Analysis of OFDI Industry Linkage Network Based on Grey Incidence: Taking the Jiangsu Manufacturing Industry as an Example

Abstract

1. Background

2. Literature Review

2.1. On the Use of Social Networks Analysis in the Economic Sphere

2.2. Research on Inter-Industry Linkages

2.3. Research on OFDI in Jiangsu Province

3. Data Sources and Study Design

3.1. Data Sources

3.2. Absolute Degree of Incidence

3.3. Social Networks Analysis

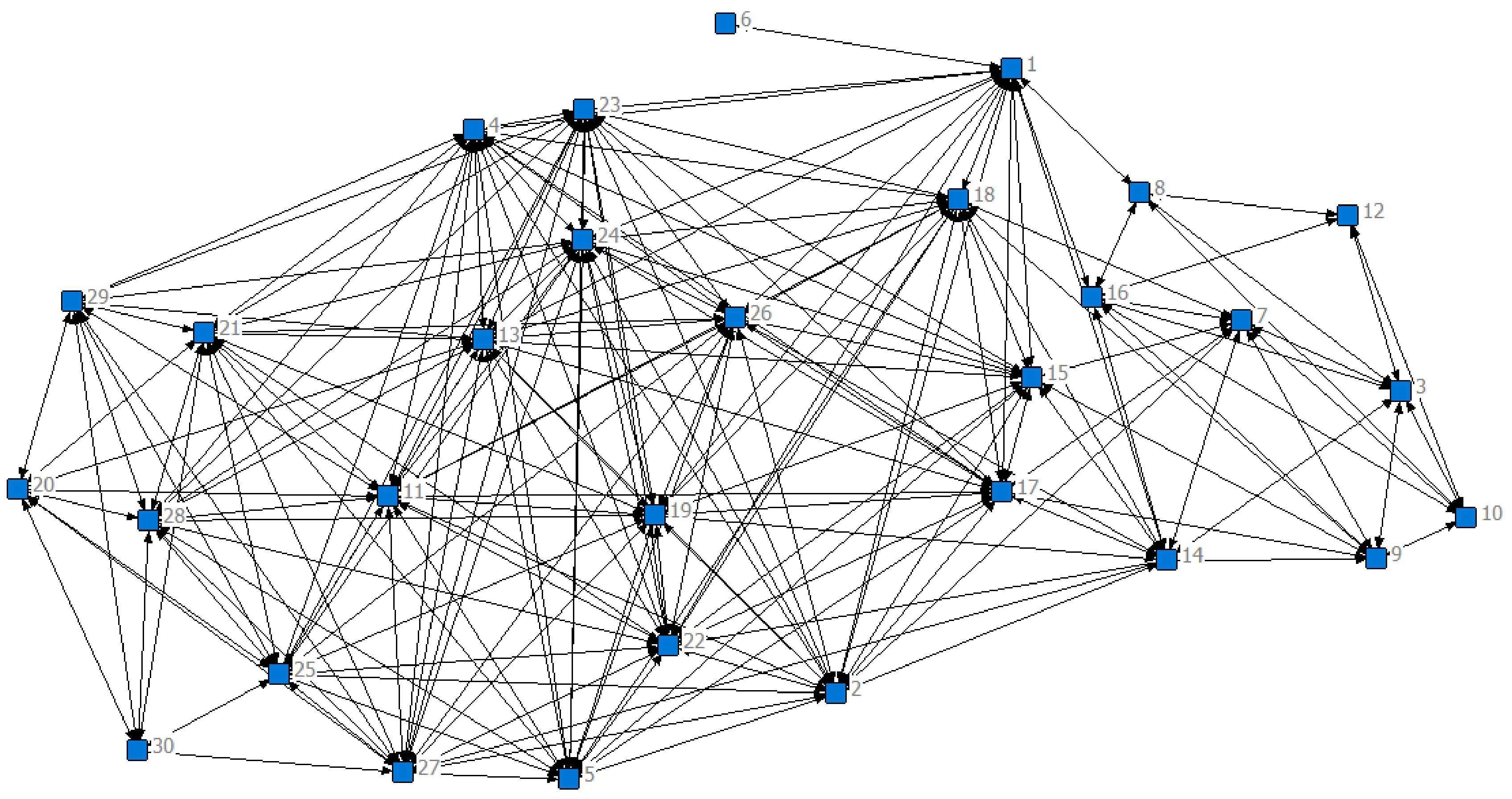

3.3.1. Industry Affiliate Network Building

3.3.2. Analysis of Network Characteristics Indicators

