Energy Management Strategy for Seaport Integrated Energy System under Polymorphic Network

Abstract

1. Introduction

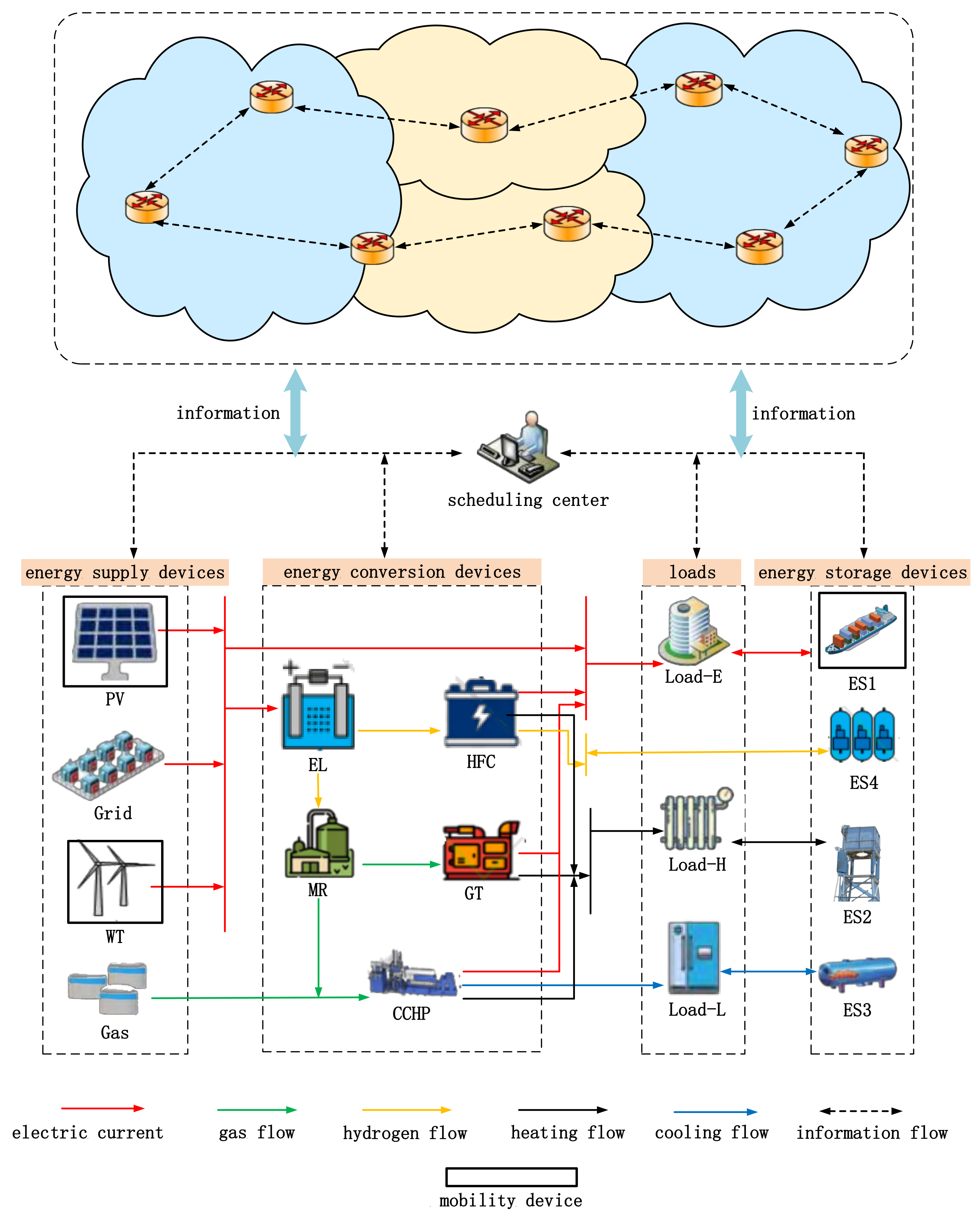

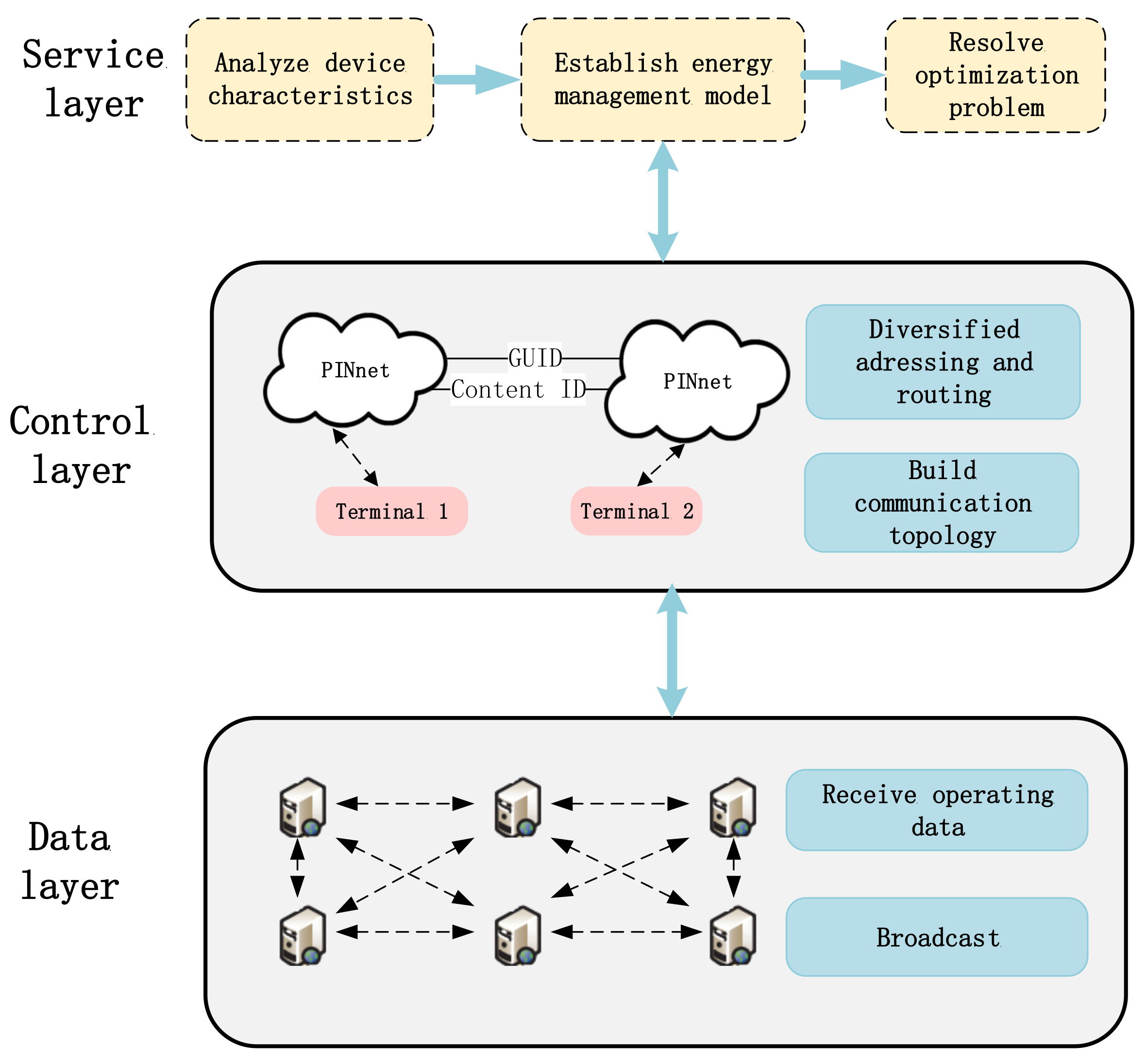

- A seaport integrated energy system under the polymorphic network is constructed. Considering heterogeneous energy devices, a polymorphic network is adopted to ensure the information interaction between different devices and provide technical support for energy management of the seaport integrated energy system. Specifically, the polymorphic network-based seaport integrated energy system includes a data layer for data forwarding, a control layer for addressing routing, and a service layer for energy management.

- An energy management model for the seaport integrated energy system is established by analyzing the features of different energy devices. The objective is to minimize the total operating cost, which includes the carbon emission cost, energy purchase cost, and clean energy generation cost. As the energy conversion hubs, the characteristics of CCHP and P2G are considered in the constraints to ensure reliable operation. Mixed integer linear programming is employed to solve the optimization problem.

