Use of a Biopolymer for Road Pavement Subgrade

Abstract

1. Introduction

2. Experimental Study

Materials and Methods

3. Experimental Results and Discussion

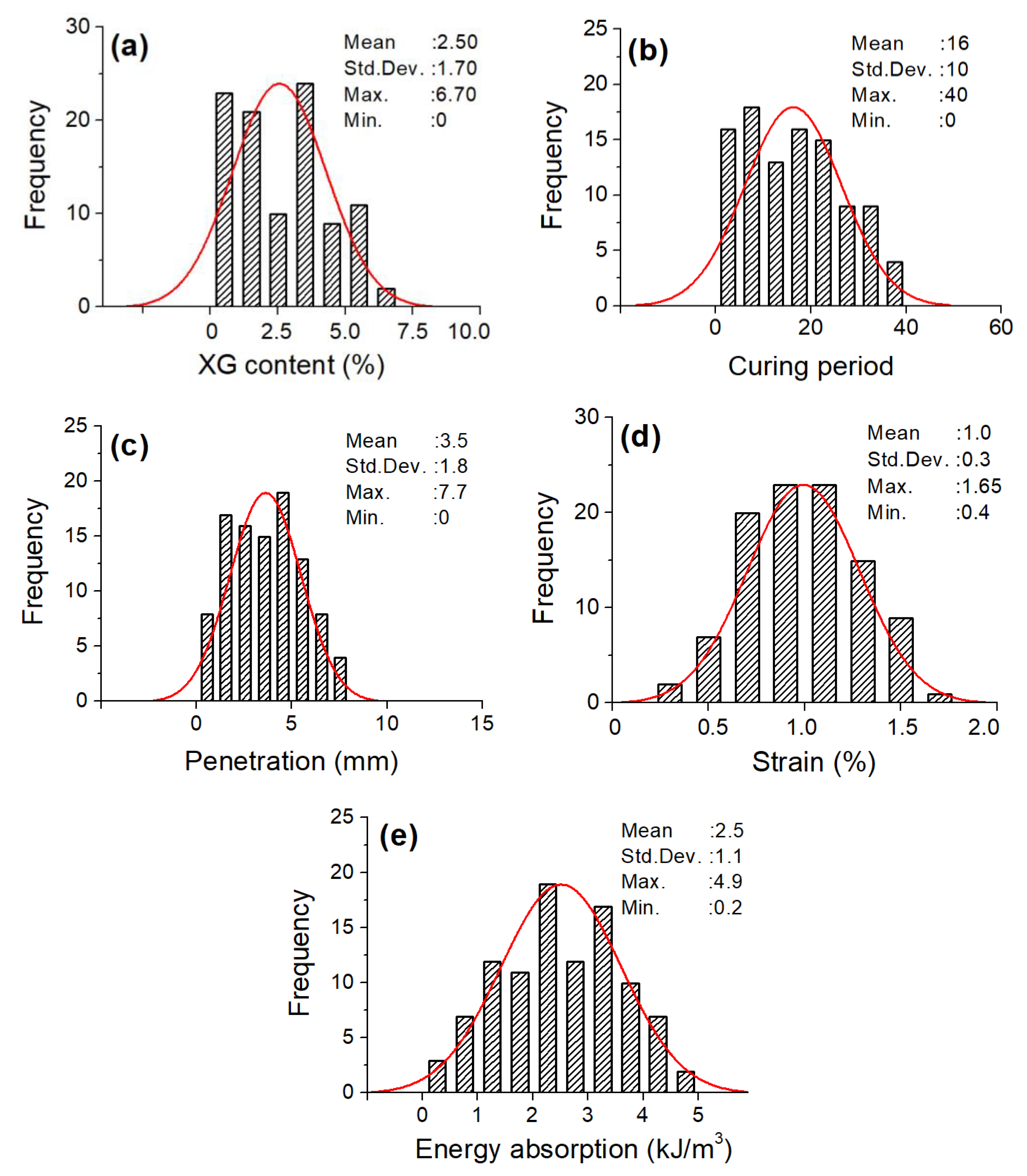

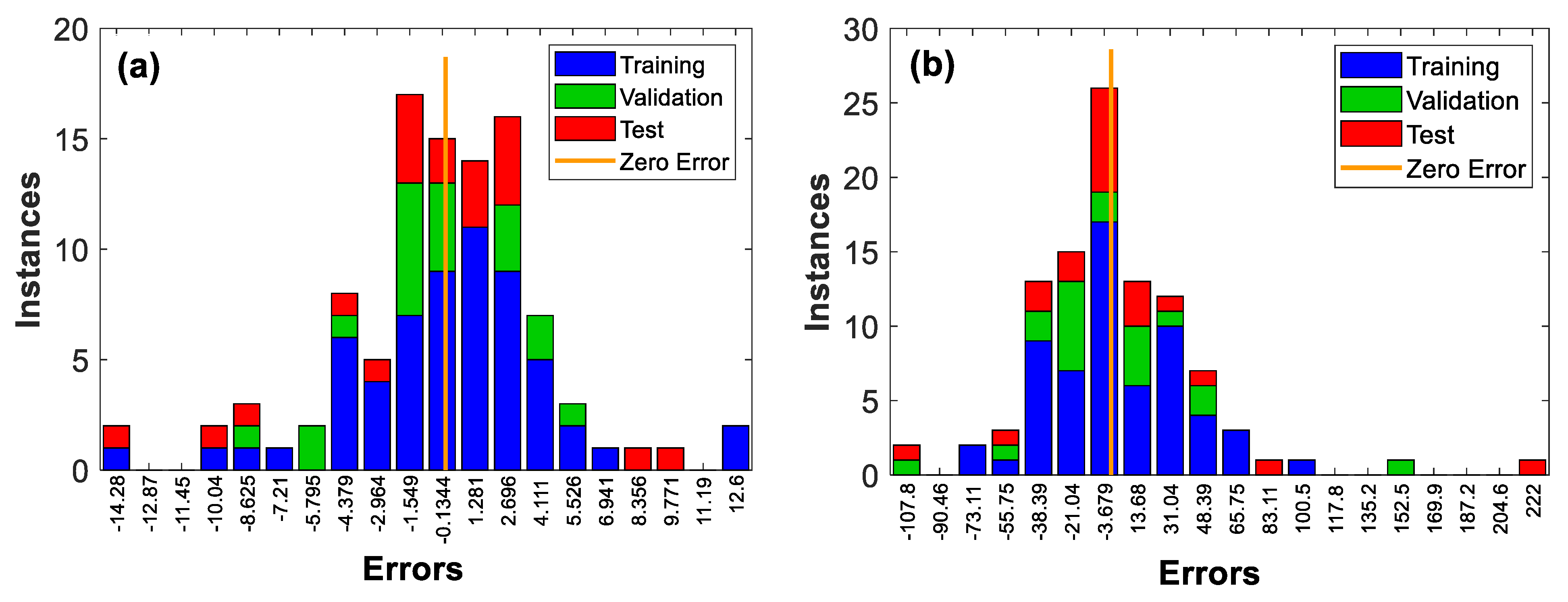

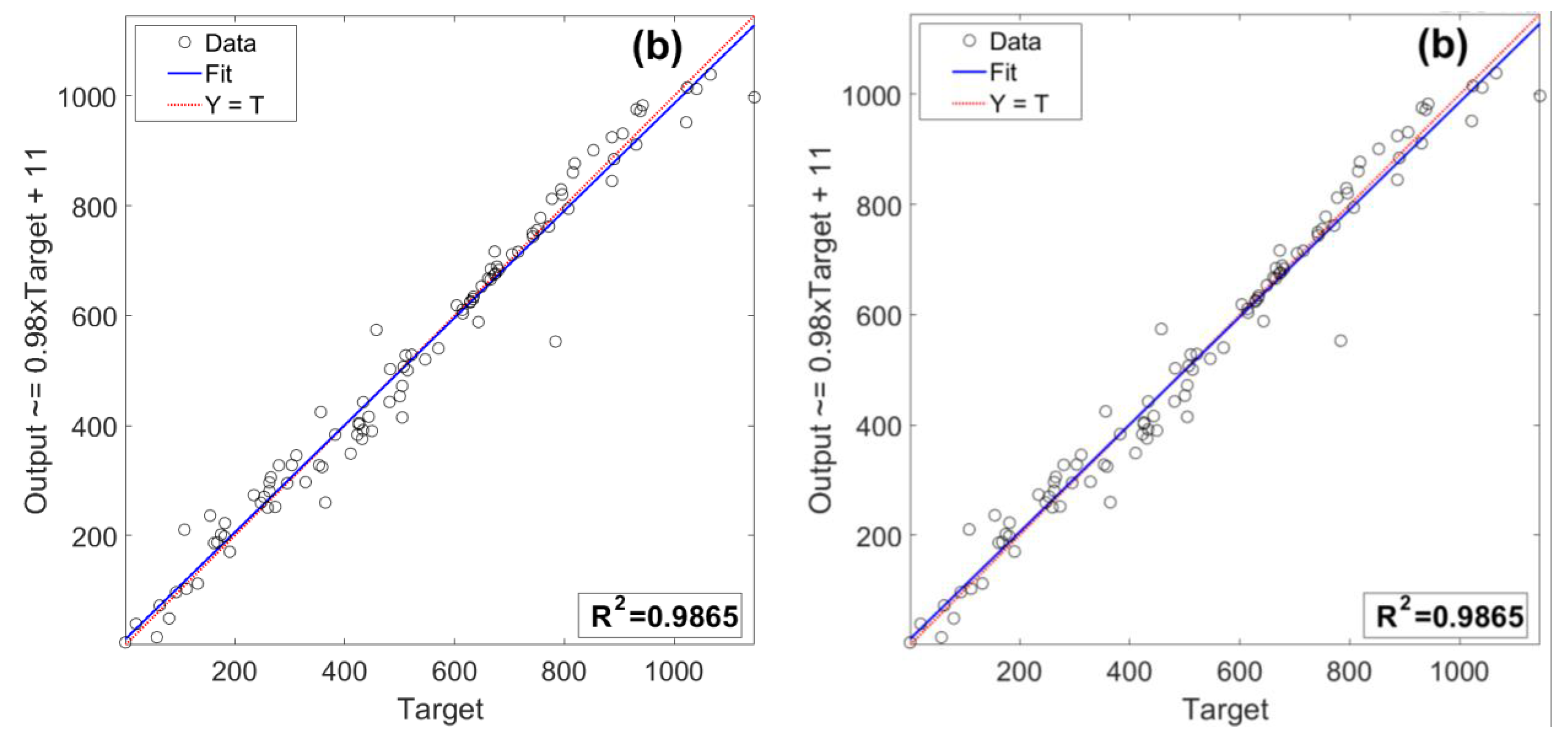

