Safety-Management Practices and the Occurrence of Occupational Accidents: Assessing the Mediating Role of Safety Compliance

Abstract

1. Introduction

2. Literature Review

2.1. Safety-Management Practices

2.2. Safety Training

2.3. Worker Involvement

2.4. Safety Rules and Procedures

2.5. Safety Promotion Policies

2.6. Safety Communication and Feedback

2.7. Management Commitment to Safety

2.8. Safety Compliance

2.9. Occupational Accidents

3. Methodology

3.1. Procedure and Participants

3.2. Measures

3.3. Sample Size and Data Collection

4. Data Analysis and Results

4.1. Common-Method Bias Variance

4.2. Multicollinearity

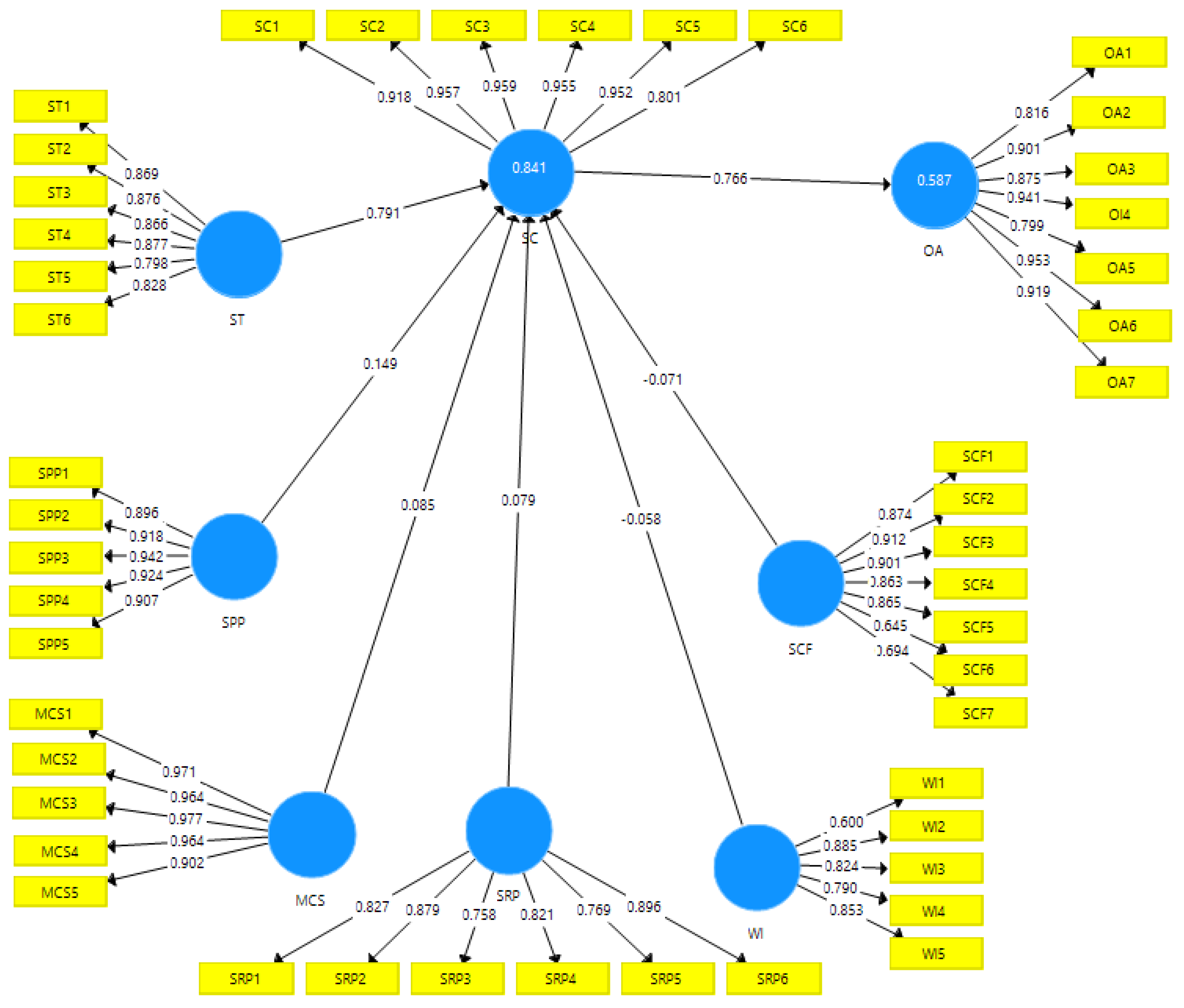

4.3. Measurement Model

4.4. Discriminant Validity

4.5. Structural Model

5. Hypotheses Testing

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanafi, W.N.W. Impact Of Safety Management Practices Enforcement toward Employee Safety in Construction Industry. In Proceedings of the 8th International Economics and Business Management Conference, Barcelona, Spain, 7–9 December 2018; pp. 541–549. [Google Scholar]

