Optimization of Biogas Production from Sewage Sludge: Impact of Combination with Bovine Dung and Leachate from Municipal Organic Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludge and Bovine Dung Sampling

2.2. Organic Waste Sampling

2.3. Feedstocks Characteristics

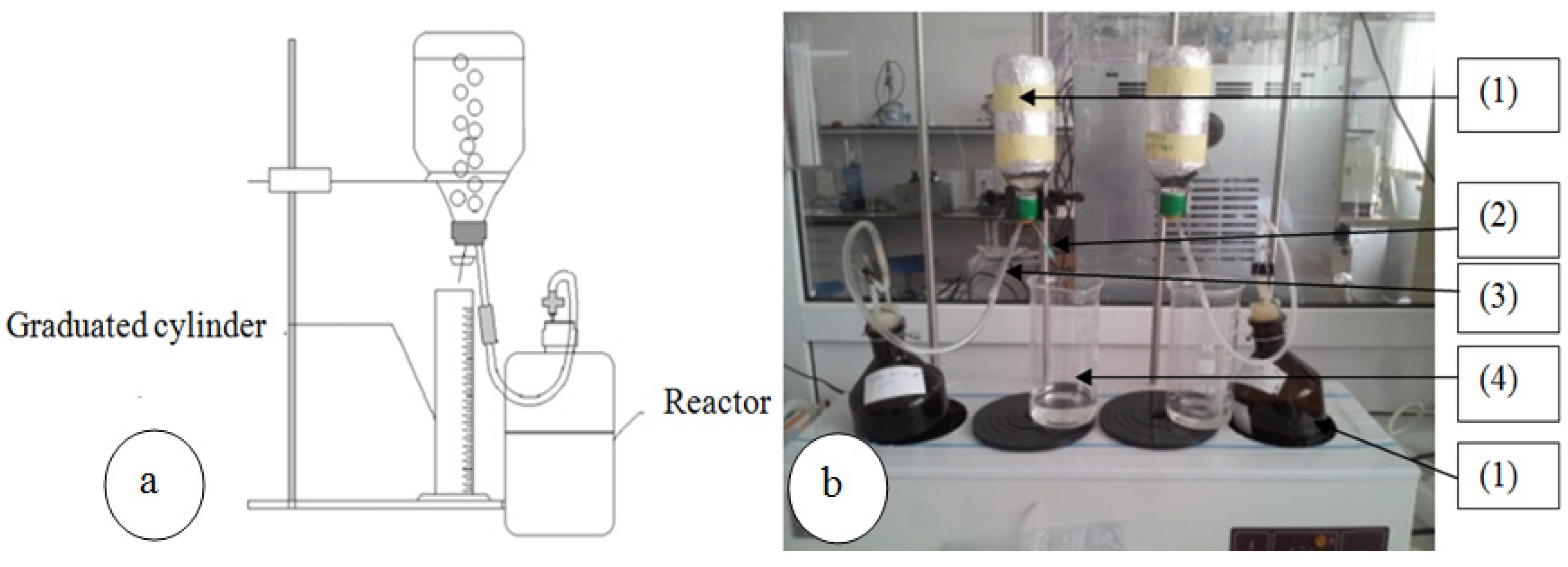

2.4. Experimental Setup and Design

2.4.1. Monitoring of Physico-Chemical Parameters during Anaerobic Digestion

2.4.2. Effect of Organic Waste Leachate and Cellulose on Biogas Production by a Mixture of Wastewater and Bovine Dung

2.4.3. Statistical Analysis

3. Results and Discussion

3.1. Physico-Chemical Characteristics of the Feedstocks

3.2. Evolution of Anaerobic Digestion Parameters

3.2.1. pH and Volatile Fatty Acid

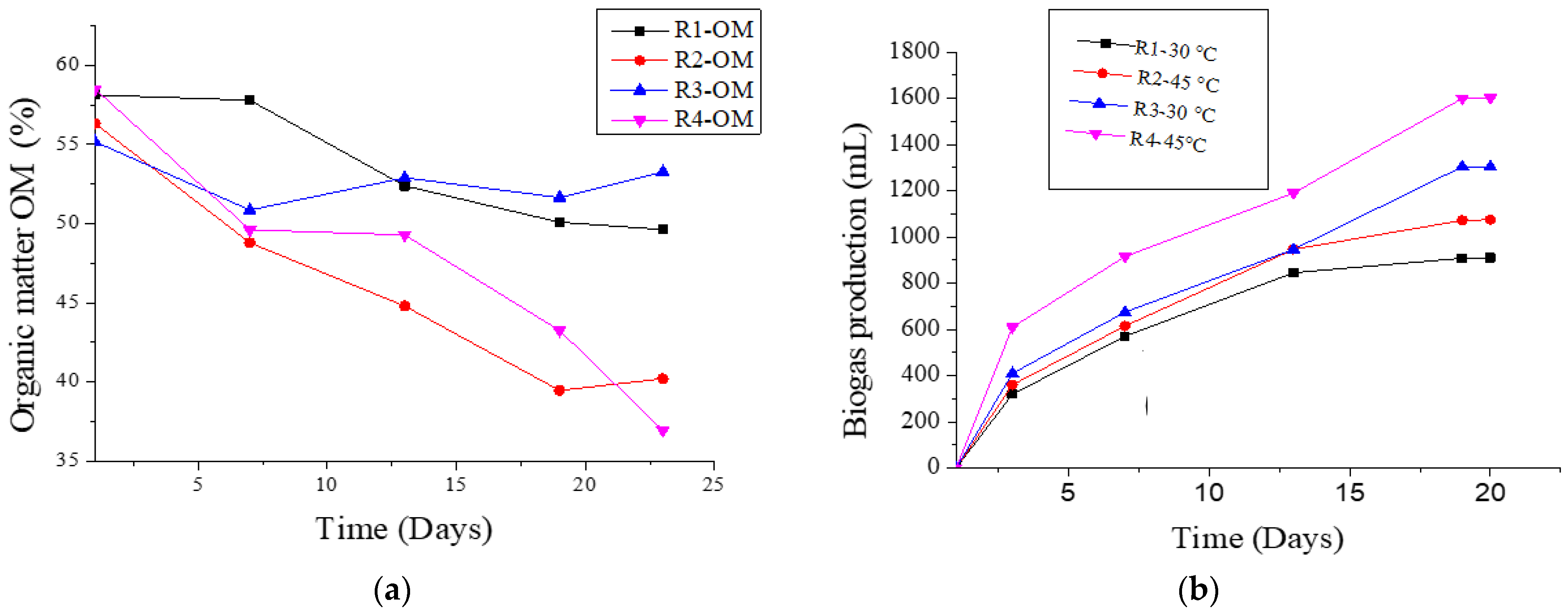

3.2.2. Organic Matter and Biogas Evolution

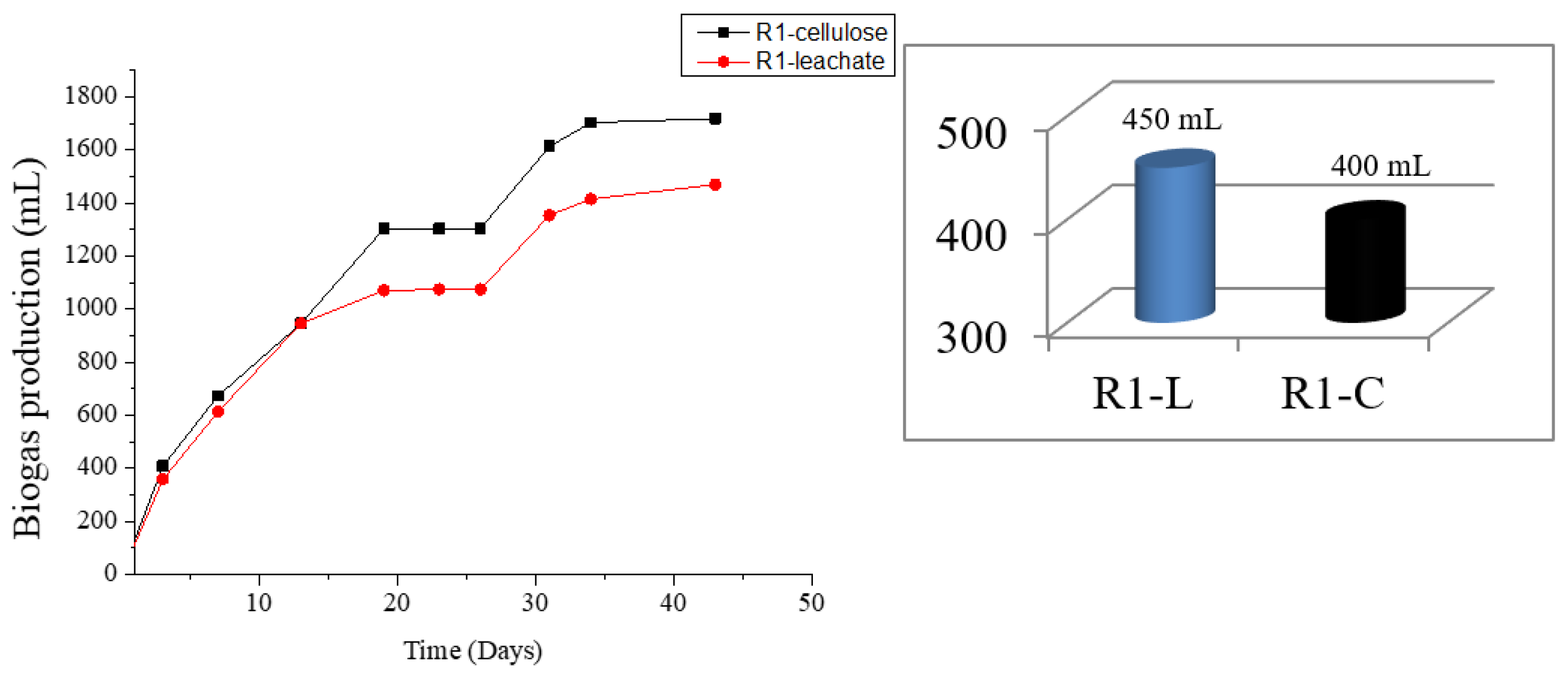

3.2.3. Effect of Leachate from Organic Waste and Cellulose on Biogas Production

