Abstract

The article presents an analysis of the impact of bio-based materials on the environment, with a special focus on polylactic acid (PLA), as it is considered one of the most popular bioplastics in the market. The results show that there are several factors that must be taken into account when choosing the best end-of-life option for this type of material, in agreement with the newly introduced concept of the circular economy, according to the physical–chemical analysis obtained at the end of this study. The ecotoxicity tests showed that all tested materials (PLA spoon, PLA filament, b2w technology bag and cocoa paper tray) could be suitable for incineration with energy recovery without producing dioxines during combustion (chlorine content in all tested materials was below 1.00% w/w). It was also determined that PLA was the material with the highest potential for energy recovery since it presented the highest calorific value and highest carbon content (18.73 MJ/kg and 52.23%, respectively). The biodegradation rate of the different bio-based materials was also tested under different environments during three months, with Baltic Sea water and medium-grain sand being the environments in which the majority of the bio-based materials showed the lowest degradation rates. An additional test in a small-scale electric composter with microbe technology was carried out in order to evaluate the degradation of the studied materials in an environment with controlled conditions, and results showed high values of weight loss for the majority of the bio-based materials (all above 80% weight loss) due to the high temperature that the device could reach during the composting process. Finally, a strategy for providing guidance in selecting routes for the waste management of bioplastics, depending mainly on the available infrastructure and material properties, was proposed as a result of this work. For the case of low- and medium-income countries, an Extended Producer Responsibility (EPR) policy is proposed as a provisional solution to control plastic waste pollution, which should be complemented by regulations and systems aimed at the successful introduction of bioplastics.

1. Introduction

The increasing plastic generation is currently creating a waste management crisis, which has been approached in different ways by countries all around the world. One of the proposed solutions is the introduction of bio-based polymers, such as polylactic acid (PLA) as the most popular currently, which, as an alternative for fossil-based polymers, are expected to contribute to the reduction of conventional plastic waste since they can be designed to be either totally biodegradable to CO2 in a matter of months or years [1] or contribute to carbon capture and storage through integration into non-degradable long-term infrastructure [2], including plastic-based municipal water and sewer piping, building and roofing materials, and road surfaces. However, the increase in a new source of polymeric waste is implied, and their waste management is still challenging due to several factors, such as the biodegradation rate of the materials in different environments, physical conditions, and parameters that may have influence on their biodegradability, as well as the physical and chemical properties of the materials, including their ecotoxicity.

Previous authors have studied the degradation of PLA polymers and other bio-based materials. Agarwal et al. [3] reported no significant differences in the degradation of PLA in abiotic and biotic environments, plus difficulties in the determination of weight loss in biotic and abiotic feed due to the fusing of PLA with particles of organic feed. Williams et al. [4] investigated the degradation of polyglycolic acid (PGA) and PLA polymers in aqueous and enzymatic environments by monitoring weight loss and lactic acid production. Kai-Lai et al. [5] reported that the degradation time of PLA in Costa Rican soil and in a leaf-composting environment was of 6 months and 3 weeks, respectively, due to a higher temperature and humidity control (55–50 °C to 100% RH). Intaraksa et al. [6] performed a study of the bio-disintegration behavior of PLA under laboratory and pilot-scale conditions according to ISO 20200:2004 and ISO 16929:2002 and reported a degree of disintegration of 100%, concluding that the thickness of PLA sheets does not influence the composting process and quality of the resulting compost. Napper et al. [7] performed a study on biodegradable, oxo-biodegradable, compostable, and high-density polyethylene materials exposed to three natural environments, reporting that none of them could be relied upon to show any substantial deterioration over a 3-year period in all of the environments. Similarly to the last study, this research analyzes the degradation of different bio-based materials in four environments to evaluate their feasibility of disintegration in real conditions. The first and most popular material to be evaluated, the PLA, possesses similar characteristics to the conventional polymers, such as good mechanical properties, high transparency and glossy rigidity, and high tear strength, and, additionally, it is compostable under industrial composting conditions [8]. Two other bio-based materials were also analyzed:

- d2w®—biodegradable plastic technology: plastics manufactured under the d2w® technology could be considered as “oxo-biodegradable”, since they require oxygen and UV exposure for the degradation process to start. However, this technology is described as a two-stage process, in which, firstly, ordinary plastic, at the end of its useful life and in the presence of oxygen, is turned into a material with a different molecular structure, while, in the second stage, it is no longer a plastic, but a material that is biodegradable (by bacteria and fungi) in the open environment [9].

