Spatial Layout Assessment of Urban Mining Pilot Bases in China Based on Multi-Source Data Collaboration

Abstract

1. Introduction

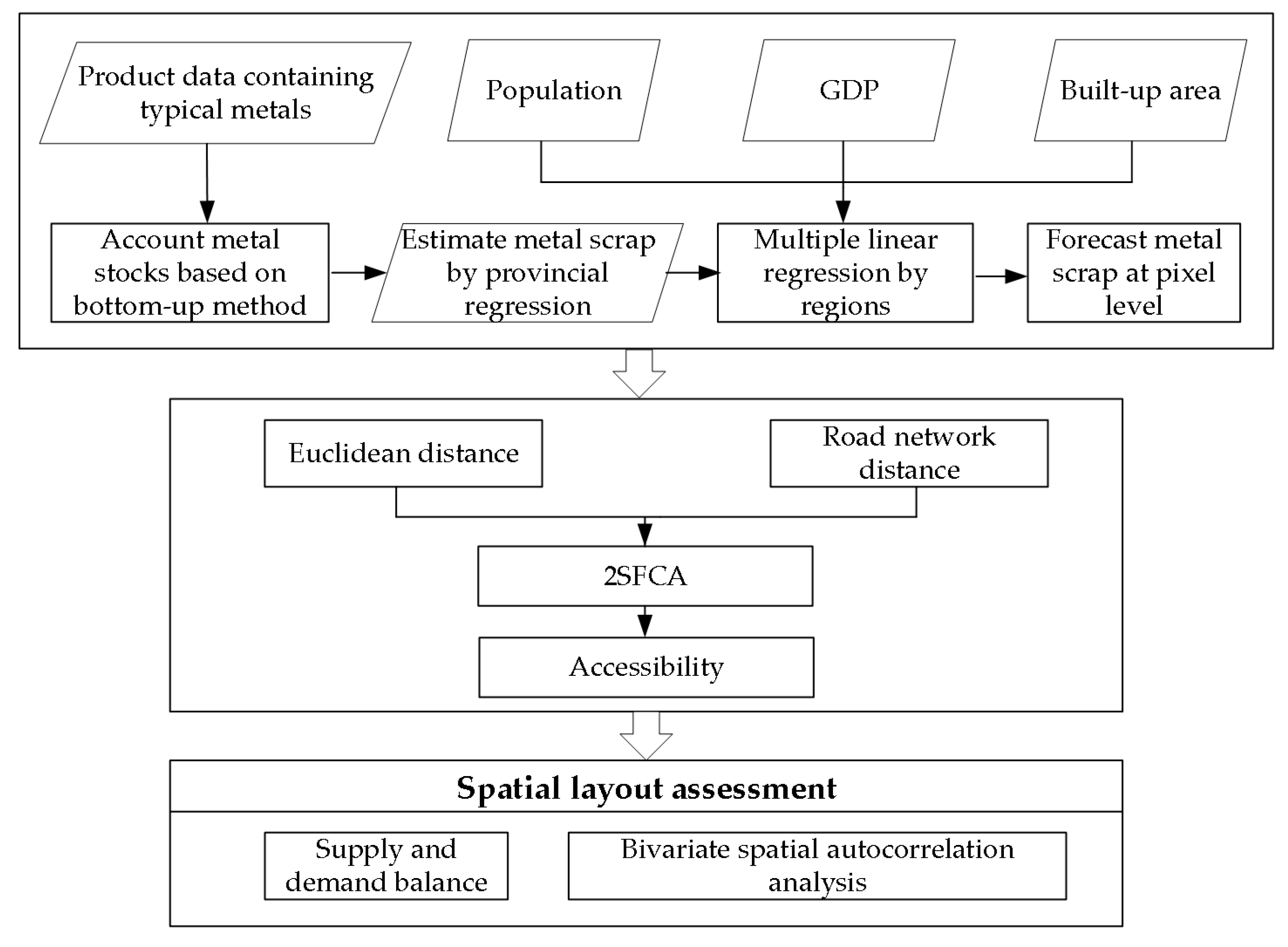

- (1)

