Impact of Compression Casting Technique on the Mechanical Properties of 100% Recycled Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions

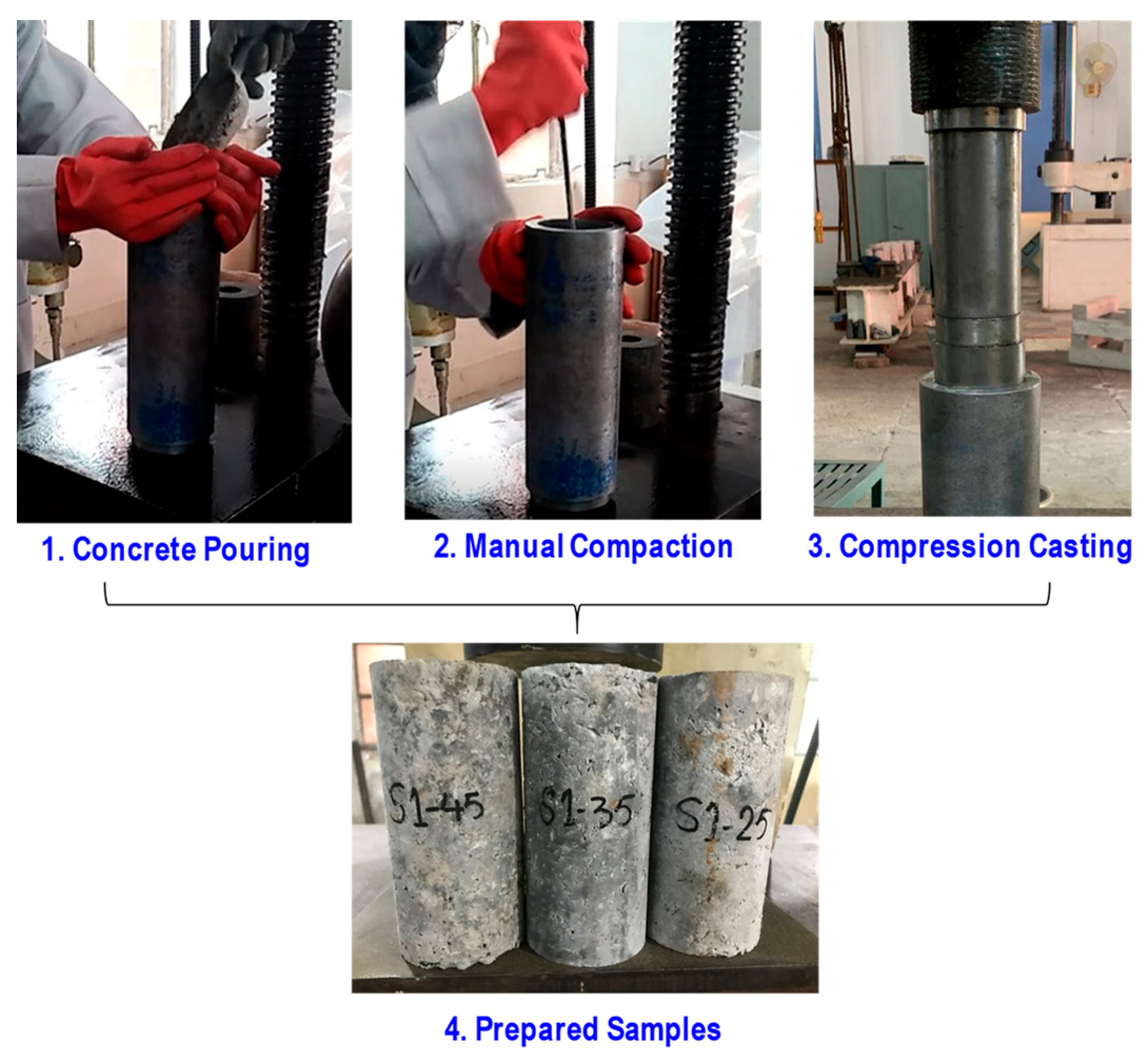

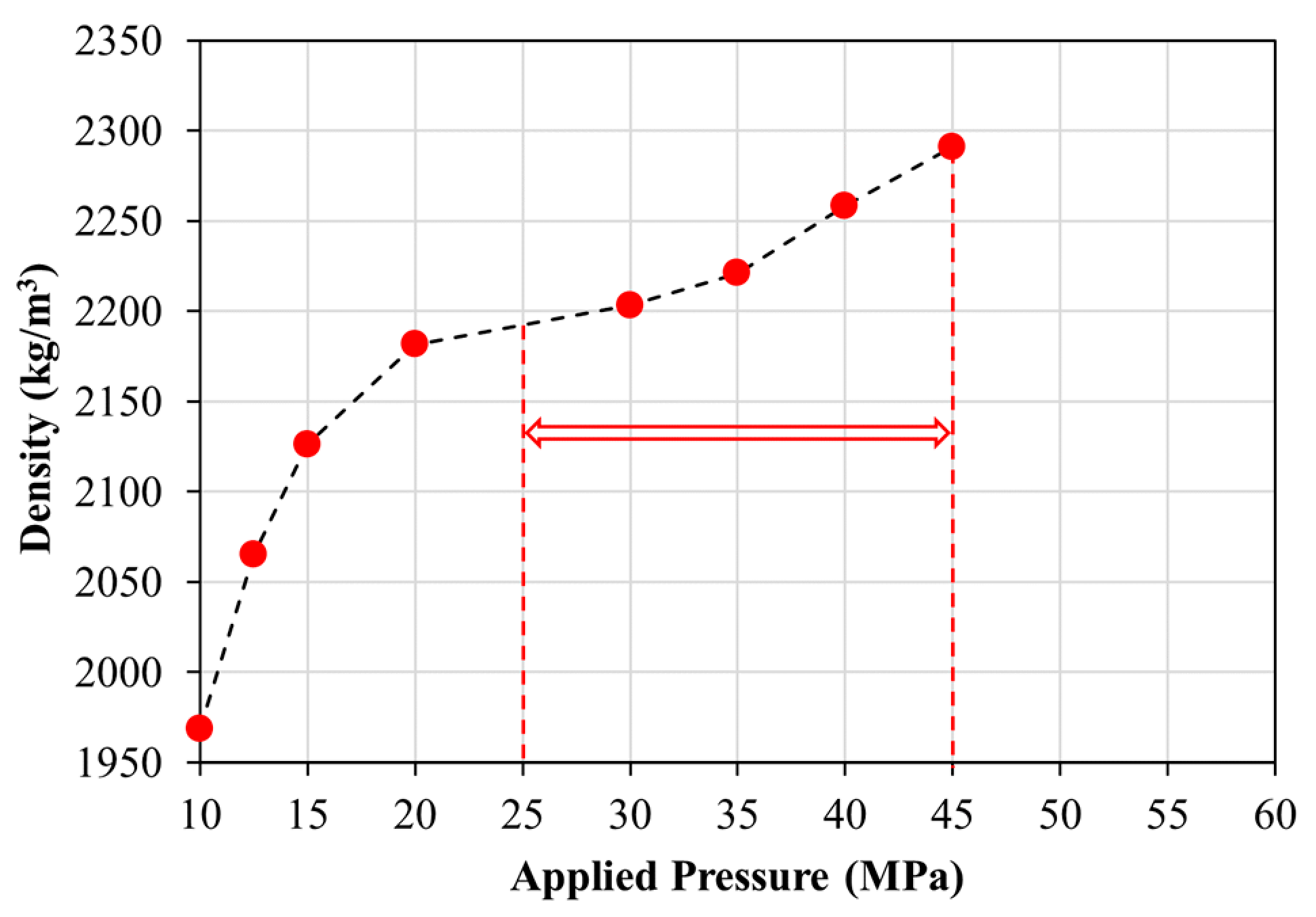

2.3. Preparation of Specimens

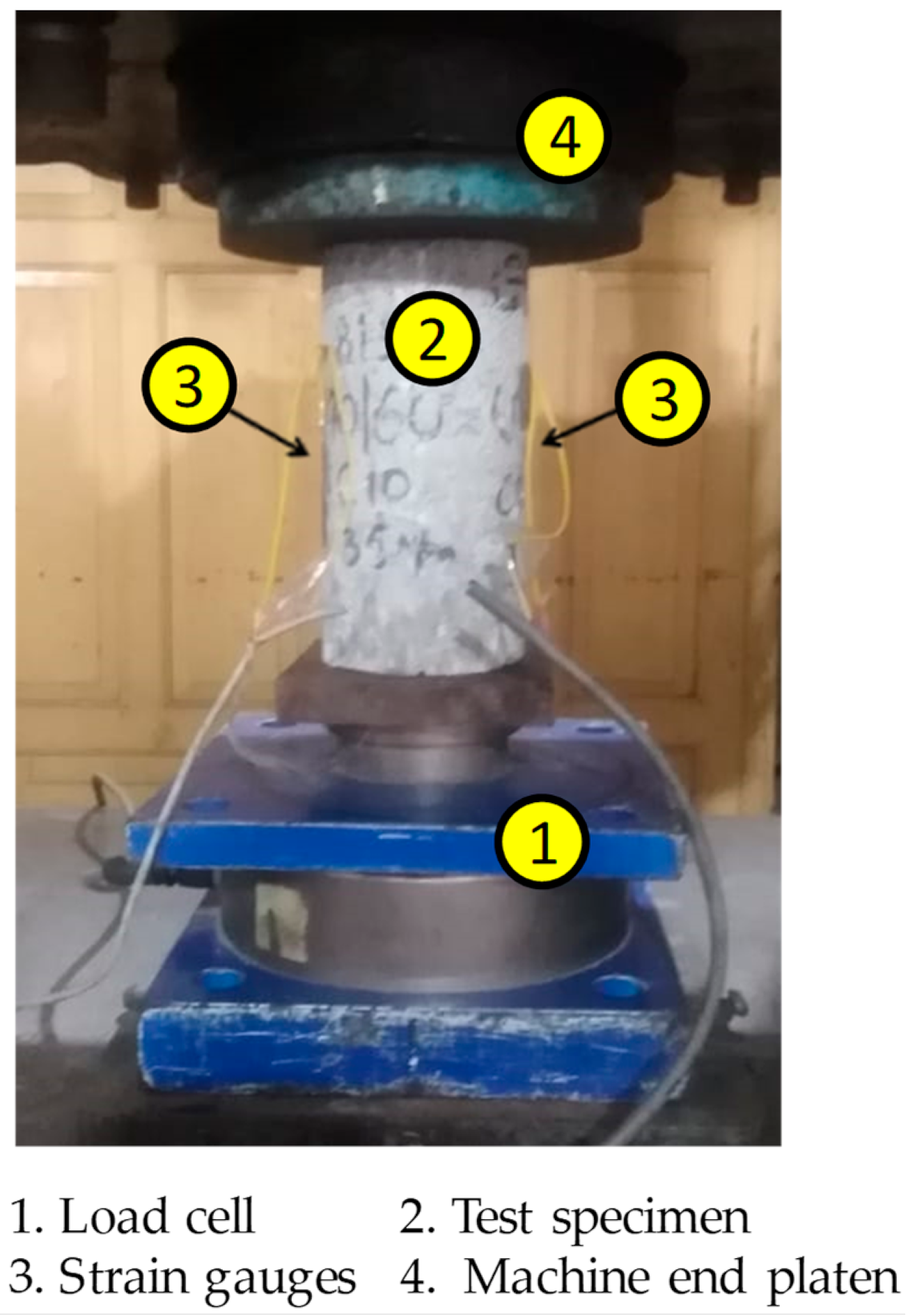

2.4. Testing Procedures

2.4.1. Density

2.4.2. Compressive Strength Test

