Competencies of Industrial Engineers for Implementing Augmented Reality Metadata Systems

Abstract

1. Introduction

- −

- They combine real and virtual;

- −

- They are interactive in real-time; and

- −

- They are registered in 3D.

- Collision analysis: by combining the real world—the production line—and the virtual model, it is possible to quickly check from all sides whether partial collisions (typically within production) will occur.

- Concept planning: using AR, various 3D sub-models of the line can be projected onto them, but it is also possible to plan sub-workplaces [20] and/or offices.

- Deviation comparison: A virtual part (i.e., actual CAD data) is projected onto the real part. It is, consequently, possible to compare how the real part corresponds to the designer’s idea within the sub-parameters of the part [21].

- Part verification: this is either a visual inspection of the part (see the previous section) or an AR verification of the assembly.

- Workshop planning: study [18] identifies the potential of AR in layout planning

- Virtual instructions and maintenance: this is one of the most researched applications of AR in the industry (e. g.. [22,23]). These are typically either used directly in production or within training applications [24]. Tutorials can be linked to phone calls as remote support [25] or [26] production and documentation, and are especially easy to trace. The principle of pick-by-vision can be used.

- Display of metadata: a display of extended information directly within the production line (see below).

- Head mounted displays (HMDs), which are worn on the user’s head. (e.g., [32])

- Hand held displays (HHDs), which are held in the user’s hand. The most common examples are mobile phones and tablets. (e.g., [33])

- Spatial displays, which are placed in space. These include projection screens placed in space or mapped images on objects (in situ projection).

- Production and quality control;

- Engineering methods;

- Simulation analysis and operations research;

- Ergonomics; and

- Material handling.

- Business Competence: competencies related to the market, customers, competitors, economy, social environment, etc.

- Technical/Professional competence: competencies specific to the job/task, e.g., specific technical knowledge/skills such as knowledge of programming, 3D modeling, etc.

- Social/Human competence: competencies needed to cooperate with others, e.g., teamwork, communication, etc.

