Abstract

Renewable fuels are alternative resources that find use in the power generation, agricultural, and transportation sectors. The sustainable utility of these renewable fuels mostly addresses the socio-economic issues of a country and reduces its dependency on fossil fuels. In addition, being environmentally friendly allows them to handle global warming more effectively. Two B20 fuel blends were produced using methyl esters of cashew nutshell and jamun seed oils to test the performance of the common rail direct injection engine. To improve the engine performance, injection parameters such as nozzle geometry, injection time, and injector opening pressure are used. Improved brake thermal efficiency and lower emissions of smoke, hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) were achieved with the help of advancing the injection timing, raising the injector opening pressure, and increasing the number of injector nozzle holes. In addition to reducing the ignition delay, extending the combustion duration, and increasing the peak pressure, the revised injection settings also boosted the heat release rates. At the maximum load, compared to CHNOB B20, JAMNSOB B20 showed a significant rise in the brake thermal efficiency (BTE) by 4.94% and a considerable decrease in smoke emissions (0.8%) with an increase in NOx (1.45%), by varying the injection timing, injection pressure, and nozzle geometry of the common rail direct injection (CRDI) engine.

1. Introduction

Compression ignition (CI) engines have a higher BTE and are more rugged than petrol engines. With the current trend, traditional fuels may run out within 10–15 years due to greater energy demand. Foreign exchange rises as a result of increased consumption of imported petroleum products and puts a burden on the country’s economy. More stringent environmental regulations have been imposed, necessitating the partial implementation or complete replacement of fossil fuels by renewable fuels such as biodiesel. A major disadvantage of CI engines is emissions (smoke, NOx, etc.), which can be reduced by the combined use of suitable biofuels, engine design, and engine operating parameters that will have a considerable effect on diesel engine combustion characteristics. Several investigators have reported the effects of engine parameters, such as the IT, injection of pressure (IOP), combustion chamber shape (CCS), and nozzle geometry (NG), including the number of holes and their size. Uniform air and fuel mixing depends on the fuel spray pattern and the combustion chamber shape and swirl occurring inside the engine cylinder. Bulk air flow and turbulence significantly affect the mixing rate. Further heat release rate (HRR) control and its manipulation are important to prevent knocking by limiting the rise of in-cylinder pressure [1]. The nozzle geometry must be perfectly matched with the combustion chamber shape chosen; this may result in the proper air and fuel mixture caused by the improved swirl and squish [2]. The adoption of diverse combustion chambers suitably addresses the use of biofuels in CI engines [3]. Bianchi G. et al. (2000) studied the influence of piston bowl geometry on emissions and the performance characteristics of a high-speed direct injection (DI) engine [4]. Mobasheri R. and Peng Z (2012) studied the effect of a reentrant chamber on the performance and combustion of a high-speed DI engine by varying the injection timings. Based on four categories (lip area, piston bowl depth, piston bottom surface, and piston bowl width), 13 chambers were considered and analyzed [5]. Mamilla. V et al., (2013) considered jatropha methyl esters blends as biodiesel and varied combustion chamber shapes. Brake thermal efficiency for the toroidal combustion chamber was observed to be higher with lower emissions compared to other shapes [6]. Lee B. H. et al., (2010) concentrated on the influence of injector holes on the combustion and emission characteristics [7]. Pandian A. K. et al., (2018) reported different methods to extract oil and biodiesel from a cashew nutshell source (CNS) and evaluated the performance of a diesel engine with hexanol as a good additive for cashew nutshell biodiesel [8]. Karikalan et al. (2020) studied the emission patterns of a CI engine using CNS blends and observed that at a low load, carbon dioxide (CO2) was lower, while a higher amount of hydrocarbon (HC) emissions was observed compared to diesel. At higher loads, the CO2 emissions were high, while the smoke opacity was almost equal to that of diesel fuel operations [9]. Kasiraman et al. (2016) investigated blends of CNS and camphor oils in a direct injection CI engine and reported that CMPRO30 exhibited improved performance, with a higher BTE and HRR at maximum load conditions [10]. Suwanmanee et al. (2020) utilized distilled cashew nutshell oil as an emulsifier for achieving stability in diesohol blends and reported that the impact on global warming was reduced by 18–26% compared to conventional diesel [11]. Loganathan et al. (2020) concentrated on the performance of CI engines powered by cashew nutshell B20 (CNSLB20)–diethyl ester–diesel–hydrogen blends in varied proportions. The results showed that with the addition of H2 in CNSLB20, the BTE and NOx emissions increased, while the CO and unburned hydrocarbon (UBHC) emissions were reduced. H2 with CNSLB20 and 6% diethyl ether blends powered a CI engine at a flow rate of 6 lpm, resulting in reduced emissions of 43% HC and 50% CO compared to CNSLB20 [12]. At full load conditions, the BTE increased by 31 to 36.5%, the HC and CO were reduced by 20% and 10%, respectively, while the NOx increased by 40%. A 10% exhaust gas recirculation (EGR) was utilized, which resulted in a 26% decrease in NOx emissions [13]. Scaldaferri and Pasa (2019) studied the effects of different parameters, such as temperature, pressure, and time, on the reactions occurring with CNSL, using a catalyst of 10% w/w palladium over activated charcoal. Higher pressures and temperatures resulted in higher hydrogenation and deoxygenation, while at lower conditions, a high degree of cracking was reported [14]. Vedharaj et al., (2016) reported a unique method of oil extraction from cashew nutshell (CNSL) using a steam treatment assisted by a crushing technique and followed by cracking using a catalyst of zeolite. The physicochemical properties of biodiesel and their blends were determined. The performance of a CI engine powered by CNSLB20 was evaluated with various injection pressures, and the results were compared with conventional fuel [15]. Velmurugan et al. (2014) studied engine performance powered by thermally cracked CNSL and their blends. Compared to the conventional fuel lower BTE, HRR and emissions (HC, and CO ) were registered, while the NOx increased [16]. Selvamuthukumar et al. (2020) studied the lubricant properties of various blends of CNSL and, from the experiments conducted, suggested an optimum blend that improved the lubrication properties by 8% when compared to SAE20 W-40 [17]. Several researchers reported on the use of biodiesel and its blends in high-pressure aided CRDI diesel engines. Electronic control engine management provides fuel injection flexibility with variable IT, IOP, and NG and their effects on CRDI diesel engines that provide an improved BTE and lower smoke and NOx emissions. Yogaraj et al., (2020) studied the characteristics of the CRDI engine utilizing karanja biodiesel at different engine parameters and compared the results with diesel fuel [18]. Santhosh et al., (2019) studied the characteristics of the CRDI diesel engine using higher alcohol (1-petanol) blends at different parameters and compared the results with diesel using different EGR rates. For the P30 blend, a drop of 3.8% in BTE and a 16.7% drop in emissions such as NOx is reported [19]. Kulandaivel et al., (2020) studied the impact of IT and EGR rates on emission, combustion, and performance characteristics of a CRDI engine powered by biodiesel derived from waste HDPE. When IT is retarded from 23° BTDC to 13° BTDC, PP and CD are reduced at different brake mean effective pressures (BMEPs). With EGR introduction, NOx emissions reduced drastically while smoke, HC and CO emissions increased [20]. Dhar et al., (2015) reported the effect of split injections and IOP on the performance of the CRDI engine by adapting. For this, different injection strategies for pilot and main injections as well as injection pressures of 500 and 1000 bars were used [21]. Edwin Geo et al., (2021) studied diesel engine characteristics of engines powered by low viscous oils derived from camphor, wintergreen, cedarwood, and lemon. For all fuel blends, experimental results showed an increase in BTE and reduced emissions other than NOx. Compared to other oils, wintergreen exhibits improved engine characteristics [22]. Kumar et al., (2020) studied the influence of various injection strategies on the CRDI engine’s performance using POME as the biofuel. Experiments were performed with varied split injection (10%, 20%, and 30%) and pilot injection (PI) and main injection (MI) angles of 33° and 23° BTDC, respectively. Enhanced engine performance was observed at 30% pilot-injection for POME20 fuel blend [23]. Saravanan et al., (2020) studied the impact of IOP on the CRDI engine by considering low viscous pine oil biofuel blends. Increasing IOP improved combustion characteristics and BTE by 6.9% while emissions decreased [24]. Wang et al., (2020) reported the impact of injection parameters IP and IT on the CRDI engine fueled with polyoxymethylene dimethyl ethers (PODE) blends [25]. Aalam (2019) studied the performance characteristics of a CRDI engine powered by nano-additive based mahua biodiesel blends. Al2O3 and Fe3O4 nanoparticles, along with cetyl-trimethyl-ammonium bromide, were used in B20 blend [26]. Karthic et al., (2020) studied the influence of IT and IOP on diesel engine performance using Syzygium cumin oil blends. Advancement in IT exhibited good results for engines powered by B30, with very low emissions compared to other blends [27]. Several researchers reported on the performance of conventional mechanical fuel injection systems (CMFIS) facilitated diesel engines powered by biofuels and their blends. Overall, the B20 blend showed overall improved engine performance with acceptable emission norms. Shrivastava and Verma (2020) reported the effect of IOP on CI engine performance when powered by roselle oil blends. Results showed improved performance for the B20 blend with lower emissions of NOx and smoke when compared to other blends [28]. Kumar et al., (2017) studied the influence of IOP on diesel engines powered by nano-additive blended vegetable oil using CeO2. Higher IOP resulted in improved engine performance associated with lower emissions [29]. Ganapathy et al., (2011) studied the impact of IT on diesel engines powered by jatropha biodiesel by varying the advancing IT and improved the engine performance in terms of increased BTE, HRR, PP, and NOx while decreasing trends for other emissions [30]. Nandakumar et al., (2020) studied the effects of NG using a different number of holes, varying from three to five, on the diesel engine performance powered by kapok biodiesel and its blends. While the B50 blend exhibited enhanced peak HRR and pressure, while adopting a 5-hole injector showed a good increment in BTE and a decrement in emissions, except for NOx [31]. Payri et al., (2009) also reported the effect of NG on the spray characteristics using CH and OH chemiluminescence techniques and studied the diesel engine combustion phenomenon. The study also provides a relationship between spray behavior, NG, and combustion growth. CH-radicals, in particular, have been shown to occur in conjunction with vapor spray. The delay is calculated using OH calculations, and certain correlations related to chamber properties are used [32]. Nikolaos Dimitrakopoulos et al., (2017) reported on diesel engines operated with partially premixed combustion (PPC) compared to conventional diesel combustion (CDC) combustion at 3-RPM levels (1200–1800–2400). The results indicate that the low load limit is posed by combustion instability, whereas the high load limit is posed by low oxygen concentration. An increase in effective expansion ratio is feasible with premixed combustion, allowing for more rapid burning and hence better efficiency was reported than with CDC operation. However, the suggested emissions were similar between premixed and CDC combustion [33]. Gabriele Di Blasio et al., (2019) reported on an advanced fuel injection system which is capable of achieving pressures greater than 2500 bar on a new engine, reducing peak firing pressure with high fuel injection pressures, which resulted in competitive performance and greater fuel economy while meeting pollution and noise regulations for diesel engines for passenger vehicle applications [34]. Luigi Sequino et al., (2018) concentrated on a single-cylinder engine to evaluate injector performance by altering the primary control settings (electrical command, etc.). The injector properties were then examined in further detail under various operating situations using digital photography to gather data on the engine’s operation. In comparison to the prior injector layout, greater control over fuel delivery has been noted. Both the circular plume and the jets emerged out of the nozzle with a fair degree of symmetry, as seen by photos taken during the injection process. The new concept injector allows for greater usage of the available space. In terms of combustion efficiency and exhaust emissions, thereby improving mixing quality, which has been proven to be beneficial [35]. P.A. Harari et al., (2021) concentrated on injection parameters of a reactivity-controlled compression ignition engine using Thevetia peruviana methyl ester as biodiesel with compressed natural gas and compressed biogas. Higher BTE was observed for CNG+diesel with low emissions except NOx compared to other combinations [36]. Munimathan Arunkumar et al., (2021) studied emission and performance characteristics of the DI engine using methyl esters of castor oil (B5 and B20) at four load conditions and two engine speeds. Both blends exhibited good characteristics with fewer emissions [37].

