Heat Transfer Studies on Solar Parabolic trough Collector Using Corrugated Tube Receiver with Conical Strip Inserts

Abstract

1. Introduction

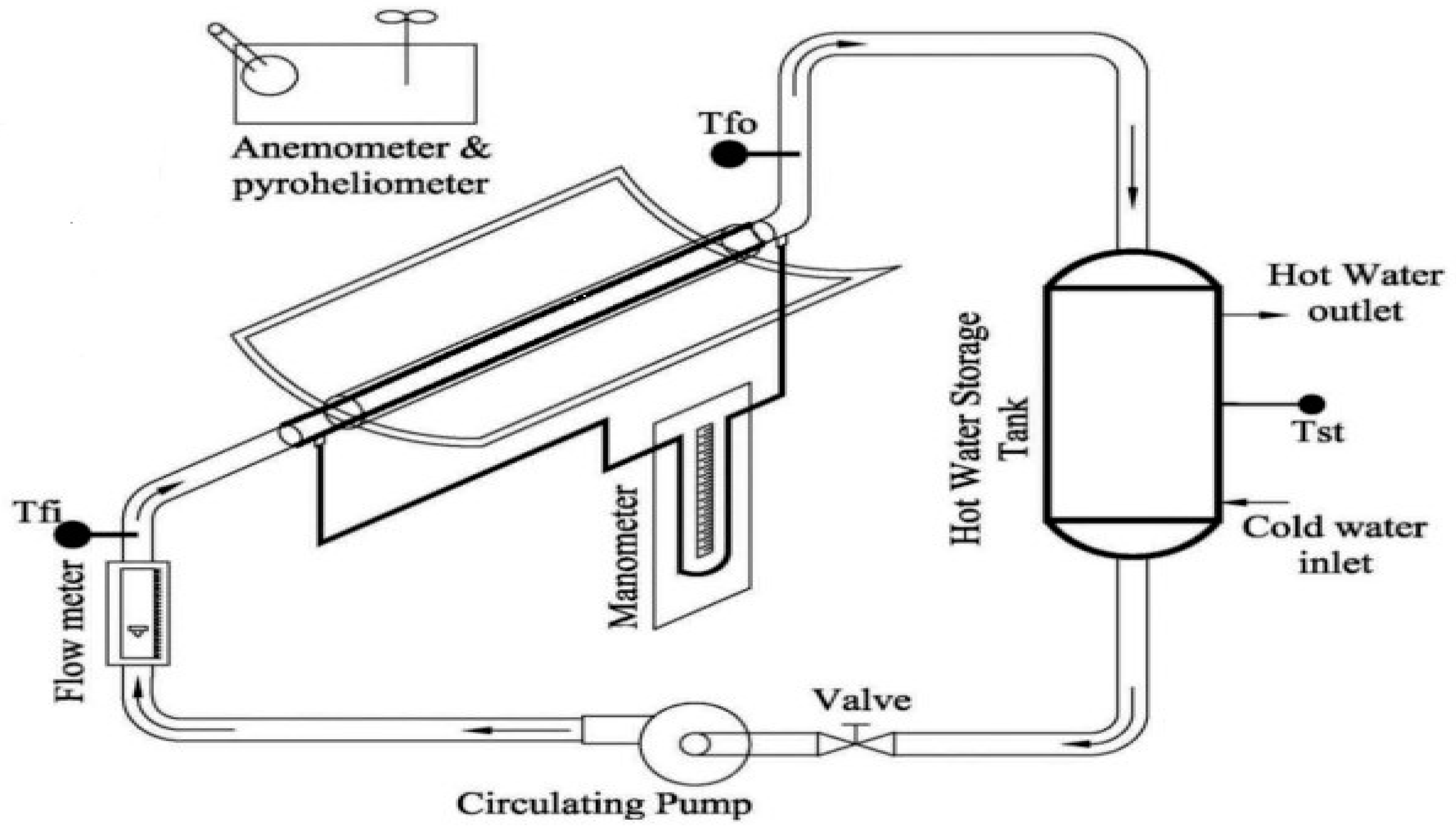

