Asymmetric Damage Mechanisms and Prevention Technology in Large-Section Gob-Side Entry Retaining

Abstract

1. Introduction

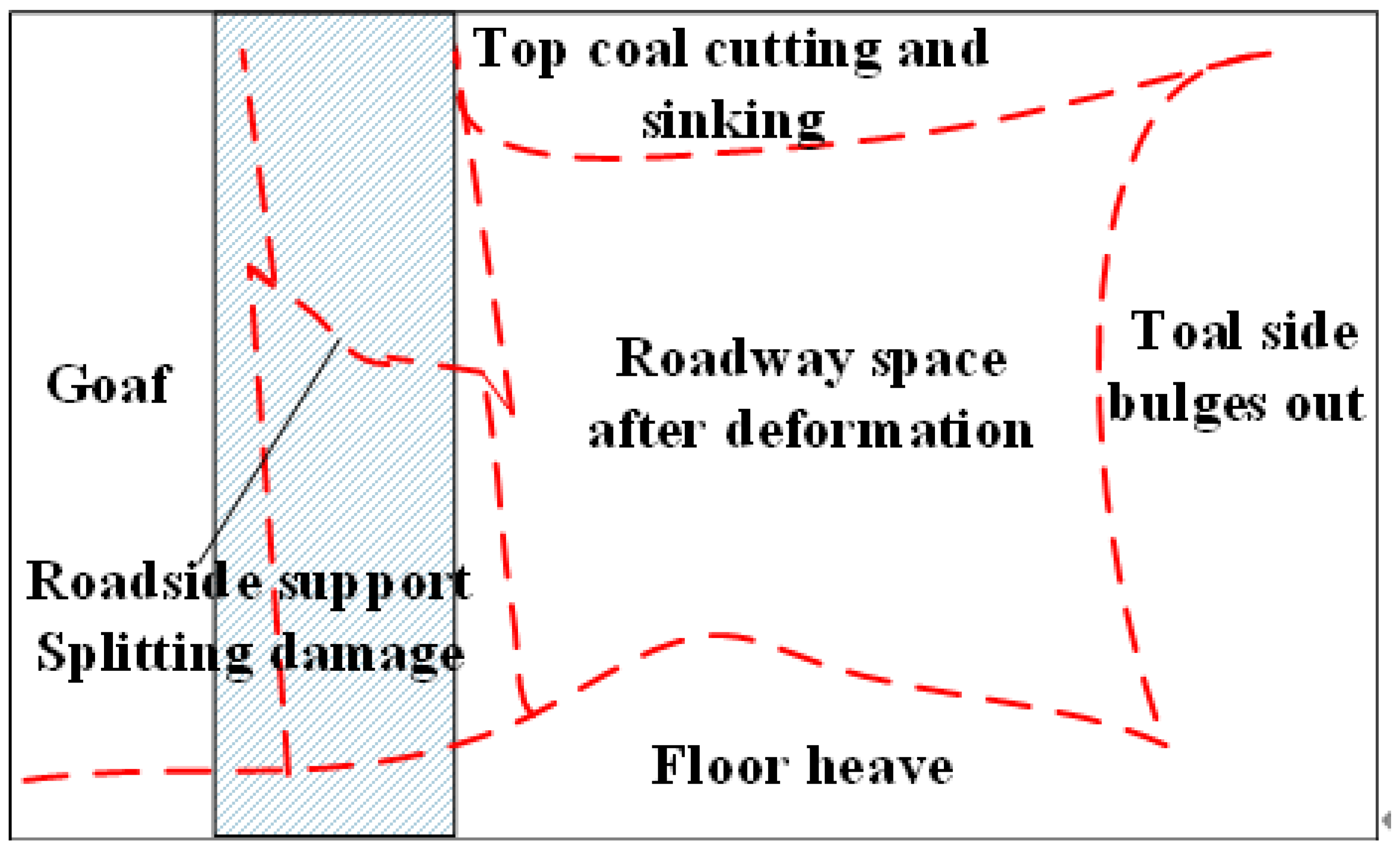

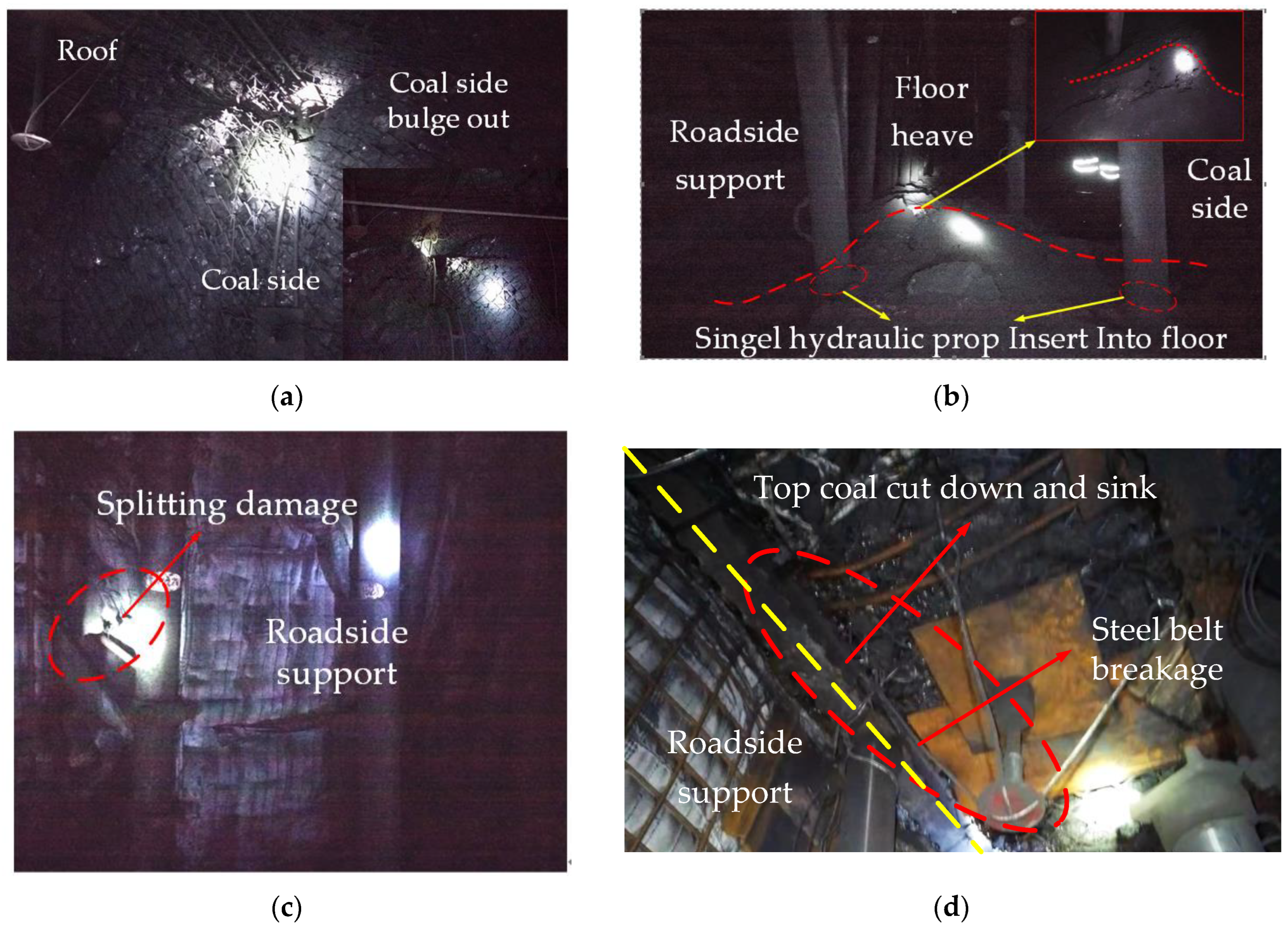

2. Asymmetric Deformation Damage Characteristics of Large-Section Gob-Side Entry Retaining

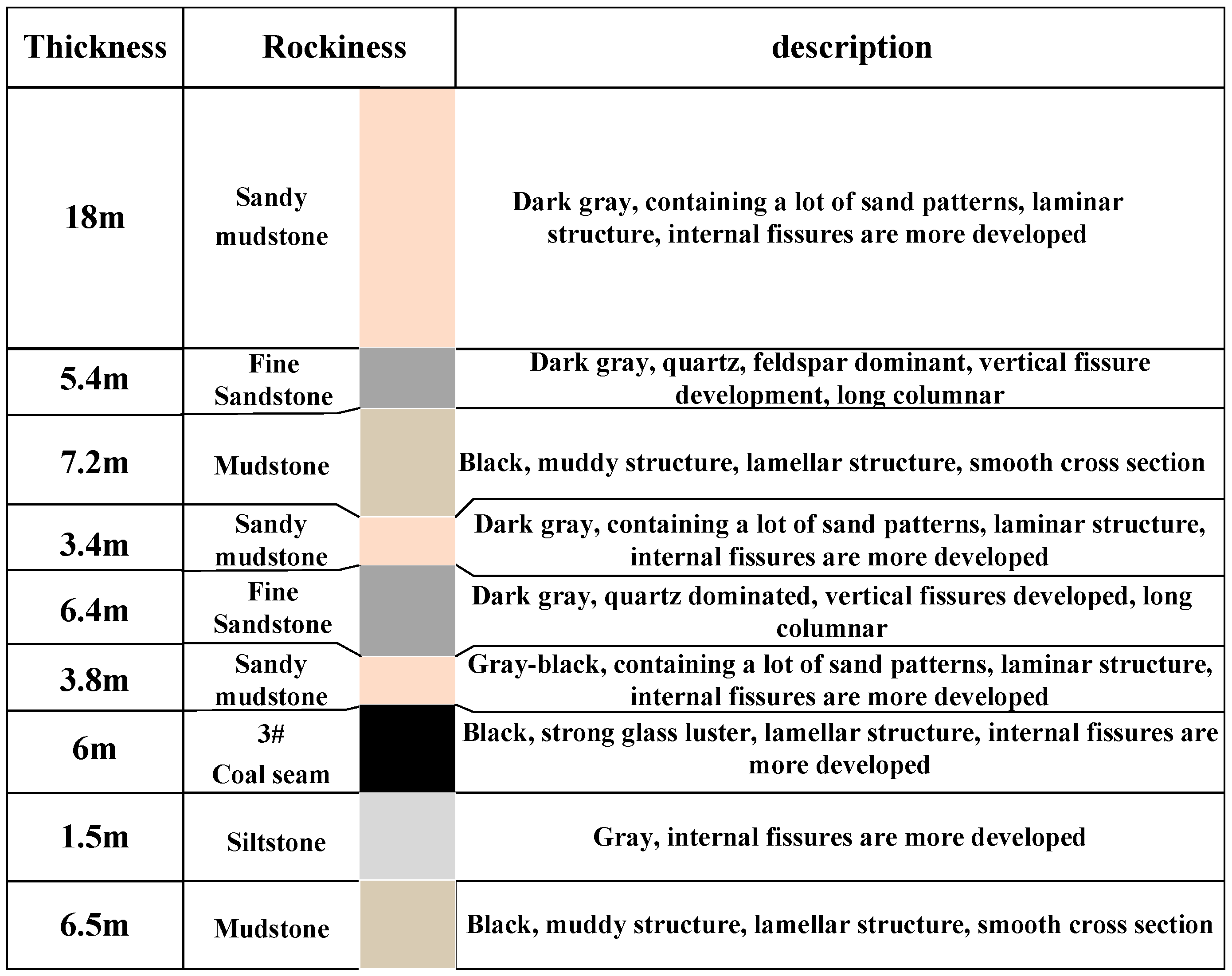

2.1. Overview of the Test Working Face

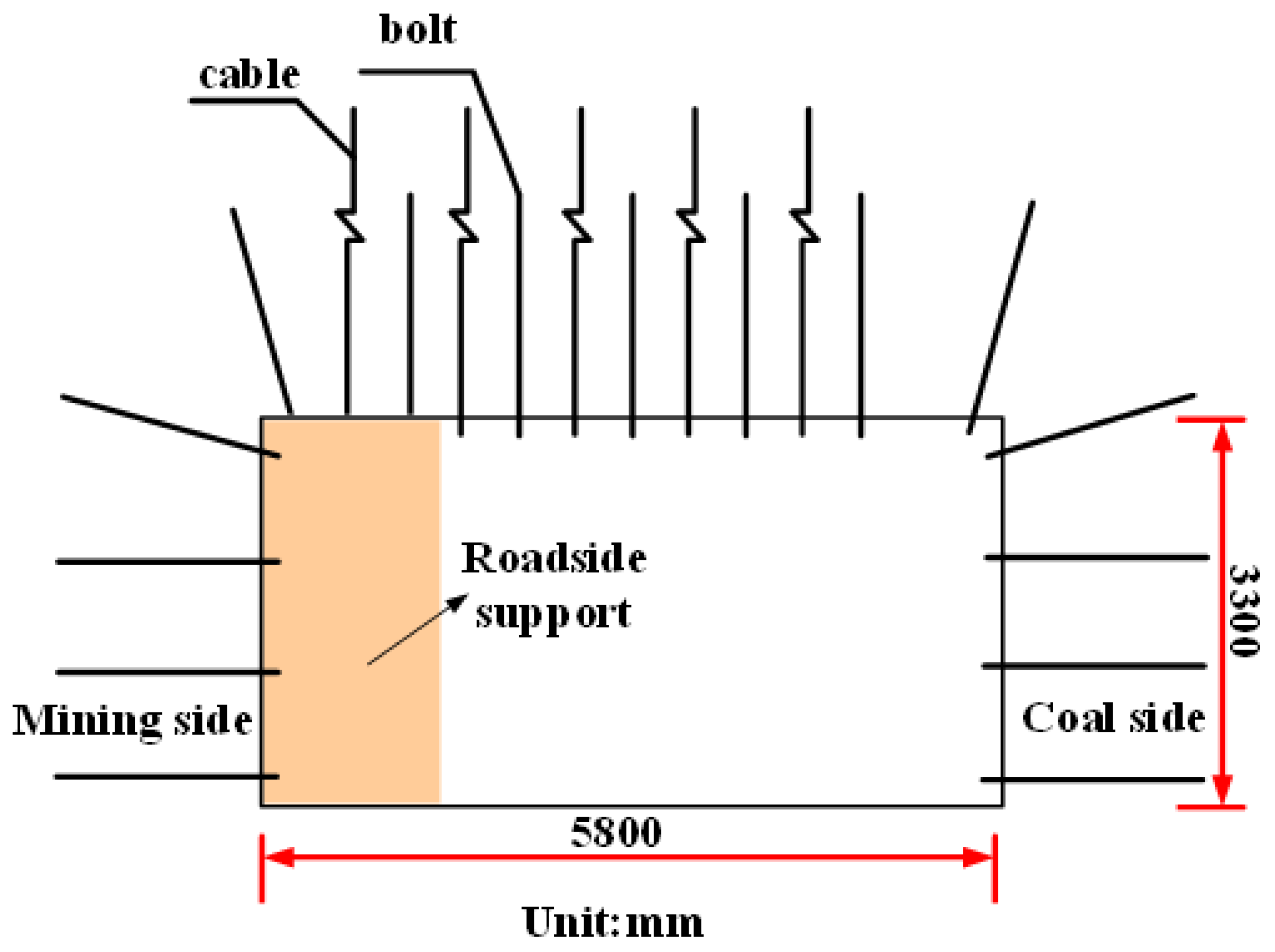

