diameter, tensile strength and elastic modulus of both types of fibres are relatively in the same range, except the glass fibres which have larger magnitudes. Also, most natural fibres have significantly larger water absorption due to their high porosity.

Improved shear strength: Both natural and synthetic fibres bring similar effects on shear and filtration behaviours of soil, however, the improvement in shear strength induced by synthetic fibres is often reported at a larger extent. For example, synthetic fibres can increase the UCS value of soil by 150–180% as shown in

Table 4.

6. Current Challenges and Future Studies

Despite the paramount effort, the use of natural fibres for geotechnical purposes is still very limited in the real practice compared to other mass-produced geosynthetics. Key reasons for this can be highlighted as follows:

The first and the most critical issue is the poor manufacturing productivity induced by the complex process of material collections and processing, making them significantly expensive over other synthetic polymer products such as polymeric PVDs, geogrids, polypropylene fibres, etc. For example, the average price per meter length of PPVDs in Australia is about AUD 0.6 (updated in March 2023 from Sydney local suppliers), whereas it would be approximately three to four times more expensive if jute fibre drains (with reference to the information from an Indonesian supply at Sydney Port) were selected.

There is a lack of practical guidelines and standards on the use of natural fibre products for geotechnical designs and construction. More importantly, natural fibres are normally less homogeneous and consistent compared to polymer geosynthetics, making the quality control of input materials during manufacturing complex and variable. For example, most natural fibres such as straw absorb a large amount of water (

Table 1), resulting in a considerable change in their size and engineering properties. There are currently various types of natural fibres as well as different ways to fabricate products for geotechnical purposes, but very few of them are examined and documented based on rigorous investigations and reliable data.

Construction processes are usually complex due to the lack of supporting technologies. While fibre drains and geotextiles have been installed very well in the field, as evidenced through past successful projects (

Table 3), effective methods to mix fibres with soils for subgrade foundations are still under debate.

Durability and biodegradation of natural fibres pose considerable concern over the long-term performance of their green geocomposites. Natural fibres such as jute with around 70% of cellulose (

Table 1) are inevitably decomposed over time when they are exposed to surrounding adverse environments due to physical and biological processes, reducing their engineering features such as permeability and tensile strength. Although pretreatments can be made to improve fibre durability [

63], they can even expand the cost while raising concern with the negative impact from the pretreatment process to the natural environment.

In view of the above, future studies can be designed to improve those challenges with close reference to practical contexts. For example, more studies on novel solutions to enhance the manufacturing process and quality control of natural fibres and their geoproducts should bring significant impacts to their wider applications. Trials and pilot tests at a field scale with well-documented outcomes are further needed to facilitate practice guidelines and confidence. Also, the demand for durable and cost-effective natural fibrous geoproducts is always imperative to make this option more achievable and comparative to the conventional geosynthetics. It is noteworthy that apart from the above common issues, each application might render different challenges to various extents. For example, the manufacture of single fibres for soil reinforcement is often simple by cutting fibres into specific lengths; however, mixing these fibres with soil, especially at deep layers, can be complex in the field. Quality control and assessment with a lack of appropriate guidelines for the industrial scale are also major barriers. On the other hand, the manufacture and use of geotextiles and other composites from natural fibres for filtration, separation and erosion control have gained the most confidence among geotechnical applications of natural fibres. The major challenge of this category is how to further enhance the durability and design method of natural fibre to promote their wider adoption in practice. For the use of natural fibres to enhance drainage and soil consolidation, the crucial question of how deep soil behaves in the long run when natural fibres are fully decomposed to organic contents needs clarifying to promote confidence of practice [

64].

