Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway

Abstract

:1. Introduction

2. Project Overview

3. Determination of the Reasonable Width of Narrow Coal Pillars

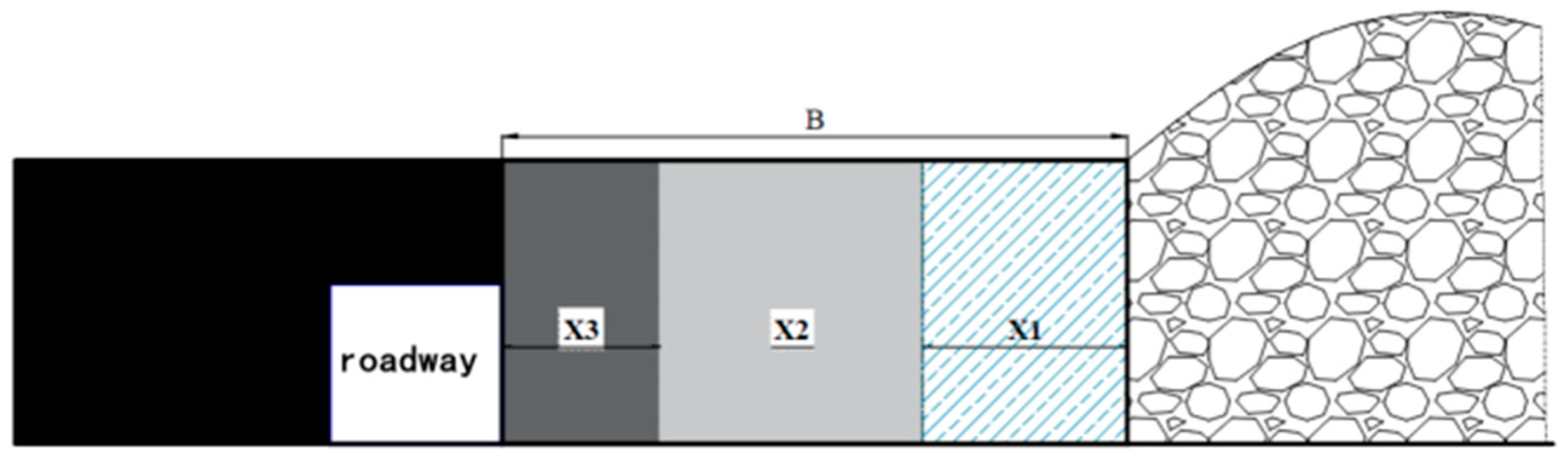

3.1. Theoretical Analysis of Coal Pillar Width Based on Limit Equilibrium Theory

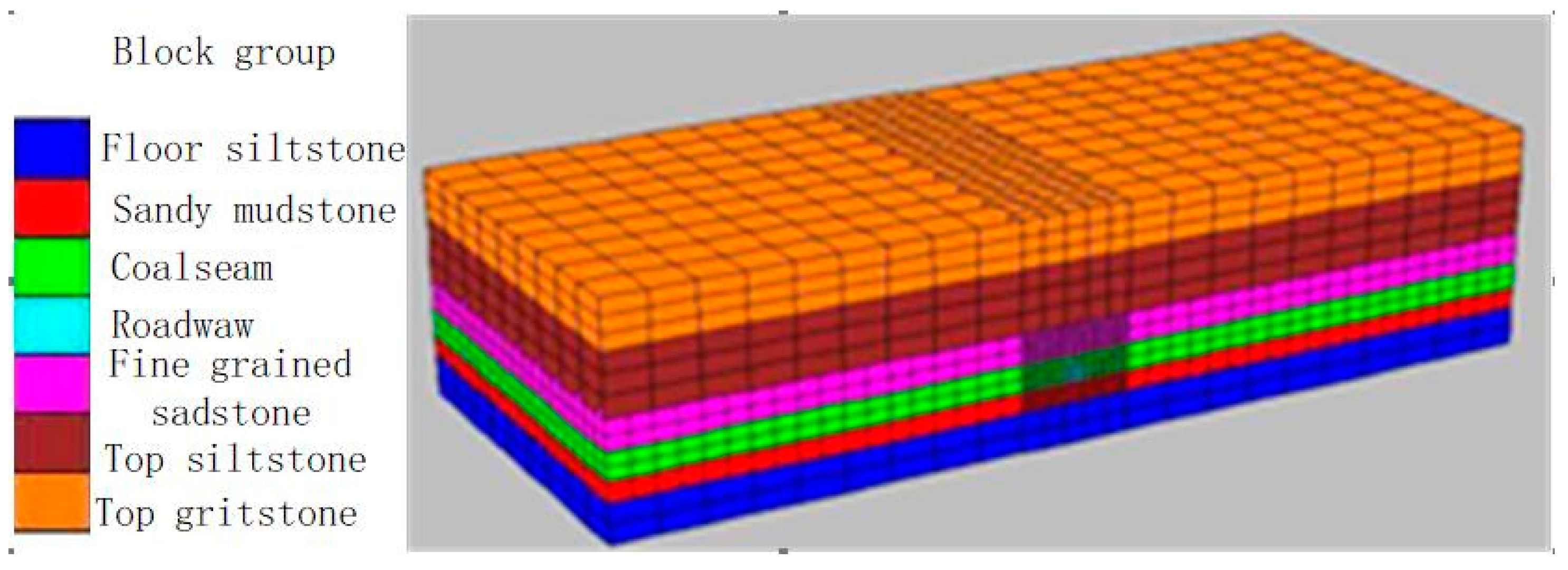

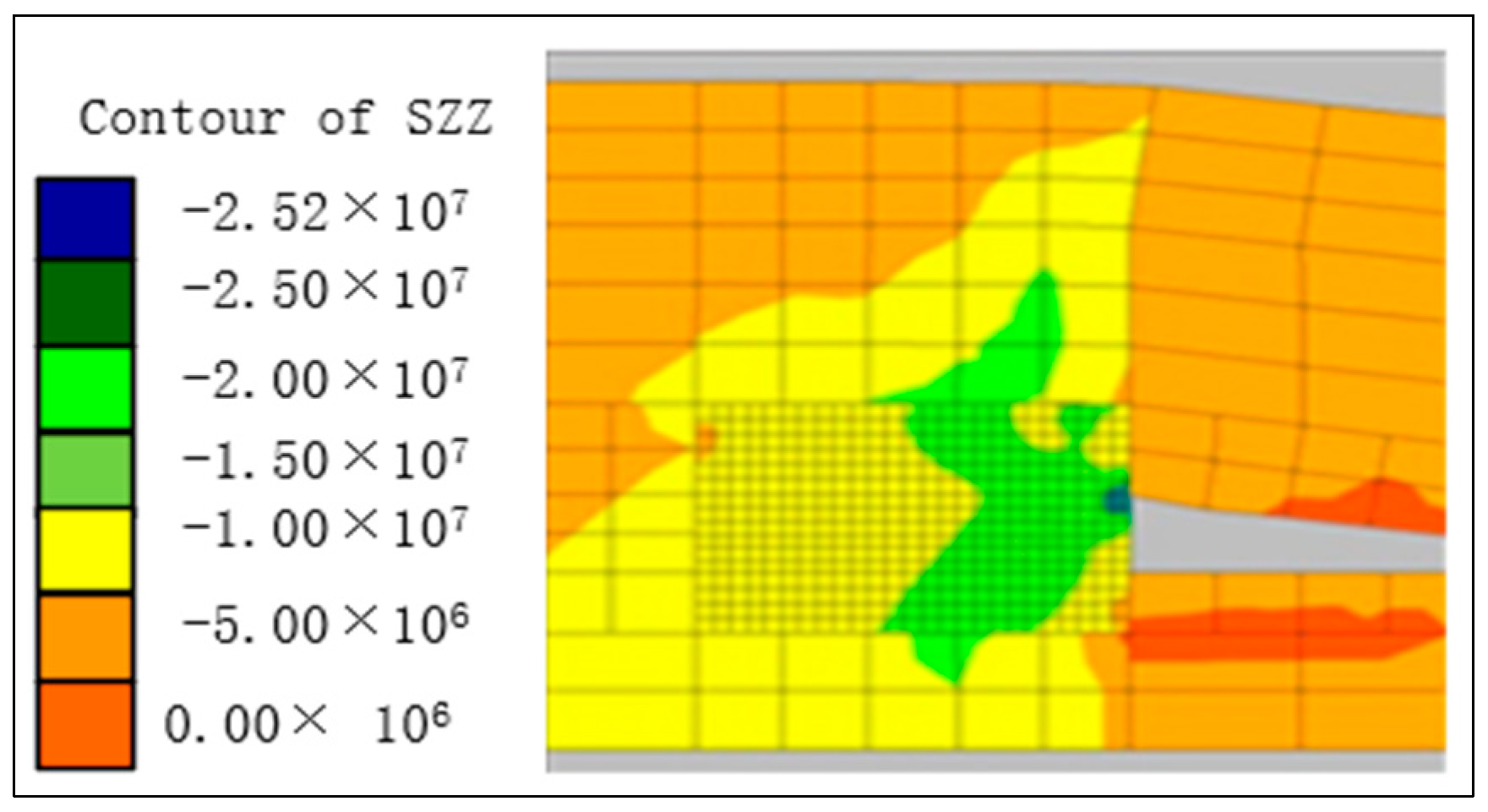

3.2. Numerical Calculation and Analysis of Optimum Width of a Narrow Coal Pillar

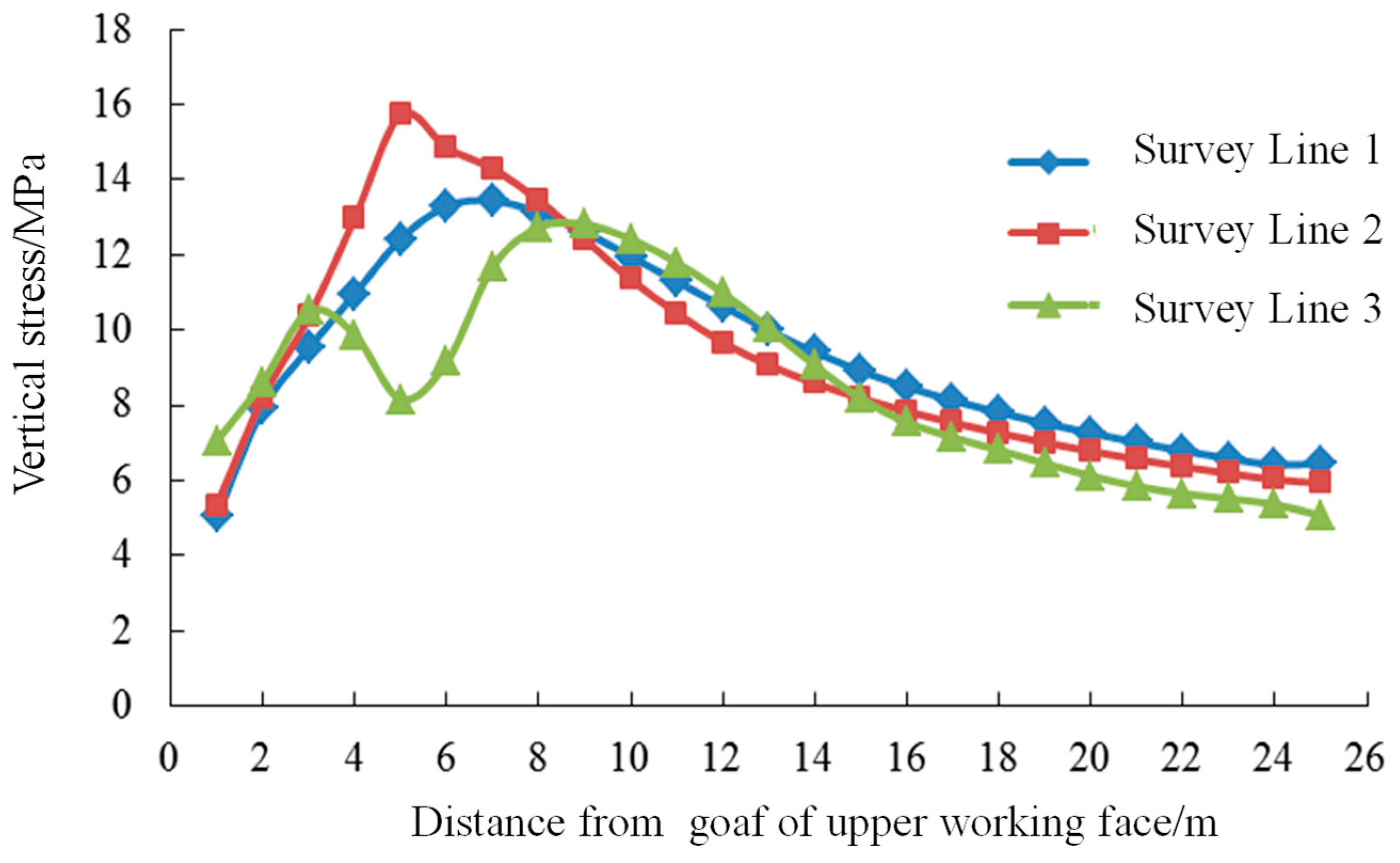

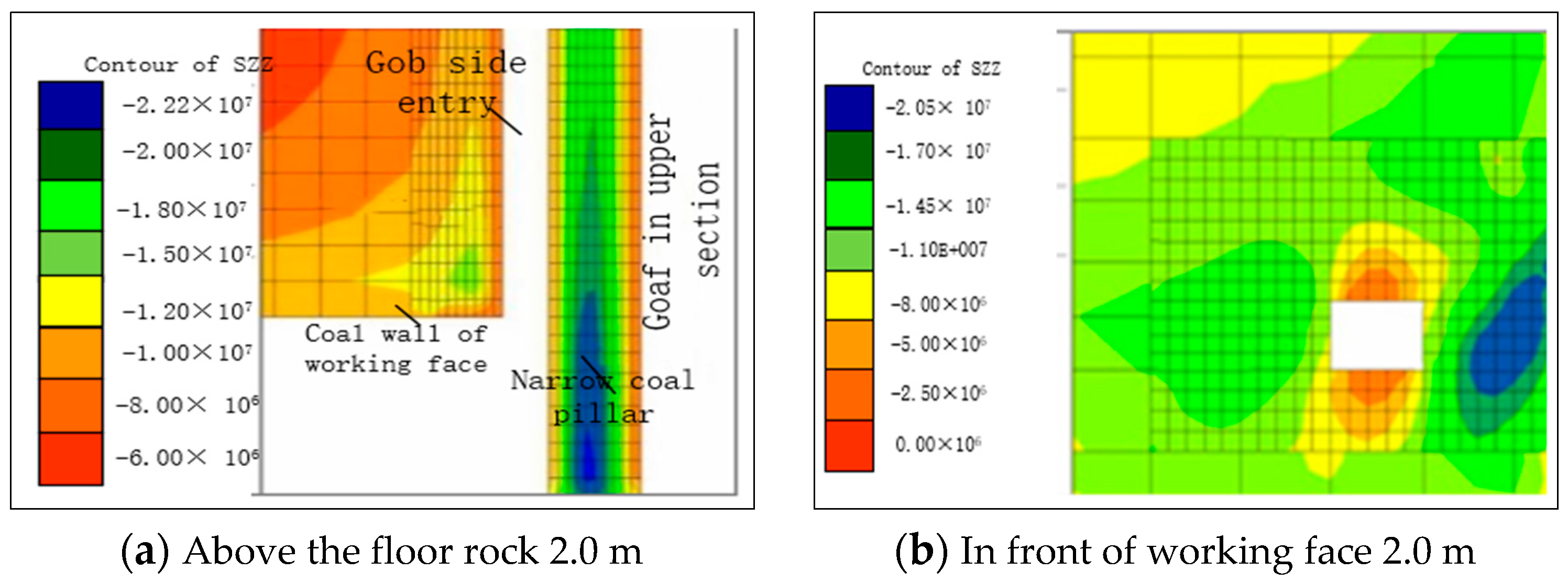

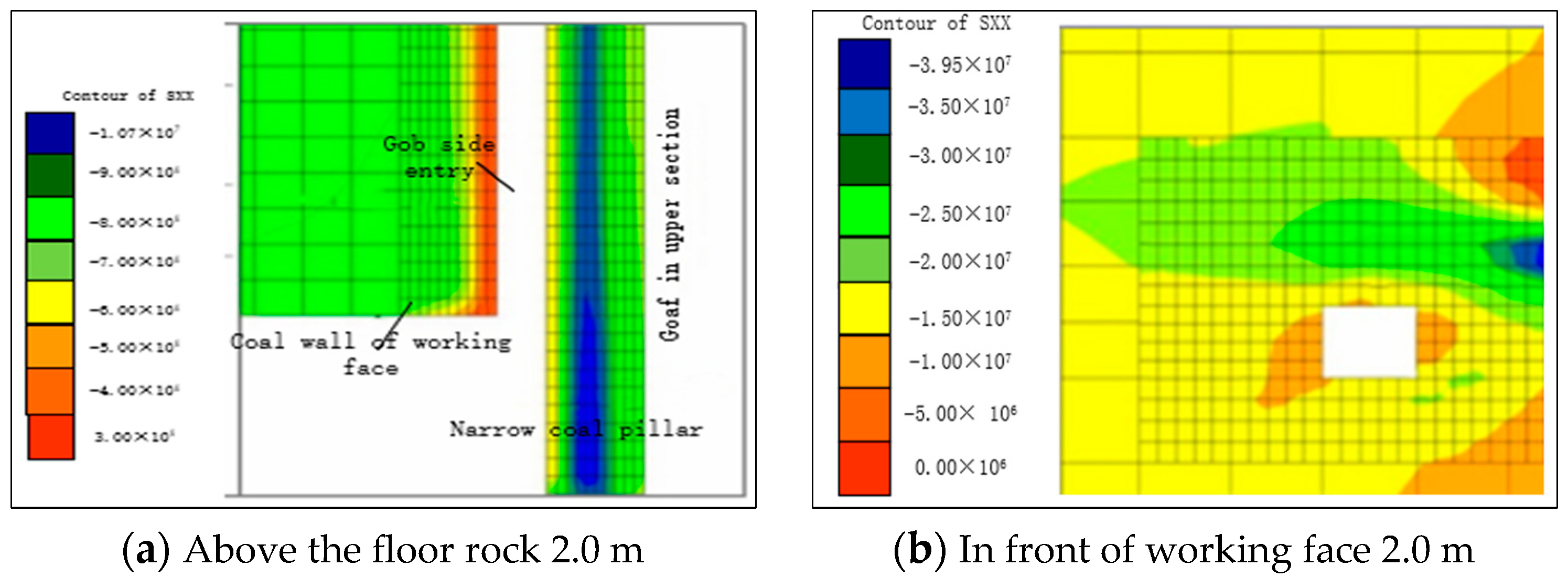

3.3. Distribution Characteristics of Lateral Abutment Pressure in Upper Working Face