2. Materials and Methods

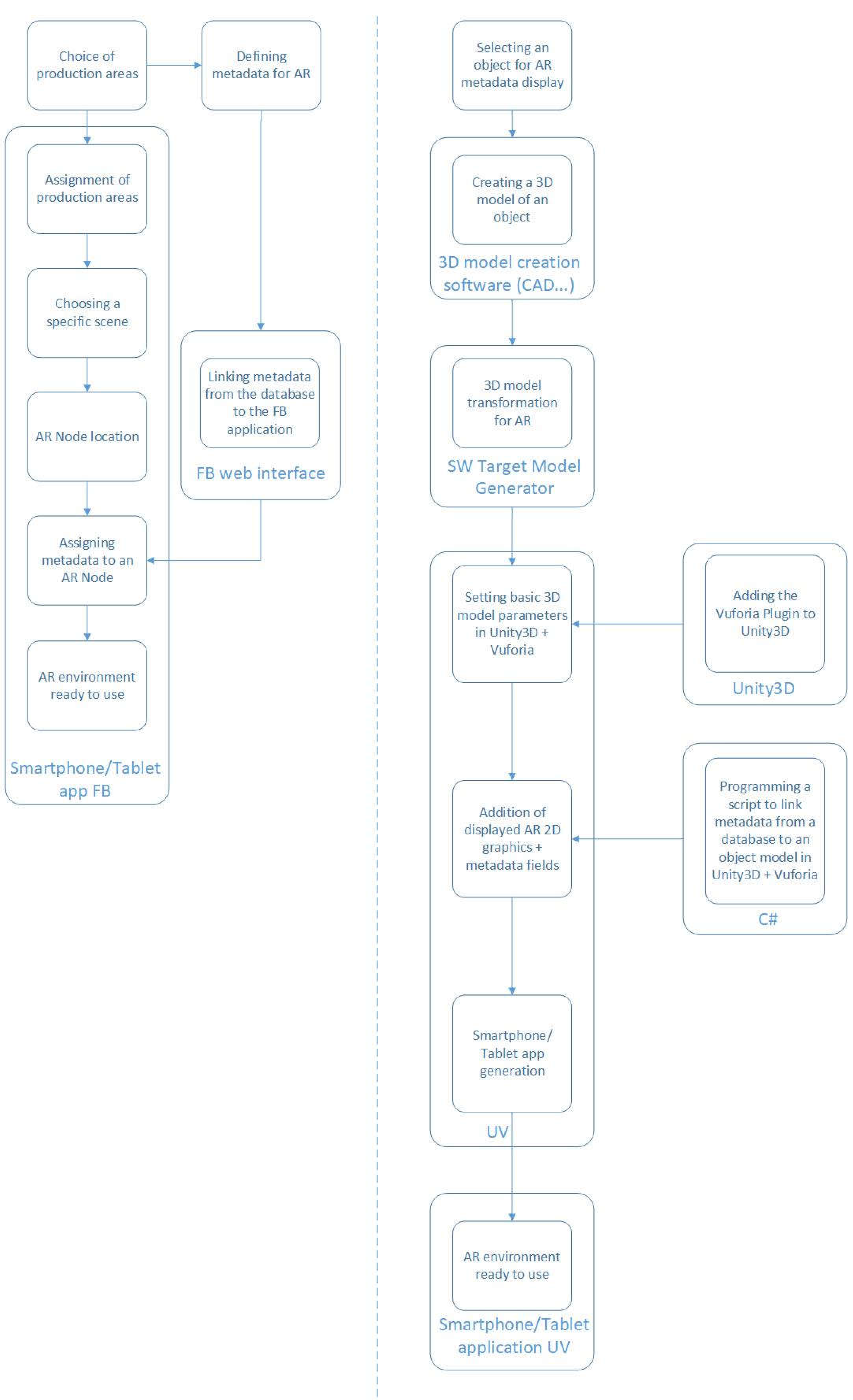

- Option A—Help Lightning Fieldbit (FB)—the FB option uses Help Lightning, Fieldbit’s COTS (commercial off-the-shelf) product, and user connection to the IoT infrastructure.

- Option B—Unity3D and Vuforia (UV)—the UV option is definitely more challenging to implement. However, it offers fundamentally more extensive possibilities in terms of development and overall output. Although it is possible to work in a “non-programmer” way, this option offers extended options for associated functionality.

- Products were tested within the Czech Republic’s education system;

- Students from the Faculty of Engineering were selected;

- Testing was carried out on final-year Industrial Engineering students; and

- The students were introduced to the issues in the form of multimedia frontal teaching (it was not a hands-on experience).

2.1. Description of the Work for Each Option

2.1.1. Help Lightning Fieldbit (FB)

2.1.2. Unity with the Vuforia Expansion (UV)

2.2. Testing Methodology

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azuma, R.T. A Survey of Augmented Reality. Presence: Teleoperators Virtual Environ. 1997, 6, 355–385. [Google Scholar] [CrossRef]

- Zion Market Research Global Augmented Reality Market to Witness Impressive Growth, Revenue to Surge to USD 128.2 Billion By 2028. Available online: https://www.zionmarketresearch.com/news/global-augmented-reality-ar-market (accessed on 17 October 2022).

- Kiryakova, G.; Angelova, N.; Yordanova, L. The potential of augmented reality to change the business. TJS 2017, 15, 394–401. [Google Scholar] [CrossRef]

- Augmented Reality and Virtual Reality Will Transform Selling. Available online: https://www.gartner.com/en/documents/3994752 (accessed on 17 October 2022).

- Caudell, T.P.; Mizell, D.W. Augmented reality: An application of heads-up display technology to manual manufacturing processes. In Proceedings of the Twenty-Fifth Hawaii International Conference on System Sciences, Kauai, HI, USA, 7–10 January 1992; IEEE: Piscataway, NJ, USA, 1992; Volume 2, pp. 659–669. [Google Scholar]

- Milgram, P.; Kishino, F. Taxonomy of mixed reality visual displays. IEICE Trans. Inf. Syst. 1994, E77-D, 1321–1329. [Google Scholar]

- Davis, L.; Rolland, J.; Hamza-Lup, F.; Yonggang, H.; Norfleet, J.; Pettitt, B.; Imielinska, C. Enabling a continuum of virtual environment experiences. IEEE Comput. Grap. Appl. 2003, 23, 10–12. [Google Scholar] [CrossRef]

- Rauschnabel, P.A.; Felix, R.; Hinsch, C.; Shahab, H.; Alt, F. What is XR? Towards a Framework for Augmented and Virtual Reality. Comput. Hum. Behav. 2022, 133, 107289. [Google Scholar] [CrossRef]

