Sustainable Additive Manufacturing and Environmental Implications: Literature Review

Abstract

1. Introduction

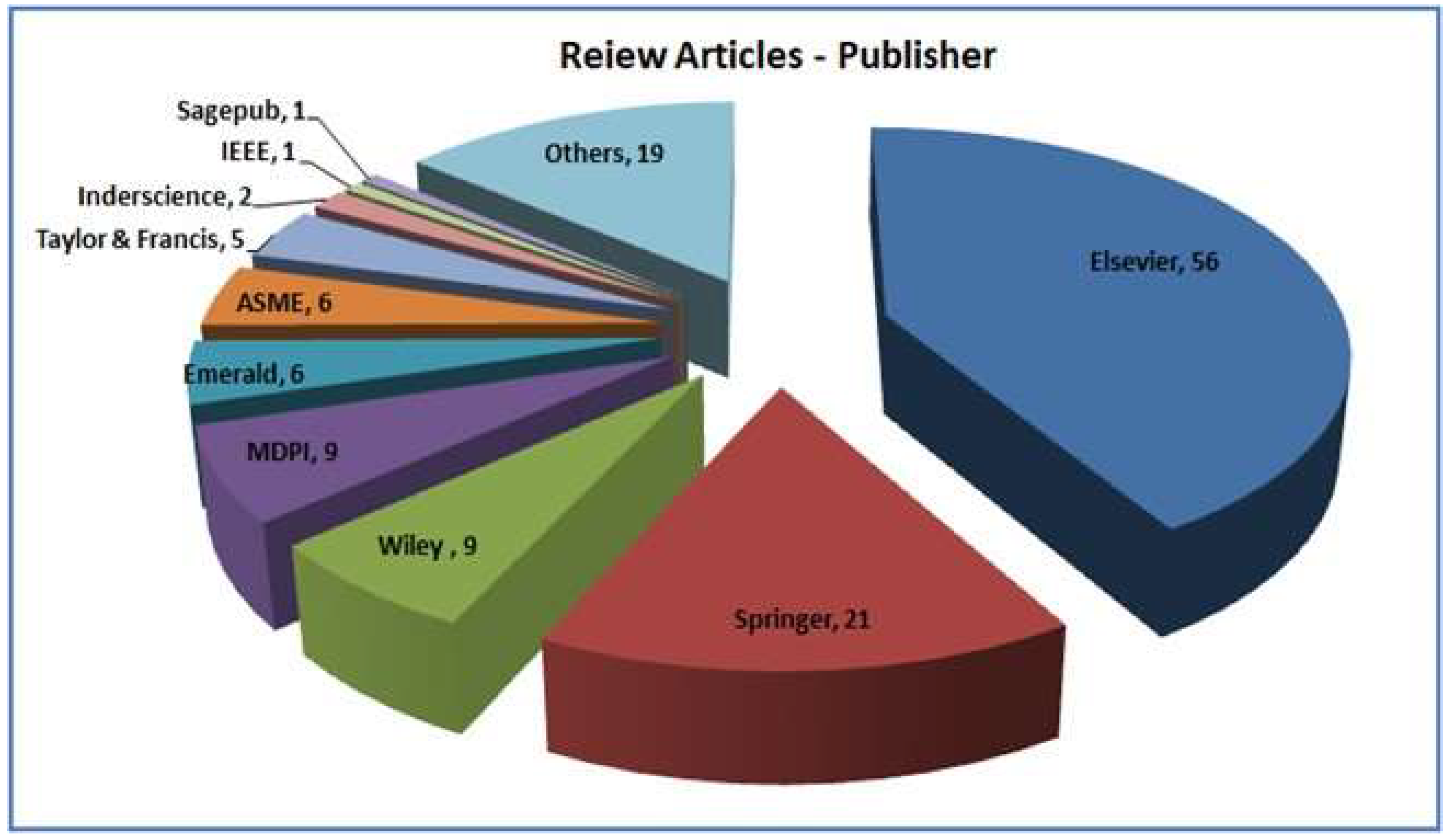

2. Materials and Methods

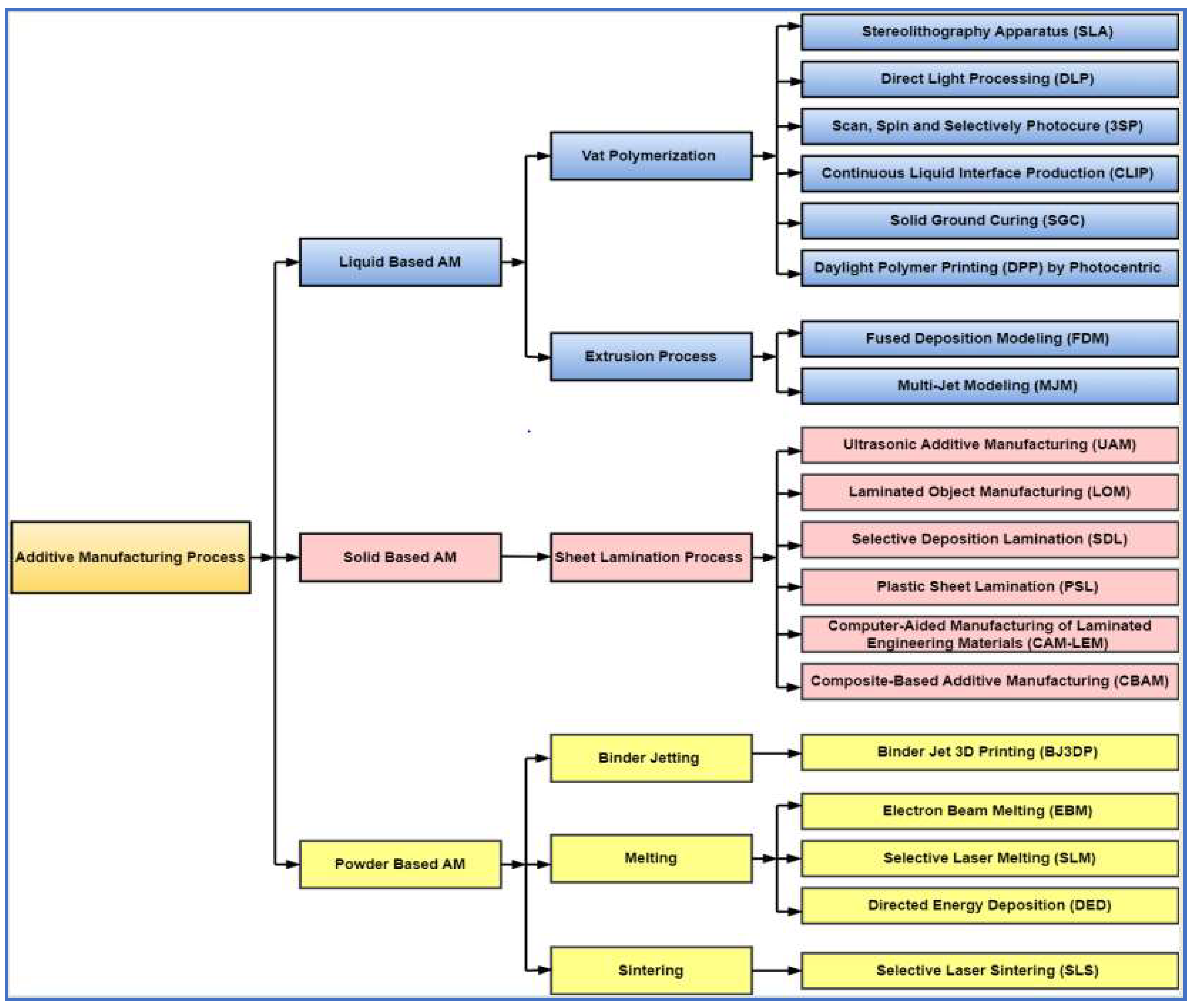

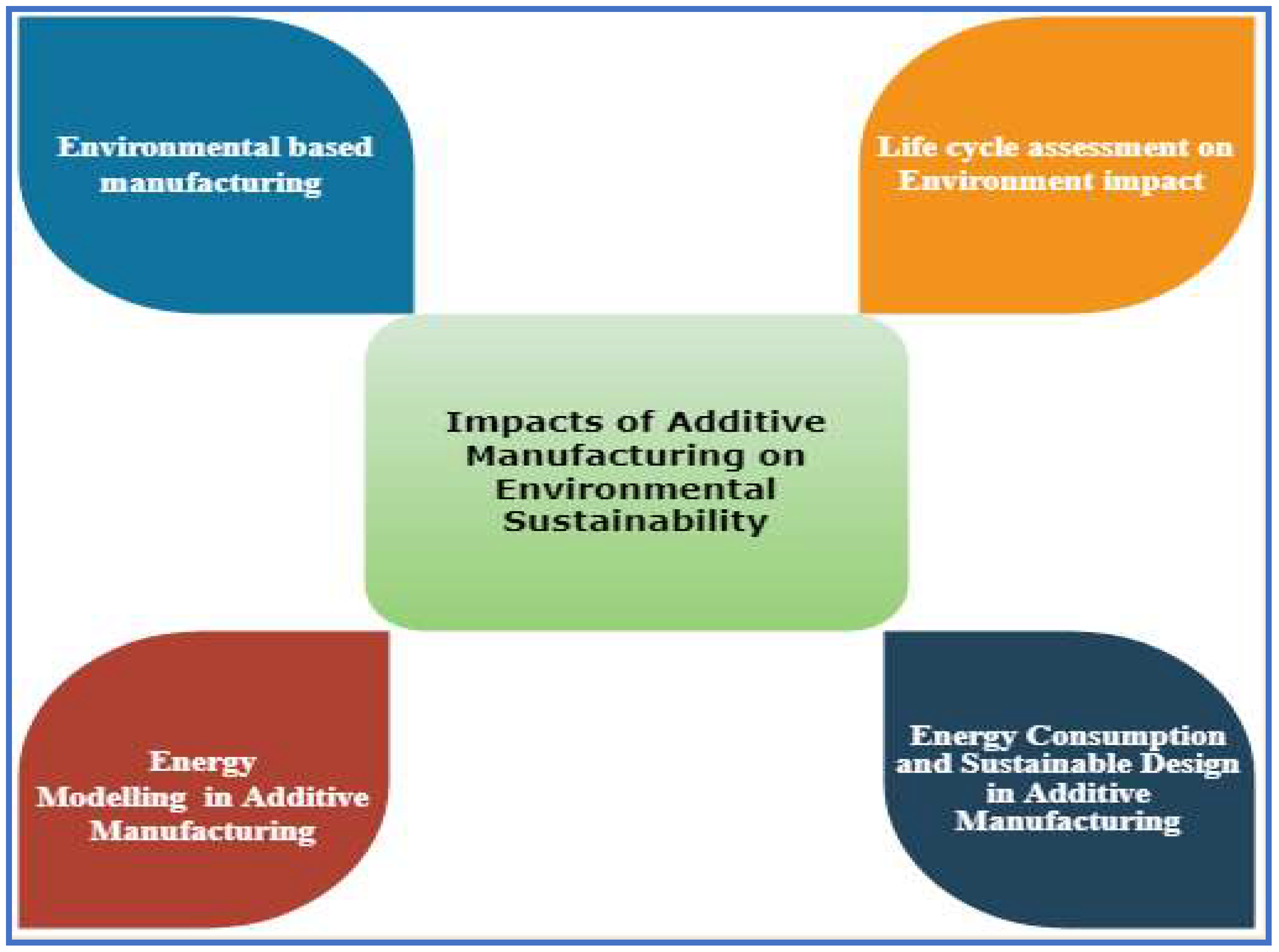

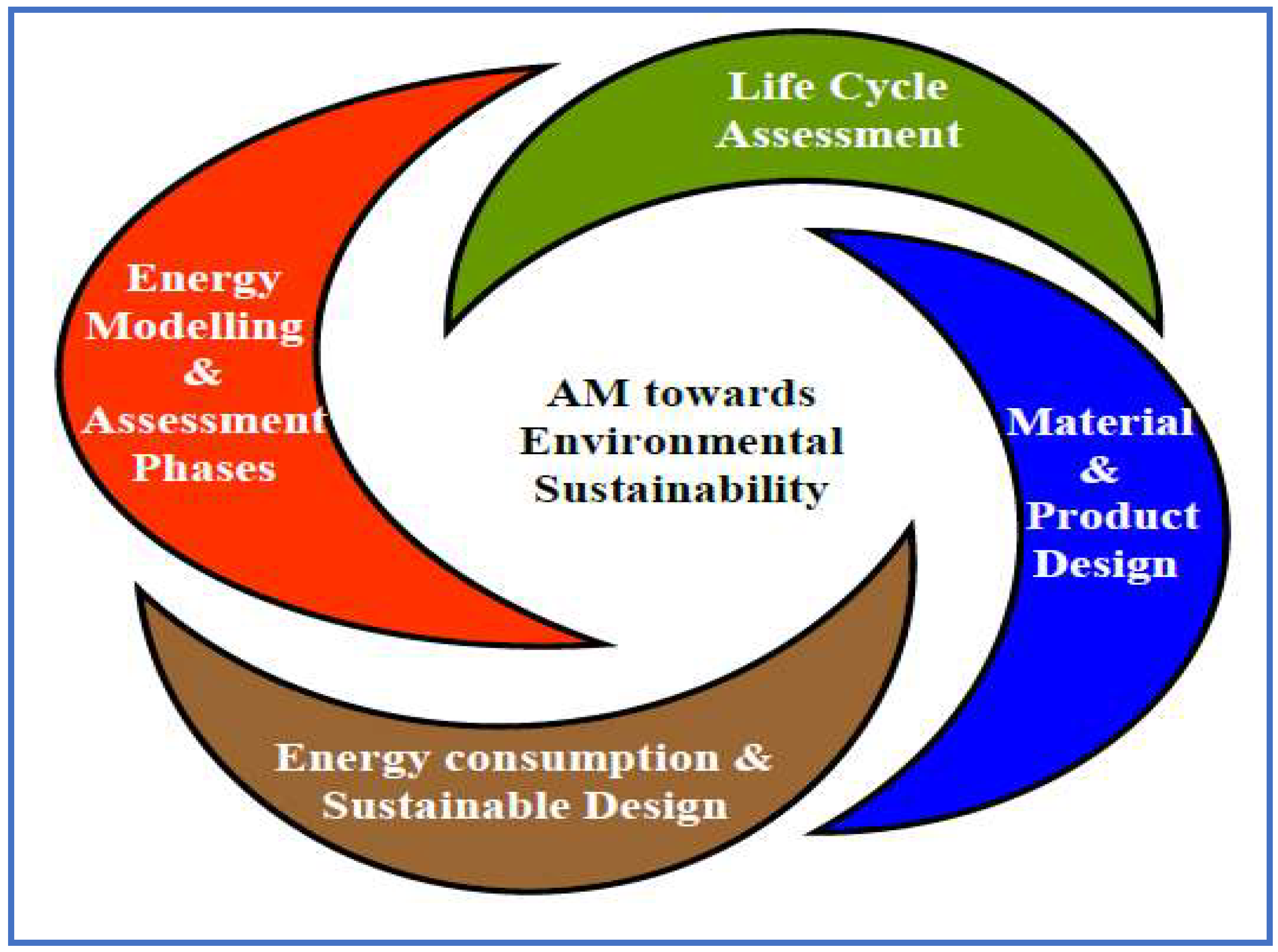

3. State-of-The-Art Study of Environmental Concepts in Additive Manufacturing

3.1. Impacts of Additive Manufacturing on Environmental-Based Manufacturing

3.2. Life Cycle Assessment on Environment Impact

3.3. Energy Modeling in Additive Manufacturing

3.4. Energy Consumption and Sustainable Design for AM

4. Discussion on Environmental-Based AM

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Sl. No. | Authors | AM Process | Raw Materials | Aspects and Impacts Analyzed and Its Results |

|---|---|---|---|---|

| 1 | Morrow et al. (2007) [25] | Metal Deposition-based manufacturing (MDM) | Metal powder | Reduction in manufacturing cost, emissions, and energy consumption |

| 2 | Lušić et al. (2015) [26] | Finite element simulation | ABS-M30 Thermoplastic | Minimization of consumption of material |

| 3 | Floriane Laverne et al.(2015) [27] | Design for additive manufacturing (A-DFAM) | Case study | To improve their design features |

| 4 | Markou et al. (2017) [28] | Early Design Stages (EDS) | Metal (Aluminum alloy)Polymer (ABS extrusion) | Design to environment approach |

| 5 | Ponche et al. 2012 [33] | Design For Additive Manufacturing (DFAM) | Stainless steel | Determination of suitable design of parts |

| 6 | Campbell et al. (2012) [35] | Objet Polyjet process | SL resins | Predicts the future of additive manufacturing |

| 7 | Dezso and Kósa (2012) [36] | OBJET Eden 350V additive machine | Plastics | Surface roughness measurement |

| 8 | Bourhis et al. (2013) [37] | Direct additivelaser manufacturing (DALM) | Metallic Aluminum Powder | Minimization of material, fluids, electricity |

| 9 | Achillas et al. (2015) [39] | multi-criteria decision aid (MCDA) and data envelopment analysis (DEA) | Polymers, metals, ceramics, and composites | Decision-making methodological framework |