4. Prediction Model

5. Conclusions

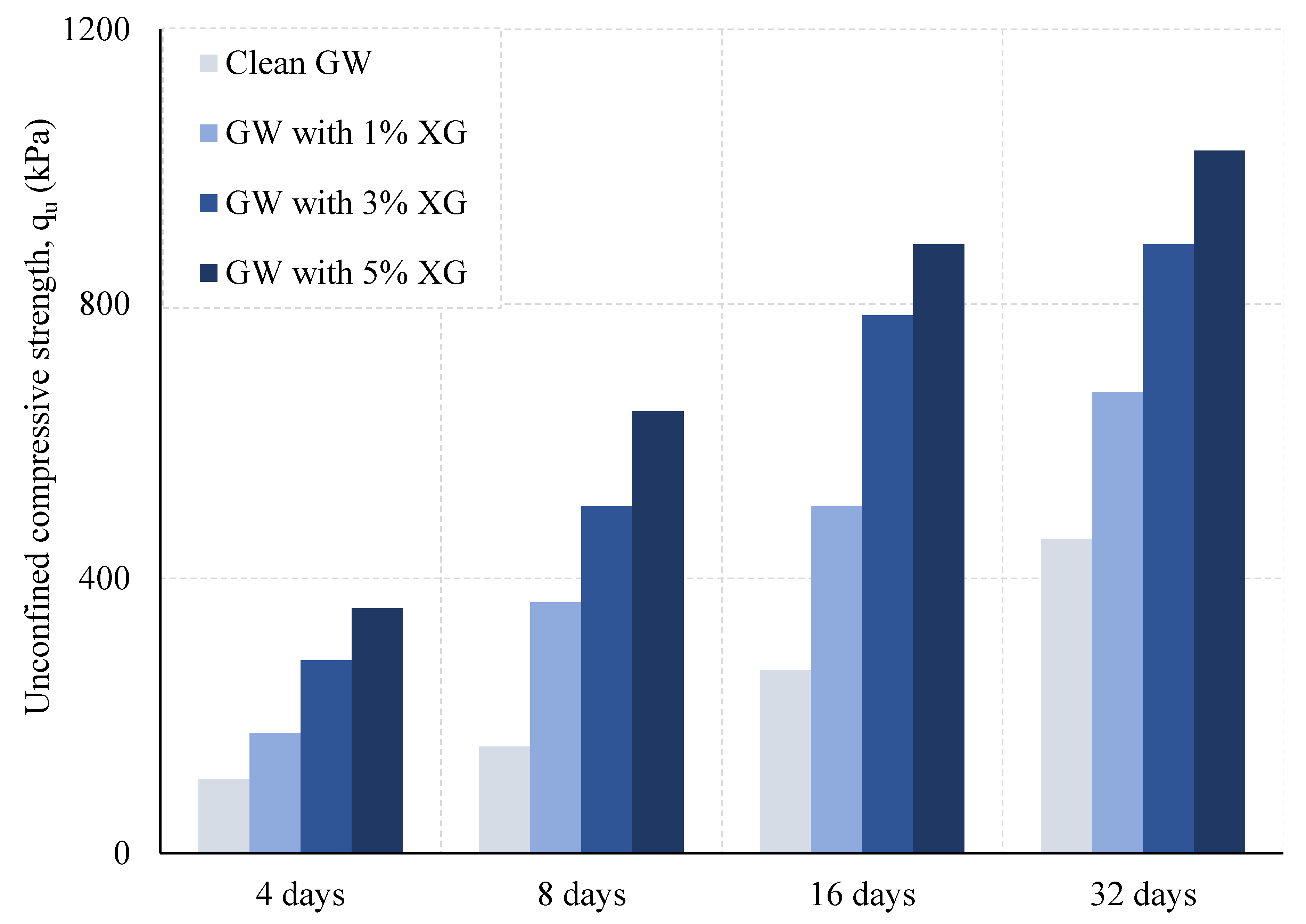

- The unconfined compressive strength (qu) value of clean gravel samples was found to be increased significantly with both XG biopolymer addition and curing time period employed.

