The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect

Abstract

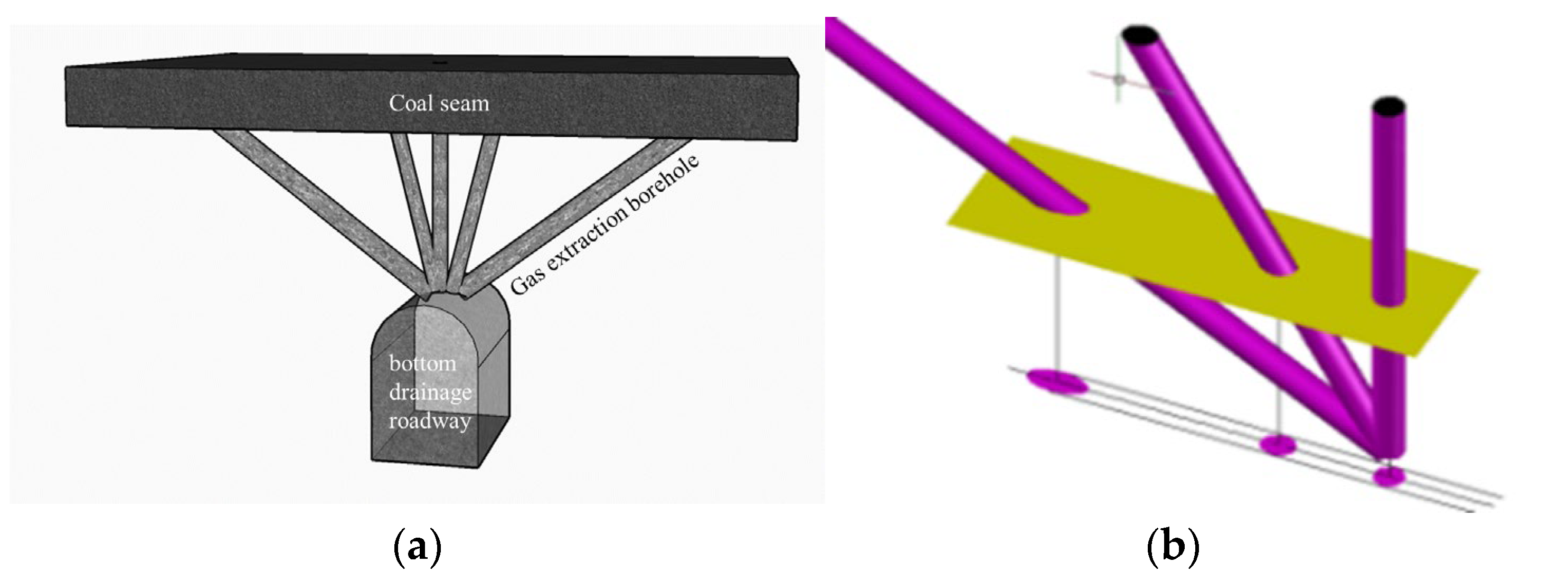

:1. Introduction

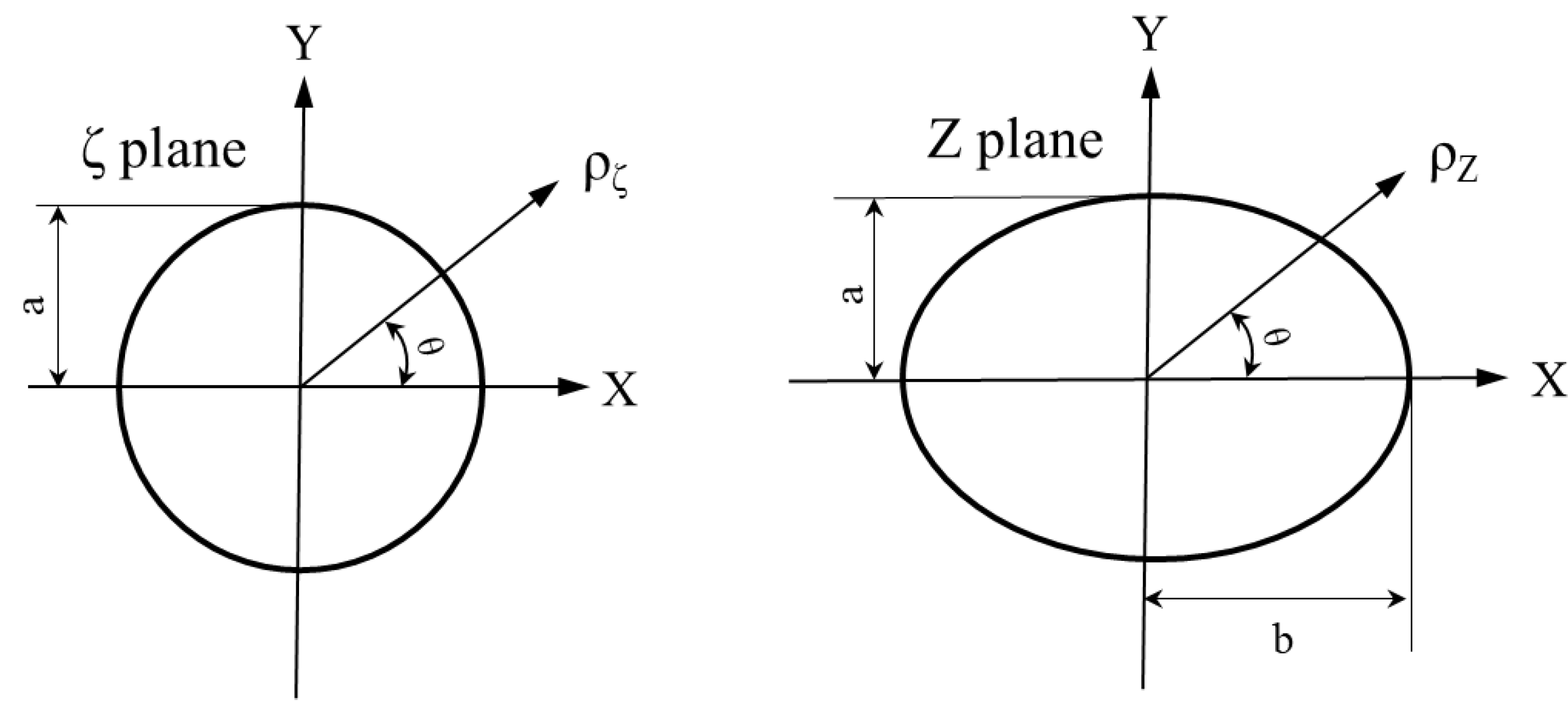