| 10 | Garg and Lam (2015) [47] | Selective laser sintering | Hydroxyapatite powder and SLS polymer powder, Polyamide-12 | To predict open porosity |

| 11 | Francesco Salamone et al. (2017) [50] | Thermographic analysis | Comparison study | To ensure the correctness of the optimized system and avoid systematic instrumental mistakes. |

| 12 | Jin et al. (2017) [54] | Skeleton-based path planning method | Material consumption model | To improve the deposition performance and surface quality |

| 13 | Peng et al. (2018) [55] | conventional manufacturing (CM), additive manufacturing (AM), and remanufacturing (RM) | Titanium alloy | Comparing the environmental consequences of several impeller manufacturing processes |

| 14 | Tagliaferri et al. (2018) [56] | Fused deposition modeling (FDM), multi-jet fusion (MJF), and selective laser sintering (SLS) | Polyamide 12,Nylon 12 | Highlight the characteristics and, performance limits, costs associated with the different processes |

| 15 | Melugiri-Shankaramurthy et al. (2018) [57] | Recycling of metal powder | Stainless Steel (SS) micro powder | To increase quantity, strength, and durability |

| 16 | Gorji et al. (2019) [58] | Selective laser melting process. | Virgin and recycled Stainless Steel | The amount of oxygen on the surface of the recycled powder and metallic oxides is growing |

| 17 | Priarone et al. (2020) [59] | Wire Arc Additive Manufacturing (WAAM) | Aluminum frame, Steel beam, Titanium bracket | For comparison, the materials’ production time, product cost, and mechanical performance were all taken into account |

| Sl. No. | Authors | AM Process | Raw Materials | Aspects and Impacts Analyzed and Its Results |

|---|---|---|---|---|

| 1 | Serres et al. (2011) [60] | Construction Laser Additive Direct Process (CLAD) | Ti6Al4V | To analyze the case of a repaired part |

| 2 | Faludi et al. (2015) [61] | ReCiPe Endpoint H methodology in SimaPro software | Steel, glass, and plastic | Lowest effects in both maximum and most minor use of machinery |