- Mařík, V. Průmysl 4.0: Výzva pro Českou Republiku, 1st ed.; Management Press: Praha, Czech Republic, 2016; ISBN 978-80-7261-440-0. [Google Scholar]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Polcar, J.; Horejsi, P. Knowledge acquisition and cyber sickness: A comparison of VR devices in virtual tours. MM Sci. J. 2015, 2015, 613–616. [Google Scholar] [CrossRef]

- Kennedy, R.S.; Lane, N.E.; Berbaum, K.S.; Lilienthal, M.G. Simulator Sickness Questionnaire: An Enhanced Method for Quantifying Simulator Sickness. Int. J. Aviat. Psychol. 1993, 3, 203–220. [Google Scholar] [CrossRef]

- Martirosov, S.; Bureš, M.; Zítka, T. Cyber sickness in low-immersive, semi-immersive, and fully immersive virtual reality. Virtual Real. 2022, 26, 15–32. [Google Scholar] [CrossRef]

- Balk, S.; Bertola, M.; Inman, V. Simulator Sickness Questionnaire: Twenty Years Later. In Driving Assessment Conference 7; University of Iowa: Iowa, IA, USA, 2013; pp. 257–263. [Google Scholar] [CrossRef]

- Kimura, K.; Reichert, J.F.; Olson, A.; Pouya, O.R.; Wang, X.; Moussavi, Z.; Kelly, D.M. Orientation in Virtual Reality Does Not Fully Measure Up to the Real-World. Sci. Rep. 2017, 7, 18109. [Google Scholar] [CrossRef]

- Quandt, M.; Freitag, M. A Systematic Review of User Acceptance in Industrial Augmented Reality. Front. Educ. 2021, 6, 1–17. [Google Scholar] [CrossRef]

- Fajnerová, I.; Greguš, D.; Hlinka, J.; Nekovářová, T.; Škoch, A.; Zítka, T.; Romportl, J.; Žáčková, E.; Horáček, J. Could Prolonged Usage of GPS Navigation Implemented in Augmented Reality Smart Glasses Affect Hippocampal Functional Connectivity? BioMed Res. Int. 2018, 2018, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Pentenrieder, K.; Bade, C.; Doil, F.; Meier, P. Augmented Reality-based factory planning—An application tailored to industrial needs. In Proceedings of the 2007 6th IEEE and ACM International Symposium on Mixed and Augmented Reality, Nara, Japan, 13–16 November 2007; IEEE: Piscataway, NJ, USA, 2008; pp. 31–42. [Google Scholar]

- De Pace, F.; Manuri, F.; Sanna, A. Augmented Reality in Industry 4.0. Am. J. Compt. Sci. Inform. Technol. 2018, 6, 1–14. [Google Scholar] [CrossRef]

- Monika, T.; Pollak, M.; Jozef, T.; Kocisko, M.; Jakub, K. Augmented Reality as a Support Tool in Machining Process. TEM J. 2020, 9, 407–411. [Google Scholar] [CrossRef]

- Sun, W.; Lu, J.; Li, D. Augmented Reality Based Factory Model Comparison Method. In The 19th International Conference on Industrial Engineering and Engineering Management; Qi, E., Shen, J., Dou, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1421–1426. ISBN 978-3-642-38390-8. [Google Scholar]

- Palmarini, R.; Erkoyuncu, J.A.; Roy, R.; Torabmostaedi, H. A systematic review of augmented reality applications in maintenance. Robot. Comput.-Integr. Manuf. 2018, 49, 215–228. [Google Scholar] [CrossRef]

- Konstantinidis, F.K.; Kansizoglou, I.; Santavas, N.; Mouroutsos, S.G.; Gasteratos, A. MARMA: A Mobile Augmented Reality Maintenance Assistant for Fast-Track Repair Procedures in the Context of Industry 4.0. Machines 2020, 8, 88. [Google Scholar] [CrossRef]

- Rivera, E.F.; Pilco, M.V.; Espinoza, P.S.; Morales, E.E.; Ortiz, J.S. Training System for Hybrid Vehicles Through Augmented Reality. In Proceedings of the CISTI’2020—15th Iberian Conference on Information Systems and Technologies, Sevilla, Spain, 24–27 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Naumov, I.; Sinakin, M.; Sinakina, O.; Voronin, V.V. Using augmented reality devices for remote maintenance and repair of industrial equipment as new challenges in the COVID-19 pandemic. In Digital Optical Technologies 2021, Proceedings of the SPIE Volume 11788, Online Only, 21–25 June 2021; Peroz, C., Kress, B.C., Eds.; SPIE: Essen, Germany, 2021; p. 4. [Google Scholar]