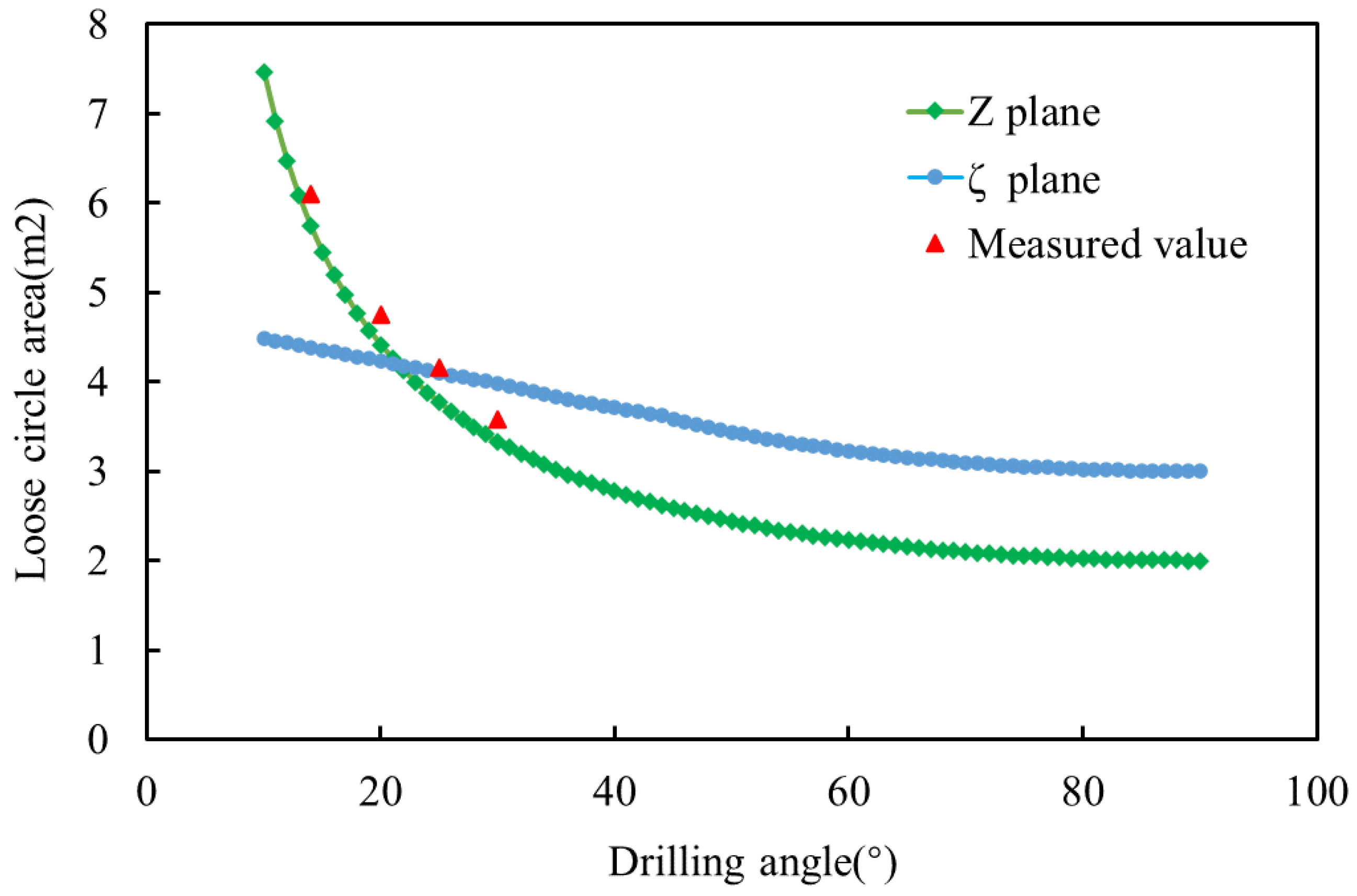

2. Influence of Drilling Angle on Area of Rock Loose Circle around Drilling

2.1. Theoretical Analysis

2.2. Result Analysis