2. Seaport Integrated Energy System under Polymorphic Network

2.1. Power to Gas

2.1.1. Electrolyzer

2.1.2. Methane Reactor

2.1.3. Hydrogen Fuel Cell

2.2. Combined Cooling Heating and Power

2.3. Polymorphic Network-Based Seaport Integrated Energy System

2.3.1. MobilityFirst

2.3.2. Structure of Polymorphic Network-Based Seaport Integrated Energy System

3. Energy Management Model for Seaport Integrated Energy System

3.1. Objective Function

3.1.1. Energy Purchase Cost

3.1.2. Carbon Emissions Cost

3.1.3. Clean Energy Cost

3.2. Constraints

3.2.1. Clean Energy Constraints

3.2.2. GT Constraint

3.2.3. Energy Storage Devices Constraints

3.2.4. Electricity Balance Constraint

3.2.5. Natural Gas Balance Constraint

3.2.6. Heat Balance Constraint

3.2.7. Cold Balance Constraint

3.2.8. Hydrogen Balance Constraint

4. Simulation

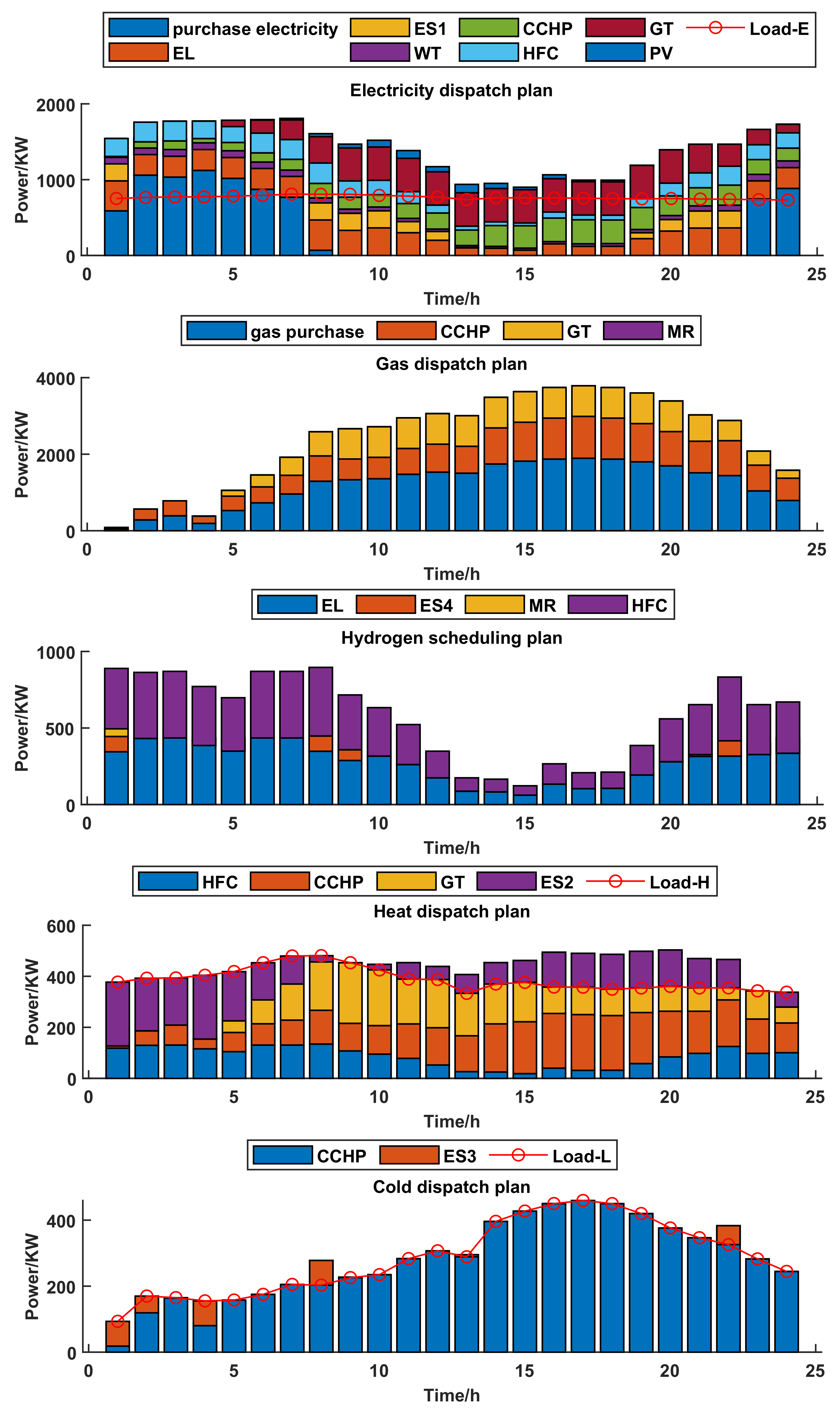

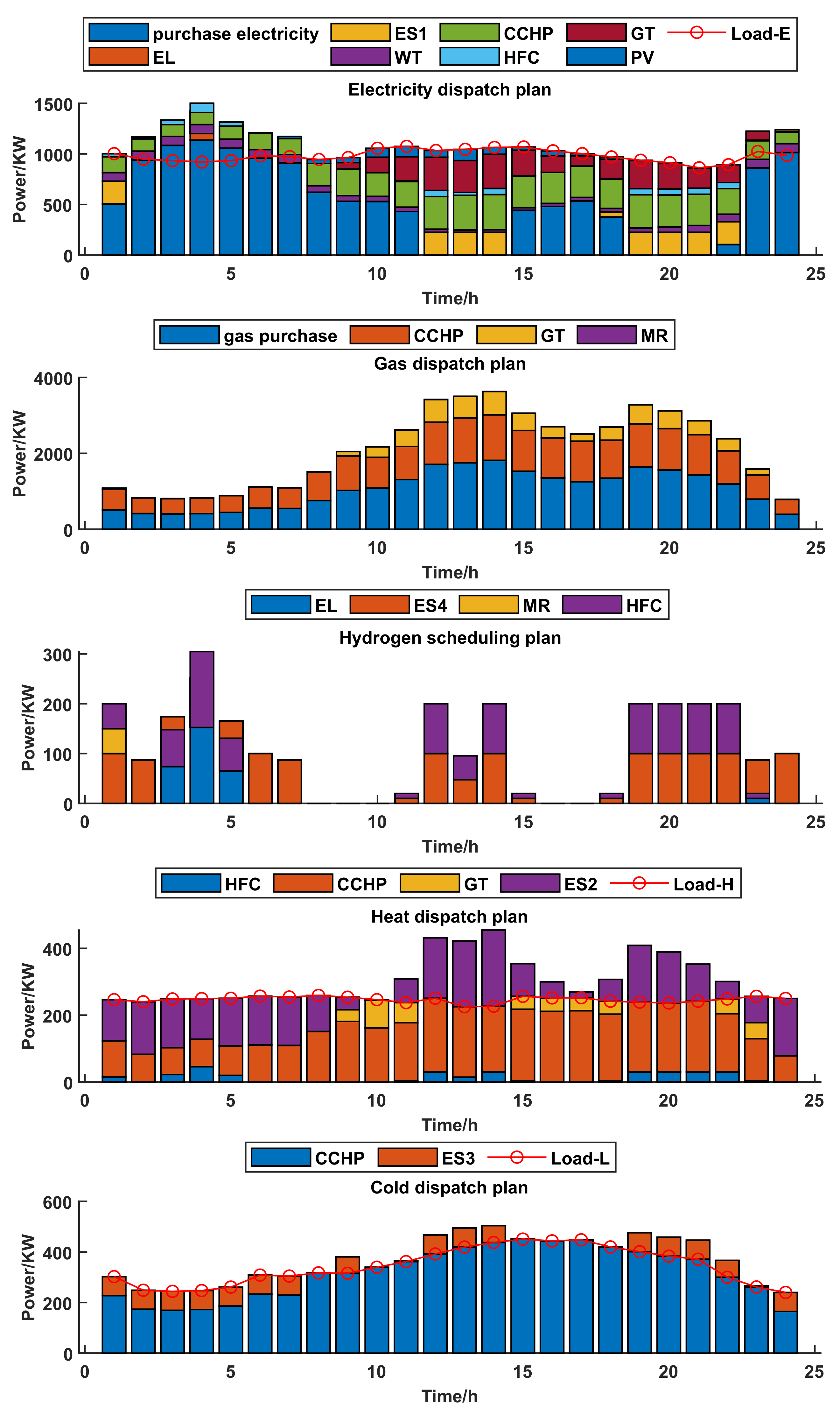

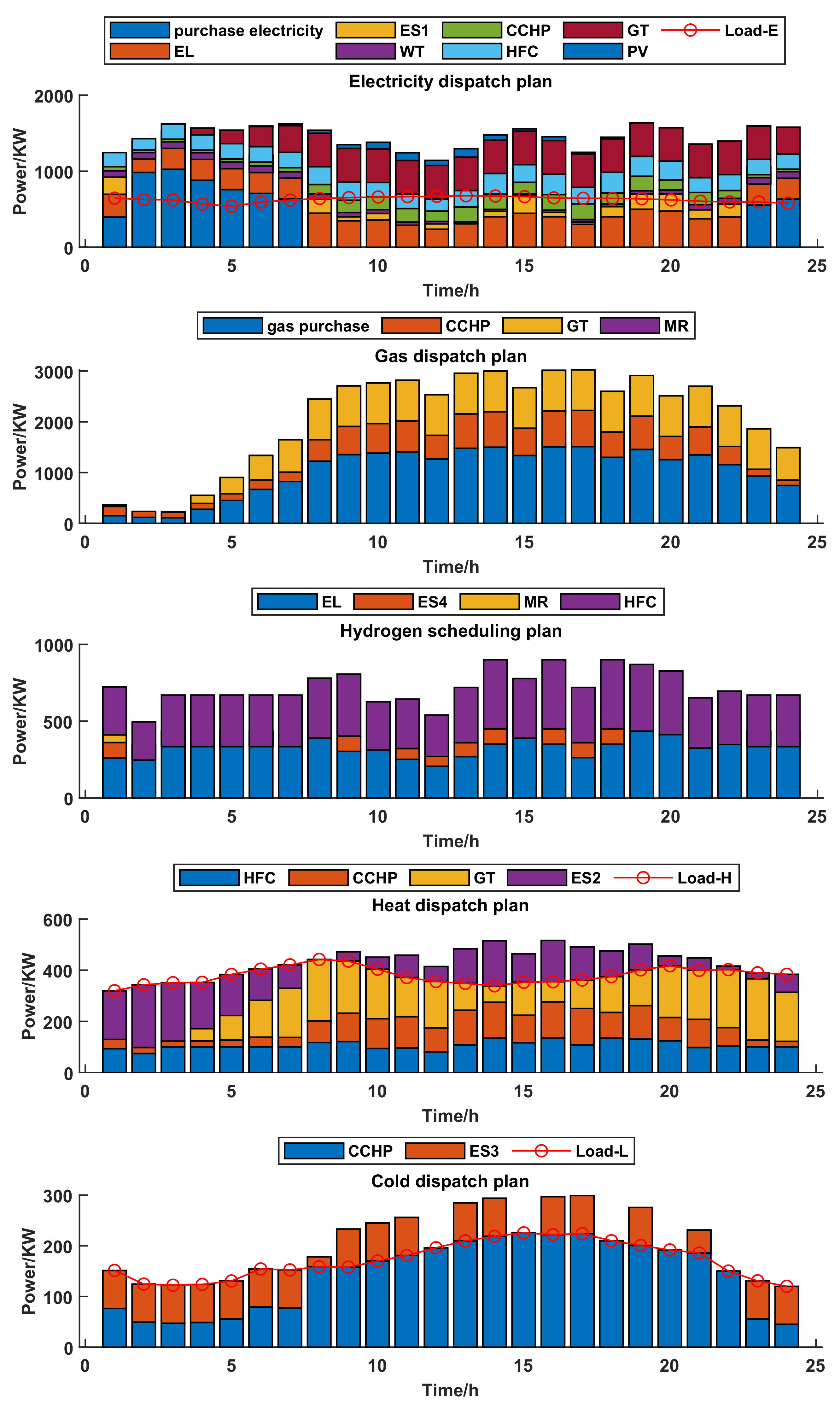

