1. Introduction

It is estimated that 1000 tons of soil are lost every other day and that arable land is reduced by 20,000 hectares every year [

1,

2,

3]. This is a serious problem that threatens the sustainability and development of society [

4,

5]. This has been the case since the mid-twentieth century, when agricultural productivity rose sharply. This situation is caused by the increasing application of new technologies in agriculture. Nevertheless, the result of intensive agriculture and mechanization has had many environmental consequences, such as soil erosion and the loss of soil organic matter. Excessive use of nitrogen fertilizers threatens the depletion of water reserves in the land and aquifers, and the excessive use of pesticides causes many environmental problems (such as eutrophication, ecotoxicity, soil degradation, and acidification) [

6]. Recently, the yield of agricultural crops has increased mainly due to the use of fertilizers. Fertilizers are a great and advanced tool to boost and increase productivity [

1,

7]. Organic fertilizers are considered to be an excellent source of nutrients, providing plants with vital vitamins, and soil acts as a medium between crops and fertilizers [

3]. Fertilizers can be divided into several types, depending on their components, shape, and various other properties. There are some negative effects caused by the uniformity of spreading fertilizers on the crops, as improper application not only pollutes the soil and the environment but also damages plant growth and quality [

1,

7].

Organic fertilizers are needed to maintain soil fertility. However, the improper use of organic fertilizers poses a risk of soil contamination. The amount of macro- and micro- nutrients involved in soil, plant, and food chain processes (precipitation, adsorption, and chelation) should be taken into account when considering the use of fertilizers. These natural processes limit the accumulation of almost all elements in plants to a level that does not harm humans, animals, wildlife, or soil organisms [

8]. Organic fertilizers are a good choice to reduce the negative environmental impact of mineral fertilizers [

9,

10,

11]. In this context, the use of organic fertilizers from municipal waste and organic waste from dairy, poultry, pigs, or horticultural activities can have a high environmental value and can be used to improve and maintain soil fertility [

12,

13,

14,

15,

16].

Meat and bone meal is an industrial by-product obtained by treating animal carcasses with heat, removing the fat, and finally drying and mincing them. These organic substances have generally been used in the preparation of cattle feed. However, following the bovine spongiform encephalopathy crisis in Europe, the addition of meat and bone meal to cattle feed as a high-protein product has been restricted [

17]. However, due to the high levels of total nitrogen (8%), phosphorus (5%), and calcium (10%) in meat and bone meal, these organic matters can be considered as useful fertilizers for soil improvement [

18,

19].

Manure is an organic fertilizer used for soil fertilization after animal waste decomposes due to bacteria and fungi. Composting manure takes a relatively long time. This decomposed manure is later used in agriculture to increase and promote soil productivity [

1,

20]. Well-decomposed manure contains N (0.5%), P

2O

5 (0.3%), and K

2O (0.5%). Manure is used as a fertilizer and improves soil productivity by providing practically all the elements needed by plants, but not always in the right amounts and proportions [

21]. Slurry and solid manure are traditionally spread directly on the soil surface as fertilizers [

22]. However, it is important to note that ammonia emissions and water run-off from nitrogen and phosphorus compounds have the greatest negative effects on the atmosphere, with manure being one of the main sources of these pollutants [

23]. This requires an appropriate selection of efficient and inexpensive manure management technologies to reduce the negative environmental impact of manure due to storage and use practices while maintaining high levels of nutrients that are beneficial to soil improvement [

23]. To achieve this goal, one of the options for manure treatment and preparation is manure granulation.

On the other hand, one of the properties of the soil that can affect soil fertility is its acidity. Soil is acidic if it is deficient in calcium and magnesium. Acidity prevents crops from absorbing the fertilizers used to eliminate nutrient deficiencies. Therefore, farms with acidic soils use liming materials, in the form of powdered calcium oxide (CaO) and calcium carbonate (CaCO

3), to increase crop yield and quality [

24].

Despite the use of different types of fertilizers in agriculture to improve soil quality, optimal soil coverage is a very important aspect of this process. It is observed that the properties and the use of organic fertilizers depend on the climate and soil quality, which promotes the conversion of organic compounds into the mineral form [

25,

26]. Despite the growing use of organic fertilizers, most fertilizer spreaders are only intended for spreading mineral fertilizers on the soil surface [

27]. It is known that the norms set during fertilization and their even distribution on the soil surface affect not only the yield of cultivated plants, but also the quality of the crop. It was found that a reduction in fertilizer application of between 30% and 15% reduced crop losses from 8.6–22.4% to 0.6–1.1%. This means that the smaller the unevenness with which the fertilizer is applied on the soil surface, the greater the effect of its application [

28]. Organic fertilizers are physically characterized by poor spreading on the soil surface and high moisture content. A traditional fertilizer spreader uses a transport mechanism to send organic fertilizer to the discharge roller or turntable, which throws organic fertilizer towards the soil at high speed [

27]. Most studies that determine the causes of uneven applications of organic fertilizers analyze their application with centrifugal fertilizer spreaders and evaluate the effects of interactions between the fertilizer particles spread with a disc, and fertilizer particles individually. Thus, the novelty of our study is characterized by the fact that a complex comparative study of organic fertilizers with different flow rates was performed, spreading the fertilizer with a manure spreader and evaluating how the physical properties of the fertilizer affected the uniformity of spreading under natural field conditions.

The aim of the study is to determine the uniformity of the distribution of different bulk organic fertilizers on the soil surface by evaluating the influence of the physical–mechanical properties of the fertilizers.

2. Materials and Methods

The design of the investigation performed is presented in

Figure 1. Each step performed during the studies is described in more detail in this chapter.

2.1. Determination of Physical–Mechanical Properties of Different Bulk Organic Fertilizers

The following physical and mechanical properties of organic fertilizers were determined: moisture content and biometric indicators (dimensions, mass, and density). These parameters were studied for meat and bone meal granular fertilizers, beef cattle manure granulated fertilizers, lime (dry and wet), and manure.

