An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs

Abstract

1. Introduction

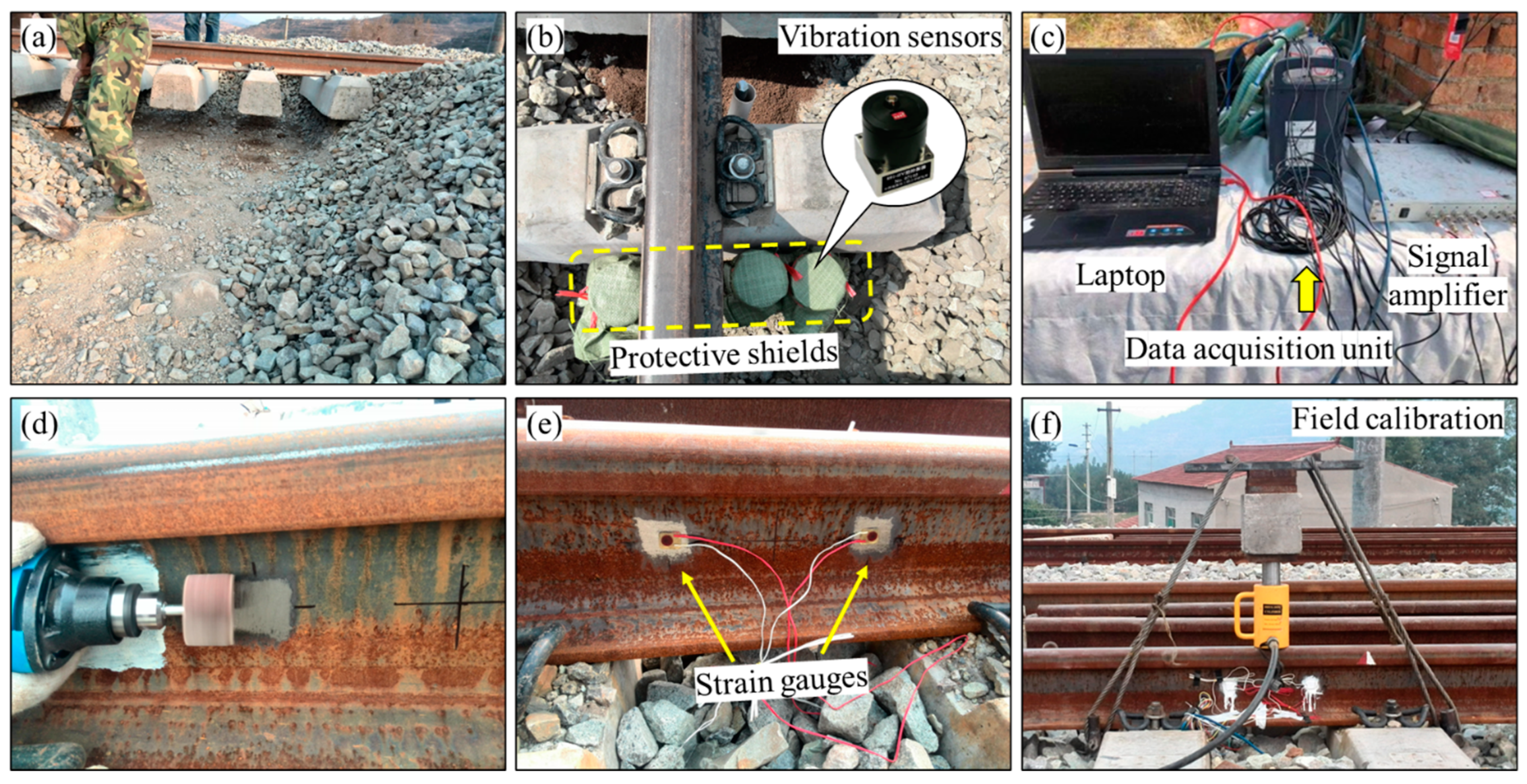

2. Field Monitoring

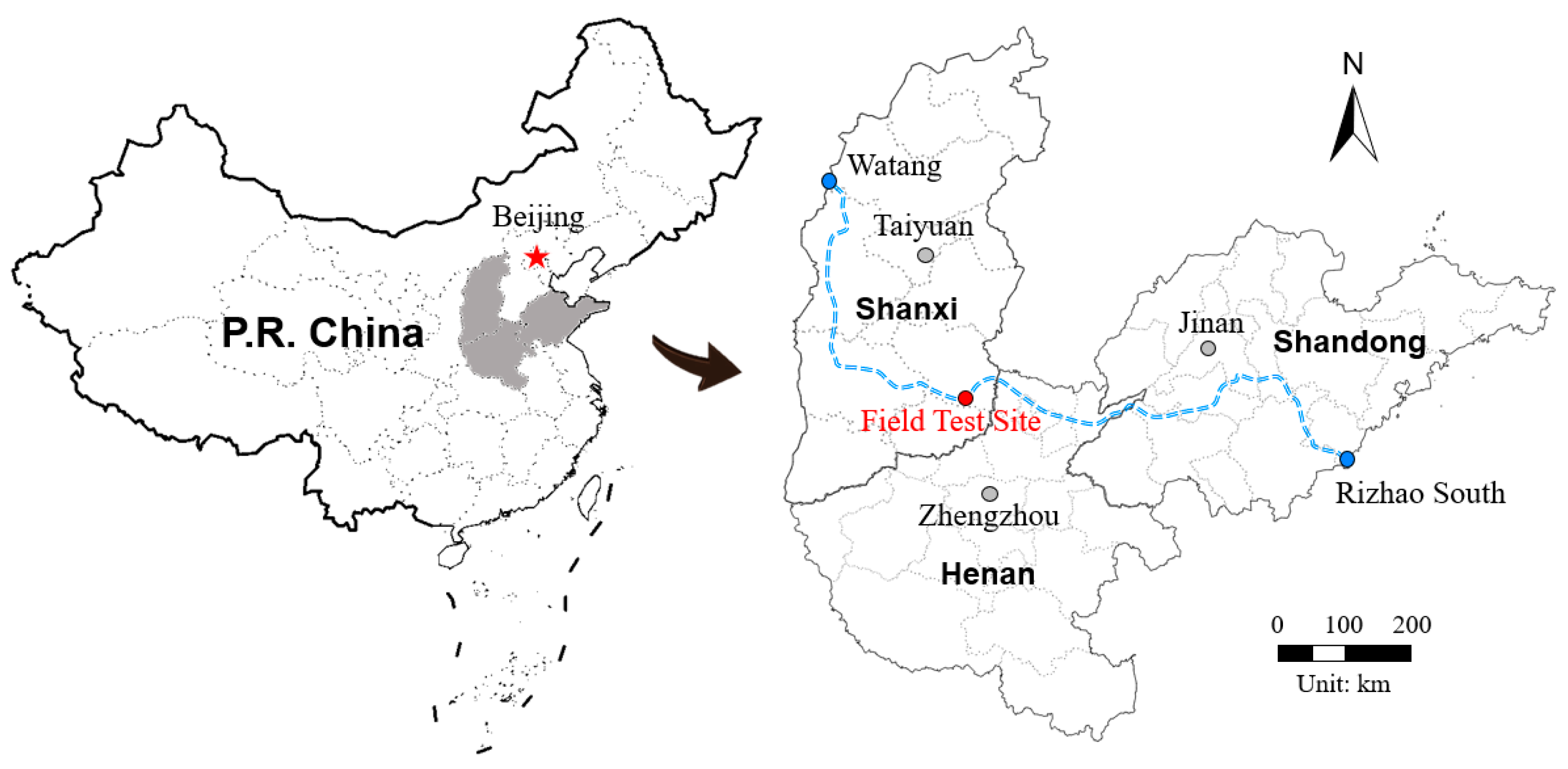

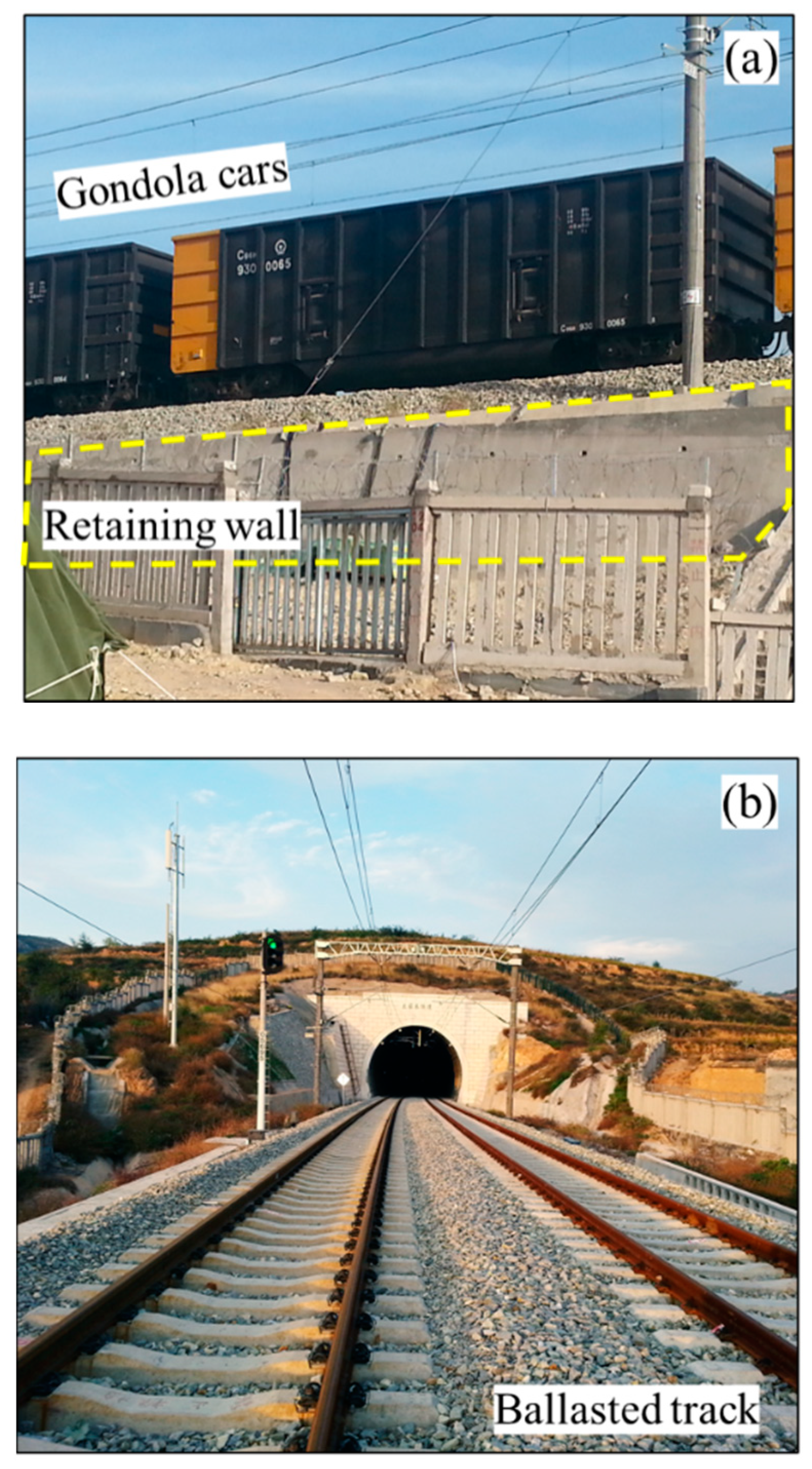

2.1. Site Description

