Affordable Electric Three-Wheeler in Bangladesh: Prospects, Challenges, and Sustainable Solutions

Abstract

1. Introduction

- Exploration of the prospect of E3Ws in Bangladesh, which can be assessed in other developing and underdeveloped countries;

- Proper information on E3Ws technical components and their current attributes;

- Investigation of the possible challenges of E3Ws in technical and environmental aspects;

- Propose feasible and sustainable solutions to the challenges that are under present Bangladesh’s socioeconomic condition;

- Overview of current and proposed policies concerning E3Ws;

- Propose recommendations for the policymakers to facilitate their decision making;

- Figure out the possible direction for future research regarding E3Ws.

2. Literature Review

3. Prospects of Electric Three-Wheelers in Bangladesh

4. Current Electric Three-Wheeler Technologies

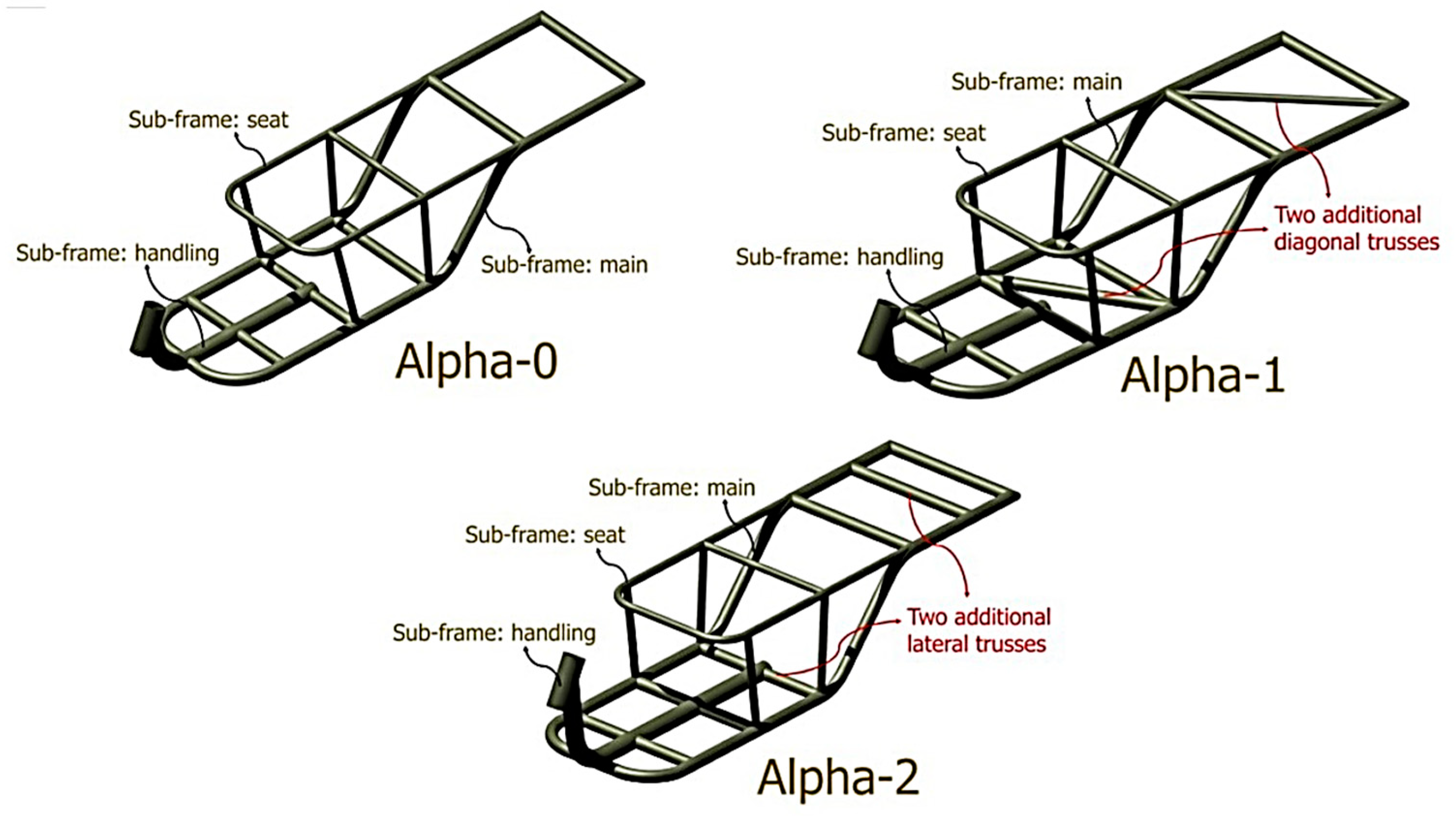

4.1. Structure

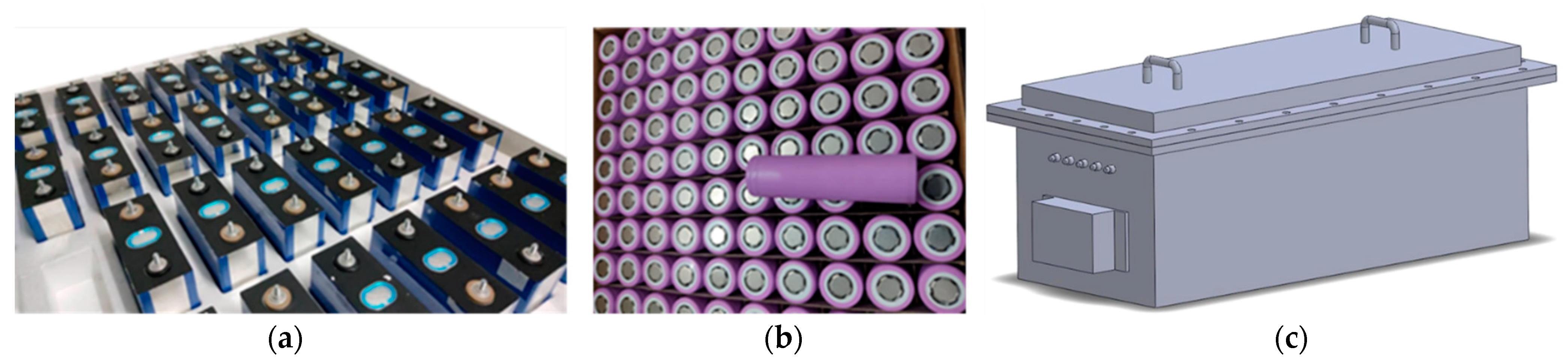

4.2. Battery

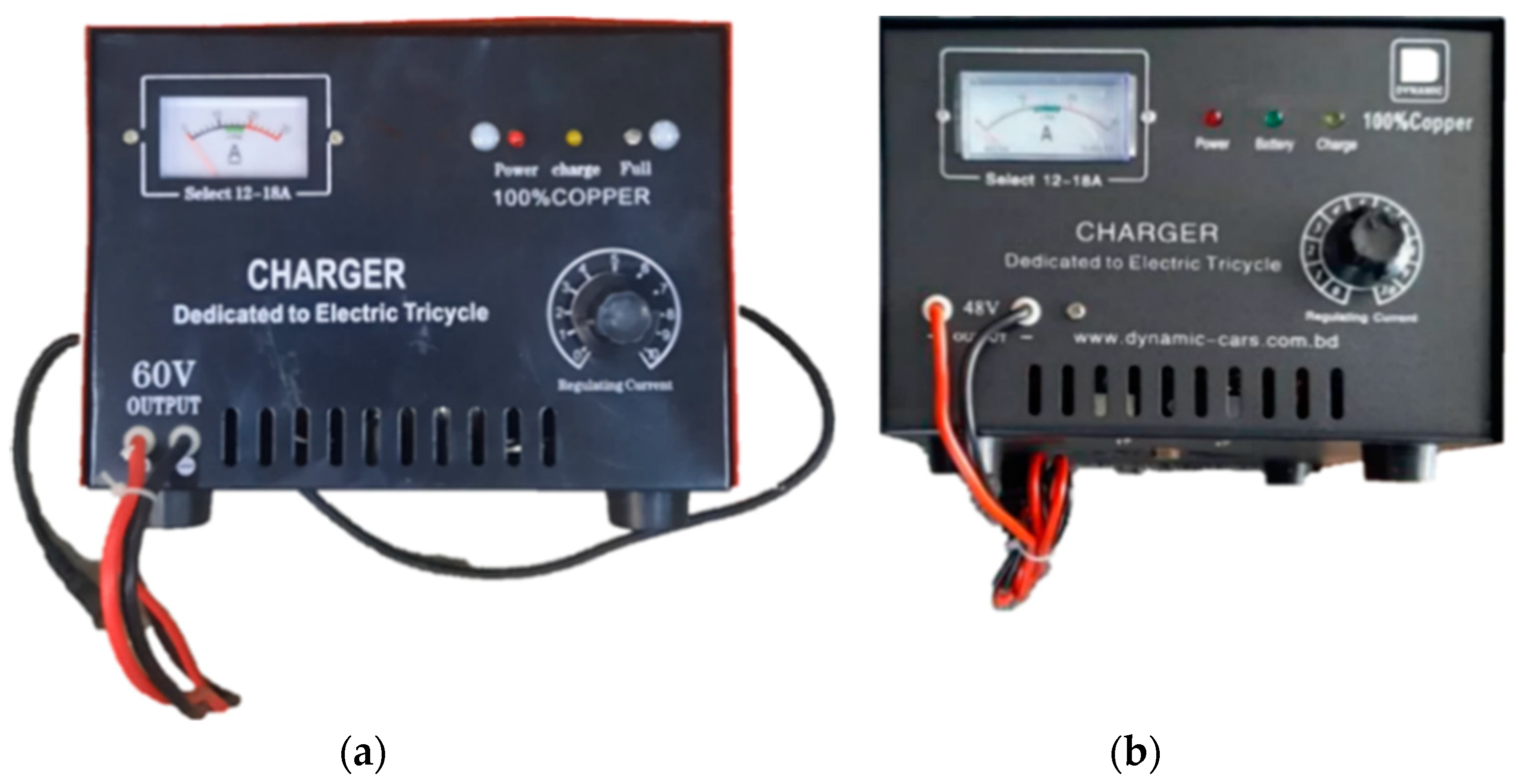

4.3. Battery Charger

4.4. Motor

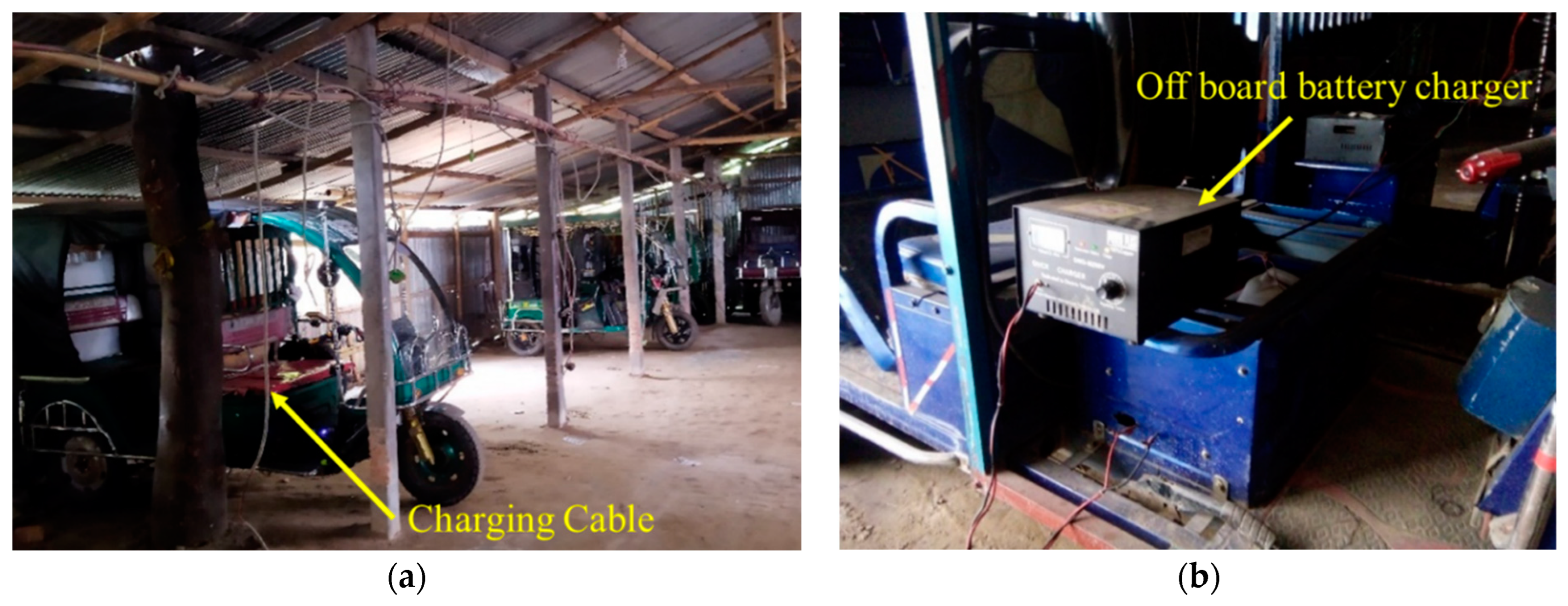

4.5. Charging Station

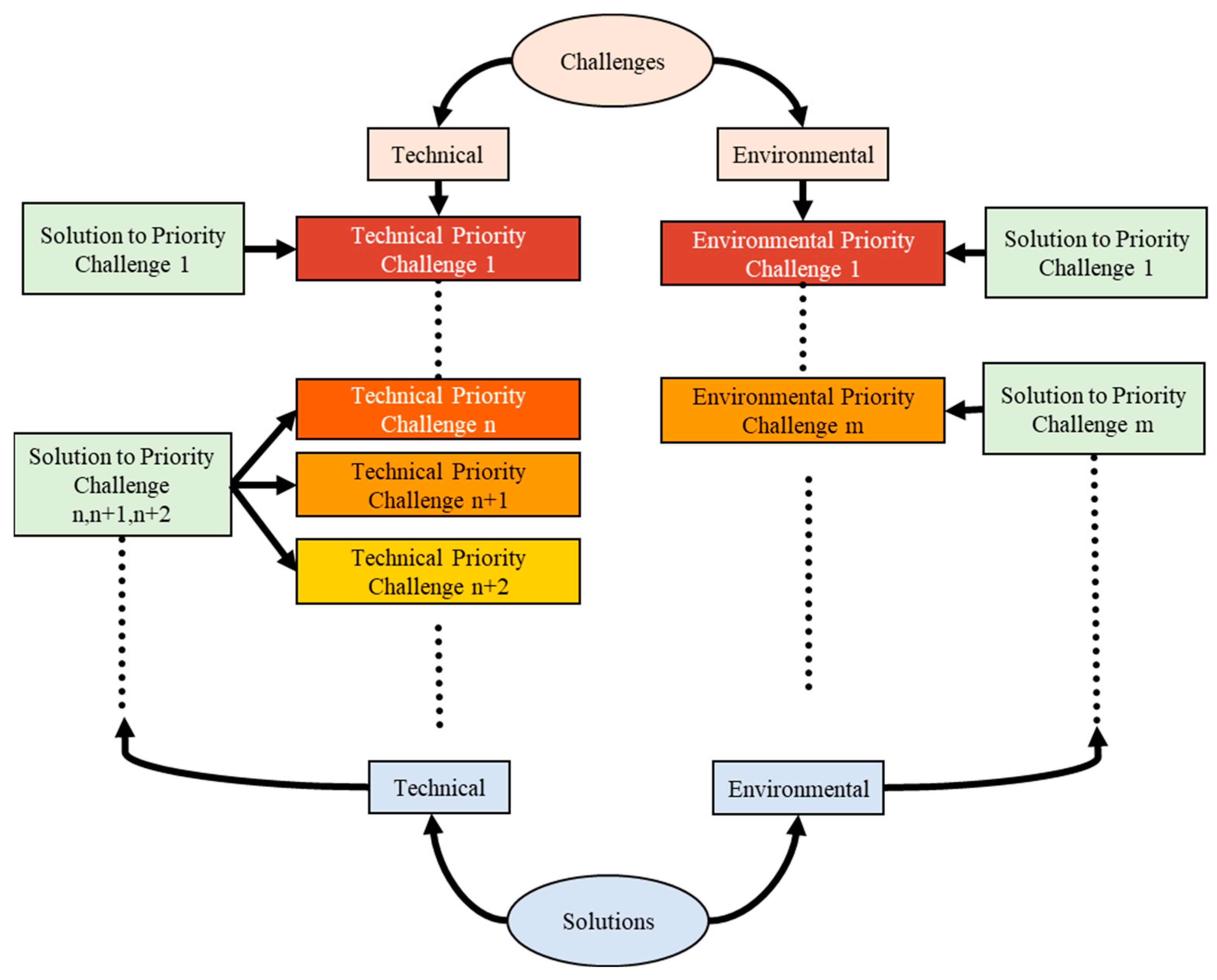

5. Methodology

6. Challenges of Electric Three-Wheelers

6.1. Technological Challenges

6.1.1. Structural Deficiency and Poor Braking System

6.1.2. Safety Concerns