- Ajmal, M.; Isha, A.S.N.; Nordin, S.M.; Sabir, A.A.; Munir, A.; Al-Mekhlafi, A.-B.A.; Naji, G.M.A. Safety Management Paradigms: COVID-19 Employee Well-Being Impact on Occupational Health and Safety Performance. J. Hunan Univ. Nat. Sci. 2021, 48. [Google Scholar]

- Ajmal, M.; Isha, A.S.N.B.; Nordin, S.M.; Kanwal, N.; Al-Mekhlafi, A.-B.A.; Naji, G.M.A. A Conceptual Framework for the Determinants of Organizational Agility: Does Safety Commitment Matters? Solid State Technol. 2020, 63, 4112–4119. [Google Scholar]

- Al-Mekhlafi, A.-B.A.; AIsha, S.N.; Sabir, A.A.; Naji, G.M.A.; Ajmal, M.; Al-Harasi, A.H. Fatigue assessment of oil and gas tanker drivers: Psychomotor vigilance test (PVT-192). Solid State Technol. 2020, 63, 4256–4262. [Google Scholar]

- Fruhen, L.S.; Griffin, M.A.; Andrei, D.M. What does safety commitment mean to leaders? A multi-method investigation. J. Saf. Res. 2019, 68, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Alingh, C.W. The ConCom Safety Management Scale: Developing and testing a measurement instrument for control-based and commitment-based safety management approaches in hospitals. BMJ Qual. Saf. 2018, 27, 807–817. [Google Scholar] [CrossRef] [PubMed]

- Anderson, V.P.; Chun, H. Workplace hazards and prevention options from a nonrandom sample of retail trade businesses. Int. J. Occup. Saf. Erg. 2014, 20, 181–195. [Google Scholar] [CrossRef] [PubMed]

- Borrott, N. Medication communication between nurses and doctors for paediatric acute care: An ethnographic study. J. Clin. Nurs. 2017, 26, 1978–1992. [Google Scholar] [CrossRef] [PubMed]

- Naji, G.M.A.; Isha, A.S.N.; Al-Mekhlafi, A.B.A.; Sharafaddin, O.; Ajmal, M. Implementation of leading and lagging indicators to improve safety performance in the upstream oil and gas industry. J. Crit. Rev. 2020, 7, 265–269. [Google Scholar]

- Ajmal, M.; Isha, N.A.S.; Nordin, M.S. Safety Management Practicesand Occupational Health and Safety Performance: An Empirical Review. Jinnah Bus. Rev. 2021, 9, 15–33. [Google Scholar] [CrossRef]

- Gray, R. Safety and Efficacy of Acceptance and Commitment Therapy (ACT) in Schizophrenia Spectrum and Other Psychotic Disorders: Protocol for a Systematic Review and Meta-Analysis. Methods Protoc. 2018, 1, 38. [Google Scholar] [CrossRef] [PubMed]

- Lotfi, Z. Relationship between ethical leadership and organisational commitment of nurses with perception of patient safety culture. J. Nurs. Manag. 2018, 26, 726–734. [Google Scholar] [CrossRef]

- McGonagle, A.K. Management Commitment to Safety, Teamwork, and Hospital Worker Injuries. J. Hosp. Adm. 2016, 5, 46–52. [Google Scholar] [PubMed]

- Slatin, C. Health, Safety, and a Sustainable Environment Require Participatory Democracy and a Commitment to Social Justice and Equality. New Solut. 2016, 26, 4–10. [Google Scholar] [CrossRef] [PubMed]

- Taha, S. Food Safety Performance in Food Manufacturing Facilities: The Influence of Management Practices on Food Handler Commitment. J. Food Prot. 2020, 83, 60–67. [Google Scholar]

- Wallace, S.L. Management commitment to safety minimizes worker compensation costs. J. Healthc. Prot. Manag. 1996, 13, 106–109. [Google Scholar]

- Schwatka, N.V.; Rosecrance, J.C. Safety climate and safety behaviors in the construction industry: The importance of co-workers commitment to safety. Work 2016, 54, 401–413. [Google Scholar] [CrossRef] [PubMed]

- Stackhouse, M.; Turner, N. How do organizational practices relate to perceived system safety effectiveness? Perceptions of safety climate and co-worker commitment to safety as workplace safety signals. J. Saf. Res. 2019, 70, 59–69. [Google Scholar]

- Suvarna, V. Industry commitment to the science of safety. Perspect. Clin. Res. 2011, 2, 119–120. [Google Scholar] [CrossRef] [PubMed]