| 3 | Malshe et al. (2015) [64] | Stereolithography | Epoxy resin (SLA 5170)Epoxy resin (SLA 5171)Epoxy resin (SLA 5172)Epoxy resin (SI 500) | Curing of a single resin type and power usage |

| 4 | Wilson et al. (2014) [66] | CAD and geometric reconstruction algorithm | SS316L turbine blade | Effectiveness of direct laser deposition in remanufacturing |

| 5 | Tang et al. (2016) [67] | BJAM | Ti-6Al-4V | Binder-jetting AM process energy and material consumption models |

| 6 | Huang et al. (2016) [69] | Lifecycle Management | Emissions calculation | Primary energy and greenhouse gas emissions |

| 7 | Yang et al. (2017) [71] | Binder jetting additive manufacturing process | Green powder, Bronze powder | Reducing energy consumption and environmental impact |

| 8 | Bours et al. (2017) [72] | Photopolymerization processing AM | Polylactic acid, PR48 materials | Minimizing their hazards and environmental impacts |

| 9 | Kafara et al. (2017) [75] | High Impact Polystyrene (HIPS) | Plaster-like material Aquapour | Comparing the environmental impact of AM with CM. |

| 10 | Paris and Mandil (2017) [77] | Electron beam melting and CNC machining processes | Titanium | The material volume of the existing part reused increases by more than 60% |

| 11 | Guarino et al. (2017) [79] | Graphene electrode position. | copper | Thermal tests showed improvements in the thermal performances of the samples |

| 12 | Nagarajan and Haapala (2018) [81] | FDM | Acrylonitrile styrene acrylate polymer | Electrical energy |

| 13 | Yosofi et al. (2018) [84] | Fused deposition modeling, Material jetting | Material consumption | Electric consumption |

| 14 | Liu et al. (2018) [85] | Inkjet Printing Extrusion, SLA FDM, LENS | Inconel 718 powders, Stellite 1 powders, AISI 4140 powders Triboloy T800, Resin, ABS, Cell, Slginate | Energy consumption |

| 15 | Bekker and Verlinden (2018) [86]. | Wire and Arc Additive Manufacturing | Stainless steel 308l | Product shape, function, materials, and process locales |