7. Conclusions

This paper has provided an overview of major practical applications of natural fibres in geotechnical engineering including (i) reinforcement, (ii) consolidation and (iii) filtration and erosion controls. Principal concepts and mechanisms were represented, followed by salient laboratory findings and field (practical) successes. In general, natural fibre composites have been proven to offer carbon-friendly green alternatives for conventional geosynthetics (polymeric), promoting both cost-effective and sustainable soil stabilization measures. Apart from being excellent substitutes to attain identical effects on soil reinforcement, consolidation and filtration in comparison to more commonly commercialised polymeric counterparts, these natural fibre products promote biological bonding with the soil media that provides additional soil stability and strengthening characteristics. For example, jute and coir geotextiles can accelerate vegetation effectively with a reduction rate of soil erosion often reported from 40% to 99% based on the soil loss measured through lab and field investigations, while significantly enhancing the tensile resistance and stability of earth structures. Despite the above obvious benefits, the inevitable biodegradation with various types of natural fibre may not be an ideal solution where their long-term service is desired. Moreover, there still exists some challenges such as the variability of properties of natural fibre from one location to another, corresponding adversities in large-scale manufacturing to attain homogeneity of products and, currently, the lack of industry standards or technical guidelines for their use in mega projects. In this regard, greater efforts are still required for improved production quality and boosting the use of natural fibre composites for more versatile geotechnical practices.

Author Contributions

T.T.N.: Conceptualization, Methodology, Investigation, Writing—Original Draft, Formal Analysis, Validation; B.I.: Resources, Methodology, Supervision, Funding acquisition, Writing—Review—Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Transport Research Centre, UTS through internal funding scheme. The APC was funded by the Journal through promotion code.

Data Availability Statement

The data used in the current study are available from the corresponding author upon reasonable request.

Acknowledgments

This research was supported by Transport Research Centre (TRC), University of Technology Sydney and Australian Research Council (ARC-DE230101127). Field data of using jute geotextiles for slope stabilization were provided by FUCONS Jsc.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guo, W.; Chu, J.; Yan, S. Effect of subgrade soil stiffness on the design of geosynthetic tube. Geotext. Geomembr. 2011, 29, 277–284. [Google Scholar] [CrossRef]

- Nguyen, B.-P.; Nguyen, T.T.; Nguyen, T.H.Y.; Tran, T.-D. Performance of Composite PVD-SC Column Foundation under Embankment through Plane-Strain Numerical Analysis. Int. J. Geomech. 2022, 22, 04022155. [Google Scholar] [CrossRef]

- Hung, H.M.; Kuwano, J.; Tachibana, S. Effect of prestress in geogrid on stiffness of confined-reinforced earth. Geosynth. Eng. J. 2015, 30, 31–36. [Google Scholar] [CrossRef]

- Hertwich, E.G. Increased carbon footprint of materials production driven by rise in investments. Nat. Geosci. 2021, 14, 151–155. [Google Scholar] [CrossRef]

- Campanale, C.; Massarelli, C.; Savino, I.; Locaputo, V.; Uricchio, V.F. A Detailed Review Study on Potential Effects of Microplastics and Additives of Concern on Human Health. Int. J. Environ. Res. Public Health 2020, 17, 1212. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Subaida, E.A.; Chandrakaran, S.; Sankar, N. Laboratory performance of unpaved roads reinforced with woven coir geotextiles. Geotext. Geomembr. 2009, 27, 204–210. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B.; Carter, J. Laboratory investigation into biodegradation of jute drains with implications for field behaviour. ASCE J. Geotech. Geoenviron. Eng. 2018, 144, 04018026. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials 2018, 11, 55. [Google Scholar] [CrossRef]

- Bordoloi, S.; Hussain, R.; Garg, A.; Sreedeep, S.; Zhou, W.-H. Infiltration characteristics of natural fiber reinforced soil. Transp. Geotech. 2017, 12, 37–44. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Cruz, A.S.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef]

- Vincenzini, A.; Augarde, C.E.; Gioffrè, M. Experimental characterization of natural fibre–soil interaction: Lessons for earthen construction. Mater. Struct. 2021, 54, 110. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Shalchian, M.M.; Arabani, M. Application of plant-derived fibers in soil reinforcement on experimental, numerical, and case study scales: A review. Bull. Eng. Geol. Environ. 2022, 82, 19. [Google Scholar] [CrossRef]

