Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia

Abstract

1. Introduction

2. Literature Review

2.1. Construct Definition

2.1.1. Green Supply Chain Practices (GSCP)

2.1.2. Green Purchasing

2.1.3. Green Production

2.1.4. Green Distribution

2.1.5. Enterprise Resource Planning (ERP)

2.1.6. Operational Performance (OP)

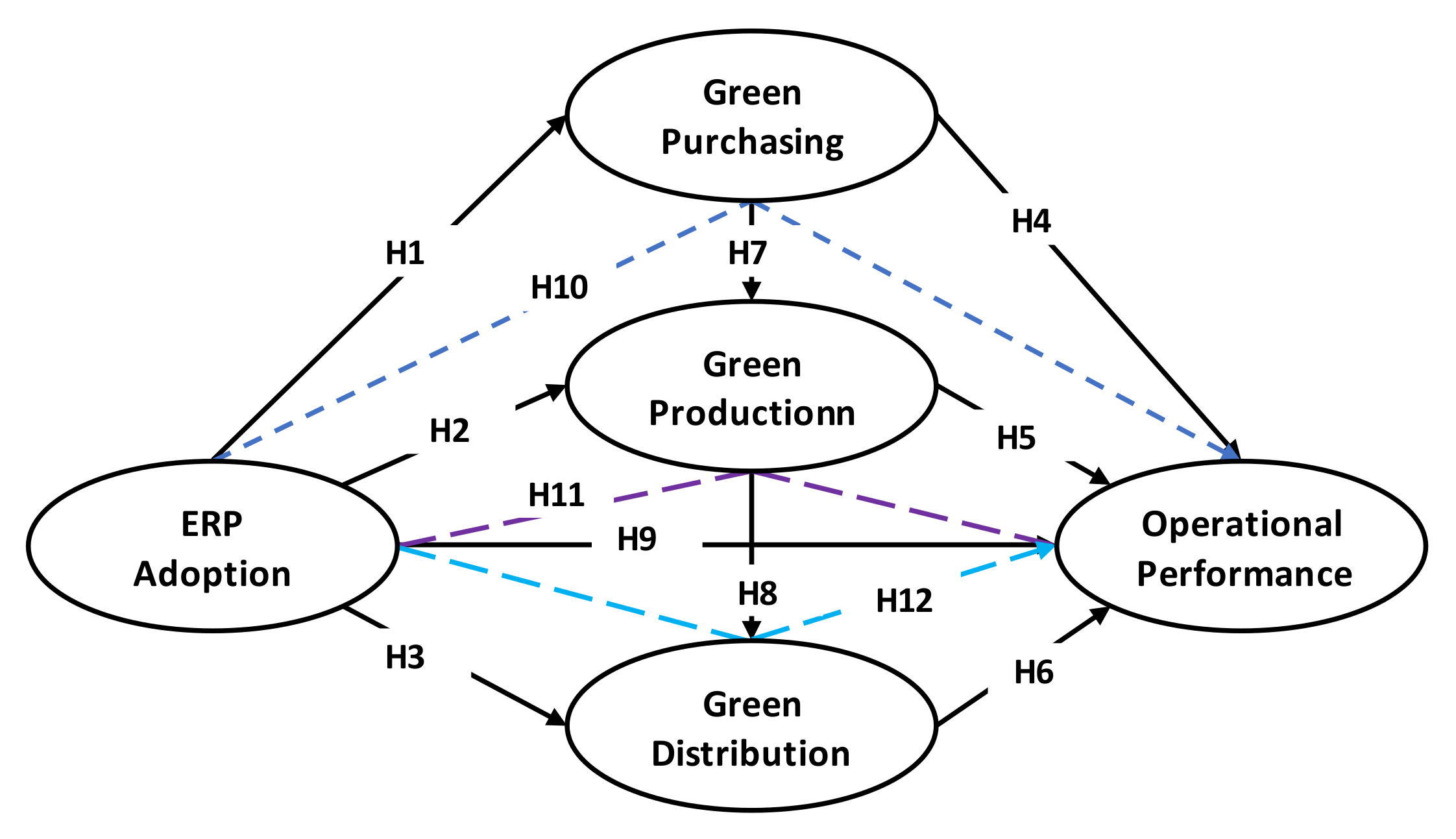

2.2. Hypotheses Development

2.2.1. Enterprise Resource Planning (ERP) Adoption and Green Purchasing

2.2.2. Enterprise Resource Planning (ERP) Adoption and Green Production

2.2.3. Enterprise Resource Planning (ERP) Adoption and Green Distribution

2.2.4. Green Purchasing and Operational Performance

2.2.5. Green Production and Operational Performance

2.2.6. Green Distribution and Operational Performance

2.2.7. Green Purchasing and Green Production

2.2.8. Green Production and Green Distribution

2.2.9. Enterprise Resource Planning (ERP) Adoption and Operational Performance

2.2.10. Enterprise Resource Planning (ERP) Adoption and Operational Performance through the Mediation of Green Purchasing

2.2.11. Enterprise Resource Planning (ERP) Adoption and Operational Performance through the Mediation of Green Production

2.2.12. Enterprise Resource Planning (ERP) Adoption and Operational Performance through the Mediation of Green Distribution