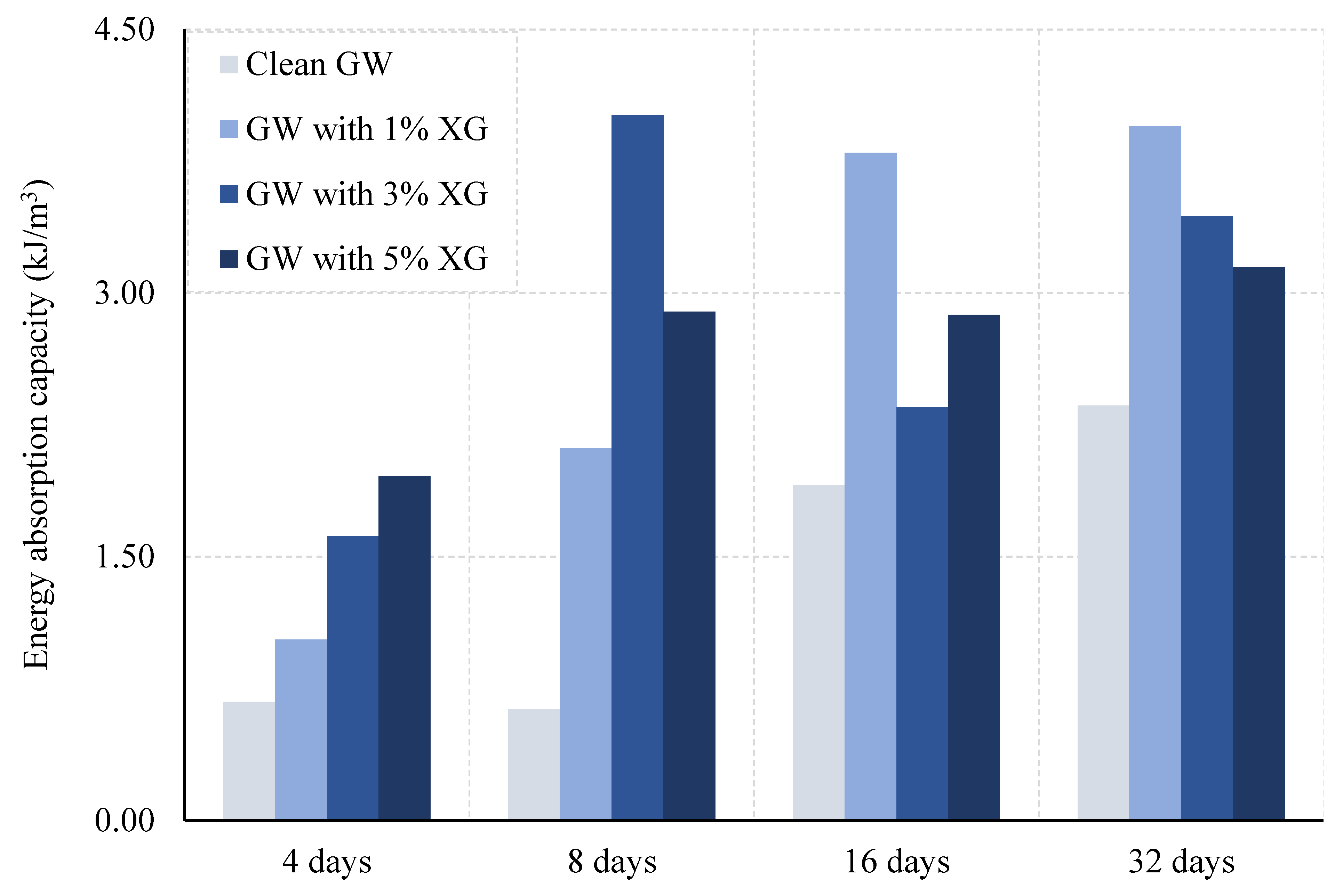

- The XG biopolymer addition in the CG samples substantially increased the energy absorption capacity of the mixtures at varying rates (from 15% to 400%) depending on the curing period employed and amount of XG biopolymer added.