2. Experimental Setup

3. Uncertainty Analysis

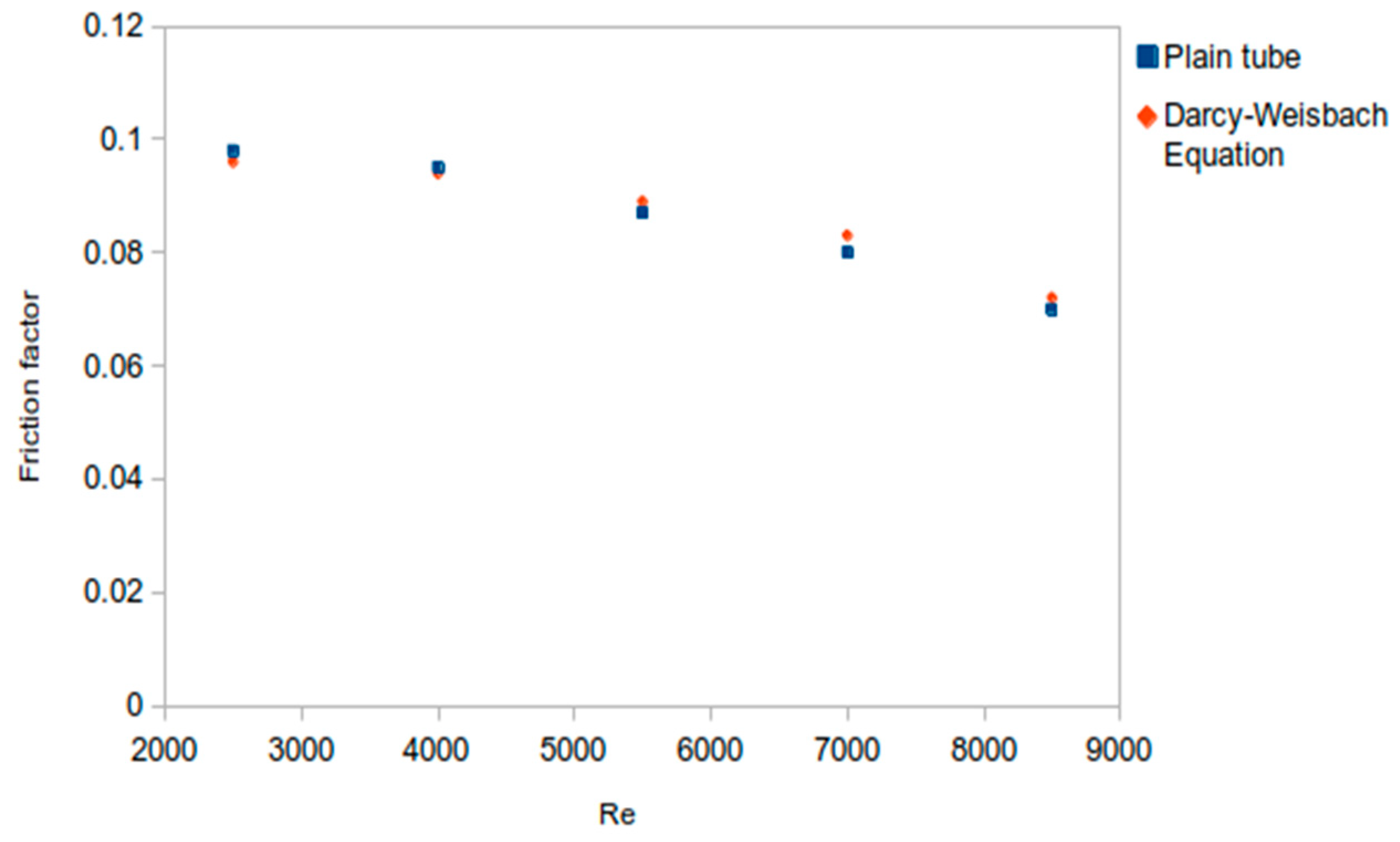

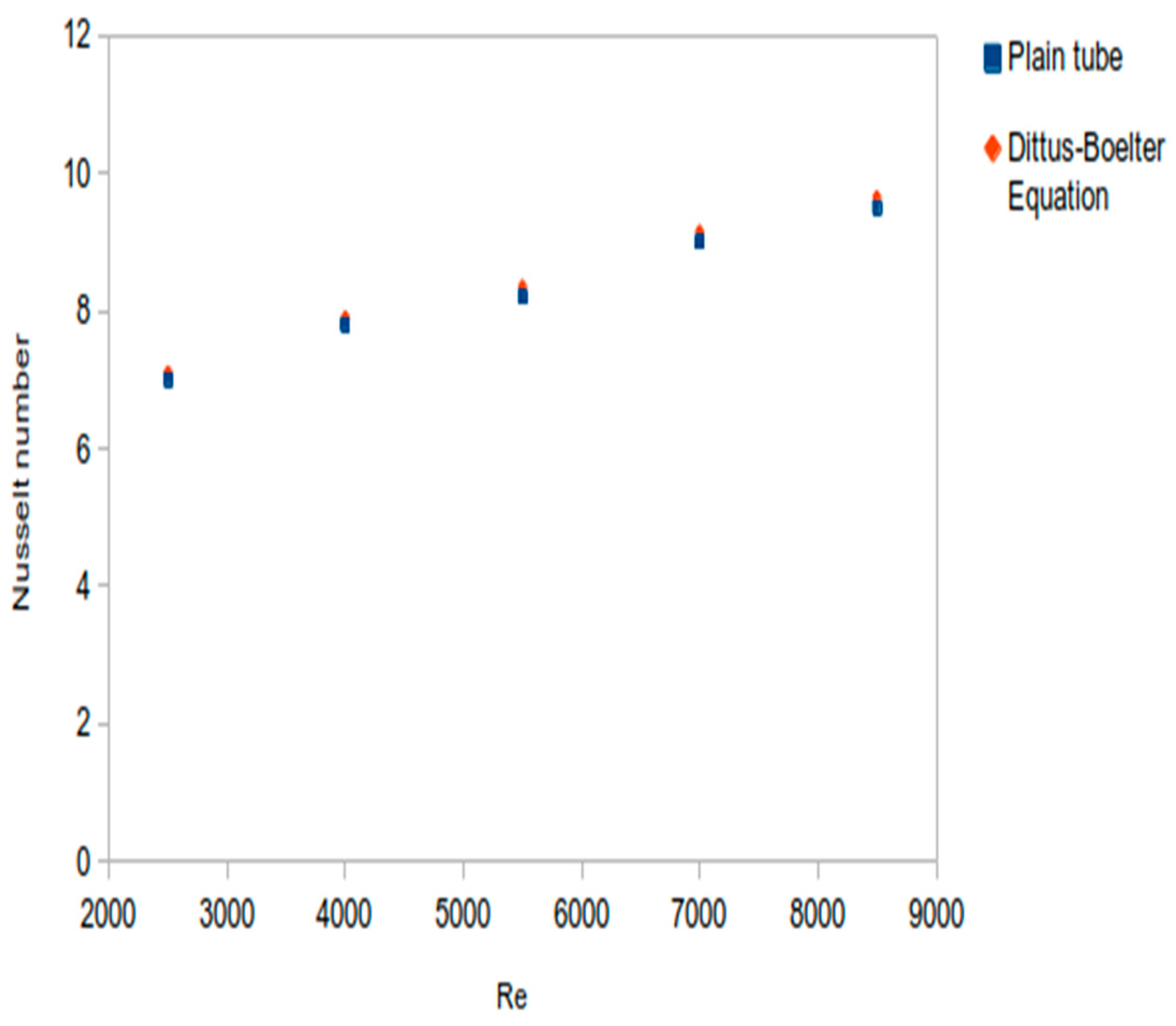

4. Heat Transfer and Pressure Drop Calculations

5. Results and Discussion