3. Methods

3.1. Study Design, Population, and Sample

3.2. Measurement Item

3.3. Data Analysis

4. Results

4.1. Respondent Demographic Profiles

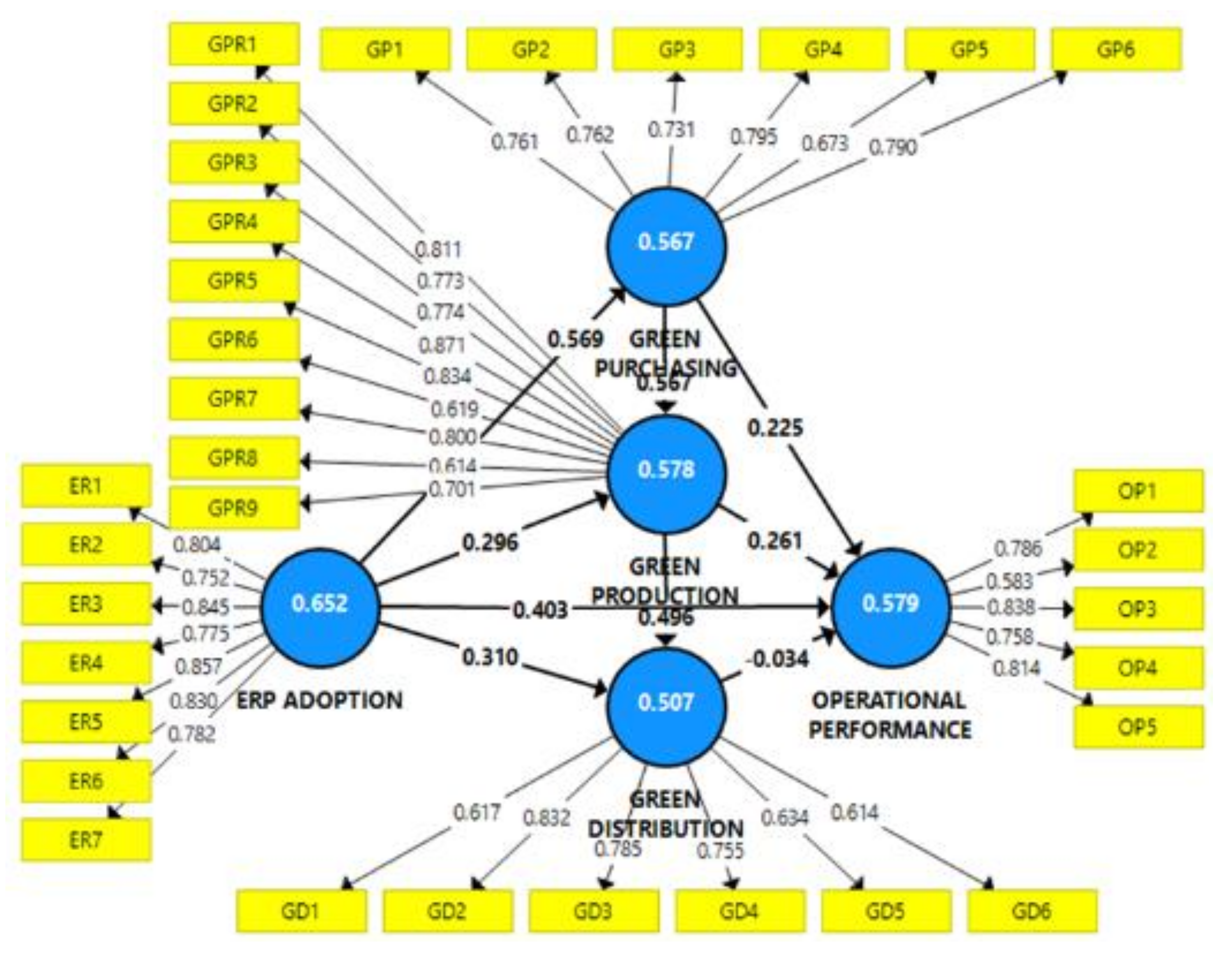

4.2. Measurement Validity and Reliability

4.3. Hypothesis Testing

5. Discussion

6. Managerial Implication and Theoretical Contribution

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The White House. Whitehouse President Biden Invites 40 World Leaders to Leaders Summit on Climate; The White House: Washington, DC, USA, 2021.

- Kalyar, M.N.; Shoukat, A.; Shafique, I. Enhancing firms’ environmental performance and financial performance through green supply chain management practices and institutional pressures. Sustain. Account. Manag. Policy J. 2020, 11, 451–476. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain Manag. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- Acar, M.F.; Zaim, S.; Isik, M.; Calisir, F. Relationships among ERP, supply chain orientation and operational performance: An analysis of structural equation modeling. Benchmarking 2017, 24, 1291–1308. [Google Scholar] [CrossRef]

- Masa’deh, R.; Alananzeh, O.; Algiatheen, N.; Ryati, R.; Albayyari, R.; Tarhini, A. The impact of employee’s perception of implementing green supply chain management on hotel’s economic and operational performance. J. Hosp. Tour. Technol. 2017, 8, 395–416. [Google Scholar] [CrossRef]

- Tilling, S.; Salmon, B. International Comparative Legal Guides: Environment & Climate Change Law 2021; Global Legal Group: London, UK, 2021. [Google Scholar]

- Wiyati, R.; Dwi Priyohadi, N.; Pancaningrum, E.; Prawironegoro, D.; Santoso, A.; Jombang, D.; Jakarta, S. Multifaceted Scope of Supply Chain: Evidence from Indonesia. Int. J. Innov. Creativity Chang. 2019, 9, 35–59. [Google Scholar]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of Enhanced Enterprise Resource Planning (ERP) on Firm Performance through Green Supply Chain Management. Sustainability 2021, 13, 4358. [Google Scholar] [CrossRef]