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Organization. Rapport Mondial des Nations Unies sur la Mise en Valeur des Ressources en eau 2021, La Valeur de L’eau. Available online: https://www.un.org/sites/un2.un.org/files/375725fre.pdf (accessed on 20 October 2021).

- Wastewater Management, UN-Water Analytical Brief 2015. Available online: https://www.unwater.org/app/uploads/2017/05/UN-Water_Analytical_Brief_Wastewater_Management.pdf (accessed on 20 June 2021).

- United Nations Organization. Clean Water and Sanitation, Sustainable Development Goal 6 Synthesis Report on Water and Sanitation 2018. Available online: https://www.unwater.org/app/uploads/2018/12/SDG6_SynthesisReport2018_WaterandSanitation_04122018.pdf (accessed on 15 September 2021).

- Canler, P.; Perret, M. La Réduction de Boues par Voie Biologique par le Procédé MycET, Document de Synthèse. 2013. Available online: http://www.fndae.fr/documentation/PDF/fndae39.pdf (accessed on 18 August 2021).

- Seiple, T.E.; Coleman, M.; Skaggs, R.L. Municipal wastewater sludge as a sustainable bioresource in the United States. J. Environ. Manag. 2017, 197, 673–680. [Google Scholar] [CrossRef] [PubMed]

- Syed-Hassan, S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- European Commission; Milieu Ltd.; WRc, Risk and Policy Analysts (RPA). Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land Final Report Part III: Project Interim Reports; Milieu Ltd.: Brussels, Belgium, 2010; Available online: https://ec.europa.eu/environment/archives/waste/sludge/pdf/part_iii_report.pdf (accessed on 10 August 2021).

- Kajyibwami, J. Modèle de Gestion Durable des Bouses de Vidance dans la Ville de Bobo-Dioulasso (Burkina Faso). Ph.D. Thesis, Institut International d’Ingénierie de l’Eau et de l’Environnement (2iE), Ouagadougou, Burkina Faso, 2018. Available online: http://www.secheresse.info/spip.php?article78558 (accessed on 10 June 2021).