From the intricate literature review carried out, the combined effects of injection strategies on the performance of CRDI engines powered by biodiesel blends of cashew nutshell oil and jamun seed have not been reported in detail. The objective of the present work is to comprehensively evaluate the effects of IT, IP, and NG on the emissions, combustion, and performance characteristics of a single-cylinder, four-stroke CRDI diesel engine powered by B20 blends of biodiesels derived from both CHNOB and JAMNSOB, respectively. CHNO represents cashew nut oil and JAMNSO jamun seed oil, respectively.

2. Materials and Methods

In terms of engine performance, combustion, and emissions, fuel physicochemical characteristics have a significant impact. For the present study biodiesels derived from cashew nutshell oil (CHNOB) and jamun seed oil (JAMNSOB) both being non-edible, are used as viable alternative fuels. In order to ensure sustainable energy supply based on their potential availability, these two biomass sources have been selected. Polyphenol, tannin, and anthocyanin can be observed in both the seed and the fruit of the jamun, which range in weight from 10.88 g to 7.10 g and 1.85 g to 1.43 g, respectively. The cashew nutshell has a honeycomb-like structure and is around 0.3 cm in thickness. “Endocarp, epicarp, and mesocarp are the three layers of the shell. The mesocarp, which is formed of natural resin, is where the shell oil is stored. Oil recovered from the cashew shell has a dark reddish-brown tint. Cashew nut shells may potentially be utilized as a source of feedstock for the production of biodiesel. When cashew nut shells are dry, they contain 90% anacardic acid and 10% cardol, respectively. Table 1 shows the fatty acid composition of the oils and biodiesels used in the study.

Table 1.

Fatty acid compositions of oils and biodiesels used.

