Cool Pavements: State of the Art and New Technologies

Abstract

1. Introduction

2. Properties and Principles of Cool Pavements Usage

- Replacement of conventional pavement with other new surfaces characterized by lower surface temperatures, especially during the summer. This kind of cool pavements includes various constructional components, such as modified mixes (roller compacted concrete, conventional Portland Concrete Pavement (PCC)), light gravel on asphalt concrete (ACP), porous or pervious or permeable asphalt surface (permeable concrete, perforated concrete blocks or plastic filled with grass or soil, and vegetated pavements) and the use of photovoltaic systems.

- Reconstruction, maintenance, and restoration of existing pavements to improve their thermal performance. These include reflective coatings, chip seals, scrub seals, microsurfacing treatment, whitetopping [45] and use of pigments (pigments and coating with small minerals as a pavement sealing (or sealcoating), and pavement tiles of different colors, using pigments with nanoparticles that are reflected in the infrared).

- Shading pavement surfaces to reduce the absorption of solar radiation [46].

2.1. The Role of Reflectivity (Solar Reflectance or Albedo)

2.2. The Role of Thermal Emittance

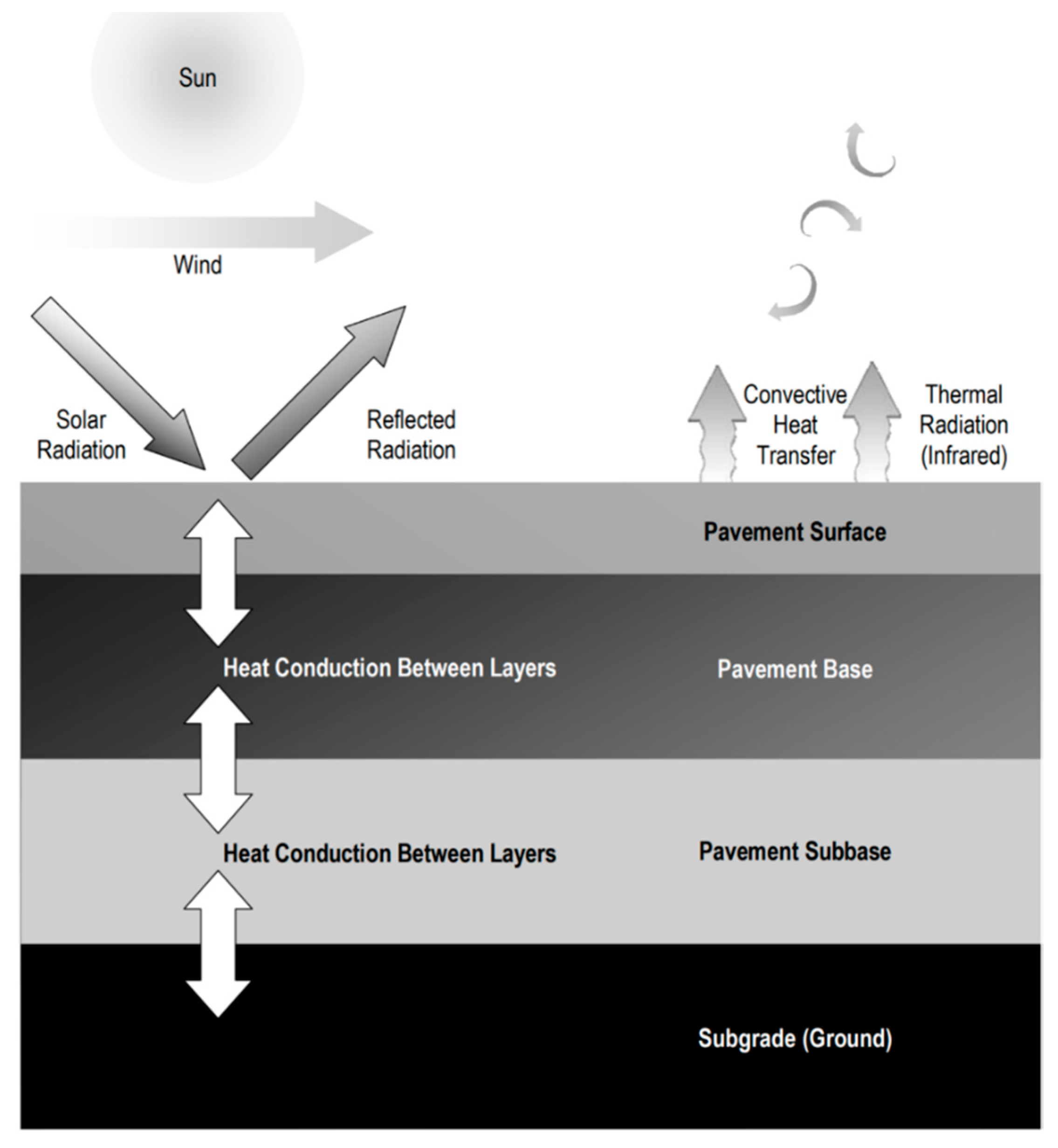

2.3. The Role of Heat Transfer and Thermal Capacity

2.4. The Effect of Permeability

3. Toward the Improvement of Thermal Performance of Cool Pavements

3.1. Improving the Thermal Performance of Pavements

- Modified mixes: conventional asphalt/concrete pavements, resin-based pavements, rolled compacted concrete pavements, PCC, ACP, rubberized asphalt pavements, texturing of open-grated course with cementitious materials, gritting with light-colored aggregates, white cement, titanium oxide (photocatalyst), and concrete additives;

- Permeable pavements: with/without vegetation, porous asphalt surfaces, pervious concrete, paving blocks/grid pavements made of concrete or plastic, or metal lattice filled with grass or soil;

- Use of photovoltaic systems.

- Reflective coatings and seals: chip seals, sand and scrub seals, conventional and rubberized slurry seals, and microsurfacing;

- Whitetopping [44];

- Use of pigments and coatings with small stones on pavements having seals, pavement tiles of different colors with the use of pigments with nanomaterials to reflect in the infrared part of the spectrum;

- Diamond grinding;

- Shot/abrasive blasting.

- Increase in the albedo of pavement surfaces in order to absorb less solar radiation (reflective pavements);

- Increase in the permeability of surfaces of vegetated or non-vegetated pavements in order to reduce their surface temperature through evaporation (permeable, porous, pervious or water retentive pavements);

- Enhancement of the thermal storage capacity of surfaces with the addition of thermally conductive or latent heat storage materials. Common materials used on pavements have high thermal capacity, which is quite difficult to increase further. However, the addition of latent heat storage materials to the mass of pavements helps to cool the surface during the day and reduces the amount of sensible heat released into the environment;

- Shading of pavements using natural or artificial methods of solar control (e.g., trees and green pergolas). Shaded surfaces have a much lower surface temperature, as the absorbed direct sunlight is reduced significantly.

3.2. Reflective Pavements

3.2.1. Existing Commercial Applications of Reflective Pavements

- “Chip seals” is a common preventive maintenance technique used for asphalt pavements, which creates a significant improvement in the SRI extending the pavement lifetime. A chip seal is made by applying a thin layer of asphalt emulsion to the existing pavement surface and then disseminating and embedding graded aggregates with a pneumatic roller. This results in an initial surface that mimics the aggregate used in the seal. The inclusion of light-colored aggregates in the chip seal results in a surface that is substantially more reflective than a typical existing asphalt pavement; however, this reflectivity will decline with time, especially when subjected to vehicle activity, which drives the particles into the asphalt [81].

- b.

- “Sand and scrub seals” are similar surface treatments, but they use fine aggregates (such as sand) and are constructed differently. A common sand seal is built similarly to a chip seal. After spraying an asphalt emulsion on the existing pavement surface, the fine aggregate is applied and compacted into the emulsion, with any surplus material removed. In the case of a scrub seal, the emulsion and aggregate are separately injected into pavement cracks and voids before being rolled into position by pneumatic tires. Due to the difference in construction methods, scrub seals are more expensive yet remain longer than sand seals. Additionally, they can be utilized to raise the SRI of a surface by applying light-colored particles [81].

- c.

- “Microsurfacing”, or sealing the surface with a highly reflective layer, can increase the reflectivity of a pavement and extend its lifetime. Many of these coatings are designed to have a high coefficient of friction in order to be safe in wet circumstances. Typically, light-colored materials are utilized to boost asphalt’s sun reflection. The researchers applied a light-colored microsurfacing material composed of cement, sand, and other materials, as well as a liquid mixture of emulsified polymeric resin, and found that the solar reflection was comparable to that of newly concrete [32]. EKrete by PolyCon Manufacturing, Inc. is an example of such a microsurfacing material. For general-purpose parking lot pavements, the E-Krete microsurfacing and Street-Bond coating may be employed. On the pavement surface, a very thin coating (1/8 to 1/4 inch) of these materials is placed [81,82].

3.2.2. Current Research Directions in Reflective Pavements

- Use of high reflective paints. Newly white paints have very high solar reflectivity, often exceeding 0.9 [82]. The usage of such paints has the potential to dramatically reduce the temperature of the pavement’s surface and the amount of sensible heat discharged into the atmosphere. Santamouris et al. investigated the application of reflective paints to the surface or mass of concrete tile pavements. Summer conditions were used to conduct the experiments, and the results were compared to those obtained with ordinary white tiles. In both cases, the albedo was between 0.8 and 0.9 [83]. Another research group evaluated the thermal performance of 14 high-reflectance white pavement surfaces that were coated with reflective colors using a variety of different technologies during the summer. Almost all materials tested had an albedo of between 0.8 and 0.9. Aluminum-free coatings had a radiation emittance greater than 0.8, while aluminum-based paints had a radiation emittance of between 0.3 and 0.4. The use of highly reflecting coatings was shown to reduce the daily surface temperature of white concrete by 4 °C and the temperature during summer nights by 2 °C. These tiles were only 2 °C warmer than air during the day and 5.9 °C colder at night, indicating a strong correlation between material emission and surface temperature at night. Pavements with aluminum-based coatings had a greater surface temperature than other types of tiles [3].