| 16 | Yosofi et al. (2019) [89] | Material jetting | Material consumption model | AM processes that allow products with complex geometries to be manufactured |

| 17 | Jiang et al. (2019) [90] | Laser Engineered Net Shaping (LENS) | AISI 4140 | Proposed to improve the sustainability of the manufacturing technologies |

| 18 | Böckin and Tillman (2019) [91] | Powder Bed Fusion (PBF) | Aluminum, Cast iron, Low-alloy steel, Stainless steel | Designing components for weight reduction. |

| 19 | Faludi et al. (2019) [92] | Compression and tensile tests | ASTM standard D638 | Comparison of 3D printers |

| 20 | Van Sice and Faludi (2021) [95] | Granta EduPack database | steel, aluminum, and titanium | To build volume, energy efficiency |

| 21 | Lyons et al. (2021) [96] | Electron beam melting | Ti-6Al-4V material | Reduction in material using the AM process |

| Sl. No. | Authors | AM Process | Raw Materials | Aspects and Impacts Analyzed and Its Results |

|---|---|---|---|---|

| 1 | Bourhis et al. (2013) [37] | Direct AdditiveLaser Manufacturing (DLAM) process | Steel | Flow consumption |

| 2 | Le Bourhis et al. (2014) [99] | CAD model, MacroCLAD | Metallic, ceramic, glass | Electrical consumption, fluids, and material consumption |

| 3 | Manogharan et al. (2016) [100] | CNC-RP and AIMS. | Ti6Al4 V | Effect of the costs in AM and SM methods. |

| 4 | Kerbrat et al. (2015) [101] | CAD model, | Material, fluids, electricity | minimize the environmental impacts |

| 5 | Panda et al. (2016) [102] | SLS, SLM, and GP | TAS and laser energy | Minimizes the energy consumption |

| 6 | Priarone and Ingarao (2017) [103] | Machining, EBM, SLS | Ti-6Al-4V, Stainless steel | Energy demand and CO2 emissions |

| 7 | Peng and Sun (2017) [104] | FDM | poly lactic acid | To assist calculation of a life cycle energy consumption |

| 8 | Zhang et al. (2018) [105] | Selective laser sintering | Titanium | Bone structure yields—lowest cost and environmental impact. |

| Sl. No. | Authors | AM Process | Raw Materials | Aspects and Impacts Analyzed and Its Results |

|---|---|---|---|---|

| 1 | Sreenivasan et al. (2010) [107] | SLS | Polyamide powder | Reduce energy consumption |

| 2 | Baumers et al. (2011) [108] | SinterstationHiQ+HS | Nylon 12 | Reducing the time-dependent energy consumption |

| 3 | Xu et al. (2015) [109] | Binder- Jetting | Stainless steel, ceramic, polymer, and glass | Part geometry design to optimize energy consumption |

| 4 | Watson and Taminger (2015) [110] | Laser or electron beam processes | Solid metallic material | Improved knowledge of the energy |

| 5 | Hapuwatte et al. (2016) [112] | ProdSI | Cobalt-Chromium alloy, Co-30Cr-5Mo | Sustainable for complex geometrical components |

| 6 | Hao et al. (2010) [32] | Selective laser melting | Aluminium, Aluminium + Iron oxide | Identify sustainable engineering materials |

| 7 | Faludi et al. (2017) [116] | SLM printing | aluminum powder | Reductions in energy consumption |

| 8 | Walachowicz et al. (2017) [118] | LBM process | Nickel-based superalloy | Energy consumption and carbon footprint |

| 9 | Yang et al. (2017) [119]. | Stereolithography (SLA) | Polymer, Epoxy resin, | Overall energy consumption |

| 10 | Nagarajan and Haapala (2017) [121] | Direct metal laser sintering | iron metal powder | Electricity consumption |

| 11 | Yang and Li (2017) [122] | SLA process | Liquid Resin | Environmental sustainability |

| 12 | Verma and Rai (2017) [123] | Selective laser sintering (SLS) | Un-sintered powder material | Sustainability is formulated and optimized |

| 13 | Despeisse et al. (2017) [124] | Sustainable Value Roadmapping Tool | Review article | Reduced lead times and low-cost customization |

| 14 | Liu et al. (2018) [85] | EBM process. | H13 tool steel | Energy consumption |

| 15 | Priarone et al. (2018) [128] | Assessment using a bottom-up approach | Ti-6Al-4V | Effect on global energy demand |

| 16 | Pan et al. (2018) [129] | FESEM/EDX | Iron, silicon, chromium, aluminum, nano-crystalline powders, polyethylene plastics | Yield strength and Young modulus analyzed |

| 17 | Jiang et al. 2019 [130] | Extrusionbased AM | Molten material | To reduce material consumption, production time, and energy consumption |

| 18 | Sardon et al. (2022) [132] | VP, FFF, DIW, PBF, and binder jetting | Polymeric materials | To reduce its carbon footprint |

References

- Davoudinejad, A.; Diaz-Perez, L.C.; Quagliotti, D.; Pedersen, D.B.; Albajez-García, J.A.; Yagüe-Fabra, J.A.; Tosello, G. Additive Manufacturing with Vat Polymerization Method for Precision Polymer Micro Components Production. Procedia CIRP 2018, 75, 98–102. [Google Scholar] [CrossRef]

- Zhang, Y.; Jarosinski, W.; Jung, Y.-G.; Zhang, J. Additive Manufacturing Processes and Equipment. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 39–51. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Schmidt, F.; Beuer, F.; Li, P.; Spintzyk, S.; Kraemer Fernandez, P. Stereolithography vs. Direct Light Processing for Rapid Manufacturing of Complete Denture Bases: An In Vitro Accuracy Analysis. J. Clin. Med. 2021, 10, 1070. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.; Park, S.; Bae, C.J. Development of ceramic additive manufacturing: Process and materials technology. Biomed. Eng. Lett. 2020, 10, 493–503. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Yang, Y.; Pan, Y. Machine learning for continuous liquid interface production: Printing speed modelling. J. Manuf. Syst. 2019, 50, 236–246. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, B.; Zeng, Y.; Gu, P. Model layout optimization for solid ground curing rapid prototyping processes. Robot. Comput.-Integr. Manuf. 2002, 18, 41–51. [Google Scholar] [CrossRef]

- Malas, A.; Isakov, D.; Couling, K.; Gibbons, G.J. Fabrication of high permittivity resin composite for vat photopolymerization 3D printing: Morphology, thermal, dynamic mechanical and dielectric properties. Materials 2019, 12, 3818. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Kitsakis, K.; Moza, Z.; Iakovakis, V.; Mastorakis, N.; Kechagias, J. An investigation of dimensional accuracy of multi-jet modeling parts. In Proceedings of the International Conference in Applied Mathematics, Computational Science and Engineering, Crete, Greece, 17–19 October 2015. [Google Scholar]

- Hehr, A.; Norfolk, M. A comprehensive review of ultrasonic additive manufacturing. Rapid Prototyp. J. 2020, 26, 445–458. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kabir, A.M.; Peralta, M.; Bruck, H.A.; Gupta, S.K. A Robotic Cell for Performing Sheet Lamination-Based Additive Manufacturing. Addit. Manuf. 2019, 27, 278–289. [Google Scholar] [CrossRef]