- Kumar, N.; Kandasami, R.K.; Singh, S. Effective utilization of natural fibres (coir and jute) for sustainable low-volume rural road construction—A critical review. Constr. Build. Mater. 2022, 347, 128606. [Google Scholar] [CrossRef]

- Lee, S.L.; Karunaratne, G.P.; Aziz, M.A. Design and performance of Fibredrain in soil improvement projects. Ground Improv. 2003, 7, 149–156. [Google Scholar] [CrossRef]

- Paul, S.; Sarkar, D. Performance evaluation of natural fiber reinforced Laterite soil for road pavement construction. Mater. Today Proc. 2022, 62, 1246–1251. [Google Scholar] [CrossRef]

- Artidteang, S.; Tanchaisawat, T.; Bergado, D.T.; Chaiyaput, S. Chapter 25—Natural Fibers in Reinforcement and Erosion Control Applications with Limited Life Geosynthetics. In Ground Improvement Case Histories; Indraratna, B., Chu, J., Rujikiatkamjorn, C., Eds.; Butterworth-Heinemann: San Diego, CA, USA, 2015; pp. 717–740. [Google Scholar]

- Lekha, B.M.; Goutham, S.; Shankar, A.U.R. Evaluation of lateritic soil stabilized with Arecanut coir for low volume pavements. Transp. Geotech. 2015, 2, 20–29. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Li, X.; Lin, H.; Liu, Y.; Yuan, H. Behavior of Fiber-Reinforced and Lime-Stabilized Clayey Soil in Triaxial Tests. Appl. Sci. 2019, 9, 900. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Beckham, W.K.; Mills, W.H. Cotton-fabric reinforced roads. Eng. News Rec. 1935, 115, 453–455. [Google Scholar]

- Rao, G.V.; Anuradha, G. Jute fibres for geosynthetics- Stratergies for growth. Indian J. Geosynth. Ground Improv. 2012, 1, 3–10. [Google Scholar]

- Sujatha, E.R.; SaiSree, S.; Prabalini, C.; Farsana, Z.A. Influence of Random Inclusion of Coconut Fibres on the Short term Strength of Highly Compressible Clay. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012056. [Google Scholar] [CrossRef]

- Tran, K.Q.; Satomi, T.; Takahashi, H. Tensile behaviors of natural fiber and cement reinforced soil subjected to direct tensile test. J. Build. Eng. 2019, 24, 100748. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, A.; Jaksa, M. Enhancing mechanical behavior of micaceous soil with jute fibers and lime additives. J. Rock Mech. Geotech. Eng. 2021, 13, 1093–1100. [Google Scholar] [CrossRef]

- Ma’ruf, M.F. Shear strength of Apus bamboo root reinforced soil. Ecol. Eng. 2012, 41, 84–86. [Google Scholar] [CrossRef]

- Moslemi, A.; Tabarsa, A.; Mousavi, S.Y.; Monfared, M.H.A. Shear strength and microstructure characteristics of soil reinforced with lignocellulosic fibers-Sustainable materials for construction. Constr. Build. Mater. 2022, 356, 129246. [Google Scholar] [CrossRef]

- Bu, F.; Liu, J.; Mei, H.; Song, Z.; Wang, Z.; Dai, C.; Qian, W. Cracking behavior of sisal fiber-reinforced clayey soil under wetting-drying cycles. Soil Tillage Res. 2023, 227, 105596. [Google Scholar] [CrossRef]

- Eab, K.H.; Likitlersuang, S.; Takahashi, A. Laboratory and modelling investigation of root-reinforced system for slope stabilization. Soils Found. 2015, 55, 1270–1281. [Google Scholar] [CrossRef]