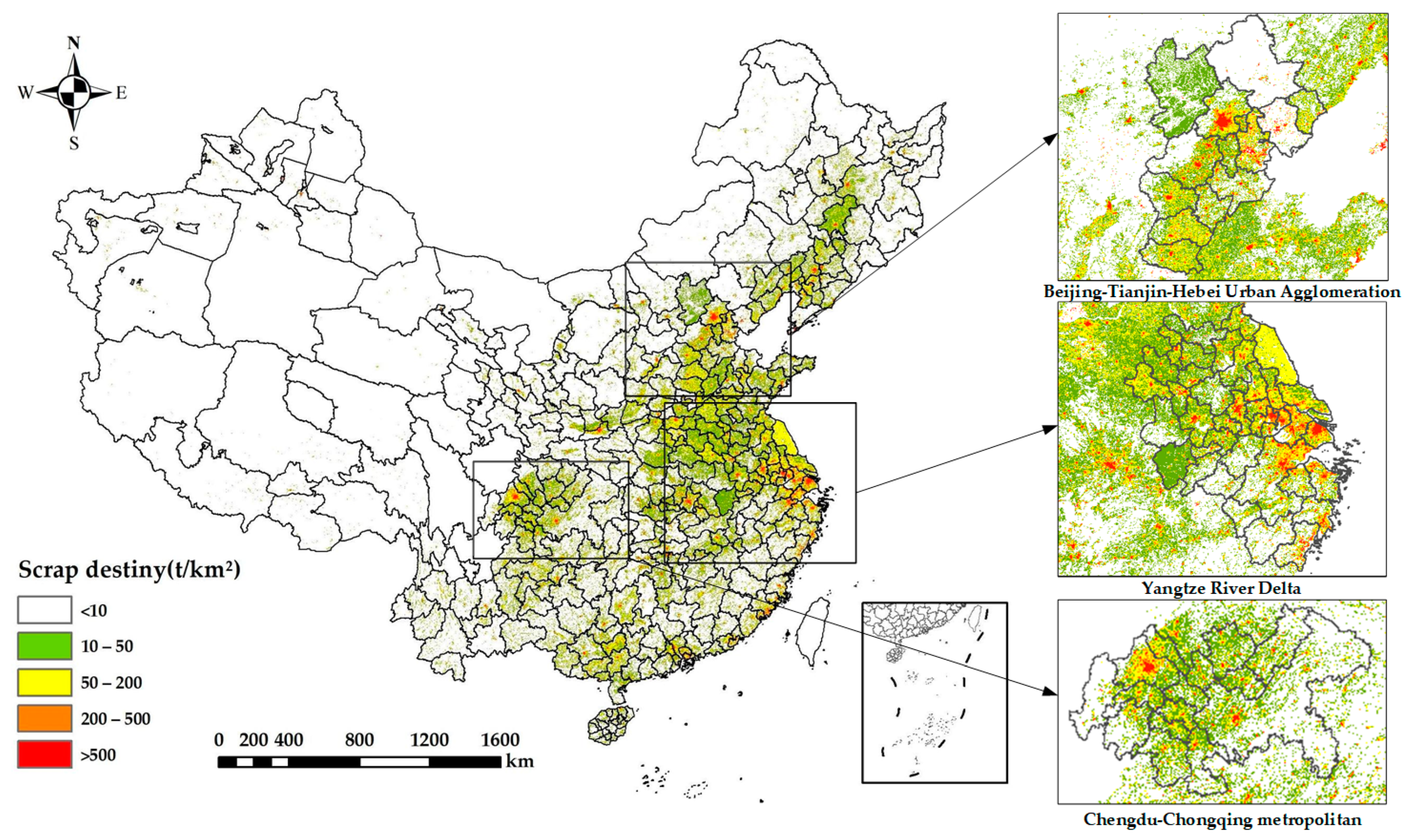

- We propose a spatialization method for metal scrap volume by region and use the method to map the scrap volume of steel, copper, and aluminum in mainland China at a 1 km resolution.

- (2)