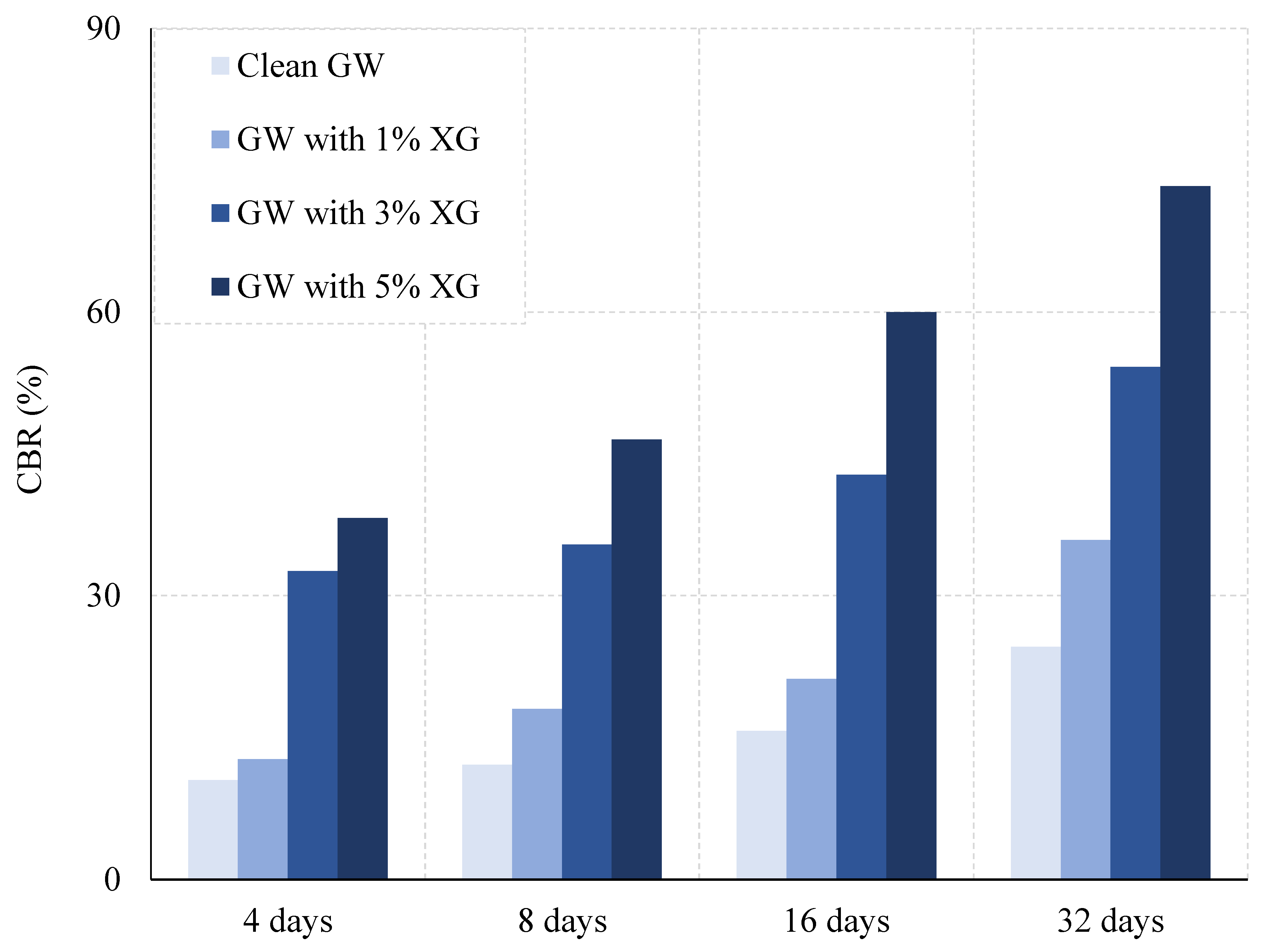

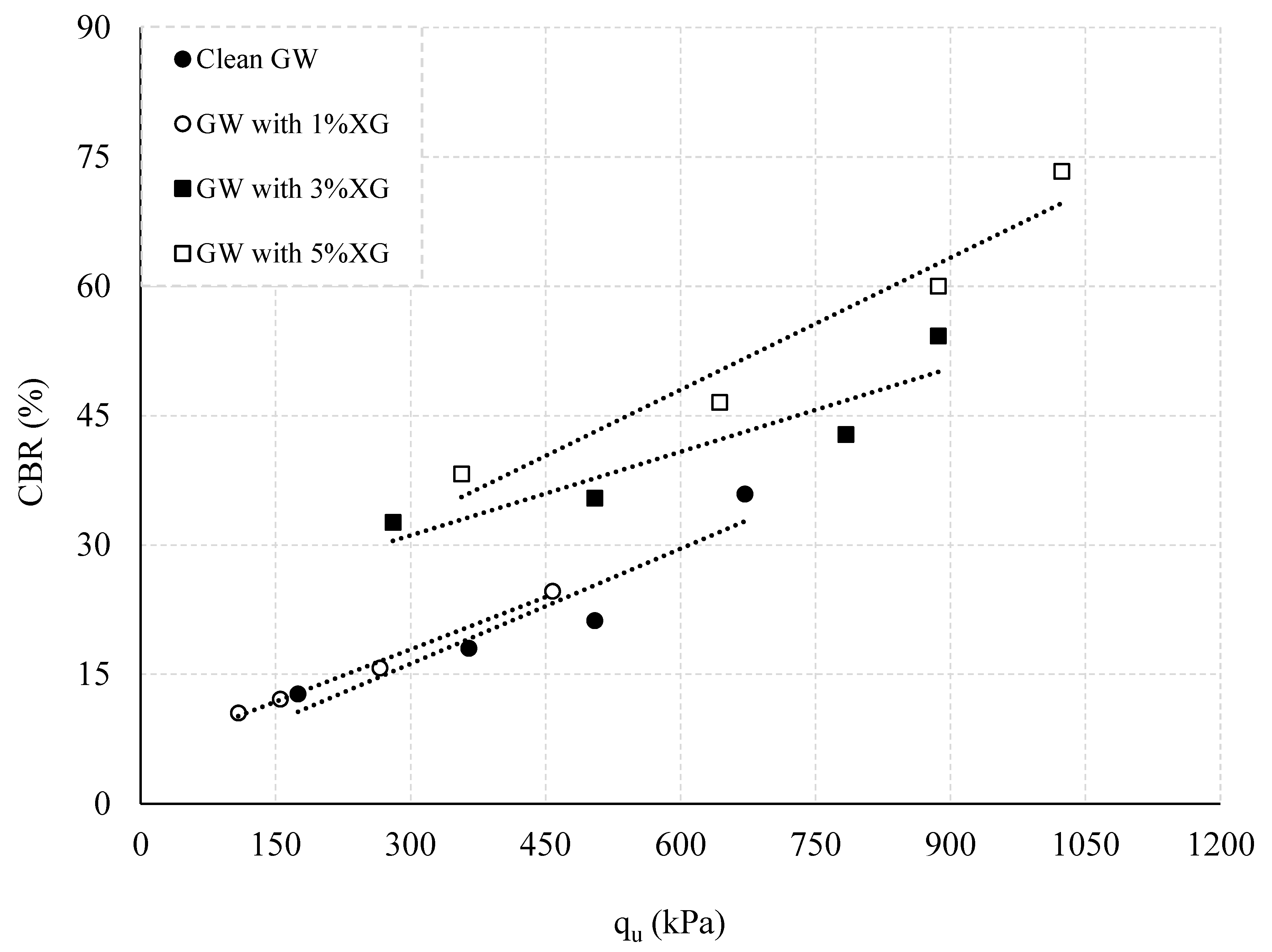

- The XG biopolymer addition in gravel samples pointed to a substantial increase in the CBR performance. Both the curing period and amount of the XG biopolymer were found to be significantly effective on the CBR testing results.