- Salam, M.A. The mediating role of supply chain collaboration on the relationship between technology, trust and operational performance: An empirical investigation. Benchmarking 2017, 24, 298–317. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Q.; Zhao, X. Manufacturer’s product choice in the presence of environment-conscious consumers: Brown product or green product. Int. J. Prod. Res. 2019, 57, 7423–7438. [Google Scholar] [CrossRef]

- Abdallah, A.B.; Al-Ghwayeen, W.S. Green supply chain management and business performance: The mediating roles of environmental and operational performances. Bus. Process Manag. J. 2020, 26, 489–512. [Google Scholar] [CrossRef]

- Purc, T.; Ioan-franc, V.; Lorin, V.; Purc, I.; Mateescu-soare, M.C.; Platon, O. Major Shifts in Sustainable Consumer Behavior in Romania and Retailers ’ Priorities in Agilely Adapting to It. Sustainability 2022, 14, 1627. [Google Scholar]

- Yu, Y.; Zhang, M.; Huo, B. The impact of supply chain quality integration on green supply chain management and environmental performance. Total Qual. Manag. Bus. Excell. 2019, 30, 1110–1125. [Google Scholar] [CrossRef]

- Madapusi, A.; D’Souza, D. The influence of ERP system implementation on the operational performance of an organization. Int. J. Inf. Manag. 2012, 32, 24–34. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T. Green supply chain management: Theoretical framework and further research directions. Benchmarking Int. J. 2017, 24, 184–218. [Google Scholar] [CrossRef]

- Ginting, K. Terdampak COVID-19, PMI Manufaktur Turun di April 2020—Iconomics. Available online: https://www.theiconomics.com/art-of-execution/terdampak-covid-19-pmi-manufaktur-turun-di-april-2020/ (accessed on 16 August 2021).