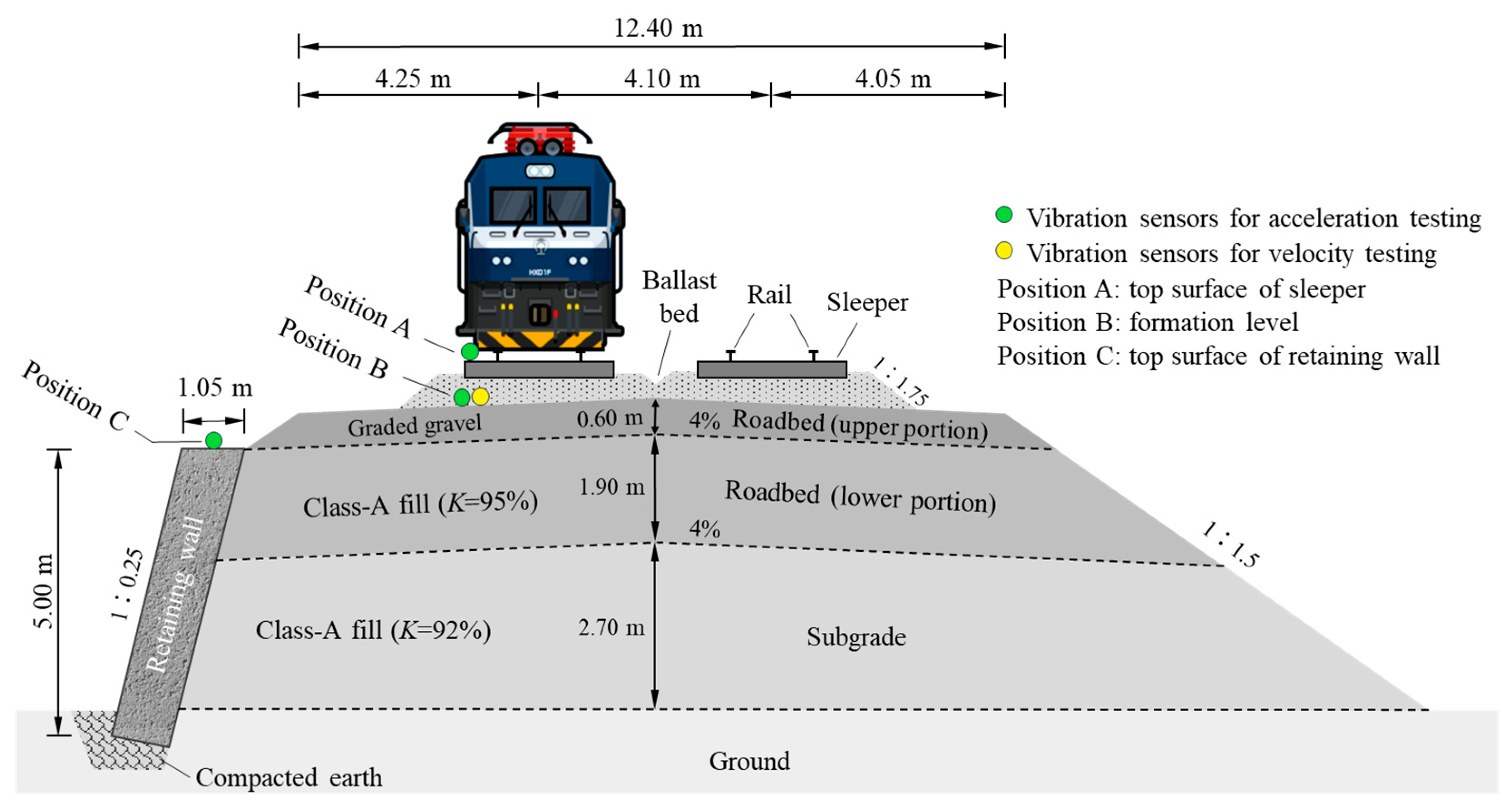

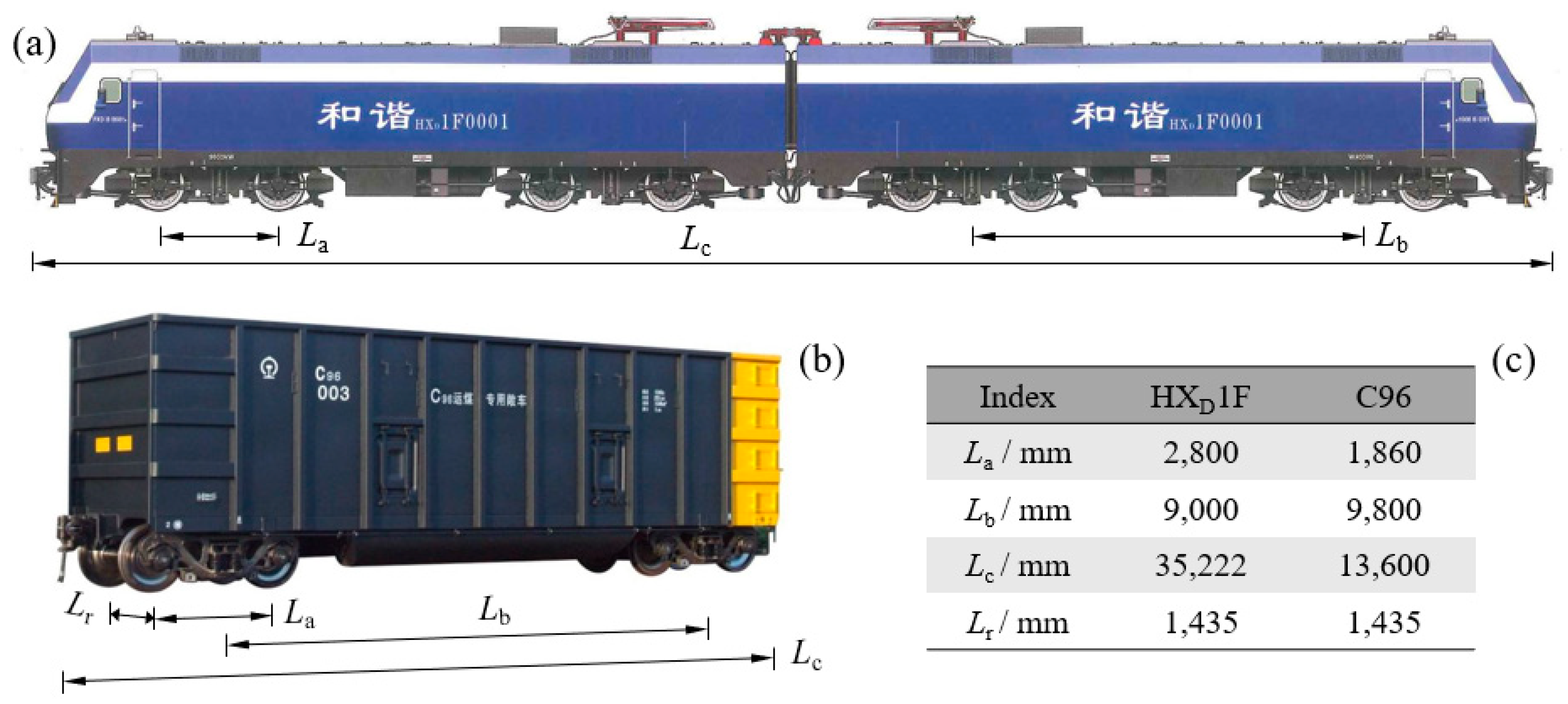

2.2. Instruments and Test Train

3. Analyses of Measured Data

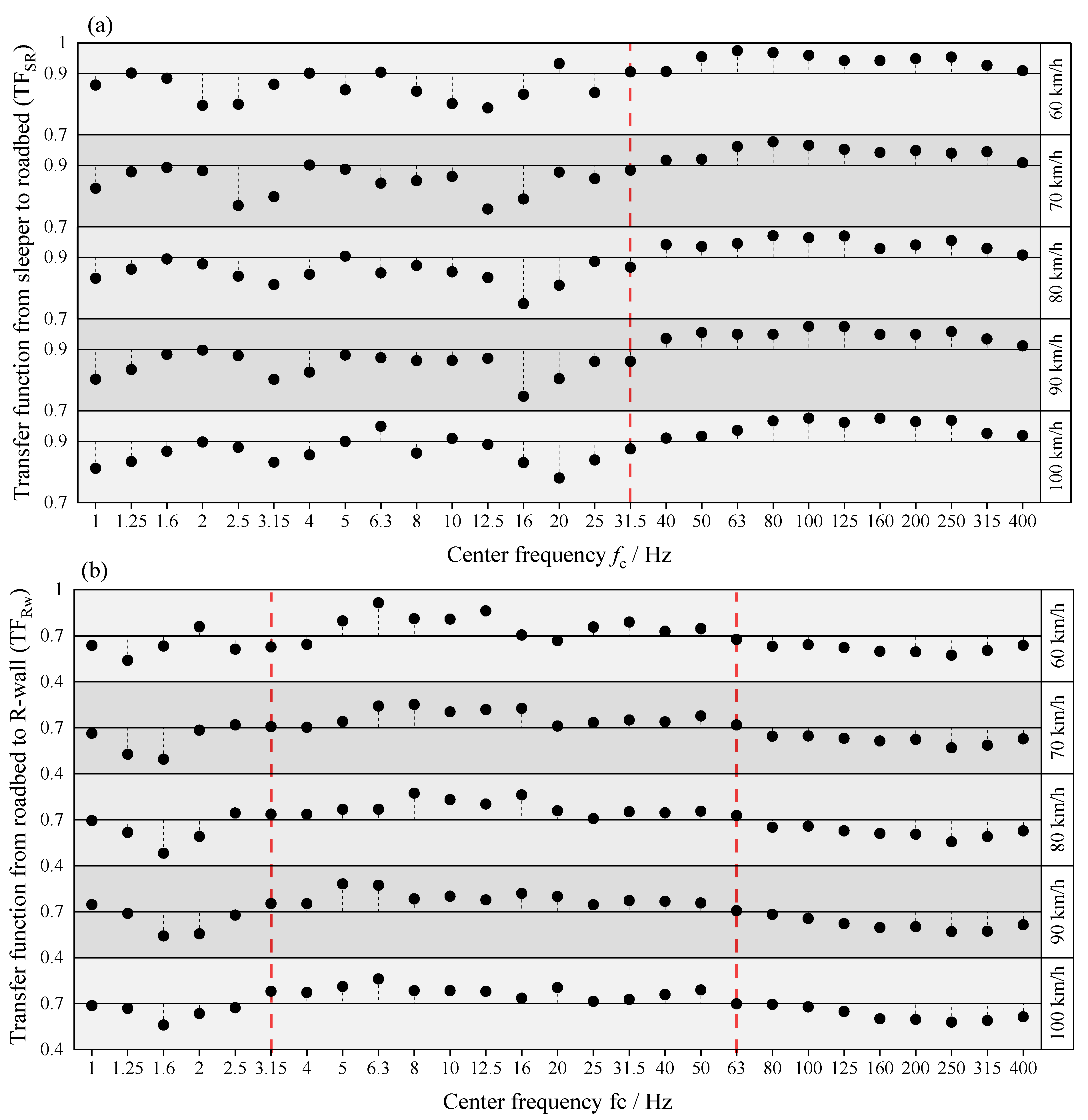

3.1. Vibration Acceleration

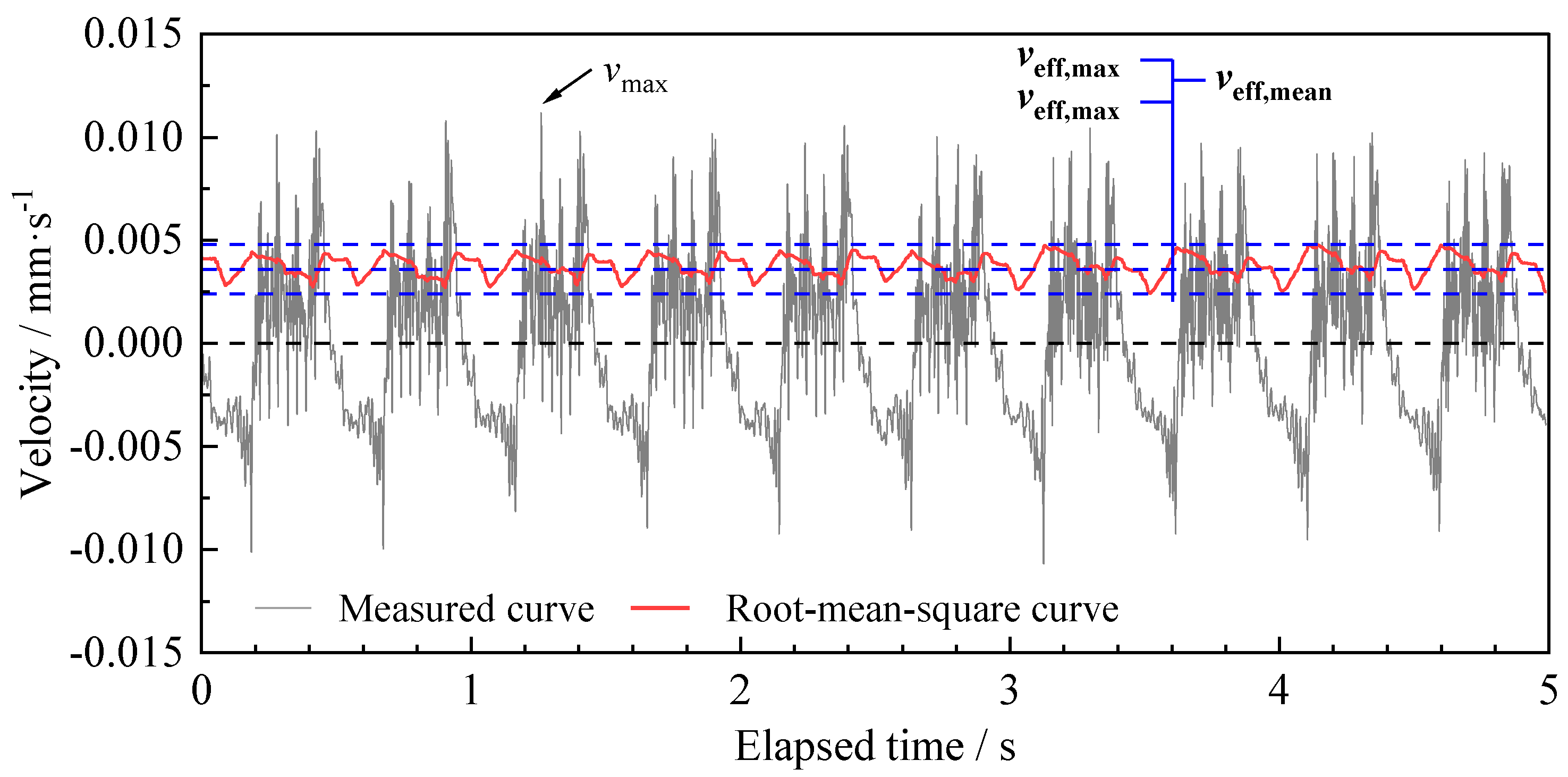