- Zohar, D. The effects of leadership dimensions, safety climate, and assigned priorities on minor injuries in work groups. J. Organ. Behav. 2002, 23, 75–92. [Google Scholar] [CrossRef]

- Zohar, D. Thirty years of safety climate research: Reflections and future directions. Accid. Anal. Prev. 2010, 42, 1517–1522. [Google Scholar] [CrossRef] [PubMed]

- Alloni, R. Compliance with the Surgical Safety Checklist Results of an Audit in a Teaching Hospital in Italy. Ann. Ital. Chir 2016, 87, 401–405. [Google Scholar] [PubMed]

- Audet, O. Terrain park feature compliance with Quebec ski area safety recommendations. Inj. Prev. 2020, 27, 215–220. [Google Scholar] [CrossRef] [PubMed]

- Almeida, R.E.; Rodrigues, M.C.S. Implementation of the surgical safety checklist for pediatric operations: Compliance assessment. Rev. Gauch. Enferm. 2019, 40, e20180270. [Google Scholar] [CrossRef] [PubMed]

- Calway, R.C. Safety and compliance-related hazards in the medical practice: Part 2. J. Med. Pr. Manag. 2001, 17, 28–31. [Google Scholar]

- Kirwan, B. Safety Management Assessment and Task Analysis A Missing Link? In Safety Management: The Challenge of Change; Elsevier: Oxford, UK, 1998. [Google Scholar]

- Reason, J.; Parker, D.; Lawton, R. Organizational controls and safety: The varieties of rule-related behaviour. J. Occup. Organ. Psychol. 1998, 71, 289–304. [Google Scholar] [CrossRef]

- Hofmann, D.A.; Morgeson, F.P. Safety-related behavior as a social exchange: The role of perceived organizational support and leader–member exchange. J. Appl. Psychol. 1999, 84, 286. [Google Scholar] [CrossRef]

- Elke, B.M.Z.a.G. Design for Health, Safety, and Comfort. In Handbook of Human Factors and Ergonomics, 3rd ed.; Salvendy, G., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Judith, G. Health Sciences Literature Review Made Easy The Matrix Method; Aspen Publication: Gaithersburg, MD, USA, 2004. [Google Scholar]

- Ajmal, M.; Isha, A.S.N.; Nordin, S.M.; Rasheed, S.; Al-Mekhlafi, A.B.A.; Naji, G.M.A. Safety management and safety outcomes in oil and gas industry in Malaysia: Safety compliance as a mediator. Process Saf. Prog. 2022, e12345. [Google Scholar] [CrossRef]

- Di Nardo, M.; Madonna, M.; Santillo, L.C. Safety Management System: A System Dynamics Approach to Manage Risks in a Process Plant. Int. Rev. Model. Simul. 2016, 2016, 9. [Google Scholar] [CrossRef]

- Marer, P.J. Residential, Industrial, and Institutional Pest Control, 2nd ed.; Pesticide Application Compendium; Agriculture and Natural Resources Communication Services; University of California: Oakland, CA, USA, 2006; p. 242. [Google Scholar]

- Institute of Makers of Explosives. Explosives Manufacturing & Processin: Guideline to Safety Training; Safety Library Publication; Institute of Makers of Explosives: Washington, DC, USA, 2006; 10p. [Google Scholar]

- Kuhns, J.B.; Knutsson, J. Police use of forc: A global perspective. In Global Crime and Justice; Praeger: Santa Barbara, CA, USA, 2010; 264p. [Google Scholar]

- Levenstein, C. At the Point of Production: The Social Analysis of Occupational and Environmental Health; Work, Health, and Environment Series; Baywood Pub: Amityville, NY, USA, 2009; 240p. [Google Scholar]

- Haslinda, A. Safety Training, Company Policy and Communication for Effective Accident Management International. J. Acad. Res. Bus. Soc. Sci. 2016, 6, 141. [Google Scholar]

- Bieder, C. Beyond Safety Trainin: Embedding Safety in Professional Skills; in Springer Briefs in Safety Management; Springer International Publishing: Cham, Switzerland, 2018; p. 1 online resource (XII, 159 pages 4 illustrations, 2 illustrations in color). [Google Scholar]

- Safety Training. In Superstore; Copyright Collection (Library of Congress): Washington, DC, USA, 2018.

- Driggers, P.F.; Dumas, E. Managing Library Volunteers. In ALA Guides for the Busy Librarian, 2nd ed.; American Library Association: Chicago, IL, USA, 2011; 313p. [Google Scholar]

- Thomson, J.R. High Integrity Systems and Safety Management in Hazardous Industries; Butterworth-Heinemann: Oxford, UK; Waltham, MA, USA, 2015; p. 342. [Google Scholar]

- Roughton, J.E.; Whiting, N.E. Safety Training Basics: A Handbook for Safety Training Program Development; Government Institutes: Rockville, MD, USA, 2000; 272p.