- Cocoa paper: newly developed material that is the result of an innovative technology that reuses scrap shells from the processing of cocoa and transforms them into paper with remarkable quality and with a natural texture [10]. Alongside being plastic-free, it is recyclable and biodegradable and waste material is used in its production, making cocoa paper a circular economy product.

As a second outcome of this research, a strategy for the best waste management practices for bio-based materials within the context of circular economy is proposed, as these materials have the potential for a closed loop in comparison to fossil-based ones, since the biogenic carbon taken up by the feedstock is released back into the atmosphere after its use [11]. The proposed strategy will be also based on regional factors, such as income level, which could affect the adequate introduction of bio-based materials as it is estimated that two billion people worldwide lack waste collection services and, as a result, resort to illegal dumping on either roads, vacant land, or drains, while, for another one billion people, waste is collected but disposed of unsafely due to the absence of disposal systems/facilities [12]. This constitutes 93% of waste for low-income countries and only 2% of waste for high-income countries that is indiscriminately dumped or buried [12]. Therefore, priority should be given to assist low- and middle-income countries, where a lack of safe waste management infrastructure prevails.

2. Materials and Methods

2.1. Biodegradation Analysis of PLA and Other Bio-Based Materials in Different Environments

An experimental study was carried out in order to evaluate different materials made from polylactic acid (PLA) and bio-based materials in different environments during a period of 3 months. This duration depended on the COVID-19 restrictions, which, at the time, were still quite rigorous in Poland, where the study took place, and prevented a longer stay in the laboratories.

Four different samples of different types of biopolymers and biodegradable materials were placed in four different environments to evaluate their biodegradation rate in controlled conditions. The samples consisted of:

- (a)

- PLA spoon (4 cm × 2 cm and 4 cm × 0.5 cm samples);

- (b)

- d2w® biodegradation technology bag (5 cm × 3 cm samples);

- (c)

- Cocoa paper tray (5 cm × 6 cm and 5 cm × 3 cm samples);

- (d)

- PLA filament (11 cm × 0.2 cm samples).

Such samples are shown in Figure 1 as follows.

Figure 1.

(a) PLA spoon, (b) d2w® biodegradation technology bag, (c) cocoa paper tray, (d) PLA filament.

Three samples of each material were placed into the following environments:

- (a)

- Soil;

- (b)

- Baltic Sea sand;

- (c)

- Medium-grain sand;

- (d)

- Saltwater with 0.7% concentration of salt.

The preparation of the samples included the shredding of some materials depending on the size of the container destined for each environment.

Some conditions and parameters related to the samples are as follows:

- Temperature: In each environment, the temperature was around 20 °C (ambient temperature), with slight changes between the winter and spring season.

- Salt concentration: The salt concentration in the saltwater environment was 0.7%, which corresponds to the one found in the Baltic Sea, Poland.

- Moisture content of each material: The moisture content of each material was also determined with the following formula:

X = (m1 − m2)/m1,

Monitoring of weight loss from each sample started from the month of March and finished on May 2021. The procedure for sample control consisted of taking the sample out of the environment, dusting off residues of soil/sand with a brush, drying the sample in an oven at 104 °C for 30 min, cooling it down on a desiccator, weighing it and repeating the last three steps until constant weight. Each sample control was performed on a weekly basis; however, during three weeks between the months of March and April, this was not possible due to COVID-19 restrictions.

2.2. Home Composting Simulation of PLA and Other Bio-Based Materials in Small-Scale Electric Composter Unit

Most PLA plastic is marketed as compostable. However, most compostable PLA requires industrial facilities to break down. Therefore, an additional test was performed for the tested materials (PLA spoon, d2w® biodegradation technology bag, cocoa paper tray and PLA filament). The reason for this was in order to evaluate their feasibility for home composting in a small-scale electric composter, which is indicated to complete a composting process and/or produce a compost product in 24 h.