3.4. Determination of Narrow Coal Pillar Width

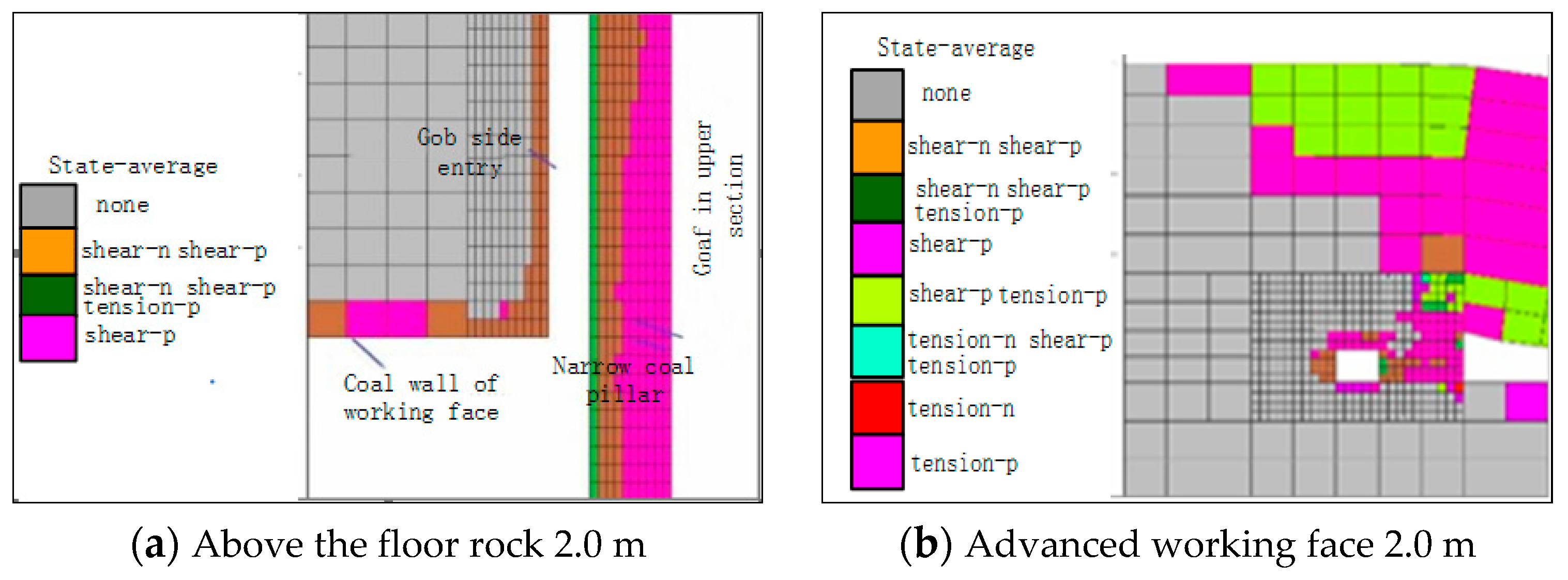

4. Simulation Analysis of Surrounding Rock Control of Gob Side Entry

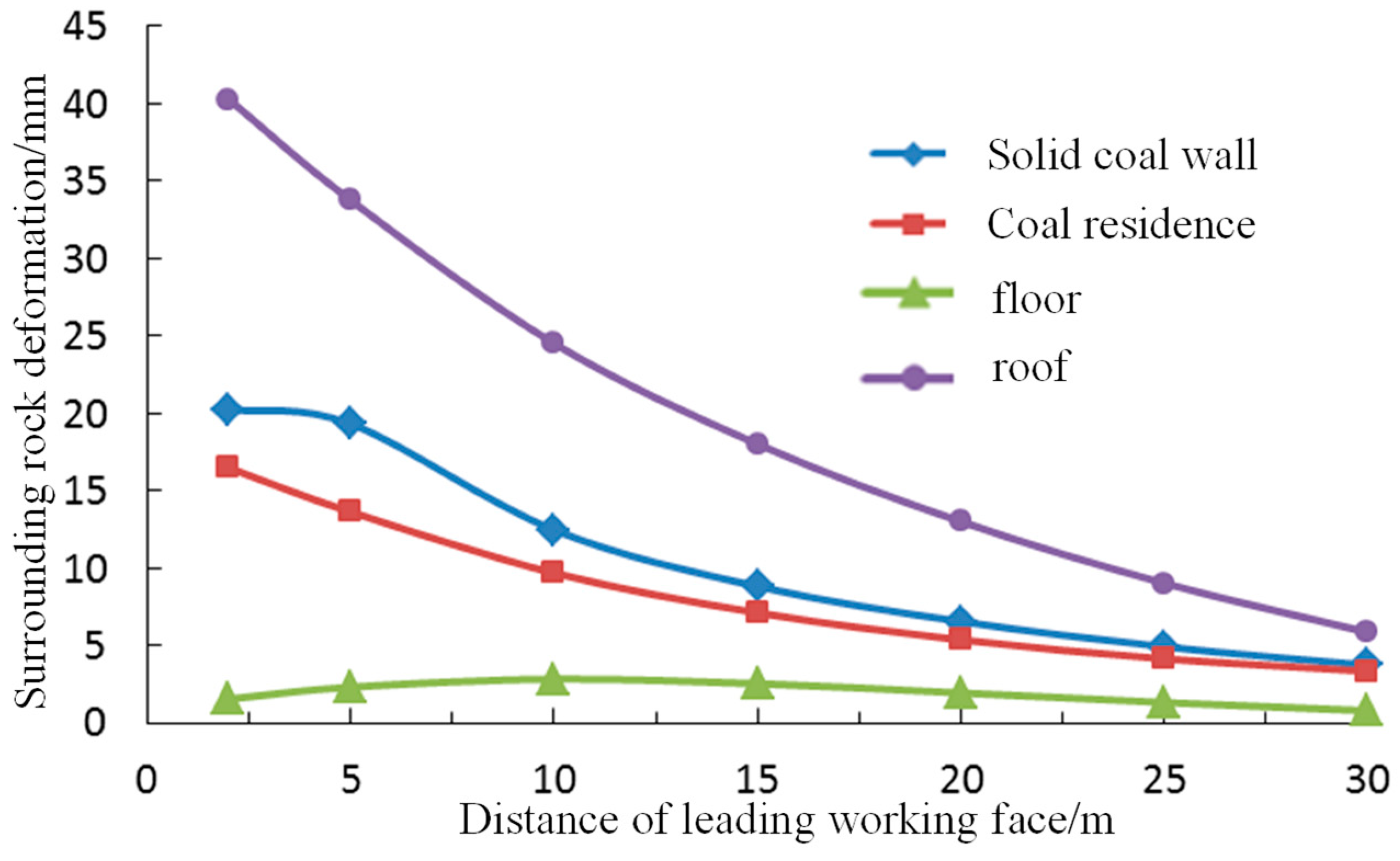

4.1. Deformation Characteristics and Cause Analysis of Roadway Surrounding Rock

- (1)

- During the influence of excavation and the stable period after excavation, the two sides of the roadway move closer than roof and floor, and there is no significant difference between the solid side and the small pillar side; the roof subsidence is relatively large. The main reason is that the roof is greatly affected by the mining and roadway excavation in the upper section, and the roof condition