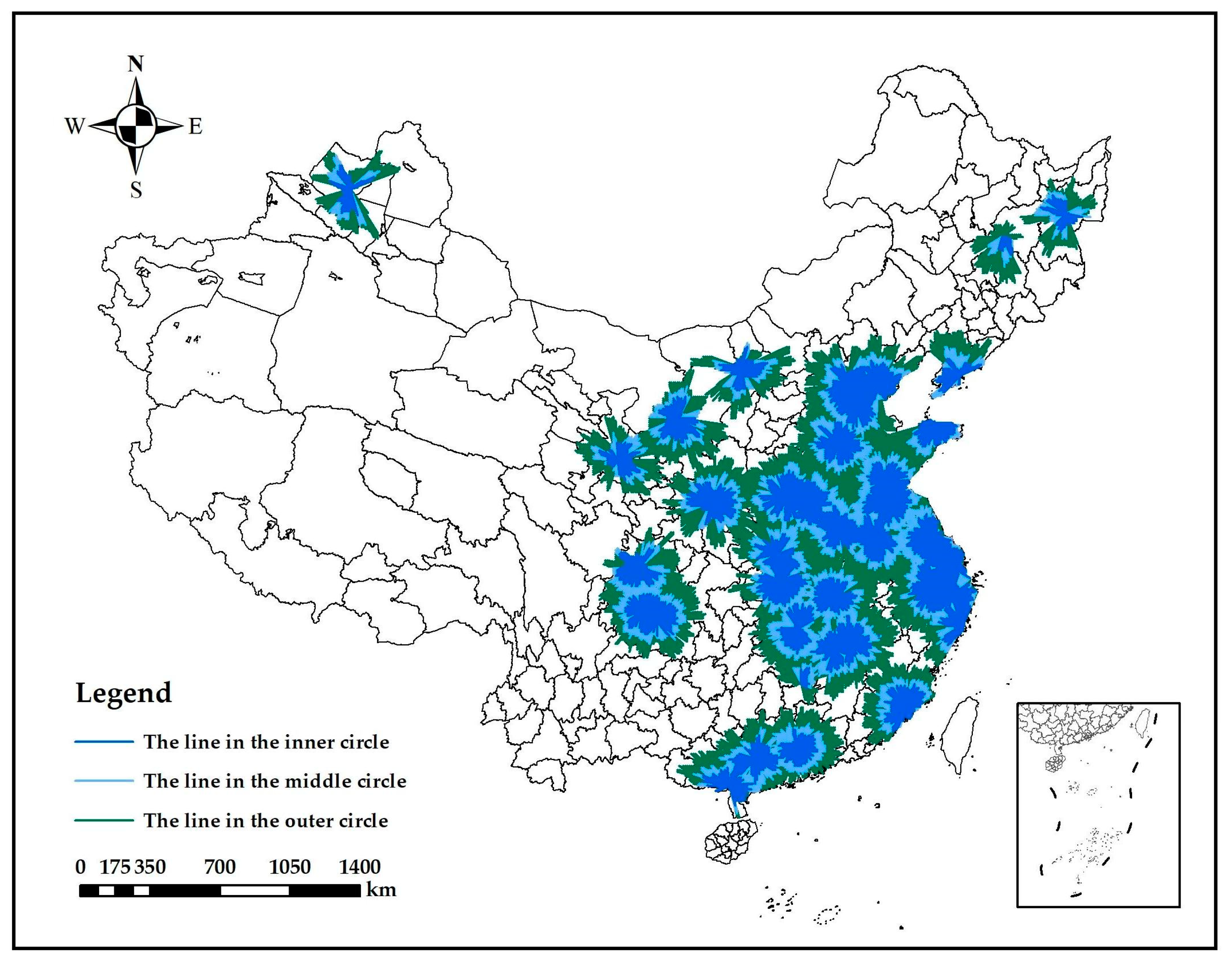

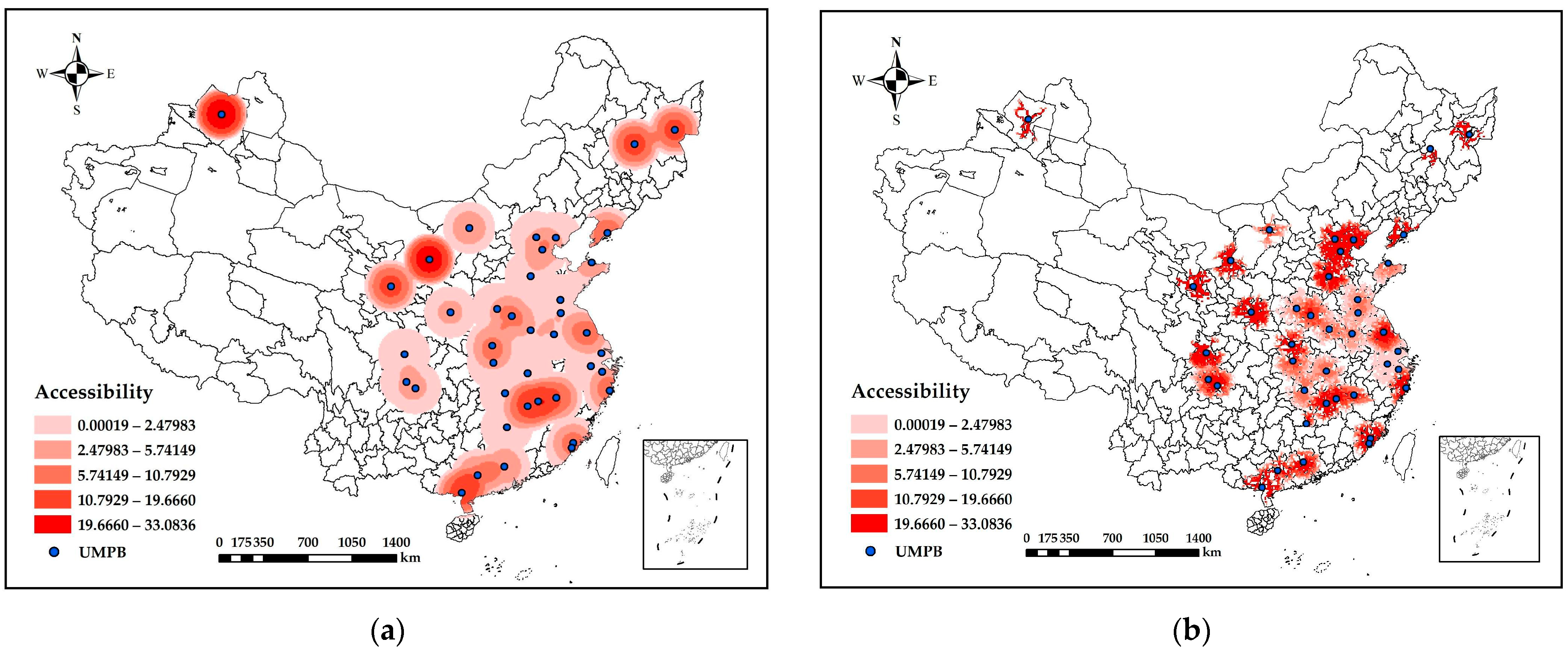

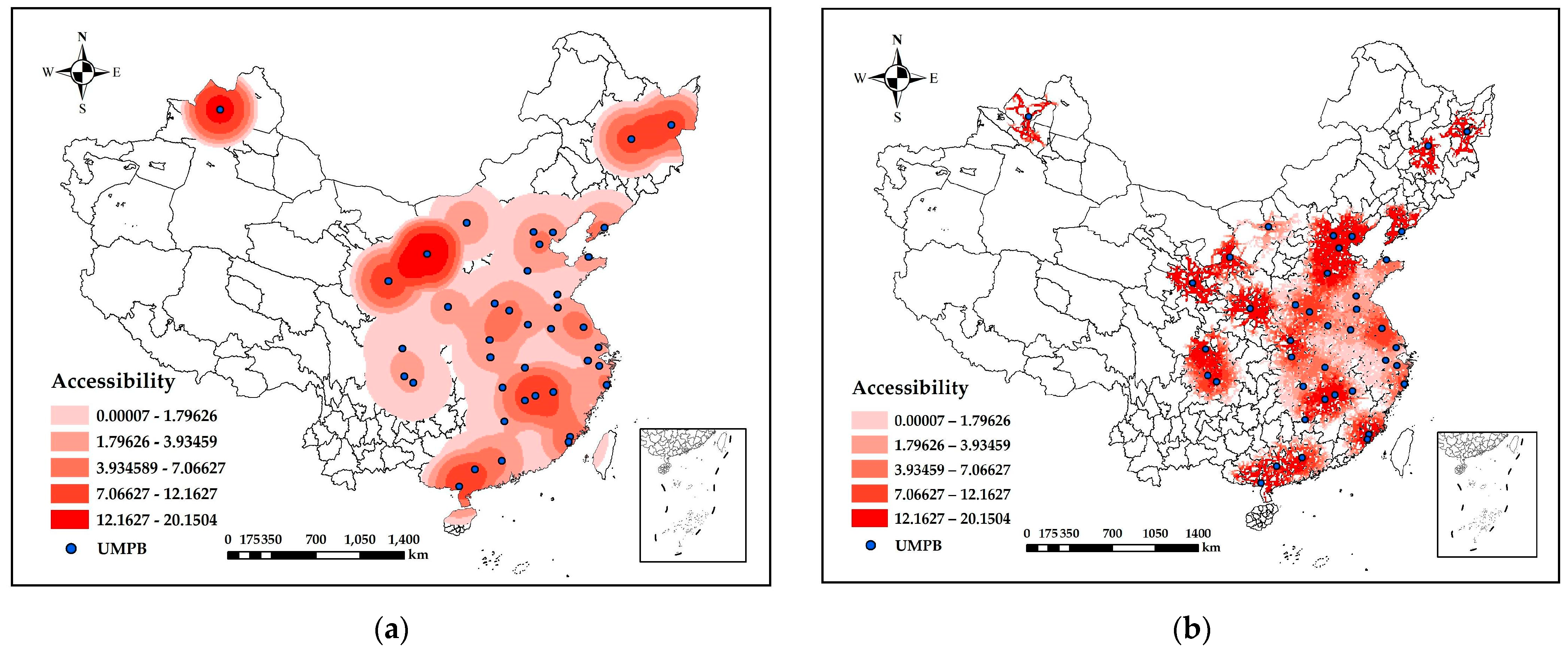

- We use road network distance to express the transportation distance from the demand point to the UMPB, which is more realistic and accurate than Euclidean distance. Additionally, based on accessibility, we measure the match between the service intensity provided by the UMPB and the actual end-of-life demand at the demand point, which provides a reference for the layout optimization of the UMPB.