- Cerra, I.; Desagnat, M.; Dubart, R.; Juven, L.; Zhou, N.; Ziani, H. Traitement des Boues des Stations D’épuration des Petites Collectivités. 2014. Available online: https://reseau-eau.educagri.fr/files/fichierRessource2_Rapport_bibliographique_traitement_boues.pdf (accessed on 10 March 2022).

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A Review of Sludge-to-Energy Recovery Methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef] [Green Version]

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj (accessed on 20 March 2021).

- Agence de la Transition Écologique (ADEME). La Composition des Ordures Menageres en France; Ministry of Ecological Transition: Paris, France, 1999.

- De Bertoldi, M.; Vallini, G.; Pera, A. The biology of composting: A review. Waste Manag. Res. 1983, 1, 157–176. [Google Scholar] [CrossRef]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 396. [Google Scholar] [CrossRef] [Green Version]

- De Montbrial, T.; Wilson, C.; De Montbrial, T. L ’énergie: Le Compte à Rebours; Jean Claude Lattes: Paris, France, 1978; pp. 50–51. [Google Scholar]

- Bernardes, A.M.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of batteries: A review of current processes and technologies. J. Power Sour. 2004, 130, 291–298. [Google Scholar] [CrossRef]

- Hao, X.; Chen, Q.; van Loosdrecht, M.C.M.; Li, J.; Jiang, H. Sustainable disposal of excess sludge: Incineration without anaerobic digestion. Water Res. 2020, 170, 115298. [Google Scholar] [CrossRef]

- Tian, X.; Trzcinski, A. Effects of Physico-Chemical Post-Treatments on the Semi-Continuous Anaerobic Digestion of Sewage Sludge. Environments 2017, 4, 49. [Google Scholar] [CrossRef] [Green Version]

- Odirile, P.T.; Marumoloa, P.M.; Manali, A.; Gikas, P. Anaerobic Digestion for Biogas Production from Municipal Sewage Sludge: A Comparative Study between Fine Mesh Sieved Primary Sludge and Sedimented Primary Sludge. Water 2021, 13, 3532. [Google Scholar] [CrossRef]

- Lacour, J. Valorisation de Résidus Agricoles et Autres Déchets Organiques par Digestion Anaérobie en Haïti. Ph.D. Thesis, L’Institut National des Sciences Appliquées de Lyon France, Lyon, France, 2012. Available online: https://tel.archives-ouvertes.fr/tel-00825479/document (accessed on 15 May 2021).

- Zhai, N.; Zhang, T.; Yin, D.; Yang, G.; Wang, X.; Ren, G.; Feng, Y. Effect of initial pH on anaerobic co-digestion of kitchen waste and cow manure. Waste Manag. 2015, 38, 126–131. [Google Scholar] [CrossRef]

- Yoon, Y.M.; Kim, S.H.; Shin, K.S.; Kim, C.H. Effects of Substrate to Inoculum Ratio on the Biochemical Methane Potential of Piggery Slaughterhouse Wastes. Asian Australas. J. Anim. Sci. 2014, 27, 600–607. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Champagne, P.; Anderson, B.C. Enhanced biogas production from anaerobic co-digestion of municipal wastewater treatment sludge and fat, oil and grease (FOG) by a modified two-stage thermophilic digester system with selected thermo-chemical pre-treatment. Renew. Energy 2015, 83, 474–482. [Google Scholar] [CrossRef]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association (APHA): Washington, WA, USA, 2005. [Google Scholar]

- Allison, L.E. Organic Carbon. Methods of Soil Analysis, Part 2 Chemical and Microbiological Properties; American Society of Agronomy, Inc.: Madison, WI, USA, 1965. [Google Scholar]

- Esposito, G.; Frunzo, L.; Liotta, F.; Panico, A.; Pirozzi, F. Bio-Methane Potential Tests to Measure the Biogas Production from the Digestion and Co-Digestion of Complex Organic Substrates. Open Environ. Eng. J. 2012, 5, 1–8. [Google Scholar] [CrossRef]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standard methods for the examination of water and wastewater. In American Public Health Association, American Water Works Association, and Water Environment Federation, 20th ed.; The Water Environment Federation: Washington, WA, USA, 1998. [Google Scholar]

- Bachmann, N.; Deront, M.; Fruteau, H.; Holliger, C.; Membrez, Y. Optimisation des Tests Standardisés de Digestibilité dans des Réacteurs Batch. 2011. Available online: https://www.aramis.admin.ch/Default?DocumentID=62224&Load=true (accessed on 24 July 2021).