4.1. Impact of Energy Storage Devices and Clean Energy in Seaport Integrated Energy System

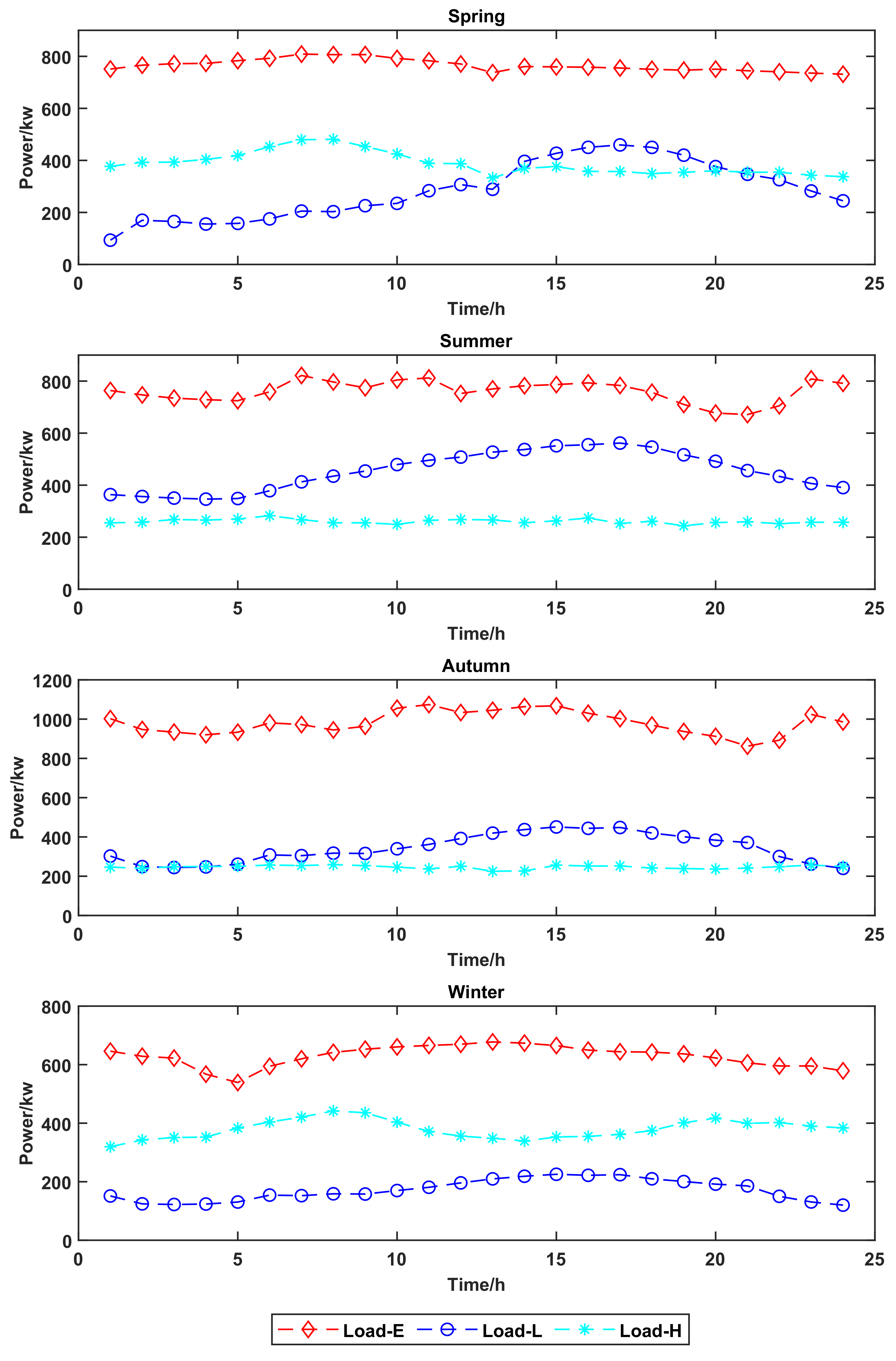

4.2. Impact of Sensonal Changes in Seaport Integrated Energy System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Acronym | Explanation |

| P2G | power to gas |

| CCHP | combined cooling heating and power |

| IMO | International Maritime Organization |

| CO2 | carbon dioxide |

| GT | gas turbine |

| WT | Wind turbine |

| PV | photovoltaic |

| EL | electrolyzer |

| MR | methane reactor |

| IPV6 | internet protocol version 6 |

| MF | MobilityFirst |

| GUID | globally unique identity |

| NAs | network addresses |

| GNRS | global name resolution service |

| GSTAR | generalized storage-aware routing |

| WAN | wide area network |

| Load-E | electricity Load |

| Load-H | heat load |

| Load-L | cold load |

| ES1 | electricity energy storage device |

| ES2 | heat energy storage device |

| ES3 | cold energy storage device |

| ES4 | hydrogen energy storage device |

References

- Gan, M.; Li, D.; Wang, J.; Zhang, J.; Huang, Q. A Comparative Analysis of the Competition Strategy of Seaports under Carbon Emission Constraints. J. Clean. Prod. 2021, 310, 127488. [Google Scholar] [CrossRef]

- Fan, H.; Yu, J.; Liu, X. Tramp Ship Routing and Scheduling with Speed Optimization Considering Carbon Emissions. Sustainability 2019, 11, 6367. [Google Scholar] [CrossRef]

- Fang, S.; Zhao, C.; Ding, Z.; Zhao, S.; Liao, R. Carbon Neutral Port Integrated Energy System (1): Typical System Structure and Key Issues. Chin. Soc. Electr. Eng. 2021, 1–22. [Google Scholar] [CrossRef]

- Fang, S.; Zhao, C.; Ding, Z.; Zhao, S.; Liao, R. A carbon-neutral oriented integrated energy system for ports (II): Flexible resources and key technologies in energy-transportation integration. Chin. J. Electr. Eng. 2021, 1–20. [Google Scholar] [CrossRef]

