Transition to a Circular Economy in Europe through New Business Models: Barriers, Drivers, and Policy Making

Abstract

1. Introduction

2. Theory and Research Context

2.1. Defining Circular Economy

Circular Economy in the Context of Sustainable Development

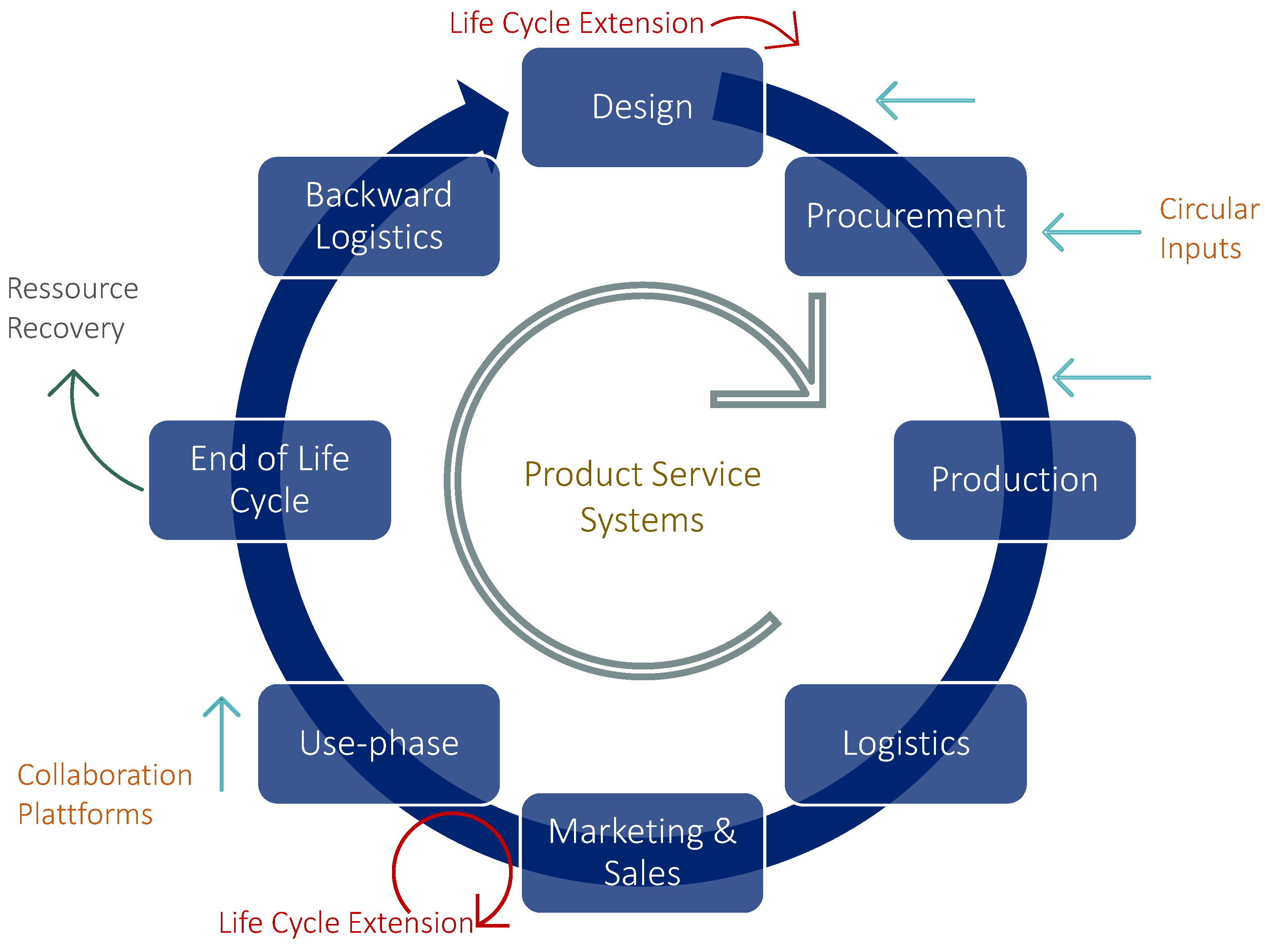

2.2. Circular Business Models

2.2.1. Strategies and Concepts of a Circular Economy

2.2.2. Circular Business Model Typology

2.3. Enabling Conditions: Political Environment and Instruments

- Economic: negative economic incentives (e.g., taxes and fees) or rewarding economic incentives (e.g., tax reductions and subsidies).

- Regulatory, e.g., legal regulations, standards, decrees, and public procurement.

- Research and Education, e.g., research funds and the establishment of faculties or research groups.

- Information Instruments, e.g., eco-labels, public campaigns for consumers, and advisory services for companies.