6.1.3. Limited Range

6.1.4. Battery Quality and Health Cycle

6.1.5. Motor Quality

6.1.6. Battery Charger

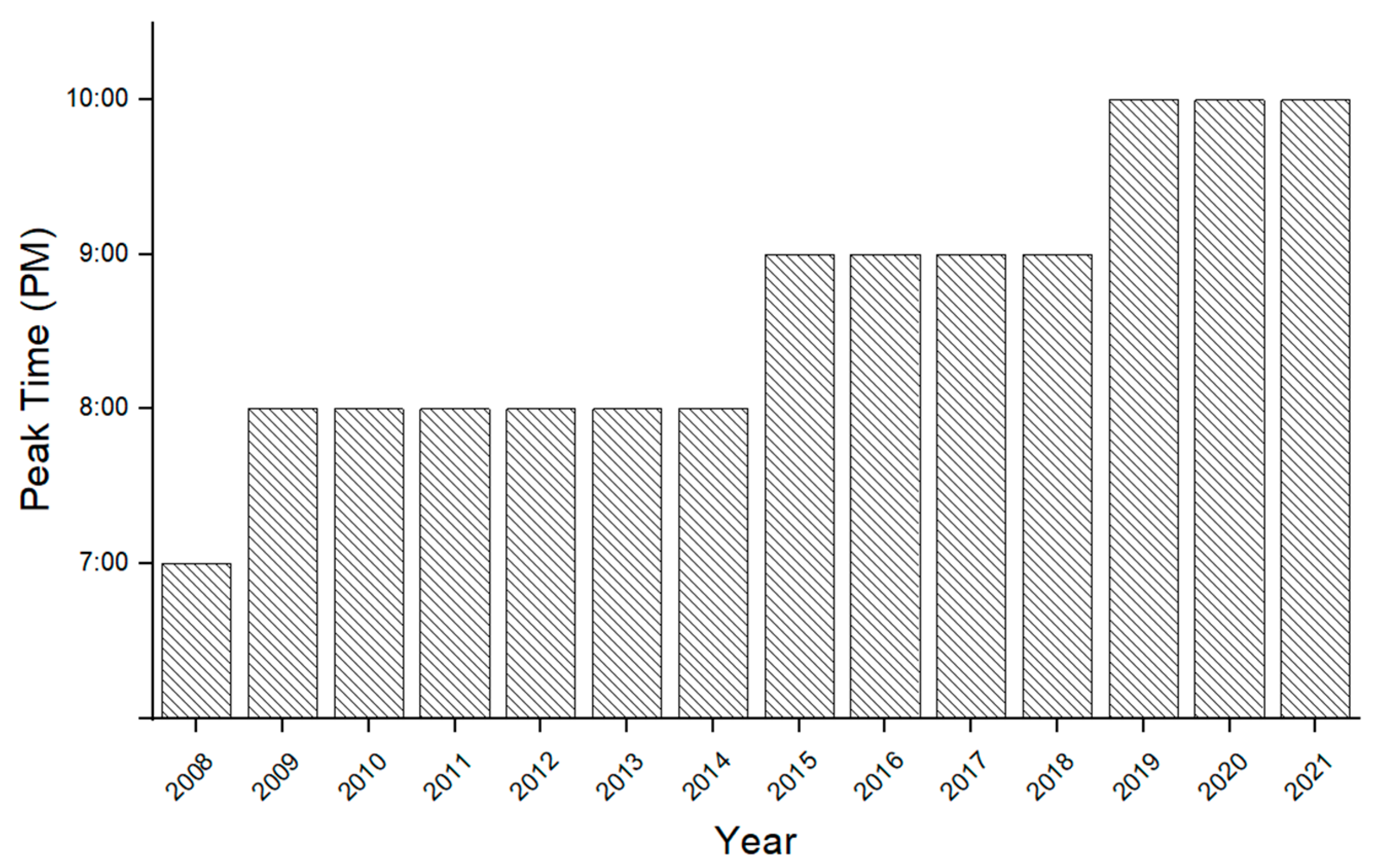

6.1.7. Grid Integration and Power Quality

6.1.8. Additional Power Supply

6.1.9. Quality Products Availability and Warranty

6.2. Environmental Challenges

6.2.1. Battery Disposal

6.2.2. Indirect Emission of Greenhouse Gas

7. Potential Solutions and Sustainability

7.1. Technological Solutions

7.1.1. Strong Vehicular Frame with Updated Braking and Suspension System

7.1.2. Charging Facilities and Battery Swapping Method

7.1.3. Replacing Lead Acid Batteries with Li-ion batteries

7.1.4. Efficient Motor and Regenerative Braking System

7.1.5. Demand-Side Management

7.1.6. Establishing the Automobile Manufacturing Industry and Market

7.1.7. Lowering the Cost of Equipment

7.2. Environmental Solution

7.2.1. Battery Recycling

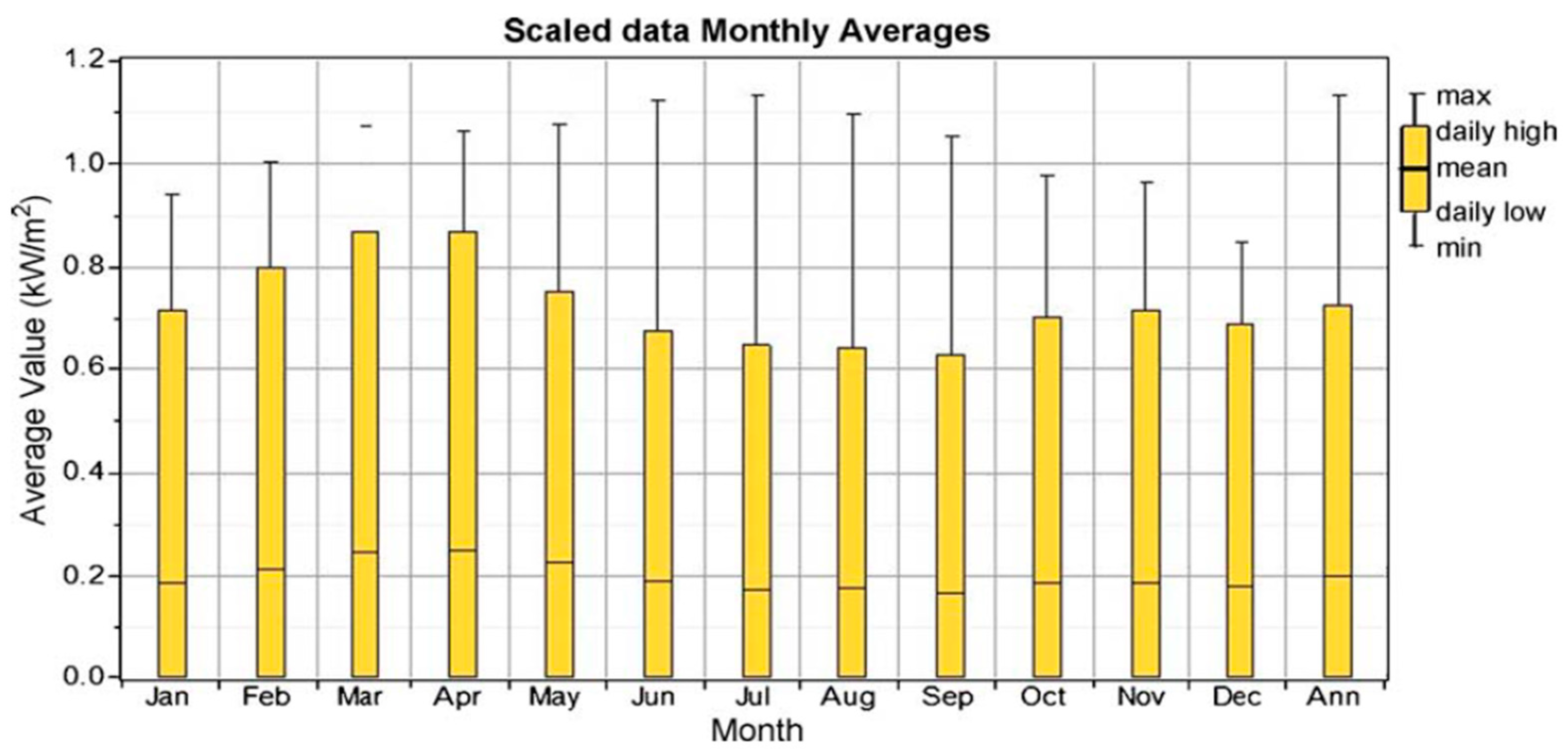

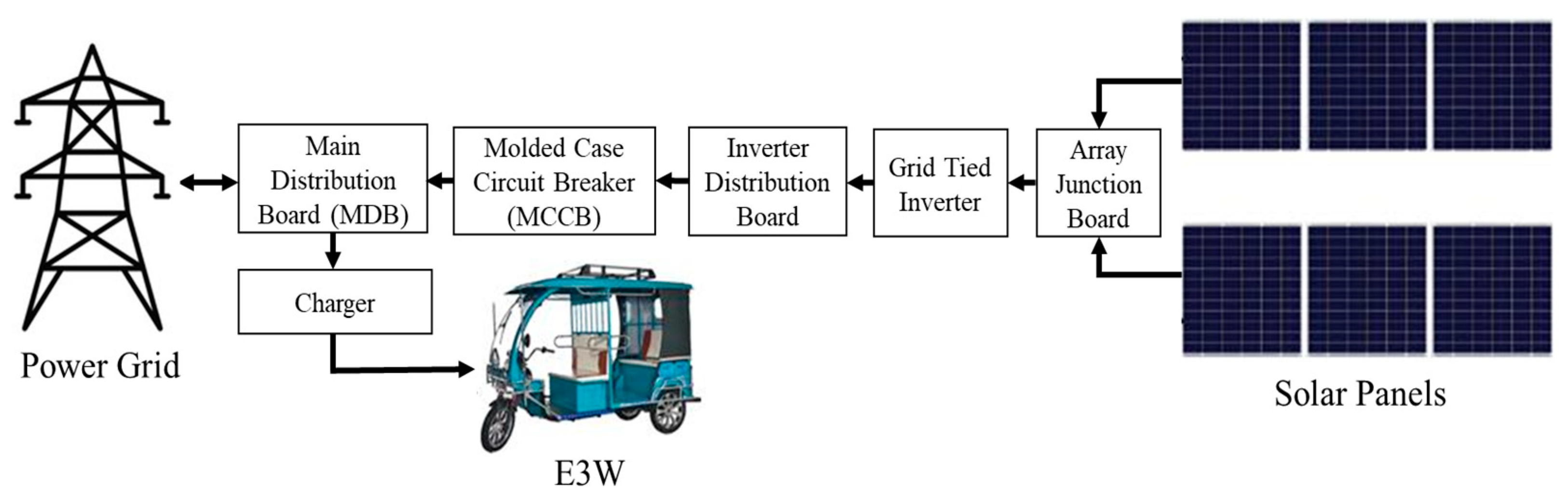

7.2.2. Incorporation of Renewable Energy in the Charging Process

8. Current Policies and Recommendations

8.1. Development of Vehicle Structure and Braking System

8.2. Movement Restriction

8.3. Regulation on Vehicle Charging Process

8.4. Development of the Automobile Market

8.5. Battery Import and Recycling

8.6. Employment Issues

9. Direction for Future Research

10. Conclusions