The moisture content of organic granular and non-granular fertilizers was determined in the Laboratory of Advanced Crop Engineering of Vytautas Magnus University. The ratio of the amount of water in the sample to the mass of the sample was determined in the laboratory. After determining the moisture content of different bulk organic fertilizers, the average value of the samples was calculated with an error. The moisture content of the fertilizer

w1 was calculated according to the formula [

29]:

where

G1 is the mass of the wet sample, g;

G2 is the mass of the dried sample, g.

In the granulation studies, the diameter and length of the granular fertilizers of the prepared cylindrical organic meat and bone meal granules and manure from beef cattle were first measured. Two granules of different diameters were measured, selecting 10 random granules for each diameter. The diameters of the granules were measured with a caliper in the center of the granules. The average values with mean of confidence of dimensions of the fertilizer granules were evaluated.

The mass of the granules was determined by weighing to 0.01 g; the calculated mass mean values are given with the mean of confidence. The volume

Vgr of the organic fertilizer granules was equal to the volume of the cylinder, calculated as follows [

29]:

where

R is the radius of the granule,

m;

h is the height of the granule, m.

The density of organic fertilizer granules

ρ gr was calculated according to the formula [

29]:

where

mgr is the weight of the granule,

kg.

2.2. Assessment of Fertilizer Spreading Unevenness and Overlap

Experimental studies of spreading organic fertilizers at different flows (manure–meat and bone meal–cattle manure granules) and amounts of lime were performed on a farm in the Taurage district, the fields of which are located at the intersection of Kaunas and Taurage counties (55.462618, 22.680871).

Pallets of organic meat and bone meal–cattle manure compost granules were purchased and delivered to the fields for testing, as they were not prepared by the team of researchers. The granulated manure and the pallets with the organic meat and bone meal fertilizer were transported, stored, and spread on the soil according to the recommendations of the manufacturer [

30]. Lime and manure were used in a consistency similar to that of conventional fertilization and soil improvement on farms. They were transported and stored according to the recommendations of [

31].

Experimental test methods and parameters for the application of granular organic fertilizers to soil were selected according to the relevant standards, ISO 5690 and ASAE S314.2 (ASAE, 2018). The quality of fertilizer application was determined by its uniformity.

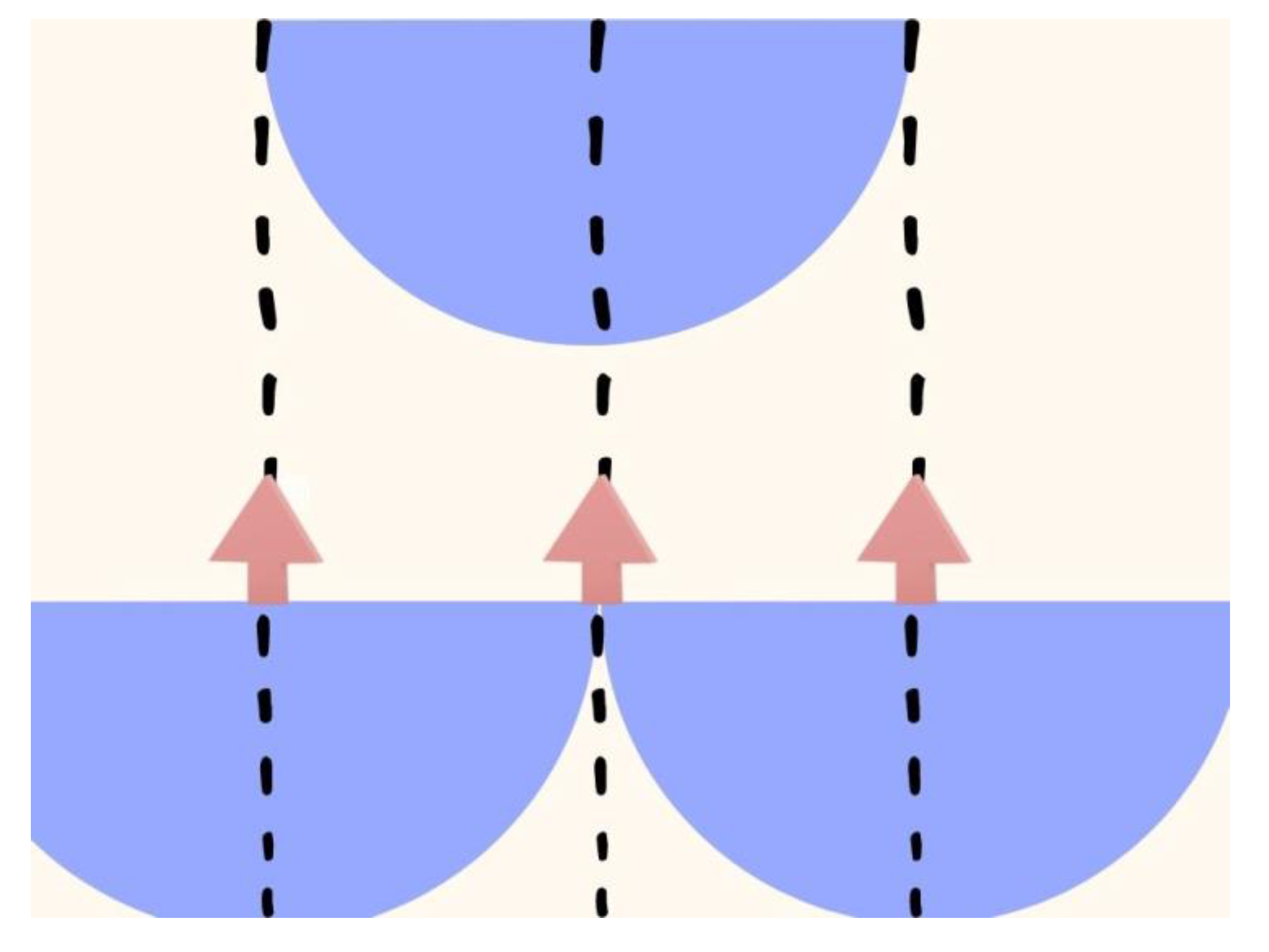

The spread fertilizer was collected over the entire working width of the fertilizer machine to determine the uniformity of the fertilizer spreading. Before the test, special boxes with a gap of at least one meter between them, measuring 500 × 400 × 10 mm, were placed over the entire working width of the fertilizer on the field surface in a line perpendicular to the direction of movement of the fertilizer unit (

Figure 2). The row of boxes was arranged so that the direction of movement of the machine coincided with the prevailing wind direction. For tests on spreading lime and granular fertilizer, cardboard dividers were placed in the boxes to prevent the fertilizer from bouncing off the bottom of the box and to collect it evenly. The amount of fertilizer accumulated in each box was weighed on an electronic balance.