- Stahl, D.L. Health and Safety in Emergency Management and Response; Wiley: Hoboken, NJ, USA, 2020; 1 online resource. [Google Scholar]

- Ajmal, M.; Isha, A.S.N.; Nordin, S.M. Capturing the Impact of Organizational Safety Management on Safety Outcome With a Mediating Role of Safety Commitment: A Conceptual Model. In Handbook of Research on Key Dimensions of Occupational Safety and Health Protection Management; IGI Global: Pennsylvania, PA, USA, 2022; pp. 47–66. [Google Scholar]

- Afferi, L. Performance and safety of treatment options for erectile dysfunction in patients with spinal cord injury: A review of the literature. Andrology 2020, 8, 1660–1673. [Google Scholar] [CrossRef]

- Barnett, M.L.; Lau, A.S.; Miranda, J. Lay Health Worker Involvement in Evidence-Based Treatment Delivery: A Conceptual Model to Address Disparities in Care. Annu. Rev. Clin. Psychol. 2018, 14, 185–208. [Google Scholar] [CrossRef] [PubMed]

- Bolis, I.; Brunoro, C.; Sznelwar, L.I. Involvement and emancipation of the worker. Action research in a university hospital. Work 2012, 41 (Suppl. 1), 2744–2752. [Google Scholar] [CrossRef] [PubMed]

- Chang, A.B. Indigenous healthcare worker involvement for Indigenous adults and children with asthma. Cochrane Database Syst. Rev. 2010. [Google Scholar] [CrossRef]

- Leggio, W.; Snodgrass, A. Small Town, Big Commitment. Public safety agencies in Nebraska City, Neb., worked together to save their own. JEMS 2017, 42, 38–40. [Google Scholar] [PubMed]

- Liu, S.; Yang, X.; Mei, Q. The effect of perceived organizational support for safety and organizational commitment on employee safety behavior: A meta-analysis. Int. J. Occup. Saf. Ergon. 2020, 27, 1154–1165. [Google Scholar] [CrossRef]

- Mearns, K. Investment in workforce health: Exploring the implications for workforce safety climate and commitment. Accid. Anal. Prev. 2010, 42, 1445–1454. [Google Scholar] [CrossRef] [PubMed]

- Montague, J. Sustaining the commitment to patient safety huddles: Insights from eight acute hospital ward teams. Br. J. Nurs. 2019, 28, 1316–1324. [Google Scholar] [PubMed]

- Smith, T.D. Examination of Safety Climate, Affective.e Organizational Commitment, and Safety Behavior Outcomes Among Fire Service Personnel. Disaster Med. Public Health Prep. 2020, 14, 559–562. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, P.A. Optimizing compliance, efficiency, and safety during surveillance of small abdominal aortic aneurysms. J. Vasc. Surg. 2007, 46, 190–195; discussion 195–196. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Auriel, E. Safety of influenza and H1N1 vaccinations in patients with myasthenia gravis, and patient compliance. Muscle Nerve 2011, 43, 893–894. [Google Scholar] [CrossRef] [PubMed]

- Boucher, B.J. Guidance on preparing local rules to help implement the Health and Safety at Work etc Act. Br. Med. J. 1979, 1, 599–601. [Google Scholar] [CrossRef] [PubMed]

- Francis, D. The National Movement in Ladder Safety: New, safer designs will help prevent those accidents when we are in a hurry or forget the basic rules. Occup. Health Saf. 2017, 86, 41. [Google Scholar]

- Adair, L. Managing patient safety through NPSGs and employee performance. Radiol. Manag. 2010, 32, 50–55. [Google Scholar]

- Aebersold, P.C.; Hitch, J.W. Development of safety performance tests for radioisotope sealed sources and devices. Hisp. Med. 1961, 7, 117–119. [Google Scholar] [PubMed]

- Alavosius, M.P.; Sulzer-Azaroff, B. The effects of performance feedback on the safety of client lifting and transfer. J. Appl. Behav. Anal. 1986, 19, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Allahyari, T. Occupational cognitive failures and safety performance in the workplace. Int. J. Occup. Saf. Ergon. 2014, 20, 175–180. [Google Scholar] [CrossRef] [PubMed]

- Alten, T.A. Safety and performance of liver biopsies in liver transplant recipients. Clin. Transpl. 2014, 28, 585–589. [Google Scholar] [CrossRef] [PubMed]

- Assum, T.; Sorensen, M. Safety Performance Indicator for alcohol in road accidents--international comparison, validity and data quality. Accid. Anal. Prev. 2010, 42, 595–603. [Google Scholar] [CrossRef]