- Calandra, D.; Cannavò, A.; Lamberti, F. Improving AR-powered remote assistance: A new approach aimed to foster operator’s autonomy and optimize the use of skilled resources. Int. J. Adv. Manuf. Technol. 2021, 114, 3147–3164. [Google Scholar] [CrossRef]

- Dünser, A.; Billinghurst, M.; Wen, J.; Lehtinen, V.; Nurminen, A. Exploring the use of handheld AR for outdoor navigation. Comput. Graph. 2012, 36, 1084–1095. [Google Scholar] [CrossRef]

- Zhang, X.; Genc, Y.; Navab, N. Taking AR into large scale industrial environments: Navigation and information access with mobile computers. In Proceedings of the IEEE and ACM International Symposium on Augmented Reality, New York, NY, USA, 29–30 October 2001; pp. 179–180. [Google Scholar]

- Gerstweiler, G.; Vonach, E.; Kaufmann, H. HyMoTrack: A Mobile AR Navigation System for Complex Indoor Environments. Sensors 2015, 16, 17. [Google Scholar] [CrossRef]

- Yoo, S.-J.; Choi, S.-H. Indoor AR Navigation and Emergency Evacuation System Based on Machine Learning and IoT Technologies. IEEE Internet Things J. 2022, 9, 20853–20868. [Google Scholar] [CrossRef]

- Van Krevelen, D.W.F.; Poelman, R. A Survey of Augmented Reality Technologies, Applications and Limitations. IJVR 2010, 9, 1–20. [Google Scholar] [CrossRef]

- Majeed Ahmad Augmented Reality Hardware: Key to HMI|Mouser. Available online: https://eu.mouser.com/applications/Augmented-Reality-Hardware-Key-to-HMI/ (accessed on 27 October 2022).

- PTC How Augmented Reality Drives Real World Gains. Available online: https://www.ptc.com/en/resources/ar/report/how-augmented-reality-drives-real-world-gains (accessed on 27 October 2022).

- Park, S.; Bokijonov, S.; Choi, Y. Review of Microsoft HoloLens Applications over the Past Five Years. Appl. Sci. 2021, 11, 7259. [Google Scholar] [CrossRef]

- Daneshjo, N.; Malega, P. Changing of the Maintenance System in the Production Plant with the Application of Predictive Maintenance. TEM J. 2020, 9, 434–441. [Google Scholar] [CrossRef]

- Devagiri, J.S.; Paheding, S.; Niyaz, Q.; Yang, X.; Smith, S. Augmented Reality and Artificial Intelligence in industry: Trends, tools, and future challenges. Expert Syst. Appl. 2022, 207, 118002. [Google Scholar] [CrossRef]

- Poor, P.; Trstenjak, M.; Basl, J. Maintenance Ideal Model in Industry 4.0-A Transformation Strategy Roadmap to Readiness Factor Calculation. In Proceedings of the Hradec Economic Days 2020, Hradec Kralove, Czech Republic, 13–14 April 2020; Jedlicka, P., Maresova, P., Firlej, K., Soukal, I., Eds.; University of Hradec Kralove: Hradec Kralove, Czech Republic; Volume 10, pp. 642–648. [Google Scholar]

- Olshannikova, E.; Ometov, A.; Koucheryavy, Y.; Olsson, T. Visualizing Big Data with augmented and virtual reality: Challenges and research agenda. J. Big Data 2015, 2, 22. [Google Scholar] [CrossRef]

- Sidani, A.; Matoseiro Dinis, F.; Duarte, J.; Sanhudo, L.; Calvetti, D.; Santos Baptista, J.; Poças Martins, J.; Soeiro, A. Recent tools and techniques of BIM-Based Augmented Reality: A systematic review. J. Build. Eng. 2021, 42. [Google Scholar] [CrossRef]

- Kalkofen, D.; Mendez, E.; Schmalstieg, D. Comprehensible Visualization for Augmented Reality. IEEE Trans. Vis. Comput. Graph. 2009, 15, 193–204. [Google Scholar] [CrossRef]

- Mašín, I.; Vytlačil, M. Cesty k Vyšší Produktivitě: Strategie Založená na Průmyslovém Inženýrství; Institut Průmyslového Inženýrství: Liberec, Czech Republic, 1996; ISBN 978-80-902235-0-9. [Google Scholar]

- Slovník průmyslového inženýrství. BusinessInfo.cz. Available online: https://www.businessinfo.cz/navody/slovnik-prumysloveho-inzenyrstvi/ (accessed on 17 October 2022).