Cashew nutshell (CHNOBB20, CHNOBB100) and jamun seed (JAMNSOB20, JAMNSOB100) biodiesel are prepared by adapting conventional transesterification and biodiesel blends are shown in Figure 1.

Figure 1.

Cashew nutshell and jamun seed oil Biodiesel blends.

Properties of diesel, cashew nutshell and jamun seed oils, and biodiesels and their blends with diesel are shown in Table 2.

Table 2.

Properties of cashew nutshell, jamun seed oil, and biodiesel blends.

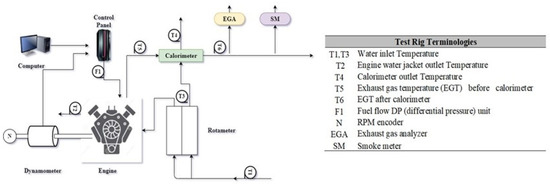

Engine tests were conducted on Kirloskar TV1 diesel engine fueled with biodiesel blends has a displacement of 660 cc. The valves are housed in an open combustion chamber. When the engine is running at 1500 rpm, CR is 17.5, and 5.2 kW of power is generated. An eddy current dynamometer is used to perform loading testing. An existing diesel engine is modified to operate in CRDI mode, which allows for high injection pressures of 1200 bar with both single- and multiple-fuel injection options. A wide range of fuel injection timings were possible with the ECU-enabled CRDI mode (ITs). To determine the pressure within the cylinder, a piezoelectric pressure transducer is installed in the cylinder head. This sensor has a resolution of 0.145 mV/kPa (PCB Piezotronics, Model-HSM 111A22). Different emissions are monitored using an exhaust gas analyzer and an AVL smoke meter.

The experimental set-up used for the investigation is shown in Figure 2.

Figure 2.

Functional flow of experimental test rig.

Since B100 fuel’s viscosity is greater than diesel’s, using it for longer timeframes might cause fuel injector blockage. There will be an increase in harmful CO, HC, and smoke emissions as a consequence. The engine’s performance might be adversely affected by a clogged fuel filter in cold weather. As a result of its low cost, good all-weather performance, low emissions, compatibility, and solvent properties, B20 is a very popular mixture. Several diesel engine manufacturers support the use of B20 in accordance with various standards, such as ASTM and European. Blends are injected at different ITs varying from 25° BTDC to 5° ATDC along with different IPs varying from 600–1200 bar, respectively.

3. Results

In this section, the effect of IT, IOP, and NG on the performance of a single-cylinder, 4-S, CRDI engine fueled by a B20 blend of CHNOB, JAMNSOB, and diesel is discussed.

3.1. Performance Characteristics:

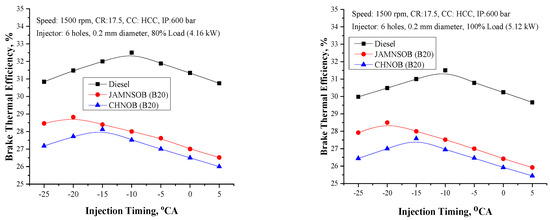

Figure 3, Figure 4 and Figure 5 show the effects of IT, IOP, and NG on the BTE of a CRDI engine fueled with B20 blends of JAMNSOB and CHNOB with diesel for 80% and 100% loads, respectively. As IT has advanced or retarded engines, BTE varies for various fuels considered. Biodiesel blends show lower BTE in comparison to diesel operations because of their comparatively low content in energy and high viscosity [38,39,40]. For the same engine power, a greater quantity of biodiesel fuel needs to be injected into the engine cylinder. From Figure 3 it follows that as the pilot fuel IT retards BTE of the engine increases for both the fuels. However, diesel engine operation shows higher BTE when IT is retarded at 10° BTDC while the two biodiesels show enhanced performance with advancing the IT [41,42,43]. For the same engine operating conditions, the varied properties of the respective fuels make the difference. JAMNSOBB20 is found to be maximum at an IT of 20° BTDC, while for CHNOBB20, BTE is found to be maximum at an IT of 15° bTDC. This is because advancing the IT for biodiesel (B20) blends increases the delay period, the air fuel mixture becomes uniform, and hence the BTE increases.

Figure 3.

Variation of BTE vs. IT at 80% and 100% loads for B20 blends.

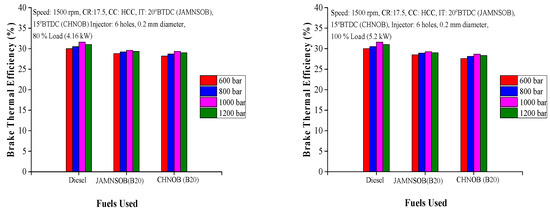

Figure 4.

Variation of BTE vs. IOP at 80% and 100% loads for B20 blends.

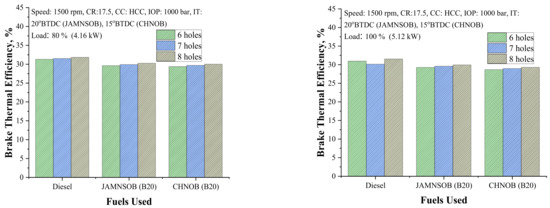

Figure 5.

Variation of BTE vs. NG at 80% and 100% loads for B20 blends.

Figure 4 indicates the impact of IOP variation on engine performance. As the IOP of the injected fuels increases, the BTE increases up to 1000 bar, then it decreases. Increased pressures tend to improve atomization of injected fuels and provide uniform air-fuel mixtures due to which ID decreases. Biodiesels, due to their higher viscosity, result in improper mixture, hence BTE deteriorates when compared to diesel fuel. But decrement of BTE at 1200 bar could be the result of a CRDI engine system limitation.

Figure 5 exhibits the influence of the number of nozzle holes on the BTE, considering 3 types of injectors having six, seven, and eight holes. As the number of nozzle holes increases, BTE also increases as a higher proportion of fuel is being vaporized and burned. Among all the NGs considered, injectors with eight holes show improved results in terms of BTE. However, viscous biodiesel blends result in lower BTE compared to diesel.

In all three cases of the above parameters, the JAMNSOB B20 blend shows higher BTE compared to the CHNOB B20 due to its comparatively lower viscosity and higher calorific value (CV) as well.

