The Effects of Portland and Sulphoaluminate Cements Solidification/Stabilization on Semi-Dynamic Leaching of Heavy Metal from Contaminated Sediment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

3. Results

3.1. Unconfined Compressive Strength Test

3.2. pH Fluctuation of the Leachate during Leaching

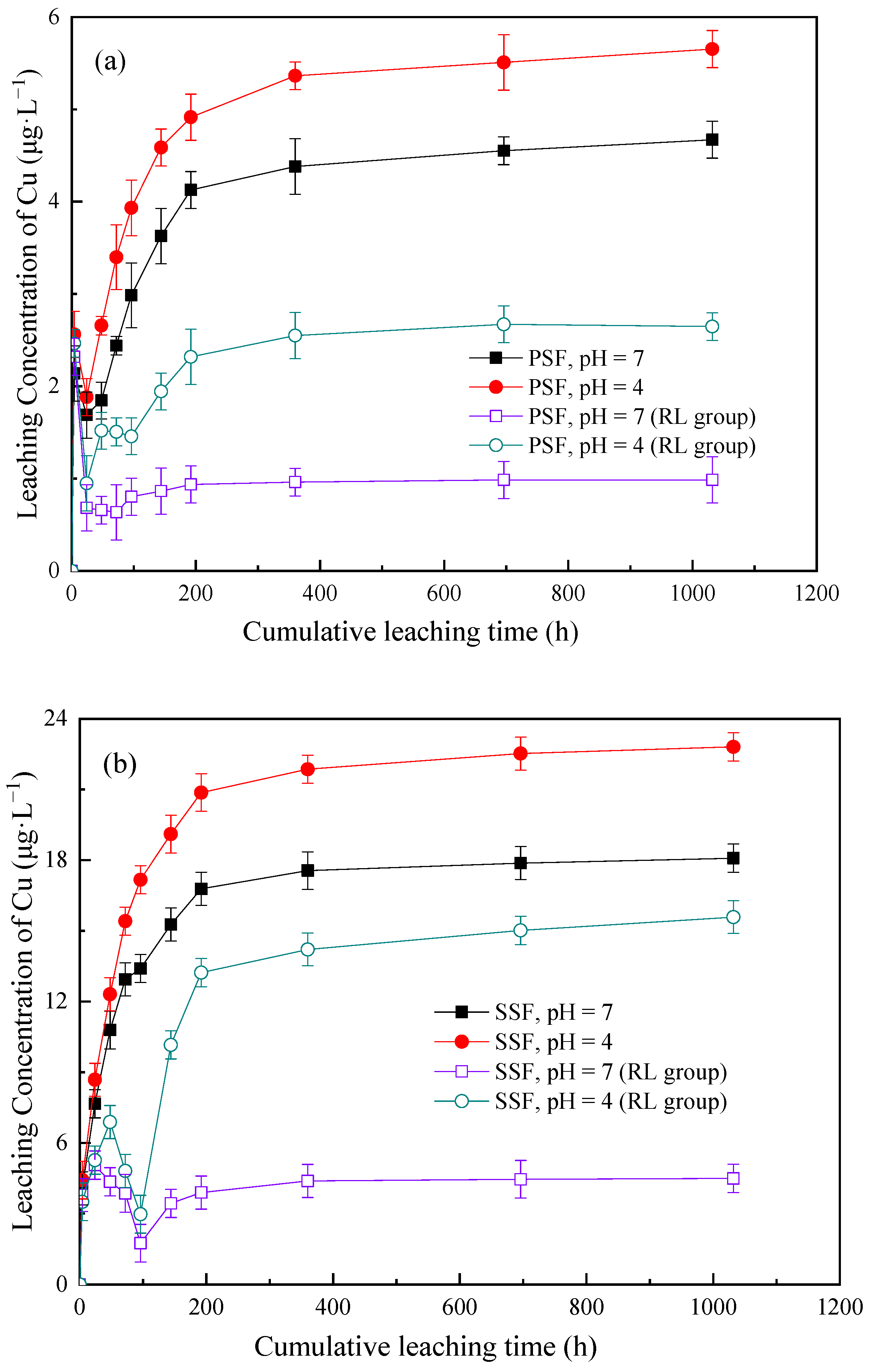

3.3. The Analysis on Cu Leaching

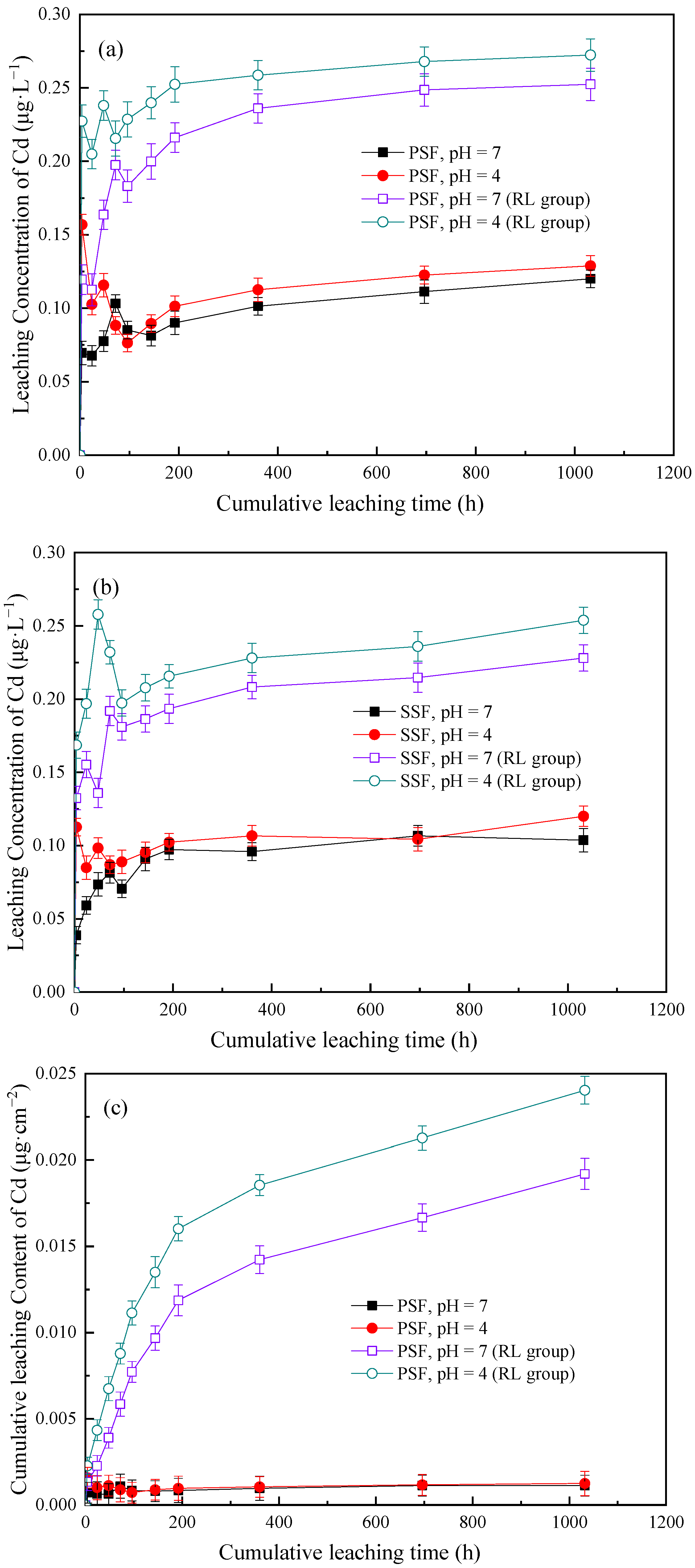

3.4. The Analysis on Cd Leaching

3.5. The Compressive Strength Change of the Solidified Form

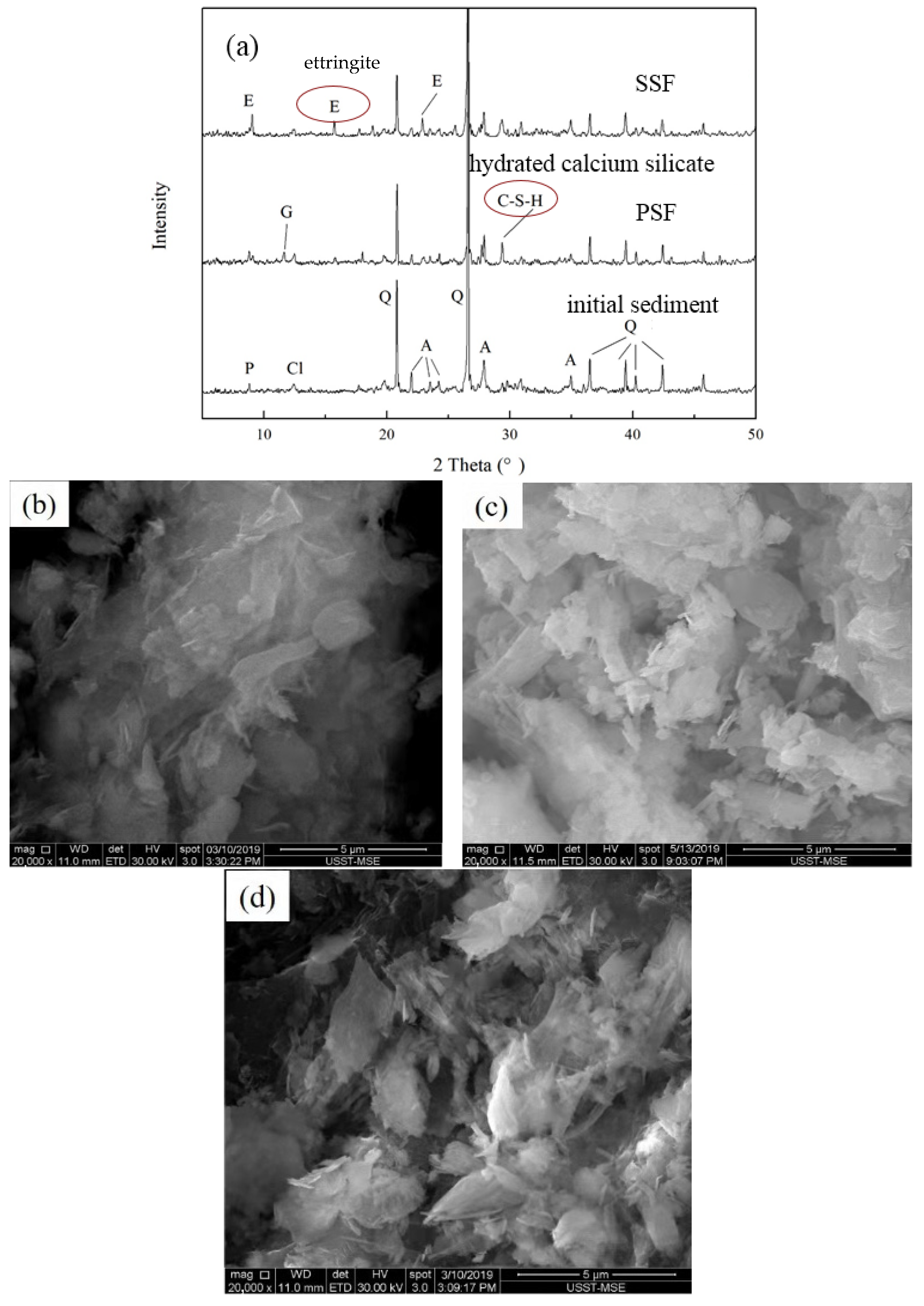

3.6. XRD and SEM

3.7. Implication

4. Conclusions

- (1)

- The compressive strength of SSF reached 0.35 MPa after curing for one day, and then decreased. The compressive strength of PSF increased with the curing time, and reached 0.75 MPa after 28 days.

- (2)

- In general, the solidification effect of Portland cement on Cu was better than that on Cd, with significantly lower mobility even in acidic conditions. The adsorption and chemical bonding force of hydrated silicate to Cu were much higher than that of calcium sulphoalmuninate which resulted in the lower release of Cu from PSF. The difference in stabilization effect of Cd using two cements was less significant than that of Cu.

- (3)

- Portland cement was more suitable for treating heavy metal-contaminated sediments due to the higher stability of PSF. When the pH of leaching solution was 4.0, the compressive strength decline of PSF and SSF after leaching was 5.3% and 14.8% respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hao, S.L.; Guo, C.Y.; Li, Z.Y.; Tu, Y.H.; Wu, T. Research progress on remediation technology of river sediment polluted by heavy metals. Shandong Chem. Ind. 2021, 50, 75–76+79. [Google Scholar]

- Hu, L.W.; Chen, M.; Yang, Q.; Tao, M.X.; Yang, T. Present situation of heavy metal pollution in sediments and its remendiation technologies. Environ. Eng. 2017, 35, 115–118+123. [Google Scholar]