The electric composting device (model Oklin’s GG-02) utilized Acidulo® microbes to compost food waste in 24 h, producing a nutrient-rich soil amendment that can be used in gardens [13]. Due to safety reasons, the temperature in the tank of the device is raised to 75 °C for one hour. This process eliminates harmful bacteria, ensuring safety and the inability to spread bacteria outside [14].

For this test, as several bio-based materials were also introduced, the total duration of it was 7 days, after which the weight loss and appearance of the PLA and bio-based materials were analyzed. It is important to mention that the study was merely a simulation of a home composting process, where standards such as ISO 20200, which specifies the method of determining the degree of disintegration of plastic materials in a laboratory-scale composting environment, are not put in practice.

2.3. Determination of Calorific Value of PLA and Bio-Based Materials

The calorific value of the tested bio-based materials was determined from the measurement of their enthalpy of combustion through a bomb and shell calorimeter. The bomb is an impermeable cylinder filled with oxygen under pressure, which is placed in the shell of constant temperature. To minimize heat transfer between the bomb and the surrounding the shell, the device contains water. A stirrer mixes the water.

2.4. Determination of Carbon and Hydrogen Content

The carbon and hydrogen content of the PLA and bio-based materials was determined with a combustion method at high temperature with the presence of oxygen. The samples were completely incinerated at a temperature of 950 °C with oxygen flow of 300 cm3/min. Due to combustion, CO2 and H2O were emitted, and from the obtained masses, the content of hydrogen and carbon elements could be calculated. The process of combustion began in a high-temperature furnace.

In the middle of the high-temperature furnace, there is a glass tube where combustion takes place. In the inlet of this tube, a rubber plug that separates the measured sample from environment is located. Oxygen is given at the beginning of the tube due to the conduction between the rod of the sample and the plug. On opposite sides are situated three absorbers connected in series. They include magnesium chloride (III) (or calcium chloride) and sodium asbestos (or sodium calcium) for the water and carbon dioxide absorption, respectively. Temperature is controlled thanks to a thermoregulator as well as a rotameter, which controls the oxygen flow rate.

2.5. Determination of Chlorine Content of PLA and Bio-Based Materials

Accurate quantification of Cl in fuels is essential to understand Cl transformation during thermochemical processes and mitigate related environmental issues. Conventional combustion-based methods such as bomb combustion, high-temperature combustion and the Eschka method are commonly used for quantifying Cl in solid fuels [15]. The determination of the chlorine content of PLA and bio-based materials in this study was performed through the Eschka method.

3. Results

3.1. Initial Values of Tested Materials

Initial weights of each sample for each environment were taken in order to compare them with the final weights at the end and during the study. The values are reported in Table 1. The tested materials are referred to as follows: PLA spoon as spoon, d2w® biodegradation technology bag as bag, cocoa paper tray as tray and PLA filament as filament.

Table 1.

Initial weights of the samples for each environment.

The initial weights of the samples introduced in the small-scale electric composter unit for the home composting simulation, as well as the weighted mass of the samples for the determination of the calorific value, can be found in Table 2.

Table 2.

Weighted mass of bio-based materials for home composting simulation and determination of calorific value.

The masses of the samples of tested materials with the respective amounts of catalyst (Al2O3) required for the determination of carbon and hydrogen content, together with the weighted mass of each sample and the required blank for the chlorine content determination, are shown in Table 3.

Table 3.

Weights of tested materials and catalyst (Al2O3) for C and H determination.

3.2. PLA and Bio-Based Materials’ Properties and Ecotoxicity Results

Results from the average values of each determination performed on the tested materials are shown in Table 4.

Table 4.

Average results of studied materials’ properties and ecotoxicity.

Regarding the calorific value of the tested materials, the PLA filament presented a higher value in comparison with the PLA spoon and the cocoa paper tray. The calorific value of the PLA filament (18.73 MJ/kg) was consistent with the value reported by NatureWorks LLC, whose resin heat content is around 19.5 MJ/kg, and also with the calorific value of 18 MJ/kg reported by Lauβmann et al. [16], who carried out comparative experiments between biopolymers, fossil-based polymers and fuels and indicated that the tested biopolymers were, without exception, suitable for thermal recovery because their calorific values were at least as high as those of wood and comparable to conventional polymers.