- Matejka, G. Les Lixiviats de Decharges D’ordures Menageres: Production et Impacts sur la Qualite des Eaux, la Gestion des déchets Ménagers et la Qualité des Eaux; OIE: Paris, France, 1995; Available online: https://www.oieau.org/eaudoc/system/files/documents/7/35040/35040_doc.pdf (accessed on 10 September 2021).

- Zeng, L.; Mangan, C.; Li, X. Ammonia recovery from anaerobically digested cattle manure by steam stripping. Water Sci. Technol. 2006, 54, 137–145. [Google Scholar] [CrossRef] [PubMed]

- Graterol, E.M.G. Biological Treatment of Industrial Wastewater for Biogas Production. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2011. [Google Scholar]

- Suárez, A.G.; Nielsen, K.; Köhler, S.; Merencio, D.O.; Reyes, I.P. Enhancement of anaerobic digestion of microcrystalline cellulose (MCC) using natural micronutrient sources. Braz. J. Chem. Eng. 2014, 31, 393–401. [Google Scholar] [CrossRef] [Green Version]

- Moletta, R. La digestion anaérobie des déchets municipaux. L’Eau l’Industrie Les Nuisances 2002, 275, 75–82. [Google Scholar]

- Chen, Y.; Chen, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef]

- Soto, M.; Mendéz, R.; Lema, J.M. Sodium inhibition and sulphate reduction in the anaerobic treatment of mussel processing wastewaters. J. Chem. Technol. Biotechnol. 1993, 58, 1–7. [Google Scholar] [CrossRef]

- Hack, G.; Fruteau de Laclos, H.; Holliger, C. Détermination de la Production de Méthane D’installations de Digestion Industrielles à Partir de Tests BMP en Laboratoire. 2015. Available online: https://infoscience.epfl.ch/record/215021?ln=en (accessed on 5 August 2021).

- Tampio, E.A.; Rasi, S.E. Volatile fatty acids (VFAs) and methane from food waste and cow slurry: Comparison of biogas and VFA fermentation processes. GCB Bioenergy 2019, 11, 72–84. [Google Scholar] [CrossRef]

- Ward, A.; Stensel, H.D.; Ferguson, J.F.; Ma, G.; Hummel, S. Effect of autothermal treatment on anaerobic digestion in the dual digestion process. Water Sci. Technol. 1998, 38, 435–442. [Google Scholar] [CrossRef]

- Lornage, R. Comparison of Three Ways of Municipal Solid Waste (MSW) Landfilling. Study of the Waste Behaviour in Pilot Scale Cells and Characterisation of Associated Liquid and Gaseous Emissions. Ph.D. Thesis, Université de Lyon, Lyon, France, 2006. [Google Scholar]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and long-term composition of MSW landfill leachate: A review. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Bouallagui, H.; Rachdi, B.; Gannoun, H.; Hamdi, M. Mesophilic and thermophilic anaerobic co-digestion of abattoir wastewater and fruit and vegetable waste in anaerobic sequencing batch reactors. Biodegradation 2008, 20, 401–409. [Google Scholar] [CrossRef] [PubMed]

- Fountoulakis, M.S.A.; Drakopoulou, S.; Terzakis, S.; Georgaki, E.; Manios, T. Potential for methane production from typical Mediterranean agro-industrial by-products. Biomass Bioenergy 2008, 32, 155–161. [Google Scholar] [CrossRef]