- b.

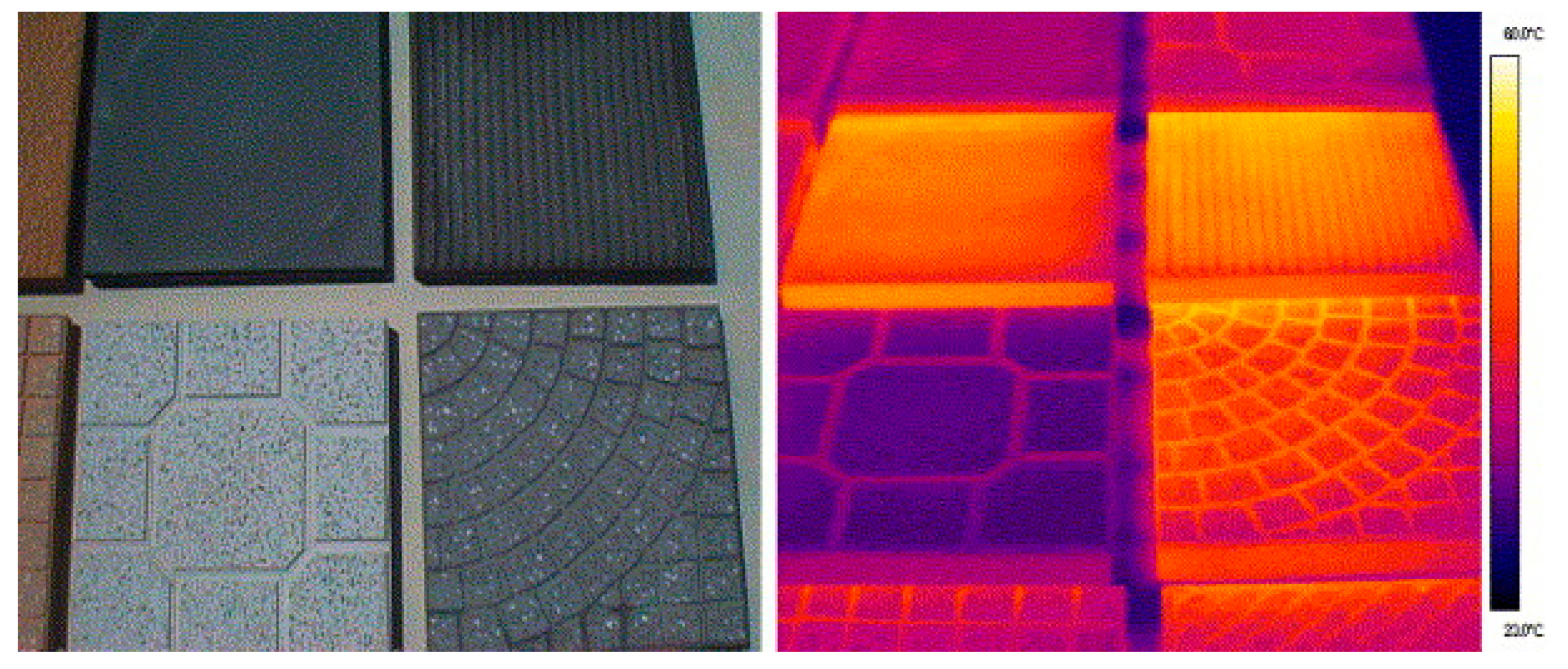

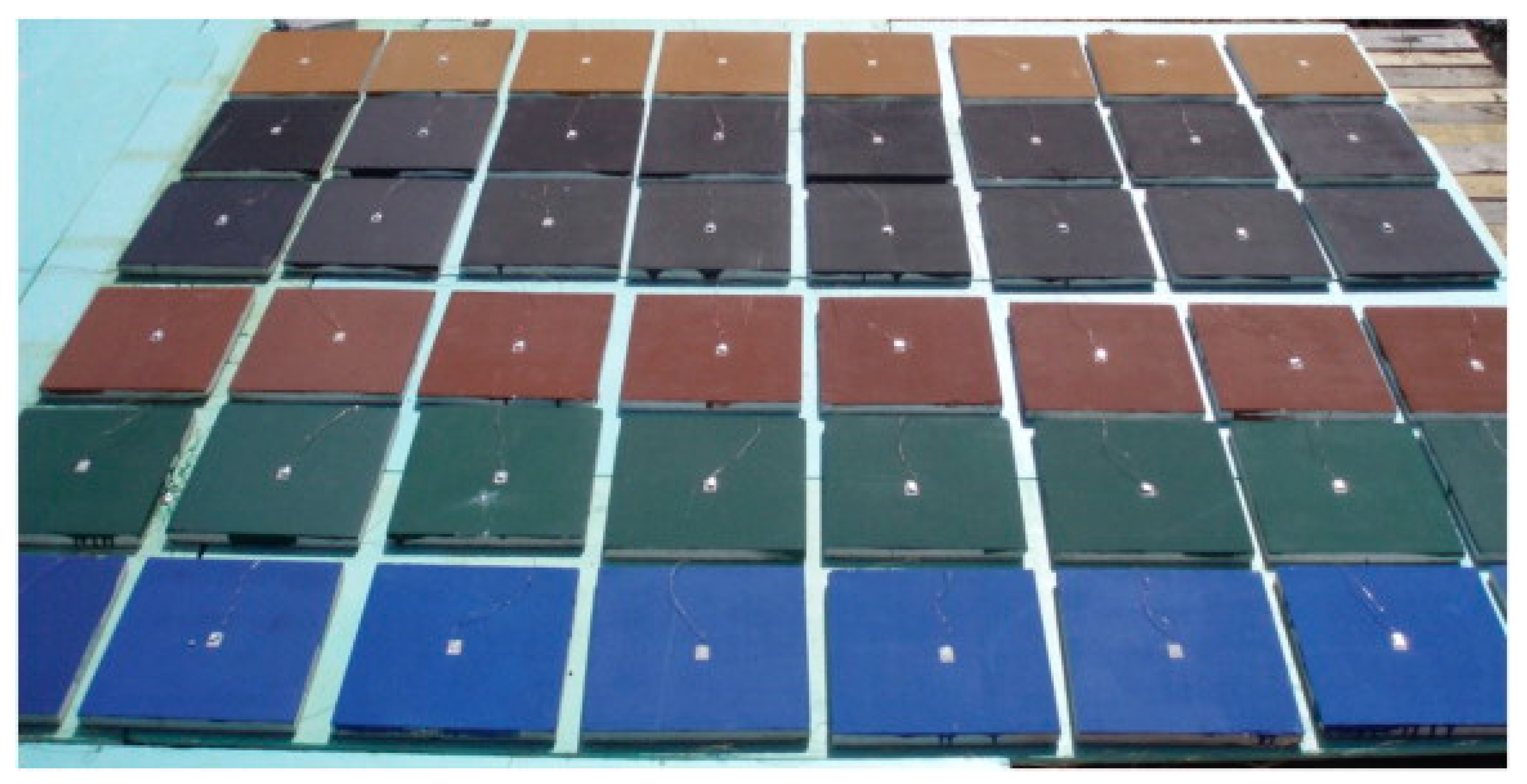

- Use of infrared reflecting colored paints. Infrared reflective pigments can be used instead of non-white pavement materials in order to increase the albedo of pavements [82]. In such a case, the pavement surface can exhibit strong reflectance in the near infrared part of the spectrum, compared to a conventional material of the same color [84,85]. The albedo of colored concrete and asphalt pavements has been modified using infrared reflective color paints [2,52]. Santamouris et al. investigated the direct application of infrared reflective color paints on concrete pavement surfaces [82]. Synnefa et al. investigated the effect of thin layers of various reflecting color paints using infrared reflective pigments on typical asphalt pavements [52]. Another study compared 10 standard cool-colored pavement materials made with infrared reflective pigments against traditional materials of the same color during the summer. As previously stated, the reflecting black material had an albedo of around 0.27 and a daily average surface temperature nearly 10 °C lower than a typical black surface with an albedo of 0.05. Simultaneously, reflecting blue had a reflectance of 0.33 and an average surface temperature of 4.5 °C lower than traditional blue [2]. In general, a nearly linear relationship between the average surface temperature and material albedo was discovered. During the night, much lower surface temperatures were also measured.

- c.

- Use of heat-reflecting paints to cover asphalt aggregates. Boriboonsomsin and Reza advised that aggregates used in asphalt pavements be covered with infrared reflecting paints. They evaluated four different types of high albedo asphalt pavements in which a heat reflecting paint was applied to each aggregate, as opposed to traditional reflective asphalt pavements, where the paint was applied solely to the surface. Pavements have an albedo of between 0.46 and 0.57. Tracking revealed that upgraded pavements have a significantly cooler surface temperature than conventional pavements, with temperature differences ranging from 10.2 to 18.8 °C [86]. Simultaneously, a similar approach was proposed for the preparation of high-albedo coatings for asphalt pavements [87]. The experiment was conducted in Japan during the summer season. When the albedo of the pavement was increased to 0.25, its surface temperature was nearly 6.8 °C lower than that of normal asphalt, while increasing the albedo to 0.6 resulted in a nearly 20 °C reduction in surface temperature. In general, it was discovered that increasing the albedo by 0.1 resulted in a decrease in surface temperature of close to 2.5 °C.

- d.