- Jabbour, C.J.C.; De Sousa Jabbour, A.B.L.; Govindan, K.; Teixeira, A.A.; De Souza Freitas, W.R. Environmental management and operational performance in automotive companies in Brazil: The role of human resource management and lean manufacturing. J. Clean. Prod. 2013, 47, 129–140. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Achillas, C.; Bochtis, D.D.; Aidonis, D.; Folinas, D. Green Supply Chain Management; Routledge: London, UK, 2018. [Google Scholar]

- Siagian, H.; Jiwa, Z.; Tarigan, H. The Impact of Top Management Commitment, Green Purchasing, and Supply Chain Management Practices on Operational Performance. Int. J. Innov. Creat. Chang. 2021, 15, 87–102. [Google Scholar]

- Li, S.; Jayaraman, V.; Paulraj, A.; Shang, K.C. Proactive environmental strategies and performance: Role of green supply chain processes and green product design in the Chinese high-tech industry. Int. J. Prod. Res. 2016, 54, 2136–2151. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Hsu, P.F.; Hu, P.J.H.; Wei, C.P.; Huang, J.W. Green Purchasing by MNC Subsidiaries: The Role of Local Tailoring in the Presence of Institutional Duality. Decis. Sci. 2014, 45, 647–682. [Google Scholar] [CrossRef]

- Sdrolia, E.; Zarotiadis, G. A comprehensive review for green product term: From definition to evaluation. J. Econ. Surv. 2019, 33, 150–178. [Google Scholar] [CrossRef]

- Dilip Maruthi, G.; Rashmi, R. Green Manufacturing: It’s Tools and Techniques that can be implemented in Manufacturing Sectors. Mater. Today 2015, 2, 3350–3355. [Google Scholar]

- Zhu, W.; He, Y. Green product design in supply chains under competition. Eur. J. Oper. Res. 2017, 258, 165–180. [Google Scholar] [CrossRef]

- Pinto, L. Green supply chain practices and company performance in Portuguese manufacturing sector. Bus. Strateg. Environ. 2020, 29, 1832–1849. [Google Scholar] [CrossRef]

- Chen, S.Y.; Lu, C.C. Exploring the relationships of green perceived value, the diffusion of innovations, and the technology acceptance model of green transportation. Transp. J. 2016, 55, 51–77. [Google Scholar] [CrossRef]

- Leonidou, C.N.; Katsikeas, C.S.; Morgan, N.A. “Greening” the marketing mix: Do firms do it and does it pay off? J. Acad. Mark. Sci. 2013, 41, 151–170. [Google Scholar] [CrossRef]

- Yildiz Çankaya, S.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Sumner, M. Enterprise Resource Planning; Pearson Education: London, UK, 2013. [Google Scholar]

- Salarzadeh Jenatabadi, H.; Hui, H.; Azina Ismail, N.; Huang, H.; Binti Mohd Satar, N.; Wan Jasimah bt Wan Mohamed Radzi, C. Impact of Supply Chain Management on the Relationship between Enterprise Resource Planning System and Organizational Performance Household Quality of Life and Children’s Environment View project New Framework and Statistical Approaches for Health Index St. Artic. Int. J. Bus. Manag. 2013, 8, 107. [Google Scholar] [CrossRef]

- Lee, R. The effect of supply chain management strategy on operational and financial performance. Sustainability 2021, 13, 5138. [Google Scholar] [CrossRef]

- Lai, K.H.; Wong, C.W.Y. Green logistics management and performance: Some empirical evidence from Chinese manufacturing exporters. Omega 2012, 40, 267–282. [Google Scholar] [CrossRef]

- Hwang, D.; Min, H. Identifying the drivers of enterprise resource planning and assessing its impacts on supply chain performances. Ind. Manag. Data Syst. 2015, 115, 541–569. [Google Scholar] [CrossRef]