becomes worse. At this time, the properties of floor surrounding rock are better than those of both sides and roof, and the floor heave is not obvious.

- (2)

- During the influence period of roadway excavation, the dilatancy of the surrounding rock in the shallow part of the roadway and the dislocation of the broken surrounding rock blocks are the main causes of surrounding rock deformation. The deformation of surrounding rock can be effectively controlled through reasonable roadway location and bolting parameters and early placement of bolting. After the roadway is stable, the main reason for roadway surrounding rock deformation is the creep of coal. Minimizing the number of days of roadway maintenance can reduce the amount of surrounding rock deformation during this period. The main reason for the large deformation during mining is that the advance abutment pressure affects the stability of the overlying rock structure, causing the continuous increase of surrounding rock stress and great increase of surrounding rock deformation speed and amount.

- (3)

- When the roadway is influenced by the mining, the deformation of surrounding rock is much larger than that of surrounding rock during excavation. The deformation of two sides of coal wall is large. The increase of vertical stress in the two sides leads to large deformation of the two sides. The deformation of solid coal side is a little bigger than that of narrow coal pillar side. The distribution of solid coal side deformation along the roadway height is uneven, and the approach of the lower part is larger than that of the lower part; the displacement of roof and floor is less than that of two sides, in which the quantity of floor heave is larger than that of roof subsidence. The main reason is that the larger vertical stress caused by mining causes the larger subsidence of two sides, which causes the larger floor heave. It is more serious near the solid coal wall, and the primary cause is that the vertical stress of solid coal wall increases greatly.