- Use of color changing paints. Numerous authors have advocated for the introduction of color changing coatings to pavements [88,89,90]. Thermochromic coatings are capable of thermally responding to the environment and reversibly altering their color and reflectivity as the temperature rises. These coatings have been created, and their thermal performance in contrast to other reflecting and common coatings has been evaluated in pavements. Eleven distinct colored tiles were produced and tested in hot summer ambient temperatures. Organic thermochromic pigments and other stabilizing elements were used to create the coatings. All pavements tested emitted a similar amount of infrared light. Daily average surface temperatures of thermochromic pavements were consistently lower than those based on infrared reflecting pigments and conventional coatings. Temperatures for thermochromic coatings ranged from 31.0 to 38.4 °C; for infrared reflective coatings, from 34.4 to 45.2 °C; and for common coatings, from 36.4 to 48.5 °C. The temperature at night was comparable for the three coating types. Spectral reflectance measurements of thermochromic coatings revealed a maximum increase in albedo of 43 percent from the colored to the colorless phase. The primary disadvantage of thermochromic coatings is their quick loss of optical properties. Significant research has been conducted to find a solution to the aging problem, and the results appear to be quite encouraging [88].

- e.

- Use of fly ash and slag as constituents of concrete leads to the production of surfaces with improved albedo values. When 70% slag was employed as a cement replacement, the combination had an albedo of 0.582, which is 71% higher than the standard blend. Although the findings are significant, there has been little progress in this field, and it is not considered a major research trend [91].

3.2.3. Actual Applications of Reflective Pavements

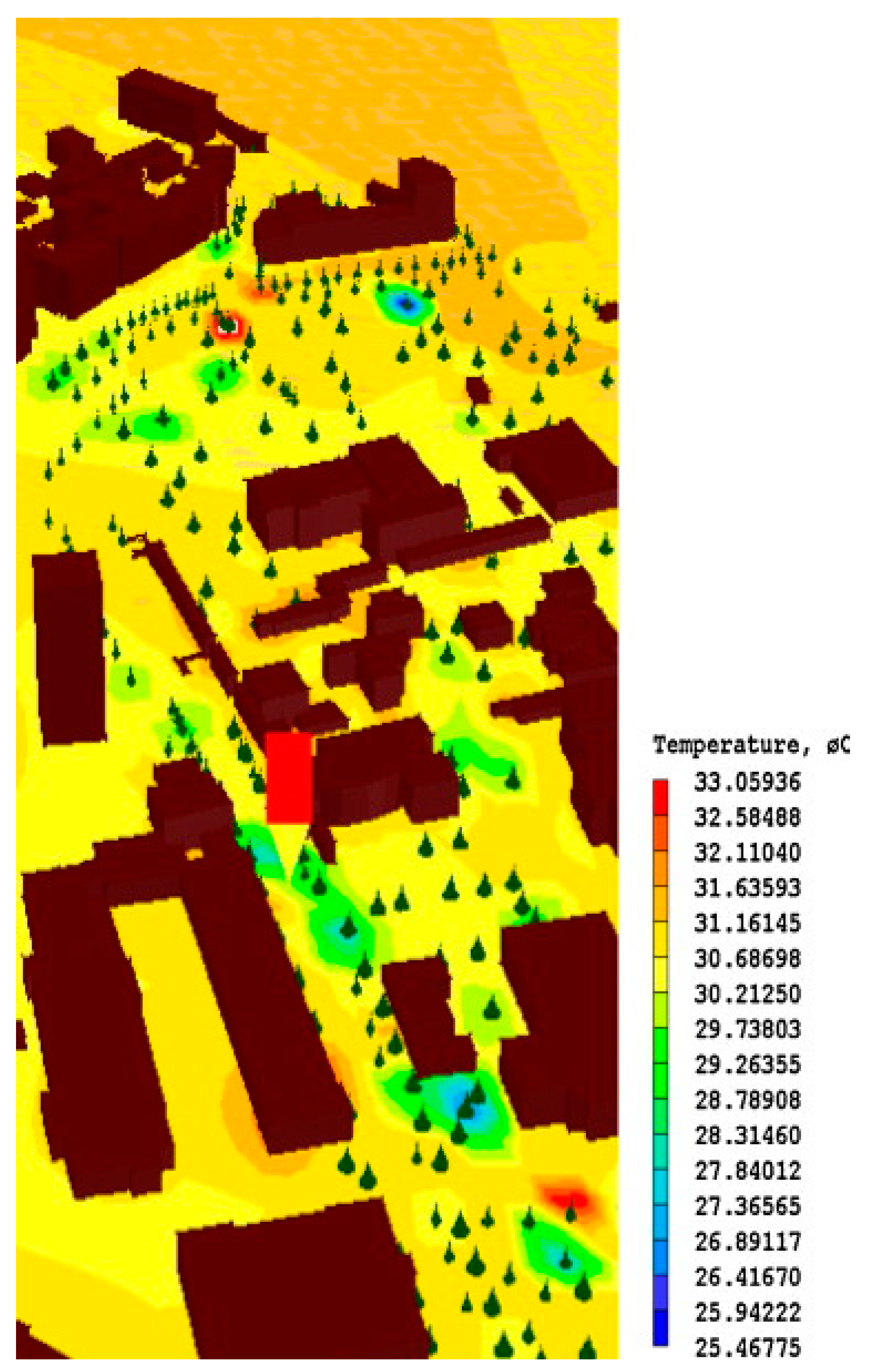

3.3. The Impact of Cool Pavements on Outdoor Thermal Comfort and Building Cooling Loads

4. Maintenance and Restoration Technologies for Cool Pavements

4.1. Whitetopping (WT) and Ultra-Thin Whitetopping (UTW)

- Easy to use;

- Avoids traditional stresses of an asphalt overlay;

- May be used on existing pavement systems;

- Quick to apply and re-open to traffic;

- Less sensitive to seasonal variations.

4.2. Use of Pigments

4.3. Permeable Pavements

4.3.1. Existing Development and Commercial Applications of Permeable Pavements

- Porous asphalt pavements are made of water permeable blocks and are mainly used to prevent floods, reduce noise, and mitigate the UHI effect. Porous asphalt is a bituminous material mixed with aggregates that is porous due to the absence of very fine particles from the mixture.

- b.

- Pervious/permeable concrete is produced using cement and concrete admixtures, such as fly ash, blast-furnace slag, pozzolans, aggregates, and water. Water permeability is normally measured between 20 and 40 mm/s; however, lower and higher values have been observed [73]. It is possible to make permeable concrete by combining cement and cement substrate substitutes, such as fissured feathers, pulverized blast furnace slag, and pozzolans or silica fumes, with cement. Its porosity is accomplished through the use of three types of pores: pores in the cement, gaps in the aggregates, and air gaps. Pores in the cement are the most common. When it comes to water permeability, air gaps are the most important factor to consider. It is mostly the binder used, the aggregates utilized, how the mixture is combined and how it is condensed, and ultimately how the calibrated aggregates are classified that determine how permeable the concrete will be in its final stage. Permeable concrete can be used in areas where rainwater runoff is undesirable, and it is suitable for low-speed traffic (less than 35 miles per hour). Views differ as to whether porous pavements are problematic in the winter: if the road surface remains completely dry, there should be no cooling issues. However, if water is trapped in pavement gaps for an extended period of time during frost, it can cause the pavement layer to deteriorate. Road sand can clog pavement pores, so other methods of controlling ice and snow for porous pavements (e.g., chemical use) might be used [32].

- c.

- Concrete pavers come in many different forms. This category comprises non-vegetated permeable concrete block and segmented concrete pavers, as well as vegetated concrete grid pavers that incorporate a concrete lattice to allow flora to grow in between. Typically, block pavers are utilized on driveways, footpaths, patios, and other outdoor recreational spaces. These pavers come in a variety of colors and are frequently utilized as decorative elements. Segmented concrete pavers are frequently used in industrial and warehouse settings due to their interlocking nature, which enables them to handle greater load conditions. Because the gap between the blocks allows water to penetrate but is insufficient for considerable growth, block pavers and segmented concrete pavers are termed non-vegetated permeable pavements. The bulk of pavers currently in use are interlocking concrete pavers, which include those for impermeable and permeable pavement applications [81].

- d.

- Non-concrete permeable pavers. Vegetated permeable pavements include grass pavers with a plastic or metal lattice. The space between the lattices is ideal for plants, such as grass, to grow. While these pavements are capable of supporting vehicle weight on a level with conventional pavements, they are often utilized in low-traffic areas, such as alleys, parking lots, and trails, to avoid harm to the vegetation. Additionally, they thrive in regions with sufficient summer moisture [32,81].

- Permeable pavements without vegetation contain gaps and are designed to allow water to drain from the surface to the substrates and to the ground. These materials may have the same good structural condition as conventional pavements, e.g., porous surfaces (pervious surfaces), such as the Open-Graded Friction Course (OGFC) [32]. More specifically, OGFCs is a type of pavement that has been used in the US since 1950. These bituminous mixtures contain only a small amount of fine aggregates, constructing a pavement with a relatively large percentage of air vents that improve pavement abrasion in a wet environment. These bituminous mixtures are made of a single coarse aggregate and have high ash content [32]. Evaporation on pervious pavements (without vegetation) and on water-holding pavements is highly dependent on the distribution of particles of the paving material and the water holding capacity of the surface [32]. Rubber asphalt has been used on roads and motorways to reduce noise. Certain types of permeable pavements may be used in areas with less traffic, such as parking areas, alleys, or paths. These types of pavements reduce rainwater drainage and improve water quality because pervious sidewalks allow rainwater to permeate the road and soil, reducing runoff and filtering dirt.

- Permeable pavements with vegetation are surfaces on which plants (usually grass) grow. A mesh of plastic, metal, or concrete is installed on the ground, which allows the vegetation to grow through the gaps. Vegetation has good reflective ability that reduces road surface temperature, and there is also the advantage of cooling the pavement through plant breeding. Pavements covered with vegetation are also permeable, which is good for water drainage. However, they require more frequent maintenance, especially during the winter and the dry season [40]. Grass coverings and concrete grids use plastic, or metal to support and allow grass or other vegetation to grow through the gaps. Although their structural integrity allows them to support the weight of a vehicle better than conventional pavements, these materials are used more often in areas with minimal traffic so that vegetation damage, demand for parking spaces, and trails are minimized. Finally, those pavements may be more suitable for climates with sufficient humidity during the summer [32].