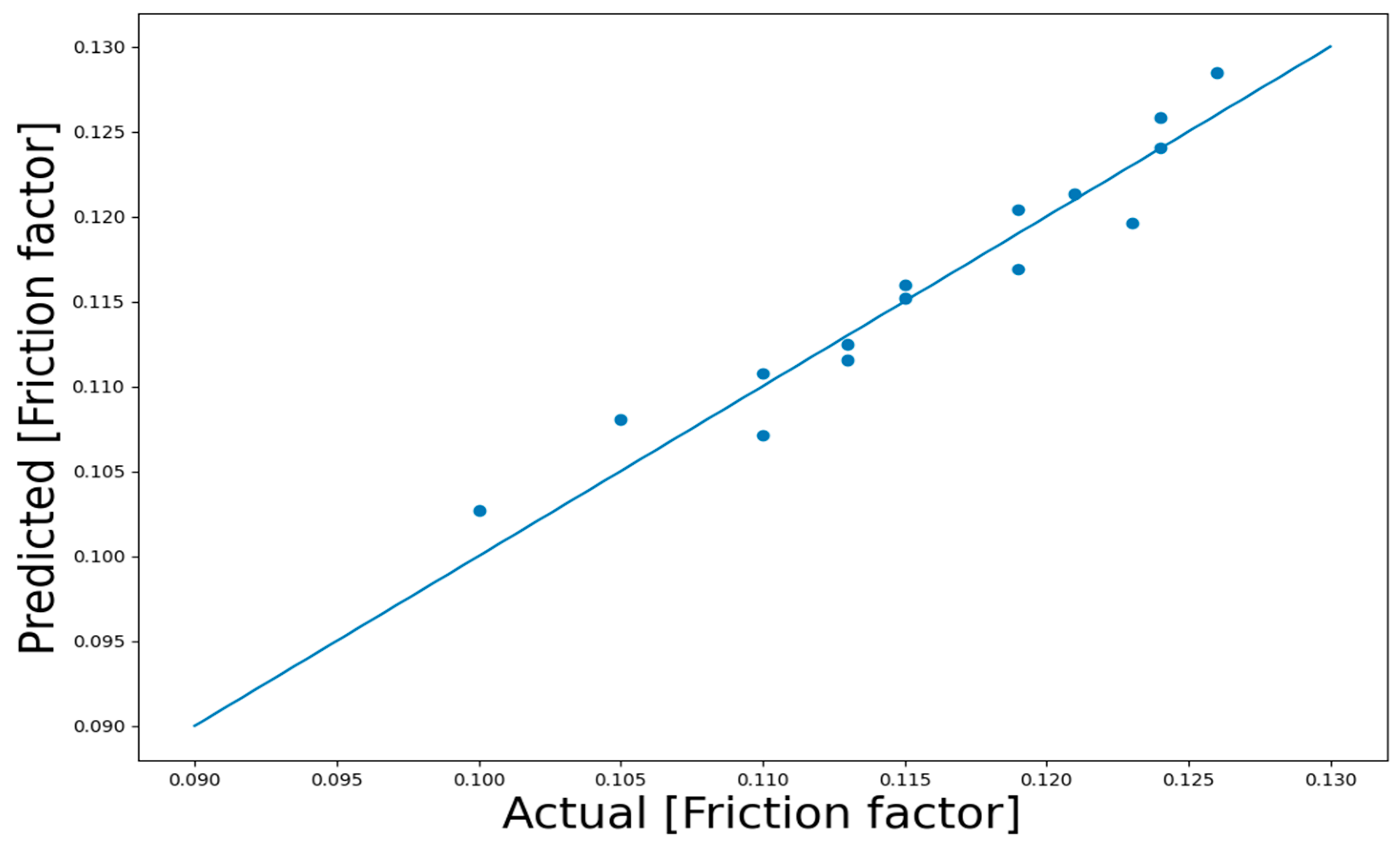

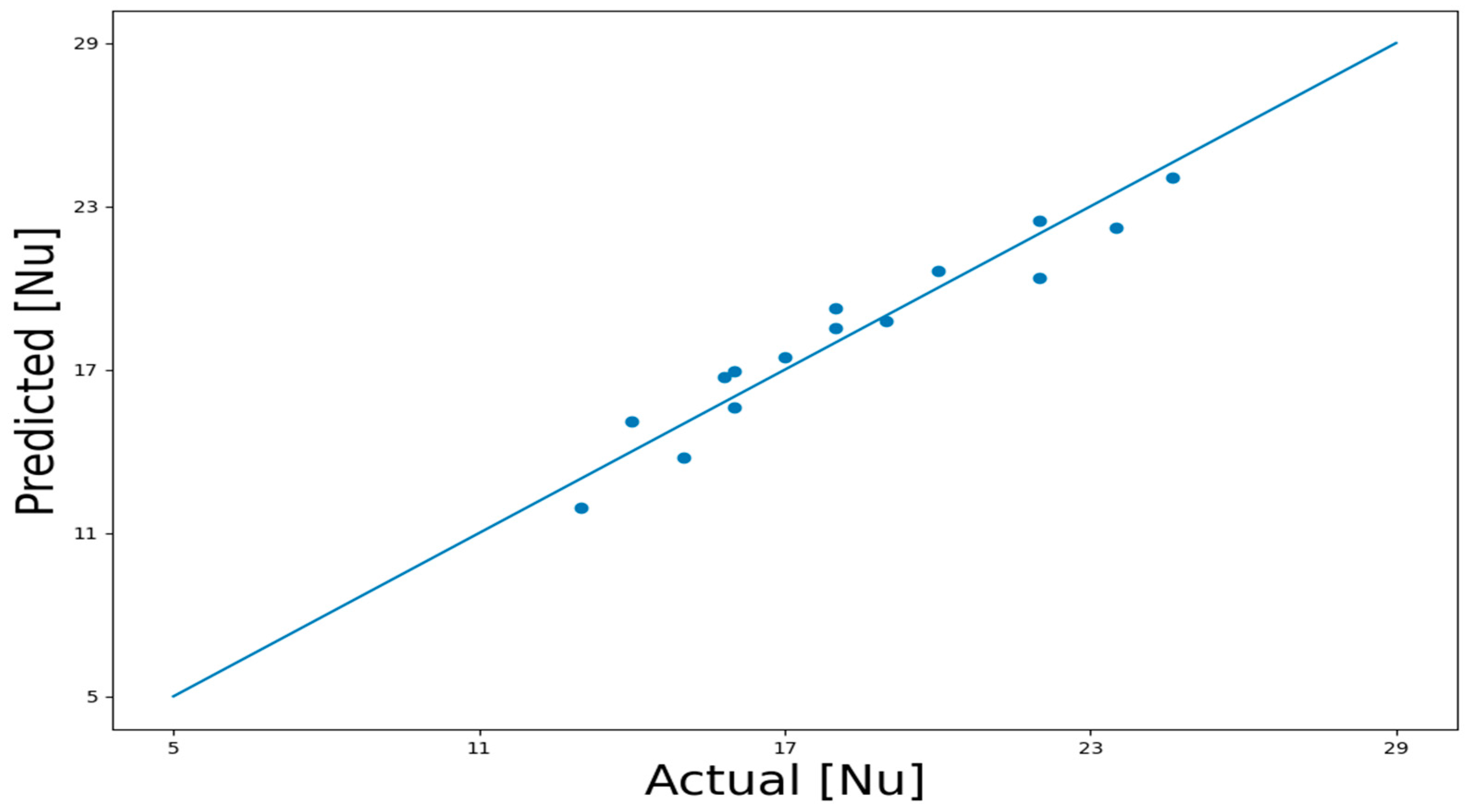

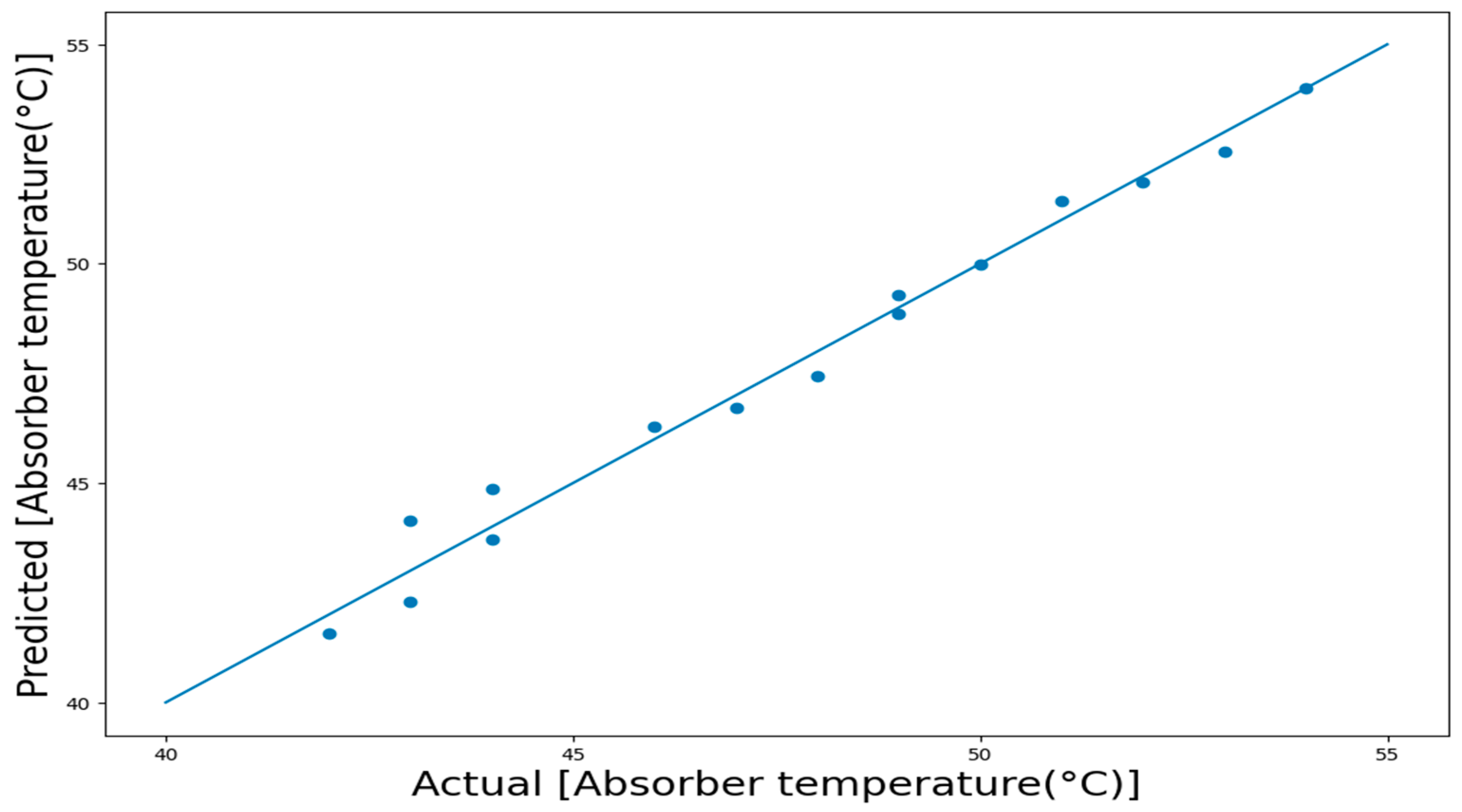

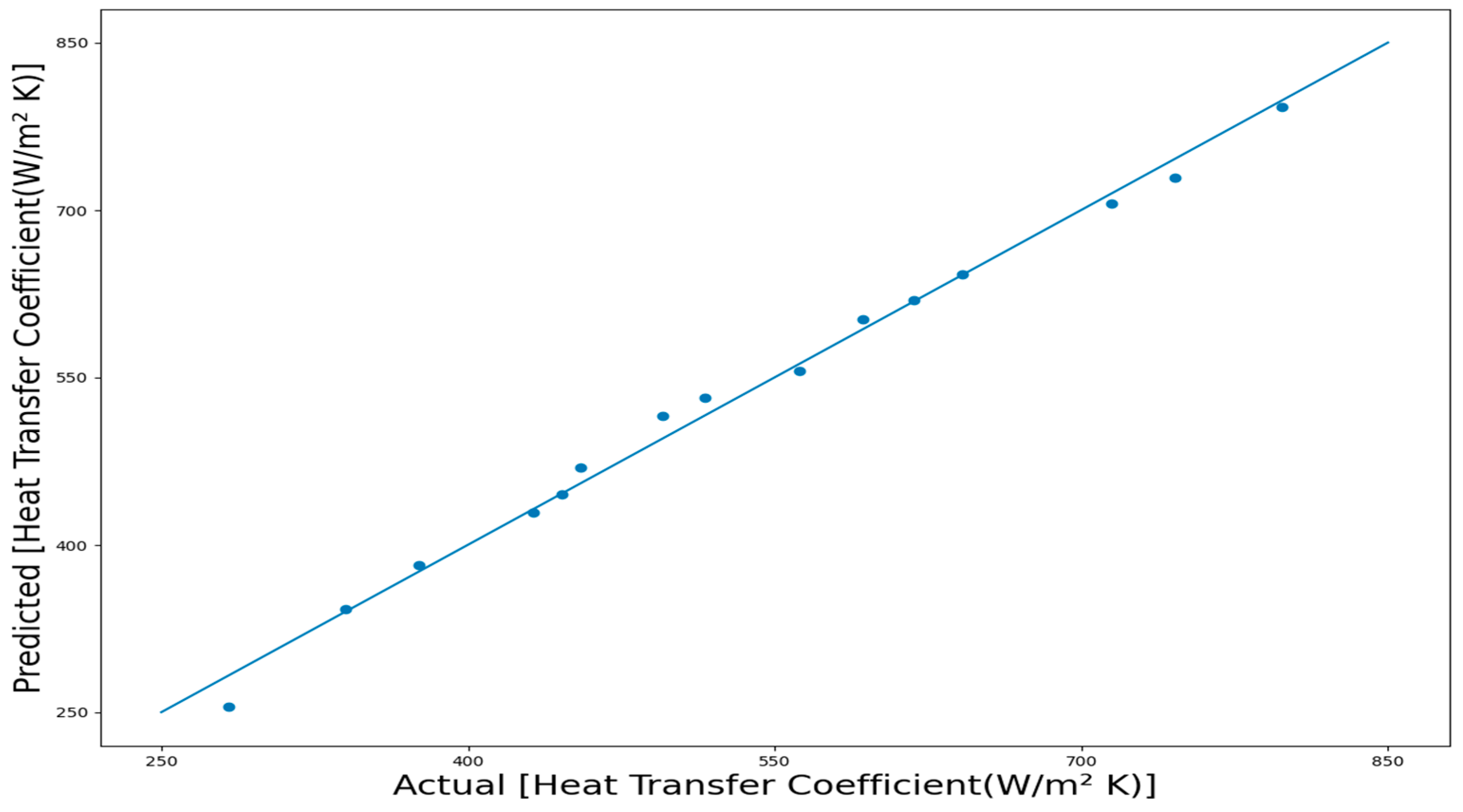

6. Linear Regression Model (Scikit-Learn)

7. Conclusions

- Experiments were carried out on a solar PTC using a corrugated tube absorber with conical strip inserts; the following conclusions may be made.