The results for two oxidizable components, carbon and hydrogen, from the tested materials showed that the PLA filament was the material with the highest value of the two components (52.23% and 4.76% for carbon and hydrogen, respectively), which can be compared with the composition of PET (61.65% and 4.19% for carbon and hydrogen, respectively [17]). As can be seen, chlorine content in the PLA spoon and cocoa paper tray was the minimum in comparison with the PLA filament and d2w® biodegradation technology bag. Nevertheless, all materials were found to be below the average values of chlorine content for Municipal Solid Waste (MSW) (1.00 % w/w) and Solid Recovered Fuel (SRF) (0.76 % w/w) [18].

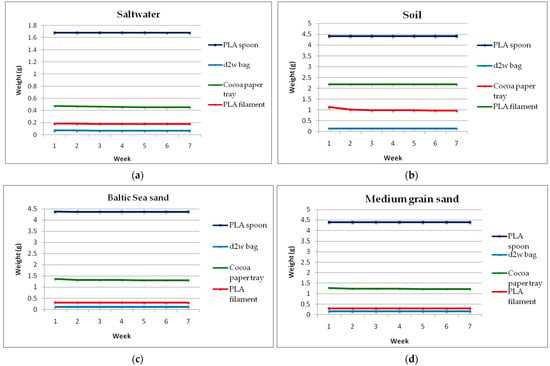

3.3. Degradation Rates in Different Environments

The biodegradation of the four materials was analyzed in four different environments during a period of three months. The average of each sample’s weight loss in each environment is presented in graphs shown in Figure 2.

Figure 2.

Degradation of bio-based materials in: (a) saltwater, (b) soil, (c) Baltic Sea sand, (d) medium-grain sand.

Table 5 presents the average biodegradation rate of each material in each environment in g/week.

Table 5.

Biodegradation rates of tested materials.

Regarding the saltwater environment, the degradation of PLA products was significantly slower than that of the cocoa paper tray and d2w® biodegradation technology bag (Figure 2a and Table 5), which might be due to the high salinity in seawater, which affects the diffusion of water into the polyester, making the degradation rate in seawater even slower than that in pure water [19]. Compared to soil and compost, the marine environment is characterized by a low temperature, high salinity, high pressure, currents and low nutrient levels (e.g., nitrate), which can affect significantly the degradation process of bio-based materials [20].

The degradation of PLA materials in soil was more favored in this environment (Figure 2b), which may be attributed to the moisture content that it naturally possessed in comparison with the two other types of sand, since the temperature for these cases in particular was the same (ambient temperature).

Regarding the Baltic Sea sand environment (Figure 2c), the material that presented a higher degradation rate was once more the cocoa paper tray (0.0057 g/week) due to its high content of cellulose, which is the most abundant organic material in the environment and usually used as a positive reference material in biodegradability tests due to its ready biodegradability in all environmental conditions [21]; however, the d2w® biodegradation technology bag was the one with the lowest degradation rate (0.0001 g/week).

For the case of the medium-grain sand environment (Figure 2d), found mainly in urbanized locations, PLA materials presented the lowest degradation rates (0.0004 for spoon and 0.0002 g/week for filament) compared with the cocoa paper tray, which presented the highest rate, and it is already considered a reference material for biodegradability [21].

3.4. Home Composting of PLA and Bio-Based Materials in Small-Scale Electric Composter Unit

The electric composter device was indicated to produce compost with organic residues after 24 h. For this test, the weight loss and appearance of the PLA and bio-based materials were analyzed.

The total weight loss in percentage is shown in Table 6.

Table 6.

Weight loss of PLA and bio-based materials in professional composter.

As can be seen from the total weight loss results of the tested materials, it appears that biodegradation was almost fully achieved for most of the materials, especially for the cocoa paper tray, for which no traces of remaining material could be found after this period of time. However, these results might not be fully accurate since the recovered residues were found through inspection with the naked eye and by turning around the resulting compost; therefore, it is possible that some residues were still present on the compost.