4.3.2. Current Research Directions in the Field of Permeable and Water-Retentive Pavements

- Use of water holding fillers made of steel by-products as an additive to porous asphalt. Nakayama et al. [111] showed and tested a new water-holding pavement made of steel that was mixed into porous asphalt and used in permeable pavements with a porosity of 0.3. The average temperature of the pavement was found to be 0.6 °C lower than that of the porous asphalt, while the air temperature above the water-retentive pavement was found to be nearly 0.5 °C lower than that of the conventional porous asphalt. Although the immediate drop in temperature caused by conventional porous asphalt was greater than that caused by water-retentive pavement, the evaporation and cooling impact of water-retentive pavement continued for a longer period of time, with a maximum duration of about 3 days.

- Use of fine blast furnace powder in water-retentive asphalt. Takahashi and Yabuta described the use on pavements of a blast furnace powder, which has been tested under real weather conditions on pavements for extended periods of time. As regards the thermal performance of the material in the third year, it was noted that its surface temperature was still 14 °C cooler than the temperature of a conventional asphalt pavement [112].

- Use of fine texture pervious mortar as an additive in pervious concrete. In 2009, Aoki [113] studied a pavement of permeable concrete combined with a fine texture pervious mortar. Mortar is a mixture of cementitious materials, aggregates, and water that is used to improve the texture of permeable concrete’s surface. The final composition had a modest water permeability (2 to 3 mm/s), and no data on the new material’s thermal performance are available.

- Use of bottom ash and peat moss as additives in porous concrete. Park et al. created and assessed a novel porous pavement utilizing bottom ash and peat moss in an experimental setting. Peat moss is a porous substance that acts as an absorbent, allowing heavy metals to be removed from aqueous solutions. Experimental comparisons were made between the created pavement and conventional asphalt and porous pavements. After rain, the proposed material’s surface temperature was found to be 18 °C cooler than asphalt, with a maximum difference of about 9 °C between the proposed material’s surface temperature and that of conventional porous pavement [114]. Additionally, it has been demonstrated that the addition of bottom ash and peat moss to porous concrete reduces surface temperatures by roughly 0.1 °C in comparison to asphalt mixtures [115].

- Use of fly ash with very narrow particle size distribution in bricks. Cultrone and Sebastián examined bricks with and without fly ash and found the texture to be very similar. The results showed that the addition of fly ash particles with diameters ranging from 0.1 to 10 μm into the bricks can cause a reduction in the density and a significant improvement in the durability of the bricks [116]. Singh et al. estimated the possibility of the production industrial bricks. Porosity affects many properties of bricks, but the most important influence is their strength. They found that, as the percentage of fly ash content increases, so does the porosity. However, temperature reduction (from 1000 to 800 °C) had a greater effect on the porosity. The firing temperature has a significant effect on the porosity of the composition, as the addition of fly ash increases the porosity of the brick significantly at both temperatures. The results indicate that adding fly ash up to 50% by weight improves the performance of sintered bricks at 1000 °C. The test findings indicate that the combination of clay and fly ash performs rather well due to their effective micro-filling capacity and pozzolanic activity. These bricks have a higher compressive strength and the added benefit of being lighter and more eco-friendly [117].

- Use of industrial waste as a raw material for ceramic tiles. Junkes et al. developed experimentally and tested the use of industrial waste as an alternative raw material for the manufacture of ceramic tiles. They demonstrated that their use could control the plasticity and shrinkage of the ceramic body without any negative impact on product properties, and that sintering can be performed at low temperatures, resulting in energy savings [118]. Instead of being disposed of in landfills, tiles can be used in highway engineering applications, reducing environmental impacts and increasing pavement thickness. The addition of waste tile particles improved the mix’s California Bearing Ratio (CBR) performance from about 8% to 14%, which can result in a significant reduction in the design thickness of highway sidewalks. Cortes et al. used asphalt as a pavement material for the ground, and a water retentive pavement as material for the main street. The water retentive pavement can reduce significantly the surface temperature. When solar radiation was most intense, the surface temperature decreased by 13.8 °C. This decrease in the surface temperature also led to cooling of the air temperature at a height of 1.5 m above the street surface. The air temperature in a water retentive pavement was found to be 0.28 °C lower. The latent and sensible heat flux resulted in a maximum decrease of up to 255 and 465 W/m2, respectively [119].

- Use of urban river sediments and clay as a primary raw material in the production of highly insulating brick. The primary objective of Xu et al. study was to determine the feasibility of fabricating porous ceramic tiles with a high thermal insulation capacity using urban river sediments as the main source. To identify the most appropriate production procedure, urban river sediments and clays were mixed in various amounts and burned at various temperatures. The thermal conductivity of burnt bricks was lowered by at least 40% when compared to clay samples due to the creation of a highly porous structure. Compressive strength decreased as the sediment content of urban rivers increased. When the thermal insulation capacity was balanced against compressive strength requirements, bricks burned at 1050 °C with 50% urban river sediments demonstrated more beneficial characteristics and met the standards of GB5101-2003 fired common bricks. The leaching test findings established that fired bricks containing urban river sediments are environmentally friendly. As a result, urban river sediments are an excellent primary raw material for the manufacture of high-insulation bricks [120].

4.3.3. Experimental Testing and Thermal Performance of Water-Permeable Pavements and Water-Retentive Pavements

4.3.4. Water Availability on Permeable Pavements

4.4. Technologies of Cool Pavements with New Construction

4.4.1. Modified Mixtures of Asphalt and Concrete

- Conventional asphalt pavements. The most frequent type of pavement surface is conventional asphalt. It can be swiftly and readily installed, and it has a wide range of uses, including low-volume parking lots, high-traffic highways, and airport runways. Asphalt pavements can last for many years with correct design and upkeep. Asphalt pavements can also be recycled and processed to create new pavements. However, standard asphalt pavements often have a low albedo due to their black and impermeable surface, making them susceptible to absorbing and storing solar radiation heat. As a result, the asphalt’s maximum surface temperature can reach 120 to 150 °C [81]. They are made up of an asphalt binder and aggregate that can be amended with high-reflectivity materials. For decades, this material has been employed in a variety of parking lots and highways [32,40]. Due to oxidation of the binder, traditional asphalt pavement will often fade in color as it ages. Asphalt concrete has an albedo of around 0.05 to 0.10 when it is first installed, and it rises to about 0.12 to 0.18 after six years [32]. Asphalt pavements can be built using high albedo materials or built traditionally and then improved with a surface treatment or coating to increase surface reflection. Light colored aggregate, paint pigments, sealants, and other high albedo materials can be utilized in the main construction. In a recently laid pavement, the use of light-colored materials was able to improve albedo by 0.15 to 0.20 [40]. Chip and sand sealing with light-colored aggregates, surface coating, and grinding (if light-colored aggregates are used) are all treatments that can be used after installation as a preventive maintenance activity while also enhancing solar reflectivity [81].

- Roller Compacted Concrete (RCC). RCC is a mixture specially shaped and positioned using a specific method. It contains a very hard mixture placed with the techniques and equipment used for asphalt pavements. The result is a strong pavement, with a smoother surface than conventional concrete pavement. It is used for heavy-load trucks and high-speed motorways, large-volume storage areas, automotive and military installations, and warehouse floors. Although some of its surface parts may become eroded over time, RCC is economical, with an initial cost lower than ordinary concrete [32] and in many markets competitive with asphalt concrete. RCC generates a natural-looking pavement by absorbing the color of the added gravel or sand. A lighter-colored RCC, like conventional concrete, has a high albedo [81].

- Conventional Portland Cement Concrete (PCC). These pavements are made of blending Portland cement with water and aggregates and may be used in a wide range of applications, including pavements and parking areas. Conventional PCC pavement has been proposed as a cool pavement because of its light color and reflection. It is used in new constructions and reconstructions [32]. Recyclable materials, such as fly ash and metal extracts [45], are used mixed with concrete in order to improve the reflectivity. The degree of surface reflection is affected both by the color of the cement and by the type and color of the aggregate, particularly because the cement surface is damaged, and the aggregate is exposed [32]. However, some satellite photographs of various types of pavements in a metropolitan area show promising results in terms of being used as cool pavements.

- Light gravel on pavement of asphalt concrete (ACP). ACP reflectivity may be reduced by using a light aggregate, such as limestone. This type of aggregate is available as a natural resource in countries such as the US (e.g., Houston and Florida) and it is used in the construction and reconstruction of conventional pavements, with a zero incremental cost. Elsewhere, however, the transportation cost of this aggregate is very high, and this method is perhaps not economically advantageous [32].

- White cement is similar to the gray cement used in conventional concrete except that it is lighter in color. This is generally accomplished by reducing the iron content of the raw materials used to make cement. Because iron is a fluxing material, changing it raises the temperature at which cement must be processed, increasing both the cost of production and the emissions connected with it. The only significant difference is that white cement is more expensive than gray cement, despite the fact that the cement’s strength and behavior, as well as the time it takes to set and acquire strength, are all similar. White cement concrete has, on average, substantially higher reflectivity than gray cement concrete. Depending on the phase of exposure, the albedo of the most reflective white-cement concrete was 0.18 to 0.39 higher than that of the most reflective gray cement concrete [40,81].