- Barbosa, C.; Azevedo, R.; Rodrigues, M.A. Occupational safety and health performance indicators in SMEs: A literature review. Work 2019, 64, 217–227. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, H. Safety performance models for urban intersections in Brazil. Accid. Anal. Prev. 2014, 70, 258–266. [Google Scholar] [CrossRef]

- Andriukaitis, V. Health and food safety: ‘promotion, protection and prevention’ Vytenis Andriukaitis, EU Commissioner for Health and Food Safety since November 2014, sets out his health priorities. Eur. J. Public Health 2015, 25, 360. [Google Scholar] [PubMed]

- Baylina, P. Healthcare Workers: Occupational Health Promotion and Patient Safety. J. Med. Syst. 2018, 42, 159. [Google Scholar] [CrossRef] [PubMed]

- Devine, S.G.; Muller, R.; Carter, A. Using the Fra.amework for Health Promotion Action to address staff perceptions of occupational health and safety at a fly-in/fly-out mine in north-west Queensland. Health Promot. J. Aust. 2008, 19, 196–202. [Google Scholar] [CrossRef]

- Fisher, M.G. Ambassador for patient safety and the promotion, protection and support of cardiac theatre staff. J. Perioper. Pr. 2016, 26 (Suppl. 7). [Google Scholar]

- Gard, G.; Larsson, A. Working conditions and workplace health and safety promotion in home care: A mixed-method study from Swedish managers’ perspectives. Arch. Environ. Occup. Health 2017, 72, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S. Effectiveness of participatory training for the promotion of work-related health and safety among Korean farmers. Ind. Health 2017, 55, 391–401. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Linnan, L.A. Workplace health promotion and safety in state and territorial health departments in the United States: A national mixed-methods study of activity, capacity, and growth opportunities. BMC Public Health 2019, 19, 291. [Google Scholar] [CrossRef] [PubMed]

- Miller, L.A. Safety promotion and error reduction in perinatal care: Lessons from industry. J. Perinat. Neonatal Nurs. 2003, 17, 128–138. [Google Scholar] [CrossRef]

- Eklof, M.; Ahlborg, G., Jr. Improving communication among healthcare workers: A controlled study. J. Workplace Learn. 2016, 28, 81–96. [Google Scholar] [CrossRef]

- Lyndon, A. Transforming communication and safety culture in intrapartum care: A multi-organization blueprint. J. Obs. Gynecol. Neonatal Nurs. 2015, 44, 341–349. [Google Scholar] [CrossRef]

- Anderson, D.S.; Miller, R.E. Health and Safety Communication: A Practical Guide Forward; Routledge/Taylor & Francis Group: London, UK; New York, NY, USA, 2017; p. 279. [Google Scholar]

- Lyndon, A.; Zlatnik, M.G.; Wachter, R.M. Effective physician-nurse communication: A patient safety essential for labor and delivery. Am. J. Obs. Gynecol. 2011, 205, 91–96. [Google Scholar] [CrossRef] [PubMed]

- Newnam, S.; Goode, N. Communication in the workplace: Defining the conversations of supervisors. J. Saf. Res. 2019, 70, 19–23. [Google Scholar] [CrossRef] [PubMed]

- Sanmiquel, L.; Bascompta, M.; Rossell, J.M.; Anticoi, H. Analysis of Occupational Accidents in the Spanish Mining Sector in the Period 2009–2018. Int. J. Environ. Res. Public Health 2021, 18, 13122. [Google Scholar] [CrossRef] [PubMed]

- Nordin, S.M. Organizational Communication Climate and Conflict Management: Communications Management in an Oil and Gas Company. Procedia-Soc. Behav. Sci. 2014, 109, 1046–1058. [Google Scholar] [CrossRef][Green Version]

- Allocco, M. Safety Analyses of Complex Systems: Considerations of Software, Firmware, Hardware, Human, and the Environment; Wiley: Hoboken, NJ, USA, 2010; 470p. [Google Scholar]

- Huang, Y.H. Management commitment to safety vs. employee perceived safety training and association with future injury. Accid. Anal. Prev. 2012, 47, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Quinlan, M.; Bohle, P. Overstretched and unrecipro.o…o.ocated commitment: Reviewing research on the occupational health and safety effects of downsizing and job insecurity. Int. J. Health Serv. 2009, 39, 1–44. [Google Scholar] [CrossRef]

- Sarudi, D. A commitment to safety. Tools for implementing JCAHO’s new patient safety standards. Trustee 2001, 54, 15–21. [Google Scholar]

- Brown, E.; Shrestha, M.; Gray, R. The safety and efficacy of acceptance and commitment therapy against psychotic symptomatology: A systematic review and meta-analysis. Braz J. Psychiatry 2020, 324–336. [Google Scholar] [CrossRef] [PubMed]