- Kosky, P.; Balmer, R.; Keat, W.; Wise, G. Exploring Engineering, 5th ed.; Elsevier Inc: Philadelphia, PA, USA, 2020; ISBN 978-0-12-815073-3. [Google Scholar]

- Průmyslový Inženýr| NSP.CZ. Available online: https://nsp.cz/jednotka-prace/prumyslovy-inzenyr (accessed on 19 April 2021).

- Virtual Reality Manufacturing | VR Engineering | DSI. Available online: https://www.dsidsc.com/virtual-reality-manufacturing/ (accessed on 27 November 2022).

- Bougaa, M.; Bornhofen, S.; Kadima, H.; Rivière, A. Virtual Reality for Manufacturing Engineering in the Factories of the Future. AMM 2015, 789–790, 1275–1282. [Google Scholar] [CrossRef]

- Bellalouna, F. Digitization of industrial engineering processes using the augmented reality technology: Industrial case studies. Procedia CIRP 2021, 100, 554–559. [Google Scholar] [CrossRef]

- Wang, Y.; Hill, K.J.; Foley, E.C. Computer programming with Python for industrial and systems engineers: Perspectives from an instructor and students. Comput. Appl. Eng. Educ. 2017, 25, 800–811. [Google Scholar] [CrossRef]

- Duka, D.; Hribar, L. Implementation of Software Competence Development Process. In Proceedings of the International Convention MIPRO, Opatija, Croatia, 23–27 May 2011; p. 592. [Google Scholar]

- Assyne, N.; Ghanbari, H.; Pulkkinen, M. The essential competencies of software professionals: A unified competence framework. Inf. Softw. Technol. 2022, 151, 107020. [Google Scholar] [CrossRef]

- Kano, N.; Seraku, N.; Takahashi, F.; Tsuji, S. Attractive quality and must-be quality. J. Jpn. Soc. Qual. Control. 1984, 14, 39–48. [Google Scholar]

- Rivera-Ibarra, J.G.; Rodríguez-Jacobo, J.; Fernández-Zepeda, J.A.; Serrano-Vargas, M.A. Competency Framework for Software Engineers. In Proceedings of the 2010 23rd IEEE Conference on Software Engineering Education and Training, Pittsburgh, PA, USA, 9–12 March 2010; pp. 33–40. [Google Scholar]

- Stofkova, J.; Poliakova, A.; Stofkova, K.R.; Malega, P.; Krejnus, M.; Binasova, V.; Daneshjo, N. Digital Skills as a Significant Factor of Human Resources Development. Sustainability 2022, 14, 13117. [Google Scholar] [CrossRef]

- Cimini, C.; Adrodegari, F.; Paschou, T.; Rondini, A.; Pezzotta, G. Digital servitization and competence development: A case-study research. CIRP J. Manuf. Sci. Technol. 2021, 32, 447–460. [Google Scholar] [CrossRef]

- Hecklau, F.; Galeitzke, M.; Flachs, S.; Kohl, H. Holistic Approach for Human Resource Management in Industry 4.0. Procedia CIRP 2016, 54, 1–6. [Google Scholar] [CrossRef]

- Istiyowati, L.S.; Syahrial, Z.; Muslim, S. Programmer’s Competencies between Industry and Education. Univers. J. Educ. Res. 2020, 8, 10–15. [Google Scholar] [CrossRef]

- Salvendy, G. Handbook of Industrial Engineering: Technology and Operations Management; John Wiley & Sons: Hoboken, NJ, USA, 2001; ISBN 978-0-471-33057-8. [Google Scholar]

- Stefanovic, M. The objectives, architectures and effects of distance learning laboratories for industrial engineering education. Comput. Educ. 2013, 69, 250–262. [Google Scholar] [CrossRef]