3.2. Emission Characteristics

3.2.1. Smoke Emission (S-E)

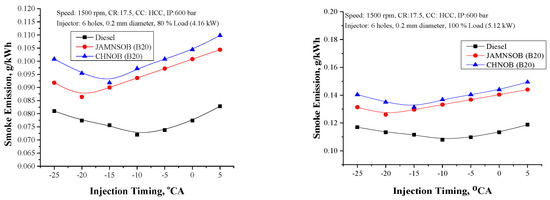

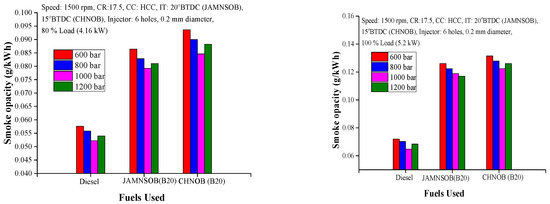

Figure 6, Figure 7 and Figure 8 depict the influence of fuel IT, IP, and NG on smoke emissions of a CRDI-engine driven by B20 blends of JAMNSOB and CHNOB at 80% and 100% loads, respectively. Smoke emissions from biodiesel fuels (BDFs) are higher than diesel. The higher viscosity of BDFs can be the reason for poor mixing inside the engine cylinder. The smoke emissions from the CRDI engine are reduced with advancing IT for JAMNSOB and CHNOB at 20° BTDC and 15° BTDC, respectively, as shown in Figure 6. Advancing IT increases the delay period and provides more time for B20 blend combustion with reduced smoke emissions. However, by retarding the IT below 10° BTDC and closer to TDC, this might be attributed to a greater diffusion combustion phase with lower BTE, which results in increased smoke emissions [44,45,46,47].

Figure 6.

Variation of S-E vs. IT at 80% and 100% loads for B20 blends.

Figure 7.

Variation of S-E vs. IOP at 80% and 100% loads for B20 blends.

Figure 8.

Variation of S-E vs. NG at 80% and 100% loads for B20 blends.

The effect of IOP on smoke emissions is shown in Figure 7. Increasing the IOP results in lower smoke emissions for all the injected fuels, and this could be a result of better atomization and improved combustion. This behavior is observed till 1000 bar, beyond which smoke emissions increase, negating the effect of higher IOPs. B20 blends show comparatively higher smoke emissions than diesel. The JAMNSOB B20 blend is observed to be lower than the CHNOB B20 due to variations in their fuel properties.

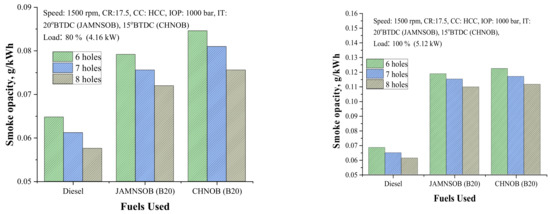

Figure 8 indicates the effect of NG on smoke emissions. Increasing the number of injector holes from six to eight reduces smoke emissions. A combination of factors, including increased vaporization and less wall impingement, would underlie these findings (8-hole type). Since BDFs have lower volatility and greater viscosity than diesel, they produce more smoke and poor atomization in all of the IPs that have been tested. In all three cases, the JAMNSOB B20 blend exhibited lower emissions than the CHNOB B20 due to its comparatively low viscosity and high calorific value (CV) as well.

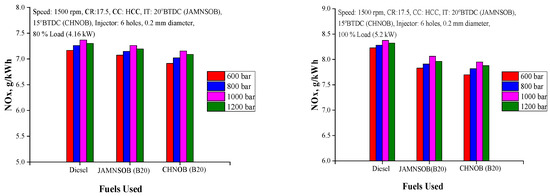

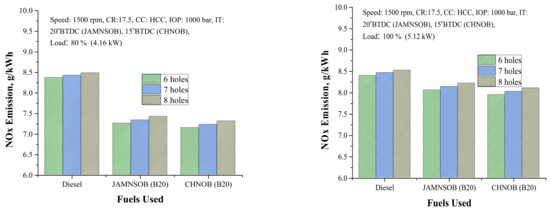

3.2.2. NOx emissions (NOx-E)

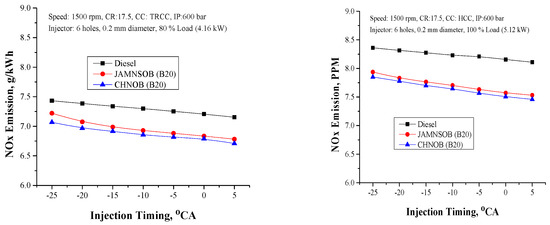

Figure 9, Figure 10 and Figure 11 depict the impact of IT, IOP, and NG on NOx emissions of CRDI-engine powered with B20 (BDFs) of JAMNSOB and CHNOB with diesel for 80% and 100% loads, respectively. By advancing IT, NOx emissions also increase due to the increased delay period with more fuel being injected, which leads to the increment of PP and HRR. Compared to diesel, BDFs emit less harmful NOx, as shown in Figure 9. Low CN and temperatures of gases in CC for BDF operation could be the reasons for these observed trends.

Figure 9.

Variation of NOx-E vs. IT at 80% and 100% loads for B20 blends.

Figure 10.

Variation of NOx-E vs. IOP at 80% and 100% loads for B20 blends.

Figure 11.

Variation of NOx-E vs. NG at 80% and 100% loads for B20 blends.

Increasing the IOP of the injected fuels from 600 to 1000 bar increases NOx emission as shown in Figure 10. Improved atomization enhances the combustion phenomenon at higher Ips, which further increases the cylinder gas temperatures attained in the cycle. BDFs show lower NOx emissions compared to diesel. With higher fuel IOP, dispersion of fuel increases and fine droplets (size) contribute to better mixing, which reduces ID. This in turn causes higher HRR and gas temperatures (in-cylinder), which raises NOx emissions even further. As compared to diesel, B20 blends have a lower premixed combustion phase and therefore marginally lower engine out NOx emissions. Moreover, CN and low adiabatic flame temperature resulted in a lower emission (NOx). Due to differences in fuel characteristics, the NOx emissions for the JAMNSOB are lower than those from the CHNOB.

From Figure 11, it follows that NOx emissions from CRDI operation for all the fuels increase with the 8-hole injector compared to others. As the mass flow rate per hole lowers, more fuel enters the combustion phase, resulting in a higher in-cylinder gas temperature, HRR and PP, and hence an increase in NOx emissions due to the elimination of wall impingement. Another reason for higher NOx may be the higher percentage of vaporization occurring with an 8-hole nozzle. In all three cases, the JAMNSOB B20 blend with diesel shows lower NOx emissions compared to CHNOB B20 due to its comparatively lower viscosity and higher CV as well.