- Wu, T.H. Root reinforcement of soil: Review of analytical models, test results, and applications to design. Can. Geotech. J. 2013, 50, 259–274. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Asha, B.S.; Mandal, J.N. Absorption and discharge capacity tests on natural prefabricated vertical drains. Geosynth. Int. 2012, 19, 263–271. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B. The permeability of natural fibre drains, capturing their micro-features. Proc. Inst. Civ. Eng. Ground Improv. 2017, 170, 123–136. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B. Micro-CT scanning to examine soil clogging behavior of natural fiber drains. J. Geotech. Geoenviron. Eng. 2019, 145, 04019037. [Google Scholar] [CrossRef]

- Jang, Y.S.; Kim, Y.W.; Park, J.Y. Consolidation efficiency of natural and plastic geosynthetic band drains. Geosynth. Int. 2001, 8, 283. [Google Scholar] [CrossRef]

- Lee, S.L.; Karunaratne, G.P.; Ramaswamy, S.D.; Aziz, M.A.; Gupta, N.D. Fibredrain for Consolidation of Soft Soils. In Proceedings of the Post-Vienna Conference on Geotextiles, Singapore, 1987. [Google Scholar]

- Asha, B.S.; Mandal, J.N. Laboratory performance tests on natural prefabricated vertical drains in marine clay. Proc. Inst. Civ. Eng.-Ground Improv. 2015, 168, 45–65. [Google Scholar] [CrossRef]

- Lee, S.L.; Lo, K.W.; Karunaratne, G.P.; Ooi, J. Improvement of peaty clay by dynamic replacement and mixing. In Proceedings of the JSSMFE-NUS-AIT Seminar on Soil Improvement and Construction Techniques in Soft Ground, Singapore, 1984; pp. 208–214. [Google Scholar]

- Lee, S.; Karunaratne, G.; Ramaswamy, S.; Aziz, M.; Das Gupta, N. Natural geosynthetic drain for soil improvement. Geotext. Geomembr. 1994, 13, 457–474. [Google Scholar] [CrossRef]

- Aboshi, H.; Sutoh, Y.; Inoue, T.; Shimizu, Y. Kinking deformation of PVD under consolidation settlement of surrounding clay. Soils Found. 2001, 41, 25–32. [Google Scholar] [CrossRef]

- Kim, J.H.; Cho, N. Pilot Scale Field Test for Natural Fiber Drain. In Proceedings of the 4th Asian Regional Conference on Geosynthetics, Shanghai, China; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Kelly, R.; Sloan, S.; Pineda, J.; Kouretzis, G.; Huang, J. Outcome of the Newcastle symposium for the prediction of embankment behaviour on soft soil. Comput. Geotech. 2018, 93, 9–14. [Google Scholar] [CrossRef]

- Miura, T.; Tou, M.; Murota, H.; Bono, M. The basic experiment on permeability characteristics of fibredrain. In Proceedings of the Annual Regional Meeting of JSCE; JSCE: Kyushu, Japan, 1995. (In Japanese) [Google Scholar]

- Nguyen, T.T.; Indraratna, B.; Singh, M. Dynamic parameters of subgrade soils prone to mud pumping considering the influence of kaolin content and the cyclic stress ratio. Transp. Geotech. 2021, 29, 100581. [Google Scholar] [CrossRef]

- Alobaidi, I.; Hoare, D.J. Qualitative criteria for anti-pumping geocomposites. Geotext. Geomembr. 1998, 16, 221–245. [Google Scholar] [CrossRef]

- Korinek, J.; Nekardova, O.; Kovar, P. The influence of woven geotextiles on ponding time and overland flow. Soil Water Res. 2016, 11, 244–249. [Google Scholar] [CrossRef]

- Kalibová, J.; Jačka, L.; Petrů, J. The effectiveness of jute and coir blankets for erosion control in different field and laboratory conditions. Solid Earth 2016, 7, 469–479. [Google Scholar] [CrossRef]