- The popularity of E3Ws is mostly attributed to their emission-free, noiseless operation and low and reasonable fare in short-distance travel and intra-city transportation.

- E3W can significantly contribute to lowering the country’s dependency on fossil fuels for the transportation sector.

- In order to ensure safe and convenient transport, proper structural design with reliable braking and suspension systems is very important and must be standard for the E3W.

- Inherent problems such as limited range inhibit the E3W from meeting the travel demand.

- New and existing technologies must be incorporated to tackle various challenges of the E3W vehicles.

- The concerns related to battery disposal must be dealt with in a proper technical manner to fulfill the promise of pollution-free transport.

- Government and non-government organizations should adopt a collaborative approach to adopt E3Ws as sustainable transport.

- Bangladesh should align with this vision and adopt an environmentally friendly transport policy, as the world is adopting electric vehicles as future transportation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IQAir. World Air Quality Report 2021—Region & City PM2.5 Ranking; IQAir: Goldach, Switzerland, 2021. [Google Scholar]

- Hossain, I.; Rahman, M.S.; Sattar, S.; Haque, M.; Mullick, A.R.; Siraj, S.; Sultana, N.; Ahsan-Uz-Zaman, M.; Samima, I.S.; Haidar, A.; et al. Environmental overview of air quality index (AQI) in Bangladesh: Characteristics and challenges in present era. Int. J. Res. Eng. Sci. Manag. 2021, 4, 110–115. [Google Scholar]

- Chowdhury, H.; Chowdhury, T.; Rashedi, A.; Banik, S.C.; Khanam, T.; Saidur, R.; Sait, S.M.; Rosen, M.A. Energy and exergy assessment with updated Reistad estimates: A case study in the transportation sector of Bangladesh. Energy Sci. Eng. 2021, 9, 1349–1358. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A review of heavy-duty vehicle powertrain technologies: Diesel engine vehicles, battery electric vehicles, and hydrogen fuel cell electric vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Saleque, A.M.; Khan, A.M.A.; Khan, S.H.; Hoque, S. Drivetrain design and feasibility analysis of electric three-wheeler powered by renewable energy sources. In Proceedings of the 4th International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 28–30 September 2017; pp. 432–438. [Google Scholar] [CrossRef]

- Rana, M.S.; Hossain, F.; Roy, S.S.; Mitra, S.K. Energy consumption by battery operated autorickshaws. Daffodil Int. Univ. J. Sci. Technol. 2013, 8, 71–76. [Google Scholar]

- Saxena, S.N. Two- and three-wheeler electric vehicles in India—Outlook 2019. Int. J. Electr. Eng. Technol. 2019, 9, 13. [Google Scholar]