- Yang, X.; Liu, K.; Leng, Z.; Liu, T.; Zhang, L.; Mei, L. Multi-dimensions Analysis of Aolar Hybrid CCHP Systems with Redundant Design. Energy 2022, 253, 124003. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Liu, H. Thermodynamic Analysis and Optimization of Two Low-grade Energy Driven Transcritical CO2 Combined Cooling, Heating and Power Systems. Energy 2022, 249, 123765. [Google Scholar] [CrossRef]

- Kang, L.; Yuan, X.; Sun, K.; Zhang, X.; Zhao, J.; Deng, S.; Liu, W.; Wang, Y. Feed-forward Active Operation Optimization for CCHP System Considering Thermal Load Forecasting. Energy 2022, 254, 124234. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, J.; Xiao, N.; Yang, L.; Zhao, W.; Geng, J.; Lu, T.; Luo, M.; Dong, C. Low Carbon Economic Dispatch Optimization of Regional Integrated Energy Systems Considering Heating Network and P2G. Energies 2022, 15, 5494. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, J.; Li, M.; Guo, J.; Xu, Z.; Li, W. Bi-Level Optimization Dispatch of Integrated-Energy Systems with P2G and Carbon Capture. Front. Energy Res. 2022, 9, 896. [Google Scholar] [CrossRef]

- Lin, S.; Lin, M.; Shen, Y.; Li, D. An Optimal Scheduling Strategy for Integrated Energy Systems Using Demand Response. Front. Energy Res. 2022, 10, 698. [Google Scholar] [CrossRef]

- Guo, Y.; Xiang, Y. Low-carbon Strategic Planning of Integrated Energy Systems. Front. Energy Res. 2022, 10, 858119. [Google Scholar] [CrossRef]

- Wang, K.; Liang, Y.; Jia, R.; Wang, X.; Du, H.; Ma, X. Configuration-dispatch Dual-layer Optimization of Multi-Microgrids Integrated Energy Systems Considering Energy Storage and Demand Response. Front. Energy Res. 2022, 10, 1217. [Google Scholar] [CrossRef]

- Liu, T.; Yang, Z.; Duan, Y.; Hu, S. Techno-economic Assessment of Hydrogen Integrated into Electrical/Thermal Energy Storage in PV+ Wind System Devoting to High Reliability. Energy Convers. Manag. 2022, 268, 116067. [Google Scholar] [CrossRef]

- Li, X.; Yu, G.; Wang, Y. Enhancing Hydroxyl Radical Production from Cathodic Ozone Reduction during the Ozone-Electrolysis Process with Flow-Through Reactive Electrochemical Membrane Cathode. Chemosphere 2022, 303, 135020. [Google Scholar] [CrossRef]

- Morimoto, S.; Kitagawa, N.; Thuy, N.; Ozawa, A.; Rustandi, R.A.; Kataoka, S. Scenario Assessment of Implementing Methanation Considering Economic Feasibility and Regional Characteristics. J. CO2 Util. 2022, 58, 101935. [Google Scholar] [CrossRef]

- Kowalczyk, T. Comparative Analysis of Hybrid Energy Storage Based on a Gas–Gas System and a Conventional Compressed Air Energy Storage Based on a Recuperated Gas Turbine round Trip Efficiency, Exergy Losses, and Heat Exchanges Start-up Losses. Energy Convers. Manag. 2022, 258, 115467. [Google Scholar] [CrossRef]

- Li, Y.; Zou, Y.; Tan, Y.; Cao, Y.; Liu, X.; Shahidehpour, M.; Tian, S.; Bu, F. Optimal stochastic operation of integrated low-carbon electric power, natural gas, and heat delivery system. IEEE Trans. Sustain. Energy 2017, 9, 273–283. [Google Scholar] [CrossRef]

- Kanellos, F.D.; Volanis, E.S.M.; Hatziargyriou, N.D. Power management method for large ports with multi-agent systems. IEEE Trans. Smart Grid 2017, 10, 1259–1268. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Y.; Mahfoud, R.J.; Alhelou, H.H.; Siano, P. Integrated Modeling of Regional and Park-Level Multi-Heterogeneous Energy Systems. Energy Rep. 2022, 8, 3141–3155. [Google Scholar] [CrossRef]

- Ma, N.; Zhang, H.; Hu, H.; Qin, Y. ESCVAD: An Energy-Saving Routing Protocol Based on Voronoi Adaptive Clustering for Wireless Sensor Networks. IEEE Internet Things J. 2021, 9, 9071–9085. [Google Scholar] [CrossRef]

- Naeem, M.A.; Ullah, R.; Meng, Y.; Ali, R.; Lodhi, B.A. Caching Content on the Network Layer: A Performance Analysis of Caching Schemes in ICN-Based Internet of Things. IEEE Internet Things J. 2021, 9, 6477–6495. [Google Scholar] [CrossRef]

- Hu, Y.; Yi, P.; Sun, P.; Wu, J. Research on a Fully Dimensionally Definable Polymorphic Intelligent Network System. J. Commun. 2019, 40, 1–12. [Google Scholar]

- Hu, Y.; Li, D.; Sun, P.; Yi, P.; Wu, J. Polymorphic Smart Network: An Open, Flexible and Universal Architecture for Future Heterogeneous Networks. IEEE Trans. Netw. Sci. Eng. 2020, 7, 2515–2525. [Google Scholar] [CrossRef]

- Tai, N.; Wang, X.; Huang, W.; Yang, L.; Huang, Y. A Review of Low-carbon Technologies for Integrated Energy Systems in Ports. Grid Technol. 2022, 46, 1–15. [Google Scholar]