On the other hand, the characteristics of the electric composter used for this test differed from other similar devices due to the fact that Oklin’s composter utilizes a different technology that involves the use of microorganisms (Acidulo) that speed up and enhance biowaste degradation, including waste coming from bio-based materials [22].

4. Discussion

Several criteria were considered in order to assess the natural degradation of different PLA and bio-based materials and determine their best waste management route. From each criterion, important points were concluded.

- (a)

- Material properties and ecotoxicity

From the three tested materials (PLA spoon, cocoa paper tray and PLA filament), the PLA filament presented the highest potential for energy recovery since its calorific value was comparable with that of wood. The PLA spoon and cocoa paper tray would have to lose moisture content in order to be suitable for energy recovery treatment. The material that presented the smallest amounts of carbon and hydrogen was the PLA spoon, showing that this type of product would not be suitable for combustion with energy recovery. The low chlorine content of all the materials indicates that they are suitable for combustion without producing dioxines. Moreover, several sources have also indicated that biodegradable plastics made from renewable resources, such as PLA, generally contain only carbon, oxygen and hydrogen atoms, and specifically do not contain chlorine [23].

- (b) Biodegradation rate

PLA degrades very slowly in seawater, mostly because of the lack of effective microorganisms, and only slow abiotic hydrolysis occurs, in addition to the low temperature of the sea, in this specific case from the Baltic Sea, which, in real conditions, possesses a temperature of around 4–5 °C.

Due to the low temperature and lack of adequate microorganisms in seawater, the hydrolysis process, one of the biodegradation stages of bio-based materials, as the speed determining step, is significantly slowed down, which delays the next step of assimilation by microbes [24]. Therefore, the key to accelerating the biodegradation of biopolymers in seawater is to accelerate the hydrolysis process. During this process of mineralization, biopolymers are first broken down into their constituents (monomers), and when their molecular weight approaches the value of 10,000 microorganisms, the process starts the digestion process of the lactic acid oligomers [19].

While plastic material could be safe before biodegradation, after degradation, its chemical composition could change, and consequently become unsafe and toxic for the environment. The biodegradation of polymers could create molecules that are accumulated in the environment, temporarily or permanently. Oligomers, monomers and metabolic intermediates can interact with living organisms in the soil, with negative effects on the environment [19].

Sand can present a harsh texture distribution, which can cause abrasion and therefore mechanical degradation. However, this distribution of the aggregates could have a negative influence on the water and gas diffusion through the sand, and on the heat transfer [19]. These parameters have a great influence on the degradation mechanisms and on the growth of the microorganisms responsible for the biodegradation. The texture of sand environments will influence the degradation of biopolymers. In the case of medium-grain sand, its larger grain size could represent faster material wear. However, sea sand, being in contact with the humidity from the sea, could have a higher impact. This is because the water content in the soil induces hydrolysis with consequent polymer bond cleavage and the formation of lower-molecular-weight molecules [24].

- (c) Biodegradation in compost

A special feature of the Oklin electrical composter is that, during the hygienization process, the temperature rises to 70 °C, which is ideal for killing weed seeds, plant diseases and most pathogens, but for the case of PLA, this is especially important because temperatures between 44 °C and 60 °C (111 °F and 140 °F) cause PLA to warp and hasten the process of breakdown [25]. EN 13432 tests use 58 °C (136.4 ℉), while ASTM D6400 uses temperatures above 50 °C (122 ℉) [21]. Furthermore, heat and aeration inside the device’s chamber are distributed through gentle “turning” by the unit’s grinding gears, so that every inch is sterilized, and emissions of methane would be significantly reduced. Taking into account these factors, it can be stated that it is possible to obtain high degradation rates of residues considering that, in a period of 24 h, there is a weight reduction of waste in the range of 80–90% according to the producer’s specifications, and that the electric composter is able to create conditions such as high temperatures, aeration and microorganisms for the faster degradation of bio-based materials labelled as industrially compostable.

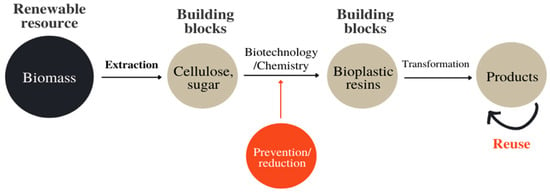

With the information provided by the physicochemical analyses, a suitable waste management strategy for these materials could be determined. The first part of the model does not consider the income level of the country where the strategy is applied or the material’s nature, but only the prevention of the waste generation itself, as illustrated in Figure 3.