2. Related Work

3. Materials and Methods

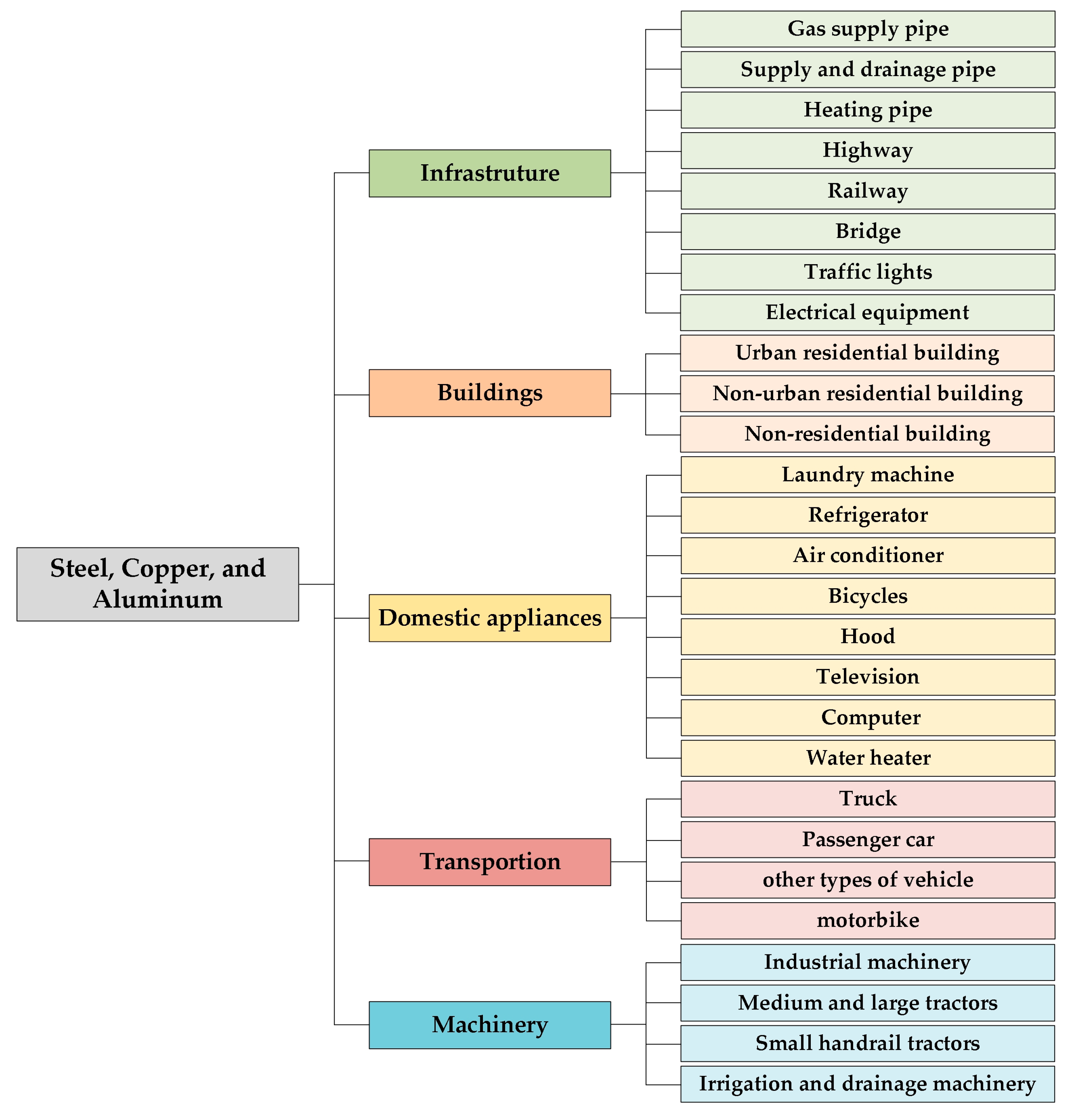

3.1. Metal in-Use Stocks and Scrap Estimation Methods

3.1.1. Account for in-Use Metal Stocks

3.1.2. Development of Multiple Linear Regression Models

3.2. Spatial Layout Assessment Method

3.2.1. Spatial Accessibility Measurement Method

3.2.2. Bivariate Spatial Autocorrelation Analysis

4. Results and Discussion

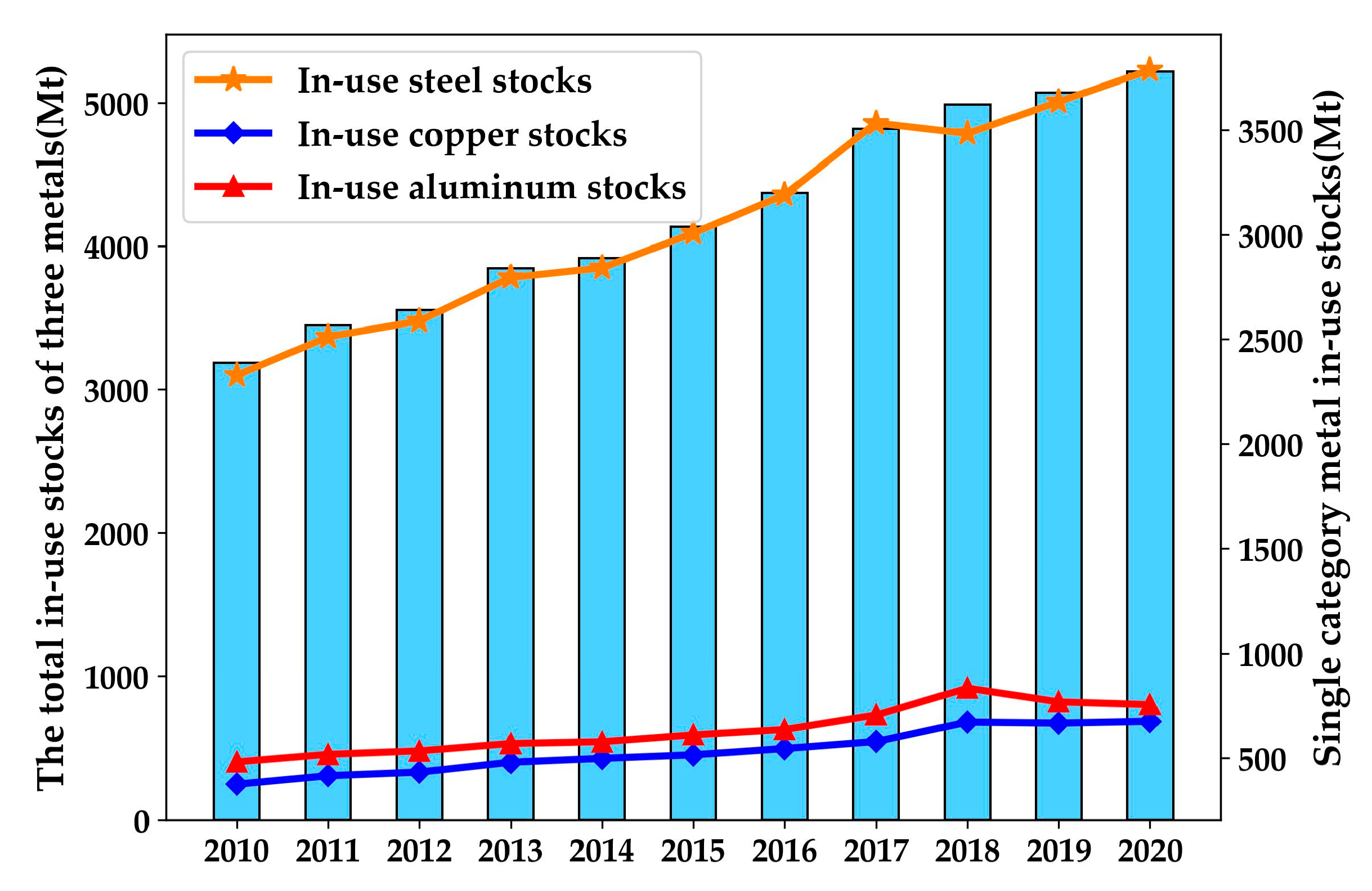

4.1. Spatial and Temporal Distribution of Typical Metal Resources

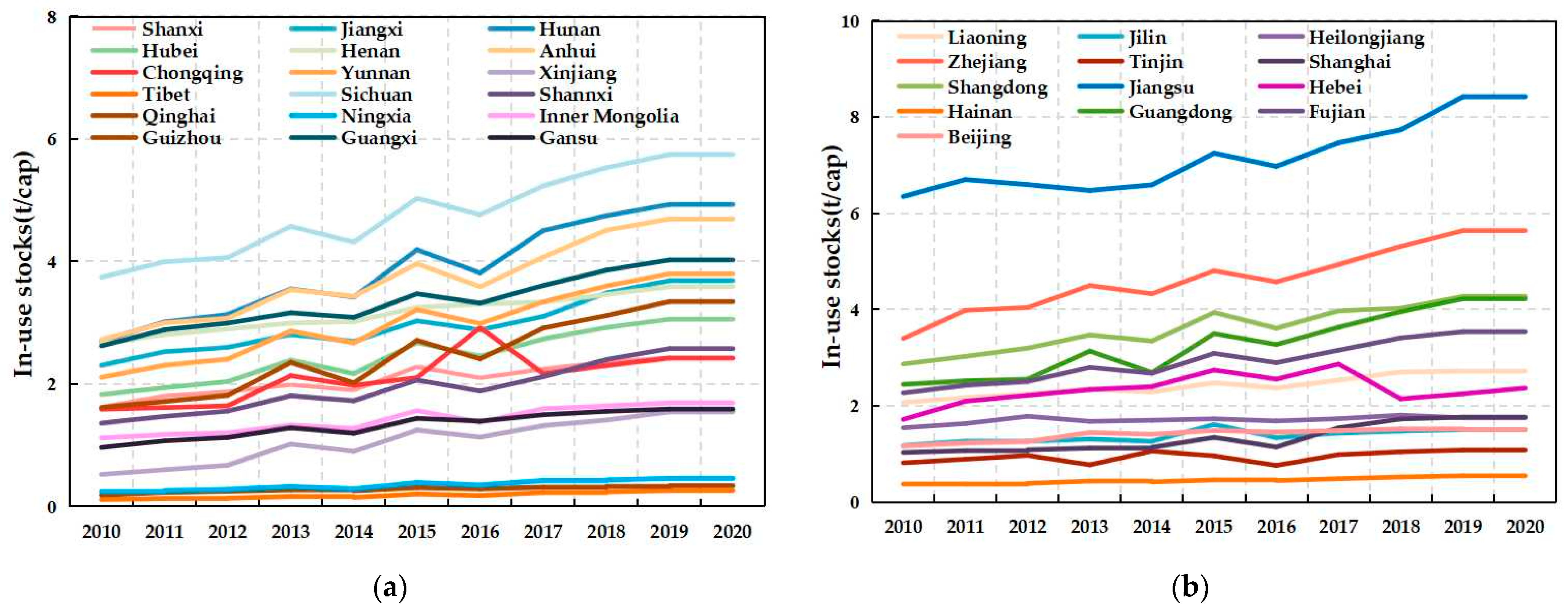

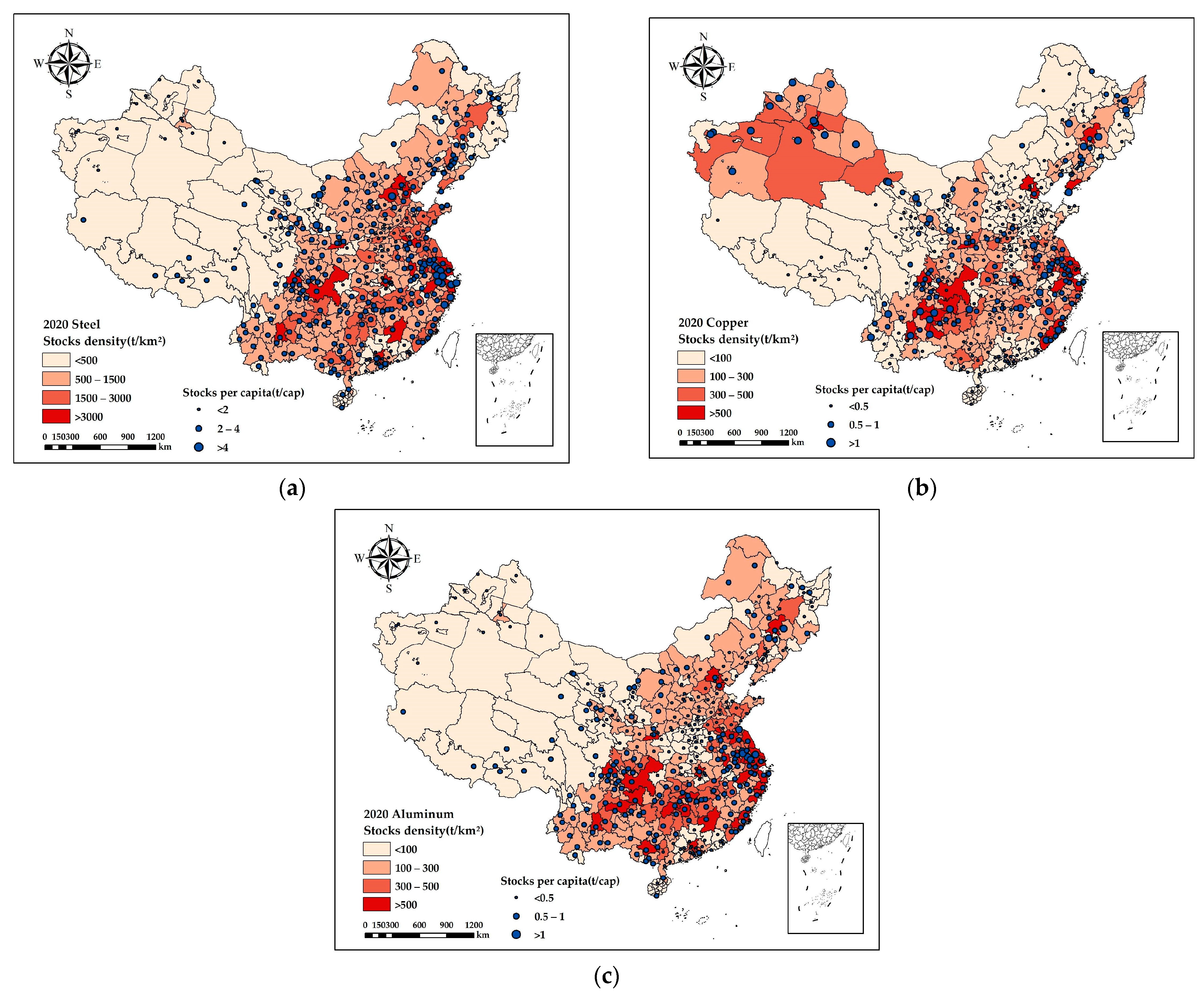

4.1.1. Historical Spatial Distribution of Typical Metal Stocks

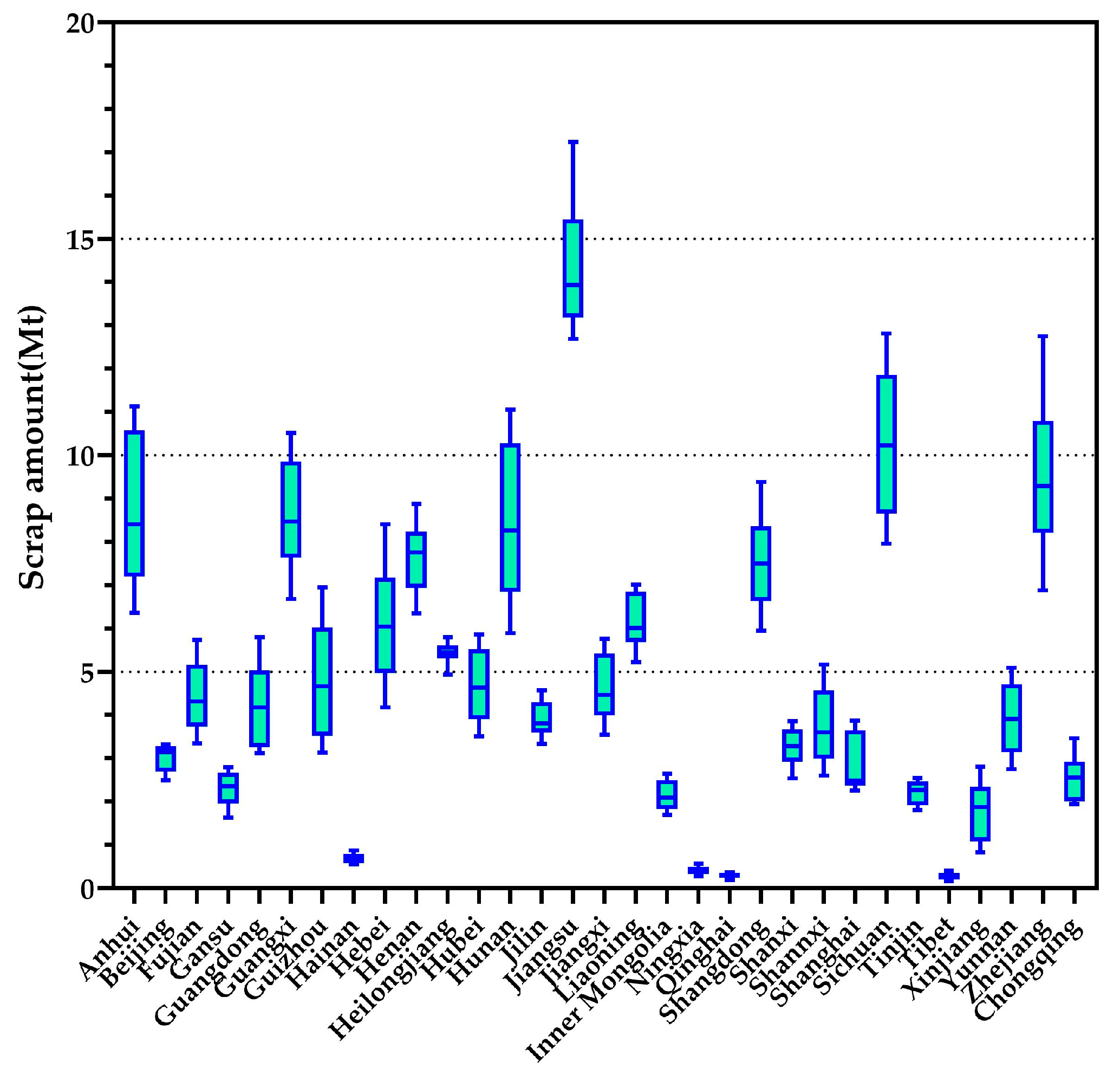

4.1.2. Changes in the Spatial and Temporal Patterns of Typical Metal Scrap

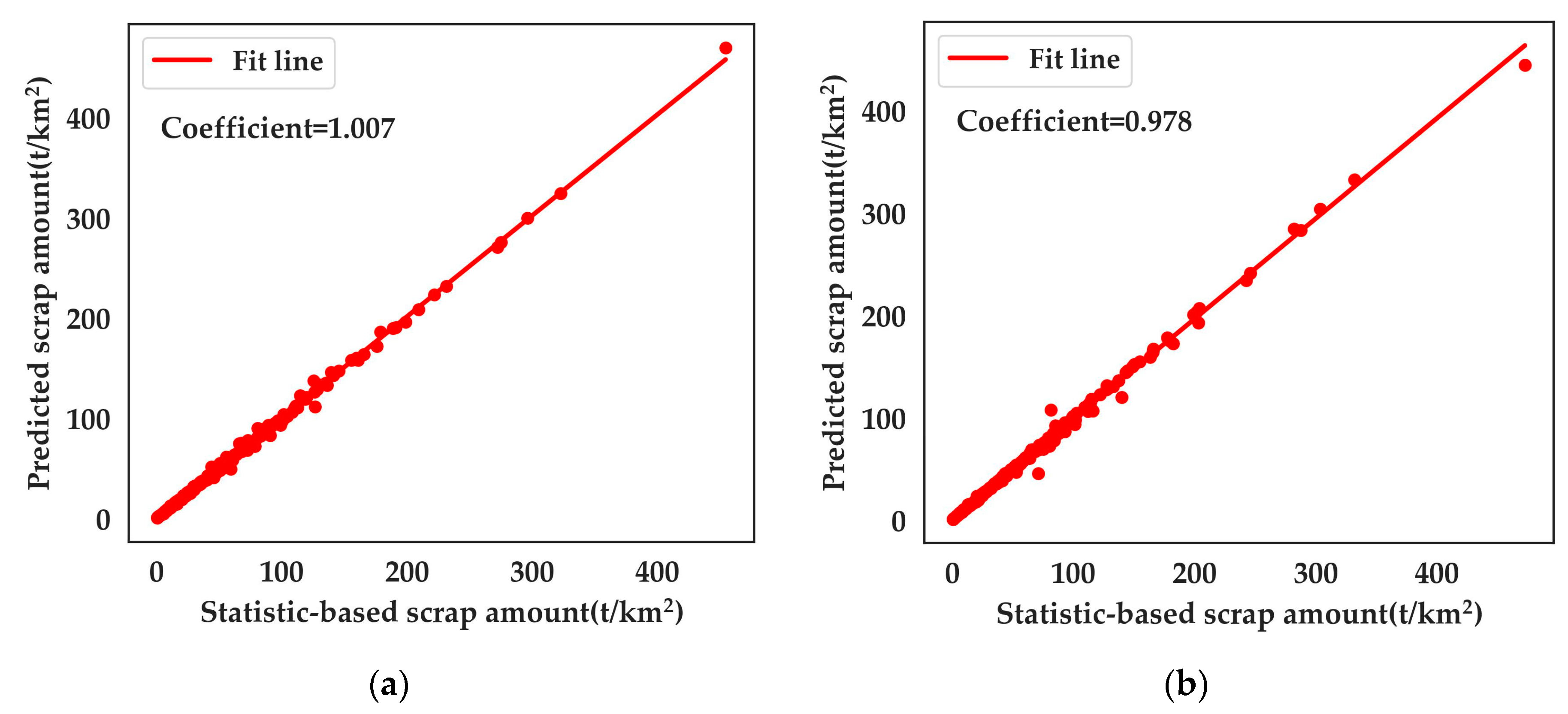

4.1.3. Downscaling Metal Scrap

4.2. Spatial Layout Assessment of the UMPB Based on Accessibility

4.2.1. Accessibility Measure Based on the 2SFCA Method

4.2.2. Spatial Layout Assessment from the Perspective of Supply–Demand Balance

5. Conclusions

- (1)

- Introduce scrap metal recycling and treatment technologies from advanced countries and increase funding for national technology research. The level of technology and equipment is an important bottleneck that limits the recycling of urban mineral