- Heinrich, A. (Ed.) 3D Printing of Optical Components; Springer: Cham, Switzerland, 2021; Volume 233. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Cawley, J.D. Computer-aided manufacturing of laminated engineering materials (CAM-LEM) and its application to the fabrication of ceramic components without tooling. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 1997; Volume 78712, p. V004T13A019. [Google Scholar]

- Uralde, V.; Veiga, F.; Aldalur, E.; Suarez, A.; Ballesteros, T. Symmetry and Its Application in Metal Additive Manufacturing (MAM). Symmetry 2022, 14, 1810. [Google Scholar] [CrossRef]

- Miyanaji, H.; Orth, M.; Akbar, J.M.; Yang, L. Process Development for Green Part Printing Using Binder Jetting Additive Manufacturing. Front. Mech. Eng. 2018, 13, 504–512. [Google Scholar] [CrossRef]

- Konda Gokuldoss, P.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting—Selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-Process Sensing in Selective Laser Melting (SLM) Additive Manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Application for additive manufacturing. In Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 451–474. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.-P.; Vleugels, J. Additive Manufacturing of Zirconia Parts by Indirect Selective Laser Sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes. In Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 245–268. [Google Scholar] [CrossRef]

- Thiede, S.; Wiese, M.; Herrmann, C. Upscaling Strategies for Polymer Additive Manufacturing: An Assessment from Economic and Environmental Perspective for SLS, MJF and DLP. Procedia CIRP 2021, 104, 653–658. [Google Scholar] [CrossRef]

- Diegel, O.; Singamneni, S.; Reay, S.; Withell, A. Tools for Sustainable Product Design: Additive Manufacturing. J. Sustain. Dev. 2010, 3, 68. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Morrow, W.R.; Qi, H.; Kim, I.; Mazumder, J.; Skerlos, S.J. Environmental Aspects of Laser-Based and Conventional Tool and Die Manufacturing. J. Clean. Prod. 2007, 15, 932–943. [Google Scholar] [CrossRef]

- Lušić, M.; Barabanov, A.; Morina, D.; Feuerstein, F.; Hornfeck, R. Towards Zero Waste in Additive Manufacturing: A Case Study Investigating One Pressurised Rapid Tooling Mould to Ensure Resource Efficiency. Procedia CIRP 2015, 37, 54–58. [Google Scholar] [CrossRef]

- Laverne, F.; Segonds, F.; Anwer, N.; Le Coq, M. Assembly Based Methods to Support Product Innovation in Design for Additive Manufacturing: An Exploratory Case Study. J. Mech. Des. 2015, 137, 121701. [Google Scholar] [CrossRef]

- Markou, F.; Segonds, F.; Rio, M.; Perry, N. A Methodological Proposal to Link Design with Additive Manufacturing to Environmental Considerations in the Early Design Stages. Int. J. Interact. Des. Manuf. IJIDeM 2017, 11, 799–812. [Google Scholar] [CrossRef]

- Floriane, L.; Frédéric, S.; Gianluca, D.; Marc, L.C. Enriching Design with X through Tailored Additive Manufacturing Knowledge: A Methodological Proposal. Int. J. Interact. Des. Manuf. IJIDeM 2017, 11, 279–288. [Google Scholar] [CrossRef]

- Drizo, A.; Pegna, J. Environmental Impacts of Rapid Prototyping: An Overview of Research to Date. Rapid Prototyp. J. 2006, 12, 64–71. [Google Scholar] [CrossRef]

- Fitzgerald, D.P.; Herrmann, J.W.; Schmidt, L.C. A Conceptual Design Tool for Resolving Conflicts Between Product Functionality and Environmental Impact. J. Mech. Des. 2010, 132, 091006. [Google Scholar] [CrossRef]

- Hao, L.; Raymond, D.; Strano, G.; Dadbakhsh, S. Enhancing the Sustainability of Additive Manufacturing. In Proceedings of the 5th International Conference on Responsive Manufacturing—Green Manufacturing (ICRM 2010), Ningbo, China, 11–13 January 2010; IET: Ningbo, China, 2010; pp. 390–395. [Google Scholar] [CrossRef]

- Ponche, R.; Hascoet, J.Y.; Kerbrat, O.; Mognol, P. A New Global Approach to Design for Additive Manufacturing: A Method to Obtain a Design That Meets Specifications While Optimizing a given Additive Manufacturing Process Is Presented in This Paper. Virtual Phys. Prototyp. 2012, 7, 93–105. [Google Scholar] [CrossRef]

- Aliakbari, M. Additive Manufacturing: State-of-the-Art, Capabilities, and Sample Applications with Cost Analysis. Master’s Thesis, KTH, Stockholm, Sweden, 2012. [Google Scholar]

- Campbell, I.; Bourell, D.; Gibson, I. Additive Manufacturing: Rapid Prototyping Comes of Age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef]

- Dezso, G.; Kósa, P. Roughness of plane faces produced by additive manufacturing. Ann. Fac. Eng. Hunedoara 2012, 10, 181. [Google Scholar]

- Bourhis, F.L.; Kerbrat, O.; Hascoet, J.-Y.; Mognol, P. Sustainable Manufacturing: Evaluation and Modeling of Environmental Impacts in Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2013, 69, 1927–1939. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetzis, D. A Methodological Framework for the Inclusion of Modern Additive Manufacturing into the Production Portfolio of a Focused Factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Beiker Kair, A.; Sofos, K. Additive Manufacturing and Production of Metallic Parts in the Automotive Industry: A Case Study on Technical, Economic and Environmental Sustainability Aspects. Master’s Thesis, KTH, Stockholm, Sweden, 2014. [Google Scholar]

- Giurco, D.; Littleboy, A.; Boyle, T.; Fyfe, J.; White, S. Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Kellens, K.; Renaldi, R.; Dewulf, W.; Kruth, J.; Duflou, J.R. Environmental Impact Modeling of Selective Laser Sintering Processes. Rapid Prototyp. J. 2014, 20, 459–470. [Google Scholar] [CrossRef]

- Mani, M.; Lyons, K.W.; Gupta, S.K. Sustainability Characterization for Additive Manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 419. [Google Scholar] [CrossRef]

- Kohtala, C. Addressing Sustainability in Research on Distributed Production: An Integrated Literature Review. J. Clean. Prod. 2015, 106, 654–668. [Google Scholar] [CrossRef]

- Short, D.B.; Sirinterlikci, A.; Badger, P.; Artieri, B. Environmental, Health, and Safety Issues in Rapid Prototyping. Rapid Prototyp. J. 2015, 21, 105–110. [Google Scholar] [CrossRef]

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct Digital Manufacturing: Definition, Evolution, and Sustainability Implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L. Measurement of Environmental Aspect of 3-D Printing Process Using Soft Computing Methods. Measurement 2015, 75, 210–217. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Doran, M.P.; Smullin, M.M.; Haapala, K.R. An Approach to Compare Sustainability Performance of Additive and Subtractive Manufacturing During Process Planning. In 21st Design for Manufacturing and the Life Cycle Conference, Proceedings of the 10th International Conference on Micro- and Nanosystems, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: Charlotte, NC, USA, 2016; Volume 4, p. V004T05A047. [Google Scholar] [CrossRef]