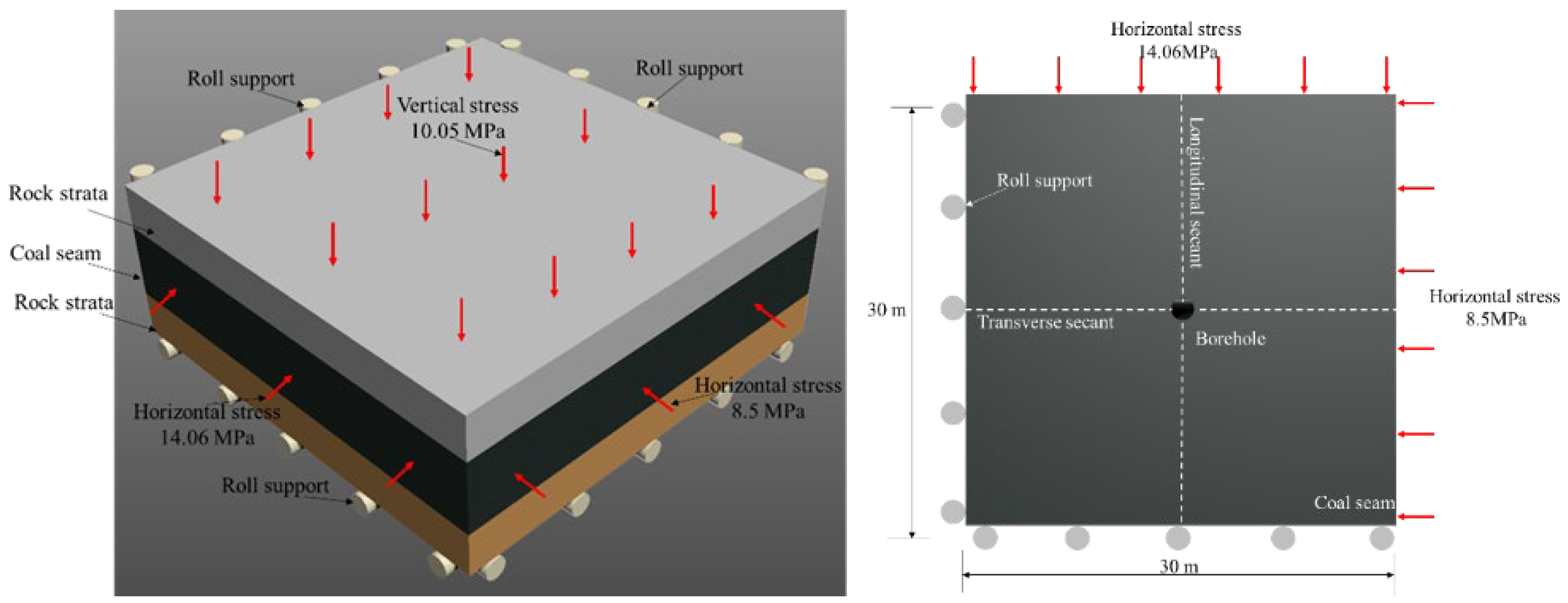

3. Influence Pattern of Drilling Angle on Gas Extraction Effect

3.1. Equation of Dynamic Change of Coal Permeability

3.2. Determination of Fluid-Solid Coupling Equation