- Weinert, J.; Ogden, J.; Sperling, D.; Burke, A. The future of electric two-wheelers and electric vehicles in China. Energy Policy 2008, 36, 2544–2555. [Google Scholar] [CrossRef]

- Hanke, B.; Goletz, M.; Wachter, C.; Kühnel, M.; Ehebrecht, D.; Rinderknecht, F.; Nickel, B.; Lenz, B.; Tolk, D.; von Maydell, K.; et al. Interdependence of charging infrastructure and battery demand of light electric 3-wheel motor taxis. In Proceedings of the Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020. [Google Scholar]

- Le, H.; Yang, Z. Market Analysis of Two- and Three-Wheeler Vehicles in Key ASEAN Member States; International Council on Clean Transportation: Washington, DC, USA, 2022. [Google Scholar]

- Arifurrahman, F.; Indrawanto; Budiman, B.A.; Santosa, S.P. Static analysis of an electric three-wheel vehicle. In Proceedings of the 5th International Conference on Electric Vehicular Technology (ICEVT), Surakarta, Indonesia, 30–31 October 2018; pp. 218–223. [Google Scholar] [CrossRef]

- Shaha, N.; Uddin, B. Hybrid energy assisted electric auto rickshaw three wheeler. In Proceedings of the International Conference on Electrical Information and Communication Technology (EICT), Khulna, Bangladesh, 13–15 February 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Saxena, S.N. Revolution in growth of three-wheeler electric vehicles in India: Providing job opportunities to semi-skilled and unskilled people. J. Glob. Tour. Res. 2019, 4, 117–126. [Google Scholar] [CrossRef]

- Khan, Z.R. Final Report on the Efficient Charging System for Electric Three Wheeler; REEP, GIZ: Dhaka, Bangladesh, 2018. [Google Scholar]

- Awal, M.R.; Rahman, M.M.; Islam, A.K.M.N.; Hossain, J.A.; Khan, M.Z.R. Energy consumption analysis of electric three wheelers in Bangladesh. In Proceedings of the IEEE International Conference on Power, Electrical, and Electronics and Industrial Applications (PEEIACON), Dhaka, Bangladesh, 29 November–1 December 2019; pp. 35–38. [Google Scholar] [CrossRef]

- Rian, M.Z.; Rahman, A.N.M.M. Study on power consumption and social aspects of battery operated auto-rickshaw. In Proceedings of the International Conference on Mechanical, Industrial and Energy Engineering, Khulna, Bangladesh, 26–27 December 2014. [Google Scholar]

- Centre for Rehabilitation of the Paralysed. Easy Bike Accidents Increase Physical Disability: CRP. Available online: http://www.newagebd.net/article/4230/easy-bike-accidents-increase-physical-disability-crp (accessed on 11 April 2022).

- Satish, S.; Saiganesh, J.; Karthik, T.; Venkateshalu, M. Design and analysis of suspension system for a three wheeler electric vehicle. J. Adv. Res. Dyn. Control Syst. 2017, 9, 1230–1238. [Google Scholar]

- Sindha, J.; Chakraborty, B.; Chakravarty, D. Automatic stability control of three-wheeler vehicles—Recent developments and concerns towards a sustainable technology. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 232, 418–434. [Google Scholar] [CrossRef]

- Awal, M.R.; Islam, A.N.; Khan, M.Z.R. Bangladesh power system peak demand shaving through demand side management of the battery operated easy bike load. In Proceedings of the 4th International Conference on Electrical Information and Communication Technology (EICT), Khulna, Bangladesh, 20–22 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Arefin, M.A.; Mallik, A.; Asfaquzzaman, M. Renewable energy–assisted hybrid three-wheeler: A numerical investigation. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Rahman, S.; Saha, S.; Islam, S.N.; Arif, M.T.; Mosadeghy, M.; Haque, M.E.; Oo, A.M.T. Analysis of power grid voltage stability with high penetration of solar PV systems. IEEE Trans. Ind. Appl. 2021, 57, 2245–2257. [Google Scholar] [CrossRef]

- Mulhall, P.; Lukic, S.M.; Wirasingha, S.G.; Young-Joo, L.; Emadi, A. Solar-assisted electric auto rickshaw three-Wheeler. IEEE Trans. Veh. Technol. 2010, 59, 2298–2307. [Google Scholar] [CrossRef]

- Lubna, J.; Aman, A.H.; Morshed, M.M.; Islam, A. Cohesive City and Urban Informality: Battery-bikes in Khulna City. Available online: https://www.academia.edu/14101065/Cohesive_City_and_Urban_Informality_Battery_bikes_in_Khulna_City (accessed on 12 November 2022).

- Iqbal, M.; Akhter, S.; Ahmad, S. Study on merits and demerits of two transport systems: Battery operated easy bike with CNG operated auto rickshaw at Sylhet City in Bangladesh. IOSR J. Mech. Civ. Eng. 2013, 5, 25–32. [Google Scholar] [CrossRef]

- Sreejith, R.; Rajagopal, K.R. An insight into motor and battery selections for three-wheeler electric vehicle. In Proceedings of the 1s IEEE International Conference on Power Electronics. Intelligent Control and Energy Systems (ICPEICES-2016), Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Arifurrahman, F.; Indrawanto, I.; Budiman, B.A.; Sambegoro, P.L.; Santosa, S.P. Frame modal analysis for an electric three-wheel vehicle. MATEC Web Conf. 2018, 197, 08001–08006. [Google Scholar] [CrossRef]

- Rajper, S.Z.; Albrecht, J. Prospects of electric vehicles in the developing countries: A literature review. Sustainability 2020, 12, 1906. [Google Scholar] [CrossRef]

- Farhana, J.N.; Haslenda, H.; Shin, H.W.; Keng, L.L.; Binti, S.N.S.; Alnie, D.; Andy, T.; Rizki, K.M.; Rika, S.; Ayu, R.S. Electric vehicle adoption in ASEAN. Prospect and challenges. Chem. Eng. Trans. 2021, 89, 625–630. [Google Scholar] [CrossRef]

- Kumar, R.; Jha, A.; Damodaran, A.; Bangwal, D.; Dwivedi, A. Addressing the challenges to electric vehicle adoption via sharing economy: An Indian perspective. Manag. Environ. Qual. Int. J. 2020, 32, 82–99. [Google Scholar] [CrossRef]

- Muzir, N.A.Q.; Mojumder, M.R.H.; Hasanuzzaman, M.; Selvaraj, J. Challenges of electric vehicles and their prospects in Malaysia: A comprehensive review. Sustainability 2022, 14, 8320. [Google Scholar] [CrossRef]

- Mukherjee, S.C.; Ryan, L. Factors influencing early battery electric vehicle adoption in Ireland. Renew. Sustain. Energy Rev. 2020, 118, 109504. [Google Scholar] [CrossRef]

- Egbue, O.; Long, S.; Samaranayake, V.A. Mass deployment of sustainable transportation: Evaluation of factors that influence electric vehicle adoption. Clean Technol. Environ. Policy 2017, 19, 1927–1939. [Google Scholar] [CrossRef]

- Åhman, M. Government policy and the development of electric vehicles in Japan. Energy Policy 2006, 34, 433–443. [Google Scholar] [CrossRef]

- Du, J.; Ouyang, M.; Chen, J. Prospects for Chinese electric vehicle technologies in 2016–2020: Ambition and rationality. Energy 2017, 120, 584–596. [Google Scholar] [CrossRef]

- Du, J.; Ouyang, M. Review of electric vehicle technologies progress and development prospect in China. World Electr. Veh. J. 2015, 6, 1086–1093. [Google Scholar] [CrossRef]

- Helveston, J.P.; Liu, Y.; Feit, E.M.; Fuchs, E.; Klampfl, E.; Michalek, J.J. Will subsidies drive electric vehicle adoption? Measuring consumer preferences in the U.S. and China. Transp. Res. Part A Policy Pract. 2015, 73, 96–112. [Google Scholar] [CrossRef]

- Vaidehi; Dhar, S.; Jayakumar, A.; Lavanya, R.; Dinesh Kumar, M. Techno-economic assessment of various motors for three-wheeler E-auto rickshaw: From Indian context. Mater. Today Proc. 2021, 45, 6572–6579. [Google Scholar] [CrossRef]

- Bagul, T.R.; Kumar, R.; Kumar, R. Real-world emission and impact of three wheeler electric auto-rickshaw in India. Environ. Sci. Pollut. Res. Int. 2021, 28, 68188–68211. [Google Scholar] [CrossRef]

- Priye, S.; Manoj, M.; Ranjan, R. Understanding the socioeconomic characteristics of paratransit drivers and their perceptions toward electric three-wheeled rickshaws in Delhi, India. IATSS Res. 2021, 45, 357–370. [Google Scholar] [CrossRef]

- The New Nation. 1m Easy-Bikes’ in Country. Available online: https://thedailynewnation.com/news/149439/1m-easy-bikes-in-country.html (accessed on 30 June 2022).