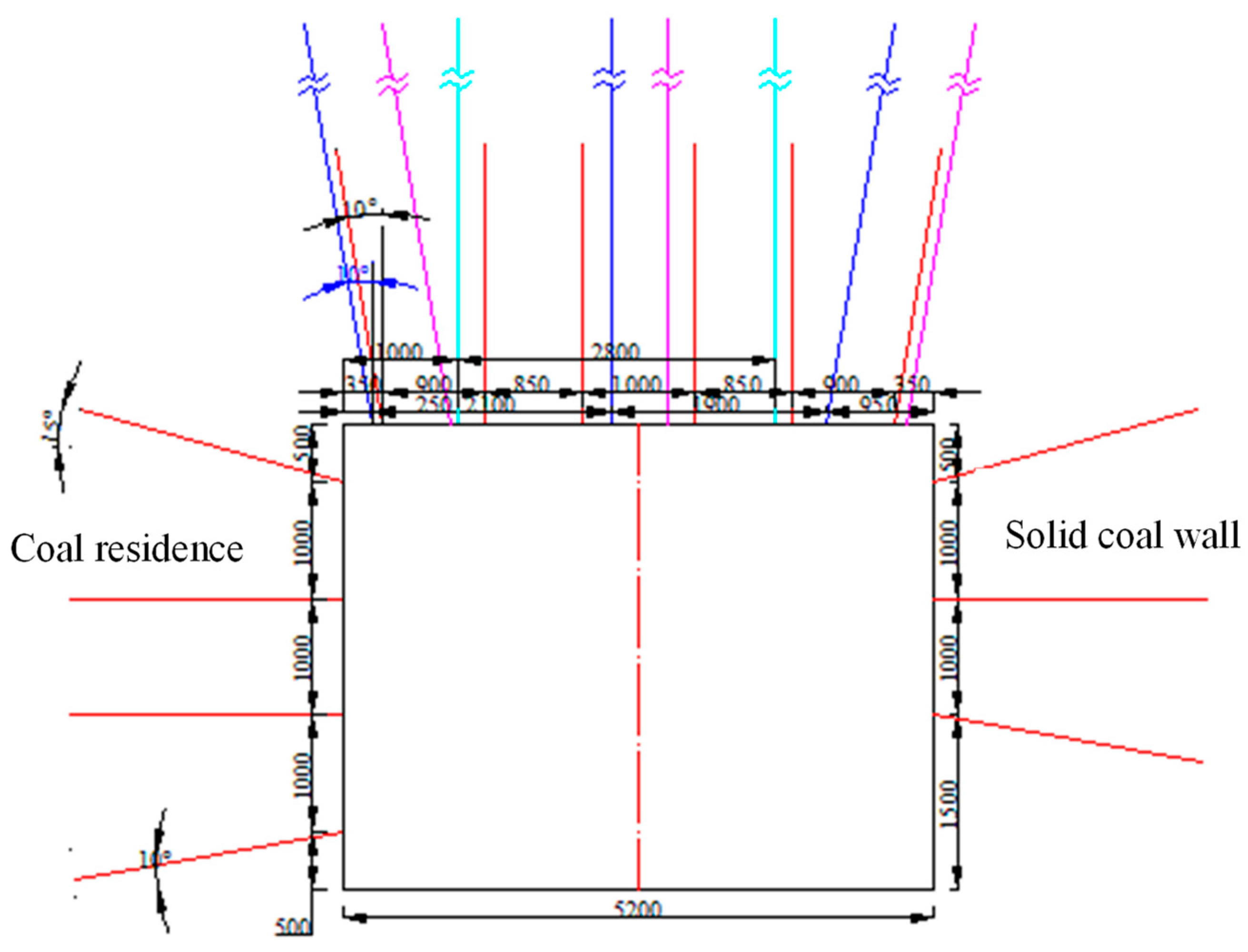

4.2. Bolt Support of Roadway Surrounding Rock

- (1)

- Roof support

- (2)

- Solid coal wall support

- (3)