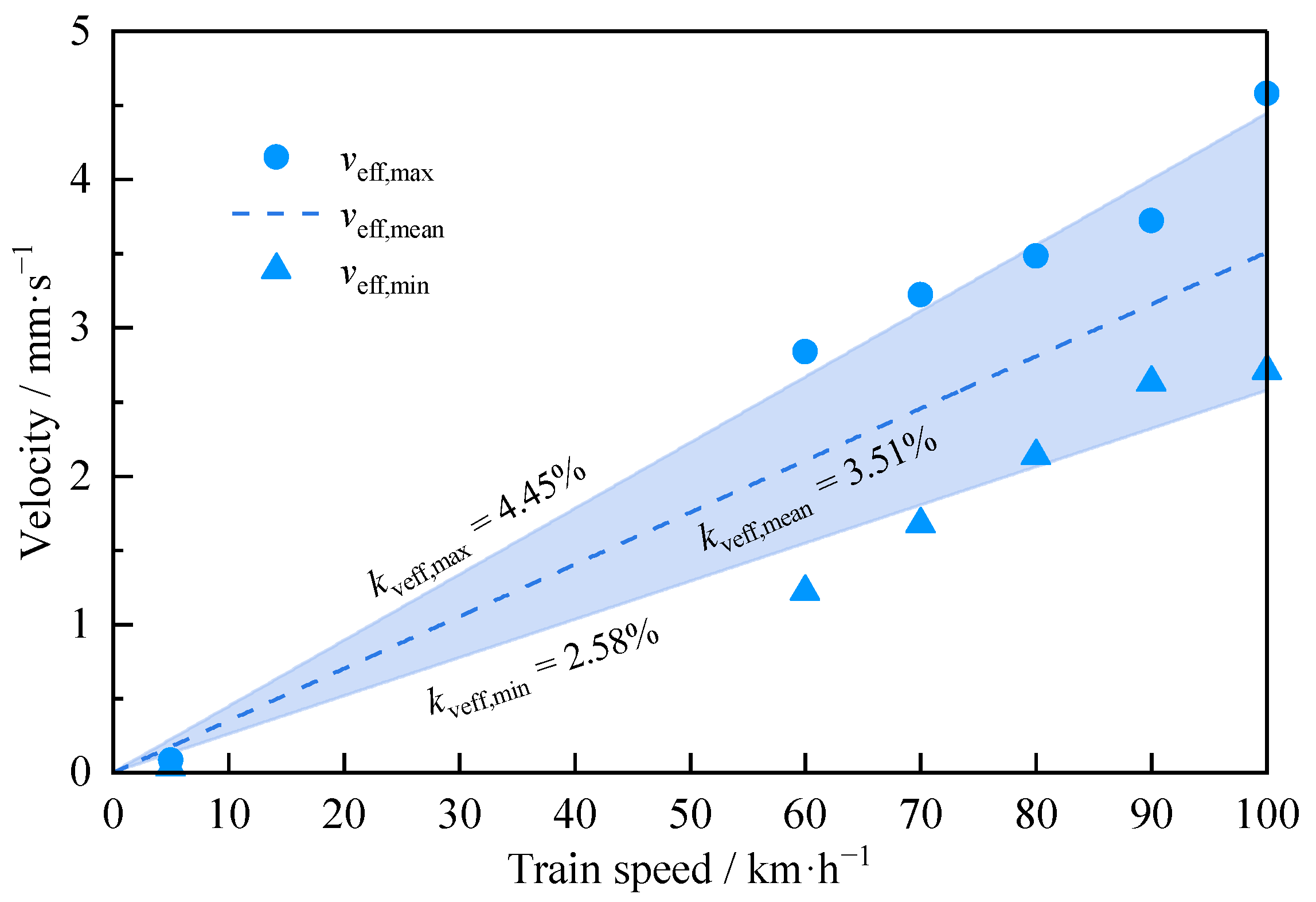

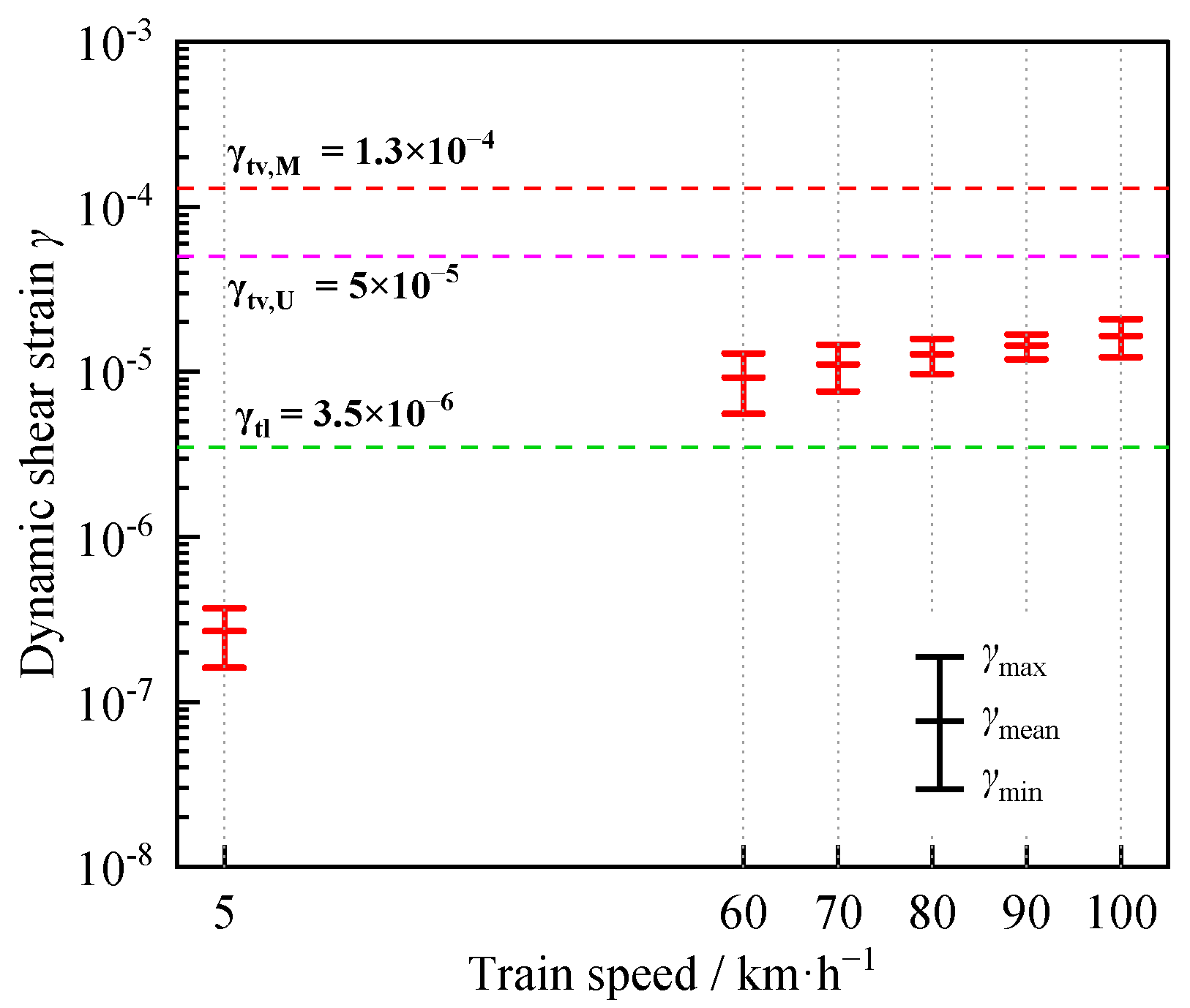

3.2. Vibration Velocity

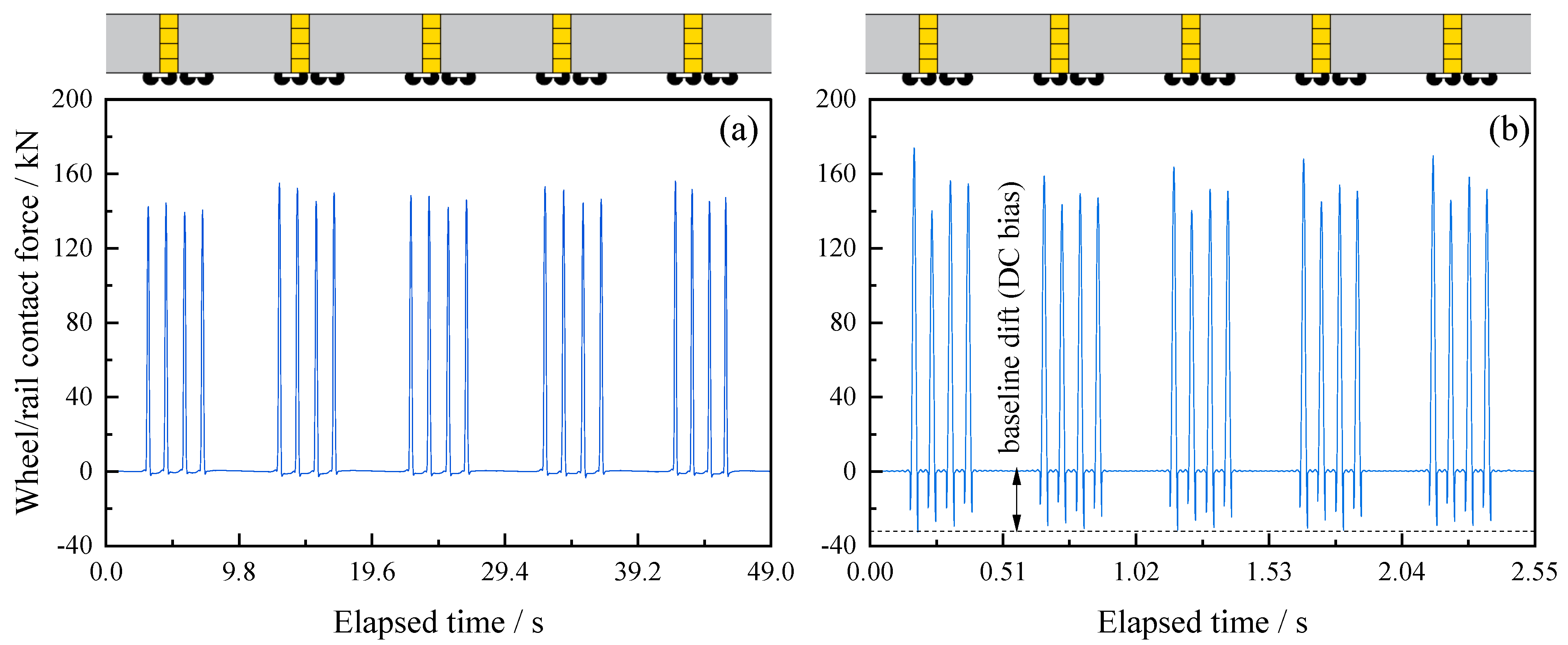

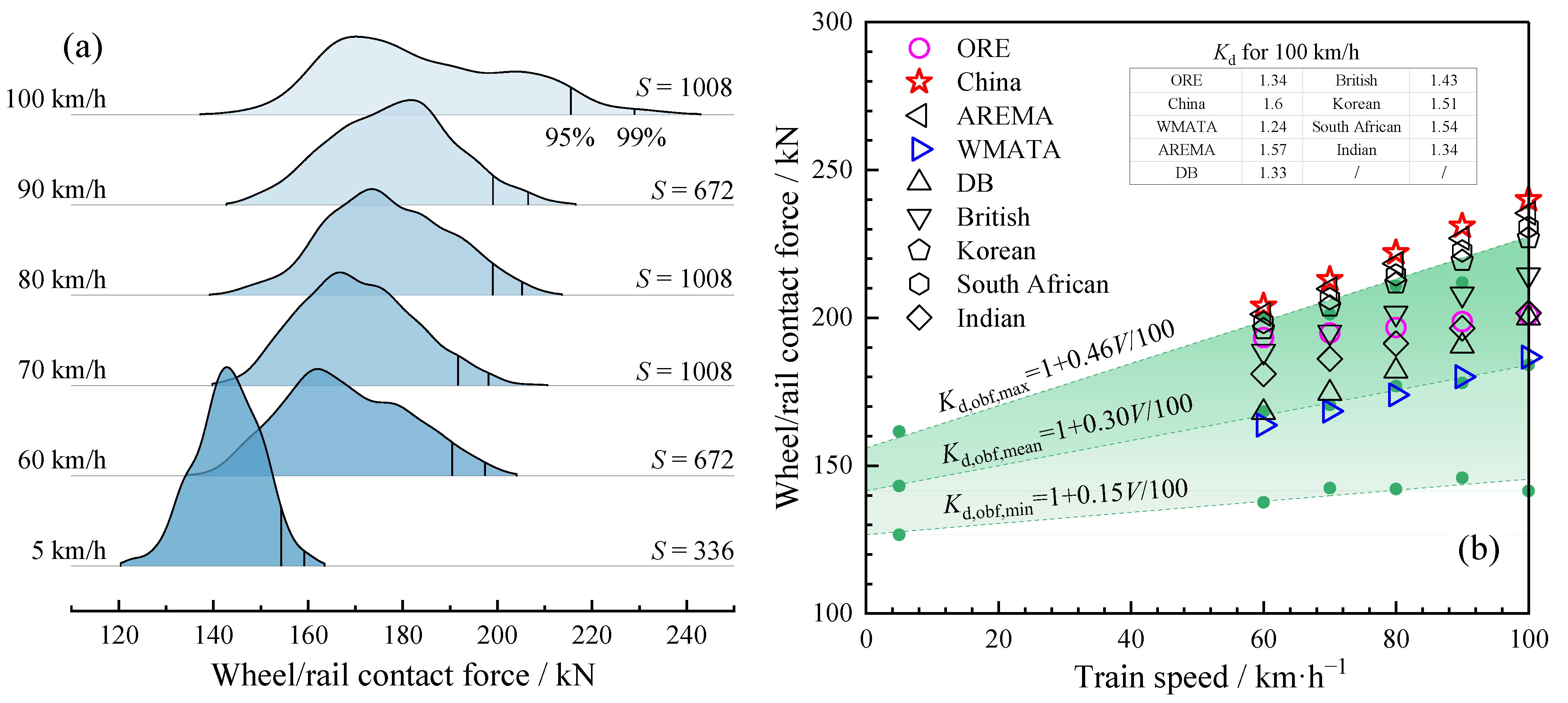

3.3. Wheel–Rail Contact Force