Fertilizer was spread on the soil surface with the tractor running in one direction (

Figure 3): A method in which successive parallel passes are made in the same direction. This method creates an overlap between right-to-left and left-to-right adjacent passages.

The fertilizer was spread on the soil surface with an organic fertilizer spreader (manure-spreader) at such a distance that the supply of fertilizer would not be performed prematurely. According to the recommendations of the American Society for Agricultural and Biological Engineers, standard ASAE S341 [

32], fertilizer spreading was started 20 m in front of the fertilizer collection boxes and stopped 50 m behind the boxes.

The evaluation of the uneven and overlapping transverse organic fertilizer application was performed using a Rollforce 5517 spreader produced by Rolland company in France. The hopper of this spreader was 17 m3. The spreading mechanism consisted of two vertical ESP21-type drums, and two TCEi spreading discs with three blades each. This spreading pattern of the mechanism ensured more accurate fertilizer spreading. The working width of the application of the organic fertilizer at different flow rates was about 14 m. For spreading bulk fertilizer, spreading vanes of the same length attached to the spreading discs were used. Fertilizer was applied at a speed of 8 km h−1. All fertilizers were spread with the same fertilization rate, 200 kg/ha.

2.3. Statistical Evaluation

All performed tests were repeated 3 times. After the experimental research, the obtained data were processed by statistical-mathematical methods. Data were evaluated by the method of analysis of variance. Arithmetic means and their standard deviations and confidence intervals at a 0.95 confidence level were determined. Statistical reliability and standard means of confidence were evaluated in the data analysis. After estimating the moisture content of the granules, the average dry matter density (DM) of different organic fertilizer granules and the confidence interval for data scattering were also calculated [

33]. The Gaussian coefficient was calculated, and a one-way analysis of variance (ANOVA) was performed. Statistical evaluation was performed with MS Excel.

3. Results

3.1. Physical–Mechanical Properties of Different Bulk Organic Fertilizers

The results of the experimental studies on the moisture content of different organic fertilizers, such as meat and bone meal granules (MBG), cattle manure compost granules (CMG), cattle manure (CM), and lime meal (LD—dry and LW—wet) are presented in

Table 1. The importance of moderate moisture in organic fertilizers for fertilizer quality has been emphasized in [

31]; the authors pointed out that the Chinese National Standard for Agricultural Organic Fertilizers (NY525-2012) states that the moisture content of organic fertilizers must be less than 30%. Lower moisture content of the fertilizer means higher quality [

34]. In addition, lower moisture contents of granular organic fertilizers facilitates their storage, transport, and incorporation into the soil [

35]. The results of the research show that the lowest moisture content was found in meat and bone meal granules—8.6 ± 0.2%, while the highest moisture content was found in organic manure—66.7 ± 6.9%. The moisture content of lime differed significantly between summer and autumn. In summer (July), the moisture content of lime was less than 10%, and in autumn, due to meteorological conditions, it increased by about 17% (during the storage of lime). These results are statistically reliable (

p < 0.05).

The biometric parameters and physical properties of organic meat and bone meal and cattle manure cylindrical granule fertilizers, such as the diameter and length, volume, weight, and density of cylindrical granules, determined by experimental studies, are presented in

Table 2. After analyzing the data of the biometric parameters of organic fertilizer granules, it was found that the average length of meat and bone meal granules was about 11.67 mm, diameter—4.86 mm, weight—0.28 g, and density—1185.6 kg m

−3 (dry matter, DM). Meanwhile, the average moisture content of cattle manure granules was 14.87%, the density of granules was 1255.9 kg m

−3 DM, length—9.5 mm, diameter—6 mm, and weight—0.3 g.

A correlation regression analysis of the physical properties of the fertilizer granules revealed that the moisture of the granules was weakly correlated with the other properties of the granules (

Table 3). As the length of the granules increased, their diameter decreased (

r = −0.802 **;

Y = 8.933–0.331

x; p < 0.01). The mass of the granules was more dependent on the diameter of the granules (

r = −0.636,

p < 0.01), and the interaction between the mass and density of the granules was weak.

Summarizing the results of the biometric properties and density of the granules, it can be stated that the studied beads were of sufficient quality, and their most important biometric indicators (length, diameter) were uniform and differed slightly. The density of the granules was high, exceeding 1000 kg m−3 and meeting the requirements.

3.2. Uniformity of the Application of Organic Fertilizers

The exact fertility rate is important for the even spread of the fertilizer on soil. Technological parameters and modes of the working parts of the fertilizer (conveyor, discs, travel speed, etc.) (manure spreader) change.