- The Daily Star. Easy Bikes Outgrowing Limitations. Available online: https://www.thedailystar.net/business/easy-bikes-outgrowing-limitations-1469200 (accessed on 30 June 2022).

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 emissions of internal combustion engine vehicle and battery electric vehicle using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Ekanayake, G.; Patil, M.S.; Seo, J.-H.; Lee, M.-Y. Numerical study of fin geometry on the heat transfer characteristics of 72 V ECU heatsink for an electric three-wheeler. J. Mech. Sci. Technol. 2019, 33, 1451–1462. [Google Scholar] [CrossRef]

- Nahar, N.; Mahiuddin, S.; Hossain, Z. The severity of environmental pollution in the developing countries and its remedial measures. Earth 2021, 2, 124–139. [Google Scholar] [CrossRef]

- Bangladesh Bureau of Statistics. Consumer Price Index (CPI), Inflation Rate and Wage Rate Index (WRI) in Bangladesh; Bangladesh Bureau of Statistics: Dhaka, Bangladesh, 2020.

- Subhana, A.; Zahin, F.; Abid, F.; Khan, M.Z.R. Emergency backup power to a rural hospital in disaster condition. In Proceedings of the 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, 25–28 November 2019. [Google Scholar] [CrossRef]

- Limited, B. Category Archives: Electric Auto Rickshaw. Available online: http://beevatech.com/category/electric-auto-rickshaw/ (accessed on 30 June 2022).

- Mandal, S.; Ahmed, S.; Rabbi, F. Impact of battery driven vehicle on the electricity of Rajshahi city, Bangladesh. In Proceedings of the International Conference on Mechanical, Industrial and Materials Engineering 2015 (ICMIME2015), Rajshahi, Bangladesh, 11–13 December 2015; pp. 1–6. [Google Scholar]

- Quang Sheng. 2018 Street Legal New Design Borak or Borac Bangladesh Dhaka Easy Bike. Available online: https://www.pcqs-china.com/2018-street-legal-new-design-borak-or-borac-bangladesh-dhaka-easy-bike.html (accessed on 14 March 2022).

- Alibaba. China Bajaj Style Auto Rickshaw Price. Available online: https://www.alibaba.com/product-detail/Auto-Rickshaw-China-Bajaj-Style-Auto_1600107839972.html?spm=a2700.7724857.normal_offer.d_image.24367186zjwWVl&s=p (accessed on 14 May 2022).

- Wahid, M.R.; Budiman, B.A.; Joelianto, E.; Aziz, M. A review on drive train technologies for passenger electric vehicles. Energies 2021, 14, 6742. [Google Scholar] [CrossRef]

- Mohammad, A.; Abedin, M.A.; Khan, M.Z.R. Implementation of a three phase inverter for BLDC motor drive. In Proceedings of the 9th International Conference on Electrical and Computer Engineering, Dhaka, Bangladesh, 20–22 December 2016. [Google Scholar]

- Hanselman, D.C. Brushless Permanent Magnet Motor Design, 2nd ed.; Magna Physics Publishing: Madison, WI, USA, 2003. [Google Scholar]

- Awal, M.R. Design and Development of an Efficient Charging System for the Battery Operated Vehicles in Bangladesh; Military Institute of Science and Technology: Dhaka, Bangladesh, 2019. [Google Scholar]

- Zhejiang Datai New Energy Co., Ltd. Product-1000W Central Motor. Available online: http://www.tzdatai.com/english/productshow.aspx?id=28 (accessed on 26 March 2022).

- Jusuf, A.; Nurprasetio, I.P.; Prihutama, A. Macro data analysis of traffic accidents in Indonesia. J. Eng. Technol. Sci. 2017, 49, 132–143. [Google Scholar] [CrossRef]

- Cheah, L.; Heywood, J. Meeting U.S. passenger vehicle fuel economy standards in 2016 and beyond. Energy Policy 2011, 39, 454–466. [Google Scholar] [CrossRef]

- Uttekar, S.S.; Phatak, S.S.; Karandikar, P.B. Social impact on hybrid and retrofitted three-wheelers. Asian J. Converg. Technol. 2021, 7, 144–149. [Google Scholar] [CrossRef]

- Chakravarty, D.; Chakraborty, B.; Sindha, J. System identification and lateral dynamics of the active tilt-controlled electric three wheeler. J. Dyn. Syst. Meas. Control 2020, 142, 091001. [Google Scholar] [CrossRef]

- New Age Bangladesh. Easy Bikes Keep Running on Dhaka Roads. Available online: https://www.newagebd.net/article/119174/easy-bikes-keep-running-on-dhaka-roads (accessed on 30 June 2022).

- bdnews24 Child Dies from Burns after Kamrangirchar Blast, Toll Rises to 3. Available online: https://bdnews24.com/bangladesh/2021/07/14/child-dies-from-burns-after-kamrangirchar-blast-toll-rises-to-3 (accessed on 14 July 2022).

- Trovão, J.P.; Dubois, M.R.; Roux, M.-A.; Ménard, É.; Desrochers, A. Battery and SuperCapacitor hybridization for a pure electric three-wheel roadster. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015. [Google Scholar]

- Podder, S.; Khan, M.Z.R. Comparison of lead acid and Li-ion battery in solar home system of Bangladesh. In Proceedings of the 5th International Conference on Informatics, Electronics and Vision (ICIEV), Dhaka, Bangladesh, 13–14 May 2016; pp. 434–438. [Google Scholar] [CrossRef]

- Dufo-López, R.; Cortés-Arcos, T.; Artal-Sevil, J.S.; Bernal-Agustín, J.L. Comparison of lead-acid and Li-Ion batteries lifetime prediction models in stand-alone photovoltaic systems. Appl. Sci. 2021, 11, 1099–1114. [Google Scholar] [CrossRef]

- Weinert, J.X.; Burke, A.F.; Wei, X. Lead-acid and lithium-ion batteries for the Chinese electric bike market and implications on future technology advancement. J. Power Sources 2007, 172, 938–945. [Google Scholar] [CrossRef]

- Arefeen, A.; Shehreen, S.; Islam, A.; Rahman, M.; Rahman, H. Measurement and assessing the effects of harmonics on the grid of Bangladesh power system during EV charging. In Proceedings of the IEEE International Conference on Power, Electrical, and Electronics and Industrial Applications (PEEIACON), Dhaka, Bangladesh, 29 November–1 December 2019; pp. 5–9. [Google Scholar] [CrossRef]

- Kudelina, K.; Asad, B.; Vaimann, T.; Rassõlkin, A.; Kallaste, A.; Lukichev, D.V. Main faults and diagnostic possibilities of BLDC motors. In Proceedings of the 27th International Workshop on Electric Drives: MPEI Department of Electric Drives 90th Anniversary (IWED), Moscow, Russia, 27–30 January 2020. [Google Scholar]

- Bang, Y.-M.; Patil, M.S.; Seo, J.-H.; Lee, M.-Y. Experimental and numerical study on the thermal performances of battery cell and ECU for an E-Bike. In Proceedings of the AETA 2016: Recent Advances in Electrical Engineering and Related Sciences, Busan, Republic of Korea, 8–10 December 2016; pp. 195–204. [Google Scholar] [CrossRef]

- Bangladesh Power Development Board. Annual Report 2019–2020; Bangladesh Power Development Board: Dhaka, Bangladesh, 2020; pp. 1–116. [Google Scholar]

- Bangladesh Power Development Board. BPDB Daily Generation. Available online: https://www.bpdb.gov.bd/bpdb_new/index.php/site/daily_generation (accessed on 11 April 2022).