2.2. The Original Gob-Side Entry Retaining Support Situation

2.3. Deformation Characteristics of Gob-Side Entry Retaining

3. Leading Factors of Asymmetric Deformation Damage in Gob-Side Entry Retaining

3.1. Water Disintegration of Roof Mudstone and Deflection under Horizontal Stress

3.2. Splitting Damage of Concrete Roadside Support under Asymmetric Load

3.3. Insufficient Support Strength of the Coal Side Leads to Damage and Expansion

3.4. Strong Dynamic Pressure of the Roof and the Influence of Pressure Relief

4. New Mutual Synergistic Deformation Control Technology of Support and Pressure Relief

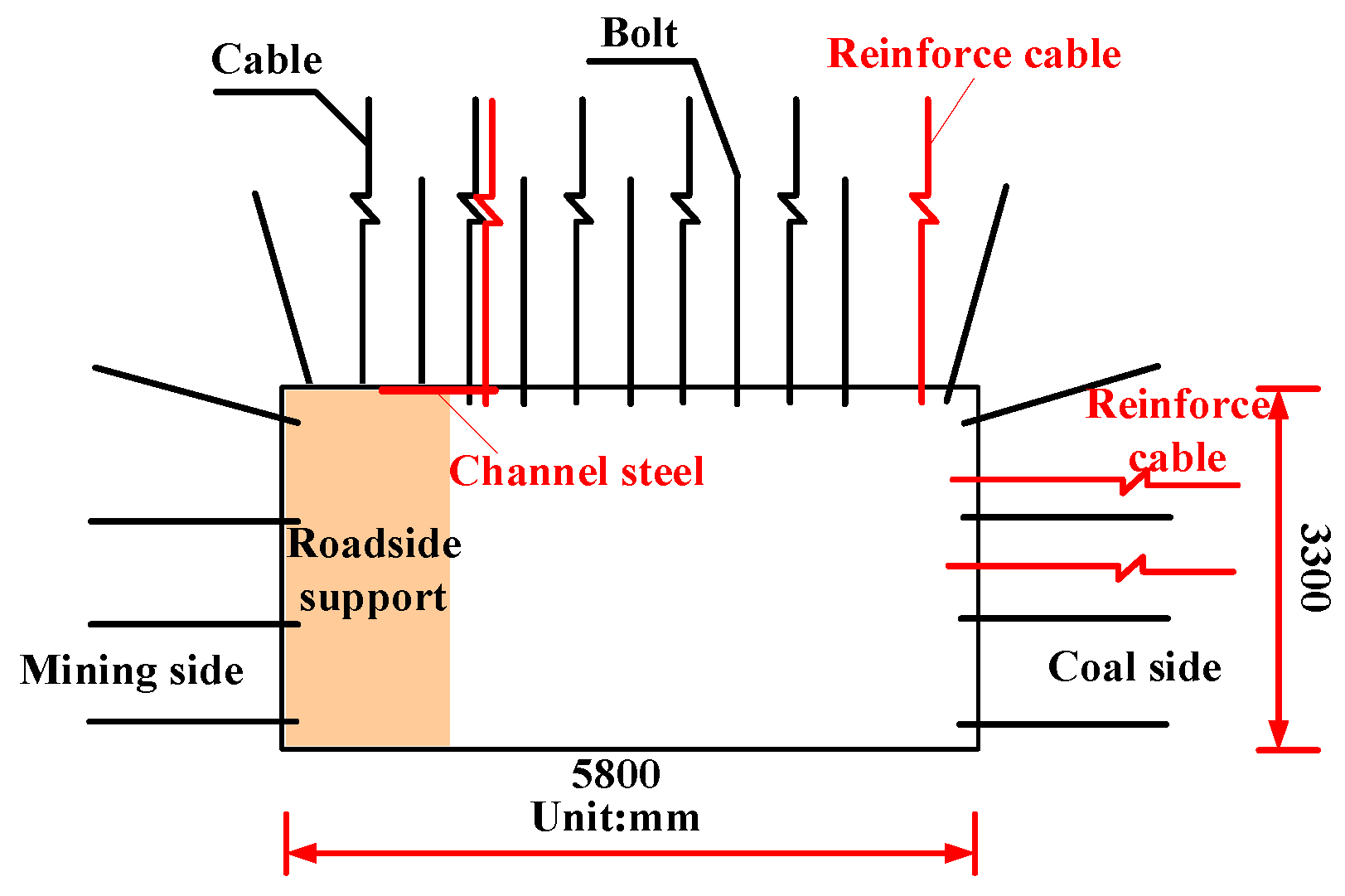

4.1. Roadside and Roadway-in Support

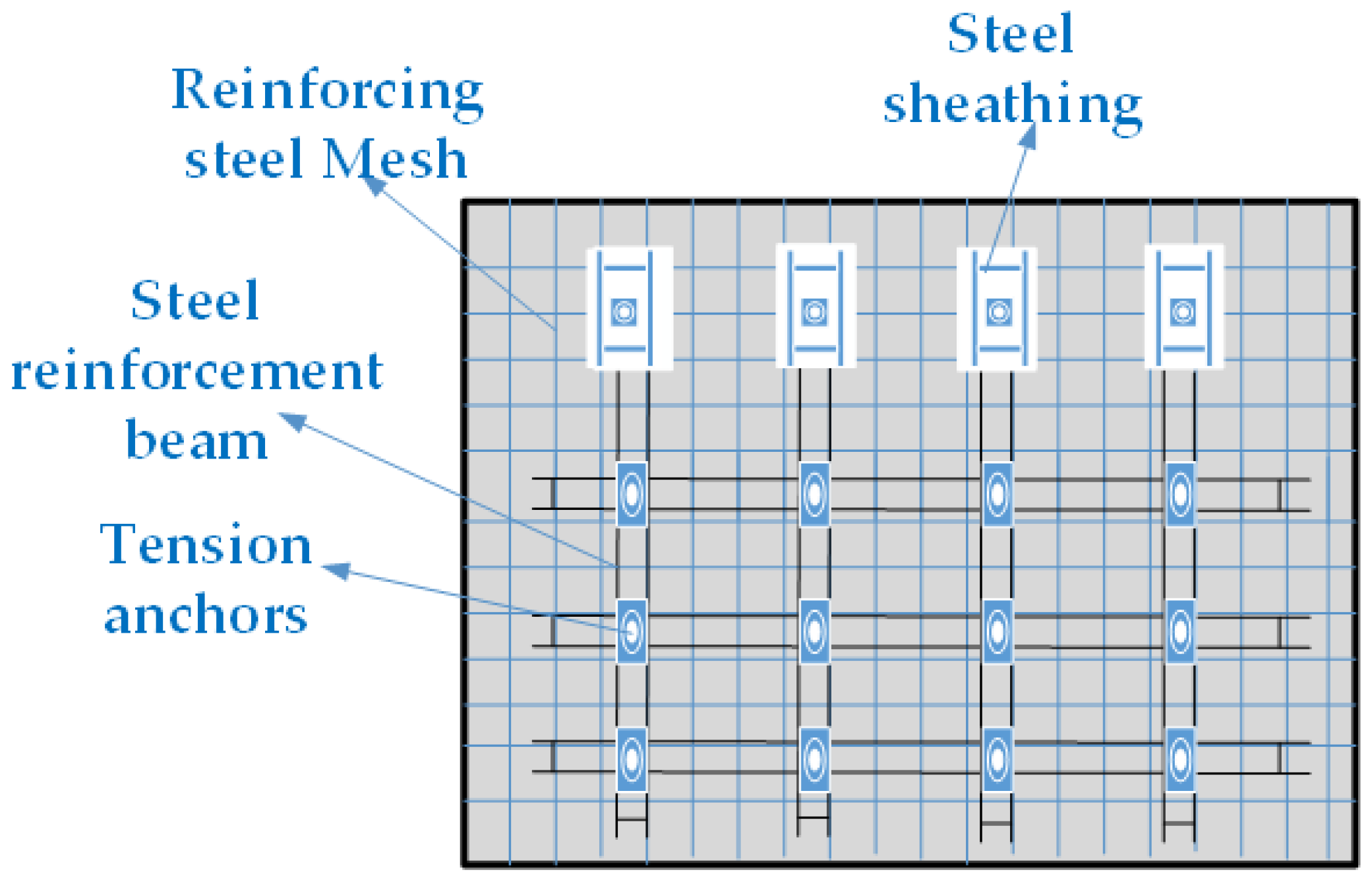

4.1.1. High-Strength, High-Stiffness, High-Ductility Roadside Support Structure