- Hong, E.; Park, J.; Lee, B.; Shi, W.; Jun, H. Improvement of Waste Dehydrated Sludge for Anaerobic Digestion through High-Temperature and High-Pressure Solubilization. Energies 2020, 13, 88. [Google Scholar] [CrossRef] [Green Version]

- Angelidaki, I.; Heinfelt, A.; Ellegaard, L. Enhanced biogas recovery by applying post-digestion in large-scale centralized biogas plants. Water Sci. Technol. 2006, 54, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Schmit, K.H.; Ellis, T.G. Comparison of Temperature-Phased and Two-Phase Anaerobic Co-Digestion of Primary Sludge and Municipal Solid Waste. Water Environ. Res. 2001, 73, 314–320. [Google Scholar] [CrossRef]

- Laskri, N.; Hamdaoui, O.; Nedjah, N. Anaerobic Digestion of Waste Organic Matter and Biogas Production. J. Clean Energy Technol. 2015, 3, 181–184. [Google Scholar] [CrossRef] [Green Version]

- Amodeo, C.; Hattou, S.; Buffière, P.; Benbelkacem, H. Temperature phased anaerobic digestion (TPAD) of organic fraction of municipal solid waste (OFMSW) and digested sludge (DS): Effect of different hydrolysis conditions. Waste Manag. 2021, 126, 21–29. [Google Scholar] [CrossRef]

- Arras, W.; Hussain, A.; Hausler, R.; Guiot, S.R. Mesophilic, thermophilic and hyperthermophilic acidogenic fermentation of food waste in batch: Effect of inoculum source. Waste Manag. 2019, 87, 279–287. [Google Scholar] [CrossRef]

- Ross, W.R.; Novella, P.H.; Pitt, A.J.; Lund, P.; Thomson, B.A.; King, P.B.; Fawcett, K.S. Anaerobic Digestion of Wastewater Sludge; WRC Project no 390, TT 55/92; Water Research Commission: Pretoria, South Africa, 1992. [Google Scholar]

- Angelidaki, I.; Ahring, B.K. Anaerobic thermophilic digestion of manure at different ammonia loads: Effect of temperature. Water Res. 1994, 28, 727–731. [Google Scholar] [CrossRef]

- Nikièma, M.; Somda, M.K.; Adéoti, K.; Traoré, D.; Baba-Moussa, F.; Toukourou, F.; Dianou, D.; Traoré, A.S. Optimization of Biogas Production from Organic Municipal Waste: Development of Activated Sludge as Digesters Inoculum. J. Environ. Prot. 2017, 8, 1674–1687. [Google Scholar] [CrossRef] [Green Version]

- Stan, C.; Collaguazo, G.; Streche, C.; Apostol, T.; Cocarta, D.M. Pilot-Scale Anaerobic Co-Digestion of the OFMSW: Improving Biogas Production and Startup. Sustainability 2018, 10, 1939. [Google Scholar] [CrossRef] [Green Version]

- Monson, K.D.; Esteves, S.R.; Guwy, A.J.; Dinsdale, R.M. Anaerobic Digestion of Biodegradable Municipal Wastes–A Review; SERC, University of Glamorgan: Wales, UK, 2007; Available online: https://www.walesadcentre.org.uk/media/1050/anaerobic-digestion-of-bmw-_compressed_-part1.pdf (accessed on 15 August 2021).

- Rapport, J.; Zhang, R.; Jenkins, B.M.; Williams, R.B. Current Anaerobic Digestion Technologies Used for Treatment of Municipal Organic Solid Waste. 2008. Available online: https://www.interwaste-ea.co.ke/wp-content/uploads/2016/08/Business-Current-Anaerobic-Digestion-technologies-used-for-treatment-of-MSW-24.07.2015.pdf (accessed on 9 August 2021).