2.4. Focus on Barriers and Drivers

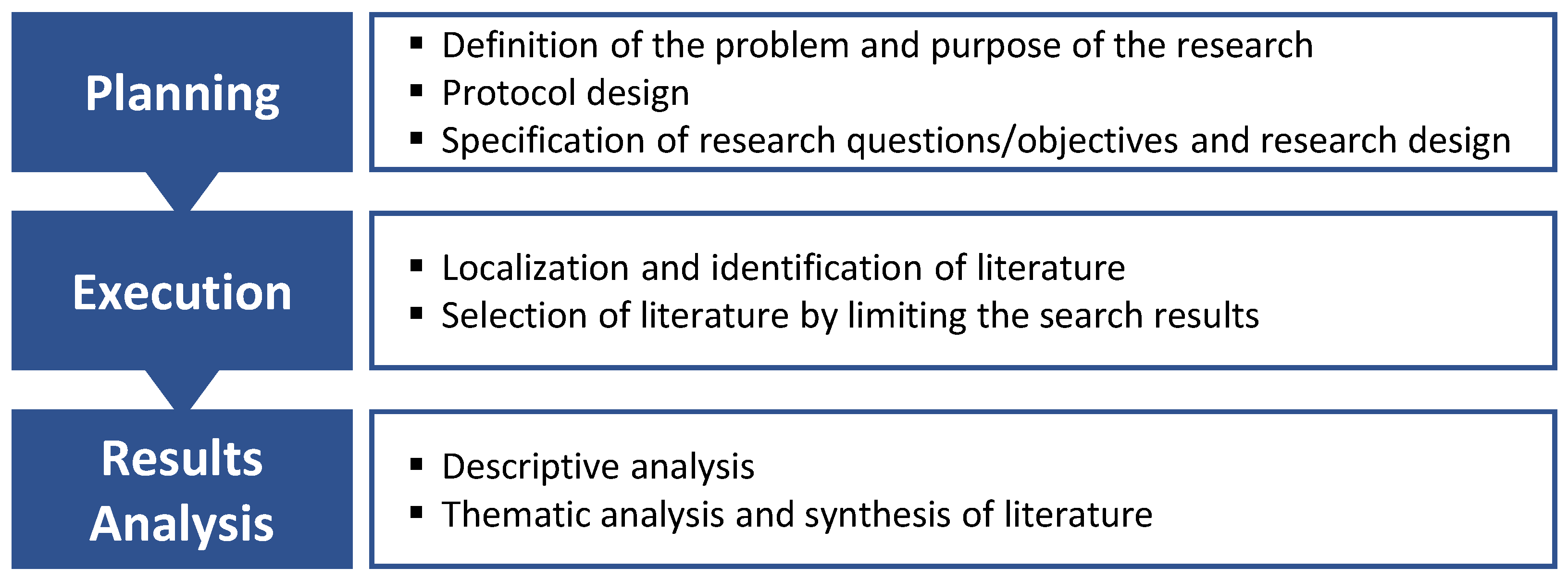

3. Research Design

3.1. Research Approach and Systematic Procedure

Three Step Procedure

3.2. Research Objectives and Questions

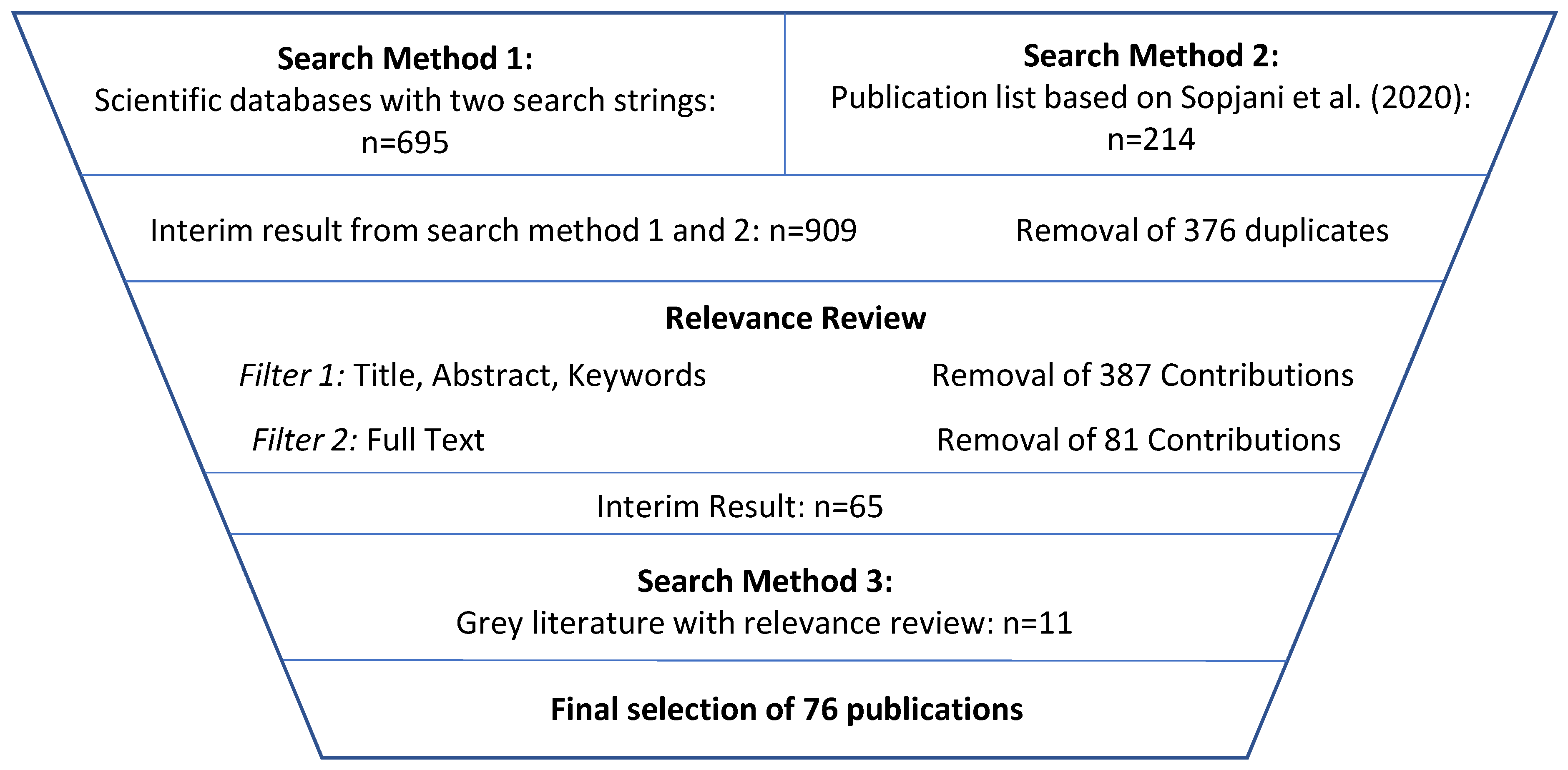

3.3. Research Process and Selection of Literature

- The publication includes barriers and/or drivers related to CBMs—either in general or specific (for one or more CBMs).

- If this is the case, studies that focus on a sector or a certain type of company (SME, large company/startup, and established company) are also included.

- Publications that analyze barriers and drivers from the macro and micro levels are excluded.

- Empirical studies focusing on countries or regions outside of Europe are excluded.

3.4. Analytical Method: Data Extraction Procedure

- Geographic context (continent/country): Does the paper have a geographic focus?

- Barriers/drivers emergence: How were the barriers/drivers identified?

- Ranking: Is there a prioritization/weighting of the barriers/drivers?

- Framework/visualization: Is there a framework in place to visualize the barriers/drivers?

- CBM strategy: Is it about slowing down or closing resource cycles?

- CBM type: Does the paper analyze a specific Circular Business Model?

- Business type: Do the barriers/drivers relate to a business type?

- Sector: Is the paper sector-specific?