3.3. Model Establishment and Boundary Condition Setting

3.4. Result Analysis

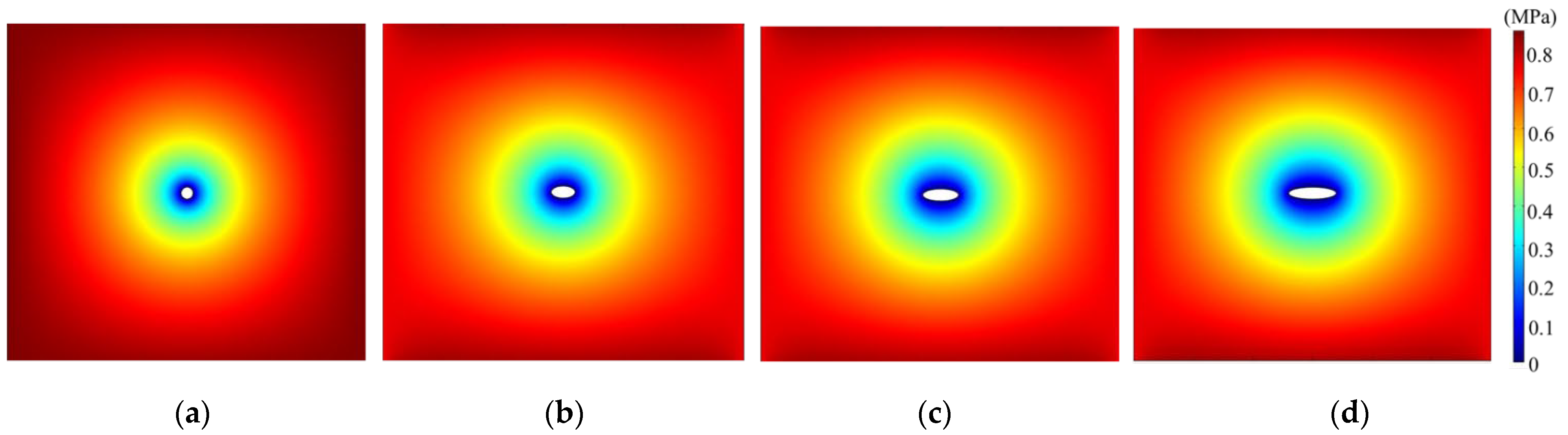

3.4.1. Varying Pattern of Coal