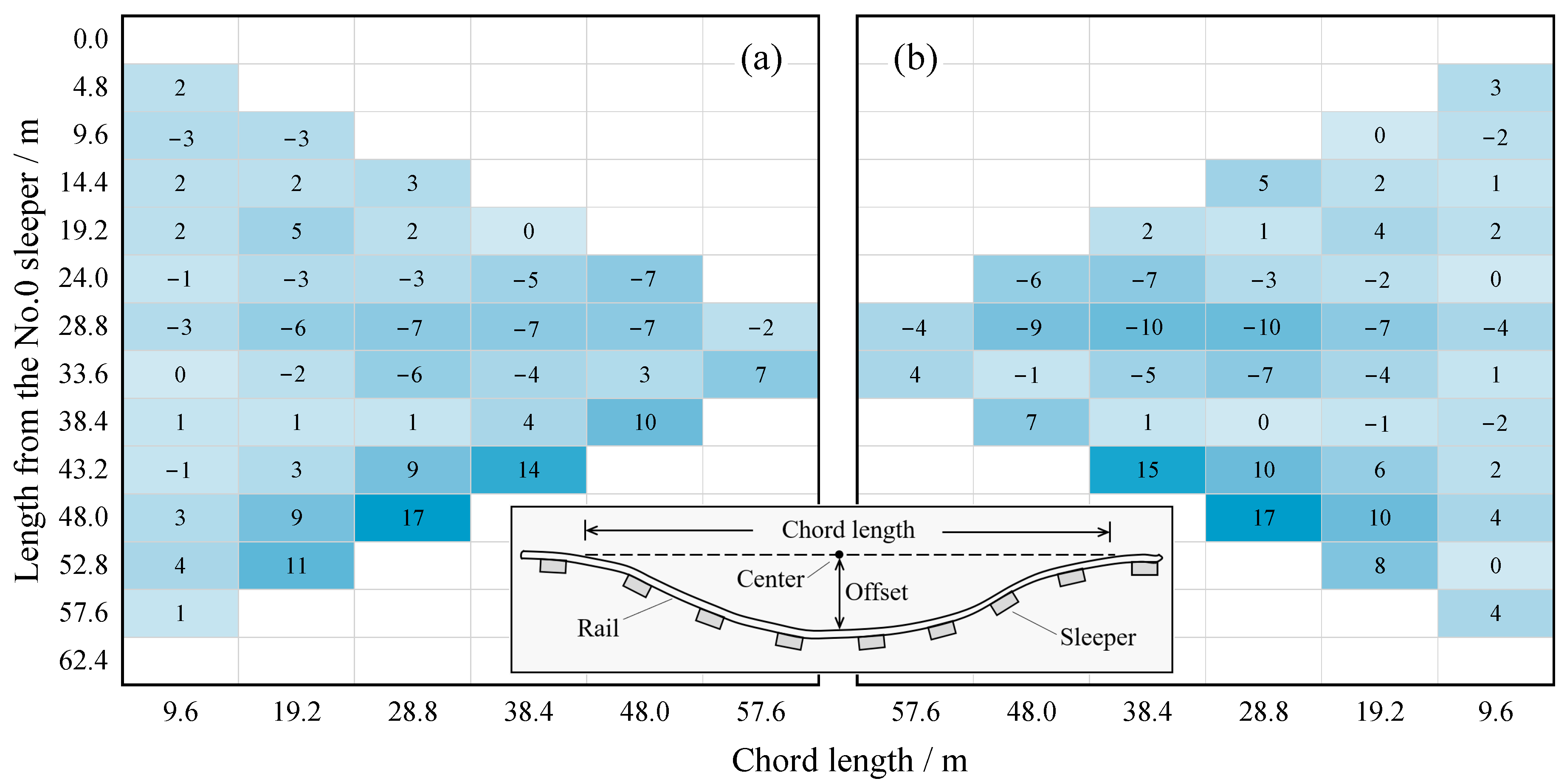

4. Numerical Modelling

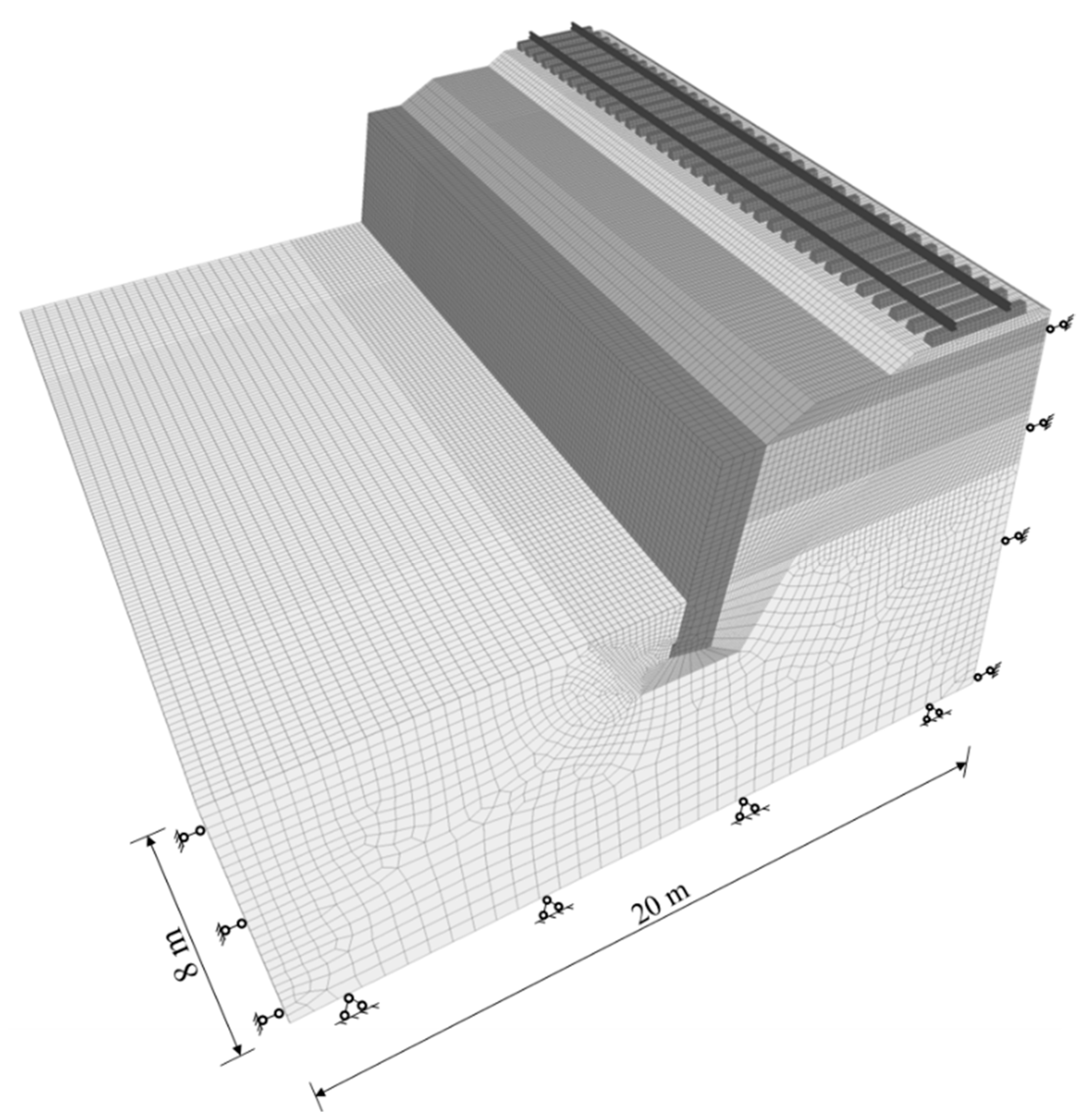

4.1. Model Development

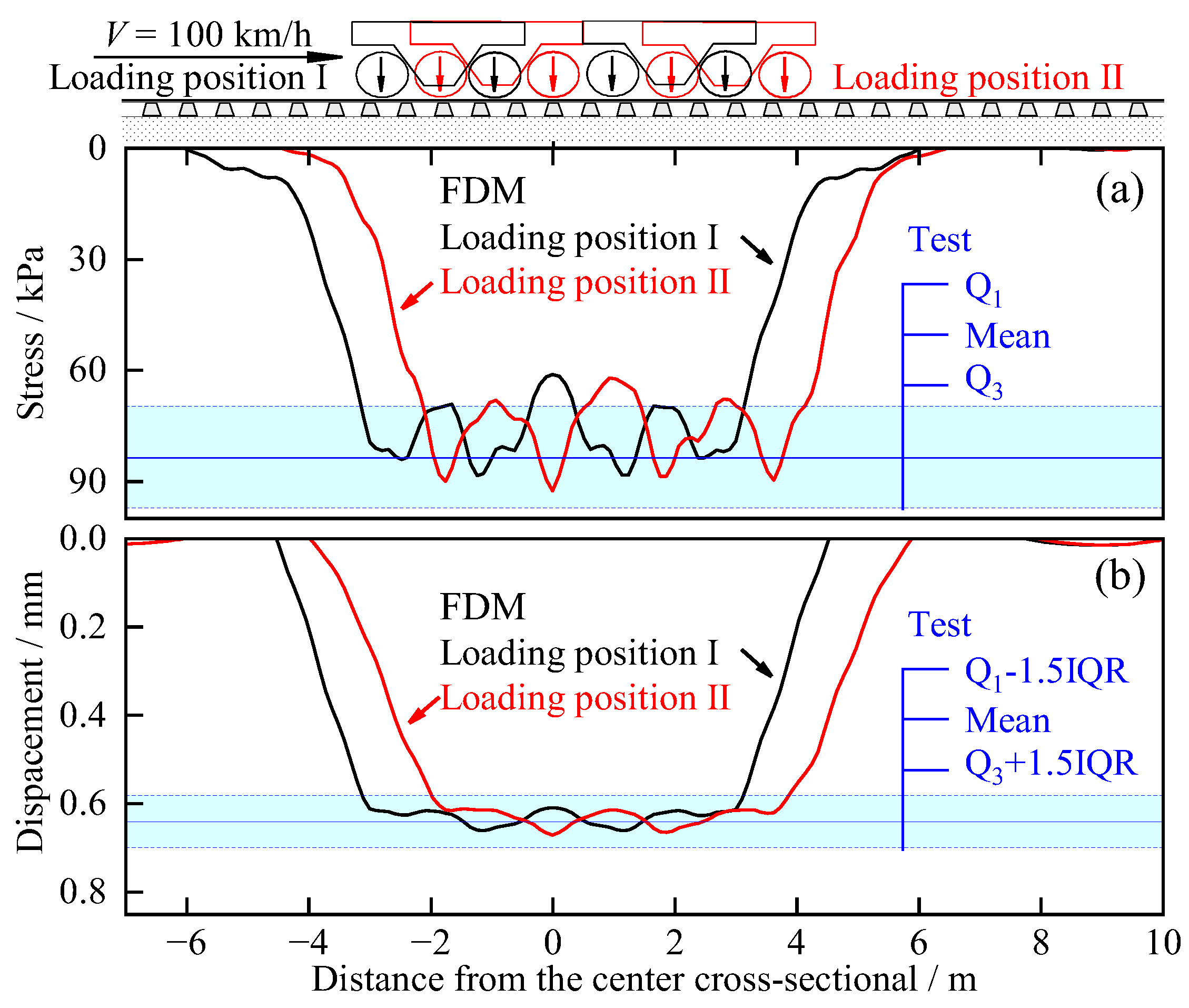

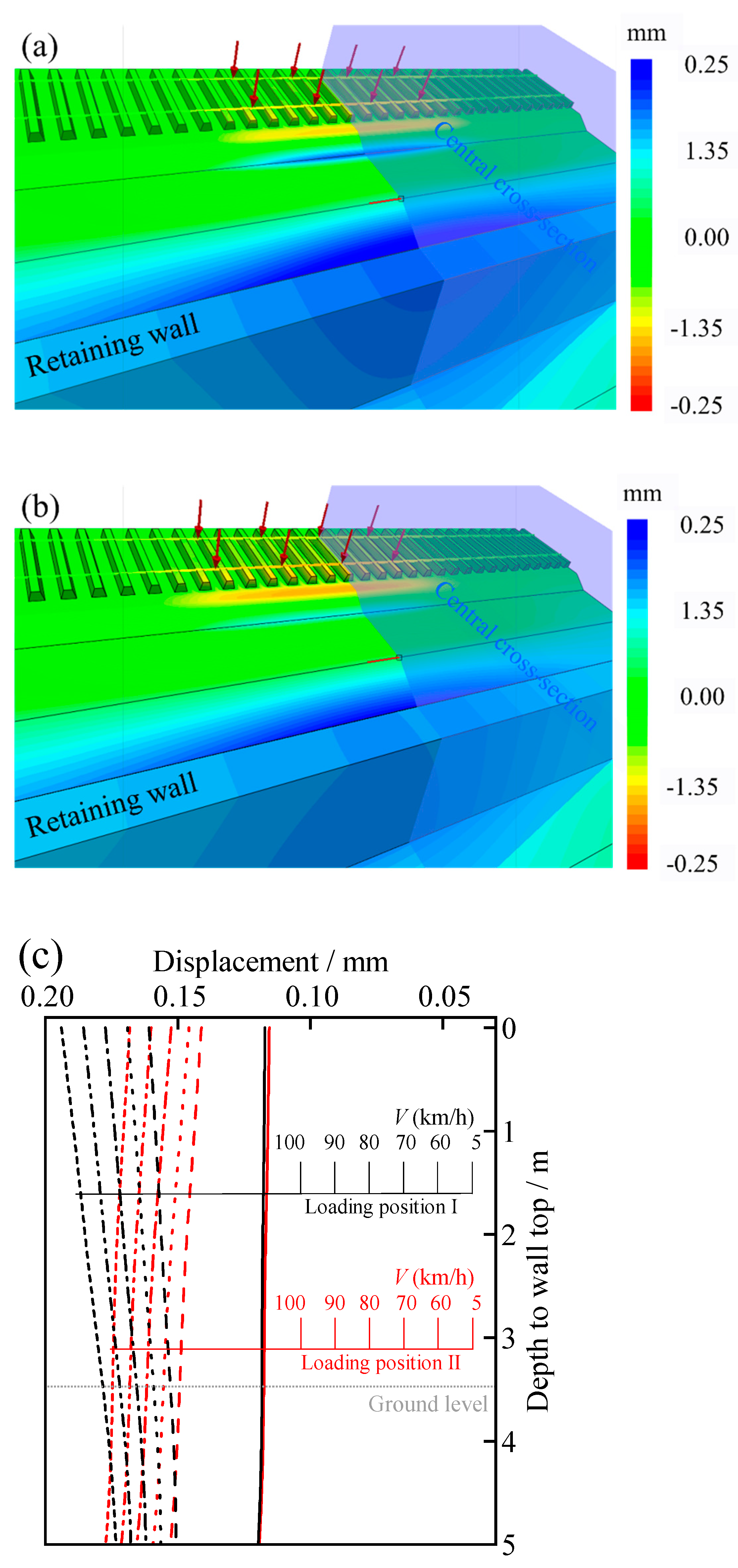

- (1)

- Four-axle loading is symmetrically distributed along both sides of the sleepers on the center cross-section of the model (Loading position I)

- (2)

- The second axle of the four-axle loads is acting directly at the central cross-section of the model (Loading position II)