- Saxena, S.; Gopal, A.; Phadke, A. Electrical consumption of two-, three- and four-wheel light-duty electric vehicles in India. Appl. Energy 2014, 115, 582–590. [Google Scholar] [CrossRef]

- Habib, A.K.M.A.; Motakabber, S.M.A.; Ibrahimy, M.I. A comparative study of electrochemical battery for electric vehicles applications. In Proceedings of the 2019 IEEE International Conference on Power, Electrical, and Electronics and Industrial Applications (PEEIACON), Dhaka, Bangladesh, 29 November–1 December 2019; pp. 43–47. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, M.Z.R. Solar energy based net metered easy-bike charging station in Bangladesh. In Proceedings of the International Conference on Information and Communication Technology for Sustainable Development (ICICT4SD), Dhaka, Bangladesh, 27–28 February 2021; pp. 220–224. [Google Scholar] [CrossRef]

- Tasnia, K.; Begum, S.; Tasnim, Z.; Khan, M.Z.R. End-of-life management of photovoltaic modules in Bangladesh. In Proceedings of the 10th International Conference on Electrical and Computer Engineering, Dhaka, Bangladesh, 20–22 December 2018. [Google Scholar]

- Wigley, T.M.L. Global-mean temperature and sea level consequences of greenhouse gas concentration stabilization. Geophys. Res. Lett. 1995, 22, 45–48. [Google Scholar] [CrossRef]

- Khan, M.A.; Bokhari, S.F.; Khan, A.; Amjad, M.S.; Butt, A.M.; Rafique, M.Z. Clean and sustainable transportation through electric vehicles—A user survey of three-wheeler vehicles in Pakistan. Environ. Sci. Pollut. Res. Int. 2022, 29, 45560–45577. [Google Scholar] [CrossRef]

- Kumar, R.R.; Chakraborty, A.; Mandal, P. Promoting electric vehicle adoption: Who should invest in charging infrastructure? Transp. Res. Part E Logist. Transp. Rev. 2021, 149, 102295. [Google Scholar] [CrossRef]

- Pramod, K.N.; Prashant, D.H.; Akash Shetty, K.K.; Abhishek, B. A review on three wheeler electric vehicle. Int. J. Sci. Res. Eng. Trends 2021, 7, 2432–2434. [Google Scholar]

- Kosai, S.; Zakaria, S.; Che, H.S.; Hasanuzzaman, M.; Tan, C.; Ahmad, R.D.R.; Abbas, A.R.; Nakano, K.; Woon, W.K.; Amer, A.H.A. Estimation of greenhouse gas emissions of petrol, biodiesel and battery electric vehicles in Malaysia based on life cycle approach. Sustainability 2022, 14, 5783. [Google Scholar] [CrossRef]

- Khaligh, A.; Zhihao, L. Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Laurischkat, K.; Jandt, D. Techno-economic analysis of sustainable mobility and energy solutions consisting of electric vehicles, photovoltaic systems and battery storages. J. Clean. Prod. 2018, 179, 642–661. [Google Scholar] [CrossRef]

- Eco-Business. Legalising Bangladesh ‘Easy Bike’ Taxis Could Drive Safer, Greener Industry. Available online: https://www.eco-business.com/news/legalising-bangladesh-easy-bike-taxis-could-drive-safer-greener-industry/ (accessed on 13 November 2022).

- Victor Chombo, P.; Laoonual, Y.; Wongwises, S. Lessons from the electric vehicle crashworthiness leading to battery fire. Energies 2021, 14, 4802. [Google Scholar] [CrossRef]

- Christensen, P.A.; Anderson, P.A.; Harper, G.D.J.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240. [Google Scholar] [CrossRef]

- Mulhall, P.; Emadi, A. Comprehensive simulations and comparative analysis of the electric propulsion motor for a solar/battery electric auto rickshaw three-wheeler. In Proceedings of the 35th Annual Conference of the IEEE Industrial Electronics Society, Porto, Portugal, 3–5 November 2009; pp. 3785–3790. [Google Scholar] [CrossRef]

- Wahid, M.R.; Joelianto, E.; Azis, N.A. System identification of switched reluctance motor (SRM) using black box method for electric vehicle speed control system. In Proceedings of the 6th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 18–21 November 2019; pp. 208–212. [Google Scholar]

- Cao, Z.; Mahmoudi, A.; Kahourzade, S.; Soong, W.L. An overview of electric motors for electric vehicles. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021; pp. 1–6. [Google Scholar]

- Xu, W.; Zhu, J.; Guo, Y.; Wang, S.; Wang, Y.; Shi, Z. Survey on electrical machines in electrical vehicles. In Proceedings of the IEEE International Conference on Applied Superconductivity and Electromagnetic Devices, Chengdu, China, 25–27 September 2009. [Google Scholar]

- Mohammadi, A.S.; Trovão, J.P.F. System-level optimization of hybrid excitation synchronous machines for a three-wheel electric vehicle. IEEE Trans. Transp. Electrif. 2020, 6, 690–702. [Google Scholar] [CrossRef]

- Mondal, M.A.H.; Denich, M. Assessment of renewable energy resources potential for electricity generation in Bangladesh. Renew. Sustain. Energy Rev. 2010, 14, 2401–2413. [Google Scholar] [CrossRef]

- Power Division, Ministry of Power, Energy and Mineral Resources, Government of the People’s Republic of Bangladesh. Energy Efficiency and Conservation Master Plan up to 2030; Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2015.

- Ministry of Power, Energy and Mineral Resources, Government of the People’s Republic of Bangladesh. Power System Master Plan 2016 Summary; Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2016.

- Uprety, S.; Sapkota, R.C. Energy scenario of three wheeler electric and gasoline vehicle in Hetauda. J. Adv. Coll. Eng. Manag. 2021, 6, 123–129. [Google Scholar] [CrossRef]

- The Financial Express. Move to Legalise Electric Vehicles. Available online: https://thefinancialexpress.com.bd/trade/move-to-legalise-electric-vehicles-1548302855 (accessed on 8 September 2022).

- Dhaka Tribune. PDB for Bringing Battery-Run Vehicles under Tariff Regulations. Available online: https://www.dhakatribune.com/bangladesh/power-energy/2017/09/27/pdb-bringing-battery-run-vehicles-tariff-regulations (accessed on 30 June 2022).

- The Financial Express. BEPRC Moves to Formulate Guideline for Easy Bikes. Available online: https://thefinancialexpress.com.bd/national/beprc-moves-to-formulate-guideline-for-easy-bikes-1615472819 (accessed on 11 April 2022).

- SREDA. Electric Vehicle Charging Guideline; Ministry of Energy and Mineral Resource, Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2022; pp. 1–22.

- IEC 61851-1: 2017-02; Electric Vehicle Conductive Charging System—Part, 1. Available online: https://webstore.iec.ch/publication/33644 (accessed on 16 December 2022).

- IEC 61851-23: 2014; Electric Vehicle Conductive Charging System—Part 23: DC Electric Vehicle Charging Station. Available online: https://webstore.iec.ch/publication/24906 (accessed on 16 December 2022).