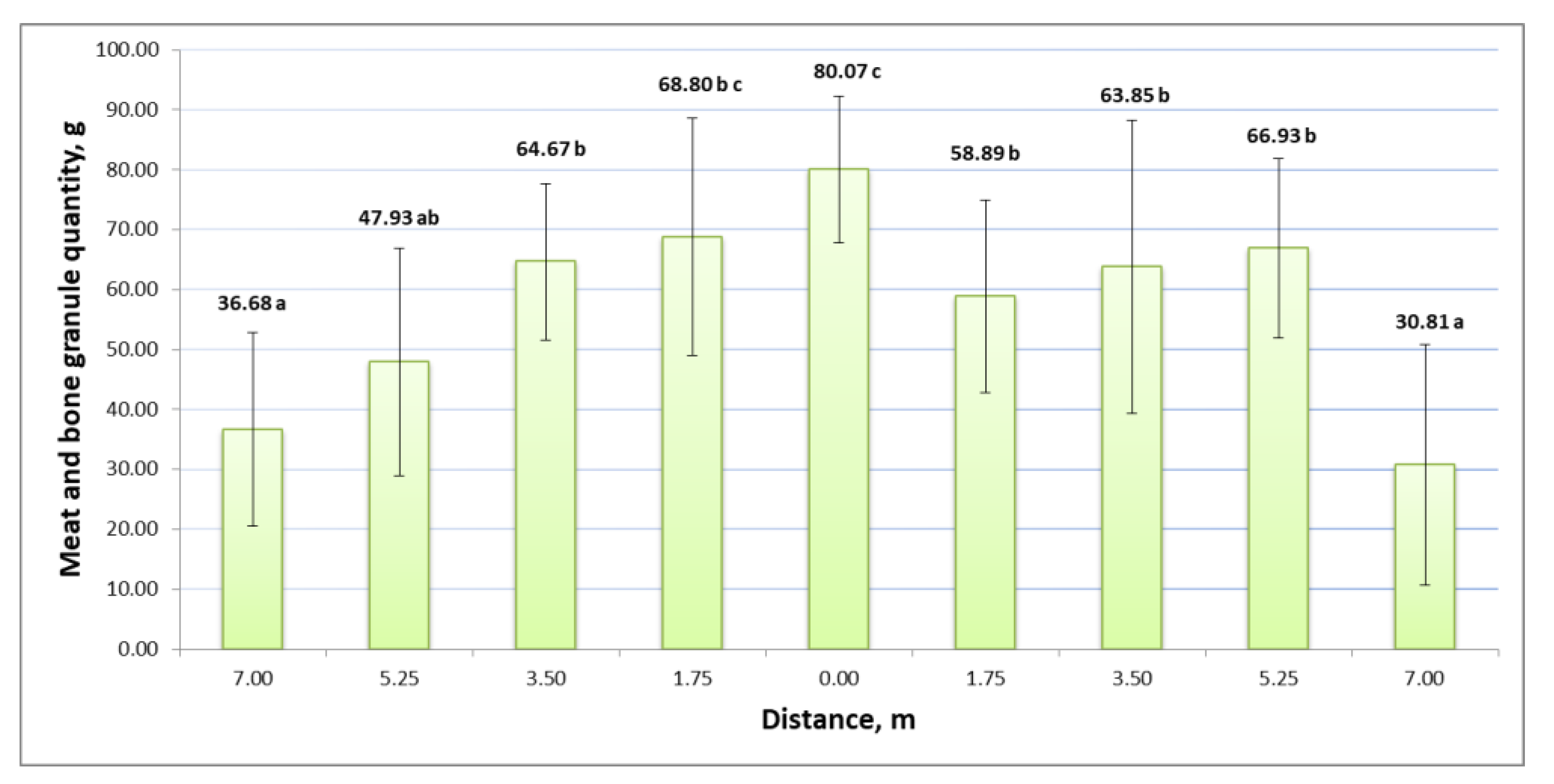

The results of experimental studies on the application of granular fertilizers of meat and bone meal to the soil are presented in

Figure 3. As can be seen from the tests in

Figure 4, the amount of organic granular fertilizer found in the boxes ranged from 30.81 g to 80.07 g. In the box, which was placed in the middle of the fertilizer, the average amount of the granulated fertilizer between the tractor and the manure spreader was the highest—80.07 g.

The results, evaluated by one-way ANOVA, are shown in

Figure 4. This means that the quantities of the spreading of the fertilizers were partly statistically different. The most reliable results for fertilizer collected in boxes are at the center of manure spreader. The results at the edges of the spreading area are less reliable. The quantities of fertilizers that do not have significant differences are marked with the same letters (a, b, c). This does not allow for predictions about the spreading uniformity; thus, the Gaussian coefficient was used for further assumptions.

The Gaussian coefficient was calculated to determine the uniformity of the data distribution. If g2 < 0, the data distribution was uneven—a tapered curve—whereas if g2 > 0, the data is evenly distributed, and the curve is flat (or close to it). Research showed that g2 was found to be as high as 7.11, which means that the spreading was not uniform (statistical reliability p < 0.05). The uniformity of the fertilizer distribution was found to be affected by the pulsating supply of granules by the conveyor towards the spreading discs. In order to improve the uniformity of the spreading of granular fertilizers with a manure spreader, it is necessary to increase the number of transverse conveyor belts in order to ensure a smooth and even supply of granules. However, the data in the figure show that the number of particles to the left of the spreader (spreader in start position) decreases steadily as the distance decreases. Meanwhile, an uneven distribution of particles is observed to the right of the spreader. It can be assumed that such research results may have been influenced by the physical properties of the fertilizer as well as the wind direction and speed. It is also observed that the amount of fertilizer in the box under the tractor (80.07 g) was about 2.3 times higher than in the boxes 7 m away. The highest standard error calculated is 18.54%, which allows us to state that the obtained results are reliable.

In the analysis of the results of the application of granular fertilizers of cattle manure to the soil, opposite results on uniformity were observed. It can be seen from the results presented in

Figure 5 that the amount of organic granular fertilizer ranged from 7.52 g to 16.55 g. The reduction of fertilizer particles in the boxes is observed in both directions from the central fertilizer collection box. The amount of fertilizer in the central box (which was under the spreader) was about 1.9–2.2 times higher than in the side collection boxes 7 m to the left and right of the tractor. In this case, the calculated g

2 is 0.46 (

p < 0.05), which means that the spreading is smooth and the curve is close to flat. The results of the fertilizer distribution in boxes evaluated by one-way ANOVA showed that the most statistically reliable results are at the center of the manure spreader (distance 0.00 m). The results at the edges of the spreading area are less reliable.