4. Jiangsu Province Manufacturing OFDI Industry Linkages and Associated Networks Analysis

4.1. Jiangsu Province Manufacturing OFDI Industry Linkage Analysis

4.2. Basic Nature of Affiliated Networks in the Manufacturing OFDI Industry in Jiangsu Province

4.2.1. Characterization Based on ‘Points’

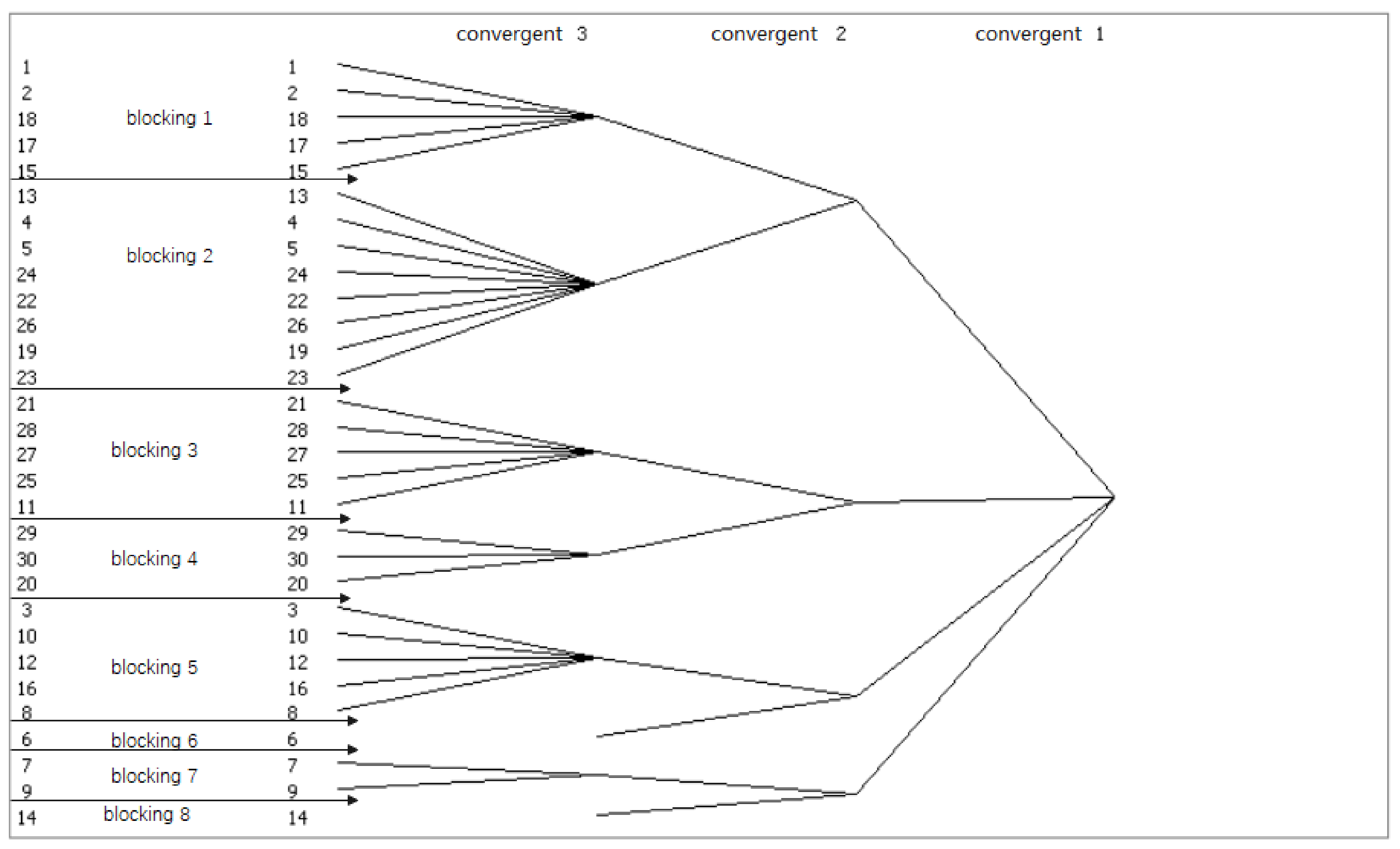

4.2.2. Characterization Based on ‘Facets’

5. Conclusions and Recommendations for Countermeasures

5.1. Conclusions

5.2. Limitations

5.3. Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lueg, C. Corporate communications and the rise of the network society. Int. J. Media Manag. 2001, 3, 161–166. [Google Scholar] [CrossRef]