2.4.3. Modulus of Elasticity Test

2.4.4. Ultrasonic Pulse Velocity Test

3. Results and Discussion

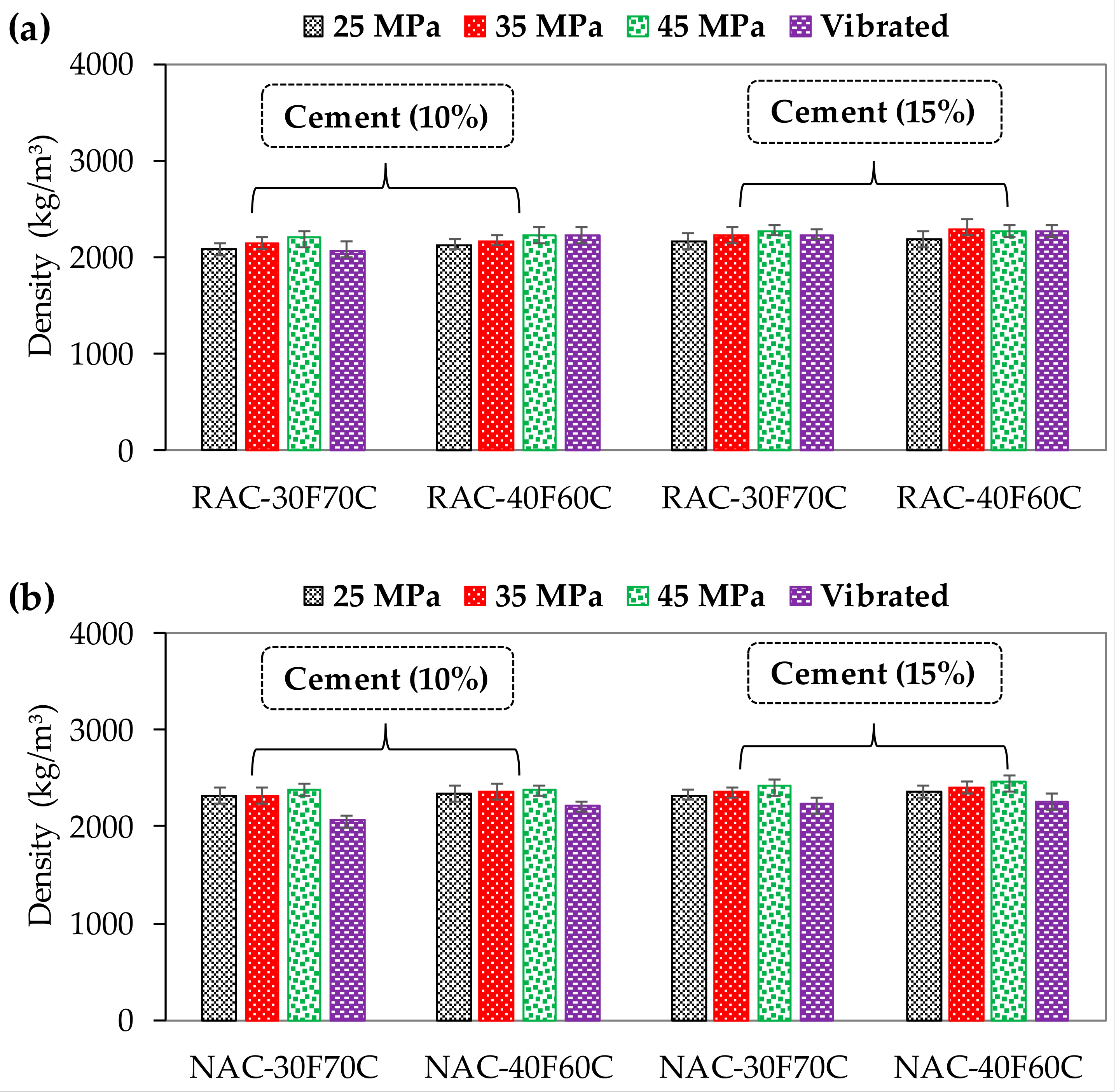

3.1. Density of Concrete

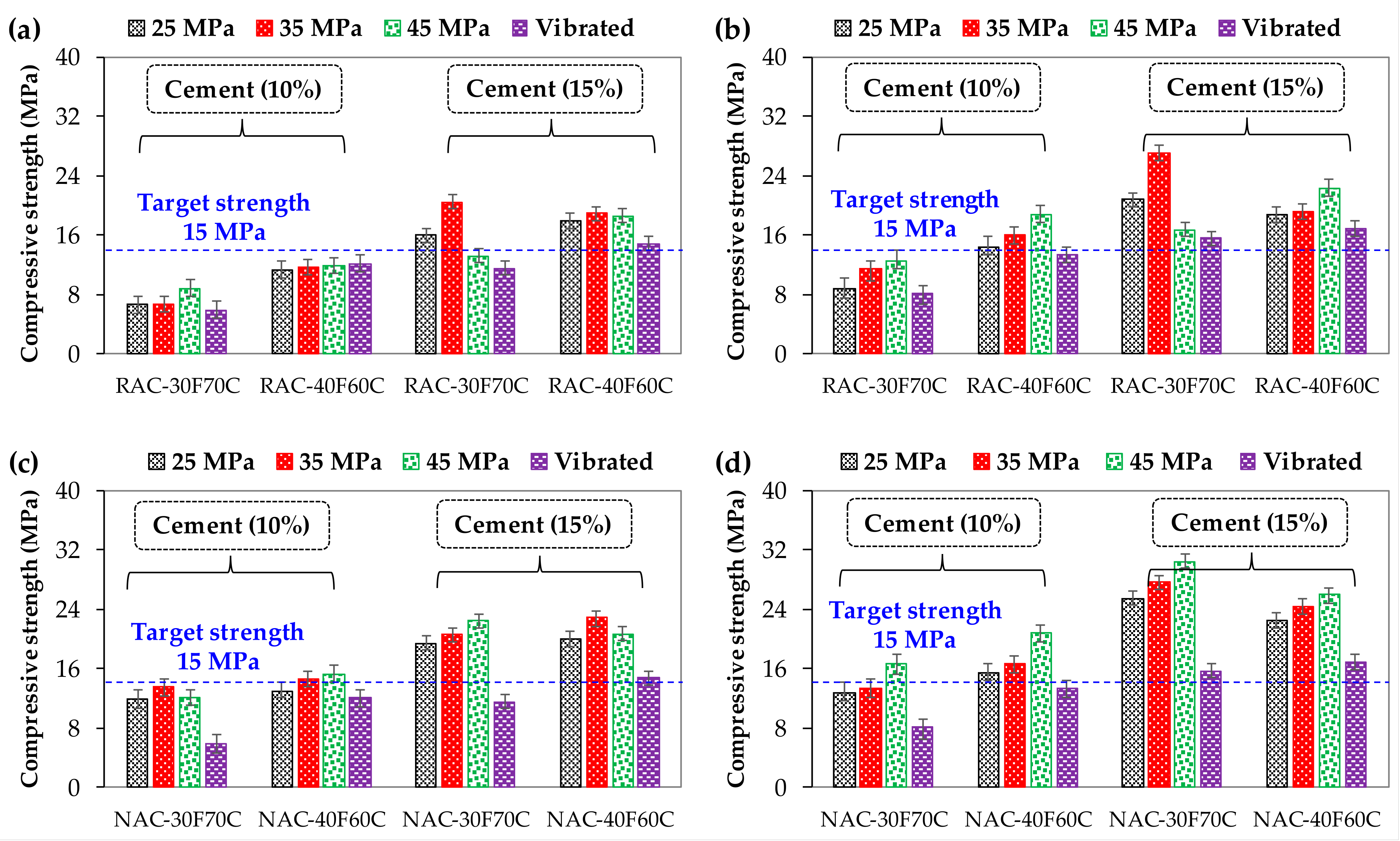

3.2. Compressive Strength

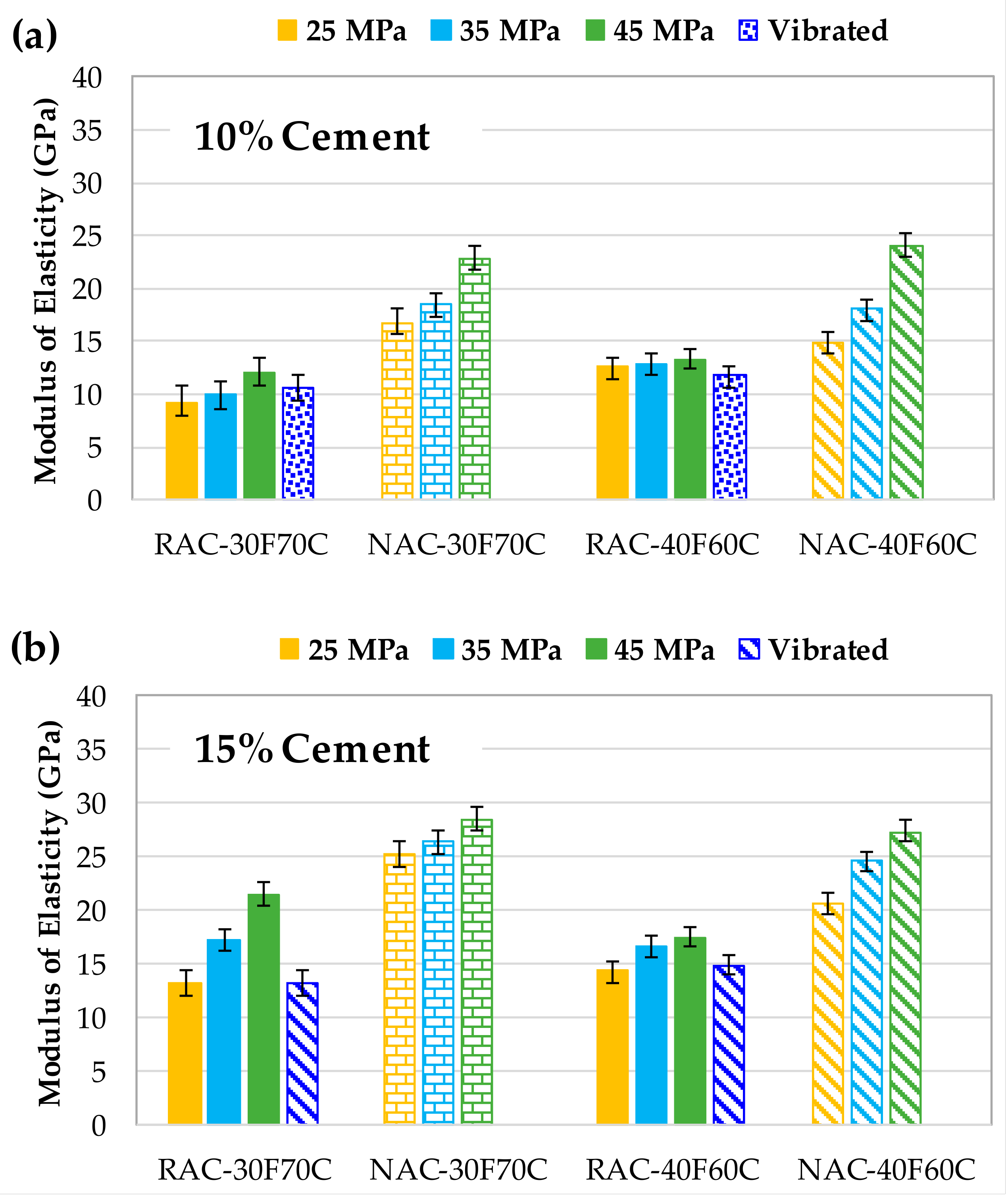

3.3. Modulus of Elasticity in Compression (Ec)

3.4. Ultrasonic Pulse Velocity (UPV)

3.5. Observations

- Concrete specimens prepared using CCT showed improvement in the various properties, such as compressive strength, modulus of elasticity, and quality assessment through UPV with the increase in the casting pressure. Accordingly, to prepare RAC mix using CCT, a higher casting pressure is recommended to obtain the improvement in the mechanical performance.