Permeability around Drilling with Inclination Angle

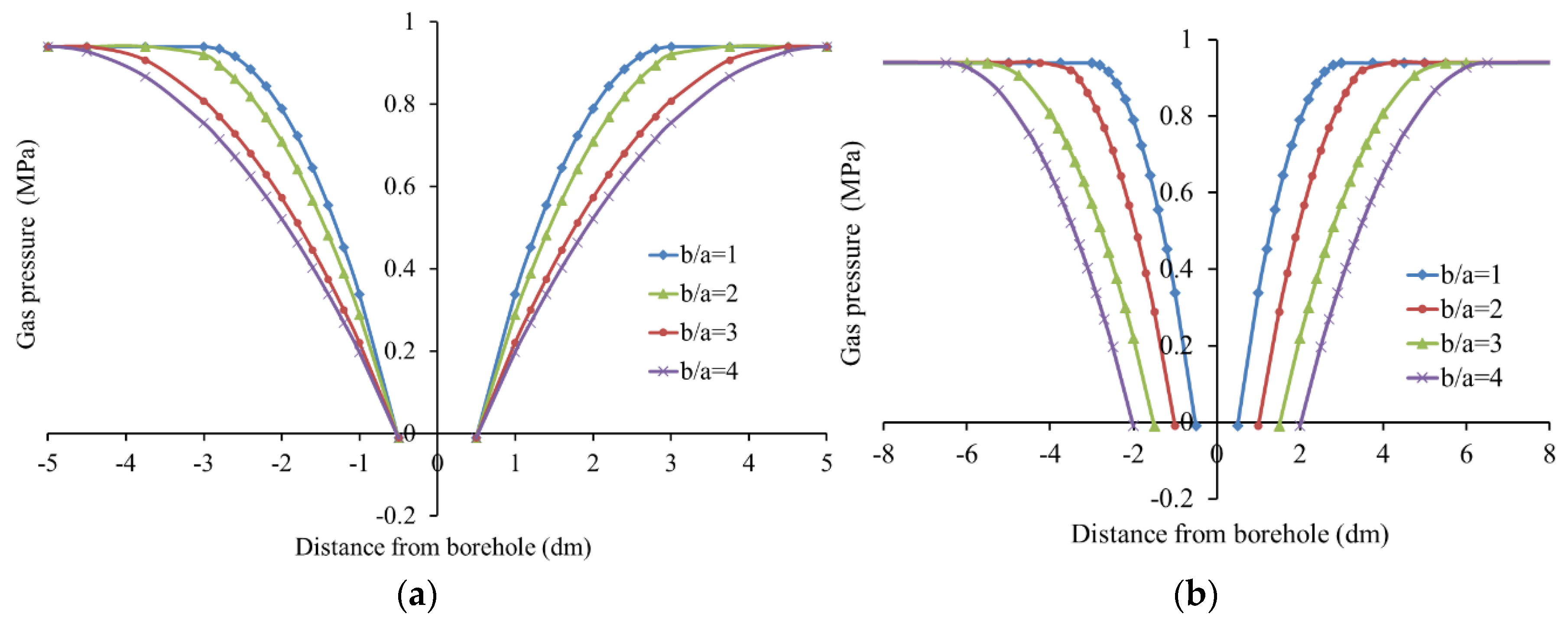

3.4.2. Varying Pattern of Gas Pressure around Drilling with Inclination Angle