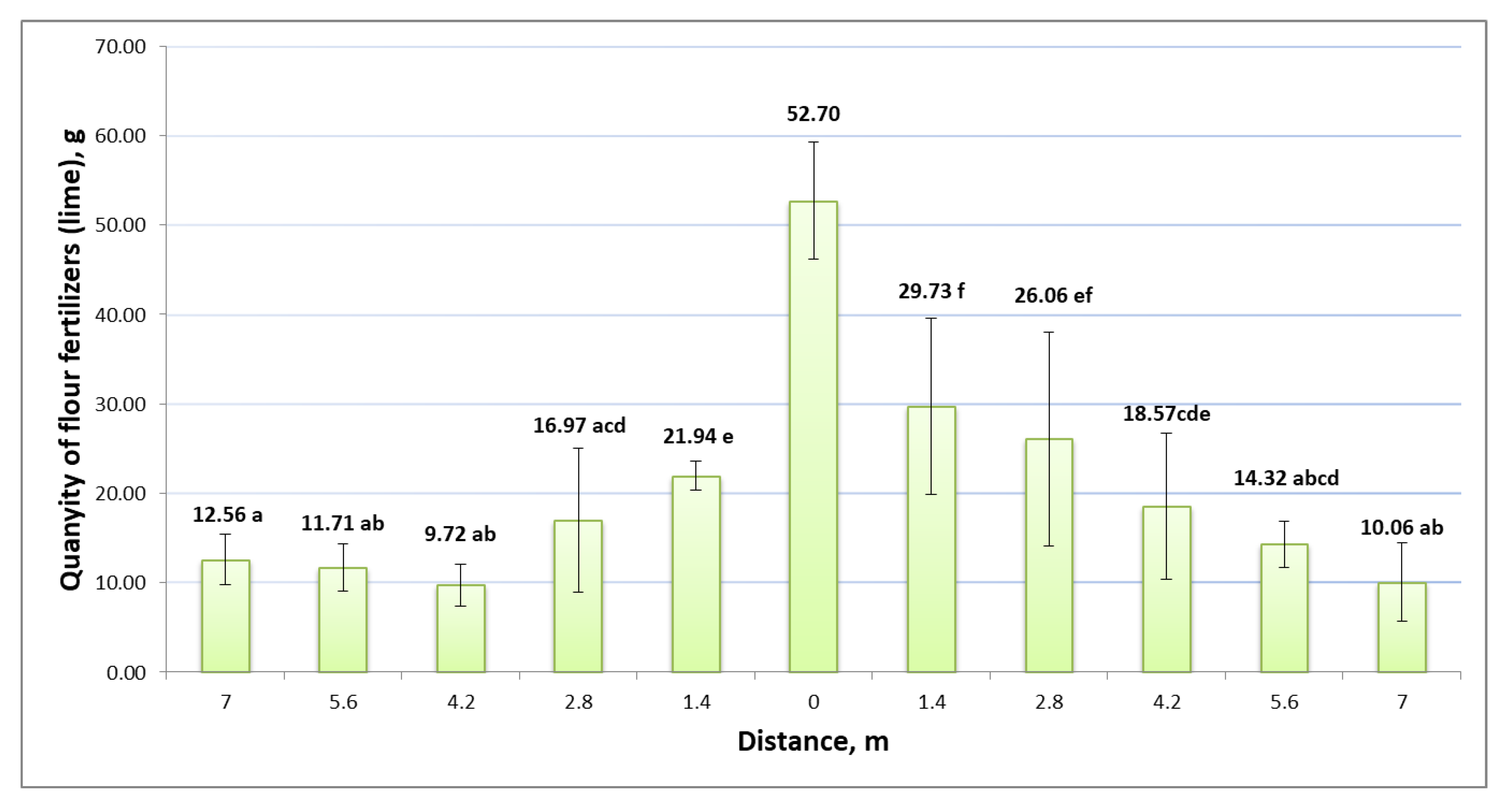

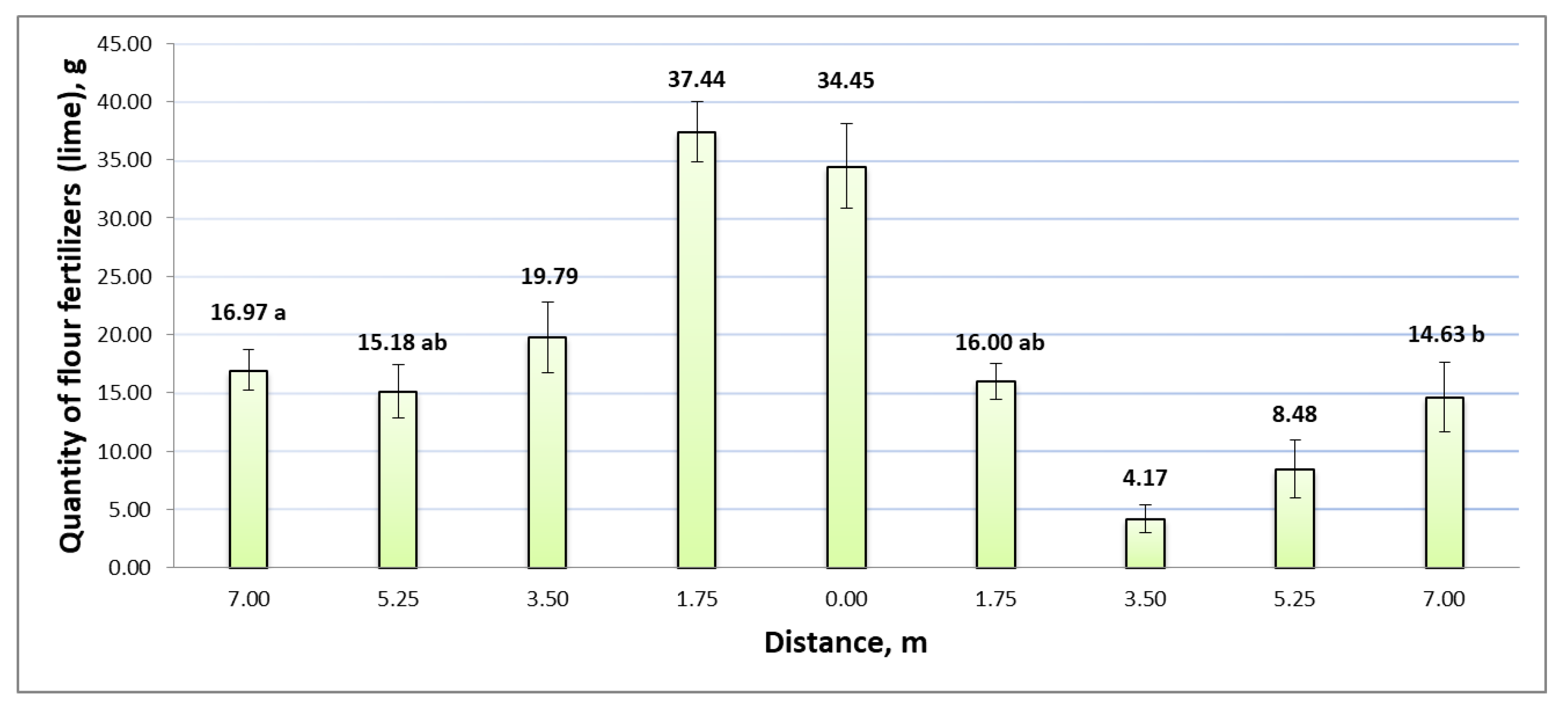

The results of the uniformity of the application of flour fertilizer (lime) are shown in

Figure 6 and

Figure 7. Experimental studies of the uniformity of the application of dry lime flour fertilizer (

Figure 6) showed that the least amount of flour fertilizer (lime) entered the boxes furthest from the spreading discs of the fertilizer machine. Meanwhile, the box in the center of the spreader had the highest amount of fertilizer. It is important that, during the study, these boxes were placed in the center, between the tractor and the fertilizer wheels. The most reliable results of the one-way ANOVA statistical evaluation of the distribution of dry flour lime fertilizer between the boxes were from the center of the manure spreader (distance 0.00 m), while the results were less reliable at the edges of the spreading area. The amount of fertilizer in the central box was 4.2–5.2 times higher than in the boxes 7 m from the center of the spreader. In order to assess the uniformity of this distribution, g

2 = 1.99 (

p < 0.05) was calculated. It can be indicated that the uniformity is lower compared to the uniformity of the application of cattle manure organic fertilizer granules.

Meanwhile,

Figure 6 shows the results of experimental studies evaluating the uniformity of the application of flour fertilizers (wet lime). From the data presented in

Figure 7, it can be seen that the amount of flour fertilizer (lime) in all test boxes ranged from 4.17 g to 37.44 g at a fertilization rate of 6.0 t ha

−1. Results evaluated by one-way ANOVA showed that the quantity of spreading of the wet flour lime fertilizers was the most reliable result at the center of the manure spreader. The results at the edges of the spreading area were less reliable.

In order to evaluate the uniformity of the application of these fertilizers, g2 was calculated. Based on the estimates of g2 when dry lime is applied (1.99) and when wet lime is applied, g2 was 0.02 (p < 0.05). A comparison of the presented average results and the Gaussian coefficients shows that the application of flour fertilizer on the field was more uniform when wet lime was applied.