4. Results

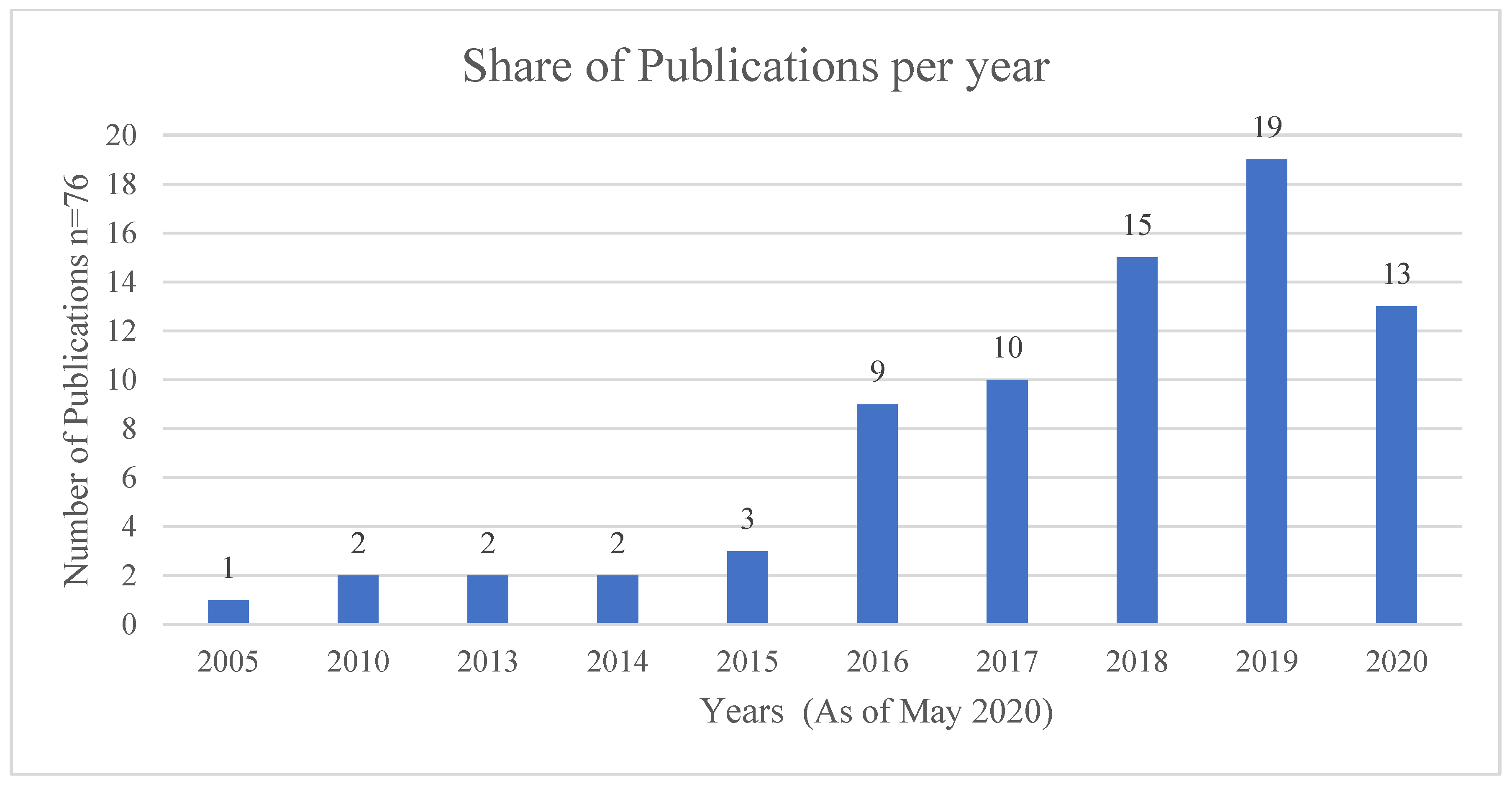

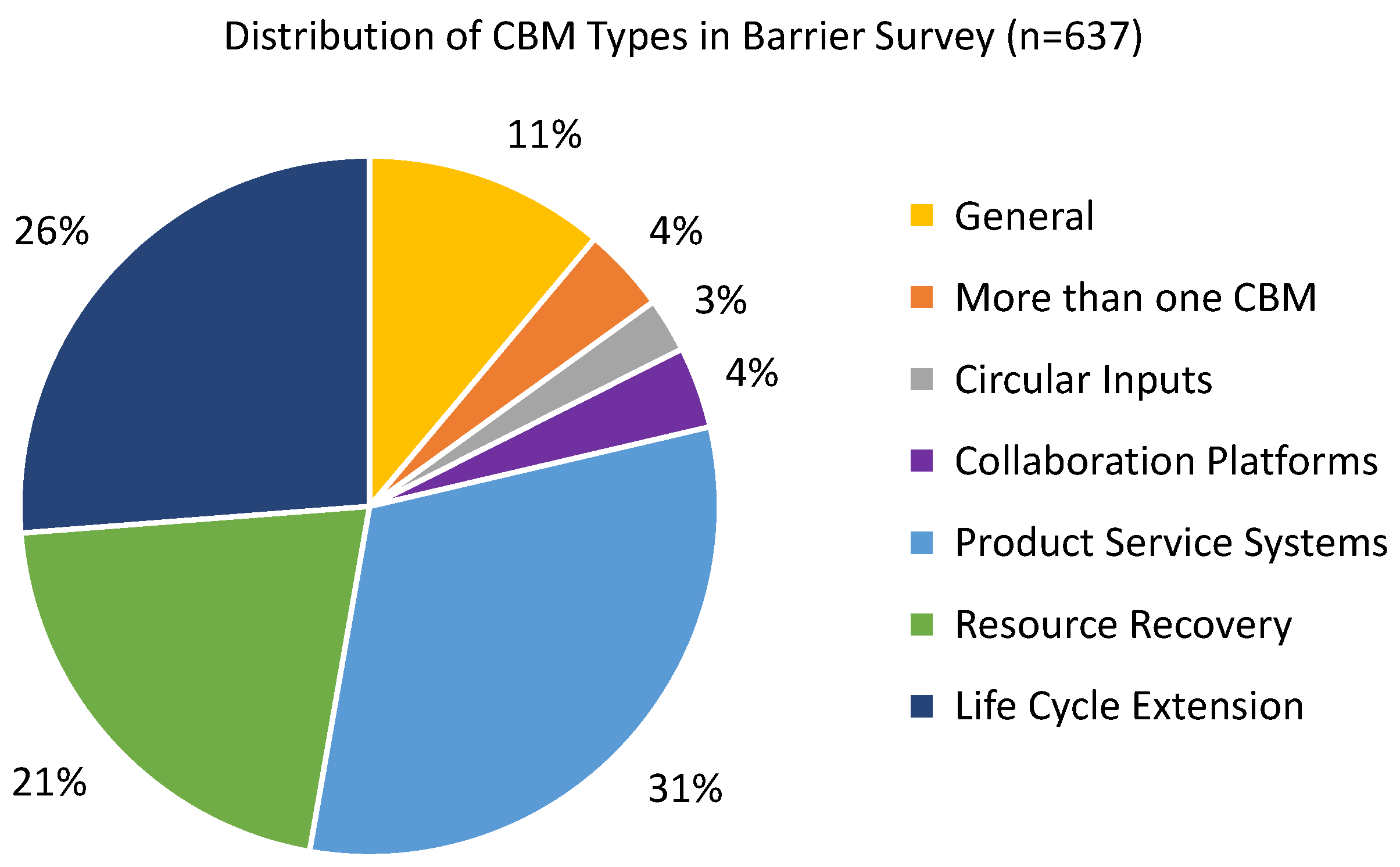

4.1. Descriptive Analysis

4.2. Thematic Analysis

4.2.1. Context and Analysis of Publications

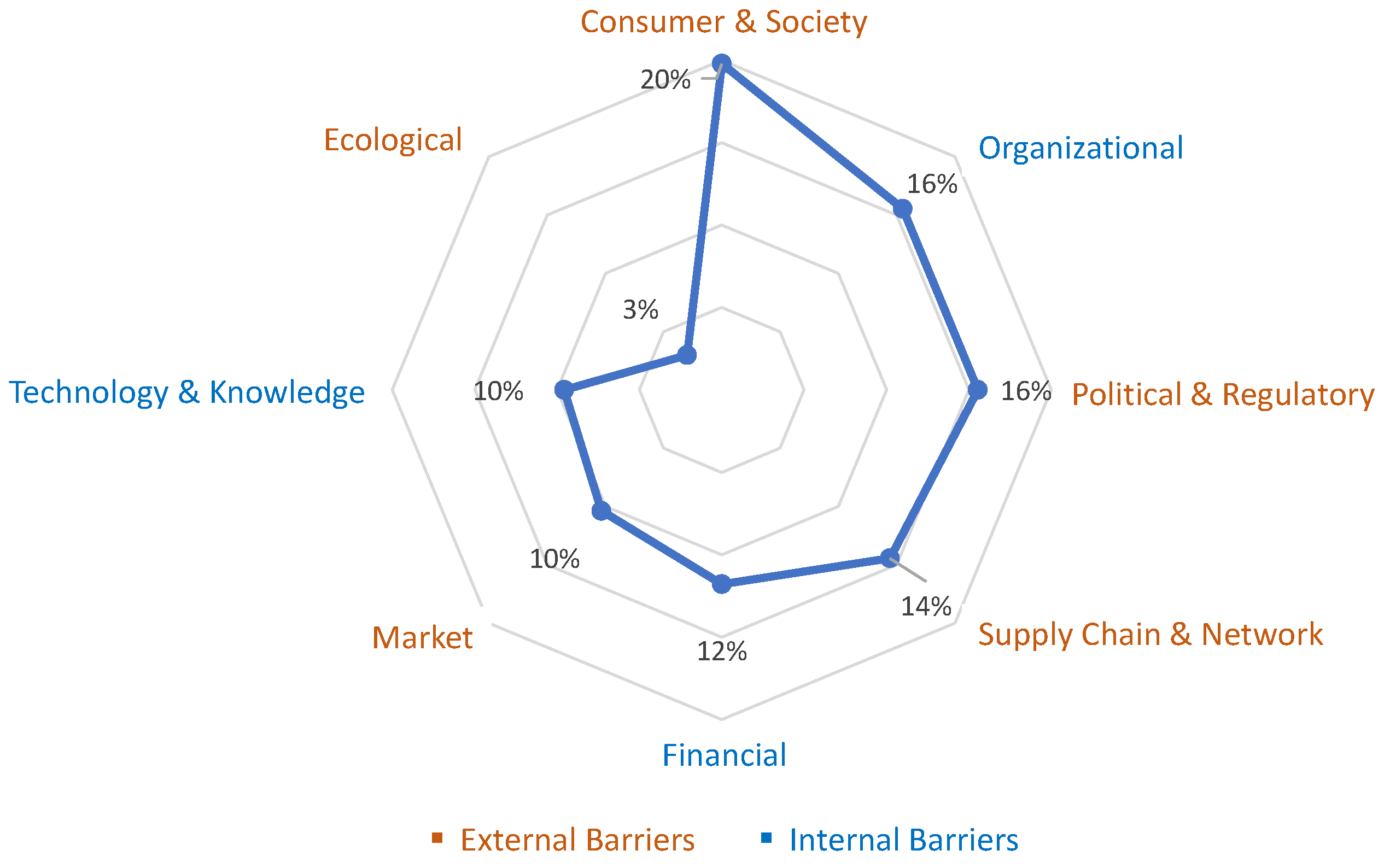

4.2.2. Barrier and Driver Categories

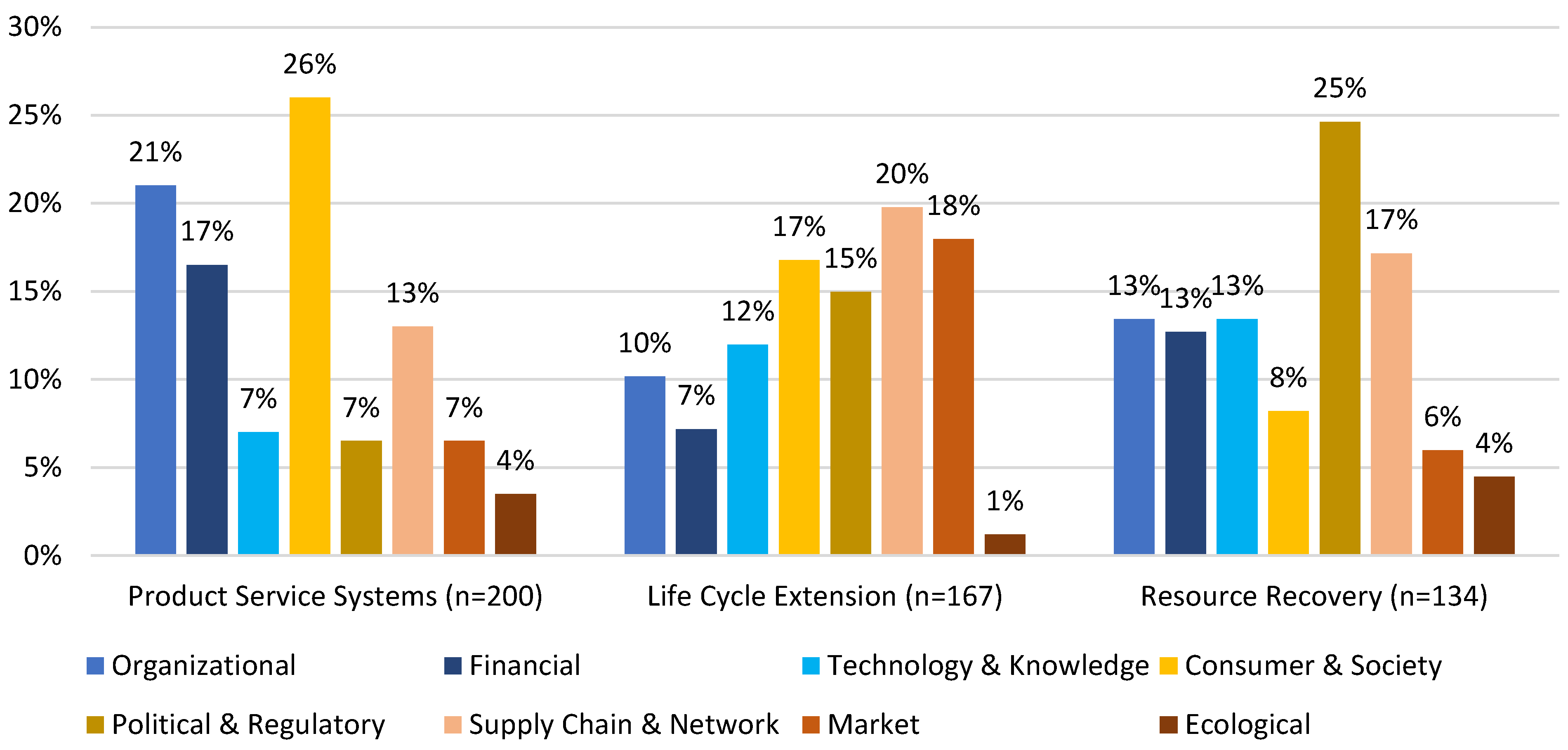

Barriers According to CBM Type

Drivers of Circular Business Models

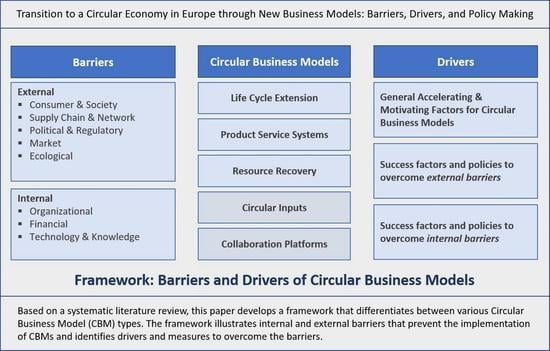

5. Framework: Barriers and Drivers of Circular Business Models

5.1. Framework Overview

5.2. Barriers of Circular Business Models

5.2.1. External Barriers

5.2.2. Internal Barriers

Summary: Barrier Framework

5.3. Drivers of Circular Business Models

5.3.1. Accelerating and Motivating Factors

- Economic: 33 (within the top 10: 33 of 77 = 43%); otherwise 33/138 = 24%.

- Social: 25 (within the top 10: 25 out of 77 = 32%); otherwise 35/138 = 18%.

- Environmental: 19 (within top 10: 19 of 77 = 25%); otherwise 33/138 = 14%.

Economic Factors

Social Factors

Environmental Factors

5.3.2. Success Factors and Policies to Overcome External Barriers

Summary on Overcoming External Barriers

5.3.3. Success Factors and Policies to Overcome Internal Barriers

Summary on Overcoming Internal Barriers

6. Discussion and Conclusions

6.1. Key Results

- (1)

- Consumer and societal barriers, including cultural dominance and status of ownership, consumer concerns about access to personal data, and invasion of privacy;

- (2)

- Internal organizational barriers, including management challenges associated with renting rather than selling and complexity, and expenses of CBM;

- (3)

- Financial barriers, including high upfront investments and long payback periods, as well as high operating costs over the entire product life-cycle.

- (1)

- Supply chain barriers, including insufficient access and availability of products and spare parts, high logistics requirements due to storage capacities, and reverse logistics;

- (2)

- Market and consumer-related barriers, including underpricing of primary raw materials, consumers misjudging quality, and value of used products;

- (3)

- Political and regulatory barriers, including high taxation of labor and lack of standards and certifications.

- (1)

- Policies and regulations, including illegal waste trade and disposal, as well as waste legislation, impedes waste processing;

- (2)

- Supply chain and network barriers, e.g., difficult cooperation, dependency on partners, and available waste volume;

- (3)

- Technology and knowledge including technically difficult handling of material and waste streams.

6.2. Implications, Limitations, and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Search Round | Search Method | Search String | Date | Number of Search Results |

|---|---|---|---|---|