- Graham, S. The Rise of the Network Society. Urban Stud. 1997, 34, 1529–1530. [Google Scholar]

- Lee, C.; Wilkinson, D.J. A Social Network Analysis of Articles on Social Network Analysis. arXiv 2018, arXiv:1810.09781. [Google Scholar]

- Mohamad, A.H.; Wang, F.; Abu Bakar, N.W.; Jatavallabhula, P.K. Social Network Analysis of B2B Networks. In Proceedings of the 6th International Conference on Computing and Informatics—Embracing Eco-Friendly Computing, Kuala Lumpur, Malaysia, 25–27 April 2017; pp. 341–349. [Google Scholar]

- Li, M.; Gao, L.; Fan, Y.; Wu, J.; Di, Z. Emergence of global preferential attachment from local interaction. New J. Phys. 2010, 12, 043029. [Google Scholar] [CrossRef]

- Yan, Q.; Tang, M. Social Network Analysis of Network Communities. In Proceedings of the 2009 Eighth International Conference on Mobile Business, Dalian, China, 27–28 June 2009; pp. 154–157. [Google Scholar] [CrossRef]

- Seongjin, K. Syrian Refugees’ Mobilities in a Network Society. East West Stud. 2021, 33, 161–190. [Google Scholar] [CrossRef]

- Baek, E.C.; Porter, M.A.; Parkinson, C. Special Issue: Computational Methods in Social neuroscience. Soc. Cogn. Affect. Neurosci. 2021, 16, 883–901. [Google Scholar] [CrossRef] [PubMed]

- Beutel, J. Analysing Fuel Subsidy and Taxation Reform with Input–Output Data. World Trade Rev. 2020, 19, S62–S87. [Google Scholar] [CrossRef]

- Arrow, K.J. Economic Welfare and the Allocation of Resources for Invention; Princeton University Press: Princeton, NJ, USA, 1962. [Google Scholar]

- Yu, Z.; Xiao, Y.; Gu, X.; Xie, X. Does imported producer service affect manufacturing export? Evidence from china. Singap. Econ. Rev. 2022, 1–30. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Q.; Choi, G. Efficiency assessment of industrial solid waste generation and treatment processes with carry-over in China. Sci. Total Environ. 2020, 726, 138274. [Google Scholar] [CrossRef]

- Dwiatmoko, H.; Hidayat, A.K.; Supriyatno, D.; Mudjanarko, S.W.; Ramli, M.I. The influence of railway development on the indonesian national economy: An input-output approach. IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 012104. [Google Scholar] [CrossRef]

- Chiu, R.-H.; Lin, Y.-C. Applying input-output model to investigate the inter-industrial linkage of transportation industry in taiwan. J. Mar. Sci. Technol. 2012, 20, 8. [Google Scholar] [CrossRef]

- Mei, Q.; Jiang, Q.; Yang, L. Research on the path of synergetic development between logistics industry and the leading industry in Fujian province. MATEC Web Conf. 2017, 119, 01040. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Lee, S.-G.; Trimi, S. Industrial linkage and spillover effects of the logistics service industry: An input–output analysis. Serv. Bus. 2021, 15, 231–252. [Google Scholar] [CrossRef]

- Huang, W.-Q.; Li, F.; Yao, S. Dynamic Volatility Spillover Network of Chinese Financial Institutions. J. Northeast. Univ. Nat. Sci. (China) 2019, 40, 596–601. [Google Scholar] [CrossRef]

- Jin, J.; Yu, Z.; Mi, C. Commercial bank credit risk management based on grey incidence analysis. In Proceedings of the 2011 IEEE International Conference on Grey Systems and Intelligent Services, Nanjing, China, 15–18 September 2011; pp. 534–538. [Google Scholar]

- Wang, R.L.; Liu, S.F. Grey incidence analysis of the third industry of Nanjing. In Proceedings of the International Conference on Systems, Man and Cybernetics, Waikoloa, HI, USA, 12 October 2005; Volumes 1–4, pp. 1546–1550. [Google Scholar]

- Lv, P.; Li, X. The Impact of Institution and Industrial Development on OFDI: Home and Host Country Perspectives. Sci. Sci. Manag. S. T. 2017, 38, 45–59. [Google Scholar]