- Hao, J.X. Spatial Distribution and Environmental Risk Assessment of Heavy Metals in Sediment of the Upstream Yellow River; Lanzhou Jiaotong University: Lanzhou, China, 2021. [Google Scholar]

- Chen, C.F. Study on Solidification and Stabilization Technology of Composite Heavy Metal Contamination in River Sediment; Guangzhou University: Guangzhou, China, 2019. [Google Scholar]

- Kuang, C.K.; Zhang, T.P. The nutrient releasing characteristics of the solidification/stabilization treatment of the polluted sediments from urban river. Ecol. Environ. Sci. 2011, 20, 1530–1535. [Google Scholar]

- Liu, J.J. Research progress on solidification and stabilization remediation technology of heavy metal polluted river sediment. J. Green Sci. Technol. 2020, 8, 81–82. [Google Scholar]

- You, C.; Qian, J.; Qin, J.; Wang, H.; Wang, Q.; Ye, Z. Effect of early hydration temperature on hydration product and strength development of magnesium phosphate cement (MPC). Cem. Concr. Res. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Liu, P.C.; Chen, X.H.; Li, J.R.; Yan, J.S.; Su, X.D.; Zheng, K. Research progress of sulphoaluminate cement. Mod. Salt Chem. Ind. 2021, 4, 18–19. [Google Scholar]

- Han, P.J.; Wang, S.; Chen, F.Y.; Bai, X.H. Mechanism of cement-stabilized soil polluted by magnesium sulfate. J. Cent. South Univ. 2015, 22, 1869–1877. [Google Scholar] [CrossRef]

- Pei, T. Study on the Performance of Ordinary Portland Cement-Sulphoaluminate Cement Composite Cementing System Concrete; AnHui University of Science and Technology: Anhui, China, 2020. [Google Scholar]

- Chen, L.J.; Huang, X.H. Migration mechanism and control strategies of heavy metals inpolluted river sediments. Environ. Eng. 2011, 29, 209–216. [Google Scholar]

- He, Y.J.; Wang, W.X.; Lv, L.N.; Wang, F.Z.; Hu, S.G. Curing of Cr3+, Pb2+ in different cement pastes. J. Mater. Sci. Eng. 2018, 36, 530–534. [Google Scholar]

- U.S. EPA. Method 1315: Mass Transfer Rates of Constituents in Monolithic and Compacted Granular Materials Using a Semi-Dynamic Tank Leaching Procedure; Office of Land and Environmental Management: Washington, DC, USA, 2017.

- ASTM. C1308-08: Standard method for accelerated leach test for diffusive release from solidified waste and a computer program to model diffusive. In Fractional Leaching from Cylindrical Waste Forms; ASTM: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Moon, D.H. Lead leachability from quicklime treated soils in a diffusion controlled environment. Environ. Eng. Res. 2005, 10, 112–121. [Google Scholar] [CrossRef]

- Moon, D.H.; Dermatas, D. An evaluation of lead leachability from stabilized/solidified soils under modified semi-dynamic leaching conditions. Eng. Geol. 2006, 85, 67–74. [Google Scholar] [CrossRef]

- Moon, D.H.; Dermatas, D.; Grubb, D.G. Release of arsenic (As) and lead (Pb) from quicklime-sulfate stabilized/solidified soils under diffusion-controlled conditions. Environ. Monit. Assess. 2010, 169, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Shao, L.; Fu, K. Remediation of sediment in complex heavy metals polluted river channel by organic acid leaching. J. Water Resour. Archit. Eng. 2021, 19, 228–234. [Google Scholar]

- Gui, C.X.; Li, D.; Hu, S.Y.; Yuan, X.Z. Study on the difference of leaching concentration and extraction rate of heavy metals in several leaching methods. J. Chongqing Tech. Bus. Univ. 2018, 35, 1–6. [Google Scholar]

- Xia, W.L.; Huang, W. Determination on dredging depth of river sediment in the comprehensive treatment project of black and odorous water bodies. China Water Wastewater 2022, 38, 44–47. [Google Scholar]

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. China Communications Press: Beijing, China, 2020.

- ASTM. D4972-2013; Standard Test Method for pH of Soils. ASTM: West Conshohocken, PA, USA, 2013.

- SYT 5163-2010; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. National Energy Administration: Beijing, China, 2010.