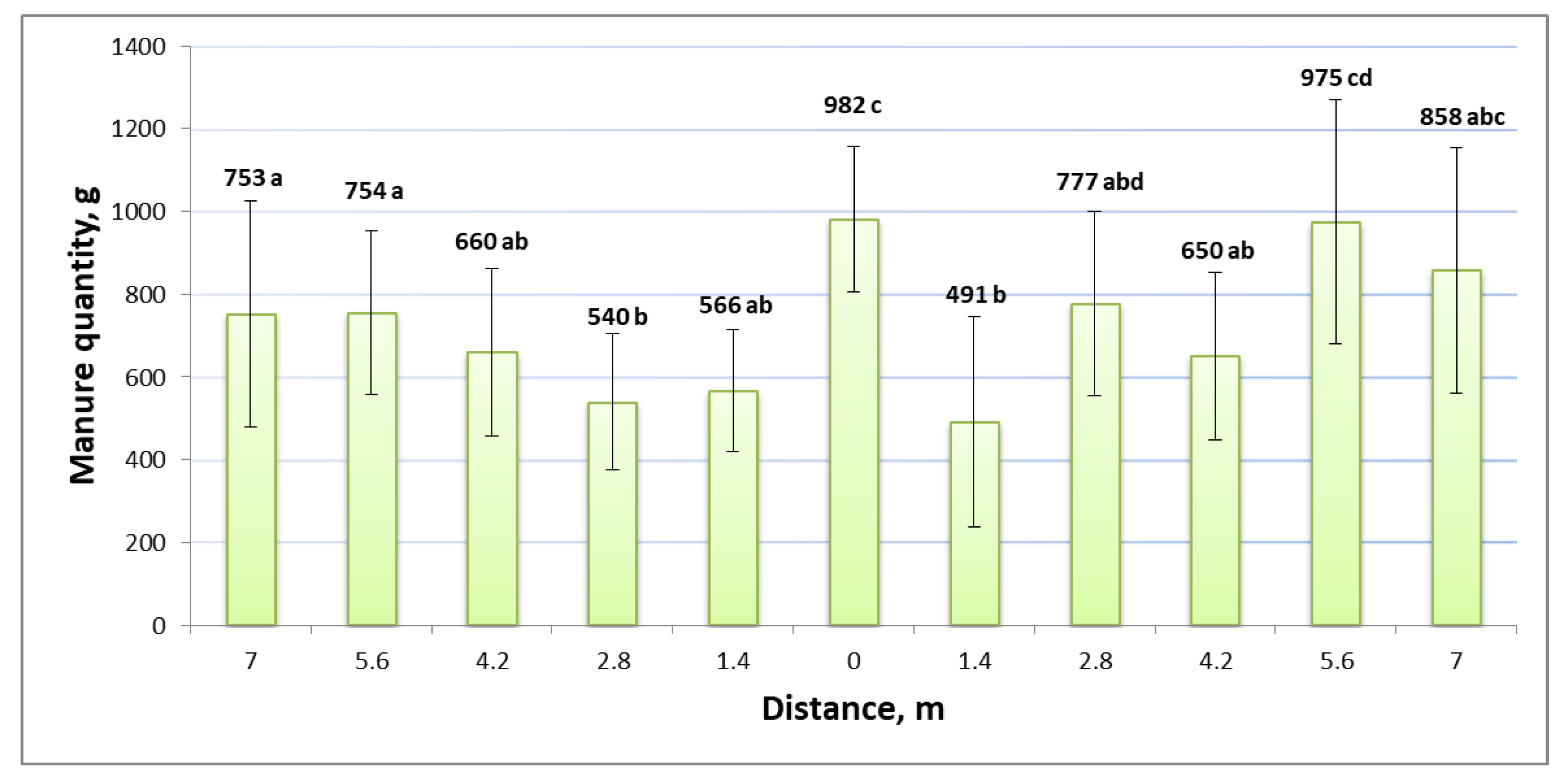

Analogous field experiments were performed with cattle manure fertilization. The average results of the uniformity of manure spreading with a manure spreader are shown in

Figure 8. The spreading of the manure fertilizers between the boxes was also evaluated by one-way ANOVA. These results were not reliable in the center and at the edges of the manure spreader. Such results and the reliability of the results may be influenced by the large particle size and mass of the fertilizer.

In these experimental studies, the amount of manure in the test boxes ranged from 490.53 g to 1017.39 g. The results of the studies presented in the histogram were evaluated by calculating the Gaussian coefficient, which is −1.15 (p < 0.05). This coefficient is g2 < 0, so it can be assumed that the uniformity of distribution is greater than that of dry lime. This is due to the fact that the manure particles are much larger and heavier, making it easier to spread them over a wider area.

4. Discussion

Hu, J. et al. conducted a study on how the rate of fertilizer application affects their spreading on the soil surface. They found that the highest amount of applied fertilizer positively correlates with the uniformity of fertilizer discharge and the speed of the horizontal scraper movement. For fertilizers from 900 to 2100 kg ha

−1, fertilization is accurate and the highest deviation between the determined fertilizer rate and the actual fertilization rate is less than 10%. Fertilizer application is good when the coefficient of variation of uniformity is lower than 7% [

27].

Other studies have shown that the uniformity of the application of liquid fertilizers can also be affected by factors such as the type of nozzle, the layout of manifold, and the concentration of the fertilizer solution [

36]. Meanwhile, the influence of the properties of fertilizers on the uniformity of the application of fertilizers is lacking research.