4.1.2. Roadway-in Reinforcement Support

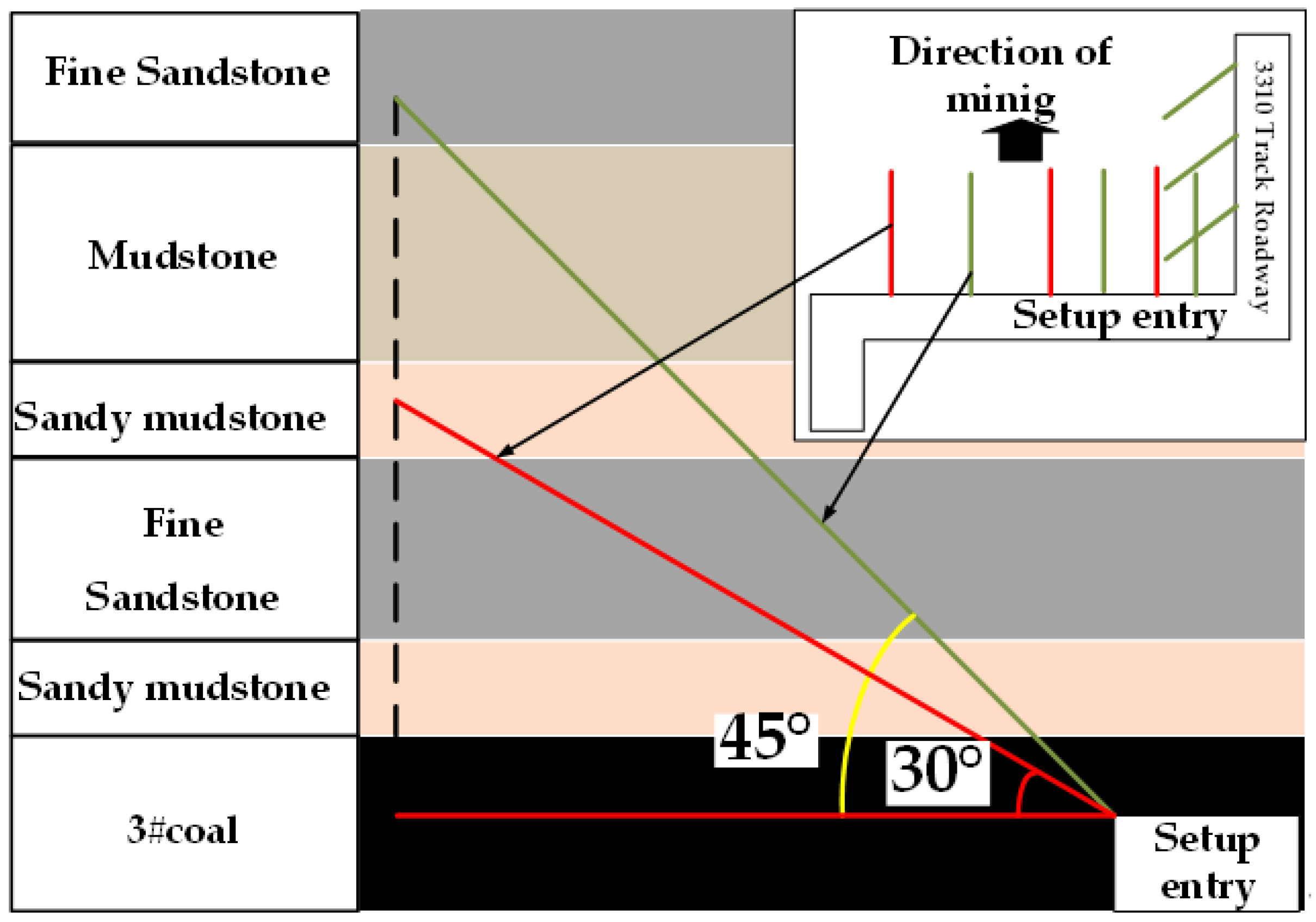

4.2. Setup Entry Hydraulic Fracturing Pressure Relief

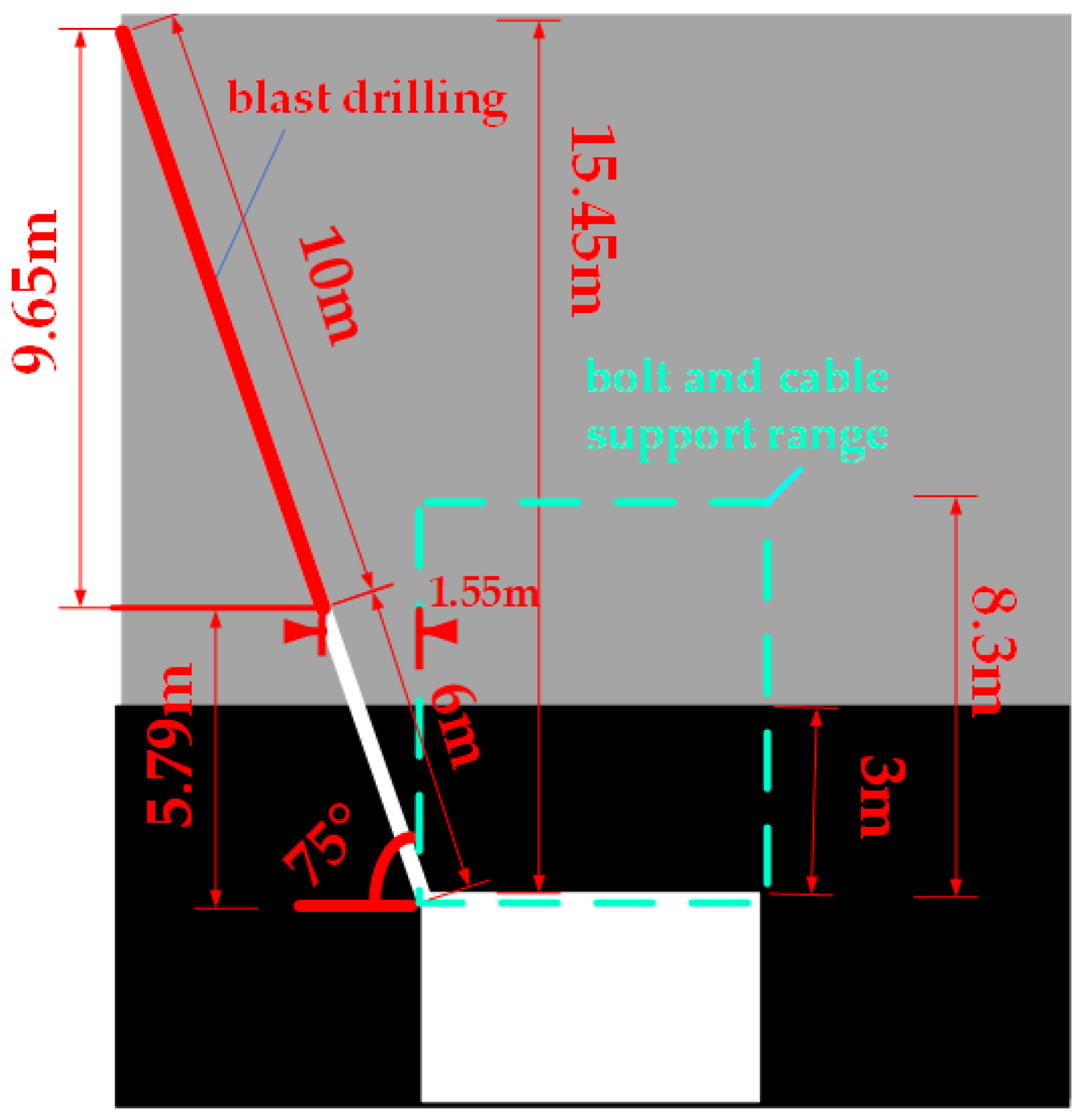

4.3. Advanced Horizontal Long Borehole “Fracturing-Jet” Pressure Relief Technology

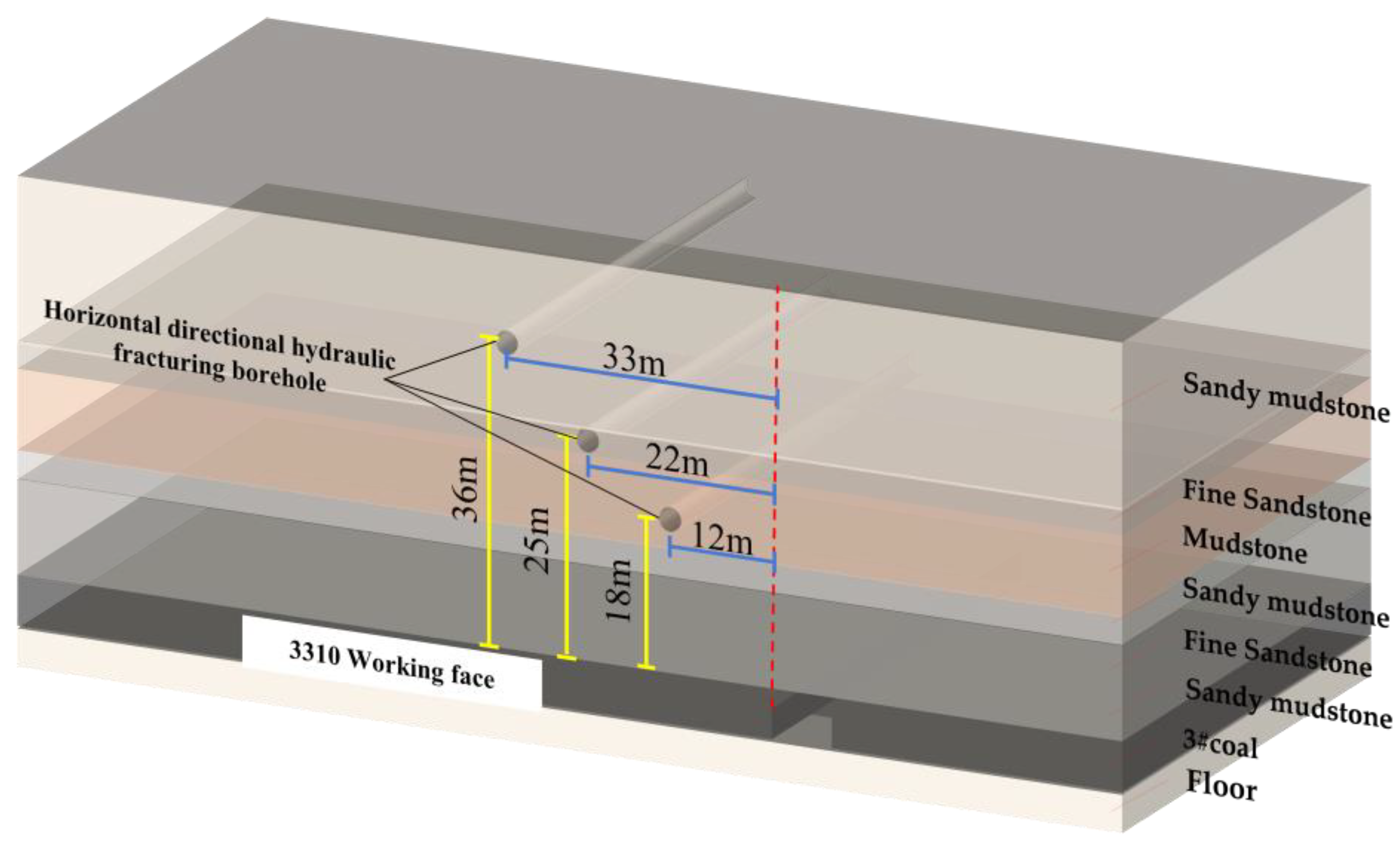

4.3.1. Horizontal Long Borehole Regional Hydraulic Fracturing Process

4.3.2. Fracturing Layer and Parameter Design