- Jayaram, U.; Jayaram, S.; Shaikh, I.; Kim, Y.; Palmer, C. Introducing quantitative analysis methods into virtual environments for real-time and continuous ergonomic evaluations. Comput. Ind. 2006, 57, 283–296. [Google Scholar] [CrossRef]

- Jackson, S.L. Research Methods and Statistics: A Critical Thinking Approach, 3rd ed.; Heinle Cengage Learning: Melbourne, Australia, 2008; ISBN 978-0-495-51001-7. [Google Scholar]

- Kiesler, N.; Thorbrügge, C. A Comparative Study of Programming Competencies in Vocational Training and Higher Education. In ITiCSE ’22: Proceedings of the 27th ACM Conference on on Innovation and Technology in Computer Science Education Vol. 1, Dublin, Ireland, 8–13 July 2022; ACM: New York, NY, USA, 2022; pp. 214–220. [Google Scholar]

- Grzona, P.; Broum, T. Augmented Reality—Industrial use case. In Proceedings of the Průmyslové Inženýrství 2022; University of West Bohemia: Pilsen, Czech Republic, 2022; Volume 10, pp. 26–33. [Google Scholar]

| Group of Skills | Competence | Help Lightning Fieldbit | Unity3D Plus Vuforia | ||||

|---|---|---|---|---|---|---|---|

| - | - | Mean Value | Standard Deviation | Not Able to Rank [%] | Mean Value | Standard Deviation | Not Able to Rank [%] |

| Soft skills | Ability to analyze problems | 2.615 | 0.961 | 0.000% | 1.385 | 0.650 | 0.000% |

| Soft skills | Ability to analyze risks | 2.615 | 0.961 | 0.000% | 2.077 | 0.760 | 0.000% |

| Soft skills | Ability to solve technical problems | 2.846 | 1.345 | 0.000% | 2.000 | 1.472 | 0.000% |

| Soft skills | Ability to reuse existing solutions | 1.769 | 0.725 | 0.000% | 1.692 | 1.182 | 0.000% |

| Soft skills | Ability to understand other people’s code | 3.154 | 1.463 | 0.000% | 2.154 | 1.345 | 0.000% |

| Soft skills | Ability to filter information | 2.077 | 0.760 | 0.000% | 1.692 | 0.630 | 0.000% |

| Soft skills | Ability to search for information | 1.769 | 0.832 | 0.000% | 1.538 | 0.660 | 0.000% |

| Soft skills | Ability to prioritize information | 1.923 | 0.641 | 0.000% | 1.615 | 0.650 | 0.000% |

| Soft skills | Ability to collaborate as a team | 2.769 | 1.092 | 0.000% | 2.077 | 0.954 | 0.000% |

| Soft skills | Ability to analyze data | 1.769 | 0.725 | 0.000% | 1.385 | 0.506 | 0.000% |

| Soft skills | Ability to test the result | 1.769 | 0.832 | 0.000% | 1.538 | 0.776 | 0.000% |

| Soft skills | Ability to work under pressure | 2.769 | 0.927 | 0.000% | 2.500 | 1.000 | 7.692% |

| Soft skills | Ability to think creatively | 2.692 | 1.032 | 0.000% | 1.538 | 1.198 | 0.000% |

| Soft skills | Ability to think abstractly | 2.000 | 0.707 | 0.000% | 1.538 | 0.519 | 0.000% |

| Hard skills | Working with 2D graphics (editing and creating images) | 2.846 | 1.345 | 0.000% | 1.615 | 0.650 | 0.000% |

| Hard skills | User-level working with a smartphone | 1.154 | 0.376 | 0.000% | 1.231 | 0.439 | 0.000% |

| Hard skills | Set up and run a development environment | 3.077 | 1.382 | 0.000% | 1.385 | 0.870 | 0.000% |

| Hard skills | Basic understanding of designing graphics for smartphone applications | 2.923 | 1.256 | 0.000% | 1.462 | 0.776 | 0.000% |

| Hard skills | Ability to compile an app for a mobile operating system | 3.167 | 1.337 | 7.692% | 2.083 | 0.900 | 7.692% |

| Hard skills | Knowledge of XML | 3.875 | 0.835 | 38.462% | 2.000 | 0.577 | 46.154% |

| Hard skills | Knowledge of JSON | 3.857 | 1.464 | 46.154% | 1.667 | 0.816 | 53.846% |