- Texturing/grouting of open-graded course with cementitious materials. Texturing is the process of laying asphalt, compacting it into a pattern, and then covering it with a polymerized cement coating. Salviacim and Densiphalt+D99 are semi-rigid procedures that combine open-graded asphalt concrete with a high-strength cementitious grout to fill gaps of between 20% and 25%. The grouted surface should have a comparable reflectivity to concrete. Additionally, densiphalt is beneficial for avoiding gasoline leaks and improving abrasion and rutting resistance [41,81].

- Gritting with light-colored aggregates. Surface gritting entails strewing light-colored particles over freshly poured hot mix asphalt (HMA) and rolling it down. Surface gritting can improve surface friction while also lightening the color of asphalt (thus skid resistance). Grit may be kicked up off the road by vehicle traffic after gritting an existing asphalt pavement, creating danger. While surface gritting may be a viable method, more research is needed to determine whether the construction process results in uncoated lightly colored aggregate adhering sufficiently to the asphalt surface [41,81,134].

- A clear tree resin replaces the traditional black petroleum-derived asphalt binder in resin-based pavements. Pure resin forms an inert aggregate when it bonds with a petroleum chemical element (C2I2n) on any part of the coating [43]. As a result, the pavement can take on the natural appearance of the various materials that were used in the mix. Resin-based pavements can be brighter and have higher solar reflectance than typical asphalt pavements because the pavement takes on the color of the particles (if light colored aggregates are used). Hiking and bicycle trails have traditionally employed resin-based pavements. Aside from resin-based pavement, light-colored aggregates can be bound with a variety of colorless and reflecting synthetic binders. These are commonly utilized as surface courses in sports and leisure activities [41,81].

- Titanium dioxide (TiO2) in certain forms can act as a photocatalyst. Ballari et al. conducted a study in which they used it on a concrete paving stone in order to reduce nitrogen oxide (NOx) pollutants. A heterogeneous kinetic expression was suggested for the degradation of nitrogen monoxide, and for the appearance or disappearance of nitrogen dioxide [135]. Lee et al. conducted an experiment in order to eliminate NOx air pollutants. The photocatalytic reaction of titanium dioxide is a mechanism by which the elimination of NOx air pollutants may be achieved, and it is necessary to use ultraviolet (UV) rays and TiO2 in the concrete. Titanium dioxide may be applied to existing roads made from concrete blocks, to reduce NOx. The study showed that concrete pavements containing titanium dioxide with surface penetration agents at an uptake of 500 g/m2 reduce airborne NOx by 50% for an L-type side ditch and interlocking blocks of concrete [136]. Investigations into the runoff from photocatalytic surfaces are currently underway [80].

4.4.2. Use of Solar Pavements

5. Conclusions and Policy Considerations

Author Contributions

Funding

Conflicts of Interest

References

- Qin, Y. A review on the development of cool pavements to mitigate urban heat island effect. Renew. Sustain. Energy Rev. 2015, 52, 445–459. [Google Scholar] [CrossRef]

- Synnefa, A.; Santamouris, M.; Apostolakis, K. On the development, optical properties and thermal performance of cool colored coatings for the urban environment. Sol. Energy 2007, 81, 488–497. [Google Scholar] [CrossRef]

- Synnefa, A.; Santamouris, M.; Livada, I. A study of the thermal performance of reflective coatings for the urban environment. Sol. Energy 2006, 80, 968–981. [Google Scholar] [CrossRef]

- Santamouris, M. Energy and Climate in the Urban Built Environment, 1st ed.; Santamouris, M., Ed.; Taylor & Francis: London, UK, 2001. [Google Scholar]

- Santamouris, M. Heat island research in Europe The state of the art. Adv. Build. Energy Res. 2007, 1, 123–150. [Google Scholar] [CrossRef]

- Akbari, H.; Davis, S.; Dorsano, S.; Huang, J.; Winert, S. Cooling Our Communities: A Guidebook on Tree Planting and White Coloured Surfacing; US Environmental Protection Agency, Office of Policy Analysis, Climate Change Division: Washington, DC, USA, 1992.

- Founda, D. Evolution of the air temperature in Athens and evidence of climatic change: A review. Adv. Build. Energy Res. 2011, 5, 7–41. [Google Scholar] [CrossRef]

- Asimakopoulos, D.; Santamouris, M.; Farrou, I.; Laskari, M.; Saliari, M.; Zanis, G.; Giannakidis, G.; Tigas, K.; Kaspomenakis, J.; Douvis, C.; et al. Modelling the energy demand projection of the building sector in Greece in the 21st century. Energy Build. 2012, 49, 488–498. [Google Scholar] [CrossRef]

- Livada, I.; Santamouris, M.; Assimakopoulos, M.N. On the variability of summer air temperature during the last 28 years in Athens. J. Geophys. Res. 2007, 112, 1–9. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Flocas, H.A.; Santamouris, M.; Helmis, C.G. Application of neural networks to the simulation of the heat island over Athens, Greece, using synoptic types as a predictor. J. Appl. Meteorol. Climatol. 2002, 41, 519–527. [Google Scholar] [CrossRef]

- Gobakis, K.; Kolokotsa, D.; Synnefa, A.; Saliari, M.; Giannopoulou, K.; Santamouris, M. Development of a model for urban heat island prediction using neural network techniques. Sustain. Cities Soc. 2011, 1, 104–115. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Papanikolaou, N.; Cartalis, C.; Tsangrassoulis, A. Simulation of the urban heat island phenomenon in Mediterranean climates. Pure Appl. Geophys. 2004, 161, 429–451. [Google Scholar] [CrossRef]

- Livada, I.; Santamouris, M.; Niachou, K.; Papanikolaou, N.; Mihalakakou, G. Determination of places in the great Athens area where the heat island effect is observed. Theor. Appl. Clim. 2002, 71, 219–230. [Google Scholar] [CrossRef]

- Pantavou, K.; Theoharatos, G.; Mavrakis, A.; Santamouris, M. Evaluating thermal comfort conditions and health responses during an extremely hot summer in Athens. Build. Environ. 2011, 46, 339–344. [Google Scholar] [CrossRef]

- Sakka, A.; Santamouris, M.; Livada, I.; Nicol, F.; Wilson, M. On the thermal performance of low income housing during heat waves. Energy Build. 2012, 49, 69–77. [Google Scholar] [CrossRef]

- Hassid, S.; Santamouris, M.; Papanikolaou, N.; Linardi, A.; Klitsikas, N.; Georgakis, C.; Assimakopoulos, D.N. The effect of the Athens heat island on air conditioning load. Energy Build. 2000, 32, 131–141. [Google Scholar] [CrossRef]

- Santamouris, M.; Papanikolaou, N.; Livada, I.; Koronakis, I.; Georgakis, C.; Argiriou, A.; Assimakopoulos, D.N. On the impact of urban climate to the energy consumption of buildings. Sol. Energy 2001, 70, 201–216. [Google Scholar] [CrossRef]

- Cartalis, C.; Synodinou, A.; Proedrou, M.; Tsangrassoulis, A.; Santamouris, M. Modifications in energy demand in urban areas as a result of climate changes: An assessment for the southeast Mediterranean region. Energy Convers. Manag. 2001, 42, 1647–1656. [Google Scholar] [CrossRef]

- Hirano, Y.; Fujita, T. Evaluation of the impact of the urban heat island on residential and commercial energy consumption in Tokyo. Energy 2012, 37, 371–383. [Google Scholar] [CrossRef]

- Taha, H.; Akbari, H.; Rosenfeld, A.; Huang, J. Residential cooling loads and the urban heat island—the effects of albedo. Build. Environ. 1988, 23, 271–283. [Google Scholar] [CrossRef]

- Kolokotroni, M.; Giannitsaris, I.; Watkins, R. The effect of the London urban heat island on building summer cooling demand and night ventilation strategies. Sol. Energy 2006, 80, 383–392. [Google Scholar] [CrossRef]

- Fung, W.Y.; Lam, K.S.; Hung, W.T.; Pang, S.W.; Lee, Y.L. Impact of urban temperature on energy consumption of Hong Kong. Energy 2006, 31, 2623–2637. [Google Scholar] [CrossRef]

- Davies, M.; Steadman, P.; Oreszczyn, T. Strategies for the modification of the urban climate and the consequent impact on building energy use. Energy Policy 2008, 36, 4548–4551. [Google Scholar] [CrossRef]

- Zhang, R.; Kuang, W.; Yang, S.; Li, Z. The influence of urban three-dimensional structure and building greenhouse effect on local radiation flux. Sci. China Earth Sci. 2021, 64, 1934–1948. [Google Scholar] [CrossRef]

- Kuang, W. Seasonal Variation in Air Temperature and Relative Humidity on Building Areas and in Green Spaces in Beijing, China. Chin. Geogr. Sci. 2020, 30, 75–88. [Google Scholar] [CrossRef]

- Kuang, W.; Li, Z.; Hamdi, R. Comparison of surface radiation and turbulent heat fluxes in Olympic Forest Park and on a building roof in Beijing, China. Urban Clim. 2020, 31, 100562. [Google Scholar] [CrossRef]

- Kuang, W. New Evidences on Anomalous Phenomenon of Buildings in Regulating Urban Climate From Observations in Beijing, China. Earth Space Sci. 2019, 6, 861–872. [Google Scholar] [CrossRef]

- Kuang, W.; Zhang, S.; Li, X.; Lu, D. A 30 m resolution dataset of China’s urban impervious surface area and green space, 2000–2018. Earth Syst. Sci. Data 2021, 13, 63–82. [Google Scholar] [CrossRef]

- Sarrat, C.; Lemonsu, A.; Masson, V.; Guedalia, D. Impact of urban heat island on regional atmospheric pollution. Atmos. Environ. 2006, 40, 1743–1758. [Google Scholar] [CrossRef]

- Stathopoulou, E.; Mihalakakou, G.; Santamouris, M.; Bagiorgas, H.S. On the impact of temperature on tropospheric ozone concentration levels in urban environments. J. Earth Syst. Sci. 2008, 117, 227–236. [Google Scholar] [CrossRef]

- Santamouris, M.; Paraponiaris, K.; Mihalakakou, G. Estimating the ecological footprint of the heat island effect over Athens, Greece. Clim. Change 2007, 80, 265–276. [Google Scholar] [CrossRef]

- Akbari, H.; Bell, R.; Brazel, T.; Cole, D.; Estes, M.; Heisler, G.; Hitchcock, D.; Johnson, B.; Lewis, M.; Mcpherson, G.; et al. Reducing Urban Heat Islands: Compendium of Strategies; EPA: Washington, DC, USA, 2008.