Figure 3.

Initial part of strategy for waste management of bio-based materials.

The inclusion of a prevention/reduction step in the waste hierarchy suggests the use of manufacturing processes and materials that optimize and minimize resource use and maximize the functional performance of the product. As a result of conventional plastics becoming increasingly thinner, lighter and stronger, and the economic and ecological demands of the market, bioplastics are also increasing in performance and resource efficiency. It is also known that biopolymers currently possess properties comparable with conventional polymers, which allow them to be reused as many times as oil-based materials [26]. However, without a change in the education system and mentality of society, improvements in the reuse and reduction of plastic and bio-based polymers will not be fully achieved.

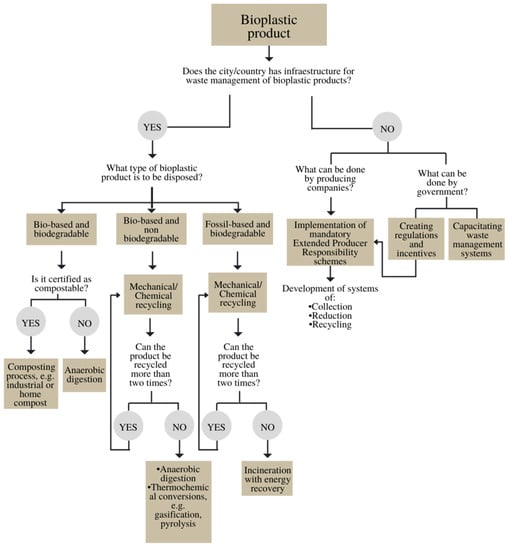

Moving forward from the reuse phase, the following flow chart shown in Figure 4 shows the routes for the waste management of bioplastics depending on different situations, such as the availability of infrastructure for their adequate treatment.

Figure 4.

Flow chart for bioplastics waste management (prepared by the authors as a result of the research).

The flow chart from Figure 4 shows the suggested routes for the adequate waste management of bio-based materials based on the information provided by this study. However, when applying this strategy, several other factors must be taken into account, such as:

- (a)

- Physical and chemical properties: the type of bioplastic must be specified, as well as information about its environmental claims, which must be truthful and accurate, and end-of-life recommendations based on the consumer’s access to them.

- (b)

- Information from life cycle assessment: from the waste management options that the product might have.

- (c)

- Availability of the waste management technologies: as shown in Figure 4, there might be adequate technology or a complete lack of it; however, there can also be only some of the proposed end-of-life options and the chosen one must be that of the lowest environmental impact.

- (d)

- Consumer’s behavior regarding waste management: the efficiency of the whole waste processing system can be increased from the sorting and collection phase; therefore, the public must have clear knowledge of the appropriate ways in which they should dispose of the bioplastic. This can be achieved with unambiguous and informative labelling as well as with education towards the public regarding the proper disposal of bioplastics.

On the other hand, it is important to mention that even when the city/country possesses the necessary infrastructure for the processing of the bioplastic waste, there are two main responsibilities that still fall on the producers, which have also been suggested by European Bioplastics [27], such as:

- (1)

- Creation of guidelines for accurate environmental communication;

- (2)

- Proper communication of end-of-life options.

5. Conclusions

All tested materials (PLA spoon, PLA filament, b2w technology bag and cocoa paper tray) presented chlorine levels below the average content for MSW (1.00% w/w) and SRF (0.76% w/w), which indicates that these materials could be suitable for incineration with energy recovery without producing dioxines during combustion. This information, together with that obtained from the tests to determine the bio-based materials’ properties, such as calorific value and hydrogen and carbon content, showed that PLA was the material with the highest potential for energy recovery since it presented the highest calorific value (18.73 MJ/kg) and highest carbon content (52.23%).