- DeVaul, R. Survey says…renewed commitment to safety needed. Occup. Health Saf. 2013, 82, 12–16. [Google Scholar]

- Feng, X.Q. The relationship between management safety commitment and patient safety culture. Int. Nurs. Rev. 2011, 58, 249–254. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, D. All things equal. We must have the same commitment to patient safety that we have to making medical advances. Hosp. Health Netw. 2003, 77, 78. [Google Scholar] [PubMed]

- Sugalski, J.; Stewart, F.M.; Carlson, R.W. NCCN’s Commitment to Medication Safety: The Vincristine Initiative. J. Natl. Compr. Cancer Netw. 2016, 14, 959–960. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Hansez, I.; Chmiel, N. Safety behavior: Job demands, job resources, and perceived management commitment to safety. J. Occup. Health Psychol. 2010, 15, 267–278. [Google Scholar] [CrossRef] [PubMed]

- Kronick, R. Patient safety: The Agency for Healthcare Research and Quality’s ongoing commitment. J. Nurs. Care Qual. 2014, 29, 195–199. [Google Scholar] [CrossRef]

- Avanzi, L.; Savadori, L.; Fraccaroli, F. Unraveling th...he organizational mechanism at the root of safety compliance in an Italian manufacturing firm. Int. J. Occup. Saf. Ergon. 2018, 24, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Biffl, W.L. Suboptimal compliance with surgical safety checklists in Colorado: A prospective observational study reveals differences between surgical specialties. Patient Saf. Surg. 2015, 9, 5. [Google Scholar] [CrossRef] [PubMed]

- Calway, R.C. Safety and compliance-related hazards in the medical practice: Part 1. J. Med. Pr. Manag. 2001, 16, 309–312. [Google Scholar]

- Leão, C.P.; Costa, S. Safety Training and Occupational Accidents–Is There a Link? In International Conference on Applied Human Factors and Ergonomics; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Hong, K.T.; Surienty, L.; Hung, D.K.M. Safety Management Practices and Safety Behaviour: A Preliminary Investigation in Malaysian Small and Medium Enterprises in Northern Corridor Economic Region (NCER) (Sponsored by USM-RU-PRGS). J. Occup. Saf. Health. 2011. Available online: http://mymedr.afpm.org.my/publications/45557 (accessed on 28 February 2022).

- Abu-Samah, A. Model-based glycemic control in a Malaysian intensive care unit: Performance and safety study. Med. Devices 2019, 12, 215–226. [Google Scholar] [CrossRef] [PubMed]

- Liu, S. Occupational Health and Safety and Turnover Intention in the Ghanaian Power Industry: The Mediating Effect of Organizational Commitment. Biomed. Res. Int. 2019, 2019, 3273045. [Google Scholar] [CrossRef]

- Michael, J.H. Management commitment to safety as organizational support: Relationships with non-safety outcomes in wood manufacturing employees. J. Saf. Res. 2005, 36, 171–179. [Google Scholar] [CrossRef]

- Lai, F.W.; Shad, M.K.; Shah, S.Q.A. Conceptualizing Corporate Sustainability Reporting and Risk Management Towards Green Growth in the Malaysian Oil and Gas Industry. EDP Sci. 2021, 124, 04001. [Google Scholar] [CrossRef]

- Mearns, K.; Whitaker, S.M.; Flin, R. Safety climate, safety management practice and safety performance in offshore environments. Saf. Sci. 2003, 41, 641–680. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Shah, S.Q.A.; Tahir, M. Determinants of CO2 emissions: Exploring the unexplored in low-income countries. Environ. Sci. Pollut. Res. 2022, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ishanuddin, N.M. Design and Implementation Content Validity Study: Development of an Instrument for Measuring Consumers’ Perception of Automatic Emergency Braking (AEB). In Proceedings of the International Conference on Applied Human Factors and Ergonomics, New York, NY, USA, 1 December 2021; Springer: Berlin, Germany, 2021. [Google Scholar]

- Gliem, J.A.; Gliem, R.R. Calculating, interpreting, and reporting Cronbach’s alpha reliability coefficient for Likert-type scales. In Proceedings of the Midwest Research to Practice Conference in Adult, Continuing, and Community Education, Manhattan, KS, USA, 8–9 October 1992; pp. 82–88. [Google Scholar] [CrossRef]

- Hair, J.; Hollingsworth, C.L.; Randolph, A.B.; Chong, A.Y.L. An updated and expanded assessment of PLS-SEM in information systems research. Ind. Manag. Data Syst. 2017. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. E-Collab. (IJEC) 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y.; Phillips, L.W. Assessing construct validity in organizational research. Adm. Sci. Q. 1991, 36, 421–458. [Google Scholar] [CrossRef]