resources. Strict pollution control and environmental management standards need to be set in all aspects of the treatment of scrap metals to achieve the synergistic development of high recycling efficiency and low pollution.

- (2)

- Explore the spatial and temporal distribution pattern of urban minerals and realize the intelligent supervision of the industry. Apply emerging information technologies such as big data and cloud computing to the field of urban minerals to monitor the changes in urban mineral resources. Encourage the introduction of local industry policies and promote successful urban mineral informatization cases nationwide.

- (3)

- Increase the number of UMPB constructions and improve the processing capacity of UMPB to meet the increasing demand for scrap metal recycling. The existing UMPBs are mainly distributed in the eastern region, and the number of UMPBs in the western region is too small to meet the demand for scrap metal recycling in the surrounding areas. It is suggested to build several new UMPBs in some cities in the west with better economic and resource bases so as to promote the development of a circular economy in the west while making the level of scrap metal recycling in China more equitable in the region.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz, E.; Navia, R. Circular economy in urban systems: How to measure the impact? Waste Manag. Res. 2021, 39, 197–198. [Google Scholar] [CrossRef] [PubMed]

- Greedy, D. The challenge of the circular economy and the fourth industrial revolution. Waste Manag. Res. 2021, 39, 1329–1330. [Google Scholar] [CrossRef] [PubMed]

- Rauch, J.N. Global mapping of Al, Cu, Fe, and Zn in-use stocks and in-ground resources. Proc. Natl. Acad. Sci. USA 2009, 106, 18920–18925. [Google Scholar] [CrossRef]

- Chen, W.-Q.; Graedel, T.E. In-use product stocks link manufactured capital to natural capital. Proc. Natl. Acad. Sci. USA 2015, 112, 6265–6270. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, J. The Economy of Cities; Random House: New York, NY, USA, 1969. [Google Scholar]

- Chen, C.; Liu, Y. Construction and demolition wastes in Beijing: Where they come from and where they go? Waste Manag. Res. 2021, 39, 555–560. [Google Scholar] [CrossRef]

- Mao, R.; Bao, Y.; Huang, Z.; Liu, Q.; Liu, G. High-Resolution Mapping of the Urban Built Environment Stocks in Beijing. Environ. Sci. Technol. 2020, 54, 5345–5355. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Steinberger, J.K.; Eisenmenger, N.; Haas, W. Maintenance and Expansion: Modeling Material Stocks and Flows for Residential Buildings and Transportation Networks in the EU25. J. Ind. Ecol. 2015, 19, 538–551. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Schnoor, J.L.; Zeng, E.Y. E-waste recycling: Where does it go from here? Environ. Sci. Technol. 2012, 46, 10861–10867. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A global perspective on e-waste recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

- Van Eygen, E.; De Meester, S.; Tran, H.P.; Dewulf, J. Resource savings by urban mining: The case of desktop and laptop computers in Belgium. Resour. Conserv. Recycl. 2016, 107, 53–64. [Google Scholar] [CrossRef]

- Guo, X.; Yan, K. Estimation of obsolete cellular phones generation: A case study of China. Sci. Total Environ. 2017, 575, 321–329. [Google Scholar] [CrossRef] [PubMed]

- Parajuly, K.; Habib, K.; Liu, G. Waste electrical and electronic equipment (WEEE) in Denmark: Flows, quantities and management. Resour. Conserv. Recycl. 2017, 123, 85–92. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, J.; Cai, Z.; Yuan, Z. Understanding the Spatial and Temporal Patterns of Copper In-Use Stocks in China. Environ. Sci. Technol. 2015, 49, 6430–6437. [Google Scholar] [CrossRef]

- Müller, E.; Hilty, L.M.; Widmer, R.; Schluep, M.; Faulstich, M. Modeling Metal Stocks and Flows: A Review of Dynamic Material Flow Analysis Methods. Environ. Sci. Technol. 2014, 48, 2102–2113. [Google Scholar] [CrossRef]