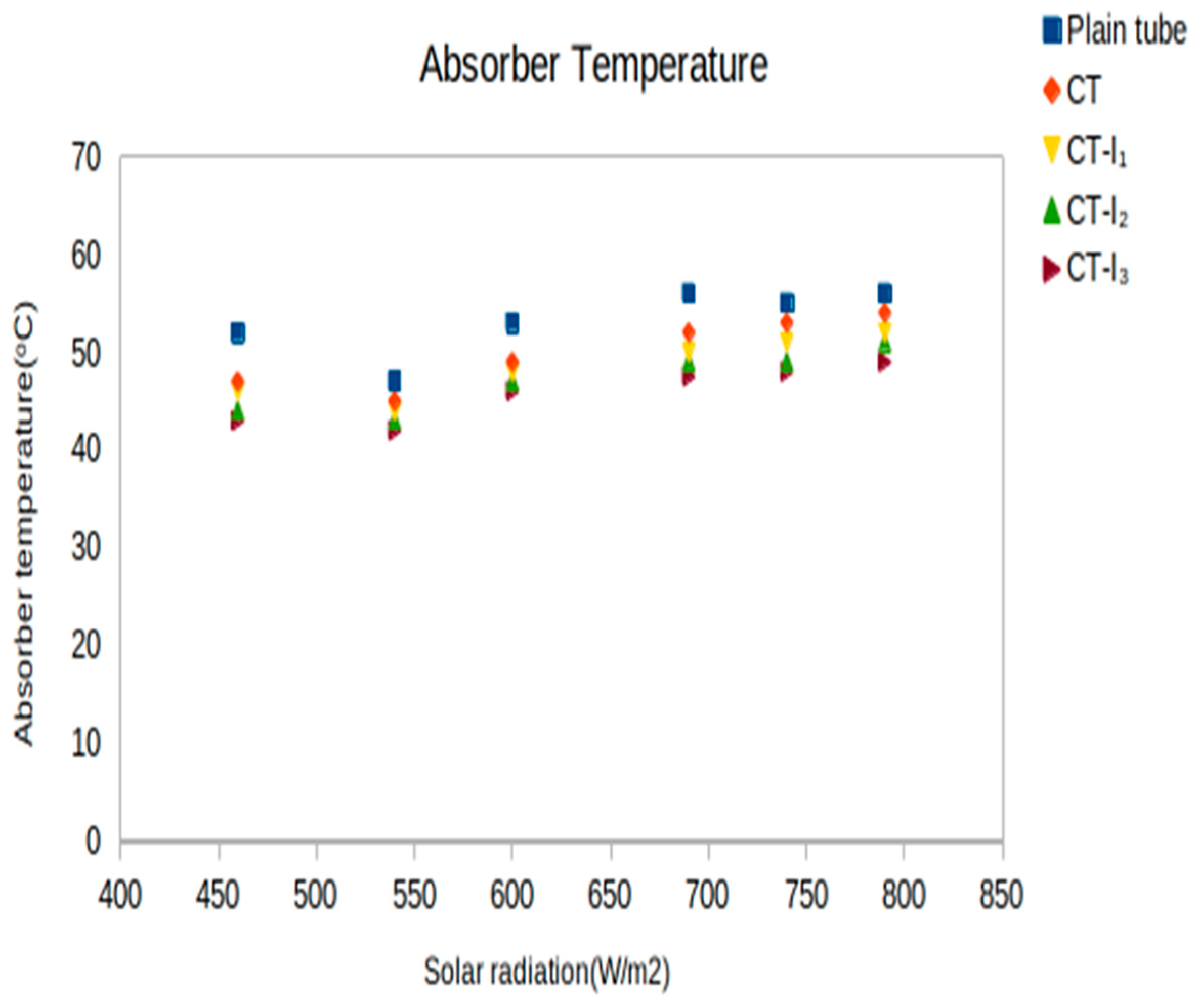

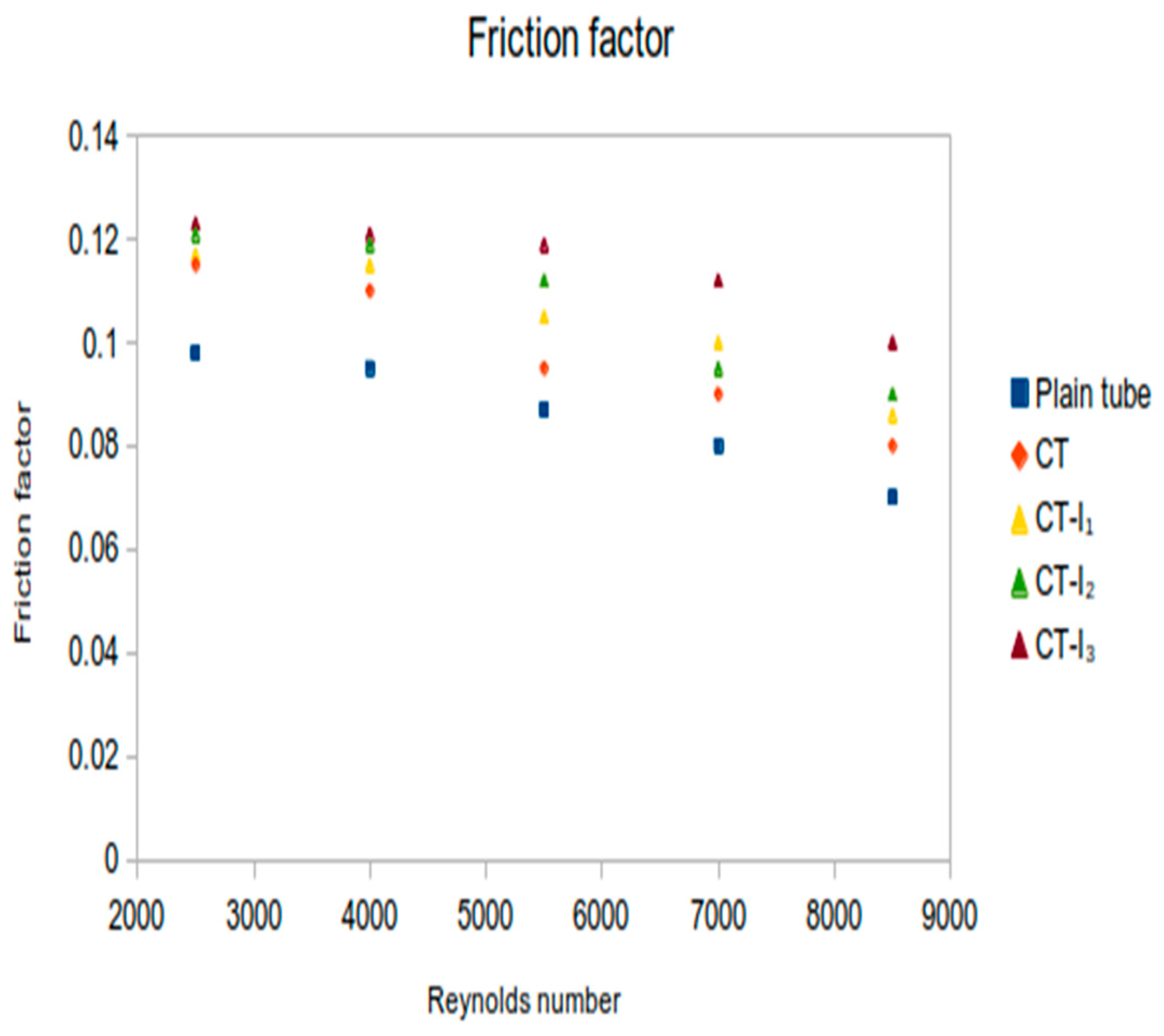

- The highest thermal performance, friction factor value, convective heat transfer and Nusselt number value were achieved using a combination of CT with I3. The highest friction factor value was achieved using CT-I3; it was 38% higher compared to that obtained using a plain tube and 25% higher compared to that with CT without insert. The Nusselt value increased to a maximum of 177% compared to that of the plain tube and 78% compared to the CT.

- The maximum convective heat transfer coefficient value of CT-I3 was 798W/m2K, i.e.,84.72% higher than that obtained with the plain tube and 41.23% higher compared to the CT without an insert.