5. Dynamic Monitoring and Analysis of Gob-Side Entry Retaining Engineering Effects

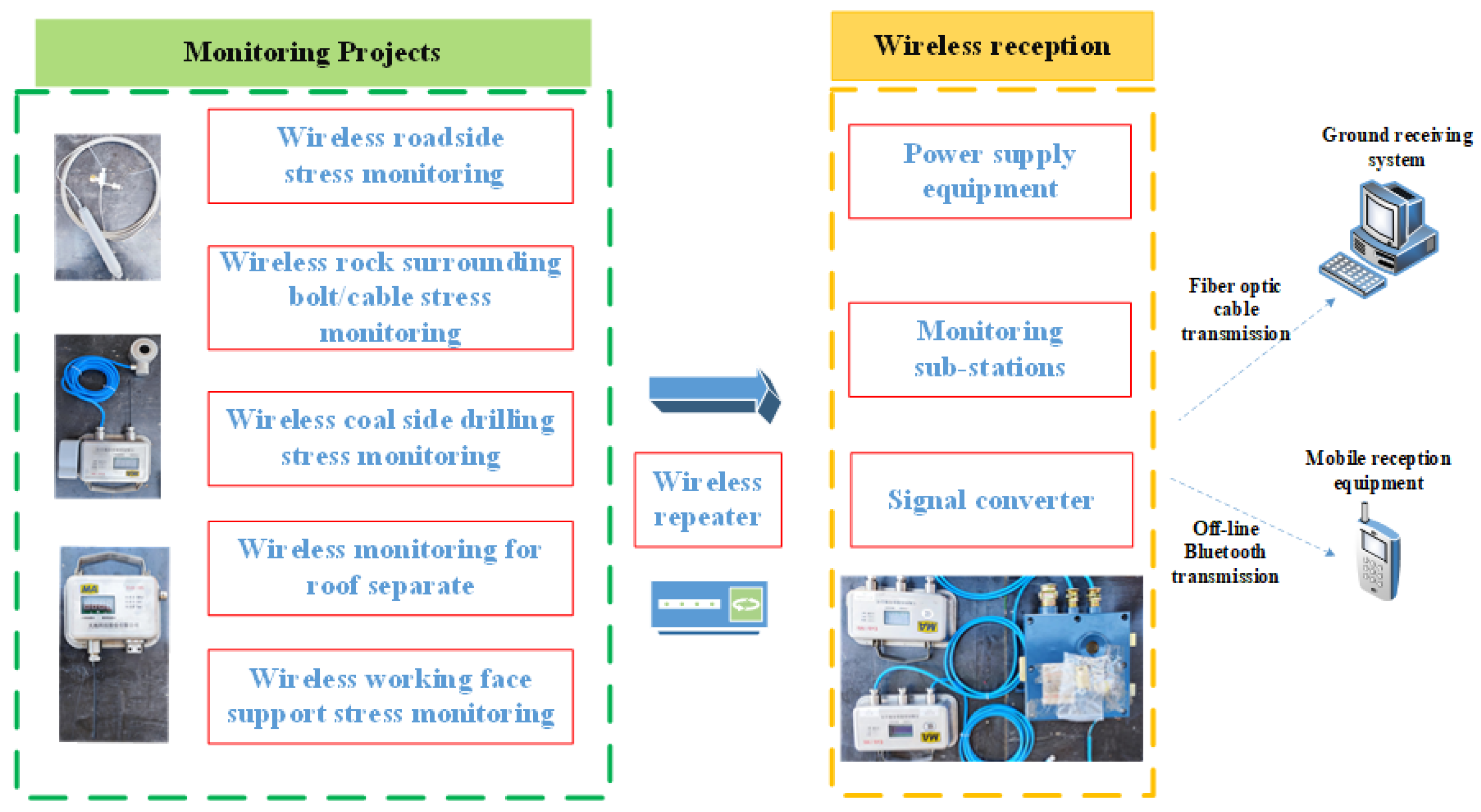

5.1. Mining Pressure Monitoring Program

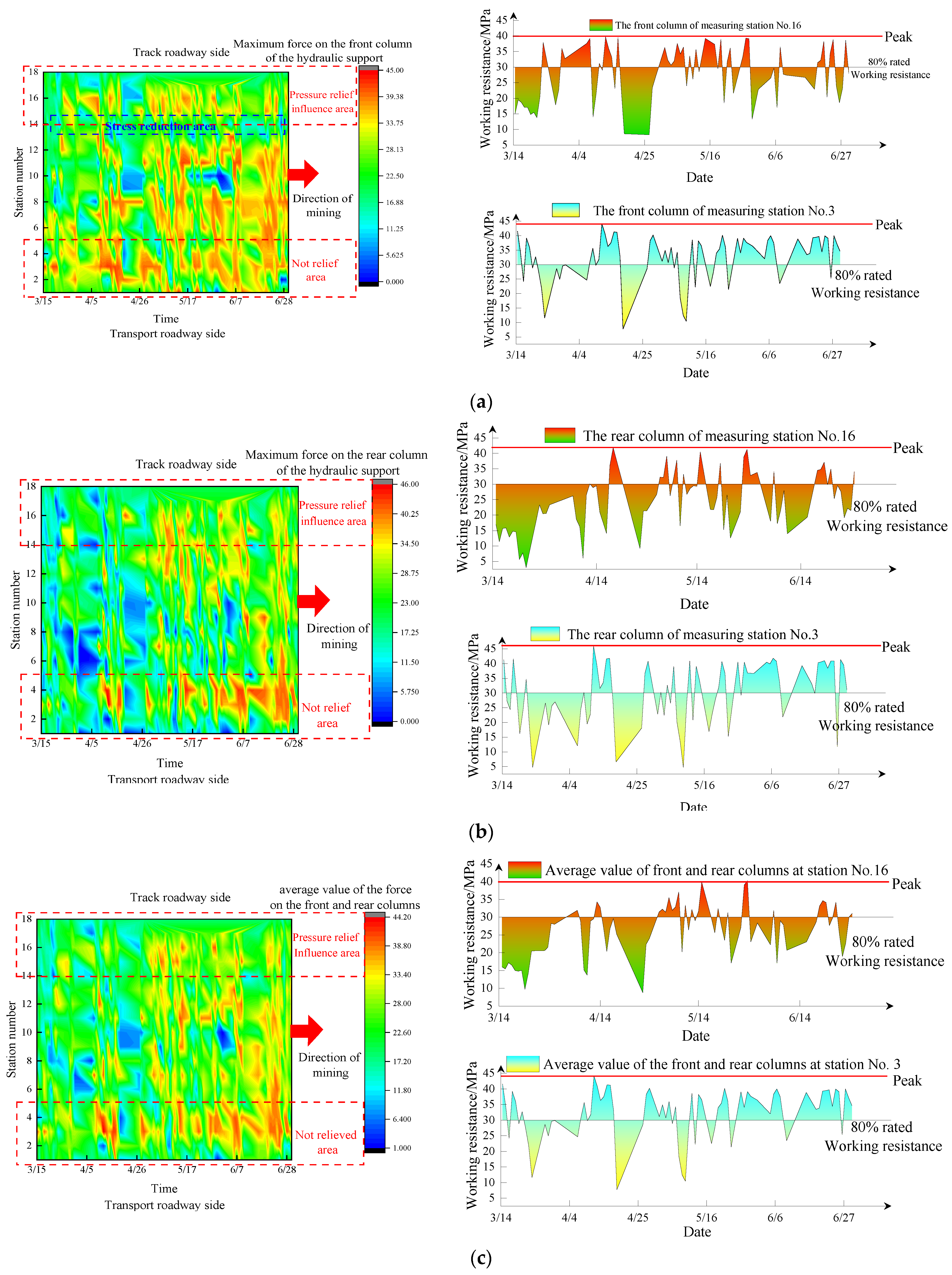

5.2. The Effect of Pressure Relief

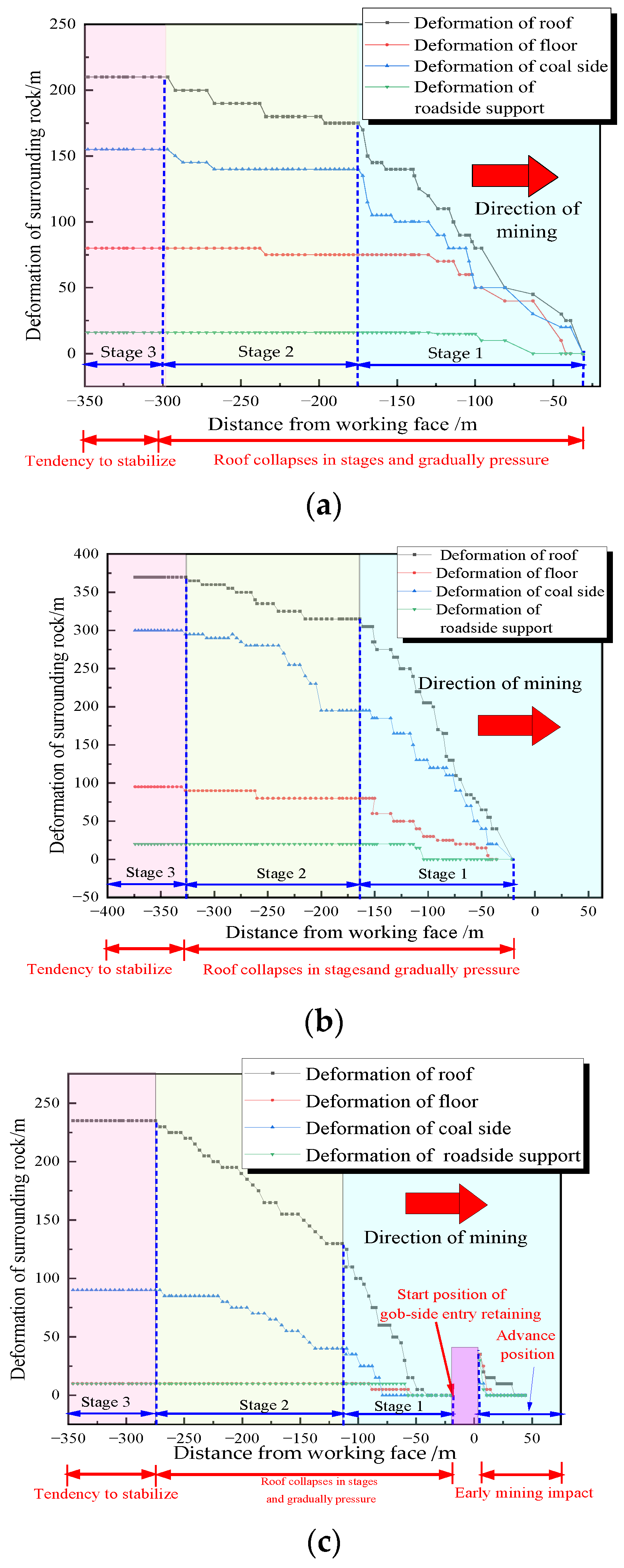

5.3. Deformation of the Surrounding Rock in Gob-Side Entry Retaining

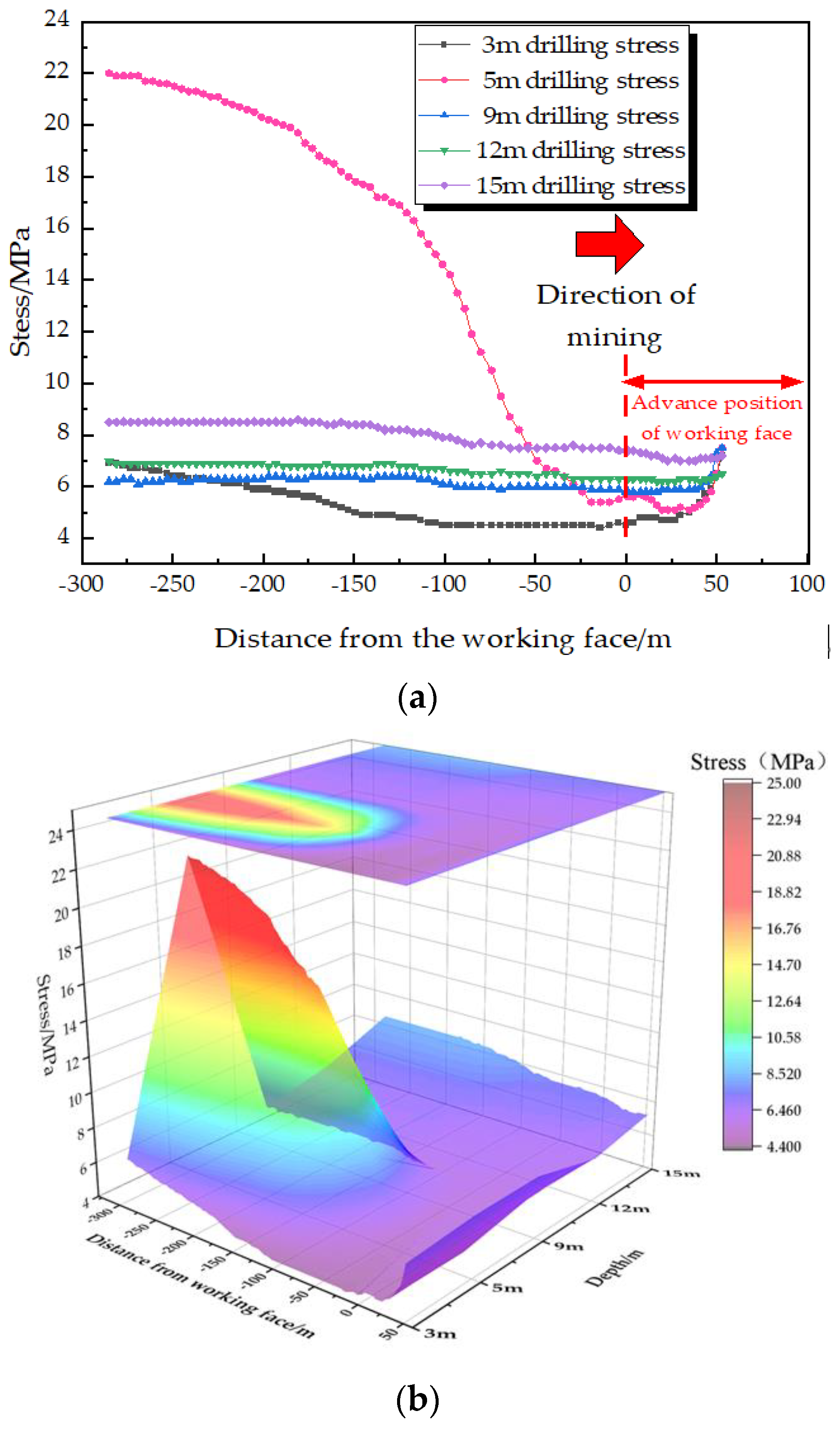

5.4. Stress Characteristics of Coal Side