- Siemsen, E.; Roth, A.; Oliveira, P. Common method bias in regression models with linear, quadratic, and interaction effects. Organ. Res. Methods 2010, 13, 456–476. [Google Scholar] [CrossRef]

- Yoo, W.; Mayberry, R.M.; Bae, S.; Singh, K.P.; He, Q.P.; Lillard, J.W. A Study of Effects of MultiCollinearity in the Multivariable Analysis. Int. J. Appl. Sci. Technol. 2014, 4, 9–19. [Google Scholar]

- El-Dereny, M.; Rashwan, N.I. Solving Multicollinearity Problem Using Ridge Regression Models. Int. J. Contemp. Math. Sci. 2011, 6, 585–600. [Google Scholar]

- Creswell, J. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches; SAGE Publications, Incorporated: Singapore, 2009. [Google Scholar]

- Vatcheva, K.P.; Lee, M.; McCormick, J.B.; Rahbar, M.H. Multicollinearity in Regression Analyses Conducted in Epidemiologic Studies. Epidemiology 2016, 6. [Google Scholar] [CrossRef]

- Sharma, R.; Yetton, P.; Crawford, J. Estimating the effect of common method variance: The method—method pair technique with an illustration from TAM Research. Mis Q. 2009, 473–490. [Google Scholar] [CrossRef]

- Hair, F.J.; Gabriel, M.; Patel, V. Amos covariance-based structural equation modeling (CB-SEM): Guidelines on its application as a marketing research tool. Braz. J. Mark. 2014, 13, 44–55. [Google Scholar] [CrossRef]

- Hair, J.F.l. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE Publications: Singapore, 2016. [Google Scholar]

- Ab Hamid, M.; Sami, W.; Sidek, M.M. Discriminant validity assessment: Use of Fornell & Larcker criterion versus HTMT criterion. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Blau, P.M. Social exchange. Int. Encycl. Soc. Sci. 1968, 7, 452–457. [Google Scholar]

- Vinodkumar, M.N.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef]

- Zohar, D. A group-level model of safety climate: Testing the effect of group climate on microaccidents in manufacturing jobs. J. Appl. Psychol. 2000, 85, 587–596. [Google Scholar] [CrossRef] [PubMed]