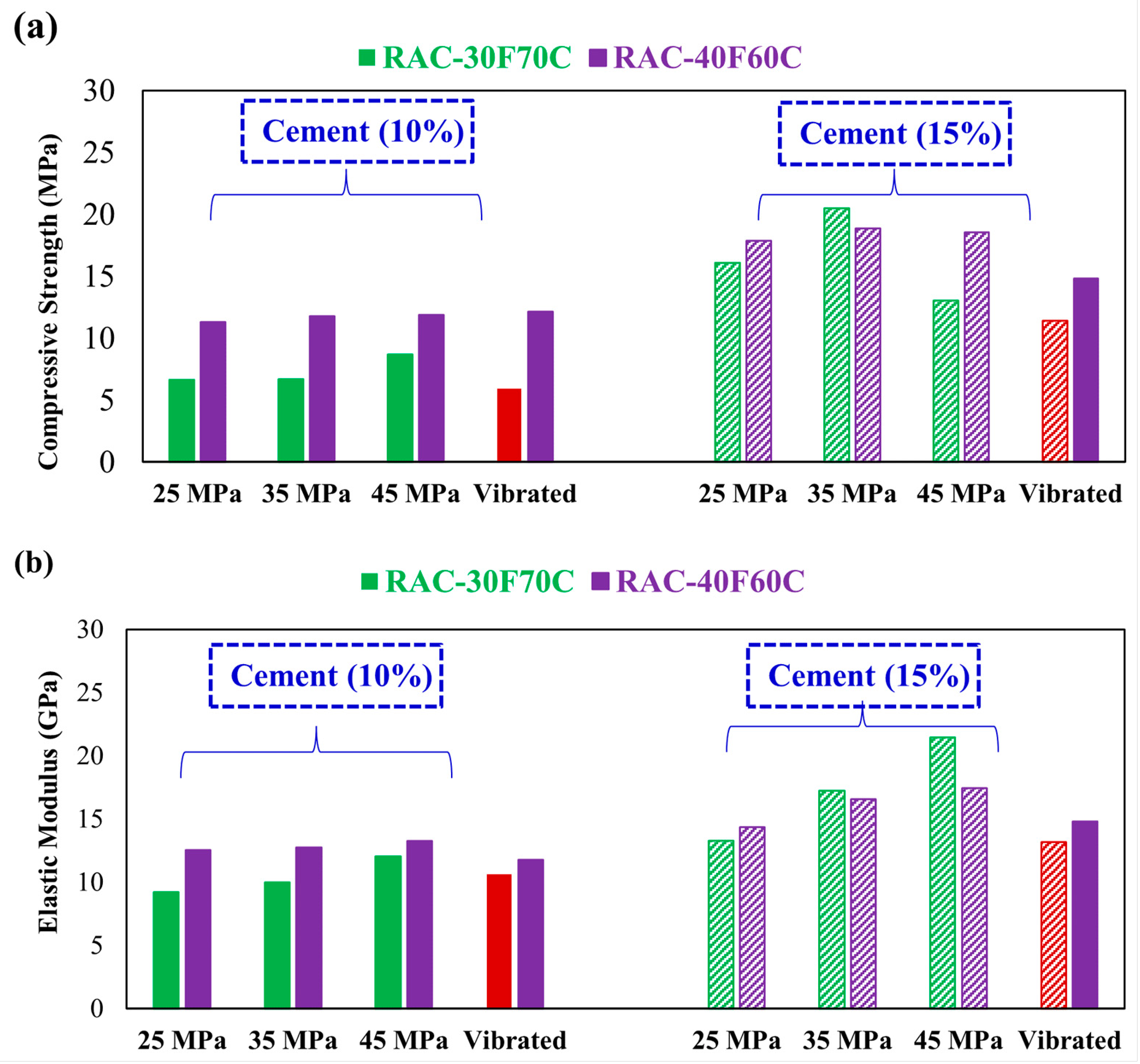

- RA and NA were used to prepare the concrete using 30:70 and 40:60 ratios of fine to coarse aggregates, respectively. The density and other mechanical properties of NAC were higher than RAC. Old mortar attached to RA increases the porosity which results in reducing the density and mechanical performance of RAC. Figure 14a,b show the influence of proportion of RFA and RCA on the compressive strength and modulus of elasticity of RAC, respectively. The compressive strength and E-value exhibited by the RAC using 40:60 ratio of RFA to RCA was higher than the other mix ratio (i.e., 30:70). Therefore, it is suggested to use 40% of RFA and 60% of RCA to prepare the RAC with the use of 100% RAs.

- Two different dosages of cement were used to prepare the concrete compositions. For RAC, the compressive strength as well as the modulus of elasticity of concrete tend to increase with the increase in cement contents as is evident from Figure 14a,b. A slight improvement in the density of concrete was also observed with increasing cement content.