- Sailor, D.J. Simulated urban climate response to modifications in surface albedo and vegetative cover. J. Appl. Meteorol. 1995, 34, 1694–1704. [Google Scholar] [CrossRef]

- Menon, S.; Akbari, H.; Mahanama, S.; Sednev, I.; Levinson, R. Radiative forcing and temperature response to changes in urban albedos and associated CO2 offsets. Environ. Res. Lett. 2010, 5, 014005. [Google Scholar] [CrossRef]

- Gaitani, N.; Michalakakou, G.; Santamouris, M. On the use of bioclimatic architecture principles in order to improve thermal comfort conditions in outdoor spaces. Build. Environ. 2007, 42, 317–324. [Google Scholar] [CrossRef]

- Asaeda, T.; Thanh, C.V.; Wake, A. Heat storage of pavement and its effect on the lower atmosphere. Atmos. Environ. 1996, 30, 413–427. [Google Scholar] [CrossRef]

- Golden, J.S.; Kaloush, K.E. Mesoscale and microscale evaluation of surface pavement impacts on the urban heat island effects. Int. J. Pavement Eng. 2006, 7, 37–52. [Google Scholar] [CrossRef]

- Streutker, D.R. A remote sensing study of the urban heat island of Houston, Texas. Int. J. Remote Sens. 2002, 23, 2595–2608. [Google Scholar] [CrossRef]

- Streutker, D.R. Satellite-measured growth of the urban heat island of Houston, Texas. Remote Sens. Environ. 2003, 85, 282–289. [Google Scholar] [CrossRef]

- Solaimanian, M.; Kennedy, T.W. Predicting maximum pavement surface temperature using maximum air temperature and hourly solar radiation. Transp. Res. Rec. 1993, 1417, 1–11. [Google Scholar]

- Bentz, D.P. A Computer Model to Predict the Surface Temperature and Time-of Wetness of Concrete Pavements and Bridge Decks; NISTIR 6551; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000.

- Gui, G.; Phelan, P.; Kaloush, K.; Golden, J.S. Impact of Pavement thermophysical properties on surface temperatures. J. Mater. Civ. Eng. 2007, 19, 683–690. [Google Scholar] [CrossRef]

- Santamouris, M.; Xirafi, F.; Gaitani, N.; Spanou, A.; Saliari, M.; Vassilakopoulou, K. Improving the microclimate in a dense urban area using experimental and theoretical techniques. The case of Marousi, Athens. Int. J. Vent. 2012, 11, 1–16. [Google Scholar] [CrossRef]

- Levine, K.K. Cool Pavements Research and Technology; Institute of Trasportation Studies Library: Berkeley, CA, USA, 2011. [Google Scholar]

- Tran, N.; Powell, B.; Marks, H.; West, R.; Kvasnak, A. Strategies for design and construction of high-reflectance asphalt pavements. Transp. Res. Rec. J. Transp. Res. Board 2009, 2098, 124–130. [Google Scholar] [CrossRef]

- American Concrete Pavement Association, R&T, Concrete Pavement Research & Technology. Albedo: A Measure of Pavement Surface Reflectance, Old Orchard Rd. 2002. Available online: https://trid.trb.org/view/920184 (accessed on 30 November 2021).

- Akbari, H.; Matthews, H.D. Global cooling updates: Reflective roofs and pavements. Energy Build. 2012, 55, 2–6. [Google Scholar] [CrossRef]

- Akbari, H.; Matthews, H.D. Global Cooling: Policies to Cool the World and Offset Global Warming from CO2 Using Reflective Roofs and Pavements. J. Heat Isl. Inst. Int. 2012, 2, 1–10. [Google Scholar]

- Doulos, L.; Santamouris, M.; Livada, I. Passive cooling of outdoor urban spaces. The role of materials. Sol. Energy 2004, 77, 231–249. [Google Scholar] [CrossRef]

- Akbari, H.; Taha, H. The impact of trees and white surfaces on residential heating and cooling energy use in four Canadian cities. Energy 1992, 17, 141–149. [Google Scholar] [CrossRef]

- Cantat, O. Contribution a L’etude des Variations du Bilan D’energie en Region Parisienne. Ph.D. Thesis, University of Paris Sorbonne, Paris, France, 1989. [Google Scholar]

- Synnefa, A.; Karlessi, T.; Gaitani, N.; Santamouris, M.; Assimakopoulos, D.N.; Papakatsikas, C. Experimental testing of cool colored thin layer asphalt and estimation of its potential to improve the urban microclimate. Build. Environ. 2011, 46, 38–44. [Google Scholar] [CrossRef]

- Stathopoulou, M.; Synnefa, A.; Cartalis, C.; Santamouris, M.; Karlessi, T.; Akbari, H. A surface heat island study of Athens using high-resolution satellite imagery and measurements of the optical and thermal properties of commonly used building and paving materials. Int. J. Sustain. Energy 2009, 28, 59–76. [Google Scholar] [CrossRef]

- Gustavsson, T.; Bogren, J. Infrared thermography in applied road climatological studies. Int. J. Remote Sens. 1991, 12, 1811–1828. [Google Scholar] [CrossRef]

- Berg, R.; Quinn, W. Use of light colored surface to reduce seasonal thaw penetration beneath embankments on permafrost. In Proceedings of the Second International Symposium on Cold Regions Engineering, Fairbanks, AK, USA, 12–14 August 1976; University of Alaska: Fairbanks, AK, USA, 1978; pp. 86–99. [Google Scholar]

- Taha, H.; Sailor, D.; Akbari, H. High-Albedo Materials for Reducing Building Cooling Energy Use; Rep. LBL-31721; Energy and Environment Division, Lawrence Berkeley Laboratory, University of California: Berkeley, CA, USA, 1992.

- ASTM E1980-11R19; Standard Practice for Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque Surfaces. ASTM International: West Conshohocken, PA, USA, 2019.

- Rymer, B.; Donavan, P.R. Determining End Limits of Quieter Pavement Projects. Transp. Res. Rec. J. Transp. Res. Board 2011, 2233, 145–151. [Google Scholar] [CrossRef]

- Rose, L.S.; Akbari, H.; Taha, H. Characterizing the Fabric of the Urban Environment: A Case Study of Greater Houston, Texas, California; Paper LBNL-44688; University of California: Oakland, CA, USA, 2003. [Google Scholar]

- Sen, S.; Roesler, J. Thermal and optical characterization of asphalt field cores for microscale urban heat island analysis. Constr. Build. Mater. 2019, 217, 600–611. [Google Scholar] [CrossRef]

- Ko, J.; Schlaerth, H.; Bruce, A.; Sanders, K.; Ban-Weiss, G. Measuring the impacts of a real-world neighborhood-scale cool pavement deployment on albedo and temperatures in Los Angeles. Environ. Res. Lett. 2022, 17, 044027. [Google Scholar] [CrossRef]

- Grimmond, C.S.B.; Cleugh, H.A.; Oke, T.R. An Objective Urban Heat Storage Model and its Comparison with Other Schemes. Atmos. Environ. Part B. Urban Atmos. 1991, 25, 311–326. [Google Scholar] [CrossRef]

- Yamagata, H.; Nasu, M.; Yoshizawa, M.; Miyamoto, A.; Minamiyama, M. Heat island mitigation using water retentive pavement sprinkled with reclaimed wastewater. Water Sci. Technol. 2008, 57, 763–771. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Zhang, X. Analyzing the effect of the longwave emissivity and solar reflectance of building envelopes on energy-saving in buildings in various climates. Sol. Energy 2011, 85, 28–37. [Google Scholar] [CrossRef]

- White, P.; Golden, J.S.; Biligiri, K.P.; Kaloush, K. Modeling climate change impacts of pavement production and construction. Resour. Conserv. Recycl. 2010, 54, 776–782. [Google Scholar] [CrossRef]

- Robinette, G. Landscape Planning for Energy Conservation; Environmental Design Press: Reston, VA, USA, 1977; p. 224. [Google Scholar]

- Ikechukwu, E.E. The Effects of Road and Other Pavement Materials on Urban Heat Island (A Case Study of Port Harcourt City). J. Environ. Prot. 2015, 6, 328–340. [Google Scholar] [CrossRef]

- Oke, T.R.; Johnson, G.T.; Steyn, D.G.; Watson, I.D. Simulation of surface urban heat islands under ‘ideal conditions at night—Part 2: Diagnosis and causation. Bound.-Layer Meteorol. 1991, 56, 339–358. [Google Scholar] [CrossRef]

- Chung, Y.; Shin, H.C. Characteristics of coefficient of thermal expansion of PCC pavement. In Transportation Research Record 2009 Annual Meeting CD-ROM; National Academy Council: Washington, DC, USA, 2008. [Google Scholar]

- Kim, K.H.; Jeon, S.E.; Kim, J.K.; Yang, S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Khan, M.I. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002, 37, 607–614. [Google Scholar] [CrossRef]

- Hermansson, A. Mathematical model for paved surface summer and winter temperature: Comparison of calculated and measured temperatures. Cold Reg. Sci. Technol. 2004, 40, 1–17. [Google Scholar] [CrossRef]

- Haselbach, L.M.; Valavala, S.; Montes, F. Permeability predictions for sand clogged Portland cement pervious concrete pavement systems. J. Environ. Manag. 2006, 81, 42–49. [Google Scholar] [CrossRef]