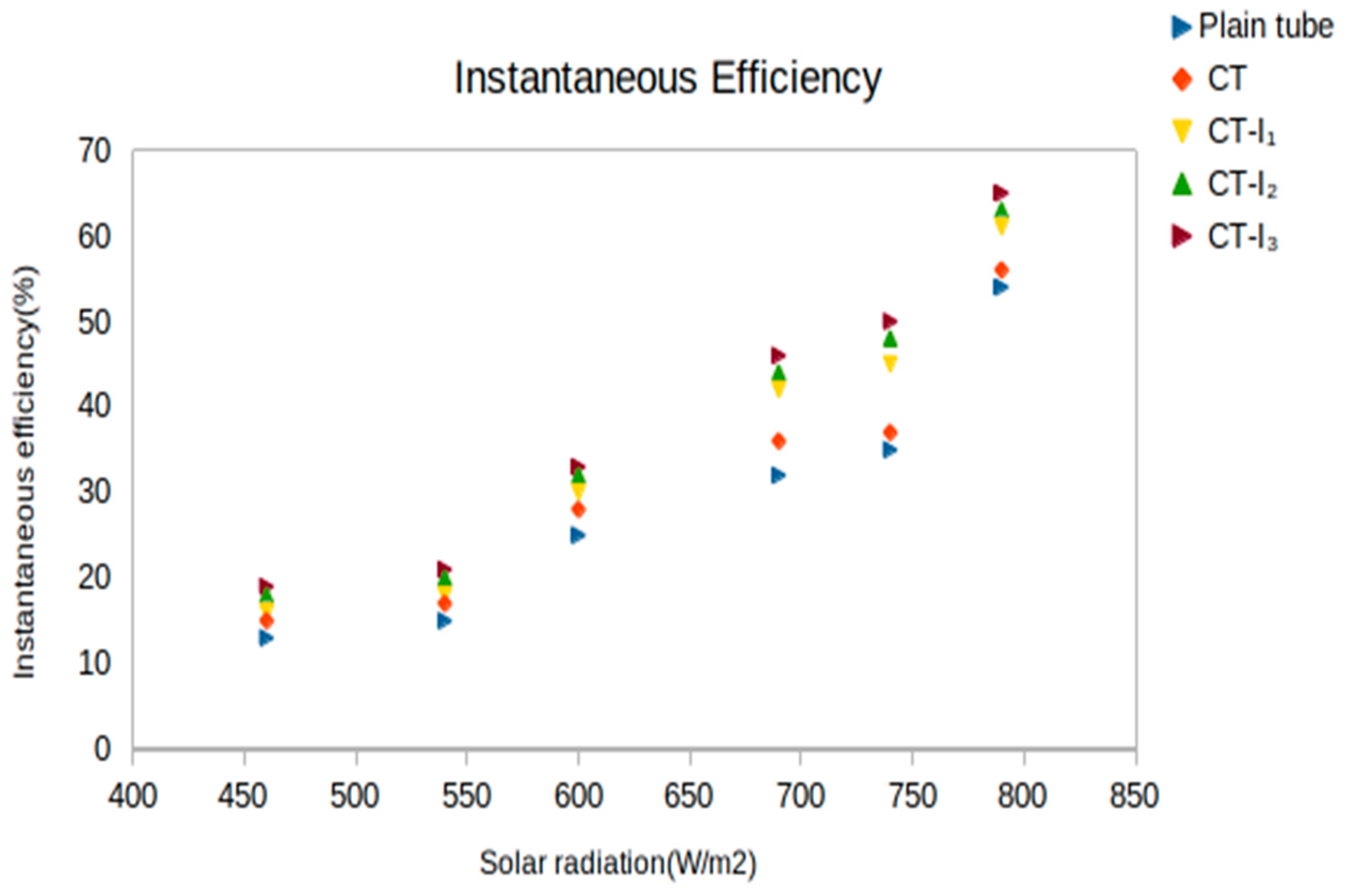

- The instantaneous efficiency of CT with I3was 26.92% higher than that obtained with the plain tube and 13.79% compared to the CT under the same working conditions.

- A maximum thermal efficiency of 59% was achieved using CT with I3, while 55% was achieved while using the plain tube.

- The best results were achieved using the combination of corrugated tube CT (hc = 2 mm, pi = 8 mm) and conical strip insert I3 (20 mm).

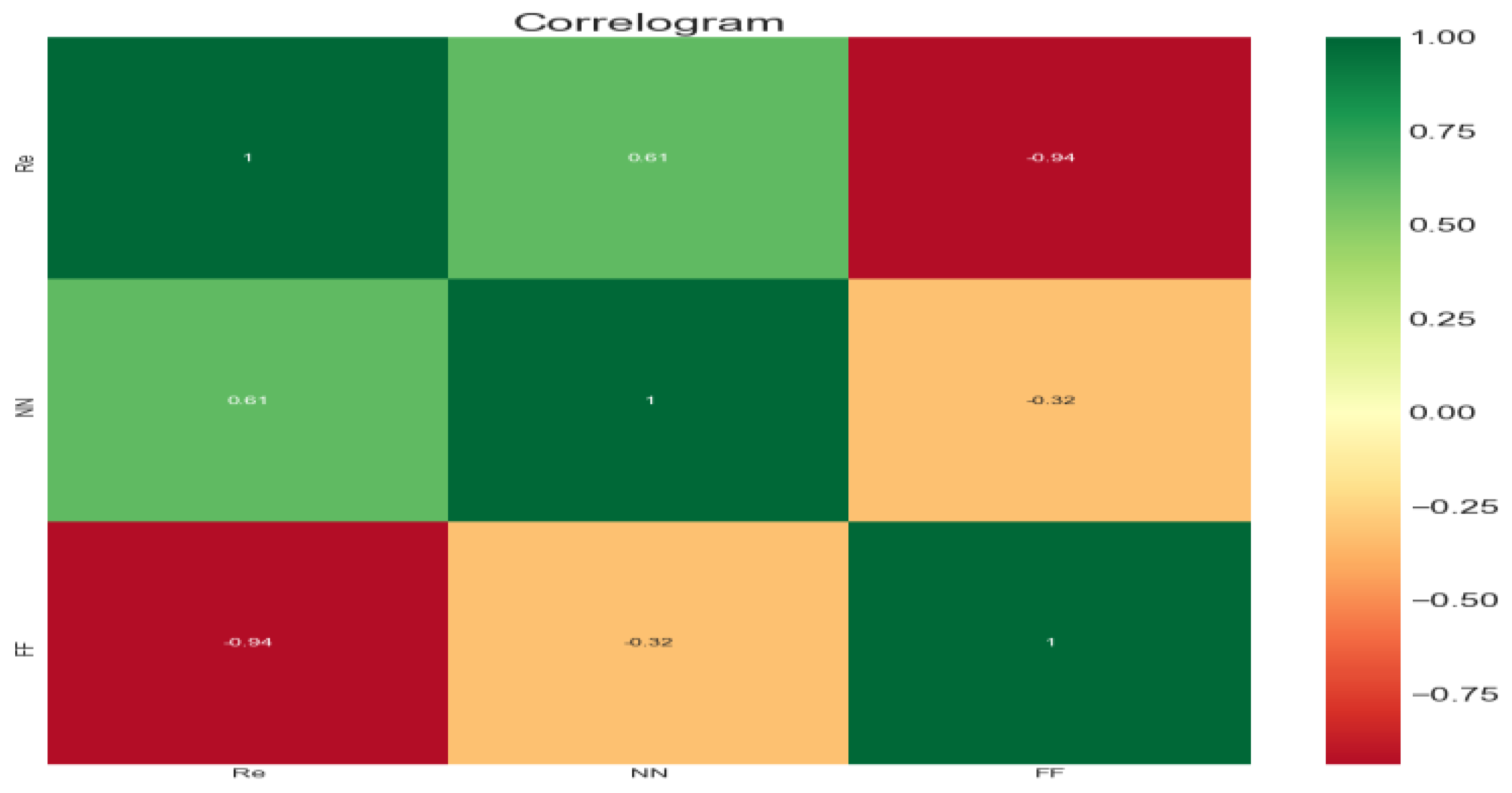

- The LR model was developed with the help of the experimental values obtained via the Scikit-Learn library in the Python programming language. The friction factor and the Nusselt number were predicted with an accuracy of 95% and 93%, respectively. Therefore, the analytical model matched the performance of the experimental model extremely well.