- Salamone, F.; Danza, L.; Meroni, I.; Pollastro, M. A Low-Cost Environmental Monitoring System: How to Prevent Systematic Errors in the Design Phase through the Combined Use of Additive Manufacturing and Thermographic Techniques. Sensors 2017, 17, 828. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; LeBouf, R.F.; Yi, J.; Ham, J.; Nurkewicz, T.; Schwegler-Berry, D.E.; Chen, B.T.; Wells, J.R.; Duling, M.G.; Lawrence, R.B.; et al. Characterization of Chemical Contaminants Generated by a Desktop Fused Deposition Modeling 3-Dimensional Printer. J. Occup. Environ. Hyg. 2017, 14, 540–550. [Google Scholar] [CrossRef] [PubMed]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental Impact of Additive Manufacturing Processes: Does AM Contribute to a More Sustainable Way of Part Manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Tateno, T.; Kondoh, S. Environmental Load Reduction by Customization for Reuse with Additive Manufacturing. Procedia CIRP 2017, 61, 241–244. [Google Scholar] [CrossRef]

- Jin, Y.; Du, J.; He, Y. Optimization of Process Planning for Reducing Material Consumption in Additive Manufacturing. J. Manuf. Syst. 2017, 44, 65–78. [Google Scholar] [CrossRef]

- Peng, S.; Li, T.; Wang, X.; Dong, M.; Liu, Z.; Shi, J.; Zhang, H. Toward a Sustainable Impeller Production: Environmental Impact Comparison of Different Impeller Manufacturing Methods: Environmental Comparison of Impeller Manufacturing. J. Ind. Ecol. 2017, 21, S216–S229. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Trovalusci, F.; Guarino, S.; Venettacci, S. Environmental and Economic Analysis of FDM, SLS and MJF Additive Manufacturing Technologies. Materials 2019, 12, 4161. [Google Scholar] [CrossRef]

- Melugiri-Shankaramurthy, B.; Sargam, Y.; Zhang, X.; Sun, W.; Wang, K.; Qin, H. Evaluation of Cement Paste Containing Recycled Stainless Steel Powder for Sustainable Additive Manufacturing. Constr. Build. Mater. 2019, 227, 116696. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Brabazon, D. XPS, XRD, and SEM Characterization of the Virgin and Recycled Metallic Powders for 3D Printing Applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 591, 012016. [Google Scholar] [CrossRef]

- Priarone, P.C.; Pagone, E.; Martina, F.; Catalano, A.R.; Settineri, L. Multi-Criteria Environmental and Economic Impact Assessment of Wire Arc Additive Manufacturing. CIRP Ann. 2020, 69, 37–40. [Google Scholar] [CrossRef]

- Serres, N.; Tidu, D.; Sankare, S.; Hlawka, F. Environmental Comparison of MESO-CLAD® Process and Conventional Machining Implementing Life Cycle Assessment. J. Clean. Prod. 2011, 19, 1117–1124. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing Environmental Impacts of Additive Manufacturing vs Traditional Machining via Life-Cycle Assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef]

- Burkhart, M.; Aurich, J.C. Framework to Predict the Environmental Impact of Additive Manufacturing in the Life Cycle of a Commercial Vehicle. Procedia CIRP 2015, 29, 408–413. [Google Scholar] [CrossRef]

- Oberti, I.; Plantamura, F. Is 3D Printed House Sustainable? In Proceedings of the International Conference CISBAT 2015 Future Buildings and Districts Sustainability from Nano to Urban Scale, Lausanne, Switzerland, 9–11 September 2015. [Google Scholar] [CrossRef]

- Malshe, H.; Nagarajan, H.; Pan, Y.; Haapala, K. Profile of Sustainability in Additive Manufacturing and Environmental Assessment of a Novel Stereolithography Process. In Materials; Biomanufacturing; Properties, Applications and Systems; Sustainable Manufacturing; American Society of Mechanical Engineers: Charlotte, NC, USA, 2015; Volume 2, p. V002T05A012. [Google Scholar] [CrossRef]

- Meyer, V.B. Prototyping the Environmental Impacts of 3D Printing: Claims and Realities of Additive Manufacturing. Master’s Thesis, Fordham University, New York, NY, USA, 2015. [Google Scholar]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of Turbine Blades by Laser Direct Deposition with Its Energy and Environmental Impact Analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Tang, Y.; Mak, K.; Zhao, Y.F. A Framework to Reduce Product Environmental Impact through Design Optimization for Additive Manufacturing. J. Clean. Prod. 2016, 137, 1560–1572. [Google Scholar] [CrossRef]

- Paris, H.; Mokhtarian, H.; Coatanéa, E.; Museau, M.; Ituarte, I.F. Comparative Environmental Impacts of Additive and Subtractive Manufacturing Technologies. CIRP Ann. 2016, 65, 29–32. [Google Scholar] [CrossRef]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and Emissions Saving Potential of Additive Manufacturing: The Case of Lightweight Aircraft Components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef]

- Mami, F.; Revéret, J.-P.; Fallaha, S.; Margni, M. Evaluating Eco-Efficiency of 3D Printing in the Aeronautic Industry. J. Ind. Ecol. 2017, 21, S37–S48. [Google Scholar] [CrossRef]

- Yang, S.; Talekar, T.; Sulthan, M.A.; Zhao, Y.F. A Generic Sustainability Assessment Model towards Consolidated Parts Fabricated by Additive Manufacturing Process. Procedia Manuf. 2017, 10, 831–844. [Google Scholar] [CrossRef]

- Bours, J.; Adzima, B.; Gladwin, S.; Cabral, J.; Mau, S. Addressing Hazardous Implications of Additive Manufacturing: Complementing Life Cycle Assessment with a Framework for Evaluating Direct Human Health and Environmental Impacts: Hazard Implications of 3D Printing Materials. J. Ind. Ecol. 2017, 21, S25–S36. [Google Scholar] [CrossRef]

- Mrazovic, N.; Mocibob, D.; Lepech, M.; Fischer, M. Assessment of Additive and Conventional Manufacturing: Case Studies from the AEC Industry. Proc. Int. Struct. Eng. Constr. 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Baumers, M.; Duflou, J.R.; Flanagan, W.; Gutowski, T.G.; Kellens, K.; Lifset, R. Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing. J. Ind. Ecol. 2017, 21, 9–14. [Google Scholar] [CrossRef]

- Kafara, M.; Süchting, M.; Kemnitzer, J.; Westermann, H.-H.; Steinhilper, R. Comparative Life Cycle Assessment of Conventional and Additive Manufacturing in Mold Core Making for CFRP Production. Procedia Manuf. 2017, 8, 223–230. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications: Environmental Dimensions of Additive Manufacturing. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. Environmental Impact Assessment of an Innovative Strategy Based on an Additive and Subtractive Manufacturing Combination. J. Clean. Prod. 2017, 164, 508–523. [Google Scholar] [CrossRef]

- Barros, K.D.S. Identification of the Environmental Impacts Contributors Related to the Use of Additive Manufacturing Technologies. Ph.D. Thesis, Université Grenoble Alpes (ComUE), Saint-Martin-d’Hères, France, 2017. [Google Scholar]

- Guarino, S.; Ucciardello, N.; Venettacci, S.; Genna, S. Life Cycle Assessment of a New Graphene-Based Electrodeposition Process on Copper Components. J. Clean. Prod. 2017, 165, 520–529. [Google Scholar] [CrossRef]