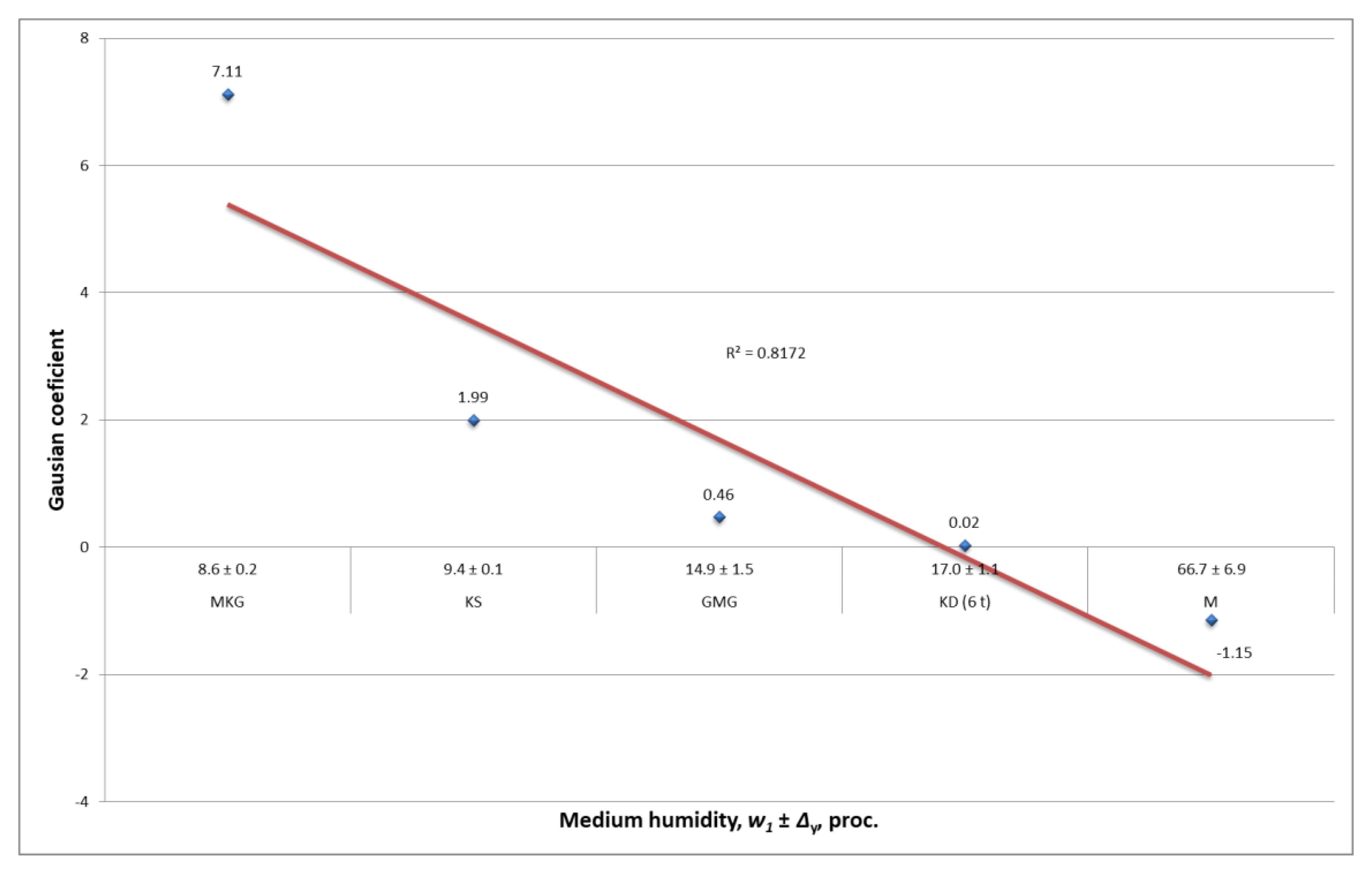

Experimental studies have shown that as the average moisture content of the fertilizer increases, the Gaussian coefficient decreases and approaches zero, which suggests that the uniformity of fertilizer application increases (

Figure 9). Moisture can significantly affect the results of the uniformity distribution due to its significant influence on the interactions between the plasticizer and enhanced granules [

37]. The dependence was evaluated by calculating the coefficient of determination R

2 = 0.817, which indicates that there is a sufficiently high relationship between the average moisture content of organic fertilizers and the spread of fertilizers on the soil surface.

According to Gavrilovic et al., it is necessary to pay attention to the physical and mechanical properties of mineral fertilizers, as they affect the uniformity and the overall quality of fertilization. The authors argue that these properties affect storage, transportation, and outdoor use [

30]. Based on the data from these studies on mineral fertilizers, it can be assumed that the physical and mechanical properties of organic fertilizers also affect the spread of the fertilizer. A comparison of the data obtained in the study—the uniformity indices of the distribution of meat and bone meal organic fertilizer granules and cattle manure organic fertilizer granules—and an evaluation of the biometric parameters of the granules revealed that the granules with higher masses and volume were more evenly distributed. However, when analyzing the granule density, different uniformity results were observed, as the density of cattle manure granules (1255.9 ± 67.0 kg m

−3) is higher than the density of meat and bone meal organic fertilizer granules (1297.2 ± 56.2 kg m

−3). In addition, the uniformity of the distribution of the granules on the soil surface results in better particles with a lower density [

36]. It is expedient to continue the research in this direction by analyzing and comparing the process and uniformity of the application of granular fertilizers of different densities to the soil surface. Other research performed on the moisture content of the fertilizers have shown that the amount of water used for irrigation and the particle size of the raw material affects the mechanical properties of organic fertilizers [

38].

Studies have shown that the biometric data of the produced granules affect the uniformity of the distribution of the granules, which allowed for evaluations and comparisons of the results using the same equipment for the application of all types of fertilizers.

Biometric and physical–mechanical properties (density, moisture, and granule dimensions) of meat and bone meal granules, cattle manure granules, lime, and manure used for fertilization were investigated and determined. After evaluating the results of the biometric and physical–mechanical properties of organic fertilizer granules, it was found that the density of organic meat and bone meal fertilizer granules reached 1185.6 ± 51.4 kg m−3 DM (dry matter), and the density of organic cattle manure granules was about 10% lower, amounting to 1068.8 ± 57.0 kg m−3 DM. The moisture content of organic meat and bone meal fertilizer granules was 8.6 ± 0.2%, and the moisture content of cattle manure fertilizer granules was almost twice as high, reaching 14.9 ± 1.5%.

Based on the results of the uniformity of fertilizer application, it can be stated that the application of cattle manure granules on the soil surface was more uniform than that of meat and bone meal granules. This statement can be justified by the fact that the cattle manure granules were wetter and influenced by their more suitable shape, shorter length (9.50 ± 0.38 mm), larger diameter (6.0 ± 0.1 mm), lower density (1255.9 ± 67.01 kg m−3), and higher mass (0.30 ± 0.03 g).

The results of the application of lime to the soil surface suggest that wet lime is more evenly distributed than dry lime due to its physical–mechanical properties, which is likely due to the fact that dry particles are lighter than wet ones and are, therefore, more exposed to wind.

The manure was spread the most evenly on the soil surface due to the high moisture, density, and mass of the particles, making it easier to spread them over a wider area.

In order to improve the uniformity of the spreading of granular fertilizers with a manure spreader, it is necessary to increase the number of transverse conveyor belts and to have a fully unloaded body at all times, in order to ensure a smooth and uniform supply of granules.

5. Conclusions

The given unique results, in which meat and bone meal granules and organic fertilizers from granulated manure were spread on the soil surface using a manure spreader, show that the biometric data of the produced granules affect the uniformity of the distribution of the granules, which makes it possible to evaluate and compare the results using the different types of fertilizers.

The results showed that the quantities of the spreading of the fertilizers were partly statistically different. Since this does not allow for predictions about the spreading uniformity, the analysis of the Gaussian coefficient was accepted for further spreading evaluations. The results showed that the moisture content of the evaluated organic fertilizers affects the uniformity of application of these fertilizers on the soil surface. The fertilizer spreading is more even on the soil when the moisture of the fertilizer (66.7 ± 6.9%) is higher. In addition, it was found that shorter lengths, larger diameters, lower densities, and higher masses of the granules may affect the uniformity of spreading.

The results of this study showed that the application of cattle manure granules on the soil surface was more uniform than that of meat and bone meal granules. This statement can be justified by the fact that the cattle manure granules were wetter and were influenced by their more suitable shape, shorter length (9.50 ± 0.38 mm), larger diameter (6.0 ± 0.1 mm), lower density (1255.9 ± 67.01 kg m−3), and higher mass (0.30 ± 0.03 g).