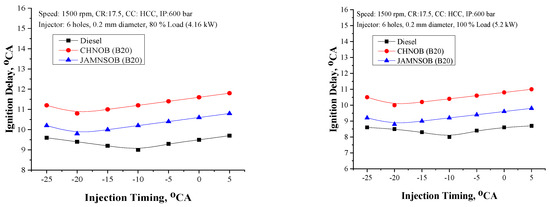

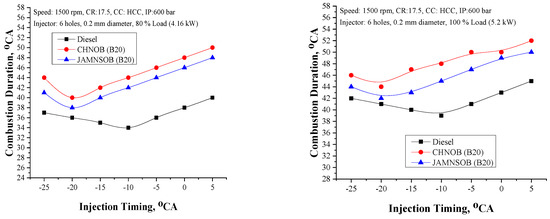

3.3. Combustion Characteristics (CC)

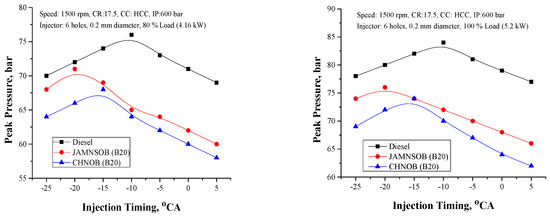

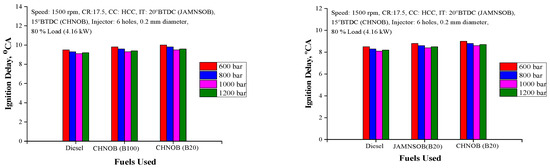

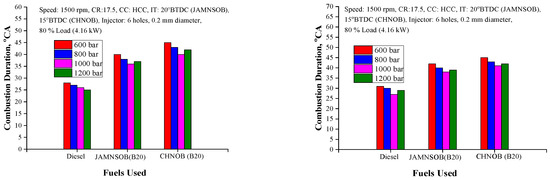

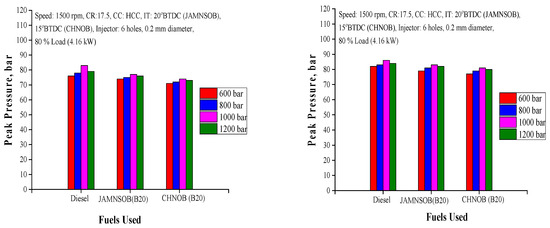

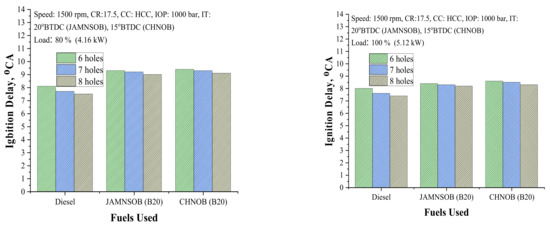

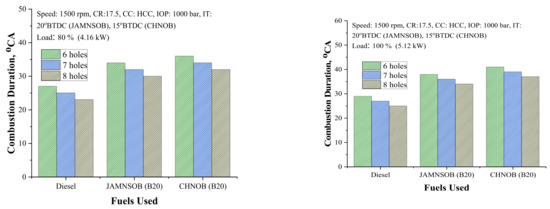

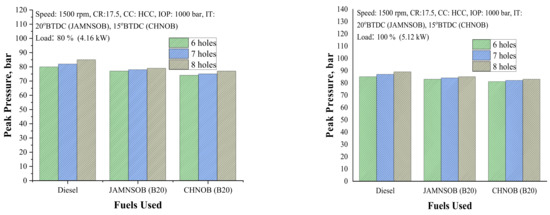

Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16 illustrates the impact of fuel IT, IOP, and NG on the (combustion parameters) ID, CD, and PP of a CRDI engine fueled with B20 blends of JAMNSOB and CHNOB with diesel for 80% and 100% loads, respectively.

Figure 12.

Variation of ID vs. IT at 80% and 100% loads for B20 blends.

Figure 13.

Variation of CD vs. IT at 80% and 100% loads for B20 blends.

Figure 14.

Variation of PP vs. IT at 80% and 100% loads for B20 blends.

Figure 15.

Variation of ID vs. IOP at 80% and 100% loads for B20 blends.

Figure 16.

Variation of CD vs. IOP at 80% and 100% loads for B20 blends.

From Figure 12, Figure 13 and Figure 14, it is observed that at all the fuel IT’s, the CD and ID of BDF’s are higher at lower PP compared to diesel. For a constant IP of 600 bar, the CD and ID of the CRDI-engine powered by JAMNSOB B20 and CHNOB B20 show decreasing trends at advanced ITs of 20° BTDC and 15° BTDC, respectively, as shown in Figure 12. These ITs may be witnessing high BTE and higher peak pressures, which might be the cause. At these optimized ITs, a large portion of the premixed combustion phase fuels results in lower values of CD and ID. Retarding the IT beyond 10° BTDC results in higher CD and ID, respectively.

From Figure 15, Figure 16 and Figure 17 it follows that, as the IOP of the fuels increases ID, the CD of the CRDI engine powered by JAMNSOB B20 and CHNOB B20 decreases while PP increases. This could be due to improved combustion of fuels injected with reduced ID being observed at higher IP. A too high IP of 1200 bar increases ID and CD. At 1200 bar a decrement in PP and HRR was observed as a result of fuel deposition in crevices that escaped combustion. ID and CD are found to be higher for B20 blends of JAMNSOB and CHNOB, respectively, compared to diesel. The JAMNSOB B20 blend shows lower ID and CD and higher PP compared to the CHNOB B20 at 1000 bar.

Figure 17.

Variation of PP vs. IOP at 80% and 100% loads for B20 blends.

Figure 18, Figure 19 and Figure 20 exhibit the effect of NG on the combustion characteristics of ID, CD, and PP. The ID and CD of BDFs were higher compared to conventional fuel at higher loads. An increase from six to eight injector holes results in low ID and CD and higher PP for all the injected fuels. The reason could be the formation of homogeneous air-fuel mixtures occurring for 8-hole injectors with higher gas temperatures inside the engine cylinder. The PP and HRR of the BDFs are found to be lower because of their energy content (low) compared to conventional. JAMNSOB B20 blend shows lower ID and CD and higher PP compared to CHNOB B20 for 8-hole injector [48,49,50,51].

Figure 18.

Variation of ID vs. NG at 80% and 100% loads for B20 blends.

Figure 19.

Variation of CD vs. NG at 80% and 100% loads for B20 blends.

Figure 20.

Variation of PP vs. NG at 80% and 100% loads for B20 blends.

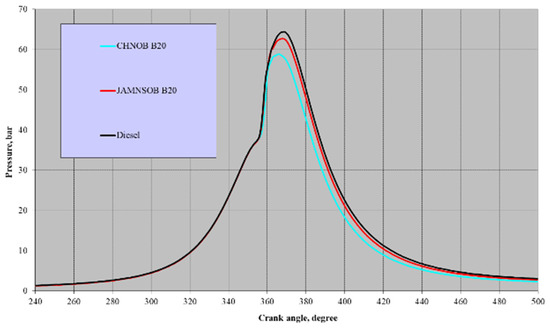

HRR and In-Cylinder Pressure

Figure 21 indicates the variation of in-cylinder pressure vs. crank angle for B20 blends of JAMNSOB and CHNOB at a load of 80%. The delay period plays a prominent role in the uncontrolled combustion phase, which influences the combustion rate. Due to rapid mixing, higher PP and HRR are observed for JAMNSOB B20 followed by CHNOB B20. Due to lower volatility, poor mixing, and higher viscosity, lower pressures are observed for CHNOB B20.

Figure 21.

Variation of pressure vs. crank angle.