4. Analytical Modeling

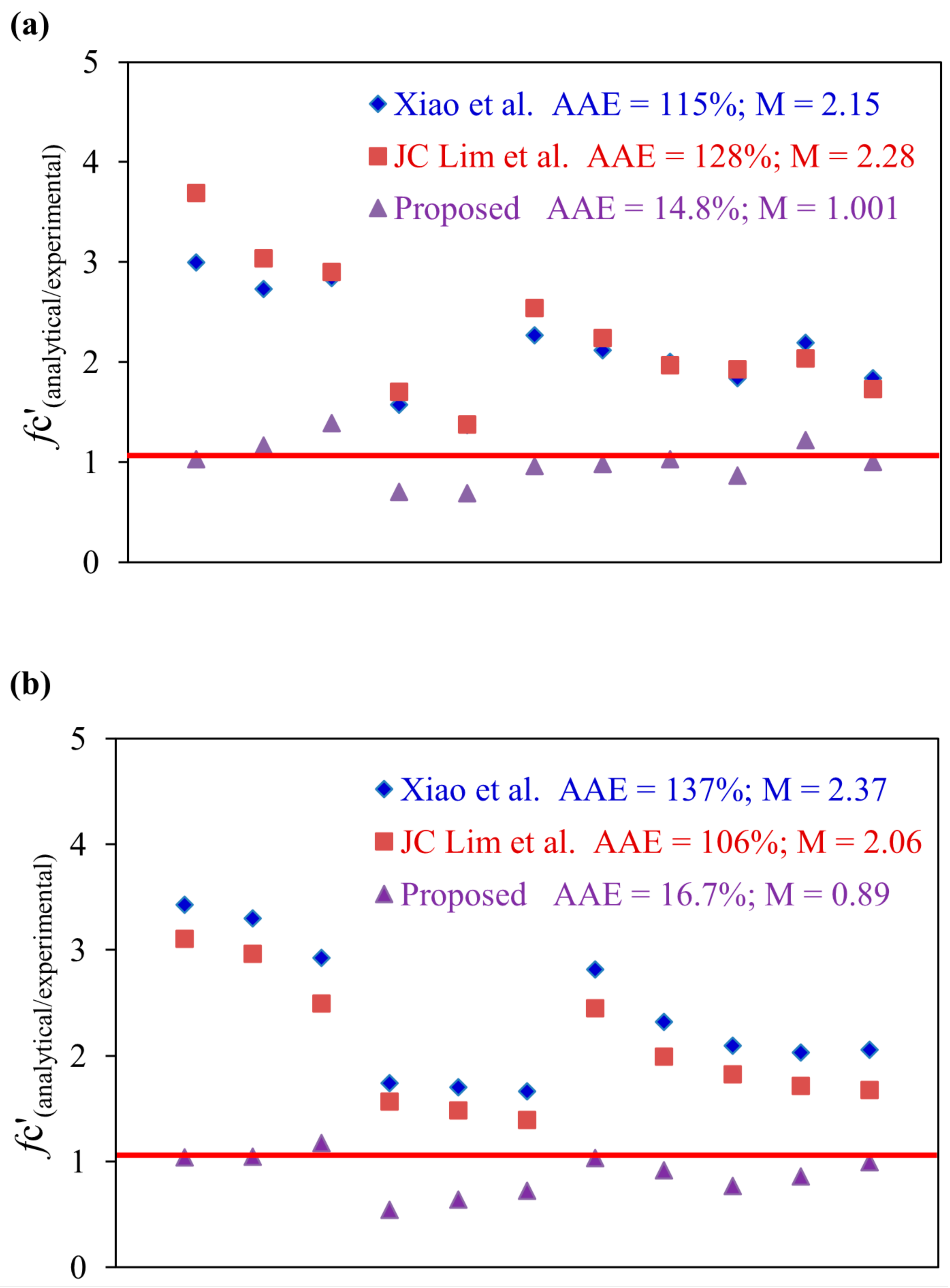

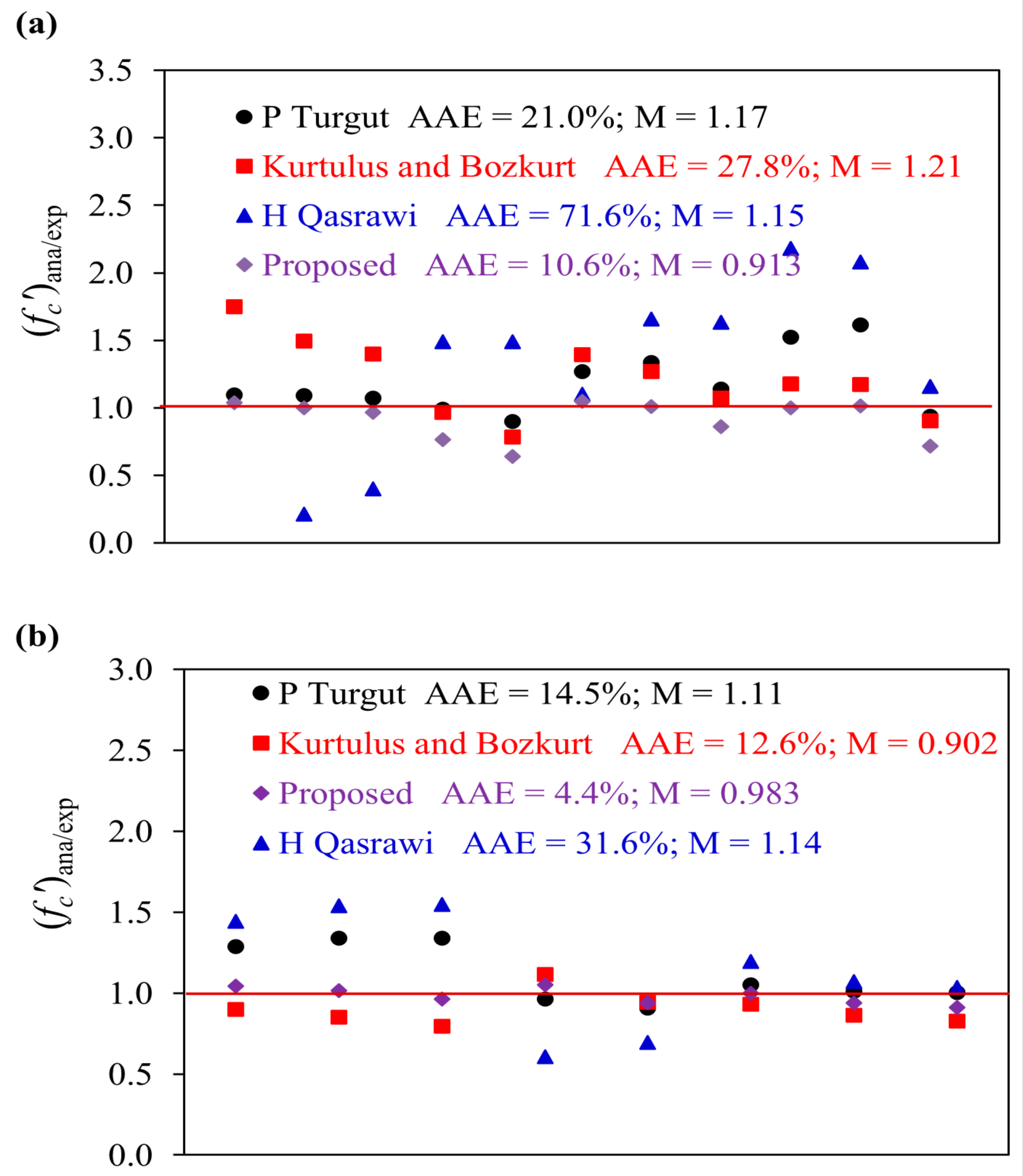

4.1. Analytical Model for Compressive Strength Based on Density of Concrete

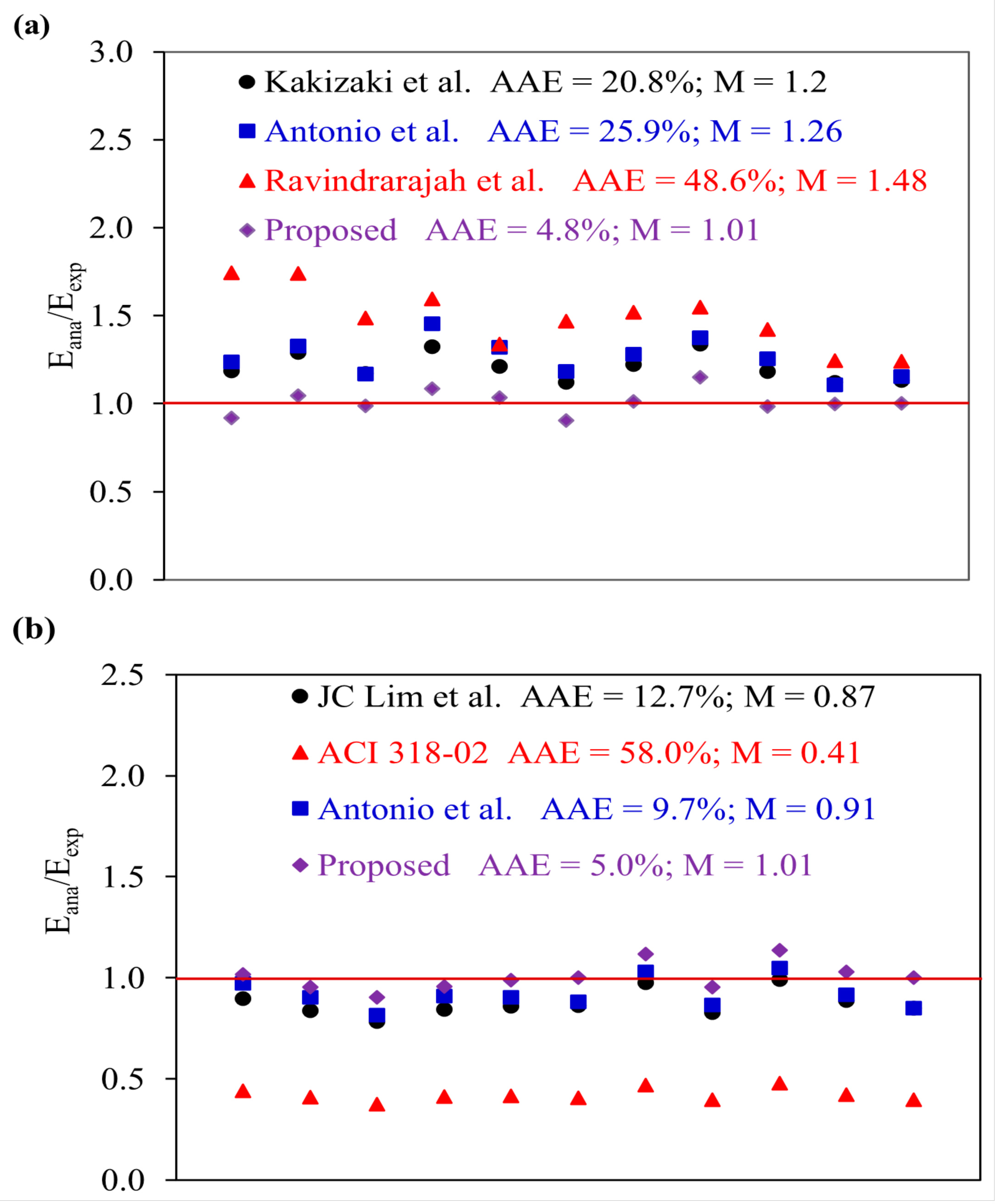

4.2. Analytical Model for Elastic Modulus Based on Compressive Strength and Density of Concrete

4.3. Relationship between Compressive Strength and Ultrasonic Pulse Velocity

4.4. Relationship between Elastic Modulus and Ultrasonic Pulse Velocity

5. Conclusions

- The compression casting technique showed a positive impact on the mechanical properties of RAC. On average, considering all compositions tested in this study, compressive strength and elastic modulus of RAC were increased by 20–80% and 15–50%, respectively, by changing the casting method from vibration to compression casting.