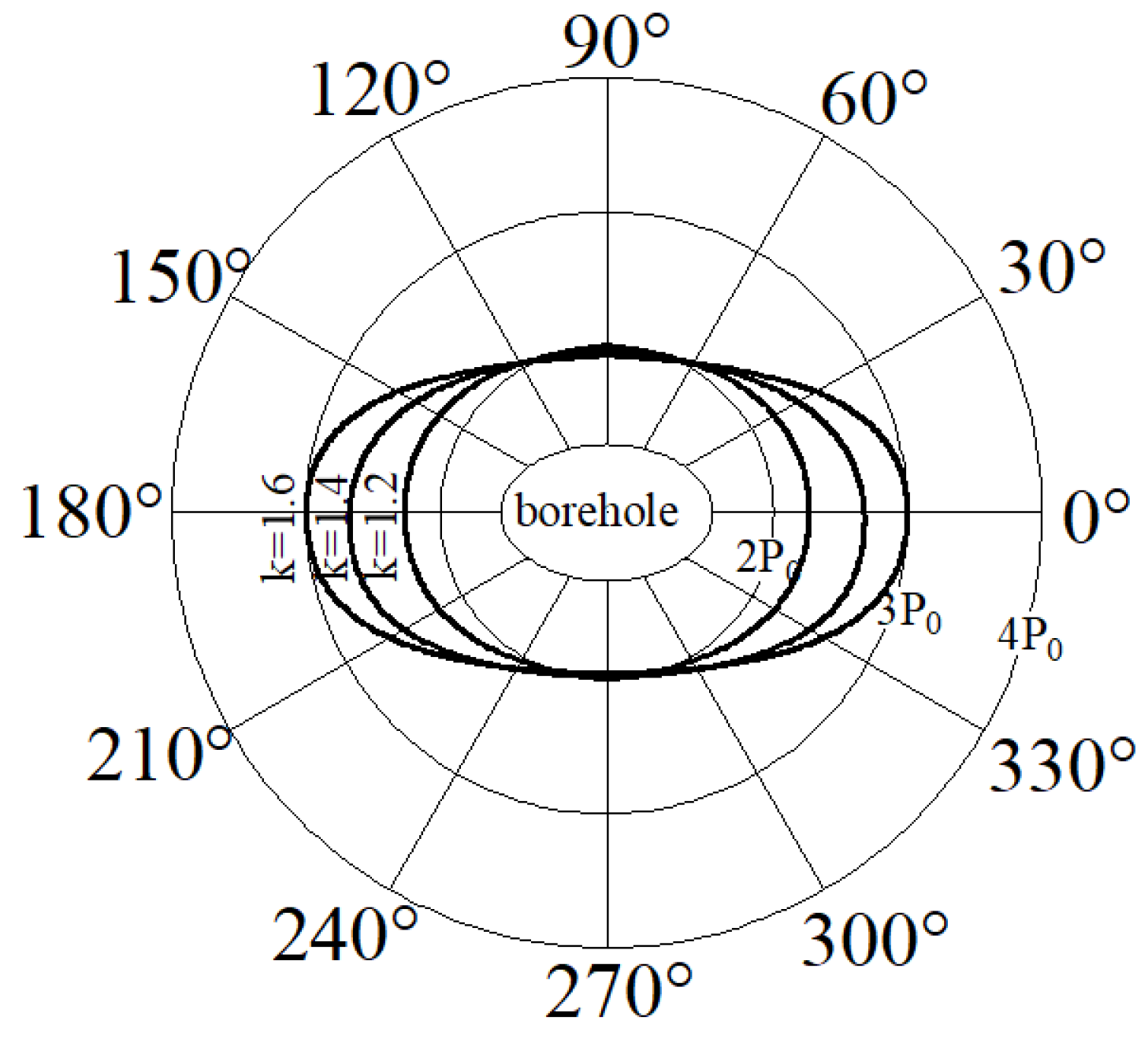

4. Arrangement Optimization for BDR

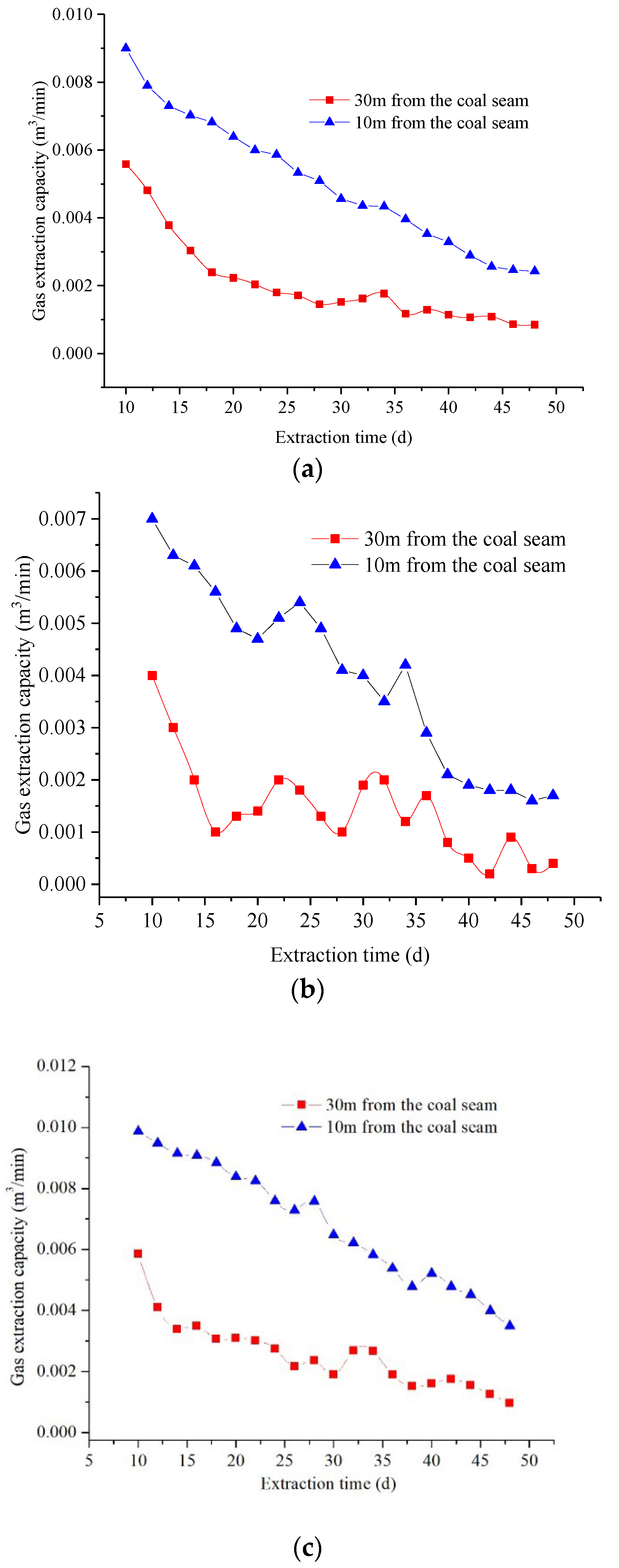

5. Engineering Applications

6. Conclusions and Discussions

- (1)