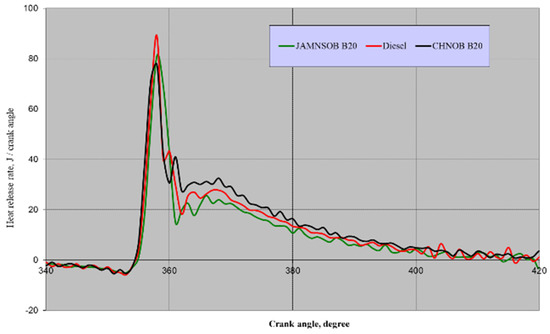

Figure 22 illustrates HRR for B20 blends of JAMNSOB and CHNOB at 80% load condition. HRR is determined by the first law of thermodynamics. A higher BTE for JAMNSOB B20 is achieved due to a significant pre-mixed burning phase. In the second peak of the graph, you can see the diffusion combustion process is greater for CHNOB B20 operation than for JAMNSOBB20 and diesel, respectively. In biodiesel blends, a lack of air entrainment, as well as lower air-fuel mixing ratios, may result in incomplete combustion. During the time period of analysis, fuel and air are less likely to combine, easing biodiesel combustion even more. Higher biodiesel combustion rates are found in the later stages, resulting in higher exhaust temperatures.

Figure 22.

Variation of HRR vs. crank angle.

4. Conclusions

The utilization of JAMNSOB B20 and CHNOB B20 in CRDI-modified diesel engines with high-pressure assistance is strongly influenced by IT, IOP, and NG. The following findings are based on the research conducted:

- Advancing the injection timing for the B20 blends of biodiesels improves the BTE, PP, and NOx with lowered emission and combustion parameters (ignition delay and combustion duration);

- Increasing the IOP for the B20 blends of biodiesels to 1000 bar improves the BTE, PP, and NOx with lowered emission and combustion parameters;

- Improved injector nozzle hole number for the B20 blends of biodiesels improves the BTE, PP, and NOx with lowered emission and combustion parameters.

With 80% load i.e., 4.16 kW condition,

- For CHNOB B20 an increment in BTE (2.54%), PP (3.03%), NOx (0.66%), and a decrement in smoke (5.5%), ID (1.92%), and CD (2.32%) is registered for IT at 15° bTDC;

- For CHNOB B20 an increment in BTE (6.64%), PP (12.1%), NOx (1.71%), and a decrement in smoke (12.9%), ID (8.6%), and CD (6.97%) is registered for IT at 15° bTDC and IOP at 1000 bar;

- For CHNOB B20 an increment in BTE (9.01%), PP (16.6%), NOx (2.29%), and a decrement in smoke (22.2%), ID (12.5%), and CD (25.5%) is registered for IT at 15° bTDC, IOP at 1000 bar and 8-hole nozzle geometry;

- For JAMNSOB B20 an increment in BTE (2.92%), PP (6.15%), NOx (1.33%) and a decrement in smoke (7.69%), ID (3.92%), and CD (9.52%) is registered for IT at 20° bTDC;

- For JAMNSOB B20 an increment in BTE (5.71%), PP (18.46%), NOx (2.67%) and a decrement in smoke (15.3%), ID (8.82%), and CD (14.28%) is registered for IT at 20° bTDC and IOP at 1000 bar;

- For JAMNSOB B20 an increment in BTE (8.03%), PP (21.5%), NOx (3.34%) and a decrement in smoke (23.07%), ID (11.76%), and CD (28.57%) is registered for IT at 20° bTDC, IOP at 1000 bar and 8-hole nozzle geometry;

With 100% load i.e., 5.12 kw condition,

- For CHNOB B20 an increment in BTE (2.37%), PP (5.71%), NOx (0.42%), and a decrement in smoke (12.9%), ID (2.12%), CD (2.17% is registered for IT at 15° bTDC;

- For CHNOB B20 an increment in BTE (6.34%), PP (15.7%)NOx (1.45%), and a decrement in smoke (10.52%), ID (8.51%), and CD (10.87%) is registered for IT at 15° bTDC and IOP at 1000 bar;

- For CHNOB B20 an increment in BTE (8.64%), PP (18.57%), NOx (2.06%), and a decrement in smoke (18.42%), ID (11.7%), and CD (19.5%) is registered for IT at 15° bTDC, IOP at 1000 bar and 8-hole nozzle geometry;

- For JAMNSOB B20 an increment in BTE (3.87%), PP (5.55%), NOx (1.11%) and a decrement in smoke (5.40%), ID (4.3%), and CD (6.66%) is registered for IT at 20° bTDC;

- For JAMNSOB B20 an increment in BTE (11%), PP (15.27%), NOx (2.57%) and a decrement in smoke (10.8%), ID (8.6%), and CD (15.55%) is registered for IT at 20° bTDC and IOP at 1000 bar;

- For JAMNSOB B20 an increment in BTE (13.59%), PP (18.05%), NOx (3.5%) and a decrement in smoke (17.56%), ID (10.87%), and CD (24.44%) is registered for IT at 20° bTDC, IOP at 1000 bar and 8-hole nozzle geometry.

Author Contributions

Data curation, Investigation, writing—original draft preparation, K.M.V.R.T.; Conceptualization, methodology, supervision and project administration, P.I.P.; Resources, Supervision, K.V.K.R.; Formal analysis, Writing-review and editing N.R.B.; funding acquisition, M.A.K. and C.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

King Khalid University (KKU) Research project Number (RGP 2/26/43).

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this research project number (RGP 2/26/43).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| CRDI | Common Rail Diesel Injection |

| bTDC | before Top Dead Center |

| aTDC | after Top Dead Center |

| NOx | Oxides of Nitrogen |

| °CA | Crank Angle degree |

| g/kWh | gram per kilo watt hour |

| IT | Injection Timing |

| IOP | Injection Of Pressure |

| NG | Nozzle Geometry |

| BTE | Break Thermal Efficiency |

| PP | Peak Pressure |

| CD | Combustion Duration |

| ID | Ignition Delay |

| CHNOB B20 | Cashew Nutshell Oil Blend −20% and Diesel −80% vol |

| JAMNSOB B20 | Jamun Seed Oil Blend −20% and Diesel −80% vol |

| HRR | Heat Release Rate |

| CR | Compression Ratio |

| cc | cubic centimeter |

| KW | Kilo Watt |

| rpm | revolution per minute |

References

- Yaliwal, V.S.; Banapurmath, N.R.; Gireesh, N.M.; Tewari, P.G. Production and utilization of renewable and sustainable gaseous fuel for power generation applications: A review of literature. Renew. Sustain. Energy Rev. 2014, 34, 608–627. [Google Scholar] [CrossRef]

- Teresa, D.; Tornese, F.; Laforgia, D. Computer aided conversion of an engine from diesel to methane. Appl. Energy 2013, 108, 8–23. [Google Scholar]

- Ellis, M.R. Effect of Piston Bowl Geometry on Combustion and Emissions of a Direct Injected Diesel Engine. Ph.D. Thesis, Brunel University School of Engineering and Design, London, UK, 1999; pp. 1–299. [Google Scholar]

- Bianchi, G.; Pelloni, P.; Corcione, F.; Mattarelli, E.; Bertoni, F.L. Numerical Study of the Combustion Chamber Shape for Common Rail HSDI Diesel Engines; Paper No. 2000-01-1179; Society of Automotive Engineers: Warrendale, PA, USA, 2000. [Google Scholar]