- da Silva Barros, K.; Zwolinski, P.; Mansur, A.I. Where do the environmental impacts of Additive Manufacturing come from? Case study of the use of 3d-printing to print orthotic insoles. In 12ème Congrès International de Génie Industriel (CIGI 2017); HAL Open Science: Compiegne, France, 2017. [Google Scholar]

- Nagarajan, H.P.N.; Haapala, K.R. Characterizing the Influence of Resource-Energy-Exergy Factors on the Environmental Performance of Additive Manufacturing Systems. J. Manuf. Syst. 2018, 48, 87–96. [Google Scholar] [CrossRef]

- Yosofi, M.; Kerbrat, O.; Mognol, P. Energy and Material Flow Modelling of Additive Manufacturing Processes. Virtual Phys. Prototyp. 2018, 13, 83–96. [Google Scholar] [CrossRef]

- Maciel, V.G.; Wales, D.J.; Seferin, M.; Sans, V. Environmental performance of 3D-Printing polymerizable ionic liquids. J. Clean. Prod. 2019, 214, 29–40. [Google Scholar] [CrossRef]

- Yosofi, M.; Kerbrat, O.; Mognol, P. Framework to combine technical, economic and environmental points of view of additive manufacturing processes. Procedia CIRP 2018, 69, 118–123. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Bekker, A.C.M.; Verlinden, J.C. Life Cycle Assessment of Wire + Arc Additive Manufacturing Compared to Green Sand Casting and CNC Milling in Stainless Steel. J. Clean. Prod. 2018, 177, 438–447. [Google Scholar] [CrossRef]

- Garcia, F.L.; Moris, V.A.d.S.; Nunes, A.O.; Silva, D.A.L. Environmental Performance of Additive Manufacturing Process—An Overview. Rapid Prototyp. J. 2018, 24, 1166–1177. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, F.; Huang, Y. Research Needs and Recommendations on Environmental Implications of Additive Manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef]

- Yosofi, M.; Kerbrat, O.; Mognol, P. Additive Manufacturing Processes from an Environmental Point of View: A New Methodology for Combining Technical, Economic, and Environmental Predictive Models. Int. J. Adv. Manuf. Technol. 2019, 102, 4073–4085. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, Z.; Li, T.; Cong, W.; Zhang, H.-C. Emergy-Based Life-Cycle Assessment (Em-LCA) for Sustainability Assessment: A Case Study of Laser Additive Manufacturing versus CNC Machining. Int. J. Adv. Manuf. Technol. 2019, 102, 4109–4120. [Google Scholar] [CrossRef]

- Böckin, D.; Tillman, A.-M. Environmental Assessment of Additive Manufacturing in the Automotive Industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Faludi, J.; Van Sice, C.M.; Shi, Y.; Bower, J.; Brooks, O.M.K. Novel Materials Can Radically Improve Whole-System Environmental Impacts of Additive Manufacturing. J. Clean. Prod. 2019, 212, 1580–1590. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Ukar, O.; Ostolaza, M.; Mugica, A. Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling. Metals 2020, 10, 261. [Google Scholar] [CrossRef]

- Shi, Y.; Faludi, J. Using Life Cycle Assessment to Determine If High Utilization Is the Dominant Force for Sustainable Polymer Additive Manufacturing. Addit. Manuf. 2020, 35, 101307. [Google Scholar] [CrossRef]

- Van Sice, C.; Faludi, J. Comparing Environmental Impacts of Metal Additive Manufacturing to Conventional Manufacturing. Proc. Des. Soc. 2021, 1, 671–680. [Google Scholar] [CrossRef]

- Lyons, R.; Newell, A.; Ghadimi, P.; Papakostas, N. Environmental Impacts of Conventional and Additive Manufacturing for the Production of Ti-6Al-4V Knee Implant: A Life Cycle Approach. Int. J. Adv. Manuf. Technol. 2021, 112, 787–801. [Google Scholar] [CrossRef]

- Dudkowiak, A.; Dostatni, E.; Rojek, I.; Mikołajewski, D. The Environmental Analysis of a Product Manufactured with the Use of an Additive Technology. In Advances in Manufacturing III; Trojanowska, J., Kujawińska, A., Machado, J., Pavlenko, I., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 76–89. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Di Bona, G.; Silvestri, C. Circular economy strategy of reusing olive mill wastewater in the ceramic industry: How the plant location can benefit environmental and economic performance. J. Clean. Prod. 2021, 326, 129388. [Google Scholar] [CrossRef]

- Le Bourhis, F.; Kerbrat, O.; Dembinski, L.; Hascoet, J.-Y.; Mognol, P. Predictive Model for Environmental Assessment in Additive Manufacturing Process. Procedia CIRP 2014, 15, 26–31. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.A.; Harrysson, O.L.A. Additive Manufacturing–Integrated Hybrid Manufacturing and Subtractive Processes: Economic Model and Analysis. Int. J. Comput. Integr. Manuf. 2016, 29, 473–488. [Google Scholar] [CrossRef]

- Kerbrat, O.; Bourhis, F.L.; Mognol, P.; Hascoët, J. Environmental Performance Modeling for Additive Manufacturing Processes. Int. J. Rapid Manuf. 2015, 5, 339–348. [Google Scholar] [CrossRef]

- Panda, B.N.; Garg, A.; Shankhwar, K. Empirical Investigation of Environmental Characteristics of 3-D Additive Manufacturing Process Based on Slice Thickness and Part Orientation. Measurement 2016, 86, 293–300. [Google Scholar] [CrossRef]

- Priarone, P.C.; Ingarao, G. Towards Criteria for Sustainable Process Selection: On the Modelling of Pure Subtractive versus Additive/Subtractive Integrated Manufacturing Approaches. J. Clean. Prod. 2017, 144, 57–68. [Google Scholar] [CrossRef]

- Peng, T.; Sun, W. Energy Modelling for FDM 3D Printing from a Life Cycle Perspective. Inter. J. Manuf. Res. 2017, 12, 83–98. [Google Scholar] [CrossRef]

- Zhang, H.; Nagel, J.K.; Al-Qas, A.; Gibbons, E.; Lee, J.J.-Y. Additive Manufacturing with Bioinspired Sustainable Product Design: A Conceptual Model. Procedia Manuf. 2018, 26, 880–891. [Google Scholar] [CrossRef]

- Ingarao, G.; Priarone, P.C.; Deng, Y.; Paraskevas, D. Environmental Modelling of Aluminium Based Components Manufacturing Routes: Additive Manufacturing versus Machining versus Forming. J. Clean. Prod. 2018, 176, 261–275. [Google Scholar] [CrossRef]

- Sreenivasan, R.; Goel, A.; Bourell, D.L. Sustainability Issues in Laser-Based Additive Manufacturing. Phys. Procedia 2010, 5, 81–90. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Bourell, D.L.; Sreenivasan, R.; Hague, R. Sustainability of Additive Manufacturing: Measuring the Energy Consumption of the Laser Sintering Process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 2228–2239. [Google Scholar] [CrossRef]

- Xu, X.; Meteyer, S.; Perry, N.; Zhao, Y.F. Energy Consumption Model of Binder-Jetting Additive Manufacturing Processes. Int. J. Prod. Res. 2015, 53, 7005–7015. [Google Scholar] [CrossRef]