- The friction factor, Nusselt number, absorber temperature and heat transfer coefficient were predicted with accuracies of 95%, 93%, 94% and 98.5%, respectively. Therefore, again, the analytical model matched the performance of the experimental model extremely well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ao | Outer surface area (m2) |

| Ai | Inner surface area (m2) |

| Cp | Specific heat of water (J/kgK) |

| di | Absorber tube inner diameter (m) |

| do | Absorber tube outer diameter (m) |

| f | Friction factor |

| h | Convective heat transfer coefficient (W/m2 K) |

| K | Thermal conductivity (W/m K) |

| l | Length of the absorber tube (m) |

| m | Mass flow rate of fluid (kg/s) |

| Nu | Nusselt number |

| ρ | Density of fluid (kg/m3) |

| Δp | Pressure drop (N/m2) |

| Q | Heat transfer rate (W) |

| Re | Reynolds number |

| Ti | Fluid inlet temperature (⸰K) |

| To | Fluid outlet temperature (⸰K) |

| U | Overall heat transfer coefficient (W/m2K) |

| V | Velocity (m/s) |

| Y | Twist ratio |

References

- Hashim, W.M.; Shomran, A.T.; Jurmut, H.A.; Gaaz, T.S.; Kadhum, A.A.H.; Al-Amiery, A.A. Case study on solar water heating for flat plate collector. Case Stud. Therm. Eng. 2018, 12, 666–671. [Google Scholar] [CrossRef]

- Pandey, K.M.; Chaurasiya, R. A review on analysis and development of solar flat plate collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- Cunio, L.; Sproul, A. Performance characterisation and energy savings of uncovered swimming pool solar collectors under reduced flow rate conditions. Sol. Energy 2012, 86, 1511–1517. [Google Scholar] [CrossRef]

- Bunea, M.; Perers, B.; Eicher, S.; Hildbrand, C.; Bony, J.; Citherlet, S. Mathematical modelling of unglazed solar collectors under extreme operating conditions. Sol. Energy 2015, 118, 547–561. [Google Scholar] [CrossRef]

- Soltau, H. Testing the thermal performance of uncovered solar collectors. Sol. Energy 1992, 49, 263–272. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A. Computational Simulation and Dimensioning of Solar-Combi Systems for Large-Size Sports Facilities: A Case Study for the Pancretan Stadium, Crete, Greece. Energies 2020, 13, 2285. [Google Scholar] [CrossRef]

- Katsaprakakis, D.A.; Zidianakis, G. Optimized Dimensioning and Operation Automation for a Solar-Combi System for Indoor Space Heating. A Case Study for a School Building in Crete. Energies 2019, 12, 177. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Katsaprakakis, D.A. Concentrating Solar Power Advances in Geometric Optics, Materials and System Integration. Energies 2021, 14, 6229. [Google Scholar] [CrossRef]

- Rawani, A.; Sharma, S.P.; Singh, D.P. Comparative performance analysis of different twisted tape inserts in the absorber tube of parabolic trough collector. Trans. Stellar 2018, 8, 643–656. [Google Scholar]

- Arun George, E.R.; Vinayprakash, E.; Rai, A.K. Fabrication and performance of solar parabolic trough concentrator with and without coating on receiver tube. Transstellar 2017, 7, 431–438. [Google Scholar] [CrossRef]

- Alexander, J.M.; Kueffer, C.; Daehler, C.; Edwards, P.J.; Pauchard, A.; Seipel, T.; Arévalo, R.J.; Cavieres, L.A.; Dietz, H.; Jakobs, G.; et al. Assembly of nonnative floras along elevational gradients explained by directional ecological filtering. Proc. Natl. Acad. Sci. USA 2011, 108, 656–661. [Google Scholar] [CrossRef]

- Diwan, K.; Soni, M.S. Heat Transfer Enhancement in Absorber Tube of Parabolic Trough Concentrators Using Wire-Coils Inserts. Univers. J. Mech. Eng. 2015, 3, 107–112. [Google Scholar] [CrossRef]

- Çağlar, A. Design of a Parabolic Trough Solar Collector Using a Concentrator with High Reflectivity. In Proceedings of the 2nd World Congress on Mechanical, Chemical, and Material Engineering (MCM’16), Budapest, Hungary, 22–23 August 2016. [Google Scholar] [CrossRef]

- Kalidasan, B.; Shankar, R.; Srinivas, T. Absorber Tube with Internal Hinged Blades for Solar Parabolic Trough Collector. Energy Procedia 2016, 90, 463–469. [Google Scholar] [CrossRef]

- Yousif, A.H.; Khudhair, M.R. Enhancement of Heat Transfer in a Tube Fitted with Passive Technique as Twisted Tape Insert—A Comprehensive Review. Am. J. Mech. Eng. 2019, 7, 20–34. [Google Scholar]

- Jamal-Abad, M.T.; Saedodin, S.; Aminy, M. Experimental investigation on a solar parabolic trough collector for absorber tube filled with porous media. Renew. Energy 2017, 107, 156–163. [Google Scholar] [CrossRef]

- Younas, T.; Bano, N.; Khalid, M.A. An Experimental Study of Modelling and Fabrication of an Autonomous Solar Parabolic Trough Collector; IEEE: Piscataway, NJ, USA, 2018; ISBN 978-1-5386-7939-5/978-1-5386-7938-8/978-1-5386-7940-1. [Google Scholar]

- Aravind, G.; Yadav, R.K.; Loganathan, C.; Sharma, S. Experimental investigation of cavity absorber in parabolic solar collector. In Proceedings of the 2016 International Conference on Recent Advances and Innovations in Engineering (ICRAIE), Jaipur, India, 23–25 December 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Aldulaimi, R.K.M. An Innovative Receiver Design for a Parabolic Trough Solar Collector Using Overlapped and Reverse Flow: An Experimental Study. Arab. J. Sci. Eng. 2019, 44, 7529–7539. [Google Scholar] [CrossRef]

- Norouzi, A.M.; Siavashi, M.; Oskouei, M.K. Efficiency enhancement of the parabolic trough solar collector using the rotating absorber tube and nanoparticles. Renew. Energy 2019, 145, 569–584. [Google Scholar] [CrossRef]

- Anbu, S.; Venkatajalapathy, S.; Suresh, S. Convective heat transfer studies on helically corrugated tubes with spiraled rod inserts using TiO2 / DI water nanofluids. J. Therm. Anal. Calorim. 2019, 137, 849–864. [Google Scholar] [CrossRef]

- Almeshaal, M.; Arunprasad, V.; Palaniappan, M.; Kolsi, L. Experimental study of a solar water heater fitted with spacer at the leading edge of Left-Right screw tapes. Case Stud. Therm. Eng. 2020, 22, 100777. [Google Scholar] [CrossRef]

- Mwesigye, Y.A.; Goksu, T.T. Enhancing the ovarall thermal performance of a large aperture SPTC using wire coil inserts. Sustain. Energy Technol. Assess. 2020, 39, 100696. [Google Scholar]

- Kumar, B.N.; Reddy, K. Numerical investigations on metal foam inserted solar parabolic trough DSJ absorber tube for mitigating thermal gradients and enhancing heat transfer. Appl. Therm. Eng. 2020, 178, 115511. [Google Scholar] [CrossRef]

- Wongcharee, K.; Eiamsaard, S. Heat transfer enhancement by using CuO/water nanofluid in corrugated tube equipped with twisted tape. Int. Commun. Heat Mass Transf. 2012, 39, 251–257. [Google Scholar] [CrossRef]

- Valenzuela, L.; Setien, E.; Zarza, E. Analysis of a failure mechanism in parabolic troughs receivers due to bellows cap overirradiation. Eng. Fail. Anal. 2020, 111, 104491. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Katsaprakakis, D.A.; Christakis, D.G. Dynamic modeling of combined concentrating solar tower and parabolic trough for increased day-to-day performance. Appl. Energy 2022, 323, 119450. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Methods for Engineers, 7th ed.; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Kalogirou, S. Solar Energy Engineering: Process and Systems, 1st ed.; Elsevier: London, UK, 2009. [Google Scholar]