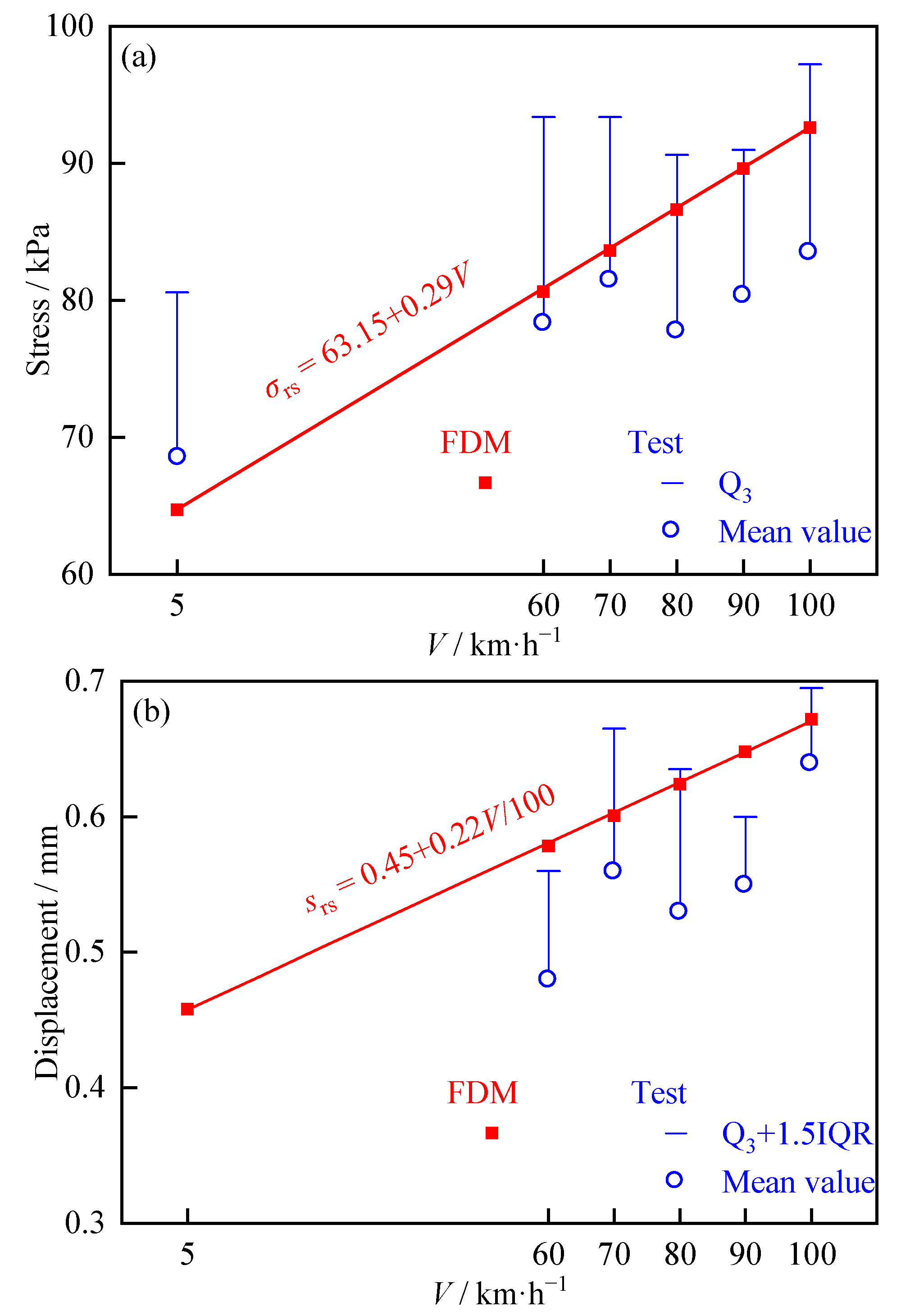

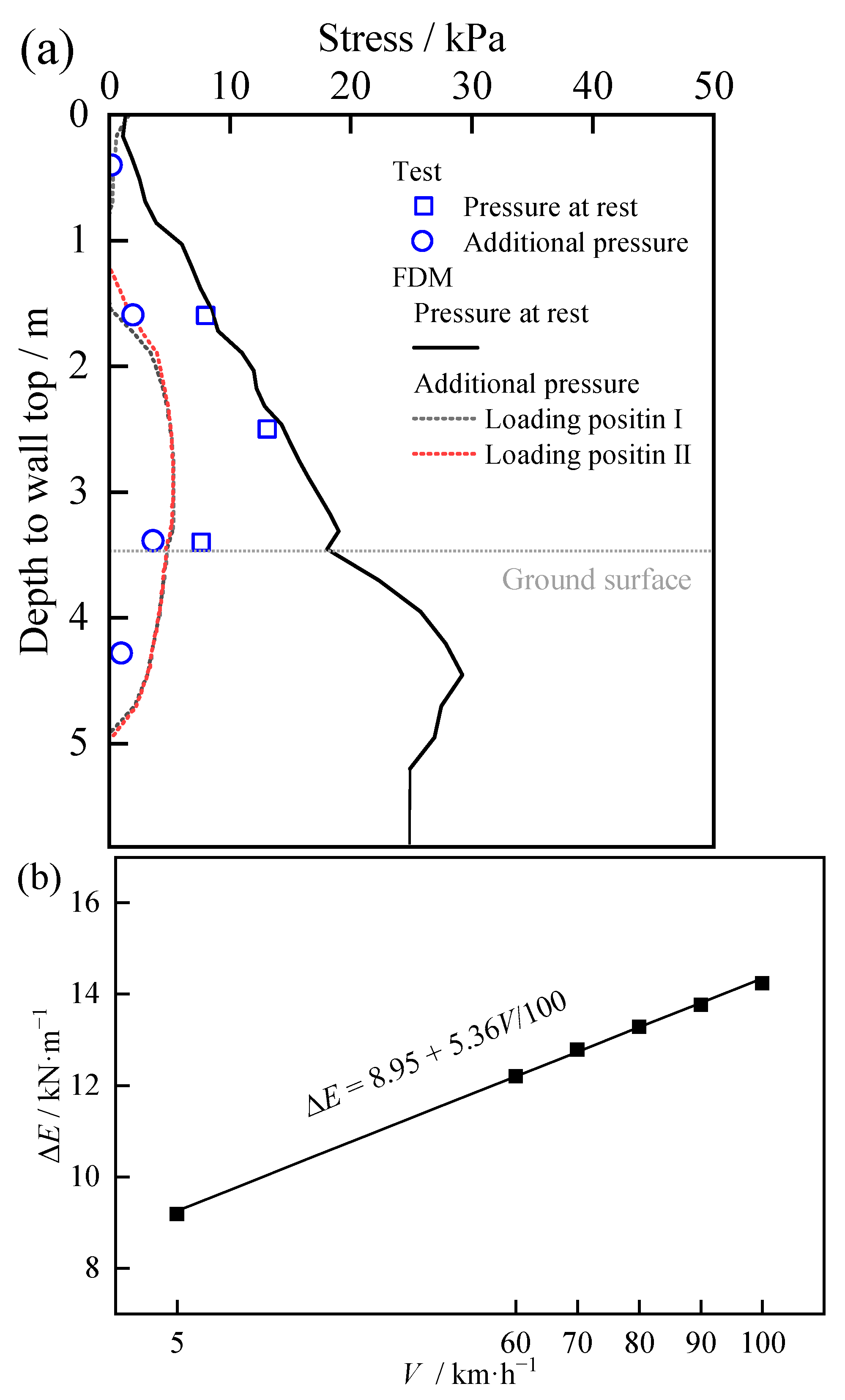

4.2. Analysis of Roadbed and Retaining Wall

5. Conclusions

- (1)

- The maximum vibration acceleration values were 8.41 m/s2 and 4.93 m/s2 for the sleeper and roadbed, meeting the requirements for dynamic acceptance. At speeds 60 km/h, the PPA on the retaining wall was two orders lower than those on the sleeper and roadbed, and the sleeper was 1.7 times greater than that on the roadbed. For the same conditions, the PPA was between 4–5 times greater than the MTVV.

- (2)

- The spectrum amplitude attenuated along the propagation path, sleeper−subgrade−retaining structure, where the maximum VALs were 114.37 dB, 112.41 dB, and 77.42 dB. The sleeper and roadbed shared a similar distribution pattern, differing from the retaining wall. Material properties were observed to contribute more to the transmission of vibrations in substructures than speed.

- (3)

- The maximum effective velocity on the roadbed surface reached 4.58 mm/s at 100 km/h, and its slope was 4.45%. The maximum value of the shear strain was lower than the volumetric cyclic threshold shear strain, ensuring the long-term dynamic stability of the track formation.

- (4)

- The measured contact forces increased at higher train speeds, yielding a maximum value of 238.7 kN at 100 km/h, thus meeting the design requirements. The dynamic impact factor derived from the field test had the relationship, Kd = 1 + 0.46 V/100.

- (5)

- The application of train loads intensified the stress and displacement on the roadbed surface and created additional earth pressure on the retaining wall, resulting in horizontal wall movement. Notably, the earth pressure increased non-linearly before reaching its peak, after which it decreased as the elevation declined.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Component | Density (kg∙m−3) | Elastic Modulus (MPa) | Poisson’s Ratio | Cohesion (kPa) | Friction Angle (°) | Dilation Angle (°) |

|---|---|---|---|---|---|---|

| Retaining wall | 2300 | 28,000 | 0.20 | — | — | — |

| Rail | 7830 | 210,000 | 0.30 | — | — | — |

| Sleeper | 2500 | 36,000 | 0.20 | — | — | — |

| Ballast bed | 2130 | 300 | 0.30 | — | — | — |

| Roadbed (upper portion) | 2100 | 241.4 | 0.25 | 0 | 41.8 | 20.9 |

| Roadbed (lower portion) | 2050 | 190.8 | 0.30 | 0 | 35.0 | 17.5 |

| Subgrade | 2000 | 166.8 | 0.30 | 0 | 34.5 | 17.25 |

| Ground | 1800 | 138.6 | 0.34 | 15.0 | 29.0 | 14.5 |

| Compacted earth | 1900 | 167.7 | 0.30 | 39.0 | 35.0 | 17.5 |

References

- Kish, A. Guidelines to Best Practices for Heavy Haul Railway Operations–Infrastructure Construction and Maintenance Issues; International Heavy Haul Associations: Virginia Beach, VA, USA, 2009. [Google Scholar]

- Connolly, D.P.; Dong, K.; Alves Costa, P.; Soares, P.; Woodward, P.K. High Speed Railway Ground Dynamics: A Multi-Model Analysis. Int. J. Rail Transp. 2020, 8, 324–346. [Google Scholar] [CrossRef]

- Fernández-Ruiz, J.; Castanheira-Pinto, A.; Costa, P.A.; Connolly, D.P. Influence of Non-Linear Soil Properties on Railway Critical Speed. Constr. Build. Mater. 2022, 335, 127485. [Google Scholar] [CrossRef]

- Hu, J.; Bian, X. Analysis of Dynamic Stresses in Ballasted Railway Track Due to Train Passages at High Speeds. J. Zhejiang Univ. Sci. A 2022, 23, 443–457. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Khakiev, Z.; Yavna, V. Dynamic Behavior and Stability of Soil Foundation in Heavy Haul Railway Tracks: A Review. Constr. Build. Mater. 2019, 205, 111–136. [Google Scholar] [CrossRef]