- A total of 100% RAC prepared by CCT at a casting pressure of 35 MPa and cement content of 15% was able to achieve compressive strength greater than 100% NAC prepared by the conventional method of casting [i.e., through vibration].

- For CCT, the value of casting pressure is of great importance with respect to density of resulting concrete. However, the decision regarding the value of casting pressure to be used must depend upon the target strength of the resulting RAC.

- For the manufacturing of masonry units of an aspect ratio equal or less than one, CCT made it possible to design a concrete of target compressive strength of 15 MPa containing significantly less quantity of cement (i.e., 10%) and 100% RAC (40% fine + 60% coarse).

- The ultrasonic pulse velocity value exhibited by 100% RAC was increased by changing the casting technique. Further, with the increase of casting pressure in CCT, UPV value was increased, indicating improvement in quality of concrete.

- The mechanical properties of RAC and NAC compositions prepared by two ratios of fine and coarse aggregates [i.e., 30:70 and 40:60] and two cement contents [10% and 15%] in this study clearly indicated that the effect CCT depends upon is the mix ratio of coarse and fine aggregates as well as cement dosage.

- Analytical models to predict different properties of RAC and NAC prepared by CCT were developed based on the regression analysis of the results obtained in this study. The proposed models were evaluated based on statistical parameters average absolute error (AAE) and the mean (M). The proposed analytical models were found to be able to predict the compressive strength and elastic modulus of RAC with reasonable accuracy as compared to the analytical models already existing in literature.

- In this study, the feasibility of using RAC incorporating 100% RA prepared by CCT for the manufacturing of masonry units is highlighted. However, only the effect of casting pressure is investigated. In order to be in line with field practice for the manufacturing concrete masonry unit, further investigation is recommended to be carried out to improve the effect of CCT by developing a setup to impart vibration to mold and compaction through compression at the same time.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rohden, B.; Garcez, M.R. Increasing the sustainability potential of a reinforced concrete building through design strategies: Case study. Case Stud. Constr. Mater. 2018, 9, e00174. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Munir, M.J.; Abbas, S.; Qazi, A.U.; Nehdi, M.L.; Kazmi, S.M.S. Role of test method in detection of alkali–silica reactivity of concrete aggregates. Proc. Inst. Civ. Eng. Constr. Mater. 2018, 171, 203–221. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Lin, X.; Ahmad, M.R. Investigation of thermal performance of concrete incorporating different types of recycled coarse aggregates. Constr. Build. Mater. 2020, 270, 121433. [Google Scholar] [CrossRef]

- Savva, P.; Ioannou, S.; Oikonomopoulou, K.; Nicolaides, D.; Petrou, M.F. A mechanical treatment method for recycled aggregates and its effect on recycled aggregate-based concrete. Materials 2021, 14, 2186. [Google Scholar] [CrossRef] [PubMed]

- Anike, E.E.; Saidani, M.; Ganjian, E.; Tyrer, M.; Olubanwo, A.O. The potency of recycled aggregate in new concrete: A review. Constr. Innov. 2019, 19, 594–613. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Lin, X.; Ahmad, M.R. Development of a novel compressive strength design equation for natural and recycled aggregate concrete through advanced computational modeling. J. Build. Eng. 2022, 55, 104690. [Google Scholar] [CrossRef]

- Upshaw, M.; Cai, C.S. Critical review of recycled aggregate concrete properties, improvements, and numerical models. J. Mater. Civ. Eng. 2020, 32, 03120005. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F. Unified strength model for spiral steel confined concrete columns. ACI Struct. J. 2021, 119, 247–255. [Google Scholar]

- Riaz, M.R.; Hameed, R.; Ilya, M.; Akram, A.; Siddiqi, Z.A. Mechanical characterization of recycled aggregate concrete. Pak. J. Eng. Appl. Sci. 2015, 16, 25–32. [Google Scholar]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Lin, X. Axial stress-strain performance of steel spiral confined acetic acid immersed and mechanically rubbed recycled aggregate concrete. J. Build. Eng. 2020, 34, 101891. [Google Scholar] [CrossRef]

- Sangthongtong, A.; Semvimol, N.; Rungratanaubon, T.; Duangmal, K.; Joyklad, P. Mechanical Properties of Pervious Recycled Aggregate Concrete Reinforced with Sackcloth Fibers (SF). Infrastructures 2023, 8, 38. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Lin, X.; Ashiq, S.Z. Development of unified elastic modulus model of natural and recycled aggregate concrete for structural applications. Case Stud. Constr. Mater. 2023, 18, e01873. [Google Scholar] [CrossRef]

- Liang, Z.; Hu, Z.; Zhou, Y.; Wu, Y.; Zhou, X.; Hu, B.; Guo, M. Improving recycled aggregate concrete by compression casting and nano-silica. Nanotechnol. Rev. 2022, 11, 1273–1290. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Jose, J.; Shameem, M.; Maslehuddin, M. A review on treatment techniques to improve the durability of recycled aggregate concrete: Enhancement mechanisms, performance and cost analysis. J. Build. Eng. 2022, 55, 104713. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Boltryk, M.; Jiménez, J.R.; Fernández, J.M. The influence of heat and mechanical treatment of concrete rubble on the properties of recycled aggregate concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef]

- Bru, K.; Touzé, S.; Bourgeois, F.; Lippiatt, N.; Ménard, Y. Assessment of a microwave-assisted recycling process for the recovery of high-quality aggregates from concrete waste. Int. J. Miner. Process. 2014, 126, 90–98. [Google Scholar] [CrossRef]

- Radević, A.; Despotović, I.; Zakić, D.; Orešković, M.; Jevtić, D. Influence of acid treatment and carbonation on the properties of recycled concrete aggregate. Chem. Ind. Chem. Eng. 2018, 24, 23–30. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Shear behavior of reinforced concrete beams using treated recycled concrete aggregate. Constr. Build. Mater. 2016, 125, 63–71. [Google Scholar] [CrossRef]

- Zeng, W.; Zhao, Y.; Zheng, H.; Poon, C.S. Improvement in corrosion resistance of recycled aggregate concrete by nano silica suspension modification on recycled aggregates. Cem. Concr. Compos. 2020, 106, 103476. [Google Scholar] [CrossRef]

- Bu, C.; Liu, L.; Lu, X.; Zhu, D.; Sun, Y.; Yu, L.; OuYang, Y.; Cao, X.; Wei, Q. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef]

- Singh, R.; Nayak, D.; Pandey, A.; Kumar, R.; Kumar, V. Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: A comparative study. J. Build. Eng. 2022, 45, 103442. [Google Scholar] [CrossRef]

- Villagrán-Zaccardi, Y.A.; Marsh, A.T.; Sosa, M.E.; Zega, C.J.; De Belie, N.; Bernal, S.A. Complete re- utilization of waste concretes–Valorisation pathways and research needs. Resour. Conserv. Recycl. 2022, 177, 105955. [Google Scholar] [CrossRef]

- Vintimilla, C.; Etxeberria, M. Limiting the maximum fine and coarse recycled aggregates -Type A used in structural concrete. Constr. Build. Mater. 2023, 380, 131273. [Google Scholar] [CrossRef]