- Olatomiwa, L.; Mekhilef, S.; Ismail, M.S.; Moghavvemi, M. Energy Management Strategies In Hybrid Renewable Energy Systems: A review. Renew. Sustain. Energy Rev. 2016, 62, 821–835. [Google Scholar] [CrossRef]

- Ding, Z.; Cao, Y.; Xie, L.; Lu, Y.; Wang, P. Integrated Stochastic Energy Management for Data Center Microgrid Considering Waste Heat Recovery. IEEE Trans. Ind. Appl. 2019, 55, 2198–2207. [Google Scholar] [CrossRef]

- Gao, D.; Kwan, T.H.; Dabwan, Y.N.; Hu, M.; Hao, Y.; Zhang, T.; Pei, G. Seasonal-regulatable Energy Systems Design and Optimization for Solar Energy Year-Round Utilization. Appl. Energy 2022, 322, 119500. [Google Scholar] [CrossRef]

- Abomazid, A.M.; El-Taweel, N.A.; Farag, H.E. Optimal Energy Management of Hydrogen Energy Facility Using Integrated Battery Energy Storage and Solar Photovoltaic Systems. IEEE Trans. Sustain. Energy 2022, 13, 1457–1468. [Google Scholar] [CrossRef]

- Fan, G.; Liu, Z.; Liu, X.; Shi, Y.; Wu, D.; Guo, J.; Zhang, S.; Yang, X.; Zhang, Y. Energy management strategies and multi-objective optimization of a near-zero energy community energy supply system combined with hybrid energy storage. Sustain. Cities Soc. 2022, 83, 103970. [Google Scholar] [CrossRef]

- Khorramdel, H.; Gitizadeh, M.; Chung, C.Y.; Othman, M.M.; Alhelou, H.H. An Adjustable Robust Economic Energy and Reserve Dispatch Problem Incorporating Large-Scale Wind Farms. IEEE Access 2022, 10, 73969–73987. [Google Scholar] [CrossRef]

- Deng, Q.; Yang, Z.; Zhang, L.; Jia, M. The Control Strategy and Economic Analysis of a New Type of Solar Cold Storage. J. Energy Storage 2022, 52, 104865. [Google Scholar] [CrossRef]

- Huang, Y.; Huang, W.; Wei, W.; Tai, N.; Li, R. Logistics-energy Collaborative Optimization Scheduling Method for Large Seaport Integrated Energy System. Chin. J. Electr. Eng. 2021, 42, 013. [Google Scholar]

- Fang, S.; Liao, R. Optimal Energy-Transport Scheduling for Bulk Seaport Integrated Energy System. In Proceedings of the 2022 IEEE/IAS 58th Industrial and Commercial Power Systems Technical Conference (I&CPS), Las Vegas, NV, USA, 2 May 2022; pp. 1–8. [Google Scholar]

- Mao, A.; Yu, T.; Ding, Z.; Fang, S.; Guo, J.; Sheng, Q. Optimal scheduling for seaport integrated energy system considering flexible berth allocation. Appl. Energy 2022, 308, 118386. [Google Scholar] [CrossRef]

- Wang, X.; Huang, W.; Wei, W.; Tai, N.; Li, R.; Huang, Y. Day-ahead Optimal Economic Dispatching of Integrated Port Energy Systems Considering Hydrogen. IEEE Trans. Ind. Appl. 2021, 58, 2619–2629. [Google Scholar] [CrossRef]

- Liu, Y.; Han, J.; You, H. Exergoeconomic Analysis and Multi-objective Optimization of a CCHP System Based on LNG Cold Energy Utilization and Flue Gas Waste Heat Recovery with CO2 Capture. Energy 2020, 190, 116201. [Google Scholar] [CrossRef]

- Kalita, A.; Brighente, A.; Khatua, M.; Conti, M. Effect of DIS Attack on 6TiSCH Network Formation. IEEE Commun. Lett. 2022, 26, 1190–1193. [Google Scholar] [CrossRef]

- Raychaudhuri, D.; Nagaraja, K.; Venkataramani, A. Mobilityfirst: A Robust and Trustworthy Mobility-Centric Architecture for the Future Internet. ACM Sigmobile Mob. Comput. Commun. Rev. 2012, 16, 2–13. [Google Scholar] [CrossRef]

- Venkataramani, A.; Kurose, J.F.; Raychaudhuri, D.; Nagaraja, K.; Mao, M.; Banerjee, S. Mobilityfirst: A Mobility-Centric And Trustworthy Internet Architecture. ACM Sigcomm Comput. Commun. Rev. 2014, 44, 74–80. [Google Scholar] [CrossRef]

- Yang, K.; Xiao, B.; Wei, Y.; Wei, Z.; Tian, K. Economic Analysis of Wind Power Projects Based on Average Power Generation Cost. Technol. Ind. 2010, 10, 78–80. [Google Scholar]

- Ma, C.; Shi, D.; Cong, X. Research on the Cost of Solar Photovoltaic Power Generation and the Problem of Grid Parity. Contemp. Econ. Sci. 2014, 36, 85–94, 127. [Google Scholar]

- Li, Y.; Wang, J.; Han, Y.; Zhao, Q. Generalized Modeling and Coordinated Management of Energy Hub Incorporating Wind Power and Demand Response. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 4214–4219. [Google Scholar]