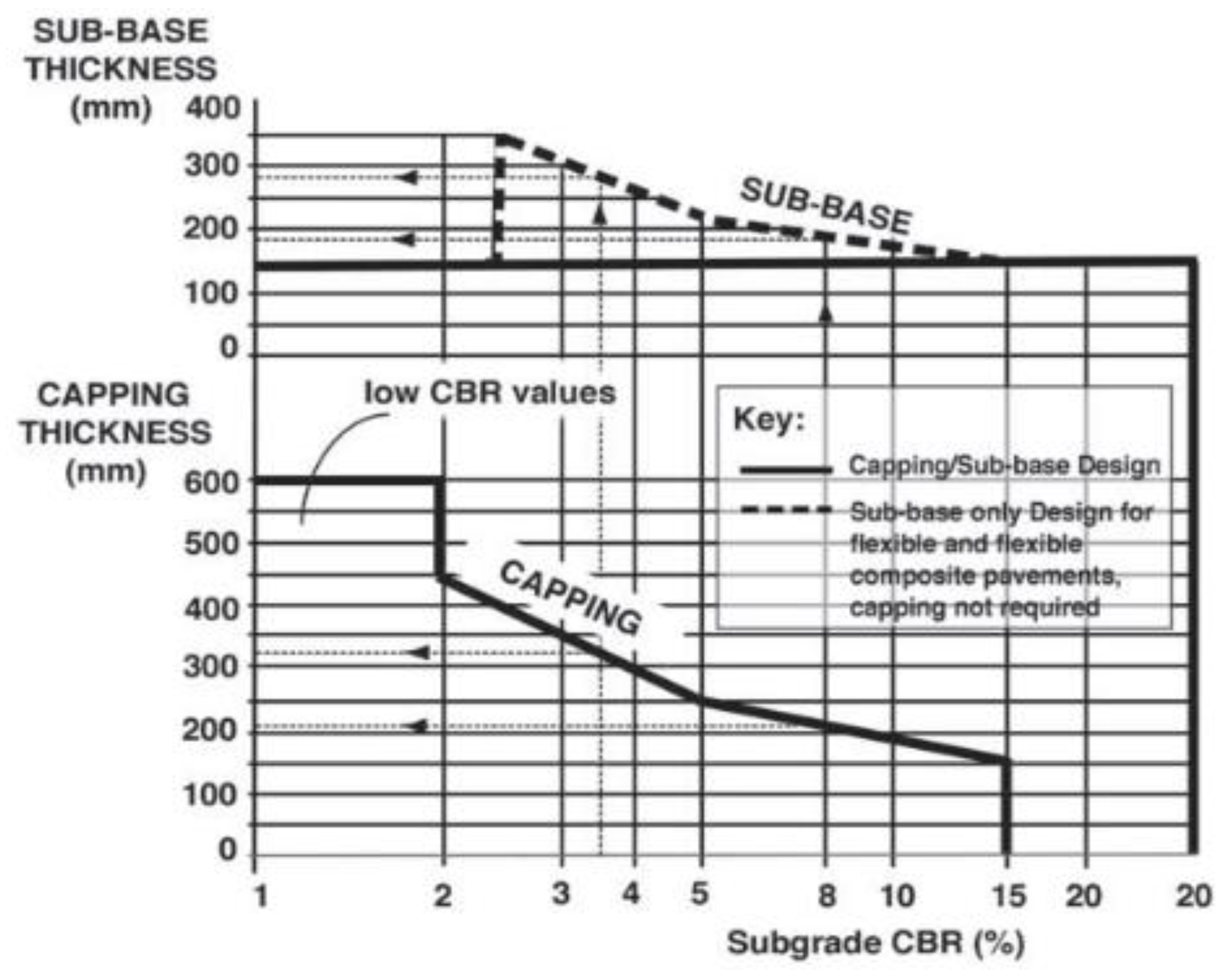

- The XG content in the gravel samples tested after the 4- and 8-daycuringtimes had a partial effect on the design thickness while, for those tested after the 16- and 32-daycuringtimes, it did not affect the design thickness.

- The SCG algorithm-based models, developed to predict the change in the UCS and CBR test results of gravel with the addition of XG, exhibited a high accuracy prediction success with the regression coefficients of R2 = 0.967 and R2 = 0.987, respectively. These results demonstrate that models based on sets with high data quality can show significant success in estimating the geotechnical properties of soils.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Media, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- De Jong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Chang, I.; Minhyeong, L.; Tran, A.T.P.; Lee, S.; Kwon, Y.M.; Im, J.; Cho, G.Y. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, W.P.; Ranjith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Chen, R.; Ramey, D.; Weiland, E.; Lee, I.; Zhang, L. Experimental investigation on biopolymer strengthening of mine tailings. J. Geotech. Geoenvironmental Eng. 2016, 142, 06016017. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Wiszniewski, M.; Skutnik, Z. Effects of xanthan gum biopolymer on the permeability, odometer, unconfined compressive and triaxial shear behavior of a sand. Soil Mech. Found. Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A novel study on using protein-based biopolymers in soil strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Awraheem, M.H.; Khalaf, M.M. Geotechnical properties of a low-plasticity clay with biopolymer. J. Mater. Civ. Eng. 2018, 30, 04018170. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Demir, S. Fall-cone testing of different size/shape sands treated with a biopolymer. Geomech. Eng. 2020, 22, 441–448. [Google Scholar] [CrossRef]

- Reddy, N.G.; Nongmaithem, R.S.; Basu, D.; Rao, B.H. Application of biopolymers for improving the strength characteristics of red mud waste. Environ. Geotech. 2020, 9, 340–359. [Google Scholar] [CrossRef]

- Cabalar, A.F. Ground Improvement by Bacteria and Synthetic Polymers. Master’s Thesis, University of Gaziantep, Gaziantep, Turkey, 2002. [Google Scholar]

- Ayeldeen, M.K.; Negm, A.M.; El Sawwaf, M.A. Evaluating the physical characteristics of biopolymer/soil mixtures. Arab. J. Geosci. 2016, 9, 371. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.C. Shear strength behavior and parameters of microbial gellan gum-treated soils: From sand to clay. Acta Geotech. 2019, 14, 361–375. [Google Scholar] [CrossRef]

- Smitha, S.; Rangaswamy, K. Effect of Biopolymer Treatment on Pore Pressure Response and Dynamic Properties of Silty Sand. J. Mater. Civ. Eng. 2020, 32, 04020217. [Google Scholar] [CrossRef]

- Lee, S.; Chung, M.; Park, H.M.; Song, K.I.; Chang, I. Xanthan Gum Biopolymer as Soil-Stabilization Binder for Road Construction Using Local Soil in Sri Lanka. J. Mater. Civ. Eng. 2019, 31, 06019012. [Google Scholar] [CrossRef]

- ASTM D1241-15:2016; Standard Specification for Materials for Soil-Aggregate Subbase, Base, and Surface Courses. ASTM International: West Conshohocken, PA, USA, 2016.