- Ogbobe, O.; Essien, K.S.; Adebayo, A. A Study of Biodegradable Geotextiles Used for Erosion Control. Geosynth. Int. 1998, 5, 545–553. [Google Scholar] [CrossRef]

- Asha, B.S.; Mandal, J. Filtration tests on marine clay–jute geotextile filter sheath systems. Electron. J. Geotech. Eng. 2012, 17, 2659–2671. [Google Scholar]

- Sreedhar, M.V.S.; Kumar, C.P.; Raju, P.T. Laboratory Evaluation of Erosion Control Using Coir Geoproducts. In Proceedings of the Indian Geotechnical Conference, Guwahati, India, 14–16 December 2017; IIT Guwahati: Guwahati, India, 2017. [Google Scholar]

- Rickson, R.; Loveday, A. Can erosion control blankets (geotextiles) aid vegetation establishment in mine restoration? In Proceedings of the Seventh International Conference on Mine Closure, Brisbane, Australia, 25–27 September 2012; Australian Centre for Geomechanics: Perth, Australia, 2012. [Google Scholar]

- Sanyal, T. Jute Geotextiles and their Applications in Civil Engineering. In Developments in Geotechnical Engineering; Springer: Singapore, 2017; p. 218. [Google Scholar]

- Choudhury, P.K.; Das, A.; Goswami, D.N.; Sanyal, T. Bio-Engineering approach with jute geotextile for slope stabilization. In Proceedings of the 4th Asian Regional Conference on Geosynthetics, Shanghai, China, 12 September 2008. [Google Scholar]

- Lekha, K.R. Field instrumentation and monitoring of soil erosion in coir geotextile stabilized slopes—A case study. Geotext. Geomembr. 2004, 22, 399–413. [Google Scholar] [CrossRef]

- Vishnudas, S.; Savenije, H.H.; Van der Zaag, P.; Anil, K.R. Coir geotextile for slope stabilization and cultivation—A case study in a highland region of Kerala, South India. Phys. Chem. Earth Parts A/B/C 2012, 47–48, 135–138. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Fullen, M.; Davies, K.; Booth, C. Use of palm-mat geotextiles for rainsplash erosion control. Geomorphology 2010, 119, 52–61. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Ray, D.; Mohanty, A.K.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Pickering, K.L., Ed.; Woodhead Publishing: New York, NY, USA, 2008; pp. 221–268. [Google Scholar]

- Nguyen, T.T.; Indraratna, B. Experimental and numerical investigations into hydraulic behaviour of coir fibre drain. Can. Geotech. J. 2017, 54, 75–87. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Atchaya, P.; Darshan, S.; Subhashini, S. Mechanical properties of glass fibre reinforced soil and its application as subgrade reinforcement. Road Mater. Pavement Des. 2021, 22, 2384–2395. [Google Scholar] [CrossRef]

- Gupta, G.; Sood, H.; Gupta, P.K. Performance Review of Polyester Fibre Reinforced Soil for Sustainable Construction. In Sustainable Development through Engineering Innovations; Springer: Singapore, 2021. [Google Scholar]

- Ramkrishnan, R.; Sruthy, M.; Sharma, A.; Karthik, V. Effect of random inclusion of sisal fibres on strength behavior and slope stability of fine grained soils. Mater. Today Proc. 2018, 5 Pt 3, 25313–25322. [Google Scholar] [CrossRef]

- Saha, P.; Roy, D.; Manna, S.; Adhikari, B.; Sen, R.; Roy, S. Durability of transesterified jute geotextiles. Geotext. Geomembr. 2012, 35, 69–75. [Google Scholar] [CrossRef]

- Indraratna, B.; Nguyen, T.T.; Carter, J.; Rujikiatkamjorn, C. Influence of biodegradable natural fibre drains on the radial consolidation of soft soil. Comput. Geotech. 2016, 78, 171–180. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).