- The complex function method is used to analyze the area of the loose circle around the elliptical borehole, which is similar to the field measured results, and is quite different from the calculated value of the area of the loose circle around the circular borehole;

- (2)

- With the increase in drilling angle, the area of the loose circle and permeability of coal around the borehole decays negatively and exponentially. It shows that with the decrease in drilling angle, the volumetric strain of coal around the borehole increases, the cracks in the coal increase, and the permeability of coal is improved. At the same time, with the decrease in drilling angle, the gas pressure of coal around the borehole decreases, and the area of gas pressure reduction expands, which is conducive to the drainage of gas in the coal seam;

- (3)

- Through theoretical calculation, it is found that the coal gas pre-drainage effect is better when the drilling angle of the 8406 longwall face of Yangmei Coal Mine is 29°, and the distance between the BDR and the coal seam is 10 m. Through field measurement, the maximum average single hole gas drainage volume is 0.0068 m3/min; the extraction rate of the boreholes with the spacing of 10 m is about 60% higher than those with the spacing of 30 m.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, F.; Wang, X.; Liu, Y. Gas drainage efficiency: An input–output model for evaluating gas drainage projects. Nat. Hazards 2014, 74, 989–1005. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Zhang, C.; Tu, S.; Chen, M.; Zhang, L. Pressure-relief and methane production performance of pressure relief gas extraction technology in the longwall mining. J. Geophys. Eng. 2016, 14, 77–89. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Lin, B.; Fu, X.; Liu, A. Mechanical criterion for coal and gas outburst: A perspective from multiphysics coupling. Int. J. Coal Sci. Technol. 2021, 8, 1423–1435. [Google Scholar] [CrossRef]

- Yi, M.; Wang, L.; Hao, C.; Liu, Q.; Wang, Z. Method for designing the optimal sealing depth in methane drainage boreholes to realize efficient drainage. Int. J. Coal Sci. Technol. 2021, 8, 1400–1410. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.; Wu, H. Study of the stress relief and gas drainage limitation of a drilling and the solving mechanism. Procedia Earth Planet. Sci. 2009, 1, 371–376. [Google Scholar]

- Yang, Z.; Cheng, Z.; Liu, Y. Influence of multiple mining of outburst coal seam group on gas extraction of cross-layer borehole. China Saf. Sci. J. 2020, 30, 66–73. [Google Scholar]

- Yin, G.; He, B.; Li, M.; Cao, J.; Qin, H.; Li, W. Coupling mechanism between flow rate of gas drainage and coal seam abutment stress under mining conditions. J. China Coal Soc. 2015, 40, 736–741. [Google Scholar]

- Dong, H.; Wang, B.; Li, C. Study on relationship between angle of penetration boreholes for pre-drainage in coal seam and gas drainage effect. J. Saf. Sci. Technol. 2015, 11, 99–104. [Google Scholar]

- Liu, T.; Lin, B.; Yang, W. Impact of matrix -fracture interactions on coal permeability: Model development and analysis. Fuel 2017, 207, 522–532. [Google Scholar] [CrossRef]

- Zang, J.; Wang, K. Gas sorption-induced coal swelling kinetics and its effects on coal permeability evolution: Model development and analysis. Fuel 2017, 189, 164–177. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Tu, S.; Hao, D.; Teng, T. Experimental and numerical study of the influence of gas pressure on gas permeability in pressure relief gas drainage. Transp. Porous Media 2018, 124, 995–1015. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, S. Study on rational layout of floor gas drainage gateway in high gassy-outburst seam. Coal Sci. Technol. 2018, 46, 155–160. [Google Scholar]

- Zhang, C.; Tu, S.; Zhang, L.; Chen, M. A study on effect of seepage direction on permeability stress test. Arab. J. Sci. Eng. 2016, 41, 4583–4596. [Google Scholar] [CrossRef]

- Zhao, N.; Dai, G.; Zhang, R. Practice on gas control technology of floor drainage gateway with two uses. Coal Sci. Technol. 2014, 42, 53–57. [Google Scholar]

- Nan, H.; Li, M.; Guan, X. Optimization research on floor drainage lane position in the burst coal. J. Henan Polytech. Univ. (Nat. Sci.) 2015, 34, 463–467. [Google Scholar]

- Zhao, Y. Study on Coupled Theory of Seepage Damage-Fracture in Fractured Rock Mass and Its Application. Ph.D. Thesis, Central South University, Changsha, China, 2009. [Google Scholar]