- Watson, J.K.; Taminger, K.M.B. A Decision-Support Model for Selecting Additive Manufacturing versus Subtractive Manufacturing Based on Energy Consumption. J. Clean. Prod. 2018, 176, 1316–1322. [Google Scholar] [CrossRef]

- Despeisse, M.; Ford, S. The role of additive manufacturing in improving resource efficiency and sustainability. In IFIP International Conference on Advances in Production Management Systems; Springer: Cham, Switzerland, 2015; pp. 129–136. [Google Scholar]

- Hapuwatte, B.; Seevers, K.D.; Badurdeen, F.; Jawahir, I.S. Total Life Cycle Sustainability Analysis of Additively Manufactured Products. Procedia CIRP 2016, 48, 376–381. [Google Scholar] [CrossRef]

- Diegel, O.; Kristav, P.; Motte, D.; Kianian, B. Additive Manufacturing and Its Effect on Sustainable Design. In Handbook of Sustainability in Additive Manufacturing; Muthu, S.S., Savalani, M.M., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer: Singapore, 2016; pp. 73–99. [Google Scholar] [CrossRef]

- Angioletti, C.M.; Sisca, F.; Taisch, M.; Rocca, R. Additive Manufacturing as an Opportunity for Supporting Sustainability through Implementation of Circular Economies. In Proceedings of the 21st Summer School Francesco Turco 2016; AIDI-Italian Association of Industrial Operations Professors: Politecnico Di Milano, Italy, 2016; p. 25. [Google Scholar]

- Kerbrat, O.; Bourhis, F.L.; Mognol, P.; Hascoët, J.Y. Environmental impact assessment studies in additive manufacturing. In Handbook of Sustainability in Additive Manufacturing; Springer: Singapore, 2016; pp. 31–63. [Google Scholar]

- Faludi, J.; Baumers, M.; Maskery, I.; Hague, R. Environmental Impacts of Selective Laser Melting: Do Printer, Powder, Or Power Dominate? J. Ind. Ecol. 2017, 21, S144–S156. [Google Scholar] [CrossRef]

- Freitas, D.; Almeida, H.A.; Bártolo, H.; Bártolo, P.J. Sustainability in Extrusion-Based Additive Manufacturing Technologies. Prog. Addit. Manuf. 2016, 1, 65–78. [Google Scholar] [CrossRef]

- Walachowicz, F.; Bernsdorf, I.; Papenfuss, U.; Zeller, C.; Graichen, A.; Navrotsky, V.; Rajvanshi, N.; Kiener, C. Comparative Energy, Resource and Recycling Lifecycle Analysis of the Industrial Repair Process of Gas Turbine Burners Using Conventional Machining and Additive Manufacturing: Additive Manufacturing Repair LCA Study. J. Ind. Ecol. 2017, 21, S203–S215. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Pan, Y.; Sun, Z. Energy Consumption Modeling of Stereolithography-Based Additive Manufacturing Toward Environmental Sustainability. J. Ind. Ecol. 2017, 21, S168–S178. [Google Scholar] [CrossRef]

- Huang, R.; Riddle, M.E.; Graziano, D.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Environmental and Economic Implications of Distributed Additive Manufacturing: The Case of Injection Mold Tooling. J. Ind. Ecol. 2017, 21, S130–S143. [Google Scholar] [CrossRef]

- Nagarajan, H.P.N.; Haapala, K.R. Environmental Performance Evaluation of Direct Metal Laser Sintering through Exergy Analysis. Procedia Manuf. 2017, 10, 957–967. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L. Evaluation of Environmental Sustainability for Additive Manufacturing Batch Production. In Additive Manufacturing; Materials; American Society of Mechanical Engineers: Los Angeles, CA, USA, 2017; Volume 2, p. V002T01A038. [Google Scholar] [CrossRef]

- Verma, A.; Rai, R. Sustainability-Induced Dual-Level Optimization of Additive Manufacturing Process. Int. J. Adv. Manuf. Technol. 2017, 88, 1945–1959. [Google Scholar] [CrossRef]

- Despeisse, M.; Yang, M.; Evans, S.; Ford, S.; Minshall, T. Sustainable Value Roadmapping Framework for Additive Manufacturing. Procedia CIRP 2017, 61, 594–599. [Google Scholar] [CrossRef]

- Villamil, C.; Nylander, J.; Hallstedt, S.I.; Schulte, J.; Watz, M. Additive Manufacturing from a Strategic Sustainability Perspective. In Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 1381–1392. [Google Scholar] [CrossRef]

- Ma, J.; Harstvedt, J.D.; Dunaway, D.; Bian, L.; Jaradat, R. An exploratory investigation of Additively Manufactured Product life cycle sustainability assessment. J. Clean. Prod. 2018, 192, 55–70. [Google Scholar] [CrossRef]

- Verhoef, L.A.; Budde, B.W.; Chockalingam, C.; García Nodar, B.; van Wijk, A.J.M. The Effect of Additive Manufacturing on Global Energy Demand: An Assessment Using a Bottom-up Approach. Energy Policy 2018, 112, 349–360. [Google Scholar] [CrossRef]

- Priarone, P.C.; Ingarao, G.; Lunetto, V.; Di Lorenzo, R.; Settineri, L. The Role of Redesign for Additive Manufacturing on the Process Environmental Performance. Procedia CIRP 2018, 69, 124–129. [Google Scholar] [CrossRef]

- Pan, G.-T.; Chong, S.; Tsai, H.-J.; Lu, W.-H.; Yang, T.C.-K. The Effects of Iron, Silicon, Chromium, and Aluminum Additions on the Physical and Mechanical Properties of Recycled 3D Printing Filaments. Adv. Polym. Technol. 2018, 37, 1176–1184. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Optimization of Process Planning for Reducing Material Waste in Extrusion Based Additive Manufacturing. Robot Comput.-Integr. Manuf. 2019, 59, 317–325. [Google Scholar] [CrossRef]

- Niaki, M.K.; Torabi, S.A.; Nonino, F. Why Manufacturers Adopt Additive Manufacturing Technologies: The Role of Sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Sardon, H.; Long, T.; Le Ferrand, H. Sustainable Additive Manufacturing of Plastics. ACS Sustain. Chem. Eng. 2022, 10, 1983–1985. [Google Scholar] [CrossRef]

- Silvestri, C.; Silvestri, L.; Forcina, A.; Di Bona, G.; Falcone, D. Green chemistry contribution towards more equitable global sustainability and greater circular economy: A systematic literature review. J. Clean. Prod. 2021, 294, 126137. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gopal, M.; Lemu, H.G.; Gutema, E.M. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability 2023, 15, 504. https://doi.org/10.3390/su15010504

Gopal M, Lemu HG, Gutema EM. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability. 2023; 15(1):504. https://doi.org/10.3390/su15010504

Chicago/Turabian StyleGopal, Mahesh, Hirpa G. Lemu, and Endalkachew Mosisa Gutema. 2023. "Sustainable Additive Manufacturing and Environmental Implications: Literature Review" Sustainability 15, no. 1: 504. https://doi.org/10.3390/su15010504

APA StyleGopal, M., Lemu, H. G., & Gutema, E. M. (2023). Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability, 15(1), 504. https://doi.org/10.3390/su15010504