| 1 | Database: Scopus | TITLE-ABS-KEY (“circular business model*” OR (“Circular Economy” AND “business model*”)) AND TITLE-ABS-KEY (“driver*” OR “levers” OR “enablers” OR “enabling factors” OR “enabling conditions” OR “facilitators” OR “opportunities” OR “success factors”) | 18 May 2020 | 163 |

| 1 | Database: Scopus | TITLE-ABS-KEY (“circular business model*” OR (“Circular Economy” AND “business model*”)) AND TITLE-ABS-KEY (“Barrier*” OR “Challenges” OR “obstacles” OR “hurdles” OR “limitations”) | 18 May 2020 | 192 |

| 1 | Database: Web of Science | TS = (“circular business model*” OR (“Circular economy” AND “business model*”)) AND TS = (“driver*” OR “levers” OR “enablers” OR “enabling factors” OR “enabling conditions” OR “facilitators” OR “opportunities” OR “success factors”) | 18 May 2020 | 145 |

| 1 | Database: Web of Science | TS = (“circular business model*” OR (“Circular economy” AND “business model*”)) AND TS = (“Barrier*” OR “Challenges” OR “obstacles” OR “hurdles” OR “limitations”) | 18 May 2020 | 172 |

| 1 | Online library search of the Technical University Berlin | German key words: (“zirkuläre geschäftsmodelle” OR (“kreislaufwirtschaft” AND “geschäftsmodell”)) AND (“Barrieren” OR “herausforderungen” OR “hürden” OR “hindernisse” OR “einschränkungen”) | 18 May 2020 | 11 |

| 1 | Online library search of the Technical university Berlin | German key words: (“zirkuläre geschäftsmodelle” OR (“kreislaufwirtschaft” AND “geschäftsmodell”)) AND (“treiber” OR “hebel” OR “befähiger” OR “günstige rahmenbedingungen” OR “erfolgsfaktoren” OR “möglichkeiten” OR “unterstützer” OR “wegbereiter”) | 18 May 2020 | 13 |

| 2 | Database by Sopjani et al. (2020) | The data base contains 527 publications. The filters “Status = Done” and “Barrier_Focus = Barrier(s) are the focus” were applied, resulting in 214 publications that were added to the sample. | 18 May 2020 | 214 |

| 3 | OECD | “Circular Business Model” | 5 July 2020 | 4 |

| 3 | Publications Office of the European Union | “Circular Business Model”, Filter: EU Publications | 5 July 2020 | 53 |

| 3 | Fraunhofer Publica | “Circular Business Model” | 5 July 2020 | 5 |

| 3 | Fraunhofer Publica | barriers circular economy | 6 July 2020 | 1 |

| 3 | Fraunhofer Publica | drivers circular economy | 6 July 2020 | 2 |

| 3 | Acatech | “circular economy” | 7 July 2020 | 2 |

| 3 | Ellen McArthur Foundation | Publication page (no search window available) | 5 July 2020 | 25 |

| 3 | Accenture | Circular Economy | 7 July 2020 | 19 |

| 3 | Circle Economy | Publication page (no search window available) | 7 July 2020 | 16 |

References

- Ellen MacArthur Foundation (Hg.). Completing the Picture: How the Circular Economy Tackles Climate Change. 2019. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/Completing_The_Picture_How_The_Circular_Economy-_Tackles_Climate_Change_V3_26_September.pdf (accessed on 7 June 2020).