- Chan, D.Y.C.; Hughes, B.D. Transient gas flow around the boreholes. Transp. Porous Media 1993, 10, 137–152. [Google Scholar] [CrossRef]

- Feng, X.; Seto, M.; Katsuyama, K. Neural dynamic modeling on earthquake magnitude series. Geophys. J. Int. 1997, 128, 547–556. [Google Scholar] [CrossRef] [Green Version]

- Ville, A.D. On the properties of compressible gas flow in a porous media. Transp. Porous Media 1998, 22, 287–306. [Google Scholar] [CrossRef]

- Lv, A.; Zhang, L. Complex Function Method for Mechanical Analysis of Underground Tunnel; Science Press: Beijing, China, 2007. [Google Scholar]

- Cai, M.F. Rock Mechanics and Engineering, 2nd ed.; Science Press: Beijing, China, 2013. [Google Scholar]

- Linghu, J.; Zhao, W.; Zhou, J.; Yan, Z.; Wang, K.; Xu, C.; Sun, C. Influence of deep magma-induced thermal effects on the regional gas outburst risk of coal seams. Int. J. Coal Sci. Technol. 2021, 8, 1411–1422. [Google Scholar] [CrossRef]

- Hu, G.; Wang, H.; Fan, X.; Yuan, Z.; Hong, S. Mathematical model of coalbed gas flow with klinkenberg effects in multi-physical fields and its analytic solution. Transp. Porous Media 2009, 76, 407–420. [Google Scholar] [CrossRef]

- Skjetne, E.; Auriault, J.L. Homogenization of wall-slip gas flow through porous media. Transp. Porous Media 1999, 36, 293–306. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, L.; Qian, Z.; Liu, S.; Ren, D. Mathematical model of low and very low permeability gas reservoir considering Klinkenberg effect. Nat. Gas Ind. 2003, 23, 100–102. [Google Scholar]

- Wu, Y.; Pruess, K. Gas flow in porous media with Klinkenberg effects. Transp. Porous Media 1998, 32, 117–137. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, J.; Zhao, Y.; Zhang, L.; Guo, J. A fluid-solid coupling method for the simulation of gas transport in porous coal and rock media. Energy Sci. Eng. 2019, 7, 1913–1924. [Google Scholar] [CrossRef] [Green Version]

- Kang, H.; Ling, J.; Yan, L.; Zhang, X.; Wu, Y.; Si, L. Study on characteristics of underground in-situ stress distribution in Shanxi coal mining fields. Chin. J. Geophys. 2009, 52, 1782–1786. [Google Scholar]

| Parameter | Value |

|---|---|

| Shear modulus G/MPa | 90.3 |

| Poisson ratio v | 0.16 |

| Density ρc/(kg·m−3) | 1400 |

| Initial porosity φ0 | 0.0456 |

| Gas dynamic viscosity coefficient μg/(Pa·s) | 1.9 × 10−6 |

| Equivalent pore pressure coefficient α | 0.1604 |

| Temperature T/°C | 20 |

| Atmospheric pressure Pn/MPa | 0.101 |

| Adsorption constant b1/(m3·kg−1) | 36.492 × 10−3 |

| Adsorption constant b2/MPa | 1.48 |

| Ash content A | 11.48% |

| Moisture content B | 3.41% |

| Bulk modulus of coal skeleton Es/MPa | 300 |

| Initial permeability k∞/m2 | 0.2748 × 10−16 |

| Gas compression factor β/(kg/(m3·Pa)) | 0.987 |

| Gas adsorbed per unit volume of coal Qs/kg/(m3·s) | 30.98 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Han, P.; Zhao, Z.; Chen, W. The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect. Sustainability 2022, 14, 5449. https://doi.org/10.3390/su14095449

Yang Y, Han P, Zhao Z, Chen W. The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect. Sustainability. 2022; 14(9):5449. https://doi.org/10.3390/su14095449

Chicago/Turabian StyleYang, Yuliang, Penghua Han, Zhining Zhao, and Wei Chen. 2022. "The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect" Sustainability 14, no. 9: 5449. https://doi.org/10.3390/su14095449

APA StyleYang, Y., Han, P., Zhao, Z., & Chen, W. (2022). The Method of Determining Layer in Bottom Drainage Roadway Taking Account of the Influence of Drilling Angle on Gas Extraction Effect. Sustainability, 14(9), 5449. https://doi.org/10.3390/su14095449