- Muszynski, M.R.; Stanley, J.V. Particle shape estimates of uniform sands: Visual and automated methods comparison. J. Mater. Civil Eng. 2012, 24, 194–206. [Google Scholar] [CrossRef]

- Powers, M.C. A new roundness scale for sedimentary particles. J. Sediment. Petrol. 1953, 23, 117–119. [Google Scholar] [CrossRef]

- Youd, T.L. Factors controlling maximum and minimum densities of sands. In Evaluation of Relative Density and Its Role in Geotechnical Projects Involving Cohesionless Soils; ASTM STP523; ASTM: West Conshohocken, PA, USA, 1973; pp. 98–112. [Google Scholar]

- Santamarina, J.C.; Cho, G.C. Soil Behaviour: The role of particle shape. In Advances in Geotechnical Engineering: The Skempton Conference; Thomas Telford: London, UK, 2004; pp. 604–617. [Google Scholar]

- Garcia-Ochoa, F.; Santos, V.E.; Casas, J.A.; Gómez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef]

- Rosalam, S.; England, R. Review of xanthan gum production from unmodified starches by Xanthomonas comprestris sp. Enzym. Microb. Technol. 2006, 39, 197–207. [Google Scholar] [CrossRef]

- ASTM D2166:2010; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: Philadelphia, PA, USA, 2010.

- ASTM D1883:2021; Standard Test Method for California Bearing Ratio of Laboratory Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- King, R.; Lodge, M. Northwest Shelf development-the foundation engineering challenge. In Proceedings of the International Conference on Calcareous Sediments, Perth, Australia, 15–18 March 1988; pp. 333–342. [Google Scholar]

- Fookes, P.G. The geology of carbonate soils and rocks and their engineering characterisation and description. In Proceedings of the International Conference on Calcareous Sediments, Perth, Australian, 15–18 March 1988; pp. 787–806. [Google Scholar]

- Coop, M.R. The mechanics of uncemented carbonate sands. Géotechnique 1990, 40, 607–626. [Google Scholar] [CrossRef]

- Lord, J.A.; Clayton, C.R.I.; Mortimore, R.N. Engineering in Chalk; Construction Industry Research and Information Association: London, UK, 2002. [Google Scholar]

- Porcino, D.; Caridi, G.; Ghionna, V.N. Undrained monotonic and cyclic simple shear behaviour of carbonate sand. Géotechnique 2008, 58, 635–644. [Google Scholar] [CrossRef]

- Wang, G.; Zha, J.J. Particle breakage evolution during cyclic triaxial shearing of a carbonate sand. Soil Dyn. Earthq. Eng. 2020, 138, 106326. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; AbdMajid, M.Z.; Rashid, A.S.A. Xanthan gum biopolymer: An eco-friendly additive for stabilization of tropical organic peat. Environ. Earth Sci. 2016, 75, 825. [Google Scholar] [CrossRef]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotechnique Lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Qureshi, M.U.; Chang, I.; Al-Sadarani, K. Strength and durability characteristics of biopolymer-treated desert sand. Geomech. Eng. 2017, 12, 785–801. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M. Enhancing mechanical behaviors of collapsible soil using two biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- Singh, S.P.; Das, R. Geo-engineering properties of expansive soil treated with xanthan gum biopolymer. Geomech. Geoengin. 2020, 15, 107–122. [Google Scholar] [CrossRef]

- Choi, S.G.; Chang, I.; Lee, M.; Lee, J.H.; Han, J.T.; Kwon, T.H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Khatami, H.R.; O’Kelly, B.C. Improving mechanical properties of sand using biopolymers. J. Geotechn. Geoenvironmental Eng. 2013, 139, 1402–1406. [Google Scholar] [CrossRef][Green Version]

- HD26/06:2006; Pavement Design and Maintenance-Foundations, Volume 7, Design Manual for Roads and Bridges (DMRB). The Stationery Office: London, UK, 2006.

- Ghorbani, A.; Hasanzadehshooiili, H. Prediction of UCS and CBR of microsilica-lime stabilized sulfate silty sand using ANN and EPR models; application to the deep soil mixing. Soils Found. 2018, 58, 34–49. [Google Scholar] [CrossRef]

- Consoli, N.C.; Cruz, R.C.; Floss, M.F.; Festugato, L. Parameters Controlling Tensile and Compressive Strength of Artificially Cemented Sand. J. Geotech. Geoenviron. Eng. 2010, 136, 759–763. [Google Scholar] [CrossRef]

- Park, H. Study for Application of Artificial Neural Networks in Geotechnical Problems. In Artificial Neural Networks-Application; IntechOpen: London, UK, 2011. [Google Scholar] [CrossRef][Green Version]

- Consoli, N.C.; Ferreira, P.M.V.; Tang, C.S.; Marques, S.F.V.; Festugato, L.; Corte, M.B. A unique relationship determining strength of silty/clayey soils: Portland cement mixes. Soils Found. 2016, 56, 1082–1088. [Google Scholar] [CrossRef]

- Statista. Cement Production in the United States from 2010 to 2022. 2020. Available online: https://www.statista.com/statistics/219343/cement-production-worldwide/?gclid=EAIaIQobChMIovKHtdP5_gIVA_d3Ch2JxgZhEAAYAiAAEgL_h_D_BwE (accessed on 13 April 2023).

- Van den Heede, V.P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Habert, G. Eco-Efficient Concrete: Environmental Impact of Portland Cement Production; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef][Green Version]

- Møller, M.F. A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw. 1993, 6, 525–533. [Google Scholar] [CrossRef]

- Vinodkumar, S.B.S. Artificial Neural Network Modelling and Economic Analysis of Black Cotton Soil Subgrade Stabilized with Flyash and Geotextile. Int. J. Earth Sci. Eng. 2016, 9, 81–86. [Google Scholar]

- Egbueri, J.C.; Igwe, O.; Omeka, M.E.; Agbasi, J.C. Development of MLR and variedly optimized ANN models for forecasting the detachability and liquefaction potential index of erodible soils. Geosyst. Geoenviron. 2022, 2, 100104. [Google Scholar] [CrossRef]

- Li, G.; Han, C.; Mei, H.; Chen, S. Application of the WNN-Based SCG Optimization Algorithm for Predicting Soft Soil Foundation Engineering Settlement. Sci. Program. Smart Internet Things 2021, 2021, 9936285. [Google Scholar] [CrossRef]

- Kisi, O.; Uncuoglu, E. Comparison of three back-propagation training algorithms for two case studies. Indian J. Eng. Mater. Sci. 2005, 12, 434–442. [Google Scholar]