- Mao, L.C.; Ye, H.; Li, F.P.; Yang, M.; Tao, H.; Wen, H.F. Enrichment assessment of Sb and trace metals in sediments with significant variability of background concentration in detailed scale. Environ. Sci. Pollut. Res. 2019, 26, 2794–2805. [Google Scholar] [CrossRef]

- Mao, L.C.; Liu, L.B.; Yan, N.X.; Li, F.P.; Tao, H.; Ye, H.; Wen, H.F. Factors controlling the accumulation and ecological risk of trace metal(loid)s in river sediments in agricultural field. Chemsphere 2020, 243, 125359. [Google Scholar] [CrossRef]

- Teng, J.Y. Contamination characteristics of heavy metals in soils from urban green space in central Shanghai. Chin. J. Soil Sci. 2021, 52, 927–933. [Google Scholar]

- Wang, Y.; Wang, Y.G.; Luo, H.L. Soil Environmental Background Values in Shanghai; China Environmental Science Press: Beijing, China, 1992. [Google Scholar]

- GB/T 50123-1999; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 1999.

- Liu, Z.P.; Du, Y.J.; Jiang, N.J.; Zhu, J.J. Leaching properties of cement-solidified lead-contaminated clay via semi-dynamic leaching tests. Chin. J. Geotech. Eng. 2013, 35, 2212–2218. [Google Scholar]

- Du, J.F.; Cheng, T.T.; Ma, J.L. The climatic characteristics and formation of acid rain in Shanghai. Trans. Atmos. Sci. 2015, 38, 137–143. [Google Scholar]

- Min, H.X. Preparation and properties of sulphoaluminate cement based high performance concrete. J. Funct. Mater. 2021, 52, 9196–9201. [Google Scholar]

- Singh, S.B.; Munjal, P.; Thammishetti, N. Role of water cement ratio on strength development of cement mortar. J. Build. Eng. 2015, 4, 94–100. [Google Scholar] [CrossRef]

- Wei, D.B.; Ding, M.; Ren, G.B.; Wu, L.D.; Li, X.M.; Wang, Q.C. Study on hydration properties of composite cementitious material based on sulphoaluminate. Mater. Rev. 2018, 32, 492–497. [Google Scholar]

- Xue, Q.; Wang, P.; Li, J.S.; Zhang, T.T.; Wang, S.Y. Investigation of the leaching behavior of lead in stabilized/solidified waste using a two-year semi-dynamic leaching test. Chemosphere 2017, 166, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Shen, Z.T.; Al-Tabbaa, A. An evaluation of stabilised/solidified contaminated model soil using PC-based and MgO-based binders under semi-dynamic leaching conditions. Environ. Sci. Pollut. Res. 2018, 25, 16050–16060. [Google Scholar] [CrossRef] [PubMed]

- Remond, S.; Bentz, D.P.; Pimienta, P. Effects of the incorporation of Municipal Solid Waste Incineration fly ash in cement pastes and mortars: II: Modeling. Cem. Concr. Res. 2002, 32, 565–576. [Google Scholar] [CrossRef]

- Rachana, M.; Rubina, C. Leaching behavior and immobilization of heavy metals in solidified/stabilized products. J. Hazard. Mater. 2006, 137, 207–217. [Google Scholar]

- Wang, W.X. Solidication of Cr, Cd, Pb in Portland Cement/Sulphoaluminate Cement; Wuhan University of Technology: Wuhan, China, 2017. [Google Scholar]

| Properties | Value | Method |

|---|---|---|

| Natural moisture content (%) | 38 | Test Methods of Soils for Highway Engineering (JTG 3430-2020) [21] |

| Liquid limit (%) | 36.8 | |

| Plastic limit (%) | 24.3 | |

| Plasticity index (%) | 12.7 | |

| pH value (L:S = 1:1) | 7.56 | ASTM D4972-13 [22] |

| Redox potential (mv) | −69.5 | Redox potential tester |

| Organic matter content (%) | 2.2 | Loss-on-ignition method |

| Particle size distribution (μm) | 5–75 | Laser particle size distribution instrument |

| Chemical composition (%) | - | Analysis method for clay minerals and ordinary non-clay minerals in sedimentary rocks by X-ray diffraction (SYT 5163-2010) [23] |