| Hard skills | Knowledge of C# | 3.556 | 1.667 | 30.769% | 1.500 | 0.707 | 23.077% |

| Hard skills | Knowledge of Unity | 3.900 | 1.595 | 23.077% | 1.300 | 0.675 | 23.077% |

| Hard skills | Knowledge of Vuforia | 4.400 | 0.966 | 23.077% | 1.200 | 0.422 | 23.077% |

| Hard skills | Knowledge of SQL | 2.909 | 1.300 | 15.385% | 1.909 | 0.831 | 15.385% |

| Hard skills | Knowledge of 3D tools (Blender, Inventor, Catia, and NX) | 3.833 | 1.030 | 7.692% | 1.667 | 0.651 | 7.692% |

| Hard skills | Basic knowledge of networks (network theory and IP address) | 2.333 | 0.888 | 7.692% | 1.750 | 0.866 | 7.692% |

| Hard skills | Ability to connect to data | 1.462 | 0.776 | 0.000% | 1.231 | 0.439 | 0.000% |

| Hard skills | Knowledge of API/MQTT | 2.000 | 1.118 | 30.769% | 1.444 | 0.882 | 30.769% |

| Hard skills | Basics of database systems | 1.917 | 0.900 | 7.692% | 1.667 | 0.888 | 7.692% |

| Hard skills | Ability to understand data architecture | 2.154 | 0.899 | 0.000% | 1.846 | 0.899 | 0.000% |

| Hard skills | Knowledge of object-oriented design principles | 2.769 | 1.166 | 0.000% | 1.615 | 0.961 | 0.000% |

| Business skills | Ability to understand technical text in English | 1.308 | 0.751 | 0.000% | 1.231 | 0.439 | 0.000% |

| Business skills | Knowledge of project management principles | 2.308 | 1.251 | 0.000% | 1.769 | 0.725 | 0.000% |

| Business skills | Knowledge of agile management principles | 2.667 | 0.985 | 7.692% | 2.364 | 0.674 | 15.385% |

| Business skills | Understand the financial aspects of implementing SW solutions | 2.462 | 1.127 | 0.000% | 1.769 | 0.725 | 0.000% |

| Group of Skills | Help Lightning Fieldbit | Unity3D Plus Vuforia | ||||

|---|---|---|---|---|---|---|

| - | Mean Value | Standard Deviation | Not Able to Rank [%] | Mean Value | Standard Deviation | Not Able to Rank [%] |

| Soft skills | 2.324 | 1.040 | 0.000% | 1.762 | 0.951 | 0.549% |

| Hard skills | 2.813 | 1.412 | 13.248% | 1.579 | 0.770 | 13.675% |

| Business skills | 2.176 | 1.144 | 1.923% | 1.760 | 0.744 | 3.846% |

| Help Lightning Fieldbit | ||

|---|---|---|

| Group of Skills | Competence | Mean Value |

| Soft skills | Ability to reuse existing solutions | 1.769 |

| Soft skills | Ability to search for information | 1.769 |

| Soft skills | Ability to analyze data | 1.769 |

| Soft skills | Ability to test the result | 1.769 |

| Soft skills | Ability to prioritize information | 1.923 |

| Soft skills | Ability to think abstractly | 2.000 |

| Soft skills | Ability to filter information | 2.077 |

| Soft skills | Ability to analyze problems | 2.615 |

| Soft skills | Ability to analyze risks | 2.615 |

| Soft skills | Ability to think creatively | 2.692 |

| Soft skills | Ability to work as part of a team | 2.769 |

| Soft skills | Ability to work under pressure | 2.769 |

| Soft skills | Ability to solve technical problems | 2.846 |

| Soft skills | Ability to understand foreign code | 3.154 |

| Hard skills | User-level working with a smartphone | 1.154 |

| Hard skills | Ability to connect to data | 1.462 |

| Hard skills | Fundamentals of database systems | 1.917 |

| Hard skills | Knowledge of API/MQTT | 2.000 |

| Hard skills | Ability to understand data architecture | 2.154 |

| Hard skills | Basic knowledge of networking (network theory and IP address) | 2.333 |

| Hard skills | Knowledge of object-oriented design principles | 2.769 |

| Hard skills | Working with 2D graphics (editing and creating images) | 2.846 |

| Hard skills | Knowledge of SQL | 2.909 |

| Hard skills | Basic understanding of designing graphics for smartphone applications | 2.923 |

