1. Introduction

Toyota first introduced lean principles as an alternative process management system. To produce process efficiency by focusing on customer and effective operations management, Toyota invented the ‘Toyota Production System (TPS)’, later known as lean philosophy [

1]. Lean philosophy focuses on stabilizing and standardizing work processes so that critical problems become apparent, and the workforce develops the ability to think critically to solve problems and improve workflow [

2]. It seeks optimal production of goods or services by eliminating waste and increasing the flow of activity throughout the entire value stream [

3].

Lean principles were born in the manufacturing industry and then—due to the opportunities and benefits it creates [

4]—have been adopted as an improvement program in various organizations such as service organizations [

5] in both public [

6] and private sectors [

7]. Nowadays, the implementation of lean principles has increased in HEIs [

8]. Lean higher education is the application of lean principles to higher education administration (admissions, add/drop credit, purchasing, facilities, hiring, and budgeting) as well as academic activities (course design and teaching, improving degree programs, student feedback, handling of assignments) [

9]. Although many service sectors still perceive lean practices are only applicable to the manufacturing sector [

10], more HEIs in developed countries such as the United Kingdom and the United States are now using lean principles to improve their operations. According to Thomas et al. [

11], compared to the amount of knowledge on lean in the manufacturing sector, the literature on applying lean principles in HEIs is still in its infancy, but this research’s extent is growing.

Currently, many businesses are concerned with sustainability. Sustainability, as defined, is a property of a process or state that can be maintained at a certain level indefinitely [

12]. Namely, the Triple Bottom Line strategy necessitates a comprehensive performance based on three pillars of sustainability, including social, economic, and environmental [

13,

14]. To measure sustainability in HEIs, Aleixo et al. [

15] presented four metrics: social, economic, environmental, and institutional/educational/political sustainability, as shown in

Table 1. The need to become involved in environmental, social, and economic sustainability and institutional/academic/political sustainability in HEIs arose primarily due to increased pressure from stakeholders. Applying sustainability in management processes and organizations contributes to the quality of life of all stakeholders and contributes to society, the economy, and environmental conservation [

16].

There is a relationship and interaction between lean and sustainability that helps increase competitiveness and efficiency in production. Camuffo et al. [

17] stated that lean principles represent sustainability and streamline costs, time, waste, and quality processes. Nawanir et al. [

13] found a positive relationship between lean principles in HEIs and sustainability performance in terms of environmental, economic, institutional, and social; this implied that HEIs could implement lean principles to improve sustainability. However, the implementation of lean sustainability in higher education is faced with the unique problem that there are no mutually agreed metrics for institutional efficiency and, in particular, the lack of metrics for student learning and teaching effectiveness [

18].

Several authors have analyzed the relationship between lean principles and sustainability criteria. Tăucean et al. [

19] explained 12 principles of sustainability, the 12 principles of lean, and the interaction between lean operation and sustainability criteria in the management process. Khodeir and Othman [

16] examined the interaction between lean and sustainability principles in the management process and found that lean and sustainability development have practically the same agenda in terms of enhancing processes and stakeholder quality of life, decreasing all forms of waste, monitoring, and self-evaluation for continuous improvement, and marketing concerns.

Kazancoglu and Ozkan-Ozen [

10] conducted a study in a business school at Turkish HEIs to identify the eight wastes in HEIs and present a model for categorizing wastes and sub-wastes using criteria and sub-criteria using The Multi-Criteria Decision Making (MCDM) application. Kazancoglu and Ozkan-Ozen [

10] identified 22 sub waste in HEIs and analyzed their cause–effect relationships. Then, an importance level could be assigned to each sub waste by assessing cause–effect relationships. This study may be used to understand better the wastes in higher education institutions (HEIs) and the causal relationships between them and develop ways to eliminate them. However, this study does not clearly explain the process of identifying wastes. Undoubtedly, brainstorming or interviews will reveal many hidden wastes in an HEI. We suggest prioritizing the significant wastes, and the insignificant wastes will usually be eliminated. Therefore, we propose w-FMEA as a waste screening instrument by considering its severity, occurrence, and detection.

Some studies have shown how lean principles have been successfully used in HEIs. Doman [

20] conducted a case study to demonstrate that through an innovative and engaging learning experience involving undergraduate students, lean principles and techniques used in industry may be successfully implemented to improve higher education operations. Höfer and Naeve [

21] showed the case studies of lean principle, i.e., customer focus, value stream, flow principle, pull principle, and pursue perfection in operational of HEI. However, the multiple case studies narrated by Höfer and Naeve [

21] only focus on lean thinking in problem-solving. Focusing on a single in-depth case study will provide a clearer picture of an established method (lean) applied to a new subject (HEI). Nicholson and Pakgohar [

22] used lean principles to solve some of the pressure points for academic workloads in a university law clinic. The studies have applied lean principles in HEI to evaluate and design the processes more effectively.