- Ramasamy, B.; Yeung, M.; Laforet, S. China’s outward foreign direct investment: Location choice and firm ownership. J. World Bus. 2012, 47, 17–25. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, D.; Bethel, B.J. Analyzing the Characteristics and Evolution of Chinese Enterprises’ Outward Forward Direct Investment Host Country Network. Sustainability 2021, 13, 9824. [Google Scholar] [CrossRef]

- Guo, H.-B. Research on the influence of OFDI on jiangsu’s regional innovation capability: Focusing on absorptive capacity. J. Asian Stud. 2020, 23, 335–348. [Google Scholar] [CrossRef]

- Xin, D.; Zhang, Y. Threshold effect of OFDI on China’s provincial environmental pollution. J. Clean. Prod. 2020, 258, 120608. [Google Scholar] [CrossRef]

- Du, L.; Lin, R. OFDI, Reverse Technology Spillovers and Provincial Innovation in China: A Threshold Test Based on Interprovincial Panel Data in China. China Soft Sci. 2018, 1, 149–162. [Google Scholar]

- Ning, Y.; Cui, X.; Wang, J. Impact of OFDI Reverse Technology Spillover on Chinas Export Competitiveness: An Empirical Analysis from Perspective of Technological Gap. J. Northeast. Univ. Nat. Sci. 2021, 42, 589–597. [Google Scholar]

- Li, H. A study of OFDI technology—Seeking motivation and productivity improvement and their heterogeneities. Stud. Sci. Sci. 2021, 39, 254–263. [Google Scholar]

- Wu, Y.; Song, Y.; Deng, G. Institutional Environment, OFDI, and TFP Growth: Evidence from China. Emerg. Mark. Financ. Trade 2017, 53, 2020–2038. [Google Scholar] [CrossRef]

- Liu, M.; Qian, X. Provincial Interdependence and China’s “Irrational” Outward Foreign Direct Investment. Open Econ. Rev. 2020, 32, 153–181. [Google Scholar] [CrossRef]

- Ju-Long, D. Control problems of grey systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar] [CrossRef]

- Deng, J.-L.; Zhou, C.-S. Sufficient conditions for the stability of a class of interconnected dynamic systems. Syst. Control Lett. 1986, 7, 105–108. [Google Scholar] [CrossRef]

- Liu, S.; Fang, Z.; Xie, N.; Yang, Y. Explanation of terms of Grey models for decision-making. Grey Syst. Theory Appl. 2018, 8, 382–387. [Google Scholar] [CrossRef]

- Deng, J.L. Grey Systems; National Defense Industry Press: Beijing, China, 1985; pp. 202–355. (In Chinese) [Google Scholar]

- Cao, M.; Dang, Y.; Mi, C. An improvement on calculation of absolute degree of grey incidence. In Proceedings of the 2006 IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006; Volumes 1–6. [Google Scholar] [CrossRef]

- Liu, J. Lectures on Whole Network Approach; Shanghai People’s Press: Shanghai, China, 2014; pp. 78–257. (In Chinese) [Google Scholar]

- Watts, D.J.; Strogatz, S.H. Collective dynamics of ‘small-world’ networks. Nature 1998, 393, 440–442. [Google Scholar] [CrossRef]

- Hubbell, C.H. An Input-Output Approach to Clique Identification. Sociometry 1965, 28, 377. [Google Scholar] [CrossRef]

- Agranoff, R.; Clift, S.; Burt, R.S. Structural Holes: The Social Structure of Competition; Cambridge: Harvard, MA, USA, 1992. [Google Scholar]

- Liao, L.; Hu, R.; Zhang, G. Structural holes analysis of fuzzy social network. J. Southeast Univ. Nat. Sci. Ed. (China) 2013, 43, 900–904. [Google Scholar] [CrossRef]

- Goo, K.H.; Yunyoung, R.O.H. The Moderating Effect of Structural Holes on the Relationship between Supplier Openness and Buyer Satisfaction. J. Mark. Thought 2017, 4, 52–58. [Google Scholar]

- Wang, X.; Li, X.; Chen, G. Network Science: An Introduction; Higher Education Press: Beijing, China, 2012; pp. 46–398. (In Chinese) [Google Scholar]

- Watts, D. Networks, dynamics and the small-world phem. Am. J. Sociol. 1999, 105, 493–527. [Google Scholar] [CrossRef]

- Boorman, S.A.; White, H.C. Social Structure from Multiple Networks. II. Role Structures. Am. J. Sociol. 1976, 81, 1384–1446. [Google Scholar] [CrossRef]