- Rodríguez-Escobar, J.A.; González-Benito, J. The role of information technology in purchasing function. J. Bus. Ind. Mark. 2015, 30, 498–510. [Google Scholar] [CrossRef]

- Dubey, R.; Bag, S.; Samar Ali, S.; Venkatesh, V. Green purchasing is key to superior performance: An empirical study. Int. J. Procure. Manag. 2013, 6, 187–210. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Vocalelli, D. “Green Marketing”: An analysis of definitions, strategy steps, and tools through a systematic review of the literature. J. Clean. Prod. 2017, 165, 1263–1279. [Google Scholar] [CrossRef]

- Ambekar, S.S.; Deshmukh, U.; Hudnurkar, M. Impact of purchasing practices, supplier relationships and use of information technology on firm performance. Int. J. Innov. Sci. 2021, 13, 118–130. [Google Scholar] [CrossRef]

- El-garaihy, W.H.; Badawi, U.A.; Seddik, W.A.S.; Torky, M.S. Investigating Performance Outcomes under Institutional Pressures and Environmental Orientation Motivated Green Supply Chain Management Practices. Sustainability 2022, 14, 1523. [Google Scholar] [CrossRef]

- Dubey, R.; Bag, S.; Ali, S.S. Green supply chain practices and its impact on organisational performance: An insight from Indian rubber industry. Int. J. Logist. Syst. Manag. 2014, 19, 20–42. [Google Scholar] [CrossRef]

- Sezen, B.; Çankaya, S.Y. Effects of Green Manufacturing and Eco-innovation on Sustainability Performance. Procedia—Soc. Behav. Sci. 2013, 99, 154–163. [Google Scholar] [CrossRef]

- Foo, M.Y.; Kanapathy, K.; Zailani, S.; Shaharudin, M.R. Green purchasing capabilities, practices and institutional pressure. Manag. Environ. Qual. Int. J. 2019, 30, 1171–1189. [Google Scholar] [CrossRef]

- Yao, X.; Cheng, Y.; Zhou, L.; Song, M. Green efficiency performance analysis of the logistics industry in China: Based on a kind of machine learning methods. Ann. Oper. Res. 2022, 308, 727–752. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The impact of implementing green supply chain management practices on corporate performance. Compet. Rev. 2016, 26, 216–245. [Google Scholar] [CrossRef]

- Chan, H.K.; He, H.; Wang, W.Y.C. Green marketing and its impact on supply chain management in industrial markets. Ind. Mark. Manag. 2012, 41, 557–562. [Google Scholar] [CrossRef]

- Hald, K.S.; Mouritsen, J. Enterprise resource planning, operations and management: Enabling and constraining ERP and the role of the production and operations manager. Int. J. Oper. Prod. Manag. 2013, 33, 1075–1104. [Google Scholar] [CrossRef]

- Santoso, O.G.; Siagian, H. Influence of IT Application to Organizational Performance mediated by warehouse management and customer relationship management. Petra Int. J. Bus. Stud. 2019, 2, 66–74. [Google Scholar] [CrossRef][Green Version]

- Siagian, H.; Tarigan, Z.J.H. The central role of it capability to improve firm performance through lean production and supply chain practices in the COVID-19 era. Uncertain Supply Chain Manag. 2021, 9, 1005–1016. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H.; Sebayang, P. The impact of implementing enterprise resources planning (ERP) project on firm performance and organizational citizenship behavior as a moderating. J. Proj. Manag. 2020, 5, 227–236. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. The role of top management commitment to enhancing the competitive advantage through ERP integration and purchasing strategy. Int. J. Enterp. Inf. Syst. 2020, 16, 53–68. [Google Scholar] [CrossRef]

- Yu, K.; Cadeaux, J.; Luo, B.N. Operational flexibility: Review and meta-analysis. Int. J. Prod. Econ. 2015, 169, 190–202. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Qianli, D. Impact of green supply chain management practices on firms’ performance: An empirical study from the perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef]