- Cevik, A.; Sezer, E.A.; Cabalar, A.F.; Gokceoglu, C. Modeling of the uniaxial compressive strength of some clay-bearing rocks using neural network. Appl. Soft Comput. 2011, 11, 2587–2594. [Google Scholar] [CrossRef]

- Yildiz, O.; Berilgen, M. Artificial Neural Network Model to Predict Anchored Pile-Wall Displacements on Istanbul Greywackes. Tek. Dergi 2020, 31, 10147–10166. [Google Scholar] [CrossRef][Green Version]

- Cabalar, A.F.; Karabas, B.; Mahmutluoglu, B.; Yildiz, O. An IDW-based GIS application for assessment of geotechnical characterization in Erzincan, Turkey. Arab. J. Geosci. 2021, 14, 2129. [Google Scholar] [CrossRef]

- Yıldız, Ö. Correlation Between Spt and Pmt Results for Sandy and Clayey Soils. Eskişehir Tech. Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2021, 22, 175–188. [Google Scholar] [CrossRef]

- Rathje, E.M.; Kottke, A.R.; Trent, W.L. Influence of input motion and site property variabilities on seismic site response analysis. J. Geotech. Geoenviron. Eng. 2010, 136, 607–619. [Google Scholar] [CrossRef]

- Field, E.H.; Jacob, K.H. Monte-Carlo simulation of the theoretical site response variability at Turkey Flat, California, given the uncertainty in the geotechnically derived input parameters. Earthq. Spectra 1993, 9, 669–701. [Google Scholar] [CrossRef]

- Andrade, J.E.; Borja, R.I. Capturing strain localization in dense sands with random density. Int. J. Numer. Methods Eng. 2006, 67, 1531–1564. [Google Scholar] [CrossRef][Green Version]

- Wang, Z.Z. Deep Learning for Geotechnical Reliability Analysis with Multiple Uncertainties. J. Geotech. Geoenviron. Eng. 2022, 148, 06022001. [Google Scholar] [CrossRef]

- Ravichandran, N.; Mahmoudabadi, V.; Shrestha, S. Analysis of the bearing capacity of shallow foundation in unsaturated soil using Monte Carlo simulation. Int. J. Geosci. 2017, 8, 1231–1250. [Google Scholar] [CrossRef][Green Version]

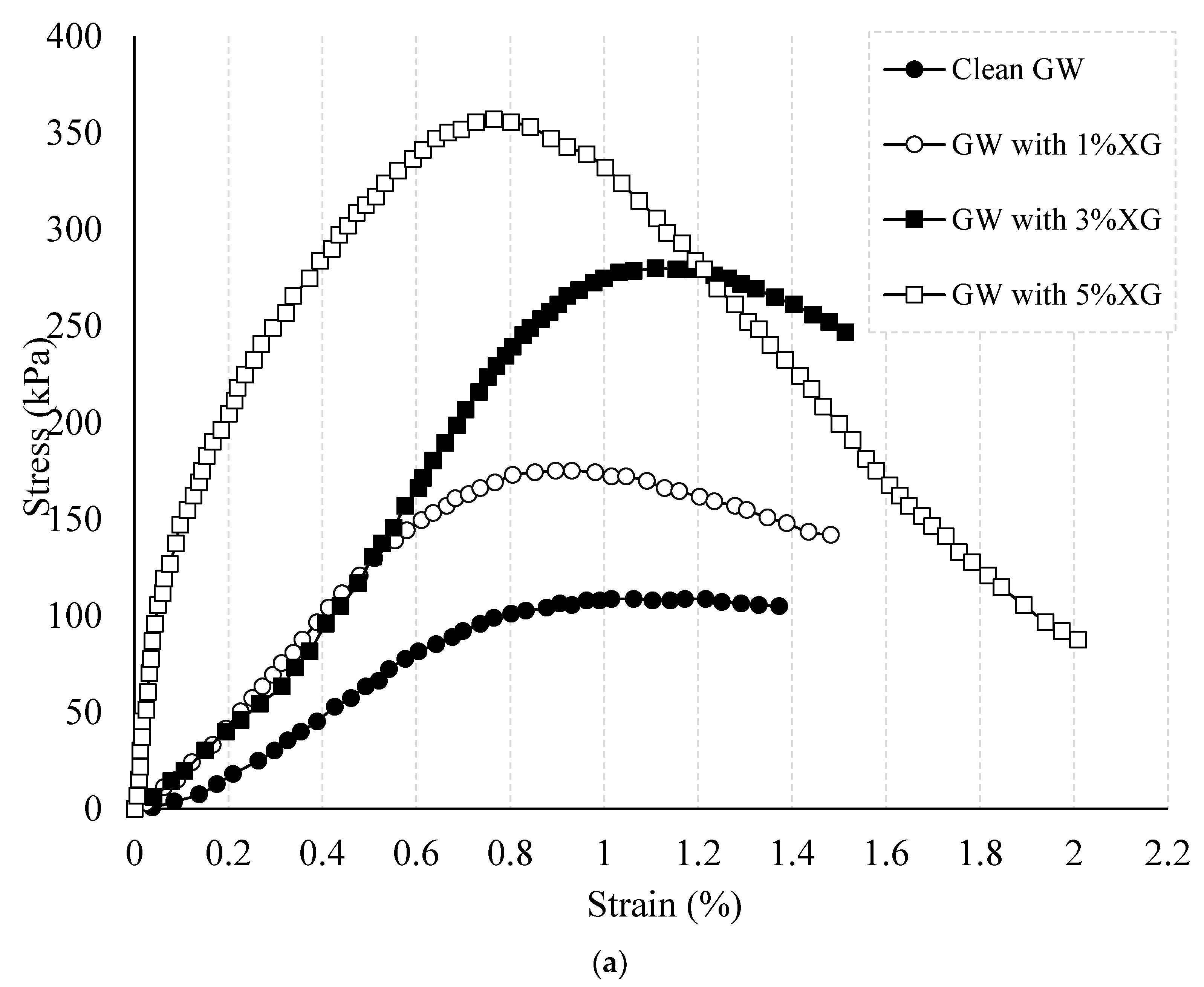

| Name of the Specimens | Host Material | Admixture Material | Admixture Content (%) | Curing Days | Total Number of Specimens Tested | Test Setup |