- Shan, Y.; Zhou, S.; Wang, B.; Ho, C.L. Differential Settlement Prediction of Ballasted Tracks in Bridge–Embankment Transition Zones. J. Geotech. Geoenviron. Eng. 2020, 146, 04020075. [Google Scholar] [CrossRef]

- Charoenwong, C.; Connolly, D.P.; Odolinski, K.; Alves Costa, P.; Galvín, P.; Smith, A. The Effect of Rolling Stock Characteristics on Differential Railway Track Settlement: An Engineering-Economic Model. Transp. Geotech. 2022, 37, 100845. [Google Scholar] [CrossRef]

- Nie, R.; Sun, B.; Leng, W.; Li, Y.; Ruan, B. Resilient Modulus of Coarse-Grained Subgrade Soil for Heavy-Haul Railway: An Experimental Study. Soil Dyn. Earthq. Eng. 2021, 150, 106959. [Google Scholar] [CrossRef]

- Chen, X.; Nie, R.; Li, Y.; Guo, Y.; Dong, J. Resilient Modulus of Fine-Grained Subgrade Soil Considering Load Interval: An Experimental Study. Soil Dyn. Earthq. Eng. 2021, 142, 106558. [Google Scholar] [CrossRef]

- Wang, T.; Luo, Q.; Liu, J.; Liu, G.; Xie, H. Method for Slab Track Substructure Design at a Speed of 400 Km/h. Transp. Geotech. 2020, 24, 100391. [Google Scholar] [CrossRef]

- Xie, H.; Luo, Q.; Wang, T.; Jiang, L.; Connolly, D.P. Stochastic Analysis of Dynamic Stress Amplification Factors for Slab Track Foundations. Int. J. Rail Transp. 2023, 1–23. [Google Scholar] [CrossRef]

- Shan, Y.; Shu, Y.; Zhou, S. Finite-Infinite Element Coupled Analysis on the Influence of Material Parameters on the Dynamic Properties of Transition Zones. Constr. Build. Mater. 2017, 148, 548–558. [Google Scholar] [CrossRef]

- Luo, Q.; Fu, H.; Liu, K.; Wang, T.; Feng, G. Monitoring of Train-Induced Responses at Asphalt Support Layer of a High-Speed Ballasted Track. Constr. Build. Mater. 2021, 298, 123909. [Google Scholar] [CrossRef]

- Xia, F.; Cole, C.; Wolfs, P. The Dynamic Wheel– Rail Contact Stresses for Wagon on Various Tracks. Wear 2008, 265, 1549–1555. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, K.; Lin, J. Modelling and Experiment of Railway Ballast Vibrations. J. Sound Vib. 2004, 270, 673–683. [Google Scholar] [CrossRef]

- Wang, T.; Luo, Q.; Zhang, L.; Xiao, S.; Fu, H. Dynamic Response of Stabilized Cinder Subgrade during Train Passage. Constr. Build. Mater. 2021, 270, 121370. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, Q.; Lu, Z.; Wu, X. Dynamic Effects of Vehicles on Tracks in the Case of Raising Train Speeds. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2001, 215, 125–135. [Google Scholar] [CrossRef]

- Sheng, X.; Jones, C.J.C.; Thompson, D.J. A Comparison of a Theoretical Model for Quasi-Statically and Dynamically Induced Environmental Vibration from Trains with Measurements. J. Sound Vib. 2003, 267, 621–635. [Google Scholar] [CrossRef]

- Milne, D.R.M.; Le Pen, L.M.; Thompson, D.J.; Powrie, W. Properties of Train Load Frequencies and Their Applications. J. Sound Vib. 2017, 397, 123–140. [Google Scholar] [CrossRef]

- Di, H.; Yu, J.; Guo, H.; Zhou, S.; He, C.; Zhang, X. Modeling of Ground Vibrations from a Tunnel in Layered Unsaturated Soil with Spatial Variability. Arch. Civ. Mech. Eng. 2022, 22, 33. [Google Scholar] [CrossRef]

- Auersch, L.; Said, S. Dynamic Track-Soil Interaction—Calculations and Measurements of Slab and Ballast Tracks. J. Zhejiang Univ. Sci. A 2021, 22, 21–36. [Google Scholar] [CrossRef]

- Dong, J.; Yang, Y.; Wu, Z.-H. Propagation Characteristics of Vibrations Induced by Heavy-Haul Trains in a Loess Area of the North China Plains. J. Vib. Control 2019, 25, 882–894. [Google Scholar] [CrossRef]