| Hard skills | Set up and run a development environment | 3.077 |

| Hard skills | Ability to compile an application for a mobile operating system | 3.167 |

| Hard skills | Knowledge of C# | 3.556 |

| Hard skills | Knowledge of 3D tools (Blender, Inventor, Catia, and NX) | 3.833 |

| Hard skills | Knowledge of JSON | 3.857 |

| Hard skills | Knowledge of XML | 3.875 |

| Hard skills | Knowledge of Unity | 3.900 |

| Hard skills | Knowledge of Vuforia | 4.400 |

| Business skills | Ability to understand technical text in English | 1.308 |

| Business skills | Knowledge of project management principles | 2.308 |

| Business skills | Understand the financial aspects of implementing a software solution | 2.462 |

| Business skills | Knowledge of agile management principles | 2.667 |

| Unity3D Plus Vuforia | ||

|---|---|---|

| Group of Skills | Competence | Mean Value |

| Soft skills | Ability to analyze problems | 1.385 |

| Soft skills | Ability to analyze data | 1.385 |

| Soft skills | Ability to search for information | 1.538 |

| Soft skills | Ability to test the result | 1.538 |

| Soft skills | Ability to think creatively | 1.538 |

| Soft skills | Ability to think abstractly | 1.538 |

| Soft skills | Ability to prioritize information | 1.615 |

| Soft skills | Ability to reuse existing solutions | 1.692 |

| Soft skills | Ability to filter information | 1.692 |

| Soft skills | Ability to solve technical problems | 2.000 |

| Soft skills | Ability to analyze risks | 2.077 |

| Soft skills | Ability to work as part of a team | 2.077 |

| Soft skills | Ability to understand other people’s code | 2.154 |

| Soft skills | Ability to work under pressure | 2.500 |

| Hard skills | Knowledge of Vuforia | 1.200 |

| Hard skills | User-level working with a smartphone | 1.231 |

| Hard skills | Ability to connect to data | 1.231 |

| Hard skills | Knowledge of Unity | 1.300 |

| Hard skills | Set up and run a development environment | 1.385 |

| Hard skills | Knowledge of API/MQTT | 1.444 |

| Hard skills | Basic understanding of designing graphics for smartphone apps | 1.462 |

| Hard skills | Knowledge of C# | 1.500 |

| Hard skills | Working with 2D graphics (editing and creating images) | 1.615 |

| Hard skills | Knowledge of object-oriented design principles | 1.615 |

| Hard skills | Knowledge of JSON | 1.667 |

| Hard skills | Knowledge of 3D tools (Blender, Inventor, Catia, and NX) | 1.667 |

| Hard skills | Basics of database systems | 1.667 |

| Hard skills | Basic knowledge of networks (network theory and IP address) | 1.750 |

| Hard skills | Ability to understand data architecture | 1.846 |

| Hard skills | Knowledge of SQL | 1.909 |

| Hard skills | Knowledge of XML | 2.000 |

| Hard skills | Ability to compile an application for a mobile operating system | 2.083 |

| Business skills | Ability to understand technical text in English | 1.231 |

| Business skills | Knowledge of project management principles | 1.769 |

| Business skills | Understand the financial aspects of implementing a software solution | 1.769 |

| Business skills | Knowledge of agile management principles | 2.364 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broum, T.; Hořejší, P.; Malaga, M.; Grzona, P. Competencies of Industrial Engineers for Implementing Augmented Reality Metadata Systems. Sustainability 2023, 15, 130. https://doi.org/10.3390/su15010130

Broum T, Hořejší P, Malaga M, Grzona P. Competencies of Industrial Engineers for Implementing Augmented Reality Metadata Systems. Sustainability. 2023; 15(1):130. https://doi.org/10.3390/su15010130

Chicago/Turabian StyleBroum, Tomáš, Petr Hořejší, Miroslav Malaga, and Pierre Grzona. 2023. "Competencies of Industrial Engineers for Implementing Augmented Reality Metadata Systems" Sustainability 15, no. 1: 130. https://doi.org/10.3390/su15010130

APA StyleBroum, T., Hořejší, P., Malaga, M., & Grzona, P. (2023). Competencies of Industrial Engineers for Implementing Augmented Reality Metadata Systems. Sustainability, 15(1), 130. https://doi.org/10.3390/su15010130