- Ellen MacArthur Foundation (Hg.). Growth Within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://ellenmacarthurfoundation.org/growth-within-a-circular-economy-vision-for-a-competitive-europe (accessed on 9 June 2020).

- Europäisches Parlament. Kreislaufwirtschaft: Definition und Vorteile. 2015. Available online: https://www.europarl.europa.eu/news/de/headlines/economy/20151201STO05603/kreis-laufwirtschaft-definition-und-vorteile (accessed on 7 June 2020).

- Global Footprint Network & WWF (Hg.). EU Overshoot Day: Living Beyond Nature’s Limits. Brussels. 2019. Available online: https://www.wwf.de/fileadmin/fm-wwf/Publikationen-PDF/WWF_EU-Overshoot-Day_Report_2019.pdf (accessed on 7 June 2020).

- Weber, T.; Stuchtey, M. Deutschland auf dem Weg zur Circular Economy: Erkenntnisse aus europäischen Strategien: Vorstudie; Acatech–Deutsche Akademie der Technikwissenschaften: Munich, Germany, 2019. [Google Scholar]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (Hg.). Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 9 June 2020).

- Dalhammar, C.; Milios, L. Policies to support reconditioning and reuse of ICT. In Proceedings of the 2016 Electronics Goes Green 2016+ (EGG), Berlin, Germany, 6–9 September 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking circular business: A framework of barriers and drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bocken, N.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Oghazi, P.; Mostaghel, R. Circular business model challenges and lessons learned—An industrial perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan—The European Green Deal: For a Cleaner and More Competitive Europe. 2020. Available online: https://ec.europa.eu/environment/circular-economy/pdf/new_circular_economy_action_plan.pdf (accessed on 30 May 2020).

- Vermunt, D.A.; Negro, S.O.; Verweij, P.A.; Kuppens, D.V.; Hekkert, M.P. Exploring barriers to implementing different circular business models. J. Clean. Prod. 2019, 222, 891–902. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (Hg.). Towards the Circular Economy: Opportunities for the Consumer Goods Sector. 2013. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-2-opportunities-for-the-consumer-goods (accessed on 9 June 2020).

- Planing, P. Business Model Innovation in a Circular Economy Reasons for Non-Acceptance of Circular Business Models. Open J. Bus. Model Innov. 2015, 1, 1–11. [Google Scholar]

- Lacy, P.; Long, J.; Spindler, W. The Circular Economy Handbook; Palgrave Macmillan: London, UK, 2020. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- von Hauff, M. Nachhaltige Entwicklung: Grundlagen und Umsetzung (2. Aktualisierte Auflage); De Gruyter Oldenbourg: Kaiserslautern, Germany, 2014. [Google Scholar] [CrossRef]

- Schaltegger, S.; Herzig, C.; Kleiber, O.; Klinke, T.; Müller, J.D. Nachhaltigkeitsmanagement in Unternehmen: Von der Idee zur Praxis: Managementansätze zur Umset-zung von Corporate Social Responsibility und Corporate Sustainability. Cent. Sustain. Manag. 2007, 3, 6–7. [Google Scholar]

- Vereinte Nationen (Hg.). Ziele für Nachhaltige Entwicklung: Bericht. New York. 2019. Available online: https://www.un.org/Depts/german/pdf/SDG%20Bericht%20aktuell.pdf (accessed on 11 June 2020).

- Rodriguez-Anton, J.M.; Rubio-Andrada, L.; Celemín-Pedroche, M.S.; Alonso-Almeida, M.D.M. Analysis of the relations between circular economy and sustainable development goals. Int. J. Sustain. Dev. World Ecol. 2019, 26, 708–720. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Bartelmus, P. The future we want: Green growth or sustainable development? Environ. Dev. 2013, 7, 165–170. [Google Scholar] [CrossRef]

- Middleton, N.; O’Keefe, P.; Moyo, S. The Tears of the Crocodile: From Rio to Reality in the Developing World; Pluto Press: London, UK, 1993. [Google Scholar]

- European Commission. Additional Analysis to Complement the Impact Assessment SWD (2014) 208 Supporting the Review of EU Waste Management Targets. Brussels. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:52015SC0259 (accessed on 11 June 2020).

- Stahel, W.R. Policy for material efficiency—Sustainable taxation as a departure from the throwaway society. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2013, 371, 20110567. [Google Scholar] [CrossRef]

- European Environment Agency. Circular Economy in Europe: Developing the Knowledge Base; EEA Report: No. 2/2016; Publications Office of the European Union: Luxembourg, 2016. [CrossRef]

- The Danish Government. Danmark uden affald II: Strategi for Affaldsforebyggelse. 2015. Available online: https://mst.dk/media/90395/danmark_uden_affald_ii_web_29042015.pdf (accessed on 9 June 2020).

- VDI Zentrum Ressourceneffizienz. Competitive Advantage: Resource Efficiency: Definitions, Basics, Facts and Examples. 2016. Available online: https://www.ressource-deutschland.de/fileadmin/user_upload/1_Themen/h_Publikationen/VDI-ZRE-competitive-advantage-resource-efficiency.pdf (accessed on 9 June 2020).

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Guldmann, E.; Huulgaard, R.D. Barriers to circular business model innovation: A multiple-case study. J. Clean. Prod. 2020, 243, 118160. [Google Scholar] [CrossRef]

- Franco, M.A. A system dynamics approach to product design and business model strategies for the circular economy. J. Clean. Prod. 2019, 241, 118327. [Google Scholar] [CrossRef]

- Fraccascia, L.; Magno, M.; Albino, V. Business models for industrial symbiosis: A guide for firms. Procedia Environ. Sci. Eng. Manag. 2016, 3, 83–93. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Henry, M.; Bauwens, T.; Hekkert, M.; Kirchherr, J. A typology of circular start-ups: Analysis of 128 circular business models. J. Clean. Prod. 2020, 245, 118528. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; Luz, L.M.d.; Piekarski, C.M.; de Francisco, A.C. Circular business models: Current aspects that influence implementation and unaddressed subjects. J. Clean. Prod. 2020, 250, 119555. [Google Scholar] [CrossRef]

- OECD. Business Models for the Circular Economy: Opportunities and Challenges for Policy; OECD Publishing: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Holst, A.; Buddemeier, P.; Machur, W. Circular Economy—Deutsche Unternehmen auf demWeg zu transformativen Geschäftsmodellen. In Management-Reihe Corporate Social Responsibility; Bungard, P., Ed.; CSR und Geschäftsmodelle: Auf dem Weg zum zeitgemäßen Wirtschaften; Springer Gabler: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Lacy, P.; Rutqvist, J.; Buddemeier, P. Wertschöpfung statt Verschwendung: Die Zukunft Gehört der Kreislaufwirtschaft (1. Aufl.). Redline Verlag. 2015. Available online: http://gbv.eblib.com/patron/FullRecord.aspx?p=4342820 (accessed on 9 June 2020).