- Chen, W.-Q.; Graedel, T. Improved Alternatives for Estimating In-Use Material Stocks. Environ. Sci. Technol. 2015, 49, 3048–3055. [Google Scholar] [CrossRef]

- Wang, T.; Müller, D.B.; Graedel, T.E. Forging the Anthropogenic Iron Cycle. Environ. Sci. Technol. 2007, 41, 5120–5129. [Google Scholar] [CrossRef]

- Pauliuk, S.; Wang, T.; Müller, D.B. Steel all over the world: Estimating in-use stocks of iron for 200 countries. Resour. Conserv. Recycl. 2013, 71, 22–30. [Google Scholar] [CrossRef]

- Augiseau, V.; Barles, S. Studying construction materials flows and stock: A review. Resour. Conserv. Recycl. 2017, 123, 153–164. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Bi, J. Estimation of copper in-use stocks in Nanjing, China. J. Ind. Ecol. 2012, 16, 191–202. [Google Scholar] [CrossRef]

- Zhang, L.; Cai, Z.; Yang, J.; Chen, Y.; Yuan, Z. Quantification and spatial characterization of in-use copper stocks in Shanghai. Resour. Conserv. Recycl. 2014, 93, 134–143. [Google Scholar] [CrossRef]

- Liang, H.; Tanikawa, H.; Matsuno, Y.; Dong, L. Modeling in-use steel stock in China’s buildings and civil engineering infrastructure using time-series of DMSP/OLS nighttime lights. Remote Sens. 2014, 6, 4780–4800. [Google Scholar] [CrossRef]

- Song, L.; Zhang, C.; Han, J.; Chen, W.-Q. In-use product and steel stocks sustaining the urbanization of Xiamen, China. Ecosyst. Health Sustain. 2019, 5, 110–123. [Google Scholar] [CrossRef]

- Hansen, W.G. How Accessibility Shapes Land Use. J. Am. Inst. Plan. 1959, 25, 73–76. [Google Scholar] [CrossRef]

- Talen, E.; Anselin, L. Assessing Spatial Equity: An Evaluation of Measures of Accessibility to Public Playgrounds. Environ. Plan. A Econ. Space 1998, 30, 595–613. [Google Scholar] [CrossRef]

- Dai, D. Racial/ethnic and socioeconomic disparities in urban green space accessibility: Where to intervene? Landsc. Urban Plan. 2011, 102, 234–244. [Google Scholar] [CrossRef]

- Shao, Y.; Luo, W. Supply-demand adjusted two-steps floating catchment area (SDA-2SFCA) model for measuring spatial access to health care. Soc. Sci. Med. 2022, 296, 114727. [Google Scholar] [CrossRef]

- Liu, L.; Lyu, H.; Zhao, Y.; Zhou, D. An Improved Two-Step Floating Catchment Area (2SFCA) Method for Measuring Spatial Accessibility to Elderly Care Facilities in Xi’an, China. Int. J. Environ. Res. Public Health 2022, 19, 11465. [Google Scholar] [CrossRef]

- Yang, Y.; He, R.; Tian, G.; Shi, Z.; Wang, X.; Fekete, A. Equity Study on Urban Park Accessibility Based on Improved 2SFCA Method in Zhengzhou, China. Land 2022, 11, 2045. [Google Scholar] [CrossRef]

- Wang, T.; Müller, D.B.; Hashimoto, S. The ferrous find: Counting iron and steel stocks in China’s economy. J. Ind. Ecol. 2015, 19, 877–889. [Google Scholar] [CrossRef]

- Recalde, K.; Wang, J.; Graedel, T. Aluminium in-use stocks in the state of Connecticut. Resour. Conserv. Recycl. 2008, 52, 1271–1282. [Google Scholar] [CrossRef]

- Song, L.; Han, J.; Li, N.; Huang, Y.; Hao, M.; Dai, M.; Chen, W.-Q. China material stocks and flows account for 1978–2018. Sci. Data 2021, 8, 303. [Google Scholar] [CrossRef] [PubMed]

- Ji, X. Potential Analysis and Layout Optimization for Urban Mining in China. Master’s Thesis, Tsinghua University, Beijing, China, June 2013. [Google Scholar]

- Liu, Q.; Cao, Z.; Liu, X.; Liu, L.; Dai, T.; Han, J.; Duan, H.; Wang, C.; Wang, H.; Liu, J.; et al. Product and metal stocks accumulation of China’s megacities: Patterns, drivers, and implications. Environ. Sci. Technol. 2019, 53, 4128–4139. [Google Scholar] [CrossRef] [PubMed]

| Region | Method | Year | Material | Earlier Studies | This Study | Difference |

|---|---|---|---|---|---|---|

| China | Bottom-up | 2010 | Steel | 3.2 Gt [31] | 2.4 Gt | −33% |

| Wuhan | Bottom-up | 2011 | Steel | 24.5 Mt [35] | 25.6 Mt | −4% |

| Xiamen | Bottom-up | 2015 | Steel | 10 ± 3 Mt [24] | 12.4 Mt | −5%~77% |

| Beijing | Bottom-up | 2016 | Steel+Copper+Aluminum | 60.5 Mt [35] | 82.5 Mt | 27% |

| Guangdong | Bottom-up | 2018 | Copper | 7.5 Mt [33] | 5.6 Mt | −25% |

| Henan | Bottom-up | 2010 | Aluminum | 7.2 Mt [33] | 7.7 Mt | 7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Xu, M.; Yang, X.; Shi, Y.; Deng, M. Spatial Layout Assessment of Urban Mining Pilot Bases in China Based on Multi-Source Data Collaboration. Sustainability 2023, 15, 7977. https://doi.org/10.3390/su15107977

Liu H, Xu M, Yang X, Shi Y, Deng M. Spatial Layout Assessment of Urban Mining Pilot Bases in China Based on Multi-Source Data Collaboration. Sustainability. 2023; 15(10):7977. https://doi.org/10.3390/su15107977

Chicago/Turabian StyleLiu, Huimin, Mengqian Xu, Xuexi Yang, Yan Shi, and Min Deng. 2023. "Spatial Layout Assessment of Urban Mining Pilot Bases in China Based on Multi-Source Data Collaboration" Sustainability 15, no. 10: 7977. https://doi.org/10.3390/su15107977

APA StyleLiu, H., Xu, M., Yang, X., Shi, Y., & Deng, M. (2023). Spatial Layout Assessment of Urban Mining Pilot Bases in China Based on Multi-Source Data Collaboration. Sustainability, 15(10), 7977. https://doi.org/10.3390/su15107977