This study, as well as many others from the literature, have shown that bioplastics are not biodegradable under every environment and circumstance, which was shown by the obtained biodegradation rates of the different bio-based materials tested under different environments, with Baltic Sea water and medium-grain sand being the environments in which the majority of the bio-based materials showed the lowest degradation rates (e.g., 0.0001 g/week in saltwater for PLA filament and 0.0004 g/week in medium-grain salt for PLA spoon).

The test to simulate home composting with a small-scale electric device showed high values of weight loss in the majority of the bio-based materials; however, a more detailed inspection according to the ISO 20200 standard would be needed in order to give a decisive conclusion regarding the compostability of such materials according to the EN 14432 standard. Another point to consider is that bio-based materials that claim to be compostable should comply with the corresponding standard to validate this claim (e.g., EN 14432); however, this will not automatically lead to the effective treatment of compostable plastics, since there are several conditions that need to be met in order for this to be possible, such as organic waste treatment infrastructure that is capable of dealing with these materials with no negative effects, bio-based materials that will perform as expected in the industrial composting facilities and effectively communicated information about the waste treatment method and the appropriate disposal actions required by the end user.

As for the next steps of scientific development in producing bio-based materials, the first one is to ensure that each material is safe for society and the environment depending on the application that it is destined for, e.g., detailed ecotoxicity tests to determine that the product would not represent a danger in the event of not being disposed of in any of the proposed and available waste management routes. The next one would be the development of additives for bio-based materials, which could enhance their degradation at the end of their useful life regardless of the environment or disposal route they take; this would allow the material to still be competitive with conventional oil-based plastics thanks to its similar properties, with the added value that it would facilitate its management once it becomes waste. Additionally, tests should be conducted in different environmental conditions with the measurement of temperature, humidity, etc.

Author Contributions

Conceptualization, M.B.; Data curation, G.L.S.; Formal analysis, G.L.S.; Funding acquisition, M.B.; Investigation, M.B.; Methodology, M.B. and G.L.S.; Project administration, M.B.; Resources, M.B.; Software, G.L.S.; Supervision, M.B.; Validation, M.B.; Visualization, G.L.S.; Writing—original draft, G.L.S.; Writing—review and editing, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

Publication supported under the Excellence Initiative—Research University Program at the Silesian University of Technology (08/030/SDU/10-22-01), year 2021/22.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rutkowska, M.; Heimowska, A.; Krasowska, K.; Janik, H. Biodegradability of Polyethylene Starch Blends in Sea Water. Pol. J. Environ. Stud. 2002, 11, 267–271. [Google Scholar]

- Carus, M.; Dammer, L. Food or Non-Food: Which Agricultural Feedstocks Are Best for Industrial Uses? Ind. Biotechnol. 2013, 9, 171–176. [Google Scholar] [CrossRef]

- Agarwal, M.; Koelling, K.W.; Chalmers, J.J. Characterization of the Degradation of Polylactic Acid Polymer in a Solid Substrate Environment. Biotechnol. Prog. 1998, 14, 517–526. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.F. Enzymic Hydrolysis of Polylactic Acid. Eng. Med. 1981, 10, 5–7. [Google Scholar] [CrossRef]

- Ho, K.-L.G.; Pometto, A.L.; Gadea-Rivas, A.; Briceño, J.A.; Rojas, A. Degradation of Polylactic Acid (PLA) Plastic in Costa Rican Soil and Iowa State University Compost Rows. J. Polym. Environ. 1999, 7, 173–177. [Google Scholar] [CrossRef]

- Intaraksa, P.; Rudeekit, Y.; Siriyota, P.; Leejarkpai, T. Comparative Study of the Bio-Disintegration Behavior of Polylactic Acid under Laboratory and Pilot-Scale Composting Conditions. Adv. Mater. Res. 2013, 747, 678–681. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Environmental Deterioration of Biodegradable, Oxo-biodegradable, Compostable, and Conventional Plastic Carrier Bags in the Sea, Soil, and Open-Air Over a 3-Year Period. Environ. Sci. Technol. 2019, 53, 4775–4783. [Google Scholar] [CrossRef] [PubMed]

- Cooper, T. Developments in Bioplastic Materials for Packaging Food, Beverages and Other Fast-Moving Consumer Goods; Woodhead Publishing Limited: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Chemsec. d2w®—Biodegradable Plastic Technology. Marketplace. Available online: https://marketplace.chemsec.org/Alternative/d2w-Biodegradable-plastic-technology--490 (accessed on 12 August 2021).