- Ju, M.; Park, K.; Park, W.J. Mechanical behavior of recycled fine aggregate concrete with high slump property in normal-and high-strength. Int. J. Concr. Struct. Mater. 2019, 13, 61. [Google Scholar] [CrossRef]

- Al-Luhybi, A.S.; Aziz, I.A.; Mohammad, K.I. Experimental assessment of mechanical and physical performance of latex modified concrete with fine recycled aggregate. Structures 2023, 45, 1932–1938. [Google Scholar] [CrossRef]

- Vlieger, J.D.; Boehme, L.; Blaakmeer, J.; Li, J. Buildability assessment of mortar with fine recycled aggregates for 3D printing. Constr. Build. Mater. 2023, 367, 130313. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Kaplan, G.; Shi, J.; Benli, A.; Bodur, B.; Turkoglu, M. The effect of steel fiber aspect-ratio and content on the fresh, flexural, and mechanical performance of concrete made with recycled fine aggregate. Constr. Build. Mater. 2023, 368, 130497. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, J.; Ding, T. Flexural performance of 3D-printed composite beams with ECC and recycled fine aggregate concrete: Experimental and numerical analysis. Eng. Struct. 2023, 283, 115865. [Google Scholar] [CrossRef]

- Wang, F.; Gao, D.; Xu, Z.; Zhang, T. Comparative study on axial compressive properties of steel fiber-reinforced recycled-fine-aggregate concrete tested by prism and cylinder specimens. Constr. Build. Mater. 2023, 367, 130311. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Wang, X.; Chin, C.S.; Xia, J. Material characterization for sustainable concrete paving blocks. Appl. Sci. 2019, 9, 1197. [Google Scholar] [CrossRef]

- Sakai, Y.; Tarekegne, B.T.; Kishi, T. Recycling of hardened cementitious material by pressure and control of volumetric change. J. Adv. Concr. Technol. 2016, 14, 47–54. [Google Scholar] [CrossRef]

- Hameed, R.; Nisa, Z.U.; Riaz, M.R.; Gillani, S.A.A. Effect of compression casting technique on the water absorption properties of concrete made using 100% recycled aggregates. Rev. Constr. 2022, 21, 387–407. [Google Scholar] [CrossRef]

- Kazmi SM, S.; Munir, M.J.; Wu, Y.F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Kazmi, S.M.S.; Wu, Y.F. Development of new layered compression casting approach for concrete. Cem. Concr. Compos. 2022, 134, 104738. [Google Scholar] [CrossRef]

- Wu, Y.F.; Kazmi SM, S.; Munir, M.J.; Zhou, Y.; Xing, F. Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J. Clean. Prod. 2020, 264, 121746. [Google Scholar] [CrossRef]

- Waheed, A.; Azam, R.; Riaz, M.R.; Zawam, M. Mechanical and durability properties of fly-ash cement sand composite bricks: An alternative to conventional burnt clay bricks. Innov. Infrastruct. Solut. 2022, 7, 24. [Google Scholar] [CrossRef]

- ICIMOD. Brick Sector in Pakistan—Fact Sheet. Available online: https://lib.icimod.org/record/34683 (accessed on 15 February 2023).

- Habib, A.; Nasim, S.; Shahab, A. Charting Pakistan’s Air Quality Policy Landscape; International Growth Centre (IGC), London School of Economic and Political Science: London, UK, 2021. [Google Scholar]

- Raza, W.; Saeed, S.; Saulat, H.; Gul, H.; Sarfraz, M.; Sonne, C.; Sohn, Z.H.; Brown, R.J.C.; Kim, K.-H. A review on the deteriorating situation of smog and its preventive measures in Pakistan. J. Clean. Prod. 2021, 279, 123676. [Google Scholar] [CrossRef]

- ASTM C33; Standard Specifications for Coarse Aggregates. ASTM International West Conshohocken: Conshohocken, PA, USA, 2018.

- ASTM C150; Standard Specification for Portland Cement. ASTM International West Conshohocken: Conshohocken, PA, USA, 2012.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International West Conshohocken: Conshohocken, PA, USA, 2021.

- ASTM C469; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International West Conshohocken: Conshohocken, PA, USA, 2022.

- ASTM C597; Standard Test Method for Pulse Velocity through Concrete. ASTM International West Conshohocken: Conshohocken, PA, USA, 2023.

- Leslie, J.R.; Cheesman, W.J. An ultrasonic method of studying deterioration and cracking in concrete structures. J. Am. Concr. Inst. 1949, 21, 17–36. [Google Scholar]

- Feldman, R.F. Non-Destructive Testing of Concrete; National Research Council of Canada, Division of Building Research: Ottawa, ON, Canada, 1977. [Google Scholar]

- Xiao, J.-Z.; Li, J.-B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2006, 39, 655–664. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Stress–strain model for normal-and light-weight concretes under uniaxial and triaxial compression. Constr. Build. Mater. 2014, 71, 492–509. [Google Scholar] [CrossRef]

- Cabral, A.E.B.; Schalch, V.; Dal Molin, D.C.C.; Ribeiro, J.L.D. Mechanical properties modeling of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- Kakizaki, M.; Harada, M.; Soshiroda, T.; Kubota, S.; Ikeda, T.; Kasai, Y. Strength and elastic modulus of recycled aggregate concrete. In Proceedings of the 2nd international RILEM symposium on demolition and reuse of concrete and masonry, Tokyo, Japan, 17 November 1988; pp. 7–11. [Google Scholar]

- Ravindrarajah, R.S.; Tam, C.T. Properties of concrete made with crushed concrete as coarse aggregate. Mag. Concr. Res. 1985, 37, 29–38. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete: (ACI 318-02) and Commentary (ACI 318R-02); American Concrete Institute: Farmington Hills, MI, USA, 2002. [Google Scholar]

- Cengiz, K.; Ali, B. Determination of concrete compressive strength of the structures in Istanbul and Izmit Cities (Turkey) by combination of destructive and non-destructive methods. Int. J. Phys. Sci. 2011, 6, 3929–3932. [Google Scholar]

- Qasrawi, H.Y. Concrete strength by combined nondestructive methods simply and reliably predicted. Cem. Concr. Res. 2000, 30, 739–746. [Google Scholar] [CrossRef]

- Turgut, P. Evaluation of Ultrasonic Velocity Data Coming on the Field. In Proceedings of the International Conference on NDT in Relation to Structural Integrity for Nuclear and Pressurized Components, Seattle, DC, USA, 22–24 May 2004. [Google Scholar]

- Kim, W.; Jeong, K.; Choi, H.; Lee, T. Correlation Analysis of Ultrasonic Pulse Velocity and Mechanical Properties of Normal Aggregate and Lightweight Aggregate Concretes in 30–60 MPa Range. Materials 2022, 15, 2952. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y.-F.; Lin, X.; Ahmad, M.R. Development of novel design strength model for sustainable concrete columns: A new machine learning-based approach. J. Clean. Prod. 2022, 357, 131988. [Google Scholar] [CrossRef]

| Property | RA | NA | ||

|---|---|---|---|---|

| Coarse | Fine | Coarse | Fine | |

| Bulk oven dry Specific Gravity | 2.26 | 2.05 | 2.84 | 2.70 |

| Bulk SSD Specific Gravity | 2.44 | 2.28 | 2.86 | 2.75 |

| Bulk Apparent Specific Gravity | 2.76 | 2.66 | 2.87 | 2.84 |

| Water Absorption (%) | 7.97 | 11.15 | 0.9 | 1.79 |

| Moisture Content (%) | 2.37 | 5.32 | 0.9 | 1.2 |

| Flakiness Index (%) | 14.1 | - | 19.6 | - |

| Elongation Index (%) | 21.25 | - | 44.1 | - |

| Bulk Density (kg/m3) | 1267 | 1335 | 1441 | 1722 |

| Los Angeles Abrasion Value (%) | 37.57 | - | 25.20 | |

| 10% Fine Value, TFV (kN) | 184.36 | - | 199.57 | |

| Aggregate Crushing Value, ACV (%) | 20.80 | - | 22.55 | |

| Aggregate Impact Value, AIV (%) | 15.36 | - | 17.70 | |

| Chemical Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 |

| 62.6% | 20.8% | 5.06% | 3.27% | 2.56% | 1.57% |

| Physical Properties | Fineness | Soundness | Initial and Final Setting | Standard Consistency |