- Rudolph, C. Geschäftsmodell Circular Economy: Gegenwart und Zukunft der (erweiterten) Kreislaufwirtschaft. In Management-Reihe Corporate Social Responsibility; Bungard, P., Ed.; CSR und Geschäftsmodelle: Auf dem Weg zum zeitgemäßen Wirtschaften; Springer Gabler: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Stuchtey, M.R.; Kranendijk, S. The Role of Business in the Circular Economy: Markets, Processes and Enabling Policies; Centre for European Policy Studies (CEPS): Brussels, Belgium, 2018. [Google Scholar]

- Eguren, J.A.; Justel, D.; Iriarte, I.; Esnaola, A. Opportunities and incentives for Remanufacturing in the Basque Country. Procedia CIRP 2018, 73, 253–258. [Google Scholar] [CrossRef]

- Chierici, E.; Copani, G. Remanufacturing with Upgrade PSS for New Sustainable Business Models. Procedia CIRP 2016, 47, 531–536. [Google Scholar] [CrossRef]

- European Commission. Products and Circular Economy: Policy Recommendations Derived from Research & Innovation Projects; Directorate-General for Research and Innovation (European Comission): Brussels, Belgium, 2020.

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- European Environment Agency. Waste Generation in Europe. 2019. Available online: https://www.eea.europa.eu/data-and-maps/indicators/waste-generation-4/assessment (accessed on 9 June 2020).

- Wachholz, C. Wird uns die zirkuläre Wirtschaftspolitik der EU zu einer nachhaltigen Entwicklung führen? In Kreislaufwirtschaft in der EU: Eine Zwischenbilanz; Eisenriegler, S., Ed.; Springer Fachmedien Wiesbaden: Berlin/Heidelberg, Germany, 2020; pp. 67–78. [Google Scholar] [CrossRef]

- Milios, L. Advancing to a Circular Economy: Three essential ingredients for a comprehensive policy mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef]

- Postpischil, R.; Jacob, K. Ressourcenpolitische Innovationen in den EU Mitgliedsstaaten: Inspirationen für Deutschland? Vertiefungsanalyse Im Proj. Ressour. 2017. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Whalen, K.A.; Milios, L.; Nussholz, J. Bridging the gap: Barriers and potential for scaling reuse practices in the Swedish ICT sector. Resour. Conserv. Recycl. 2018, 135, 123–131. [Google Scholar] [CrossRef]

- Mura, M.; Longo, M.; Zanni, S. Circular economy in Italian SMEs: A multi-method study. J. Clean. Prod. 2020, 245, 118821. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving ‘leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Gumley, W. An Analysis of Regulatory Strategies for Recycling and Re-Use of Metals in Australia. Resources 2014, 3, 395–415. [Google Scholar] [CrossRef]

- Fedotkina, O.; Gorbashko, E.; Vatolkina, N. Circular economy in Russia: Drivers and barriers for waste management development. Sustainability 2019, 11, 5837. [Google Scholar] [CrossRef]

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strategy Environ. 2019, 28, 274–285. [Google Scholar] [CrossRef]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Ecoinnovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- Salim, H.K.; Stewart, R.A.; Sahin, O.; Dudley, M. Drivers, barriers and enablers to end-of-life management of solar photovoltaic and battery energy storage systems: A systematic literature review. J. Clean. Prod. 2019, 211, 537–554. [Google Scholar] [CrossRef]

- da Costa Fernandes, S.; Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Towards product-service system oriented to circular economy: A systematic review of value proposition design approaches. J. Clean. Prod. 2020, 257, 120507. [Google Scholar] [CrossRef]

- Brown, T.; Churchill, G.A.; Suter, T.A. Basic Marketing Research: Customer Insights and Managerial Action, 8th ed.; Cengage Learning: Boston, MA, USA, 2014. [Google Scholar]

- Davies, P. Exploratory Research. In The Sage Dictionary of Social Research Methods; Jupp, V., Ed.; Sage: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- De Almeida Biolchini, J.C.; Mian, P.G.; Natali, A.C.C.; Conte, T.U.; Travassos, G.H. Scientific research ontology to support systematic review in software engineering. Adv. Eng. Inform. 2007, 21, 133–151. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Ghisetti, C.; Montresor, S. On the adoption of circular economy practices by small and medium-size enterprises (SMEs): Does “financing-as-usual” still matter? J. Evol. Econ. 2019. advance online publication. [Google Scholar] [CrossRef]

- Singh, P.; Giacosa, E. Cognitive biases of consumers as barriers in transition towards circular economy. Manag. Decis. 2019, 57, 921–936. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. The role of digital technologies to overcome Circular Economy challenges in PSS Business Models: An exploratory case study. Procedia CIRP 2018, 73, 216–221. [Google Scholar] [CrossRef]

- D’Amato, D.; Veijonaho, S.; Toppinen, A. Towards sustainability? Forest-based circular bioeconomy business models in Finnish SMEs. For. Policy Econ. 2020, 110, 101848. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef]

- Sopjani, L.; Arekrans, J.; Laurenti, R.; Ritzén, S. Unlocking the Linear Lock-In: Mapping Research on Barriers to Transition. Sustainability 2020, 12, 1034. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Inc.: New York, NY, USA, 2009. [Google Scholar]

- Chappin, E.J.L.; Ligtvoet, A. Transition and transformation: A bibliometric analysis of two scientific networks researching socio-technical change. Renew. Sustain. Energy Rev. 2014, 30, 715–723. [Google Scholar] [CrossRef]

- Franciosi, C.; Voisin, A.; Miranda, S.; Riemma, S.; Iung, B. Measuring maintenance impacts on sustainability of manufacturing industries: From a systematic literature review to a framework proposal. J. Clean. Prod. 2020, 260, 121065. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-oriented Innovation: A Systematic Review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Content Analysis: Theoretical Foundation, Basic Procedures and Software Solution. 2014. Available online: https://www.ssoar.info/ssoar/bitstream/handle/document/39517/ssoar-2014-mayring-Qualitative_content_analysis_theoretical_foundation.pdf?sequence=1 (accessed on 19 June 2020).

- Bastein, T.; Diaz Lopez, F.J.; Dittrich, K.; Koers, W.; Becker, J. Business Barriers to the Uptake of Resource Efficiency Measures; Deliverable D1.5 Report; Netherlands Organisation for Applied Scientific Research: The Hague, The Netherlands, 2014. [Google Scholar]

- Hannon, M.J.; Foxon, T.J.; Gale, W.F. ‘Demand pull’ government policies to support Product-Service System activity: The case of Energy Service Companies (ESCos) in the UK. J. Clean. Prod. 2015, 108, 900–915. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product–Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D.; Zwolinski, P. The strategy for implementing remanufacturing process in a commercial enterprise, the case study of a French company. Procedia CIRP 2019, 80, 554–559. [Google Scholar] [CrossRef]

- Ongondo, F.O.; Williams, I.D.; Dietrich, J.; Carroll, C. ICT reuse in socio-economic enterprises. Waste Manag. 2013, 33, 2600–2606. [Google Scholar] [CrossRef]

- Almefelt, L.; Rexfelt, O. A tool for assessing customers’ barriers for consuming remanufactured products. In Proceedings of the 21st International Conference on Engineering Design (ICED17), Vancouver, BC, Canada, 21–25 August 2017; Volume 1. [Google Scholar]

- Yang, S.; Raghavendra, M.R.A.; Kaminski, J.; Pepin, H. Opportunities for Industry 4.0 to Support Remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Besch, K. Product-service systems for office furniture: Barriers and opportunities on the European market. J. Clean. Prod. 2005, 13, 1083–1094. [Google Scholar] [CrossRef]

- Petrulaityte, A.; Ceschin, F.; Pei, E.; Harrison, D. Supporting Sustainable Product—Service System Implementation through Distributed Manufacturing. Procedia CIRP 2017, 64, 375–380. [Google Scholar] [CrossRef]

- Barnes, S.J.; Mattsson, J. Understanding current and future issues in collaborative consumption: A four-stage Delphi study. Technol. Forecast. Soc. Chang. 2016, 104, 200–211. [Google Scholar] [CrossRef]

- Colley-Jones, R.; Accili, A.; Campadello, L.; Emmerich, J. Chapter 11. Plastics in Electronic Waste: Results from the PolyCE Project. In Issues in Environmental Science and Technology; Eduljee, G.H., Harrison, R.M., Eds.; Electronic Waste Management: London, UK, 2019; pp. 313–337. [Google Scholar] [CrossRef]

- Martinez, V.; Bastl, M.; Kingston, J.; Evans, S. Challenges in transforming manufacturing organisations into product-service providers. J. Manuf. Technol. Manag. Bingley UK 2010, 21, 449–469. [Google Scholar] [CrossRef]