- Karasawa, A.; Toriiminami, K.; Ezumi, N.; Kamaya, K. Evaluation of performance of water-retentive concrete block pavements. In Proceedings of the 8th International Conference on Concrete Block Paving, San Francisco, CA, USA, 6–8 November 2006. [Google Scholar]

- Santamouris, M. Using cool pavements as a mitigation strategy to fight urban heat island—A review of the actual developments. Renew. Sustain. Energy Rev. 2013, 26, 224–240. [Google Scholar] [CrossRef]

- Mallick, R.B.; Chen, B.L.; Bhowmick, S. Reduction of urban heat island effect through harvest of heat energy from asphalt pavements. In Proceedings of the Heat Island Conference LBNL, Berkeley, CA, USA, 21–23 September 2009. [Google Scholar]

- De Bondt, A.H.; Jansen, R. Generation and Saving of Energy via Asphalt Pavement Surfaces; Ooms Nederland Holding B.V.: Scharwoude, The Netherlands, 2006. [Google Scholar]

- Gilbert, H.E.; Rosado, P.J.; Ban-Weiss, G.; Harvey, J.T.; Li, H.; Mandel, B.H.; Millstein, D.; Mohegh, A.; Saboori, A.; Levinson, R.M. Energy and environmental consequences of a cool pavement campaign. Energy Build. 2017, 157, 53–77. [Google Scholar] [CrossRef]

- Pomerantz, M.; Pon, B.; Akbari, H.; Chang, S.C. The Effects of Pavements’ Temperatures on Air Temperatures in Large Cities; LBNL-43442; Heat Island Group, Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2000. [Google Scholar]

- Hunter, R.N. Bituminous Mixtures in Road Construction; Thomas Telford Ltd.: London, UK, 1994. [Google Scholar]

- Nichols Consulting Engineers (NCE). Pavement Management Program, Final Report; NCE: City of Blue Lake, CA, USA, 2012. [Google Scholar]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Santamouris, M.; Synnefa, A.; Kolokotsa, D.; Dimitriou, V.; Apostolakis, K. Passive cooling of the built environment—Use of innovative reflective materials to fight heat island and decrease cooling needs. Int. J. Low-Carbon Technol. 2008, 3, 71–82. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Reilly, J.C. Cooler tile-roofed buildings with near-infrared-reflective non-white coatings. Build. Environ. 2007, 42, 2591–2605. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Berdahl, P.; Wood, K.; Skilton, W.; Petersheim, J. A novel technique for the production of cool colored concrete tile and asphalt shingle roofing products. Sol. Energy Mater. Sol. Cells 2010, 94, 946–954. [Google Scholar] [CrossRef]

- Boriboonsomsin, K.; Reza, F. Mix Design and Benefit Evaluation of High Solar Reflectance Concrete for Pavements. Transp. Res. Rec. 2007, 2011, 11–20. [Google Scholar] [CrossRef]

- Kawakami, A.; Kubo, K. Development of a cool pavement for mitigating the urban heat island effect in Japan. In Proceedings of the 1st International Symposium on Asphalt Pavements and Environment, Zurich, Switzerland, 18–20 August 2008; International Society for Asphalt Pavements: Zurich, Switzerland, 2008. [Google Scholar]

- Karlessi, T.; Santamouris, M.; Apostolakis, K.; Synnefa, A.; Livada, I. Development and testing of thermochromic coatings for buildings and urban structures. Sol. Energy 2009, 83, 538–551. [Google Scholar] [CrossRef]

- Ma, Y.; Zhu, B.; Wu, K. Preparation and solar reflectance spectra of chameleon-type building coatings. Sol. Energy 2001, 70, 417–422. [Google Scholar]

- Ma, Y.; Zhang, X.; Zhu, B.; Wu, K. Research on reversible effects and mechanism between the energy-absorbing and energy-reflecting states of chameleon-type building coatings. Sol. Energy 2002, 72, 511–520. [Google Scholar] [CrossRef]

- Santamouris, M.; Gaitani, N.; Spanou, A.; Saliari, M.; Gianopoulou, K.; Vasilakopoulou, K.; Kardomateas, T. Using cool paving materials to improve microclimate of urban areas—Design realisation and results of the Flisvos project. Build. Environ. 2012, 53, 128–136. [Google Scholar] [CrossRef]

- Guntor, N.A.A.; Din, M.F.M.; Ponraj, M.; Iwao, K. Thermal Performance of Developed Coating Material as Cool Pavement Material for Tropical Regions. J. Mater. Civ. Eng. 2014, 26, 755–760. [Google Scholar] [CrossRef]

- Fintikakis, N.; Gaitani, N.; Santamouris, M.; Assimakopoulos, M.; Assimakopoulos, D.N.; Fintikaki, M.; Albanis, G.; Papadimitriou, K.; Chryssochoides, E.; Katopodi, K.; et al. Bioclimatic design of open public spaces in the historic centre of Tirana, Albania. Sustain. Cities Soc. 2011, 1, 54–62. [Google Scholar] [CrossRef]

- Gaitani, N.; Spanou, A.; Saliari, M.; Synnefa, A.; Vassilakopoulou, K.; Papadopoulou, K.; Pavlou, K.; Santamouris, M.; Papaioannou, M.; Lagoudaki, A. Improving the microclimate in urban areas: A case study in the centre of Athens. Build. Serv. Eng. Res. Technol. 2011, 32, 53–71. [Google Scholar] [CrossRef]

- Shahidan, M.F.; Jones, P.J.; Gwilliam, J.; Salleh, E. An evaluation of outdoor and building environment cooling achieved through combination modification of trees with ground materials. Build. Environ. 2012, 58, 245–257. [Google Scholar] [CrossRef]

- Xu, X.; Jafari, H.A.; Gregory, J.; Norford, L.; Kirchain, R. An integrated model for quantifying the impacts of pavement albedo and urban morphology on building energy demand. Energy Build. 2020, 211, 109759. [Google Scholar] [CrossRef]

- Yaghoobian, N.; Kleissl, J. Effect of reflective pavements on building energy use. Urban Clim. 2012, 2, 25–42. [Google Scholar] [CrossRef]

- Li, H.; Saboori, A.; Cao, X. Information synthesis and preliminary case study for life cycle assessment of reflective coatings for cool pavements. Int. J. Transp. Sci. Technol. 2016, 5, 38–46. [Google Scholar] [CrossRef]

- Erell, E.E.; Pearlmutter, D.; Boneh, D.; Kutiel, P.B. Effect of high-albedo materials on pedestrian heat stress in urban street canyons. Urban Clim. 2014, 10, 367–386. [Google Scholar] [CrossRef]

- Faragallah, R.N.; Ragheb, R.A. Evaluation of thermal comfort and urban heat island through cool paving materials using ENVI-Met. Ain Shams Eng. J. 2022, 13, 101609. [Google Scholar] [CrossRef]

- Aboelata, A. Reducing outdoor air temperature, improving thermal comfort, and saving buildings’ cooling energy demand in arid cities—Cool paving utilization. Sustain. Cities Soc. 2021, 68, 102762. [Google Scholar] [CrossRef]

- Mohammad, P.; Aghlmand, S.; Fadaei, A.; Gachkar, S.; Gachkar, D.; Karimi, A. Evaluating the role of the albedo of material and vegetation scenarios along the urban street canyon for improving pedestrian thermal comfort outdoors. Urban Clim. 2021, 40, 100993. [Google Scholar] [CrossRef]

- Djekic, J.; Djukic, A.; Vukmirovic, M.; Djekic, P.; Brankovic, M.D. Thermal comfort of pedestrian spaces and the influence of pavement materials on warming up during summer. Energy Build. 2018, 159, 474–485. [Google Scholar] [CrossRef]

- Taleghani, M.; Berardi, U. The effect of pavement characteristics on pedestrians’ thermal comfort in Toronto. Urban Clim. 2018, 24, 449–459. [Google Scholar] [CrossRef]

- Karlessi, T.; Santamouris, M.; Synnefa, A.; Assimakopoulos, D.; Didaskalopoulos, P.; Apostolakis, K. Development and testing of PCM doped cool colored coatings to mitigate urban heat island and cool buildings. Build. Environ. 2011, 46, 570–576. [Google Scholar] [CrossRef]

- Hasebe, M.; Kamikawa, Y.; Meiarashi, S. Thermoelectric generators using solar thermal energy in heated road pavement. In Proceedings of the 25th International Conference on Thermoelectric, Vienna, Austria, 6–10 August 2006. [Google Scholar]

- Van Bijsterveld, W.T.; Houben, L.J.M.; Scarpas, A.; Molenaar, A.A.A. Using Pavement as Solar Collector: Effect on Pavement Temperature and Structural Response. Transp. Res. Rec. J. Transp. Res. Board 2001, 1778, 140–148. [Google Scholar] [CrossRef]

- Wayne, L.K.W.; Correia, A.J. A Pilot Study for Investigation of Novel Methods to Harvest Solar Energy from Asphalt Pavements; A final report for Korea Institute of Construction Technology (KICT); Korea Institute of Construction Technology (KICT): Goyang-si, Korea, 2010. [Google Scholar]

- Ferguson, B.K. Porous Pavements, 1st ed.; Taylor and Francis: London, UK, 2005. [Google Scholar]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build. Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Nakayama, T.; Fujita, T. Cooling effect of water-holding pavements made of new materials on water and heat budgets in urban areas. Landsc. Urban Plan. 2010, 96, 57–67. [Google Scholar] [CrossRef]

- Takahashi, K.; Yabuta, K. Road Temperature Mitigation Effect of “Road Cool” a Water-Retentive Material Using Blast Furnace Slag; JFE Technical Report, No. 13; Available online: https://www.jfe-steel.co.jp/en/research/report/013/pdf/013-12.pdf (accessed on 20 October 2021).