| 8% | 9 mm | 105–215 | 30% |

| Sr. No. | Concrete Designation | Cement Content, % (kg/m3) | Fine Aggregates, kg/m3 | Coarse Aggregates, kg/m3 | Water/Cement Ratio | Applied Pressure, MPa |

|---|---|---|---|---|---|---|

| 1 | RAC-30F70C | 10 (195) | 580 | 1355 | 0.5 | 25 |

| 2 | 35 | |||||

| 3 | 45 | |||||

| 4 | 15 (290) | 580 | 1355 | 25 | ||

| 5 | 35 | |||||

| 6 | 45 | |||||

| 7 | RAC-40F60C | 10 (205) | 825 | 1230 | 25 | |

| 8 | 35 | |||||

| 9 | 45 | |||||

| 10 | 15 (310) | 825 | 1230 | 25 | ||

| 11 | 35 | |||||

| 12 | 45 | |||||

| 13 | NAC-30F70C | 10 (195) | 580 | 1355 | 0.5 | 25 |

| 14 | 35 | |||||

| 15 | 45 | |||||

| 16 | 15 (290) | 580 | 1355 | 25 | ||

| 17 | 35 | |||||

| 18 | 45 | |||||

| 19 | NAC-40F60C | 10 (205) | 825 | 1230 | 25 | |

| 20 | 35 | |||||

| 21 | 45 | |||||

| 22 | 15 (310) | 825 | 1230 | 25 | ||

| 23 | 35 | |||||

| 24 | 45 | |||||

| 25 | RAC-30F70C-V | 10 (195) | 580 | 1355 | 0.5 | Compaction by Vibration (Conventional method) |

| 26 | 15 (290) | 580 | 1355 | |||

| 27 | RAC-40F60C-V | 10 (205) | 825 | 1230 | ||

| 28 | 15 (310) | 825 | 1230 |

| Sr. No. | Concrete Designation | Cement Content | Applied Pressure MPa | Density kg/m3 | Compressive Strength, MPa | Elastic Modulus MPa | Ultrasonic Pulse Velocity | ||

|---|---|---|---|---|---|---|---|---|---|

| A.R = 2 | A.R = 1 | Values km/s | Quality | ||||||

| 1 | RAC-30F70C | 10% | 25 | 2073 | 6.62 | 9.0 | 9.2 | 3.337 | Questionable |

| 2 | 35 | 2137 | 6.7 | 11.5 | 10 | 3.573 | Questionable | ||

| 3 | 45 | 2201 | 8.7 | 12.6 | 12.05 | 3.646 | Good | ||

| 4 | 15% | 25 | 2156 | 16.1 | 20.8 | 13.27 | 4.053 | Good | |

| 5 | 35 | 2218 | 20.5 | 27.0 | 17.24 | 4.215 | Good | ||

| 6 | 45 | 2278 | 13.04 | 16.7 | 21.47 | 3.580 | Questionable | ||

| 7 | RAC-40F60C | 10% | 25 | 2133 | 11.3 | 13.7 | 12.54 | 3.890 | Good |

| 8 | 35 | 2173 | 11.76 | 16.0 | 12.78 | 4.091 | Good | ||

| 9 | 45 | 2233 | 11.86 | 19.0 | 13.25 | 4.104 | Good | ||

| 10 | 15% | 25 | 2181 | 17.86 | 18.7 | 14.37 | 4.369 | Good | |

| 11 | 35 | 2293 | 18.88 | 19.2 | 16.55 | 4.452 | Good | ||

| 12 | 45 | 2277 | 18.57 | 22.3 | 17.45 | 4.066 | Good | ||

| 13 | NAC-30F70C | 10% | 25 | 2318 | 11.82 | 12.8 | 16.74 | 4.443 | Good |

| 14 | 35 | 2328 | 13.6 | 13.5 | 18.51 | 4.463 | Good | ||

| 15 | 45 | 2390 | 12.17 | 16.7 | 22.87 | 4.602 | Excellent | ||

| 16 | 15% | 25 | 2325 | 19.29 | 25.4 | 25.193 | 4.504 | Excellent | |

| 17 | 35 | 2368 | 20.71 | 27.7 | 26.492 | 4.626 | Excellent | ||

| 18 | 45 | 2416 | 22.5 | 30.4 | 28.472 | 4.716 | Excellent | ||

| 19 | NAC-40F60C | 10% | 25 | 2337 | 13.05 | 14.5 | 14.861 | 3.804 | Good |

| 20 | 35 | 2363 | 14.69 | 16.7 | 18.07 | 3.814 | Good | ||

| 21 | 45 | 2383 | 15.26 | 20.8 | 24.037 | 3.969 | Good | ||

| 22 | 15% | 25 | 2363 | 19.92 | 22.4 | 20.571 | 4.185 | Good | |

| 23 | 35 | 2406 | 22.84 | 24.5 | 24.64 | 4.234 | Good | ||

| 24 | 45 | 2460 | 20.69 | 26.0 | 27.34 | 4.285 | Good | ||

| 25 | RAC-30F70C-V | 10% | Compaction by vibration | 2068 | 5.9 | 8.5 | 10.65 | 3.791 | Good |

| 26 | 15% | 2230 | 11.43 | 15.2 | 13.18 | 3.995 | Good | ||

| 27 | RAC-40F60C-V | 10% | 2221 | 12.14 | 13.5 | 11.77 | 3.831 | Good | |

| 28 | 15% | 2265 | 14.83 | 17.4 | 14.82 | 3.890 | Good | ||

| Sr. No. | Reference | Analytical Model | Casting Technique and Aggregate Type |

|---|---|---|---|

| 1 | Xiao et al. [54] | Conventional casting using recycled aggregates | |

| 2 | Lim et al. [55] | Conventional casting using natural aggregates |

| Sr. No. | Reference | Prediction Equation | Casting Technique and Aggregate Type |

|---|---|---|---|

| 1 | Kakizaki et al. [57] | Conventional casting and RA | |

| 2 | Antonio et al. [56] | Conventional casting and RA | |

| 3 | Ravindrarajahet al. [58] | Conventional casting and RA | |

| 4 | Antonio et al. [56] | Conventional casting and NA | |

| 5 | Lim et al. [55] | Conventional casting and NA | |

| 6 | ACI 318-02 [59] | Conventional casting and NA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hameed, R.; Tahir, M.; Zaib-un-Nisa; Shahzad, S.; Kazmi, S.M.S.; Munir, M.J. Impact of Compression Casting Technique on the Mechanical Properties of 100% Recycled Aggregate Concrete. Sustainability 2023, 15, 8153. https://doi.org/10.3390/su15108153

Hameed R, Tahir M, Zaib-un-Nisa, Shahzad S, Kazmi SMS, Munir MJ. Impact of Compression Casting Technique on the Mechanical Properties of 100% Recycled Aggregate Concrete. Sustainability. 2023; 15(10):8153. https://doi.org/10.3390/su15108153

Chicago/Turabian StyleHameed, Rashid, Muhammad Tahir, Zaib-un-Nisa, Shaban Shahzad, Syed Minhaj Saleem Kazmi, and Muhammad Junaid Munir. 2023. "Impact of Compression Casting Technique on the Mechanical Properties of 100% Recycled Aggregate Concrete" Sustainability 15, no. 10: 8153. https://doi.org/10.3390/su15108153

APA StyleHameed, R., Tahir, M., Zaib-un-Nisa, Shahzad, S., Kazmi, S. M. S., & Munir, M. J. (2023). Impact of Compression Casting Technique on the Mechanical Properties of 100% Recycled Aggregate Concrete. Sustainability, 15(10), 8153. https://doi.org/10.3390/su15108153