5.5. Strength and Force of Roadside Support

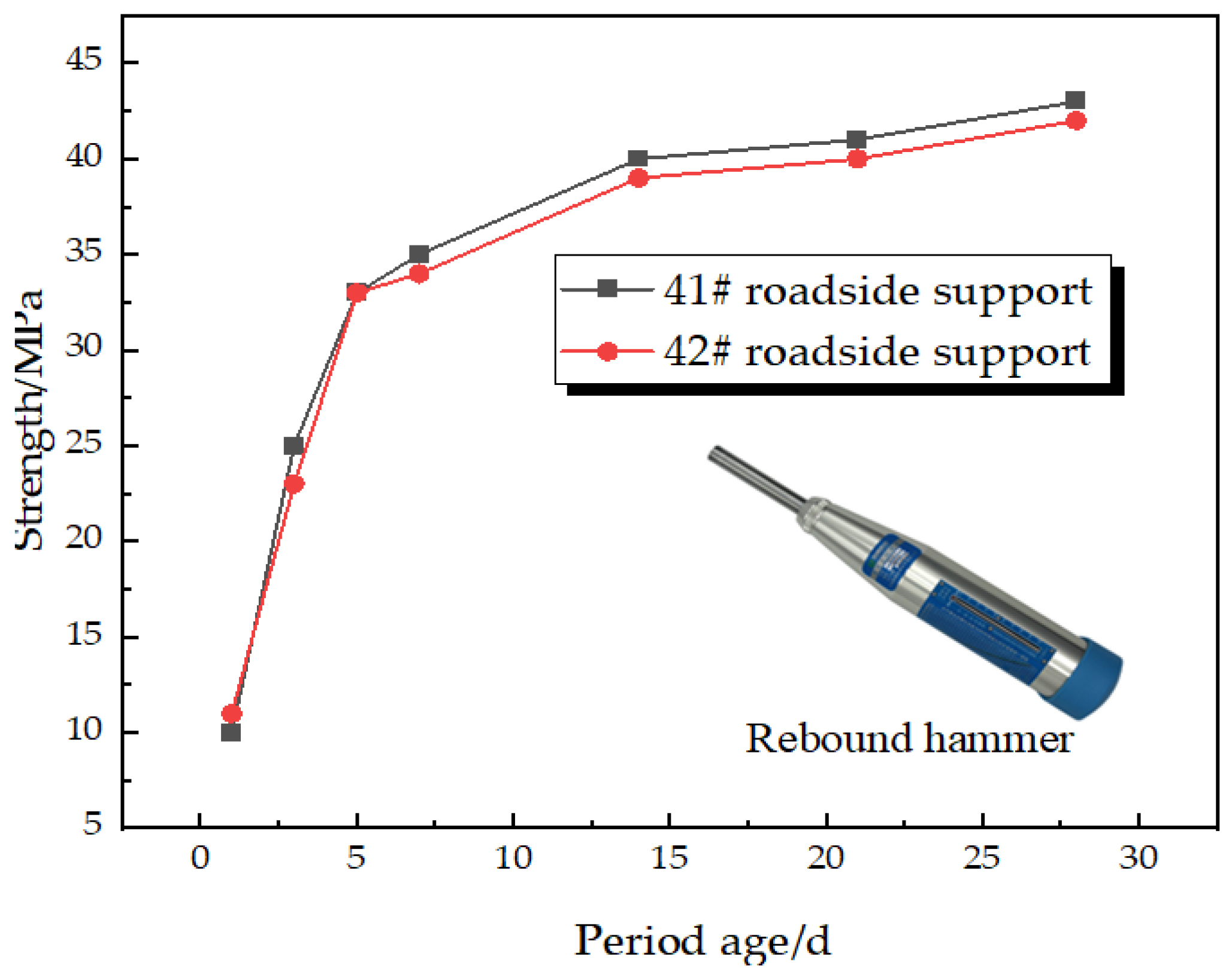

5.5.1. Roadside Support Strength Test

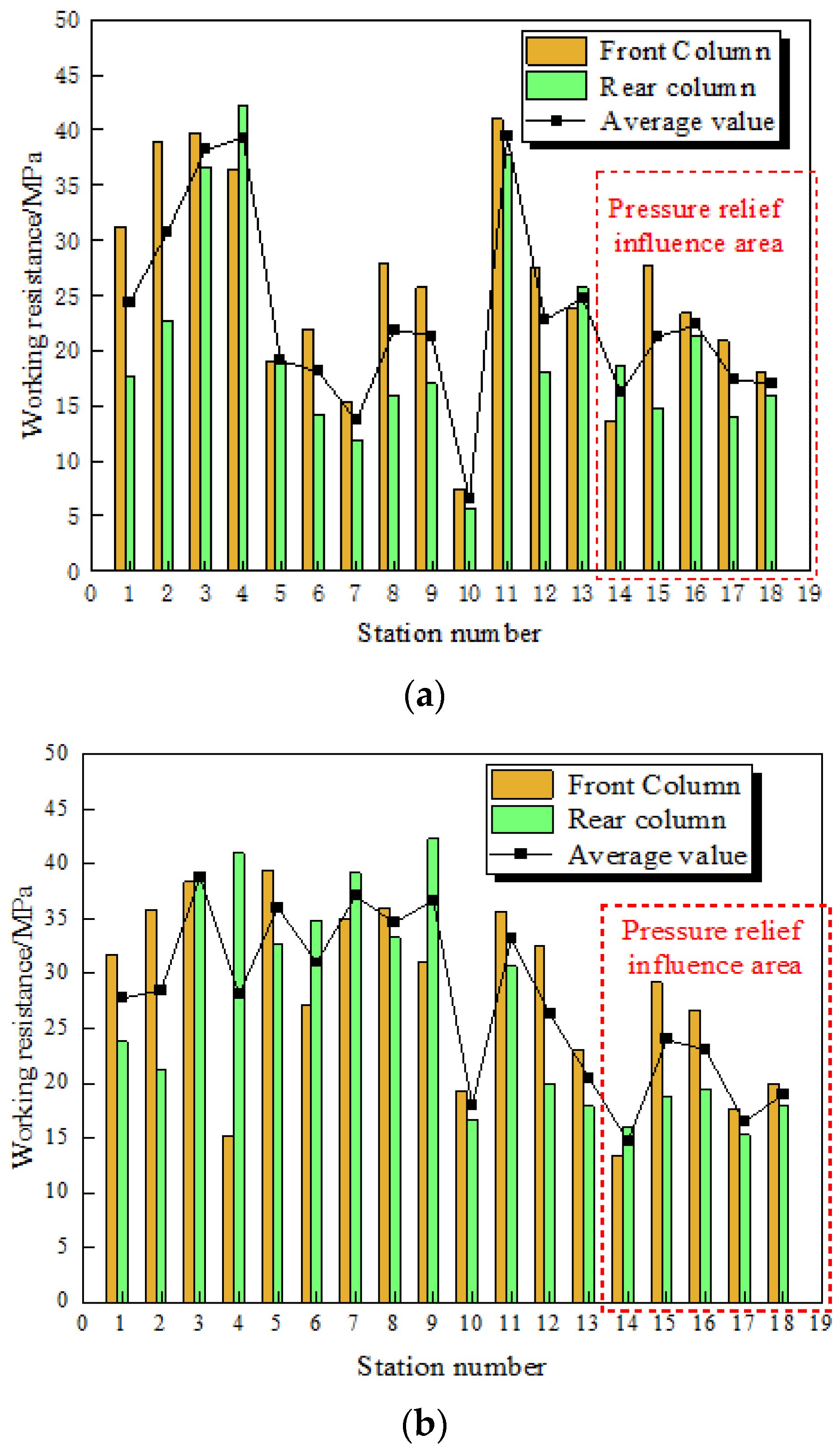

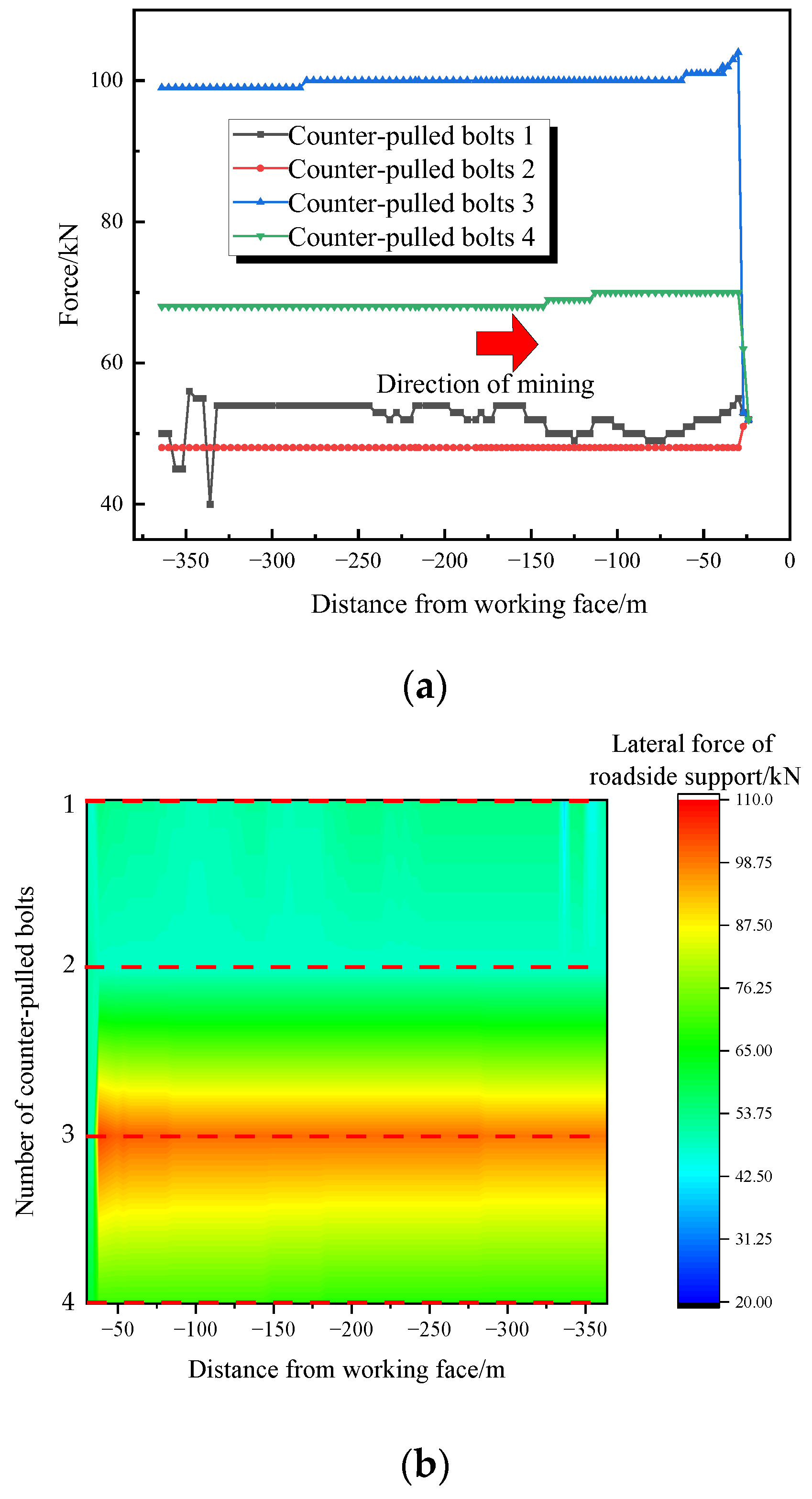

5.5.2. Force Analysis of Roadside Support

5.6. Cable Stress Characteristics

5.7. Overall Effect of Gob-Side Entry Retaining

6. Conclusions

- (1)

- The investigated gob-side entry retaining in a mining face experiencing top-coal caving had typical “asymmetric” overall deformation damage characteristics. In addition, the top coal was sinking along the inner side of the roadside support, the concrete roadside support structure was skewing and showing splitting damage, the floor was heaving, and the coal side bolt support structure was losing its support ability and was bulging out of the coal side as a whole.