|---|---|---|---|---|---|---|

| Clean GW | GW | XG biopolymer | 0 | 3, 7, 14, 28 | 16 | UCS, and CBR |

| GW with 1% XG | 1 | 3, 7, 14, 28 | ||||

| GW with 3% XG | 3 | 3, 7, 14, 28 | ||||

| GW with 5% XG | 5 | 3, 7, 14, 28 |

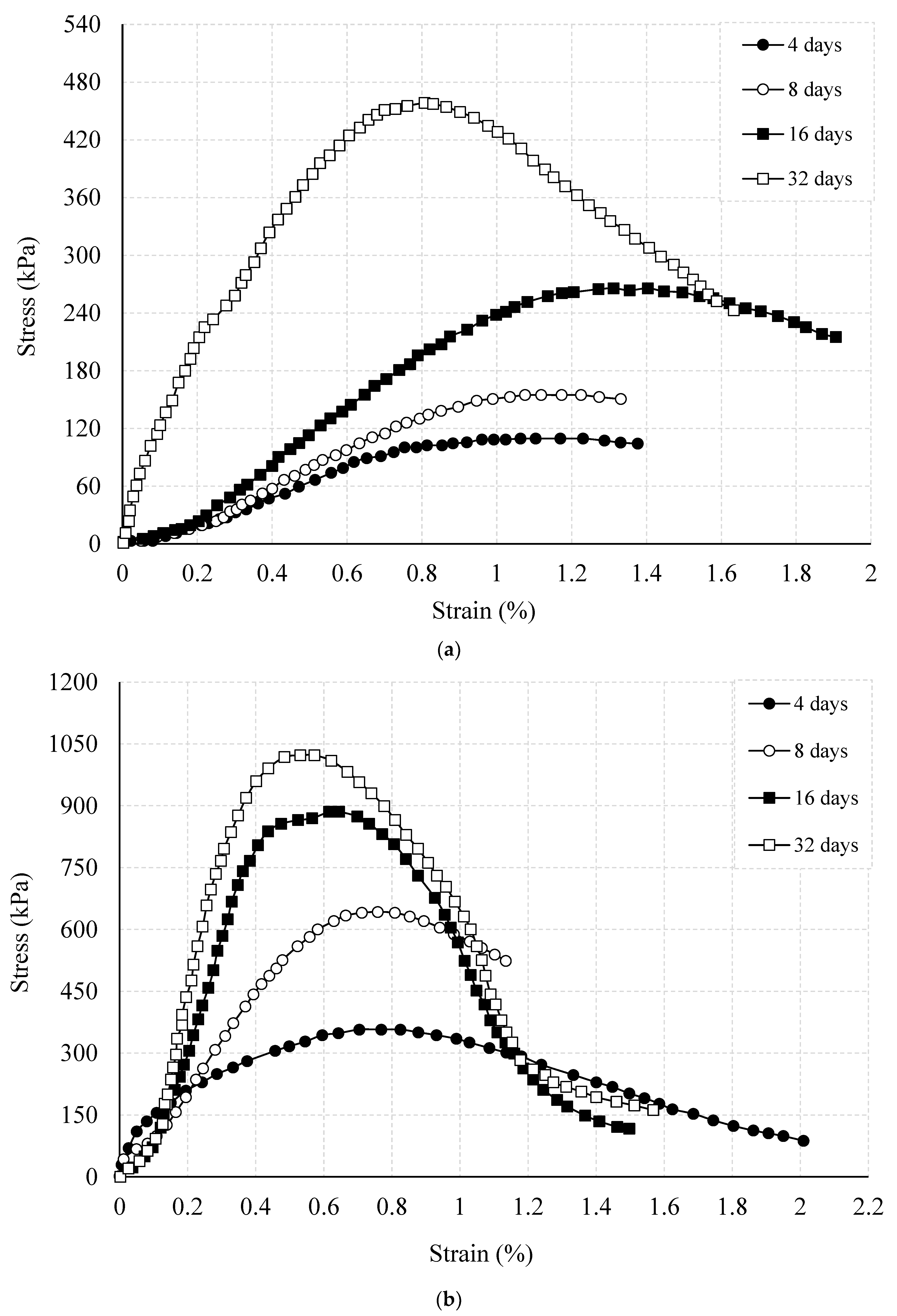

| Curing Period | Sample | CBR (%) | qu (kPa) | Energy Absorption Capacity (kJ/m3) | Pavement Design Alternatives | ||

|---|---|---|---|---|---|---|---|

| Alternative 1 | Alternative 2 | ||||||

| Subbase (mm) | Capping (mm) | Subbase (mm) | |||||

| 4-Day | Clean GW | 10.5 | 110 | 80 | 150 | 195 | 173 |

| GW with 1% XG | 12.7 | 170 | 92 | 150 | 173 | 162 | |

| GW with 3% XG | 32.6 | 280 | 173 | 150 | n.a. | 150 | |

| GW with 5% XG | 38.2 | 360 | 201 | 150 | n.a. | 150 | |

| 8-Day | Clean GW | 12.1 | 160 | 100 | 150 | 230 | 165 |

| GW with 1% XG | 18.0 | 360 | 198 | 150 | n.a. | 150 | |

| GW with 3% XG | 35.4 | 620 | 430 | 150 | n.a. | 150 | |

| GW with 5% XG | 46.5 | 660 | 284 | 150 | n.a. | 150 | |

| 16-Day | Clean GW | 15.7 | 270 | 213 | 150 | n.a. | 150 |

| GW with 1% XG | 21.2 | 510 | 425 | 150 | n.a. | 150 | |

| GW with 3% XG | 42.8 | 780 | 385 | 150 | n.a. | 150 | |

| GW with 5% XG | 60.0 | 890 | 338 | 150 | n.a. | 150 | |

| 32-Day | Clean GW | 24.6 | 460 | 236 | 150 | n.a. | 150 |

| GW with 1% XG | 35.9 | 670 | 391 | 150 | n.a. | 150 | |

| GW with 3% XG | 54.2 | 880 | 342 | 150 | n.a. | 150 | |

| GW with 5% XG | 73.3 | 1020 | 316 | 150 | n.a. | 150 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabalar, A.F.; Akbulut, N.; Demir, S.; Yildiz, O. Use of a Biopolymer for Road Pavement Subgrade. Sustainability 2023, 15, 8231. https://doi.org/10.3390/su15108231

Cabalar AF, Akbulut N, Demir S, Yildiz O. Use of a Biopolymer for Road Pavement Subgrade. Sustainability. 2023; 15(10):8231. https://doi.org/10.3390/su15108231

Chicago/Turabian StyleCabalar, Ali Firat, Nurullah Akbulut, Suleyman Demir, and Ozgur Yildiz. 2023. "Use of a Biopolymer for Road Pavement Subgrade" Sustainability 15, no. 10: 8231. https://doi.org/10.3390/su15108231

APA StyleCabalar, A. F., Akbulut, N., Demir, S., & Yildiz, O. (2023). Use of a Biopolymer for Road Pavement Subgrade. Sustainability, 15(10), 8231. https://doi.org/10.3390/su15108231