- Kafa, N.; Hani, Y.; El Mhamedi, A. Sustainability performance measurement for green supply chain management. IFAC Proc. Vol. 2013, 6, 71–78. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Choi, T.M.; Sethi, S.P. Green supply chain management in Chinese firms: Innovative measures and the moderating role of quick response technology. J. Oper. Manag. 2020, 66, 958–988. [Google Scholar] [CrossRef]

- Badan Pusat Statistik Provinsi Jawa Timur. Direktori Perusahaan Industri Besar dan Sedang Provinsi Jawa Timur 2020; Badan Pusat Statistik Provinsi Jawa Timur: Tenggilis Mejoyo, Indonesia, 2020; ISBN 978-623-7521-40-2. [Google Scholar]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill Building Approach, 7th ed.; John Wiley & Sonsy: Chichester, UK, 2016. [Google Scholar]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; SAGE Publications: New York, NY, USA, 2017; ISBN 9781483377438. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Henseler, J.; Sarstedt, M. Goodness-of-fit indices for partial least squares path modeling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef]

- Tenenhaus, M.; Vinzi, V.E.; Chatelin, Y.-M.; Lauro, C. PLS path modeling. Comput. Stat. Data Anal. 2005, 48, 159–205. [Google Scholar] [CrossRef]

| Category | Frequency | Percentage |

|---|---|---|

| Gender | ||

| Males | 87 | 71 |

| Females | 35 | 29 |

| Total | 122 | 100 |

| Job position | ||

| Supervisor | 73 | 60 |

| Manager | 47 | 38 |

| General Manager | 1 | 1 |

| Director/CEO | 1 | 1 |

| Total | 122 | 100 |

| Working experiences (in years) | ||

| 1–2 | 12 | 10 |

| 3–5 | 62 | 51 |

| 6–10 | 40 | 33 |

| >10 | 8 | 6 |

| Total | 122 | 100 |

| Departement | Frequency | Percentage (%) |

|---|---|---|

| Purchasing | 7 | 7% |

| Procurement | 11 | 9% |

| Warehousing | 8 | 8% |

| Logistics/Distribution | 12 | 10% |

| PPIC | 12 | 10% |

| Production | 25 | 20% |

| Marketing | 6 | 5% |

| Quality Control | 16 | 13% |

| Engineering | 10 | 9% |

| Others department | 11 | 9% |

| ERP Software | Frequency | Percentage (%) |

|---|---|---|

| SAP | 39 | 32% |

| Oracle | 9 | 7% |

| BAAN | 13 | 11% |

| MFG Pro | 17 | 14% |

| JD Edwards | 11 | 9% |

| People Soft | 6 | 5% |

| Others brand | 27 | 22% |

| Construct | Item Number | Mean | Factor Loading | Outer VIF | Composite Reliability | AVE |