- IEC 61851-23: 2014; Electric Vehicle Conductive Charging System—Part 24: Digital Communication between a d.c. EV Charging Station and an Electric Vehicle for Control of d.c. Charging. Available online: https://webstore.iec.ch/publication/6033 (accessed on 16 December 2022).

- ISO 17409:2020; Electrically Propelled Road Vehicles—Conductive Power Transfer—Safety Requirements. Available online: https://www.iso.org/standard/72880.html (accessed on 16 December 2022).

- IEC 60947-2:2016; Low-Voltage Switchgear and Controlgear—Part 2: Circuit-Breakers. Available online: https://webstore.iec.ch/publication/65448 (accessed on 16 December 2022).

- IEC 60947-6-2:2020; Low-Voltage Switchgear and Controlgear—Part 6-2: Multiple Function Equipment—Control and Protective Switching Devices (or Equipment) (CPS). Available online: https://webstore.iec.ch/publication/61649 (accessed on 16 December 2022).

- IEC 60364; International Standard on Electrical Installations of Buildings. Available online: https://webstore.iec.ch/searchform&q=60364 (accessed on 16 December 2022).

- IEC 62305:2022; SER Series. Protection against Lightning—ALL PARTS. Available online: https://webstore.iec.ch/publication/6797 (accessed on 16 December 2022).

- IEC 62893-1:2017; Charging Cables for Electric Vehicles for Rated Voltages up to and Including 0.6/1 kV—Part 1: General Requirements. Available online: https://webstore.iec.ch/publication/30590 (accessed on 16 December 2022).

- IEC 60529:1989/AMD2:2013/COR1:2019; Corrigendum 1—Amendment 2—Degrees of Protection Provided by Enclosures (IP Code). Available online: https://webstore.iec.ch/publication/64427 (accessed on 16 December 2022).

- Newage Bangladesh. BRTA Initiates Move to Finalise Electric Vehicle Guidelines. Available online: https://www.newagebd.net/article/127407/brta-initiates-move-to-finalise-electric-vehicle-guideline (accessed on 11 November 2022).

- The Daily Star. Govt Readies Rules to Pave Way for Electric Vehicles. Available online: https://www.thedailystar.net/business/economy/news/govt-readies-rules-pave-way-electric-vehicles-2912346 (accessed on 10 November 2022).

- Dhaka Tribune. E-Vehicle Guideline Delay Frustrates Local Manufacturers. Available online: https://www.dhakatribune.com/bangladesh/2022/07/13/e-vehicle-guideline-delay-frustrates-local-manufacturers (accessed on 10 November 2022).

- Ministry of Industries, Government of the People’s Republic of Bangladesh. Automobile Industry Development Policy, 2020 (Draft); Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 2020.

- Bokare, P.S.; Maurya, A.K. Study of acceleration behaviour of motorized three wheeler in India. Transp. Res. Procedia 2016, 17, 244–252. [Google Scholar] [CrossRef]

| Factors | CNG Operated Auto Rickshaw | Battery Operated Electric Three-Wheeler |

|---|---|---|

| Maintenance Cost (Monthly) | 60–80 USD | 40–60 USD |

| Daily Income (Driver) | 20–24 USD | 14–16 USD |

| Daily Expenses (Driver) | 4–5 USD | 3–4 USD |

| Owner Daily Income | 800 BDT (10 USD) | 560 BDT (6.5 USD) |

| Retail Cost (With Assembly) | 6000–8000 USD (from India), 6000–7000 USD (from China) | 2375–2625 USD (from China) |

| Specification | Value |

|---|---|

| Overall length (mm) | 2850 |

| Overall width (mm) | 1080 |

| Overall height (mm) | 1850 |

| Wheelbase (mm) | 2200 |

| Ground clearance (mm) | 250 |

| Climbing ability (degree) | 20 |

| Tire (front and rear) | 4.0–12 tubeless |

| Net weight (excluding battery) (Kg) | 320 |

| Specification | Value |

|---|---|

| Rated power (W) | 1000 |

| Rated voltage (V) | 60 |

| No-load speed (RPM) | 3800 |

| Rated speed (RPM) | 3420 |

| Rated current (A) | 22 |

| No-load current (A) | 5 |

| Rated torque (NM) | 3.9 |

| Maximum efficiency (%) | ≥84 |

| Reduction ratio | 1:5.44 |

| Number of slots | 12 |

| Number of poles (magnets) | 8 |

| Challenges | Priority Class | Challenges |

|---|---|---|

| Technical | 1 | Structural Deficiency and Poor Braking System |

| Safety Concerns | ||

| 2 | Limited Range | |

| Battery Quality and Health Cycle | ||

| 3 | Motor Quality | |

| Battery Charger | ||

| 4 | Grid Integration | |

| Additional Power Supply | ||

| 5 | Quality Products and Warranty | |

| Environmental | 1 | Battery Disposal |

| 3 | Indirect Emission of Greenhouse Gas |

| Details (as of 2020) | Energy in Giga Units (1 Unit = 1 kWh) | |

|---|---|---|

| Total Energy Generation in Bangladesh in one year | 71,419 | |

| Total Energy Generation in Bangladesh in one day | 365 days | 195.66 |

| Number of E3W approximated | 1 million | |

| Average energy consumed by one E3W | 11 units | |

| Number of average units consumed by all E3Ws | 11 |

| Characteristics | Lead Acid Battery | Li-ion Battery |

|---|---|---|

| Nominal Voltage (Volt) | 2 | 3.6 |

| Energy Density (Wh/L) | 35 | 118–250 |

| Specific Energy (Wh/kg) | 30–50 | 120–140 |

| Specific Power (W/Kg) | 180 | 200–430 |

| Operating Temperature (C) | −15 to 50 | −20 to 60 |

| Life Cycle | 1000 | 2000 |

| Production Cost (USD/kWh) | 60 | 150 |

| Schemes | Standard |

|---|---|

| Electrical Vehicle Conductive Charging System | IEC 61851-1:2017 [99], IEC 61851-23:2014 [100], IEC 61851-24:2014 [101] |

| Conductive Power Transfer | ISO 17409:2020 [102] |

| Over Current Protective Device | IEC 60947-2 [103], IEC 60947-6-2 [104], IEC 60269 [105] |

| Earthing | IEC 60364 [105] |

| Thundering Protection | IEC 62305 [106] |

| Insulation Of Charging Equipment | IEC 61851-1 [99] |

| Charging Cable | IEC 62893-1 [107] |

| Charging Station Equipment Protection | IEC 60529 [108] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.J.A.; Hasan, M.Z.; Hasanuzzaman, M.; Khan, M.Z.R.; Ahsan Habib, M. Affordable Electric Three-Wheeler in Bangladesh: Prospects, Challenges, and Sustainable Solutions. Sustainability 2023, 15, 149. https://doi.org/10.3390/su15010149

Hossain MJA, Hasan MZ, Hasanuzzaman M, Khan MZR, Ahsan Habib M. Affordable Electric Three-Wheeler in Bangladesh: Prospects, Challenges, and Sustainable Solutions. Sustainability. 2023; 15(1):149. https://doi.org/10.3390/su15010149

Chicago/Turabian StyleHossain, Md Junaed Al, Md. Zakir Hasan, Md Hasanuzzaman, Md. Ziaur Rahman Khan, and Mohammad Ahsan Habib. 2023. "Affordable Electric Three-Wheeler in Bangladesh: Prospects, Challenges, and Sustainable Solutions" Sustainability 15, no. 1: 149. https://doi.org/10.3390/su15010149

APA StyleHossain, M. J. A., Hasan, M. Z., Hasanuzzaman, M., Khan, M. Z. R., & Ahsan Habib, M. (2023). Affordable Electric Three-Wheeler in Bangladesh: Prospects, Challenges, and Sustainable Solutions. Sustainability, 15(1), 149. https://doi.org/10.3390/su15010149