| Demographic | Frequency (N = 280) | Percentage |

|---|---|---|

| Gender | ||

| Male | 223 | 79.6% |

| Female | 57 | 20.4% |

| Department | ||

| Operation | 184 | 65.7% |

| Production | 96 | 34.3% |

| Ethnicity | ||

| Malay | 238 | 85% |

| Chinese | 28 | 10% |

| Indian | 14 | 5% |

| Education | ||

| PhD | 0 | 0% |

| Master | 95 | 33.9% |

| Bachelor | 147 | 52.5% |

| High School Certificate | 27 | 9.6% |

| Diploma | 11 | 3.9% |

| Age | ||

| 20–29 | 126 | 45% |

| 30–39 | 89 | 31.8% |

| 40–49 | 55 | 19.6% |

| 50–59 | 10 | 3.6% |

| Experience | ||

| 0–5 | 124 | 44.3% |

| 6–10 | 66 | 23.6% |

| 11–15 | 38 | 13.6% |

| 16–20 | 24 | 8.6% |

| Above −20 | 28 | 10% |

| Extracted Sums of Squared Loadings | ||

|---|---|---|

| Total | % Of Variance | Cumulative % |

| 16.61 | 35.35 | 35.35 |

| Variables | Items | Loadings | Composite Reliability | AVE |

|---|---|---|---|---|

| Safety Training | ST1 | 0.869 | 0.941 | 0.727 |

| ST2 | 0.876 | |||

| ST3 | 0.866 | |||

| ST4 | 0.877 | |||

| ST5 | 0.798 | |||

| ST6 | 0.828 | |||

| Worker Involvement | WI1 | 0.600 | 0.895 | 0.635 |

| WI2 | 0.885 | |||

| WI3 | 0.824 | |||

| WI4 | 0.790 | |||

| WI5 | 0.853 | |||

| Safety Rules and Procedures | SRP1 | 0.827 | 0.928 | 0.683 |

| SRP2 | 0.879 | |||

| SRP3 | 0.758 | |||

| SRP4 | 0.821 | |||

| SRP5 | 0.769 | |||

| SRP6 | 0.896 | |||

| Safety-Promotion Policies | SPP1 | 0.896 | 0.964 | 0.842 |

| SPP2 | 0.918 | |||

| SPP3 | 0.942 | |||

| SPP4 | 0.924 | |||

| SPP5 | 0.907 | |||

| Safety Communication and Feedback | SCF1 | 0.874 | 0.938 | 0.685 |

| SCF2 | 0.912 | |||

| SCF3 | 0.901 | |||

| SCF4 | 0.863 | |||

| SCF5 | 0.865 | |||

| SCF6 | 0.645 | |||

| SCF7 | 0.694 | |||

| Management Commitment to Safety | MCS1 | 0.971 | 0.981 | 0.914 |

| MCS2 | 0.964 | |||

| MCS3 | 0.977 | |||

| MCS4 | 0.964 | |||

| MCS5 | 0.902 | |||

| Safety Compliance | SC1 | 0.918 | 0.973 | 0.857 |

| SC2 | 0.957 | |||

| SC3 | 0.959 | |||

| SC4 | 0.955 | |||

| SC5 | 0.952 | |||

| SC6 | 0.801 | |||

| Occupational Accidents | OA1 | 0.816 | 0.963 | 0.789 |

| OA2 | 0.901 | |||

| OA3 | 0.875 | |||

| OA4 | 0.799 | |||

| OA5 | 0.953 | |||

| OA6 | 0.919 | |||

| OA7 | 0.941 |

| ST | WI | SRP | SPP | SCF | MCS | SC | OA | |

|---|---|---|---|---|---|---|---|---|

| ST | 0.956 | |||||||

| WI | 0.051 | 0.888 | ||||||

| SRP | 0.248 | 0.766 | 0.925 | |||||

| SPP | 0.762 | 0.128 | 0.217 | 0.828 | ||||

| SCF | 0.408 | 0.677 | 0.755 | 0.386 | 0.918 | |||

| MCS | 0.332 | 0.106 | 0.221 | 0.291 | 0.298 | 0.827 | ||

| SC | 0.187 | 0.821 | 0.904 | 0.202 | 0.746 | 0.151 | 0.853 | |

| OA | 0.305 | 0.110 | 0.183 | 0.306 | 0.270 | 0.525 | 0.195 | 0.797 |

| Relationships | β | STEDV | t-Value | R2 | f2 | Q2 | Decision | Hypothesis |

|---|---|---|---|---|---|---|---|---|

| ST- > SC | 0.791 | 0.051 | 15.513 | 0.841 | 0.656 | 0.444 | Supported | H1 |

| WI- > SC | 0.058 | 0.022 | 2.621 | 0.587 | 0.014 | 0.711 | Supported | H2 |

| SRP- > SC | 0.079 | 0.025 | 3.201 | 0.027 | Supported | H3 | ||

| SPP- > SC | 0.149 | 0.058 | 2.590 | 0.049 | Supported | H4 | ||

| SCF- > SC | 0.071 | 0.039 | 1.837 | 0.013 | Not supported | H5 | ||

| MCS- > SC | 0.085 | 0.046 | 1.866 | 0.025 | Not supported | H6 | ||

| SC- > OA | 0.766 | 0.099 | 7.727 | 0.412 | Supported | H7 | ||

| ST- > SC- > OA | 0.606 | 0.096 | 6.342 | Supported | H8 | |||

| WI- > SC- > OA | 0.044 | 0.016 | 2.688 | Supported | H9 | |||

| SRP- > SC- > OA | 0.061 | 0.018 | 3.472 | Supported | H10 | |||

| SPP- > SC- > OA | 0.114 | 0.046 | 2.477 | Supported | H11 | |||

| SCF- > SC- > OA | 0.054 | 0.026 | 2.101 | Supported | H12 | |||

| MCS- > SC- > OA | 0.065 | 0.029 | 2.249 | Supported | H13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajmal, M.; Isha, A.S.N.; Nordin, S.M.; Al-Mekhlafi, A.-B.A. Safety-Management Practices and the Occurrence of Occupational Accidents: Assessing the Mediating Role of Safety Compliance. Sustainability 2022, 14, 4569. https://doi.org/10.3390/su14084569

Ajmal M, Isha ASN, Nordin SM, Al-Mekhlafi A-BA. Safety-Management Practices and the Occurrence of Occupational Accidents: Assessing the Mediating Role of Safety Compliance. Sustainability. 2022; 14(8):4569. https://doi.org/10.3390/su14084569

Chicago/Turabian StyleAjmal, Muhammad, Ahmad Shahrul Nizam Isha, Shahrina Md Nordin, and Al-Baraa Abdulrahman Al-Mekhlafi. 2022. "Safety-Management Practices and the Occurrence of Occupational Accidents: Assessing the Mediating Role of Safety Compliance" Sustainability 14, no. 8: 4569. https://doi.org/10.3390/su14084569

APA StyleAjmal, M., Isha, A. S. N., Nordin, S. M., & Al-Mekhlafi, A.-B. A. (2022). Safety-Management Practices and the Occurrence of Occupational Accidents: Assessing the Mediating Role of Safety Compliance. Sustainability, 14(8), 4569. https://doi.org/10.3390/su14084569