- Ecopack. “Cocoa Paper Baking Moulds: Welcome to a New Generation of Food Packaging”, Greenearth Food Packaging Ltd. 2020. Available online: http://pdfs.findtheneedle.co.uk/50701.pdf (accessed on 11 August 2021).

- European Bioplastics. Bioplastics and the Circular Economy. 2016. Available online: https://docs.european-bioplastics.org/publications/pp/EUBP_PP_Circular_economy_package.pdf (accessed on 12 August 2021).

- Williams, M.; Gower, R.; Green, J.; Whitebread, E.; Lenkiewicz, Z.; Schröder, P. No Time to Waste: Tackling the Plastic Pollution Crisis Before It’s Too Late; Tearfund: Teddington, UK, 2019. [Google Scholar]

- Oklin. SMALL-SCALE GG-02. Available online: http://oklininternational.com/small-scale-composters/ (accessed on 11 August 2021).

- Green Tree. OKLIN Composters. Jestem Kompostowalny. Available online: https://www.greentree.com.pl/en/oklin-t35#! (accessed on 11 August 2021).

- Rahim, M.U.; Gao, X.; Wu, H. Determination of chlorine in solid fuels using an improved Eschka method. Fuel 2014, 129, 314–317. [Google Scholar] [CrossRef]

- Laußmann, C.; Land, U.; Münster, B.; Endres GH, J.; Hannover, F.; Giese, G.U.; Kitzler, A.-S.; Papierveredelung, A. Disposal of bio-polymers via energy recovery. Bioplastics Mag. 2010, 5, 42–43. [Google Scholar]

- Zhao, L.; Giannis, A.; Lam, W.-Y.; Lin, S.-X.; Yin, K.; Yuan, G.-A.; Wang, J.-Y. Characterization of Singapore RDF resources and analysis of their heating value. Sustain. Environ. Res. 2016, 26, 51–54. [Google Scholar] [CrossRef] [Green Version]

- Gerassimidou, S.; Velis, C.A.; Williams, P.T.; Castaldi, M.J.; Black, L.; Komilis, D. Chlorine in waste-derived solid recovered fuel (SRF), co-combusted in cement kilns: A systematic review of sources, reactions, fate and implications. Crit. Rev. Environ. Sci. Technol. 2020, 51, 140–186. [Google Scholar] [CrossRef]

- Siracusa, V. Microbial Degradation of Synthetic Biopolymers Waste. Polymers 2019, 11, 1066. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.; Chen, G.; Wang, J. Microplastics in the Marine Environment: Sources, Fates, Impacts and Microbial Degradation. Toxics 2021, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Kliem, S.; Kreutzbruck, M.; Bonten, C. Review on the Biological Degradation of Polymers in Various Environments. Materials 2020, 13, 4586. [Google Scholar] [CrossRef] [PubMed]

- Green Tree. Oklin GG02 Composting Machine. Sklep Green Tree. Available online: https://sklep.greentree.com.pl/maszyna-kompostujaca-oklin-gg02-p-99.html (accessed on 11 August 2021).

- European Bioplastics. Bioplastics–End-of-Life Options. Available online: http://www.bioplastics.guide/ref/bioplastics/end-of-life-options (accessed on 9 June 2021).

- Martin, R.T.; Camargo, L.P.; Miller, S.A. Marine-degradable polylactic acid. Green Chem. 2014, 16, 1768–1773. [Google Scholar] [CrossRef]

- Rogers, T. Everything You Need to Know About Polylactic Acid (PLA), Creative Mechanisms Blog, 7 October 2015. Available online: https://www.creativemechanisms.com/blog/learn-about-polylactic-acid-pla-prototypes (accessed on 3 March 2022).

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A Review of the Applications and Biodegradation of Polyhydroxyalkanoates and Poly(lactic acid) and Its Composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- European Bioplastics. Bioplastics—Furthering Efficient Waste Management; European Bioplastics: Berlin, Germany, 2015; pp. 1–4. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).