- Karrer, B.; Newman, M.E.J. Stochastic blockmodels and community structure in networks. Phys. Rev. E 2011, 83, 016107. [Google Scholar] [CrossRef]

- Moyer, D.; Gutman, B.; Prasad, G.; Faskowitz, J.; Ver Steeg, G.; Thompson, P. Blockmodels for Connectome Analysis. Proc. SPIE 2015, 9681, 96810A. [Google Scholar] [CrossRef]

- Zhang, K.; Zhong, Q.; Feng, J.; Zhou, H.; Feng, H. Absolute Degree of Grey Incidences for Matrix Sequence and Its Application. J. Grey Syst. 2018, 30, 56. [Google Scholar]

- Li, Q. Weighted absolute degree of grey incidence with TOPSIS and its application. Grey Syst. Theory Appl. 2016, 6, 281–291. [Google Scholar] [CrossRef]

- Li, Y.; Sun, H.; Huang, J.; Huang, Q. Low-End Lock-In of Chinese Equipment Manufacturing Industry and the Global Value Chain. Sustainability 2020, 12, 2981. [Google Scholar] [CrossRef]

- Lu, R.; Reve, T. Guanxi, structural hole and closure. J. Strat. Manag. 2011, 4, 275–288. [Google Scholar] [CrossRef]

- Jessop, A. Blockmodels with maximum concentration. Eur. J. Oper. Res. 2003, 148, 56–64. [Google Scholar] [CrossRef][Green Version]

- Tang, D.; Wang, L.; Bethel, B.J. An Evaluation of the Yangtze River Economic Belt Manufacturing Industry Level of Intelligentization and Influencing Factors: Evidence from China. Sustainability 2021, 13, 8913. [Google Scholar] [CrossRef]