- Coal pillar support

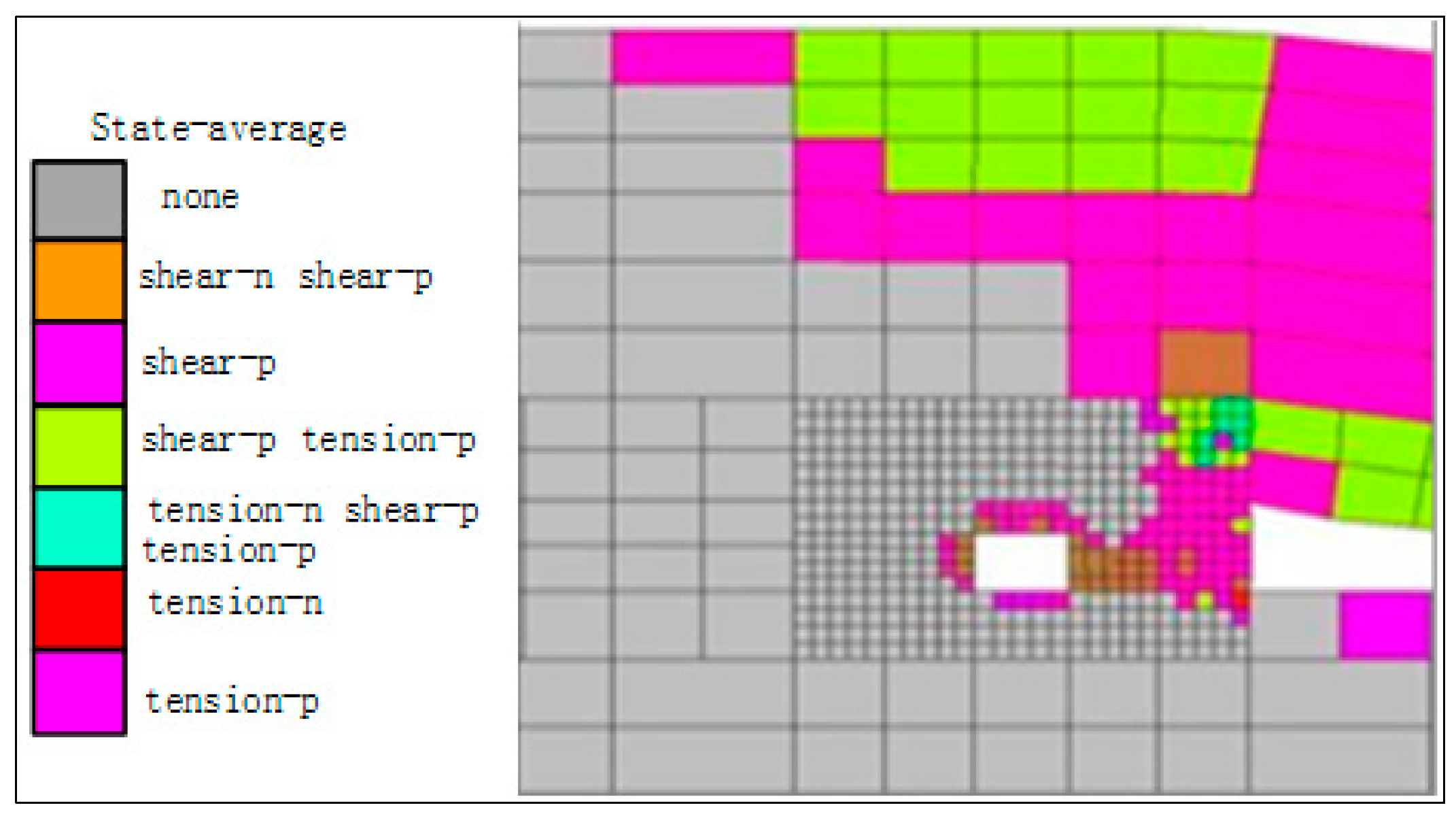

4.3. Analysis on Control Effect of Roadway Surrounding Rock

- (1)

- Effect of surrounding rock control during roadway excavation

- (2)

- Control effect of surrounding rock during mining

5. Conclusions

- (1)

- It is the most advantageous for the stability of the roadway and the support pillar to arrange the roadway along the goaf in the area of stress reduction in the inner side of the coal wall at the edge of the goaf. According to the limit equilibrium theory, the width of the narrow pillar is 9.81 m.

- (2)

- The lateral support stress of goaf plays a crucial role in the width of roadway pillar. The lateral vertical stress of goaf decreases in the range of 8.0~23.0 m, and the width of plastic zone in the lateral coal body of working face 414,109 is 5.0~6.0 m. Combined with the theoretical calculation and numerical calculation, it is suggested that the width of narrow coal pillar should be 10 m in the auxiliary calculation of working face 414,110.

- (3)

- By analyzing of the development range of plastic failure of surrounding rock and the law of deformation and failure, the support design should focus on strengthening the support of the coal pillar side and the roof close to the coal pillar side.

- (4)

- The deformation and failure of surrounding rock of gob side entry under the action of high strength bolt and cable support is significantly reduced compared with that without support.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hou Chaojiong Team. Roadway Surrounding Rock Control; China University of Mining and Technology Press: Xuzhou, China, 2013. [Google Scholar]

- Li, C.; Liu, Y.; Bai, J.; Ge, Q. Study on stability of filling wall under lateral large-span composite hinge fracture of hard critical block. Sci. Prog. 2021, 104, 21694. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.Q.; Shi, L.; Wang, P.; Wu, C. A Novel Gob-Side Entry Method in China: A Case Study. Geotech. Geol. Eng. 2019, 38, 215–226. [Google Scholar] [CrossRef]

- Fei, L.; Han, Y. Deformation Mechanismand Control of the Surrounding Rock during GobSide Entry Driving along Deeply Fully Mechanized Caving Island Working Face. Geofluids 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Fuxing, X.; Sandro, C. Control of Gob-Side Roadway with Large Mining Height in Inclined Thick Coal Seam: A Case Study. Shock. Vib. 2021, 2021, 6687244. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; He, W.; Li, L.; He, F. Study on Coal Pillar Width and Surrounding Rock Control of Gob-Side Entry in Extra-thick Coal Seam. Geotech. Geol. Eng. 2020, 38, 1–14. [Google Scholar] [CrossRef]

- Wang, W.; Feng, T.; Hou, C. Analysis on relationship between stress distribution of solid coal wall and surrounding rock damage in gob side entry driving. J. Rock Mech. Eng. 2002, 11, 1590–1593. [Google Scholar]

- Zhang, N.; Li, X.; Gao, M. Pre tension support and engineering application of gob side entry driving in Yingmei mining face. J. Rock Mech. Eng. 2004, 12, 2100–2105. [Google Scholar]

- Bai, J.; Hou, C.; Huang, H. Numerical simulation study on stability of narrow coal pillar in gob side entry driving. J. Rock Mech. Eng. 2004, 20, 3475–3479. [Google Scholar]

- Lu, S.; Liu, S.; Wan, Z.; Zhang, H.; Xing, K.; He, X. Deformation and control measures of narrow coal pillar in gob side entry driving. Min. Res. Dev. 2020, 40, 28–31. [Google Scholar]

- Li, J. Study on reasonable width of narrow coal pillar in gob side entry driving. Shandong Coal Sci. Technol. 2020, 5, 73–75+78. [Google Scholar]

- Zhang, K. Research on reasonable width design of narrow coal pillar in gob side entry driving. Energy Environ. Prot. 2019, 41, 159–162+166. [Google Scholar]

- Yu, J. Stability analysis of narrow coal pillar and Research on surrounding rock control technology of gob side entry in fully mechanized top coal caving. Coal Mine Modernization 2020, 1, 139–141+144. [Google Scholar]

- Xue, C.; Cao, A.; Guo, W.; Wang, S.; Liu, Y.; Shen, Z.; Wang, P. Mechanism of Coal Burst and Prevention Practice in Deep Asymmetric Isolated Coal Pillar: A Case Study from YaoQiao Coal Mine. Shock. Vib. 2021, 2021, 3751146. [Google Scholar] [CrossRef]