| Fe2O3 | 5.72 | |

| Na2O | 1.12 | |

| SiO2 | 63.75 | |

| CaO | 5.33 | |

| MgO | 3.27 | |

| K2O | 3.11 | |

| Al2O3 | 15.98 | |

| Soil classification | Sandy clay |

| Heavy Metals | Cd | Cr | Ni | Pb | Zn | Cu |

|---|---|---|---|---|---|---|

| Sediment from Fuxing Island Canal | 0.35 | 82.7 | 26.5 | 68.5 | 96.4 | 45.2 |

| Background value [26,27] | 0.13 | 75.0 | 31.9 | 25.5 | 86.1 | 28.6 |

| Prepared sediment | 0.98 | 68.0 | 26.9 | 158 | 92.3 | 68.5 |

| Group | Time (h) | CLR-t1/2 Slope | R2 | De/m2·s−1 | Mobility |

|---|---|---|---|---|---|

| PSF, pH = 7.0 | 0~96 | 2.82 × 10−7 | 0.9152 | 8.69 × 10−18 | low |

| 96~1032 | 1.43 × 10−7 | 0.9615 | 2.24 × 10−18 | low | |

| PSF, pH = 4.0 | 0~96 | 4.59 × 10−7 | 0.9633 | 2.31 × 10−17 | low |

| 96~1032 | 3.63 × 10−7 | 0.9713 | 1.44 × 10−17 | low | |

| SSF, pH = 7.0 | 0~96 | 1.20 × 10−6 | 0.9964 | 1.57 × 10−16 | low |

| 96~1032 | 6.12 × 10−7 | 0.9702 | 4.10 × 10−17 | low | |

| SSF, pH = 4.0 | 0~96 | 1.52 × 10−6 | 0.9806 | 2.53 × 10−16 | low |

| 96~1032 | 2.02 × 10−6 | 0.9744 | 4.47 × 10−16 | low |

| Group | Time (h) | CLRt1/2 Slope | R2 | De/m2·s−1 | Mobility |

|---|---|---|---|---|---|

| PSF, pH = 7.00 | 0~96 | 5.54 × 10−6 | 0.9852 | 3.37 × 10−15 | low |

| 96~1032 | 2.34 × 10−6 | 0.9977 | 6.01 × 10−16 | low | |

| PSF, pH = 4.00 | 0~96 | 7.09 × 10−6 | 0.9952 | 5.50 × 10−15 | low |

| 96~1032 | 2.54 × 10−6 | 0.9975 | 7.09 × 10−16 | low | |

| SSF, pH = 7.00 | 0~96 | 5.35 × 10−6 | 0.9907 | 3.13 × 10−15 | low |

| 96~1032 | 2.06 × 10−6 | 0.9973 | 4.66 × 10−16 | low | |

| SSF, pH = 4.00 | 0~96 | 6.56 × 10−6 | 0.9955 | 4.72 × 10−15 | low |

| 96~1032 | 2.27 × 10−6 | 0.9973 | 5.64 × 10−16 | low |

| Solidified Form | Compressive Strength (MPa) | Loss Rate of Compressive Strength (%) |

|---|---|---|

| PSF, initial | 0.75 | - |

| SSF, initial | 0.27 | - |

| PSF, leaching solution pH = 7.0 | 0.72 | 4.0 |

| PSF, leaching solution pH = 4.0 | 0.71 | 5.3 |

| SSF, leaching solution pH = 7.0 | 0.23 | 14.8 |

| SSF, leaching solution pH = 4.0 | 0.23 | 14.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, D.; Tao, H.; Yang, Y. The Effects of Portland and Sulphoaluminate Cements Solidification/Stabilization on Semi-Dynamic Leaching of Heavy Metal from Contaminated Sediment. Sustainability 2022, 14, 5681. https://doi.org/10.3390/su14095681

Sun Y, Zhang D, Tao H, Yang Y. The Effects of Portland and Sulphoaluminate Cements Solidification/Stabilization on Semi-Dynamic Leaching of Heavy Metal from Contaminated Sediment. Sustainability. 2022; 14(9):5681. https://doi.org/10.3390/su14095681

Chicago/Turabian StyleSun, Yan, Daofang Zhang, Hong Tao, and Yang Yang. 2022. "The Effects of Portland and Sulphoaluminate Cements Solidification/Stabilization on Semi-Dynamic Leaching of Heavy Metal from Contaminated Sediment" Sustainability 14, no. 9: 5681. https://doi.org/10.3390/su14095681

APA StyleSun, Y., Zhang, D., Tao, H., & Yang, Y. (2022). The Effects of Portland and Sulphoaluminate Cements Solidification/Stabilization on Semi-Dynamic Leaching of Heavy Metal from Contaminated Sediment. Sustainability, 14(9), 5681. https://doi.org/10.3390/su14095681