- Sommer, K.H. Study and Portfolio Review of the Projects on Industrial Symbiosis in DG Research and Innovation: Findings and Recommendations; European Commission: Luxembourg, 2020. [Google Scholar]

- Kalverkamp, M. Hidden potentials in open-loop supply chains for remanufacturing. Int. J. Logist. Manag. 2018, 29, 1125–1146. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Nygaard Rasmussen, F.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Paletta, A.; Leal Filho, W.; Balogun, A.-L.; Foschi, E.; Bonoli, A. Barriers and challenges to plastics valorisation in the context of a circular economy: Case studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

- Leder, N.; Kumar, M.; Rodrigues, V.S. Influential factors for value creation within the Circular Economy: Framework for Waste Valorisation. Resour. Conserv. Recycl. 2020, 158, 104804. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding roles for the Swedish waste management sector in inter-organizational resource management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- EREK. The Implementation of the Circular Economy in Europe: Perspectives of EU Industry Cluster Managers and Regional Policymakers; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Öhgren, M.; Milios, L.; Dalhammar, C.; Lindahl, M. Public procurement of reconditioned furniture and the potential transition to product service systems solutions. Procedia CIRP 2019, 83, 151–156. [Google Scholar] [CrossRef]

- van Barneveld, J.; van der Veen, G.; Enenkel, K.; Mooren, C.; Talman-Gross, L.; Eckartz, K.; Ostertag, K.; Duque-Ciceri, N.; Fischer, T.; Gama, M.; et al. Regulatory Barriers for the Circular Economy: Lessons from Ten Case Studies; Technopolis Group: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Agrawal, V.V.; Atasu, A.; van Wassenhove, L.N. OM Forum—New Opportunities for Operations Management Research in Sustainability. Manuf. Serv. Oper. Manag. 2019, 21, 1–12. [Google Scholar] [CrossRef]

- Tingley, D.D.; Cooper, S.; Cullen, J. Understanding and overcoming the barriers to structural steel reuse, a UK perspective. J. Clean. Prod. 2017, 148, 642–652. [Google Scholar] [CrossRef]

- Pessôa, M.V.P.; Becker, J.M.J. Overcoming the Product-Service Model Adoption Obstacles. Procedia CIRP 2017, 64, 163–168. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- van Loon, P.; van Wassenhove, L.N. Transition to the circular economy: The story of four case companies. Int. J. Prod. Res. 2020, 58, 3415–3422. [Google Scholar] [CrossRef]

- Svensson, N.; Funck, E.K. Management control in circular economy. Exploring and theorizing the adaptation of management control to circular business models. J. Clean. Prod. 2019, 233, 390–398. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Herzog, M.; Meuris, D.; Bender, B.; Sadek, T. The Nature of Risk Management in the Early Phase of IPS2 Design. Procedia CIRP 2014, 16, 223–228. [Google Scholar] [CrossRef]

- Kraanen, F. Money Makes the World Go Around: (and Will it Help to Make the Economy Circular as Well?). Netherlands. 2016. Available online: https://publish.circle-economy.com/moneymakestheworldgoround (accessed on 19 June 2020).

- Chen, C.-W. Improving circular economy business models: Opportunities for Business and Innovation A new framework for businesses to create a truly circular economy. Johns. Matthey Technol. Rev. 2020, 64, 48–58. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Archer, S.A.; Gomes, H.I.; Christgen, B.; Lag-Brotons, A.J.; Purnell, P. Circular economy and the matter of integrated resources. Sci. Total Environ. 2019, 689, 963–969. [Google Scholar] [CrossRef]

- Becker-Leifhold, C.; Iran, S. Collaborative fashion consumption—Drivers, barriers and future pathways. J. Fash. Mark. Manag. Int. J. 2018, 22, 189–208. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; de Rijck, R.; Dewit, I. Internal levers for servitization: How product-oriented manufacturers can upscale product-service systems. Int. J. Prod. Res. 2018, 56, 2184–2198. [Google Scholar] [CrossRef]

- Gullstrand Edbring, E.; Lehner, M.; Mont, O. Exploring consumer attitudes to alternative models of consumption: Motivations and barriers. J. Clean. Prod. 2016, 123, 5–15. [Google Scholar] [CrossRef]

- Parajuly, K.; Fitzpatrick, C.; Muldoon, O.; Kuehr, R. Behavioral change for the circular economy: A review with focus on electronic waste management in the EU. Resour. Conserv. Recycl. X 2020, 6, 100035. [Google Scholar] [CrossRef]

- Hazée, S.; Delcourt, C.; van Vaerenbergh, Y. Burdens of Access: Understanding Customer Barriers and Barrier-Attenuating Practices in Access-Based Services. J. Serv. Res. 2017, 20, 441–456. [Google Scholar] [CrossRef]

- Cantele, S.; Moggi, S.; Campedelli, B. Spreading Sustainability Innovation through the Co-Evolution of Sustainable Business Models and Partnerships. Sustainability 2020, 12, 1190. [Google Scholar] [CrossRef]

- Antikainen, M.; Uusitalo, T.; Kivikytö-Reponen, P. Digitalisation as an Enabler of Circular Economy. Procedia CIRP 2018, 73, 45–49. [Google Scholar] [CrossRef]

- Flynn, A.; Hacking, N. Setting standards for a circular economy: A challenge too far for neoliberal environmental governance? J. Clean. Prod. 2019, 212, 1256–1267. [Google Scholar] [CrossRef]

- Mahler, A.; Runkel, M.; Ludewig, D.; Klusmann, B.; Zerzawy, F. Die Finanzierung Deutschlands über Steuern auf Arbeit, Kapital und Umweltverschmutzung. 2017. Available online: https://foes.de/pdf/2017-06-Hintergrundpapier-Steuerstruktur.pdf (accessed on 1 July 2020).

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe: Typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Clemente, D.H.; Abadia, L.G.; Araujo Galvão, G.D.; de Carvalho, M.M. Product—Service Systems (PSS) and Public Policies: Lessons from the Literature. Procedia CIRP 2018, 73, 284–290. [Google Scholar] [CrossRef]

| RQ | Research Question | Objective |

|---|---|---|

| 1 | What is the current state of research on the barriers and drivers of circular business models and how do the contributions differ? | Evaluation of state-of-the-art on the barriers and drivers of circular business models and the identification of future research needs. |

| 2 | Which barrier category, regardless of the type of circular business model, is the most common in the literature? | Quantitative identification across the literature of the general trend in the largest barrier categories for CBMs, providing an initial indication of the role of various stakeholders. |

| 3 | Do the barriers differ between different circular business models, and if so, how? | Proportion comparison of the barrier categories between CBMs. If they differ, this is a basis for the development of a framework that shows the most relevant barriers for each CBM. |

| 4 | What drivers are accelerating the spread of CBMs and what actions can policy makers and businesses take to overcome these barriers? | Differentiation of the term driver and the assignment of possible measures to overcome the barriers, thus revealing indications for the role of politics and companies. |

| Level | Category | Definition |

|---|---|---|

| Internal | Organizational | Companies as social systems, influenced by goals, routines, organizational structures, lack of time, and personnel, etc. |

| Financial | Financial aspects such as financing of CBM, special features in costs, and revenue model. | |

| Technology and Knowledge | Availability of technology and knowledge that positively or negatively influences the production processes or business activities. | |

| External | Consumer and Societal | Behavioral and attitude-related factors of consumers and society. |

| Political and Regulatory | Barriers/drivers triggered by actions of political institutions and current laws, standards, tax systems, etc. | |

| Supply Chain and Network | Procurement, transport, and logistics aspects, as well as barriers and drivers in network collaboration. | |

| Market | Market conditions, competitor relationships, market demand-related barriers, and drivers. | |

| Ecological | Positive or negative environmental impacts associated with CBMs. |

| Barrier Category | Circular Business Models | ||

|---|---|---|---|

| External | Product Service Systems | Life-Cycle Extension | Resource Recovery |

| Consumer and Society |

|

| No barrier identified with more than three citations |

| Supply Chain and Network |

|

|

|

| Political and Regulatory | No barrier identified with more than three citations |

|

|

| Market |

|

|

|

| Ecological |

| No barrier identified with more than three citations | No barrier identified with more than three citations |