| Mean | 0.67 | Skewness | 0.63 |

| Standard Error | 0.01 | Area | 0.50 |

| Median | 0.63 | Min | 0.50 |

| Plural | 0.72 | Maximum | 0.999 |

| Standard deviation | 0.14 | Summation | 312.56 |

| Variance | 0.02 | Number of observations | 465 |

| Kurtosis | −0.72 | Confidence level (95.0%) | 0.01 |

| Node | DC | EC | CC | Hubble Influence | Structural Hole Measures | |||

|---|---|---|---|---|---|---|---|---|

| EffSize | Efficie | Constra | Hierarc | |||||

| 1 | 0.52 | 0.18 | 65.18 | 1.02 | 6.67 | 0.44 | 0.16 | 0.01 |

| 2 | 0.59 | 0.24 | 67.44 | 1.010 | 4.79 | 0.28 | 0.19 | 0.01 |

| 3 | 0.24 | 0.02 | 43.32 | 1.023 | 3.08 | 0.44 | 0.37 | 0.03 |

| 4 | 0.59 | 0.24 | 65.18 | 1.021 | 4.67 | 0.28 | 0.19 | 0.01 |

| 5 | 0.55 | 0.24 | 58.59 | 1.02 | 3.19 | 0.20 | 0.20 | 0.01 |

| 6 | 0.03 | 0.01 | 40.00 | 1.002 | 1.00 | 1.00 | 1.00 | 1.00 |

| 7 | 0.31 | 0.07 | 51.79 | 1.013 | 4.00 | 0.44 | 0.25 | 0.02 |

| 8 | 0.17 | 0.02 | 45.31 | 1.006 | 2.22 | 0.44 | 0.44 | 0.03 |

| 9 | 0.28 | 0.06 | 50.02 | 1.011 | 3.63 | 0.45 | 0.27 | 0.01 |

| 10 | 0.21 | 0.01 | 37.95 | 1.007 | 2.46 | 0.41 | 0.43 | 0.04 |

| 11 | 0.59 | 0.24 | 60.42 | 1.023 | 4.71 | 0.28 | 0.19 | 0.01 |

| 12 | 0.14 | 0.01 | 34.53 | 1.006 | 1.25 | 0.31 | 0.54 | 0.00 |

| 13 | 0.66 | 0.26 | 67.48 | 1.025 | 5.47 | 0.29 | 0.19 | 0.02 |

| 14 | 0.45 | 0.14 | 61.22 | 1.015 | 5.83 | 0.45 | 0.19 | 0.02 |

| 15 | 0.52 | 0.20 | 63.74 | 1.020 | 4.53 | 0.30 | 0.19 | 0.01 |

| 16 | 0.28 | 0.03 | 49.17 | 1.011 | 4.25 | 0.53 | 0.31 | 0.01 |

| 17 | 0.55 | 0.21 | 65.91 | 1.021 | 4.94 | 0.31 | 0.19 | 0.01 |

| 18 | 0.55 | 0.21 | 65.91 | 1.021 | 4.94 | 0.31 | 0.19 | 0.01 |

| 19 | 0.59 | 0.24 | 67.44 | 1.023 | 4.77 | 0.28 | 0.18 | 0.01 |

| 20 | 0.28 | 0.10 | 45.69 | 1.010 | 1.57 | 0.20 | 0.29 | 0.02 |

| 21 | 0.52 | 0.20 | 54.72 | 1.020 | 4.20 | 0.28 | 0.21 | 0.01 |

| 22 | 0.62 | 0.25 | 67.50 | 1.024 | 4.61 | 0.26 | 0.19 | 0.01 |

| 23 | 0.62 | 0.25 | 67.44 | 1.024 | 4.78 | 0.27 | 0.19 | 0.01 |

| 24 | 0.62 | 0.25 | 67.44 | 1.024 | 4.78 | 0.27 | 0.19 | 0.01 |

| 25 | 0.55 | 0.22 | 55.24 | 1.019 | 4.48 | 0.28 | 0.21 | 0.02 |

| 26 | 0.59 | 0.24 | 67.44 | 1.023 | 4.24 | 0.25 | 0.19 | 0.01 |

| 27 | 0.59 | 0.22 | 60.65 | 1.023 | 5.71 | 0.34 | 0.19 | 0.02 |

| 28 | 0.48 | 0.19 | 53.70 | 1.019 | 3.86 | 0.28 | 0.21 | 0.01 |

| 29 | 0.38 | 0.14 | 49.58 | 1.014 | 2.64 | 0.24 | 0.24 | 0.01 |

| 30 | 0.21 | 0.07 | 40.92 | 1.009 | 1.00 | 0.17 | 0.33 | 0.00 |

| Index | Density | Degree Centralization | In/Out Centralization | Clustering Coefficient | Average Distance |

|---|---|---|---|---|---|

| VALUE | 0.431 | 22.91% | 26.45%/23.59% | 0.750 | 1.846 |

| Distances | Frequen | Proport |

|---|---|---|

| 1 | 375.000 | 0.431 |

| 2 | 296.000 | 0.340 |

| 3 | 159.000 | 0.183 |

| 4 | 38.000 | 0.044 |

| 5 | 2.000 | 0.002 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.975 | 0.2 | 0 | 0.08 | 0.2 | 0.7 | 1 |

| 2 | 0.975 | 0.964 | 0.925 | 0.125 | 0 | 0 | 0 | 0.25 |

| 3 | 0.16 | 0.975 | 1 | 0.933 | 0 | 0 | 0 | 0 |

| 4 | 0 | 0.208 | 0.933 | 1 | 0 | 0 | 0 | 0 |

| 5 | 0.08 | 0 | 0 | 0 | 0.95 | 0 | 0.6 | 0.4 |

| 6 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 7 | 0.7 | 0 | 0 | 0 | 0.5 | 0 | 1 | 1 |

| 8 | 1 | 0.375 | 0.2 | 0 | 0.4 | 0 | 1 | |

| (R − squared = 0.787) | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Tang, D.; Li, Y.; Boamah, V.; Liu, Y. Analysis of OFDI Industry Linkage Network Based on Grey Incidence: Taking the Jiangsu Manufacturing Industry as an Example. Sustainability 2022, 14, 5680. https://doi.org/10.3390/su14095680

Zhang X, Tang D, Li Y, Boamah V, Liu Y. Analysis of OFDI Industry Linkage Network Based on Grey Incidence: Taking the Jiangsu Manufacturing Industry as an Example. Sustainability. 2022; 14(9):5680. https://doi.org/10.3390/su14095680

Chicago/Turabian StyleZhang, Xiaoling, Decai Tang, Yi Li, Valentina Boamah, and Yisi Liu. 2022. "Analysis of OFDI Industry Linkage Network Based on Grey Incidence: Taking the Jiangsu Manufacturing Industry as an Example" Sustainability 14, no. 9: 5680. https://doi.org/10.3390/su14095680

APA StyleZhang, X., Tang, D., Li, Y., Boamah, V., & Liu, Y. (2022). Analysis of OFDI Industry Linkage Network Based on Grey Incidence: Taking the Jiangsu Manufacturing Industry as an Example. Sustainability, 14(9), 5680. https://doi.org/10.3390/su14095680