- Ren, J.; Wang, J.; Li, X.; Wei, K.; Li, H.; Deng, S. Influence of Cement Asphalt Mortar Debonding on the Damage Distribution and Mechanical Responses of CRTS I Prefabricated Slab. Constr. Build. Mater. 2020, 230, 116995. [Google Scholar] [CrossRef]

- Deng, S.; Ren, J.; Wei, K.; Ye, W.; Du, W.; Zhang, K. Fatigue Damage Evolution Analysis of the CA Mortar of Ballastless Tracks via Damage Mechanics-Finite Element Full-Couple Method. Constr. Build. Mater. 2021, 295, 123679. [Google Scholar] [CrossRef]

- Auersch, L. The Excitation of Ground Vibration by Rail Traffic: Theory of Vehicle–Track–Soil Interaction and Measurements on High-Speed Lines. J. Sound Vib. 2005, 284, 103–132. [Google Scholar] [CrossRef]

- Mei, H.; Leng, W.; Nie, R.; Liu, W.; Chen, C.; Wu, X. Random Distribution Characteristics of Peak Dynamic Stress on the Subgrade Surface of Heavy-Haul Railways Considering Track Irregularities. Soil Dyn. Earthq. Eng. 2019, 116, 205–214. [Google Scholar] [CrossRef]

- Ye, Q.; Luo, Q.; Connolly, D.P.; Wang, T.; Xie, H.; Ding, H. The Effect of Asphaltic Support Layers on Slab Track Dynamics. Soil Dyn. Earthq. Eng. 2023, 166, 107771. [Google Scholar] [CrossRef]

- Beben, D.; Anigacz, W.; Ukleja, J. Diagnosis of Bedrock Course and Retaining Wall Using GPR. NDT E Int. 2013, 59, 77–85. [Google Scholar] [CrossRef]

- Bian, X.; Chao, C.; Jin, W.; Chen, Y. A 2.5 D Finite Element Approach for Predicting Ground Vibrations Generated by Vertical Track Irregularities. J. Zhejiang Univ. Sci. A 2011, 12, 885–894. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, B.; Lv, P.; Zhou, Q. Behaviour of Geogrid Reinforced Soil Retaining Wall with Concrete-Rigid Facing. Geotext. Geomembr. 2009, 27, 350–356. [Google Scholar] [CrossRef]

- Esen, A.F.; Woodward, P.K.; Laghrouche, O.; Čebašek, T.M.; Brennan, A.J.; Robinson, S.; Connolly, D.P. Full-Scale Laboratory Testing of a Geosynthetically Reinforced Soil Railway Structure. Transp. Geotech. 2021, 28, 100526. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, L.; Song, X. An Improved Matrix Split-Iteration Method for Analyzing Underground Water Flow. Eng. Comput. 2022. [Google Scholar] [CrossRef]

- The National Railway Administration (NRA). Code for Design of Retaining Structure of Railway Earthworks (TB 10025-2019); China Railway Publishing House Co., Ltd.: Beijing, China, 2019. [Google Scholar]

- The National Railway Administration (NRA). Code for Design of Railway Earth Structure (TB 10001-2016); China Railway Publishing House Co., Ltd.: Beijing, China, 2016. [Google Scholar]

- The National Railway Administration (NRA). Code for Design of Railway Track (TB 10082-2017); China Railway Publishing House Co., Ltd.: Beijing, China, 2017. [Google Scholar]

- ISO 2631-1; Mechanical vibration and shock — Evaluation of human exposure to whole-body vibration — Part 1: General requirements. ISO: Geneva, Switzerland, 1997.

- Feng, G.; Wang, T. Raw_acceleration_data.xlsx. 2023. Available online: https://figshare.com/articles/dataset/Raw_acceleration_data_xlsx/21946421 (accessed on 24 January 2023).

- Kouroussis, G.; Verlinden, O.; Conti, C. Free Field Vibrations Caused by High-Speed Lines: Measurement and Time Domain Simulation. Soil Dyn. Earthq. Eng. 2011, 31, 692–707. [Google Scholar] [CrossRef]

- The National Railway Administration (NRA). Technical Regulations for Dynamic Acceptance for Mixed Passenger and Freight Railways Construction (TB 10461-2019). China Railway Publishing House Co., Ltd.: Beijing, China, 2019. [Google Scholar]

- Chen, C.; Chang, L.; Loh, C. A Review of Spectral Analysis for Low-Frequency Transient Vibrations. J. Low Freq. Noise Vib. Act. Control 2021, 40, 656–671. [Google Scholar] [CrossRef]

- Hu, Y.; Li, N. Theory of Ballastless Track-Subgrade for High Speed Railway, 1st ed.; China Railway Publishing House: Beijing, China, 2010; ISBN 978-7-113-11729-0. [Google Scholar]

- Qu, C.; Kang, K.; Wei, L.; Guo, K.; He, Q. Dynamic Response Characteristics and Long-Term Dynamic Stability of Subgrade-Culvert Transition Zone in High-Speed Railway. Rock Soil Mech. 2020, 41, 3432–3442. [Google Scholar]

- DS 836-1997; Tilbagetrukket. Havebrugsmaskiner. Motoriserede plæneklippere. Sikkerhed. Dansk: Mount Kisco, NY, USA, 1998.

- Xiao, G. Test Study on Railway Subgrade Reinforced by Sand Compacted Pile and Geocell. Master’s thesis, Southwest Jiaotong University, Chengdu, China, 2005. [Google Scholar]

- Vucetic, M. Cyclic Threshold Shear Strains in Soils. J. Geotech. Eng. 1994, 120, 2208–2228. [Google Scholar] [CrossRef]

- Sarikavak, Y.; Goda, K. Dynamic Wheel/Rail Interactions for High-Speed Trains on a Ballasted Track. J. Mech. Sci. Technol. 2022, 36, 689–698. [Google Scholar] [CrossRef]

- Liang, C.; Si, D.; Liu, H. Comparative Analysis of Dynamic Load Coefficient of Railway Track Structures at Home and Abroad. Railw. Eng. 2021, 61, 100–103. [Google Scholar] [CrossRef]

- Choi, J.; Yun, S.; Chung, J.; Kim, S. Comparative Study of Wheel–Rail Contact Impact Force for Jointed Rail and Continuous Welded Rail on Light-Rail Transit. Appl. Sci. 2020, 10, 2299. [Google Scholar] [CrossRef]

- Doyle, N.F. Railway Track Design: A Review of Current Practice; Australian Government Publishing Service: Canberra, Australia, 1980; ISBN 0-642-05014-7. [Google Scholar]

- Eisenmann, J. Germans Gain a Better Understanding of Track Structure. Railw. Gaz. Int. 1972, 128, 305–308. [Google Scholar]

- Bose, T.; Levenberg, E. A Priori Determination of Track Modulus Based on Elastic Solutions. KSCE J. Civ. Eng. 2020, 24, 2939–2948. [Google Scholar] [CrossRef]

- Wang, F.; Qi, J.; Du, J. Dynamic Deformation Analysis Method and Reliability on the Subgrade Surface of the High-Speed Ballast Track. J. Saf. Environ. 2016, 16, 144–149. [Google Scholar]

- Feng, G.; Zhang, L.; Luo, Q.; Wang, T.; Xie, H. Monitoring the Dynamic Response of Track Formation with Retaining Wall to Heavy-Haul Train Passage. Int. J. Rail Transp. 2022, 1–19. [Google Scholar] [CrossRef]

| Item | Sleeper ID | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 | 88 | 96 | 104 | |

| LS0/m | 0 | 4.8 | 9.6 | 14.4 | 19.2 | 24 | 28.8 | 33.6 | 38.4 | 43.2 | 48 | 52.8 | 57.6 | 62.4 |

| RL/mm | 277 | 325 | 376 | 421 | 469 | 521 | 571 | 616 | 661 | 707 | 752 | 803 | 861 | 921 |

| RR/mm | 297 | 342 | 393 | 440 | 489 | 541 | 593 | 638 | 684 | 727 | 773 | 827 | 881 | 942 |

| Cross level/mm | 0 | −3 | −3 | −1 | 0 | 0 | 2 | 2 | 3 | 0 | 1 | 4 | 0 | 1 |

| PPA/m·s−2 | ||||||

|---|---|---|---|---|---|---|

| Sensor Location | 5 km/h | 60 km/h | 70 km/h | 80 km/h | 90 km/h | 100 km/h |

| Sleeper | 0.05 | 5.04 | 5.88 | 7.04 | 7.79 | 8.41 |

| Subgrade surface | 0.03 | 3.04 | 3.54 | 3.97 | 4.49 | 4.93 |

| Retaining wall top | 0.02 | 0.05 | 0.06 | 0.06 | 0.07 | 0.07 |

| MTVV/m·s−2 | ||||||

| Sensor Location | 5 km/h | 60 km/h | 70 km/h | 80 km/h | 90 km/h | 100 km/h |

| Sleeper | 0.02 | 1.05 | 1.30 | 1.44 | 1.87 | 2.07 |

| Subgrade surface | 0.01 | 0.63 | 0.81 | 0.88 | 1.02 | 0.99 |

| Retaining wall top | 0.00 | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 |

| No. | Reference | Relationship |

|---|---|---|

| 1 | The Office of Research and Experiments of the International Union of Railways (ORE, UIC) | |

| 2 | China [47] | |

| 3 | Washington Metropolitan Area Transit Authority, U.S. (WMATA) | |

| 4 | American Railway Engineering and Maintenance-of-Way Association (AREMA) | |

| 5 | Deutsche Bahn, Germany (DB) | |

| 6 | Clarke, British | |

| 7 | Korean [48] | |

| 8 | South African | |

| 9 | Indian |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, G.; Luo, Q.; Lyu, P.; Connolly, D.P.; Wang, T. An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs. Sustainability 2023, 15, 7984. https://doi.org/10.3390/su15107984

Feng G, Luo Q, Lyu P, Connolly DP, Wang T. An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs. Sustainability. 2023; 15(10):7984. https://doi.org/10.3390/su15107984

Chicago/Turabian StyleFeng, Guishuai, Qiang Luo, Pengju Lyu, David P. Connolly, and Tengfei Wang. 2023. "An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs" Sustainability 15, no. 10: 7984. https://doi.org/10.3390/su15107984

APA StyleFeng, G., Luo, Q., Lyu, P., Connolly, D. P., & Wang, T. (2023). An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs. Sustainability, 15(10), 7984. https://doi.org/10.3390/su15107984