| Internal | Product Service Systems | Life-Cycle Extension | Resource Recovery |

| Organizational |

|

|

|

| Financial |

|

|

|

| Technology and Knowledge | No barrier identified with more than three citations |

|

|

| Consumer and Society | ||||

|---|---|---|---|---|

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Consumer concerns about access to personal data and privacy | LCE, PSS, and RR | Digital technologies automatically determine maintenance needs without invading customer privacy | ||

| Failure to recognize the quality and value of used and remanufactured products | LCE and PSS | Provision of additional services such as warranties on the products, which includes a free technical support service | Label and standards for remanufactured products Quality certification system for repair and remanufacturing work | Information |

| Lack of consumer awareness and understanding | LCE, PSS, and RR | Transparent communication of advantages and possible difficulties to customers | Public relations campaigns to educate consumers about benefits | Information |

| Cultural dominance and preference of ownership | PSS | Communicate transparency about costs of owning rather than renting | Public relations campaigns to educate consumers about benefits Behavioral economic incentives | Information |

| Consumers prefer new/current products | LCE and PSS | Digital, technical, and aesthetic product upgrades | ||

| Low readiness of consumers to pay for used products | LCE, PSS, and RR | Transparency over the costs of the entire usage phase Flexible termination options for PSS models | Provide economic incentives, e.g., reduced VAT rates for remanufactured products | Economically incentivized |

| Supply Chain and Network | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Lack of or difficult cooperation with partners | LCE, PSS, and RR | Critical success factors of collaborative networking (shared values, commitment, and role model function of an influential actor, etc.) | Grants for CE projects from companies, universities, and communities | Research and education |

| Required logistic infrastructure (reverse logistics, transport, and storage capacities) | LCE, PSS, and RR | Technologies such as sensors or RFID for product traceability Partnership with external logistics providers for reverse logistics Geographically distributed factories eliminate the need to collect products over long distances | ||

| Uncertainties about quantity, quality, time, and place of returned products | PSS | Reduce operational risk through digital technologies and information collection on product condition and usage, component failure, and aging rates | ||

| Insufficient access to and availability of products, spare parts, or materials | LCE, PSS, and RR | Buffer, stock material, or set up different material sources | Requirement for original equipment manufacturers that spare parts are available and affordable for a certain number of years | Regulatory |

| Lack of suitable suppliers/partners or too much dependence on them | LCE, PSS, and RR | Stimulation of current or new suppliers to develop materials for CE through collaboration and co-investment | Establish online platforms or databases to coordinate the supply of products and suppliers | Information |

| Political and Regulatory | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Orientation and criteria of public procurement | LCE, PSS, and RR | (European) targets and criteria for green public procurement | Regulatory | |

| High taxation of labor | LCE, PSS, and RR | Reducing taxes on the factor labor | Economically incentivized | |

| Lack of standards/certifications | LCE, PSS, and RR | Labels, standards, and quality certification systems with CE principles | Information | |

| Legislation complicates the (further) processing of waste | RR | Harmonizing the legal definition and regulations regarding the use of waste and byproducts | Regulatory | |

| Illegal waste trade and disposal | RR | Higher landfill tax Increase waste tax Enforce landfill bans more strongly | Burdening economic | |

| Uncertain, unsteady, and short-sighted governance | RR | Corporate lobbying and political participation to make decision-makers aware of problems and needs | Long-term political agenda that ensures stability for at least 10 years Increased leadership of political actors on CE | Regulatory |

| Market | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Cannibalization effect | LCE and PSS | Evaluation tools for cost−benefit calculation or tools for assessing the profitability and sustainability of CBM vs. LBM | ||

| Underpricing of new raw materials and products | LCE, RR | Regulation of higher prices for primary raw materials (e.g., through the internalization of external effects) | Regulatory | |

| Resistance of original equipment manufacturers to third-party companies | LCE | Clarification of the rights and obligations of third-party suppliers and remanufacturers | Regulatory | |

| Lack of or unclear demand from the market | LCE, RR | Demand forecasting through AI | Green public procurement as a driver to increase demand for CBM | Regulatory |

| Ecological | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Risk of rebound effects | PSS | Provide financial incentives for low-impact use Apply life-cycle assessment (LCA) Capture user behavior through digital technologies | Research to quantify environmental benefits and greenhouse gas emissions | Research and education |

| Organization | ||||

|---|---|---|---|---|

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Management challenges and strategic decisions | LCE, PSS, | Review criteria for the value proposition’s adequacy as a PSS; Adapt assessment principles and indicators for management decisions | Research on performance indicators related to product circularity Systematic identification of products that are suited for PSS | Research and education |

| Resistance to change in the company and predominance of linear thinking and corporate culture | LCE, PSS, RR | Spread and communicate sustainability values to employees; Set strategic goals and communicate them to all employees; Commitment of employees and management | ||

| Complexity and effort of CBM | LCE, PSS | Outsourcing of various activities (e.g., legal aspects of customer contracts or technical maintenance) | ||

| Lack of resources, knowledge, and competencies in the company | LCE, PSS, RR | Support information and knowledge distribution to companies (e.g., best practices, consulting services, and assessment tools) | Information | |

| Financial | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| High upfront investment and long payback period | PSS | Alternative forms of financing such as crowdfunding Contracts between product manufacturers and service providers for shared revenues can reduce large upfront investments Financing via third parties, e.g., real estate investors (e.g., for integrated washing machines for each apartment in the PSS model) | Economic incentives, especially more favorable financing to cover the initial costs of PSS projects Bridge funding for traditional manufacturing companies to operate as service providers during the transition period Government subsidies | Economically incentivized |

| Changed and uncertain cash flow | LCE, PSS | Manufacturers looking to move to a PSS model need significant cash reserves to deal with longer cash-to-cash cycles Deposits from customers and minimum-lease terms lower financial risk | ||

| Disadvantages of high capital commitment and cost responsibility over the entire product life cycle | PSS | Demand and order-driven production prevents companies from accruing costs in connection with unsold goods | Credit institutions need to adapt their mindset and risk definitions | Information |

| High costs due to the high proportion of manual work | LCE, PSS | Lowering taxes on labor | Economically incentivized | |

| High process costs (e.g., for collection and sorting) | RR | |||

| Technology and Knowledge | ||||

| Barriers | CBM | Success Factors | Political Measures | Instruments |

| Technical challenges in the design of production processes and remanufacturing | LCE, PSS | Experimenting with technologies and developing knowledge; knowledge research and exchange in (other) sectors. | Engage original equipment manufacturers to publish product information for improved third-party reparability Create a comprehensive data management platform with product-relevant information for remanufacturers | Regulatory and information |

| Improved and current product technology stays in conflict with durable products | LCE, PSS | Technical and digital product upgrades | ||

| Poor circular product design leads to technical challenges in remanufacturing | LCE | Standards and labels | Set mandatory minimum requirements for product lifetime, reparability, and recyclability | Regulatory |

| Technical challenges in handling material flows | RR | Share relevant data on waste streams, as well as their classification, composition and quantities through platforms Establish a resource management office that monitors environmental performance and collects data on primary and secondary material flows to support decision-making and investment | Information | |

| Technical solutions are not available on a commercial scale | RR | Co-financing of innovative technologies within a network for the creation of industrial symbiosis | Investment into the research and development of waste separation and treatment technologies | Research and cooperation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Försterling, G.; Orth, R.; Gellert, B. Transition to a Circular Economy in Europe through New Business Models: Barriers, Drivers, and Policy Making. Sustainability 2023, 15, 8212. https://doi.org/10.3390/su15108212

Försterling G, Orth R, Gellert B. Transition to a Circular Economy in Europe through New Business Models: Barriers, Drivers, and Policy Making. Sustainability. 2023; 15(10):8212. https://doi.org/10.3390/su15108212

Chicago/Turabian StyleFörsterling, Gabi, Ronald Orth, and Benjamin Gellert. 2023. "Transition to a Circular Economy in Europe through New Business Models: Barriers, Drivers, and Policy Making" Sustainability 15, no. 10: 8212. https://doi.org/10.3390/su15108212

APA StyleFörsterling, G., Orth, R., & Gellert, B. (2023). Transition to a Circular Economy in Europe through New Business Models: Barriers, Drivers, and Policy Making. Sustainability, 15(10), 8212. https://doi.org/10.3390/su15108212