- Mobasheri, R.; Peng, Z. Analysis of the Effect of Re-Entrant Combustion Chamber Geometry on Combustion Process and Emission Formation in a HSDI Diesel Engine; Paper No. 2012-01-0144; Society of Automotive Engineers: Warrendale, PA, USA, 2012. [Google Scholar]

- Mamilla, V.; Mallikarjun, M.V.; Rao, G.L.N. Effect of combustion chamber design on a DI diesel engine fuelled with jatropha methyl esters blends with diesel. International Conference on Design and Manufacturing, (IConDM). Procedia Eng. 2013, 64, 479–490. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.H.; Song, J.H.; Chang, Y.J.; Jeon, C.H. Effect of the number of fuel injector holes on characteristics of combustion and emissions in a diesel engine. Int. J. Automot. Technol. 2010, 11, 783–791. [Google Scholar] [CrossRef]

- Pandian, A.K.; Munuswamy, D.B.; Radhakrishanan, S.; Devarajan, Y.; Bapu, R.; Ramakrishnan, B.; Nagappan, B. Emission and performance analysis of a diesel engine burning cashew nut shell oil bio diesel mixed with hexanol. Pet. Sci. 2018, 15, 176–184. [Google Scholar] [CrossRef] [Green Version]

- Karikalan, L.; Sukenraj, K.; Chandrasekaran, M. Performance and pollutant analysis of diesel engine with cashew shell oil as bio-material. Mater. Today Proc. 2021, 37, 685–689. [Google Scholar] [CrossRef]

- Kasiraman, G.; Geo, V.E.; Nagalingam, B. Assessment of cashew nut shell oil as an alternate fuel for CI (Compression ignition) engines. Energy 2016, 101, 402–410. [Google Scholar] [CrossRef]

- Suwanmanee, U.; Bangjang, T.; Kaewchada, A.; Jaree, A. Greenhouse gas emissions and energy assessment of modified diesohol using cashew nut shell liquid and biodiesel as additives. Sustain. Prod. Consum. 2020, 24, 232–253. [Google Scholar] [CrossRef]

- Loganathan, M.; Madhavan, V.M.; Balasubramanian, K.A.; Thanigaivelan, V.; Vikneswaran, M.; Anbarasu, A. Investigation on the effect of diethyl ether with hydrogen enriched cashew nut shell (CNS) biodiesel in direct injection (DI) diesel engine. Fuel 2020, 277, 118165. [Google Scholar] [CrossRef]

- Loganathan, M.; Thanigaivelan, V.; Madhavan, V.M.; Anbarasu, A.; Velmurugan, A. The synergetic effect between hydrogen addition and EGR on cashew nut shell liquid biofuel-diesel operated engine. Fuel 2020, 266, 117004. [Google Scholar] [CrossRef]

- Scaldaferri, C.A.; Pasa, V.M.D. Green diesel production from upgrading of cashew nut shell liquid. Renew. Sustain. Energy Rev. 2019, 111, 303–313. [Google Scholar] [CrossRef]

- Vedharaj, S.; Vallinayagam, R.; Yang, W.M.; Saravanan, C.G.; Roberts, W.L. Synthesis and utilization of catalytically cracked cashew nut shell liquid in a diesel engine. Exp. Therm. Fluid Sci. 2016, 70, 316–324. [Google Scholar] [CrossRef] [Green Version]

- Velmurugan, A.; Loganathan, M.; Gunasekaran, E.J. Experimental investigations on combustion, performance and emission characteristics of thermal cracked cashew nut shell liquid (TC-CNSL)-diesel blends in a diesel engine. Fuel 2014, 132, 236–245. [Google Scholar] [CrossRef]

- Selvamuthukumar, M.; Babu, B.H.; Bobba, S.; Baskar, S.; Joy, N. Investigation on the lubricating behavior of cashew nut shell liquid oil as a renewable and reliable petrochemical product. Mater. Today Proc. 2021, 44, 3583–3588. [Google Scholar] [CrossRef]

- Yogaraj, D.; Ragothaman, G.; Devaraj, A.; Udhayakumar, K. Performance and emission characteristics evaluation of CRDI engine using alternate fuel. Mater. Today Proc. 2021, 37, 1893–1896. [Google Scholar] [CrossRef]

- Santhosh, K.; Kumar, G.N.; Radheshyam; Sanjay, P.V. Experimental analysis of performance and emission characteristics of CRDI diesel engine fueled with 1-pentanol/diesel blends with EGR technique. Fuel 2019, 267, 117187. [Google Scholar] [CrossRef]

- Kulandaivel, D.; Rahamathullah, I.G.; Sathiyagnanam, A.P.; Gopal, K.; Damodharan, D.; Victor, D.P.M. Effect of retarded injection timing and EGR on performance, combustion and emission characteristics of a CRDI diesel engine fueled with WHDPE oil/diesel blends. Fuel 2020, 278, 118304. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Experimental investigations of the effect of pilot injection on performance, emissions and combustion characteristics of Karanja biodiesel fuelled CRDI engine. Energy Convers. Manag. 2015, 93, 357–366. [Google Scholar] [CrossRef]

- Geo, V.E.; Fol, G.; Aloui, F.; Thiyagarajan, S.; Stanley, M.J.; Sonthalia, A.; Brindhadevi, K.; Saravanan, C.G. Experimental analysis to reduce CO2 and other emissions of CRDI CI engine using low viscous biofuels. Fuel 2021, 283, 118829. [Google Scholar] [CrossRef]

- Kumar, A.N.; Kishore, P.S.; Raju, K.B.; Nanthagopal, K.; Ashok, B. Experimental study on engine parameters variation in CRDI engine fuelled with palm biodiesel. Fuel 2020, 276, 118076. [Google Scholar] [CrossRef]

- Saravanan, C.G.; Kiran, K.R.; Vikneswaran, M.; Rajakrishnamoorthy, P.; Yadav, S.P.R. Impact of fuel injection pressure on the engine characteristics of CRDI engine powered by pine oil biodiesel blend. Fuel 2020, 264, 116760. [Google Scholar] [CrossRef]

- Wang, T.; Liu, J.; Sun, P.; Ji, Q.; Gao, W.; Yang, C. Influence of injection parameters on combustion, gaseous emissions and particle size distribution of a CRDI diesel engine operating with PODE/diesel blends. Fuel 2020, 281, 118733. [Google Scholar] [CrossRef]

- Aalam, C.S. Investigation on the combustion and emission characteristics of CRDI diesel engine fuelled with nano Al2O3 and Fe3O4 particles blended biodiesel. Mater. Today Proc. 2020, 33, 2540–2546. [Google Scholar] [CrossRef]

- Karthic, S.V.; Kumar, M.S.; Nataraj, G.; Pradeep, P. An assessment on injection pressure and timing to reduce emissions on diesel engine powered by renewable fuel. J. Clean. Prod. 2020, 255, 120186. [Google Scholar] [CrossRef]