- Aoki, Y. Development of Pervious Concrete. Master’s Thesis, University of Technology, Sydney Faculty of Engineering and Information Technology, Sydney, Australia, 2009. [Google Scholar]

- Park, J.B.; Sangho, L.; Chae-Sung, G.; Pyun, H.B. Experimental Study of Non-sintering Block for Reducing Surface Temperature Using Recycling Bottom Ash. Mater. Sci. Forum 2009, 620–622, 105–108. [Google Scholar] [CrossRef]

- Kevern, J.T.; Haselbach, L.; Schaefer, V.R. Hot weather comparative heat balances in pervious concrete and impervious concrete pavement systems. In Proceedings of the Second International Conference on Countermeasures to Urban Heat Islands, Berkeley, CA, USA, 21–23 September 2009. [Google Scholar]

- Cultrone, G.; Sebastián, E. Fly ash addition in clayey materials to improve the quality of solid bricks. Constr. Build. Mater. 2009, 23, 1178–1184. [Google Scholar] [CrossRef]

- Singh, H.; Brar, G.; Mudahar, G. Evaluation of characteristics of fly ash-reinforced clay bricks as building material. J. Build. Phys. 2017, 40, 530–543. [Google Scholar] [CrossRef]

- Junkes, J.A.; Carvalho, M.A.; Segadães, A.M.; Hotza, D. Ceramic Tile Formulations from Industrial Waste. Interceram 2011, 60, 36–41. [Google Scholar]

- Cortes, A.; Shimadera, H.; Matsuo, T.; Kondo, A. Evaluation of Water Retentive Pavement as Mitigation Strategy for Urban Heat Island Using Computational Fluid Dynamics. Asian J. Atmos. Environ. 2016, 10, 179–189. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Xu, B.; Ruan, X.; Wei, Z. The use of urban river sediments as a primary raw material in the production of highly insulating brick. Ceram. Int. 2014, 40, 8833–8840. [Google Scholar] [CrossRef]

- Yilmaz, H.; Toy, S.; Irmak, M.A.; Yilmaz, S.; Bulut, Y. Determination of temperature differences between asphalt, concrete, soil and grass surfaces of the city of Erzurum, Turkey. Athmosphera 2008, 21, 135–146. [Google Scholar]

- Buyung, N.R.; Ghani, A.N.A. Permeable pavements and its contribution to cooling effect of surrounding temperature. AIP Conf. Proc. 2017, 1892, 170003. [Google Scholar] [CrossRef]

- Liu, Z.; Tian, Y.; Ma, B.; Si, W.; Wang, X. Numerical analysis of temperature reduction effect of permeable pavements. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Asaeda, T.; Thanh, C.V. Characteristics of permeable pavement during hot summer weather and impact on the thermal environment. Build. Environ. 2000, 35, 363–375. [Google Scholar] [CrossRef]

- Kevern, J.T.; Schaefer, V.R. Temperature response in a pervious concrete system designed for stormwater treatment. Geotech. Spec. Publ. GeoCongress 2008, 1137–1144. [Google Scholar] [CrossRef]

- Haselbach, L.; Gaither, A. Preliminary field testing: Urban heat island impacts and pervious concrete. In Proceedings of the NRMCA 2008 Concrete Technology Forum Focus on Sustainable Development, Silver Spring, MD, USA, 20–22 May 2008. [Google Scholar]

- Li, H.; Harvey, J.T.; Holland, T.J.; Kayhanian, M. The use of reflective and permeable pavements as a potential practice for heat island mitigation and stormwater management. Environ. Res. Lett. 2013, 8, 015023. [Google Scholar] [CrossRef]

- Van Seters, T.; Drake, J. Five Year Performance Evaluation of Permeable Pavements. Sustainable Technologies Evaluation Program; Toronto and Region Conservation Authority: Toronto, ON, Canada, 2015. [Google Scholar]

- Flower, W.; Burian, S.J.; Pomeroy, C.A.; Pardyjak, E.R. Surface Temperature and Heat Exchange Differences between Pervious Concrete and Traditional Concrete and Asphalt Pavements. In Proceedings of the Low Impact Development Conference, San Francisco, CA, USA, 11–14 April 2010. [Google Scholar]

- Kinouchi, T.; Kanda, M.; Kuriki, M.; Kobayashi, H. An observation of the climatic effect of watering on paved roads. Proc. Hydraul. Eng. JSCE 1994, 38, 381–386. [Google Scholar] [CrossRef][Green Version]

- Hendel, M. Pavement-Watering for Cooling the Built Environment: A Review. <hal-01426167>. 2016. Available online: https://hal.archives-ouvertes.fr/hal-01426167 (accessed on 4 January 2017).

- Kinoshita, S.; Yoshida, A.; Okuno, N. Evaporation performance analysis for water retentive material based on outdoor heat budget and transport properties. J. Heat Isl. Inst. Int. 2012, 7, 222–230. [Google Scholar]

- Misaka, I.; Narita, K.; Yokoyama, H. Evaluation of evaporation ability of the system for mitigating urban heat island. In Proceedings of the Seventh International Conference on Urban Climate, Yokohama, Japan, 29 June–3 July 2009. [Google Scholar]

- Yinfei, D.; Jiaqi, C.; Zheng, H.; Weizheng, L. A Review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar]

- Ballari, M.M.; Hunger, M.; Husken, G.; Brouwers, H.J.H. NOx photocatalytic degradation employing concrete pavement containing titanium dioxide. Appl. Catal. B Environ. 2010, 95, 245–254. [Google Scholar] [CrossRef]

- Lee, S.W.; Ahn, H.R.; Kim, K.S.; Kim, Y.K. Applicability of TiO2 Penetration Method to Reduce Particulate Matter Precursor for Hardened Concrete Road Structures. Sustainability 2021, 13, 3433. [Google Scholar] [CrossRef]

- Gelegenis, J.; Michalena, E. Paying or saving? The Greek drama that leads to achievement of Sustainable Development Goals (SDGs). In Higher Education and Sustainability: Opportunities and Challenges for Achieving Sustainable Development Goals; de Miranda Azeiteiro, U.M., Davim, J.P., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 169–195. [Google Scholar]

- Kuang, W.; Du, G.; Lu, D.; Dou, Y.; Li, X.; Zhang, S.; Chi, W.; Dong, J.; Chen, G.; Yin, Z.; et al. Global Observation of Urban Expansion and Land-Cover Dynamics Using Satellite Big-Data. Sci. Bull. 2021, 66, 297–300. [Google Scholar] [CrossRef]

- Kuang, W. 70 Years of Urban Expansion Across China: Trajectory, Pattern, and National Policies. Sci. Bull. 2020, 65, 1970–1974. [Google Scholar] [CrossRef]

- Paravantis, J.A.; Tasios, P.D.; Dourmas, V.; Andreakos, G.; Velaoras, K.; Kontoulis, N.; Mihalakakou, G. A Regression Analysis of the Carbon Footprint of Megacities. Sustainability 2021, 13, 1379. [Google Scholar] [CrossRef]

- Michalena, E.; Hills, J.M. Renewable Energy Governance: Is it Blocking the Technically Feasible? In Renewable Energy Governance—Complexities and Challenges; the series Lecture Notes in Energy; Springer Publisher Ltd.: London, UK, 2013; pp. 3–8. [Google Scholar]

- Hills, J.M.; Michalena, E.; Chalvatzis, K.J. Innovative Technology in the Pacific: Building Resilience for Vulnerable Communities. Technol. Forecast. Soc. Chang. 2018, 129, 16–26. [Google Scholar] [CrossRef]

| Permeable (New) | Reflective (Maintenance) | |

|---|---|---|

| Advantages | Improved air quality | Improved air quality |

| Driving safety | Nighttime illumination | |

| Pollutant reduction | Improved sustainability related to traffic and transport | |

| Energy conservation | Social safety in dark rural areas | |

| Water conservation implications | High albedo | |

| Stormwater implications | Energy conservation | |

| Runoff reduction | Pavement durability | |

| Noise reduction of vehicular roadway traffic | Reduction of power plant emissions | |

| Disadvantages | Smaller durability | Difficult installation |

| High maintenance cost | Easy reflective cracking | |

| Limiting factors: climate, locally available materials | Additional time for removal of bitumen skin |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kappou, S.; Souliotis, M.; Papaefthimiou, S.; Panaras, G.; Paravantis, J.A.; Michalena, E.; Hills, J.M.; Vouros, A.P.; Ntymenou, A.; Mihalakakou, G. Cool Pavements: State of the Art and New Technologies. Sustainability 2022, 14, 5159. https://doi.org/10.3390/su14095159

Kappou S, Souliotis M, Papaefthimiou S, Panaras G, Paravantis JA, Michalena E, Hills JM, Vouros AP, Ntymenou A, Mihalakakou G. Cool Pavements: State of the Art and New Technologies. Sustainability. 2022; 14(9):5159. https://doi.org/10.3390/su14095159

Chicago/Turabian StyleKappou, Sophia, Manolis Souliotis, Spiros Papaefthimiou, Giorgos Panaras, John A. Paravantis, Evanthie Michalena, Jeremy Maxwell Hills, Andreas P. Vouros, Aikaterini Ntymenou, and Giouli Mihalakakou. 2022. "Cool Pavements: State of the Art and New Technologies" Sustainability 14, no. 9: 5159. https://doi.org/10.3390/su14095159

APA StyleKappou, S., Souliotis, M., Papaefthimiou, S., Panaras, G., Paravantis, J. A., Michalena, E., Hills, J. M., Vouros, A. P., Ntymenou, A., & Mihalakakou, G. (2022). Cool Pavements: State of the Art and New Technologies. Sustainability, 14(9), 5159. https://doi.org/10.3390/su14095159