- Wang, Z.; Zhong, Q.; Wang, P. Research on narrow coal pillar width of gob side entry driving in high stress soft rock gently inclined coal seam. Coal Mine Saf. 2020, 51, 216–221+228. [Google Scholar]

- Li, W. Technology and application of gob side entry driving in 2102 working face of Heilong coal industry. Coal Sci. Technol. 2019, 40, 79–82. [Google Scholar]

- Li, J. Study on stress and surrounding rock deformation law of narrow coal pillar in gob side entry driving. Coal Technol. 2019, 38, 43–46. [Google Scholar]

- Chen, J.; Liu, P.; Zhao, H.; Zhang, C.; Zhang, J. Analytical studying the axial performance of fully encapsulated rock bolts. Eng. Fail. Anal. 2021, 128, 105580. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, H.; He, F.; Zhang, J.; Tao, K. Studying the performance of fully encapsulated rock bolts with modified structural elements. Int. J. Coal Sci. Technol. 2021, 8, 64–76. [Google Scholar] [CrossRef]

- Chang, Q.; Tang, W.; Xu, Y.; Zhou, H. Research on the width of filling body in gob-side entry retaining with high-water materials. Int. J. Min. Sci. Technol. 2018, 28, 519–524. [Google Scholar] [CrossRef]

- Chang, Q.L.; Sun, Y.F.; Leng, Q.; Liu, Z.X.; Zhou, H.Q.; Sun, Y.T. Stability Analysis of Paste Filling Roof by Cut and Fill Mining. Sustainability 2021, 13, 10899. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, T.; Wang, Y. Study on influencing factors of surrounding rock deformation and asymmetric support technology for roadway driving along goaf with narrow coal pillars. J. Henan Polytech. Univ. 2021, 40, 24–33. [Google Scholar]

- Zhang, H.; Zuo, A. Reasonable width of coal pillar and asymmetric support technology in gob-side entry. Saf. Coal Mines. 2021, 52, 129–135. [Google Scholar]

- Xu, Z.; Li, Q.; Li, X. Overburden Migration and Failure Characteristics in Mining Shallow Buried Coal Seam with Thick Loose Layer. Adv. Mater. Sci. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Han, C.; Yang, H.; Zhang, N.; Li, X.; Liu, Y.; Liu, W.; Yao, W. Study on Reasonable Coal Pillar Width of Gob-Side Roadway Excavating with Multi-Layer Hard Roof in Western Deep Mine. Geotech. Geol. Eng. 2021, prepublish. [Google Scholar] [CrossRef]

- Chen, A. Width Design of Small Coal Pillar of Gob-Side Entry Driving in Soft Rock Working Face and Its Application of Zaoquan Coal Mine. Adv. Civ. Eng. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, J.; Chen, Y.; Ding, H.; Ma, H.; Feng, R. The Relationship between Mining-Induced Stress and Coal Gas under an Optimized Support Scheme: A Case Study in the Guanyinshan Coal Mine, China. Geofluids 2021, 2021, 1–17. [Google Scholar] [CrossRef]

- Ming, Z.; Shuai, Z.; Yong, C. Reasonable Width of Narrow Coal Pillar of Gob-side Entry Driving in Large Mining Height. IOP Conf. Ser.: Earth Environ. Sci. 2017, 59, 12025. [Google Scholar] [CrossRef] [Green Version]

- Tai, Y.; Yu, B.; Xia, B.; Li, Z.; Xia, H. Research on stress release for the gob-side roadway using the roof-cutting technology with a chainsaw arm. R. Soc. Open Sci. 2020, 7. [Google Scholar] [CrossRef] [Green Version]

- Qi, F.; Zhou, Y.; Li, J.; Wang, E.; Cao, Z.; Li, N. Top-coal deformation control of gob-side entry with narrow pillars and its application for fully mechanized mining face. Int. J. Min. Sci. Technol. 2016, 26, 417–422. [Google Scholar] [CrossRef]

| Stratum Name | Bulk Modulus/GPa | Shear Modulus/GPa | Density/kg/m3 | Cohesion/MPa | Internal Friction Angle/° | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| Bottom siltstone | 9.70 | 6.61 | 2470 | 2.40 | 36.2 | 1.86 |

| Bottom sandy mudstone | 7.30 | 5.21 | 2560 | 4.40 | 32.4 | 1.26 |

| 4-1 coal seam | 2.83 | 1.87 | 1460 | 1.41 | 27.3 | 0.83 |

| Top fine grained sandstone | 7.60 | 5.19 | 2430 | 6.00 | 27.6 | 1.87 |

| Top siltstone | 9.66 | 6.44 | 2380 | 2.70 | 36.3 | 2.34 |

| Top gritstone | 10.30 | 6.87 | 2420 | 4.14 | 31.4 | 3.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Q.; Ge, S.; Shi, X.; Sun, Y.; Wang, H.; Li, M.; Wang, Y.; Wu, F. Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway. Sustainability 2022, 14, 4848. https://doi.org/10.3390/su14084848

Chang Q, Ge S, Shi X, Sun Y, Wang H, Li M, Wang Y, Wu F. Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway. Sustainability. 2022; 14(8):4848. https://doi.org/10.3390/su14084848

Chicago/Turabian StyleChang, Qingliang, Shiguo Ge, Xianyuan Shi, Yesong Sun, Haibin Wang, Mengda Li, Yizhe Wang, and Fengfeng Wu. 2022. "Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway" Sustainability 14, no. 8: 4848. https://doi.org/10.3390/su14084848

APA StyleChang, Q., Ge, S., Shi, X., Sun, Y., Wang, H., Li, M., Wang, Y., & Wu, F. (2022). Determination of Narrow Coal Pillar Width and Roadway Surrounding Rock Support Technology in Gob Driving Roadway. Sustainability, 14(8), 4848. https://doi.org/10.3390/su14084848