- Saravanan, A.; Murugan, M.; Reddy, M.S.; Kumar, P.; Elumalai, P.V. Performance Enhancement of Tubular Solar Still With Various Rotating Wicked Materials—An Experimental Approach. J. Therm. Sci. Eng. Appl. 2022, 14, 1–22. [Google Scholar] [CrossRef]

- Murugan, M. An overview on energy and exergy analysis of solar thermal collectors with passive performance enhancers. Alex. Eng. J. 2022, 61, 8123–8147. [Google Scholar] [CrossRef]

- Saravanan, A.; Murugan, M.; Reddy, M.S.; Ranjit, P.; Elumalai, P.; Kumar, P.; Sree, S.R. Thermo-hydraulic performance of a solar air heater with staggered C-shape finned absorber plate. Int. J. Therm. Sci. 2021, 168, 107068. [Google Scholar] [CrossRef]

| Length of the collector (L) | 2 m |

| Width of the Collector (w) | 1 m |

| Focal distance (f) | 0.25 m |

| Receiver inner diameter | 18 mm |

| Receiver outer diameter | 20 mm |

| Envelope cover inner diameter | 22 mm |

| Envelope cover outer diameter | 26 mm |

| Concentration ratio (C) | 25.46 |

| Absorptance of the receiver (α) | 0.97 |

| Emissivity of the receiver (åa) | 0.25 |

| Envelope tube emissivity (åe) | 0.94 |

| Tracking mechanism | Electronic type |

| No. | Inner Diameter/Outer Diameter (mm) | Pitch pc (mm) | Height hc (mm) |

|---|---|---|---|

| CT | 14/20 | 8 | 2 |

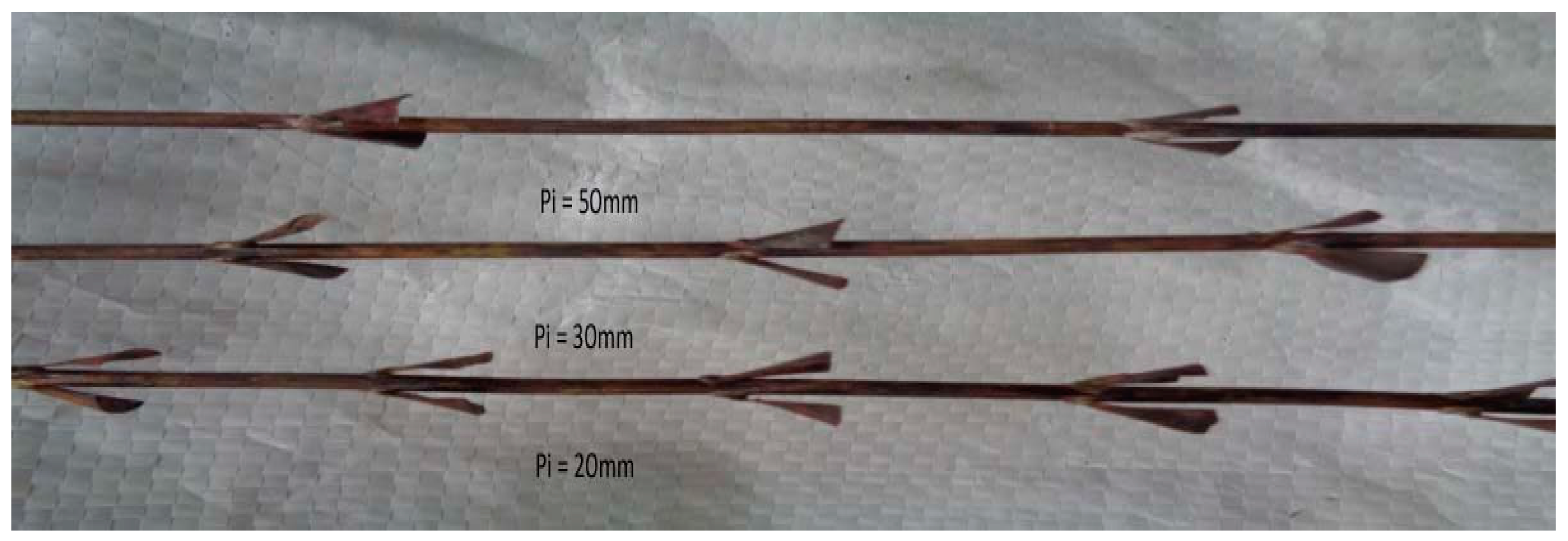

| No. | Diameter of Test Section (mm) | Pitch (mm) | The Angle of Inclination of the Strip |

|---|---|---|---|

| I1 | 10 | 50 | 20° |

| I2 | 10 | 30 | 20° |

| I3 | 10 | 20 | 20° |

| Statistical Attributes | Reynolds Number | Nusselt Number | Friction Factor |

|---|---|---|---|

| count | 15 | 15 | 15 |

| mean | 5500 | 18.26 | 0.1158 |

| std | 2195.78 | 3.52 | 0.0075 |

| min | 2500 | 13 | 0.1 |

| 25% | 4000 | 15.9 | 0.1115 |

| 50% | 5500 | 18 | 0.115 |

| 75% | 7000 | 21 | 0.122 |

| max | 8500 | 24.6 | 0.126 |

| ML Model | Friction Factor | Nusselt Number | ||||||

|---|---|---|---|---|---|---|---|---|

| R2 | MSE | RMSE | MAE | R2 | MSE | RMSE | MAE | |

| LR algorithm | 0.95 | 0.00002 | 0.00458 | 0.00374 | 0.94 | 0.99309 | 0.99658 | 0.87264 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkatesaperumal, R.; Syed Jafar, K.; Elumalai, P.V.; Abbas, M.; Cuce, E.; Shaik, S.; Saleel, C.A. Heat Transfer Studies on Solar Parabolic trough Collector Using Corrugated Tube Receiver with Conical Strip Inserts. Sustainability 2023, 15, 378. https://doi.org/10.3390/su15010378

Venkatesaperumal R, Syed Jafar K, Elumalai PV, Abbas M, Cuce E, Shaik S, Saleel CA. Heat Transfer Studies on Solar Parabolic trough Collector Using Corrugated Tube Receiver with Conical Strip Inserts. Sustainability. 2023; 15(1):378. https://doi.org/10.3390/su15010378

Chicago/Turabian StyleVenkatesaperumal, Ramalingam, Kutbudeen Syed Jafar, Perumal Venkatesan Elumalai, Mohamed Abbas, Erdem Cuce, Saboor Shaik, and Chanduveetil Ahamed Saleel. 2023. "Heat Transfer Studies on Solar Parabolic trough Collector Using Corrugated Tube Receiver with Conical Strip Inserts" Sustainability 15, no. 1: 378. https://doi.org/10.3390/su15010378

APA StyleVenkatesaperumal, R., Syed Jafar, K., Elumalai, P. V., Abbas, M., Cuce, E., Shaik, S., & Saleel, C. A. (2023). Heat Transfer Studies on Solar Parabolic trough Collector Using Corrugated Tube Receiver with Conical Strip Inserts. Sustainability, 15(1), 378. https://doi.org/10.3390/su15010378