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, S. Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Nges, I.A.; Nistor, M.; Liu, J. Determination of methane yield of cellulose using different experimental setups. Water Sci. Technol. 2014, 70, 599–604. [Google Scholar] [CrossRef] [PubMed]

- Raposo, F.; Fernandez-Cegri, V.; De la Rubia, M.A.; Borja, R.; Béline, F.; Cavinato, C.; Demirer, G.Ö.K.S.E.L.; Fernández, B.; Fernández-Polanco, M.; Frigon, J.C.; et al. Biochemical methane potential (BMP) of solid organic substrates: Evaluation of anaerobic biodegradability using data from an international interlaboratory study. J. Chem. Technol. Biotechnol. 2011, 86, 1088–1098. [Google Scholar] [CrossRef]

| Reactor | Combination | Temperature | MS (mL) | Bovine Dung (mL) | Primary Sludge (mL) |

|---|---|---|---|---|---|

| R1 | 10% BD + 90% PS | 30 °C | 20 | 50 | 450 |

| R2 | 10% BD + 90% PS | 45 °C | 20 | 50 | 450 |

| R3 | 30% BD+ 70% PS | 30 °C | 20 | 150 | 350 |

| R4 | 30% BD+ 70% PS | 45 °C | 20 | 150 | 350 |

| Parameters | Unit | Average | ||

|---|---|---|---|---|

| Primary Sludge | Boving Dung | Leachate from Organic Waste | ||

| pH | - | 7.25 | 7.21 | 5.17 |

| Sal | g/L | 5.2 | 3.8 | 4 |

| TDS | g/L | 9.23 | 6.82 | 7.29 |

| X | mS/cm | 9.22 | 6.82 | 7.29 |

| e | Ω·cm | 108.30 | 146.70 | 137.1 |

| VFA | mg (acetic acid)/L | 1120 | 740 | 3600 |

| TAC | mg (CaCO3)/L | 2058.33 | 250 | <1 |

| VFA/TAC | - | 0.54 | 2.96 | >3600 |

| TS | g/L | 23.32 | 15.66 | 14.5 |

| SV | % | 50.51 | 72.41 | 70.48 |

| Ash | % | 49.49 | 27.59 | 29.52 |

| TOC | % | 29.03 | 41.61 | 40.88 |

| BOD5 | mg/L | - | - | 2025 |

| Reactor | Combination | Temperature | Biogas mL/g SV |

|---|---|---|---|

| R1 | 10% BD + 90% PS | 30 °C | 80.74 d |

| R2 | 10% BD + 90% PS | 45 °C | 95.38 c |

| R3 | 30% BD+ 70% PS | 30 °C | 124.17 b |

| R4 | 30% BD+ 70% PS | 45 °C | 152.43 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikiema, M.; Barsan, N.; Maiga, Y.; Somda, M.K.; Mosnegutu, E.; Ouattara, C.A.T.; Dianou, D.; Traore, A.S.; Nedeff, V.; Ouattara, A.S. Optimization of Biogas Production from Sewage Sludge: Impact of Combination with Bovine Dung and Leachate from Municipal Organic Waste. Sustainability 2022, 14, 4380. https://doi.org/10.3390/su14084380

Nikiema M, Barsan N, Maiga Y, Somda MK, Mosnegutu E, Ouattara CAT, Dianou D, Traore AS, Nedeff V, Ouattara AS. Optimization of Biogas Production from Sewage Sludge: Impact of Combination with Bovine Dung and Leachate from Municipal Organic Waste. Sustainability. 2022; 14(8):4380. https://doi.org/10.3390/su14084380

Chicago/Turabian StyleNikiema, Mahamadi, Narcis Barsan, Ynoussa Maiga, Marius K. Somda, Emilian Mosnegutu, Cheik A. T. Ouattara, Dayeri Dianou, Alfred S. Traore, Valentin Nedeff, and Aboubakar S. Ouattara. 2022. "Optimization of Biogas Production from Sewage Sludge: Impact of Combination with Bovine Dung and Leachate from Municipal Organic Waste" Sustainability 14, no. 8: 4380. https://doi.org/10.3390/su14084380

APA StyleNikiema, M., Barsan, N., Maiga, Y., Somda, M. K., Mosnegutu, E., Ouattara, C. A. T., Dianou, D., Traore, A. S., Nedeff, V., & Ouattara, A. S. (2022). Optimization of Biogas Production from Sewage Sludge: Impact of Combination with Bovine Dung and Leachate from Municipal Organic Waste. Sustainability, 14(8), 4380. https://doi.org/10.3390/su14084380