- Shrivastava, P.; Verma, T.N. Effect of fuel injection pressure on the characteristics of CI engine fuelled with biodiesel from Roselle oil. Fuel 2020, 265, 117005. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Bran, I. Influence of nanoparticles on the performance and emission characteristics of a biodiesel fuelled engine: An experimental analysis. Energy 2017, 140, 98–105. [Google Scholar] [CrossRef]

- Ganapathy, T.; Gakkhar, R.P.; Murugesan, K. Influence of injection timing on performance, combustion and emission characteristics of Jatropha biodiesel engine. Appl. Energy 2011, 88, 4376–4386. [Google Scholar] [CrossRef]

- Nandakumar, C.; Raman, V.; Saravanan, C.G.; Vikneswaran, M.; Yadav, S.P.; Thirunavukkarasu, M. Effect of nozzle hole geometry on the operation of kapok biodiesel in a diesel engine. Fuel 2020, 276, 118114. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Morena, J. Effects of nozzle geometry on direct injection diesel engine combustion process. Appl. Therm. Eng. 2009, 29, 2051–2060. [Google Scholar] [CrossRef] [Green Version]

- Dimitrakopoulos, N.; Belgiorno, G.; Tuner, M.; Tunestal, P.; Di Blasio, G.; Beatrice, C. PPC Operation with Low RON Gasoline Fuel. A Study on Load Range on a Euro 6 Light Duty Diesel Engine. In Proceedings of the 9th International Conference on Modeling and Diagnostics for Advanced Engine Systems (COMODIA 2017), Okayama, Japan, 25–28 July 2017. [Google Scholar] [CrossRef]

- Di Blasio, G.; Vassallo, A.; Pesce, F.C.; Beatrice, C.; Belgiorno, G.; Avolio, G. The Key Role of Advanced, Flexible Fuel Injection Systems to Match the Future CO 2 Targets in an Ultra-Light Mid-Size Diesel Engine. SAE Int. J. Engines 2019, 12, 129–144. [Google Scholar] [CrossRef]

- Sequino, L.; Belgiorno, G.; Di Blasio, G.; Mancaruso, E.; Beatrice, C.; Vaglieco, B.M. Assessment of the New Features of a Prototype High-Pressure “Hollow Cone Spray” Diesel Injector by Means of Engine Performance Characterization and Spray Visualization; SAE Technical Paper 2018-01-1697; Society of Automotive Engineers: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Harari, P.A.; Banapurmath, N.R.; Yaliwal, V.S.; Khan, T.M.Y.; Badruddin, I.A.; Kamangar, S.; Mahlia, T.M.I. Effect of Injection Timing and Injection Duration of Manifold Injected Fuels in Reactivity Controlled Compression Ignition Engine Operated with Renewable Fuels. Energies 2021, 14, 4621. [Google Scholar] [CrossRef]

- Arunkumar, M.; Mohanavel, V.; Afzal, A.; Sathish, T.; Ravichandran, M.; Khan, S.A.; Abdullah, N.A.; Azami, M.H.B.; Asif, M. A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters. Energies 2021, 14, 4320. [Google Scholar] [CrossRef]

- Afzal, A.; Kareemullah, M.; Kaladgi, A.R.R. Production of biodiesel from various sources and comparative engine performance studies by using different biodiesel blends. J. Eng. Res. 2018, 6, 1–21. [Google Scholar]

- Soudagar, M.E.M.; Nik-Ghazali, N.N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Khan, T.M.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257, 116015. [Google Scholar] [CrossRef]

- Kareemullah, M.; Afzal, A.; Rehman, K.F. Performance and emission analysis of compression ignition engine using biodiesels from Acid oil, Mahua oil, and Castor oil. Heat Transf.-Asian Res. 2019, 49, 858–871. [Google Scholar] [CrossRef]

- Marikatti, M.; Banapurmath, N.R.; Yaliwal, V.S.; Basavarajappa, Y.H.; Soudagar, M.E.M.; Márquez, F.P.G.; Mujtaba, M.; Fayaz, H.; Naik, B.; Khan, T.M.Y.; et al. Hydrogen Injection in a Dual Fuel Engine Fueled with Low-Pressure Injection of Methyl Ester of Thevetia Peruviana (METP) for Diesel Engine Maintenance Application. Energies 2020, 13, 5663. [Google Scholar] [CrossRef]

- Hussain, F.; Elahi, M.; Soudagar, M.E.M.; Afzal, A.; Abbas, M.M.; Fattah, I.M.R.; Naik, B.; Mulla, M.M.; Badruddin, I.A.; Khan, T.M.Y.; et al. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.R.; Afzal, A.; Hossain, N.; Nizamuddin, S.; Hossain, N.M.M.N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel—Diesel fuel blend. Sci. Rep. 2020, 10, 15326. [Google Scholar] [CrossRef]

- Krishnakumar, S.; Khan, T.M.T.; Rajashekhar, C.R.; Soudagar, M.E.M.; Afzal, A.; Elfasakhany, A. Influence of Graphene Nano Particles and Antioxidants with Waste Cooking Oil Biodiesel and Diesel Blends on Engine Performance and Emissions. Energies 2021, 14, 4306. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Rajak, U.; Polat, F.; Afzal, A.; Verma, T.N. Effects of high-dosage copper oxide nanoparticles addition in diesel fuel on engine characteristics. Energy 2021, 229, 120611. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.A.; Safaei, M.R.; Afzal, A.; Raju, D.V.; Ahmed, W.; Banapurmath, N.R.; Hossain, N.; Bashir, S.; Badruddin, I.A.; et al. Effect of Sr@ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M.; Lalvani, J.S.C.I.J.R.; Mehboob, H.; Samuel, O.D.; Enweremadu, C.C.; Saleel, C.A.; Afzal, A. Effect of injection timing in reducing the harmful pollutants emitted from CI engine using N-butanol antioxidant blended eco-friendly Mahua biodiesel. Energy Rep. 2021, 7, 6205–6221. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Kareemullah, M. Waste coconut oil methyl ester with and without additives as an alternative fuel in diesel engine at two different injection pressures. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Razzaq, L.; Mujtaba, M.A.; Soudagar, M.E.M.; Ahmed, W.; Fayaz, H.; Bashir, S.; Fattah, I.M.R.; Ong, H.C.; Shahapurkar, K.; Afzal, A.; et al. Engine performance and emission characteristics of palm biodiesel blends with graphene oxide nanoplatelets and dimethyl carbonate additives. J. Environ. Manage. 2021, 282, 111917. [Google Scholar] [CrossRef] [PubMed]

- Wategave, S.P.; Banapurmath, N.R.; Sawant, M.S.; Soudagar, M.E.M.; Mujtaba, M.A.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A.; et al. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Aneeque, M.; Alshahrani, S.; Kareemullah, M.; Afzal, A.; Saleel, C.A.; Soudagar, M.E.M.; Hossain, N.; Subbiah, R.; Ahmed, M.M. The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability 2021, 13, 7345. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).