- Yang, H.; Zhang, Y.; Ma, Y.; Zhang, D.; Sun, L.; Xia, S. Reliability Assessment of Integrated Energy System Considering the Uncertainty of Natural Gas Pipeline Network System. IET Gener. Transm. Distrib. 2019, 13, 5033–5041. [Google Scholar] [CrossRef]

- Huang, B.; Zheng, S.; Wang, R.; Wang, H.; Xiao, J.; Wang, P. Distributed Optimal Control of DC Microgrid Considering Balance of Charge State. IEEE Trans. Energy Convers. 2022, 37, 2162–2174. [Google Scholar] [CrossRef]

| WT (kw) | 1:00 | 2:00 | 3:00 | 4:00 | 5:00 | 6:00 | 7:00 | 8:00 |

| 85.04 | 86.43 | 88.64 | 88.64 | 89.20 | 89.47 | 84.90 | 83.38 | |

| 9:00 | 10:00 | 11:00 | 12:00 | 13:00 | 14:00 | 15:00 | 16:00 | |

| 65.37 | 55.68 | 50.14 | 43.21 | 31.02 | 24.10 | 25.20 | 26.60 | |

| 17:00 | 18:00 | 19:00 | 20:00 | 21:00 | 22:00 | 23:00 | 24:00 | |

| 29.64 | 34.35 | 35.46 | 42.66 | 52.63 | 67.59 | 74.24 | 85.46 | |

| PV (kw) | 1:00 | 2:00 | 3:00 | 4:00 | 5:00 | 6:00 | 7:00 | 8:00 |

| 0 | 0 | 0 | 0 | 0.06 | 6.54 | 20.19 | 39.61 | |

| 9:00 | 10:00 | 11:00 | 12:00 | 13:00 | 14:00 | 15:00 | 16:00 | |

| 49.64 | 88.62 | 101.59 | 66.78 | 110.46 | 67.41 | 31.53 | 50.76 | |

| 17:00 | 18:00 | 19:00 | 20:00 | 21:00 | 22:00 | 23:00 | 24:00 | |

| 20.6 | 22.08 | 2.07 | 0 | 0 | 0 | 0 | 0 |

| Period | Electricity Price (yuan/kW·h) |

|---|---|

| 01:00–07:00 | 0.38 |

| 08:00–11:00 | 0.68 |

| 12:00–14:00 | 1.20 |

| 15:00–18:00 | 0.68 |

| 19:00–22:00 | 1.20 |

| 22:00–24:00 | 0.38 |

| Equipment | Operating Parameters | Numerical Value |

|---|---|---|

| EL | output bound (kw) | 500 |

| electrolysis efficiency | 0.87 | |

| climb constraint | 0.2 | |

| MR | output bound (kw) | 250 |

| efficiency | 0.6 | |

| climb constraint | 0.2 | |

| GT | output bound (kw) | 800 |

| electrical efficiency | 0.55 | |

| heat efficiency | 0.3 | |

| climb constraint | 0.2 | |

| HFC | output bound (kw) | 450 |

| electrical efficiency | 0.6 | |

| heat efficiency | 0.3 | |

| climb constraint | 0.2 | |

| CCHP | output bound (kw) | 1200 |

| electrical efficiency | 0.29 | |

| heat efficiency | 0.2 | |

| cold efficiency | 0.42 | |

| climb constraint | 0.2 | |

| electricity storage device | capacity (kw) | 450 |

| capacity cap constraint | 0.9 | |

| capacity lower bound | 0.1 | |

| climb constraint | 0.2 | |

| heat storage device | capacity (kw) | 500 |

| capacity cap constraint | 0.9 | |

| capacity lower bound | 0.1 | |

| climb constraint | 0.2 | |

| cold storage device | capacity (kw) | 150 |

| capacity cap constraint | 0.9 | |

| capacity lower bound | 0.1 | |

| climb constraint | 0.2 | |

| hydrogen storage device | capacity (kw) | 200 |

| capacity cap constraint | 0.9 | |

| capacity lower bound | 0.1 | |

| climb constraint | 0.2 |

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| energy purchase cost | 11,885 | 11,847 | 11,169 | 11,169 |

| carbon cost | 10,997 | 10,816 | 10,311 | 10,311 |

| WT and PV cost | 0 | 256.37 | 256.37 | 256.37 |

| total cost | 22,882 | 22,928 | 21,745 | 21,745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, F.; Zhang, Q.; Zou, T.; Zhu, J.; Tu, Y.; Feng, Q. Energy Management Strategy for Seaport Integrated Energy System under Polymorphic Network. Sustainability 2023, 15, 53. https://doi.org/10.3390/su15010053

Teng F, Zhang Q, Zou T, Zhu J, Tu Y, Feng Q. Energy Management Strategy for Seaport Integrated Energy System under Polymorphic Network. Sustainability. 2023; 15(1):53. https://doi.org/10.3390/su15010053

Chicago/Turabian StyleTeng, Fei, Qing Zhang, Tao Zou, Jun Zhu, Yonggang Tu, and Qian Feng. 2023. "Energy Management Strategy for Seaport Integrated Energy System under Polymorphic Network" Sustainability 15, no. 1: 53. https://doi.org/10.3390/su15010053

APA StyleTeng, F., Zhang, Q., Zou, T., Zhu, J., Tu, Y., & Feng, Q. (2023). Energy Management Strategy for Seaport Integrated Energy System under Polymorphic Network. Sustainability, 15(1), 53. https://doi.org/10.3390/su15010053