- (2)

- The dominant factors of deformation damage are water disintegration of the floor mudstone, deflection deformation under horizontal stress, splitting damage in the concrete roadside support under asymmetric load, damage and expansion due to the insufficient strength of the coal side support, the strong dynamic pressure of the roof, and the mutual influence of support and pressure relief.

- (3)

- Based on the analysis of the dominant factors of the deformation of the surrounding rocks, a new high-strength, high-stiffness, and high-ductility roadside support structure was designed, and the latest advanced horizontal long borehole regional fracturing pressure relief technology using a large displacement water pump was applied to the lateral roof structure of the gob-side entry retaining to relieve pressure. Together with the steel-cable and belt reinforcement support of the roof inner the roadway, the top-cutting control reinforcement support in the gob-side entry retaining, setup entry hydraulic fracturing pressure relief, and innovative synergistic support and pressure relief scheme to control large deformations in gob-side entry retaining was finally formed. The effect of the industrial test results show that the new roadside support structure significantly optimizes the mechanical properties of the concrete roadside support, the regional pressure relief scheme effectively optimizes the stress environment of gob-side entry retaining space, the deformation control effect of surrounding rock is remarkable, and the gob-side entry retaining fully meets the reuse requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; He, M.; Yang, J.; Gao, H.; Jiang, H.; Yu, H. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for longwall mining in coal mines. Int. J. Rock Mech. Min. Sci. 2018, 110, 1–8. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.; Zhao, Z.; Xu, Q.; Wang, J.; Ding, K. Roadside support schemes numerical simulation and field monitoring of gob-side entry retaining in soft floor and hard roof. Arab. J. Geosci. 2018, 11, 563. [Google Scholar] [CrossRef]

- Zhang, Z.; Shimada, H.; Qian, D.; Sasaoka, T. Application of the retained gob-side gateroad in a deep underground coalmine. Int. J. Min. Reclam. Environ. 2016, 30, 371–389. [Google Scholar] [CrossRef]

- Ishwar, S.G.; Kumar, D. Application of DInSAR in mine surface subsidence monitoring and prediction. Curr. Sci. 2017, 112, 46–51. [Google Scholar] [CrossRef]

- Kan, J.; Zhang, N.; Wu, J.; Wu, H. Effect of main roofs fracture position on the secondary gob-side entry retaining stability. Disaster Adv. 2013, 6, 189–199. [Google Scholar]

- Zhang, Y.; Xu, H.; Song, P.; Sun, X.; He, M.; Guo, Z. Stress evolution law of surrounding rock with gob-side entry retaining by roof cutting and pressure release in composite roof. Adv. Mate. Sci. Eng. 2020, 2020, 1961680. [Google Scholar] [CrossRef]

- Li, H. Control design of roof rocks for gob-side entry. Chin. J. Rock Mech. Eng. 2000, 19, 651–654. [Google Scholar]

- Jaouhar, E.; Li, L.; Aubertin, M. An analytical solution for estimating the stresses in vertical backfilled stopes based on a circular arc distribution. Geomech. Eng. 2018, 15, 889–898. [Google Scholar]

- Venticinque, G.; Nemcik, J.; Ren, T. A new fracture model for the prediction of longwall caving characteristics. Int. J. Min. Sci. Technol. 2014, 24, 369–372. [Google Scholar] [CrossRef]

- Zhen, E.; Gao, Y.; Wang, Y.; Wang, S. Comparative study on two types of non-pillar mining techniques by roof cutting and by filling artificial materials. Adv. Civ. Eng. 2019, 2019, 5267240. [Google Scholar]

- Li, H.; Zu, H.; Zhang, K.; Qian, J. Study on filling support design and ground pressure monitoring scheme for gob-side entry retention by roof cutting and pressure relief in high-gas thin coal seam. Int. J. Environ. Res. Public Health 2022, 19, 3913. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Wang, E.; Chen, D.; Li, H.; Jiang, Z.; Yang, H. Stability analysis and control technology of gob-side entry retaining with double roadways by filling with high-water material in gently inclined coal seam. Int. J. Coal Sci. Technol. 2022, 9, 52. [Google Scholar] [CrossRef]

- Xie, S.; Wang, E.; Chen, D.; Sun, Y.; Cheng, Q.; Ji, C.; Yan, Z.; Xiao, H. Failure analysis and control mechanism of gob-side entry retention with a 1.7-m flexible-formwork concrete wall: A case study. Eng. Fail. Anal. 2020, 117, 104816. [Google Scholar] [CrossRef]

- Du, Z.; Chen, S.; Ma, J.; Guo, Z.; Yin, D. Gob-side entry retaining involving bag filling material for support wall construction. Sustainability 2020, 12, 6353. [Google Scholar] [CrossRef]

- Liu, X.; Hua, X.; Yang, P.; Huang, Z. A study of the mechanical structure of the direct roof during the whole process of non-pillar gob-side entry retaining by roof cutting. Energy Explor. Exploit. 2020, 38, 1706–1724. [Google Scholar] [CrossRef]

- He, M.; Ma, X.; Yu, B. Analysis of strata behavior process characteristics of gob-side entry retaining with roof cutting and pressure releasing based on composite roof structure. Shock Vib. 2019, 2019, 2380342. [Google Scholar] [CrossRef]

- Xie, W.; Da, J.; Feng, G. Mechanism of controlliing surrounding rock around gob-side entry retaining in top-caol caving mining face. J. Cent. South Univ. Sci. Tech. 2004, 35, 5. [Google Scholar]

- Yuan, L. Theory and practice of integrated pillarless coal production and methane extraction in multiseams of low permeability. Eng. Sci. 2009, 11, 72–80. [Google Scholar]

- Zhang, N.; Han, C.; Kan, J. Theory and practice of surrounding rock control for pillarless gob-side entry retaining. Chin. Coal Soc. 2014, 39, 1635–1641. [Google Scholar]

- Kang, H.; Niu, D.; Zhang, Z.; Lin, J.; Li, Z.; Fan, M. Deformation characteristics of surrounding rock and supporting technology of gob-side entry retaining in deep coal mine. Chin. J. Rock Mech. Eng. 2010, 29, 977–1987. [Google Scholar]

- Bai, J.; Zhang, Z.; Wang, X. Stress control and surrounding rock strengthening mechanismof gob-side entry retaining with high-water content material filling and its application. Coal Sci. Technol. 2022, 50, 16–28. [Google Scholar]

- He, M.; Gao, Y.; Yang, J. An energy-gathered roof cutting technique in no-pillar mining and its impact on stress variation in surrounding rocks. Chin. J. Rock Mech. Eng. 2017, 36, 1314–1325. [Google Scholar]

- He, M.; Wang, Y.; Yang, J. Zonal characteristics and its influence factors of working face pressure using roof cutting and pressure-relief mining method with no pillar and roadway formed automaticil. J. Chin. Univ. Min. Techn. 2018, 47, 1157–1165. [Google Scholar]

- Gao, Y.; Wang, Y.; Yang, J.; Zhang, X.; He, M. Meso- and macroeffects of roof split blasting on the stability of gateroad surroundings in an innovative nonpillar mining method. Tunn. Undergr. Space Technol. 2019, 90, 99–118. [Google Scholar] [CrossRef]

- Li, Y.; Hua, X. The stability of key block and calculating the width of roadside backfill in a secondary gob-side entry retaining. J. Min. Saf. Eng. 2012, 29, 783–789. [Google Scholar]

- Li, Y.; Hua, X. Mechanical anlysis on the stability of surrounding rock structure of gob-side entry retaining. J. Chin. Coal Soc. 2017, 42, 8. [Google Scholar]

- Wang, D.; Yang, H.; Yuan, W. “Support and pressure relief” ground control technology for double-used roadway with fully-mechanized caving method in thick coal seam. J. Min. Strat. Contr. Eng. 2022, 4, 043014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Wang, D.; Ju, W.; Yuan, W.; Su, C. Asymmetric Damage Mechanisms and Prevention Technology in Large-Section Gob-Side Entry Retaining. Sustainability 2023, 15, 739. https://doi.org/10.3390/su15010739

Yang H, Wang D, Ju W, Yuan W, Su C. Asymmetric Damage Mechanisms and Prevention Technology in Large-Section Gob-Side Entry Retaining. Sustainability. 2023; 15(1):739. https://doi.org/10.3390/su15010739

Chicago/Turabian StyleYang, Hongzhi, Dongpan Wang, Wenjun Ju, Weiming Yuan, and Chao Su. 2023. "Asymmetric Damage Mechanisms and Prevention Technology in Large-Section Gob-Side Entry Retaining" Sustainability 15, no. 1: 739. https://doi.org/10.3390/su15010739

APA StyleYang, H., Wang, D., Ju, W., Yuan, W., & Su, C. (2023). Asymmetric Damage Mechanisms and Prevention Technology in Large-Section Gob-Side Entry Retaining. Sustainability, 15(1), 739. https://doi.org/10.3390/su15010739