|---|---|---|---|---|---|---|

| ERP adoption | ER1 | 5.93 | 0.80 | 2.308 | 0.92 | 0.65 |

| ER2 | 5.97 | 0.75 | 2.036 | |||

| ER3 | 5.62 | 0.85 | 2.956 | |||

| ER4 | 5.67 | 0.78 | 2.019 | |||

| ER5 | 5.73 | 0.86 | 3.071 | |||

| ER6 | 5.5 | 0.83 | 3.251 | |||

| ER7 | 5.84 | 0.78 | 2.062 | |||

| Green purchasing | GP1 | 5.92 | 0.76 | 2.371 | 0.89 | 0.57 |

| GP2 | 5.8 | 0.76 | 2.631 | |||

| GP3 | 5.49 | 0.73 | 1.754 | |||

| GP4 | 5.52 | 0.79 | 1.932 | |||

| GP5 | 6.03 | 0.67 | 2.174 | |||

| GP6 | 5.51 | 0.79 | 2.818 | |||

| Green production | GPR1 | 5.43 | 0.81 | 4.169 | 0.92 | 0.58 |

| GPR2 | 6.07 | 0.77 | 2.247 | |||

| GPR3 | 5.77 | 0.77 | 2.165 | |||

| GPR4 | 5.97 | 0.87 | 3.723 | |||

| GPR5 | 5.82 | 0.83 | 4.201 | |||

| GPR6 | 6.1 | 0.62 | 1.784 | |||

| GPR7 | 6.11 | 0.8 | 2.502 | |||

| GPR8 | 5.96 | 0.61 | 1.521 | |||

| GPR9 | 6.04 | 0.7 | 2.130 | |||

| Green distribution | GD1 | 5.25 | 0.62 | 1.518 | 0.86 | 0.51 |

| GD2 | 5.77 | 0.83 | 2.336 | |||

| GD3 | 5.7 | 0.79 | 2.040 | |||

| GD4 | 5.36 | 0.76 | 1.771 | |||

| GD5 | 6.12 | 0.63 | 1.476 | |||

| GD6 | 6.21 | 0.61 | 1.273 | |||

| Operational performance | OP1 | 6.32 | 0.79 | 1.731 | 0.87 | 0.58 |

| OP2 | 5.84 | 0.58 | 1.237 | |||

| OP3 | 6.16 | 0.84 | 2.098 | |||

| OP4 | 6.31 | 0.76 | 1.609 | |||

| OP5 | 6.13 | 0.81 | 2.001 |

| Variable | ERP Adoption | Green Distribution | Green Production | Green Purchasing | Operational Performance |

|---|---|---|---|---|---|

| ERP Adoption | 0.807 | ||||

| Green Distribution | 0.617 | 0.712 | |||

| Green Production | 0.618 | 0.688 | 0.760 | ||

| Green Purchasing | 0.569 | 0.696 | 0.735 | 0.753 | |

| Operational Performance | 0.671 | 0.551 | 0.652 | 0.622 | 0.761 |

| Variable | R Square | Q Square |

|---|---|---|

| ERP Adoption Green Purchasing | - 0.324 | - 0.170 |

| Green Production | 0.600 | 0.340 |

| Green Distribution | 0.533 | 0.250 |

| Operational Performance | 0.562 | 0.310 |

| Relationship | Path Coefficient | T Statistics | p Values | Remark |

|---|---|---|---|---|

| ERP Adoption -> Green Purchasing (H1) | 0.569 | 9.33 | 0.000 | supported |

| ERP Adoption -> Green Production (H2) | 0.296 | 3.44 | 0.001 | supported |

| ERP Adoption -> Green Distribution (H3) | 0.310 | 3.17 | 0.002 | supported |

| Green Purchasing -> Operational Performance (H4) | 0.225 | 2.05 | 0.042 | supported |

| Green Production -> Operational Performance (H5) | 0.261 | 2.34 | 0.021 | supported |

| Green distribution -> Operational Performance (H6) | −0.034 | 0.31 | 0.760 | not supported |

| Green Purchasing -> Green Production (H7) | 0.567 | 7.29 | 0.000 | supported |

| Green Production -> Green Distribution (H8) | 0.497 | 5.92 | 0.000 | supported |

| ERP Adoption -> Operational Performance (H9) | 0.403 | 4.46 | 0.000 | supported |

| Indirect Relationship | Path Coefficient | T Statistics | p Values |

|---|---|---|---|

| ERP Adoption -> Green Purchasing -> Operational Performance (H10) | 0.128 | 2.012 | 0.045 |

| ERP Adoption -> Green Production -> Operational Performance(H11) | 0.077 | 2.096 | 0.036 |

| ERP Adoption -> Green Distribution -> Operational Performance (H12) | −0.011 | 0.289 | 0.773 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santoso, R.W.; Siagian, H.; Tarigan, Z.J.H.; Jie, F. Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia. Sustainability 2022, 14, 4944. https://doi.org/10.3390/su14094944

Santoso RW, Siagian H, Tarigan ZJH, Jie F. Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia. Sustainability. 2022; 14(9):4944. https://doi.org/10.3390/su14094944

Chicago/Turabian StyleSantoso, Ruben Wahyu, Hotlan Siagian, Zeplin Jiwa Husada Tarigan, and Ferry Jie. 2022. "Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia" Sustainability 14, no. 9: 4944. https://doi.org/10.3390/su14094944

APA StyleSantoso, R. W., Siagian, H., Tarigan, Z. J. H., & Jie, F. (2022). Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia. Sustainability, 14(9), 4944. https://doi.org/10.3390/su14094944