HEIs are now operating in an increasingly complex and challenging situation [

20] as they have to meet growing student demand and the continuous organizational improvement it entails [

21]. Educational institutions are now facing unprecedented competition for students, research funds, prestige, quality ratings, incubated companies, fundraising, academicians, skilled workers, and so on [

9]. There are specific conflicting goals for service providers with customers inside and outside HEIs [

22]. Globalization has also encouraged HEIs to constantly develop robust quality-assurance systems for faculty improvement, research funding, and academic and technological programs. These have motivated HEIs to redesign their business processes to reduce administration overheads and improve services for stakeholders [

21].

Similar to the application in other industries, the goal of lean practices in HEIs is to add value without wasting resources [

23]. If it is applied correctly, lean practices will eliminate waste—making processes more efficient and delivering better values to customers of HEIs—with core processes covering teaching-learning, research, and dissemination of new knowledge and information [

22]. However, It is necessary to define waste and how they are interconnected to identify and eliminate the root causes [

10].

Previous studies have identified lean wastes in HEIs by adapting the conceptual wastes in the manufacturing industry. Some identified seven types of waste, others eight [

24]. The former was postulated by Narayanamurthy et al. [

25], but then the categories were cut down into six, i.e., motion, waiting, overproduction, over-processing, defect, and rework. The latter was coined by Anthony et al. [

26], with the eight categories being excess motion, excess transportation, underutilized human resource, inventory, defects, overproduction, waiting, and over-processing. Hartanti et al. [

27] then conducted a systematic literature review and concluded that there are nine types of waste: excess motion, excess transportation, underutilized human resource, inventory, defects, overproduction, waiting, over-processing, and excess information.

Wastes such as the above may cause system failures that lead to discontent for a set of customers inside and outside HEIs. Therefore, HEIs must implement good risk management from the outset and throughout the systems. In risk management practice, risk analyses are needed to investigate and estimate the impacts and consequences of risks and comprehend the nature, sources, and causes. Failure Mode and Effect Analysis (FMEA) is a valuable risk management tool to identify potential system failures and assess the causes and effects, thereby preventing them from occurring [

28]. FMEA is used in the review process or decision-making in a product or system design to improve safety and reliability [

29]. The FMEA steps are as follows: (1) selecting a process; (2) designing a multidisciplinary team; (3) gathering and organizing information; (4) conducting a hazard analysis; (5) developing and implementing actions; (6) measuring the outcome [

30]. The risk for each element is expressed as Risk Priority Number (RPN) and calculated as a product of severity (S), occurrence (Oc), and detection (D) [

31]. Because FMEA in this study is employed to identify waste, the term w-FMEA is used. Then, RPN is also translated as Waste Priority Number (WPN). The WPN will rank the impact of each waste based on the S, Oc, and D.

After finding the rank of each waste, ISM will then be used to examine the relationship of the influential wastes so that a solution can be proposed. The hypothesis proposed in this study is that waste identification and waste mapping will provide insights that lead to the discovery of practical solutions to ensure the sustainability of an HEI. ISM is a qualitative tool to understand the complex interrelationships between elements [

32,

33]. ISM is frequently used to understand complex problems and build an action plan to resolve complex issues [

34]. ISM describes how aspects are related to one another and discovers the pattern among the elements [

33]. Elements in this research are the identified wastes in the HEI. The analysis of ISM is usually integrated with MICMAC [

35]. MICMAC cartesian diagram will group each waste into four quadrants (autonomous, linkage, driver, and dependent) based on its driving power and dependencies. With MICMAC analysis, a more comprehensive waste analysis can be generated.

Sustainability in HEIs

Nawanir et al. [

13] divided lean practices in HEIs into seven categories: waste identification, work standardization, level and balance workloads, built-in quality, pull system, multifunctional employees, and continuous improvement. Lean practices in HEIs as a systemic approach play an important role in sustainability because of their potential effect on sustainability performance. The primary purpose of lean principles is to maximize stakeholder value and eliminate all waste to optimize the entire process [

18,

19]. Applying lean principles in HEI can improve student satisfaction.

HEIs are a good candidate for lean and sustainable practices [

18]. In the last few years, there have been many studies on successful sustainable development in HEIs, e.g., [

13,

15,

17,

36,

37]. Aleixo et al. [

15] pointed out five sustainable development activities in HEIs—education, research, campus operations, community outreach, and raising awareness in the community—that need communication and coordination with the different stakeholders. These circumstances triggered waste in day-to-day activities related to many cross-functional or departmental processes, so it requires more time or steps.

The aims of this study are (a) to assess waste in HEIs based on lean principles and even their potential effect on sustainability; (b) to establish the relationship among wastes; (c) to develop a structural model using ISM; (d) to carry out the MICMAC analysis. By identifying the critical wastes, HEIs can focus on developing strategies for waste minimization and improving the quality of HEIs. The results of this study exemplified priorities for HEIs to start the utilization of lean practices as well as define actions to reduce the most critical wastes and practice sustainable development in HEIs.

4. Discussion

In the manufacturing sector, lean implementation has proved quite successful as it reduces waste and increases efficiency. This success encourages another sector to implement lean principles to improve the quality of its services. In the recent decade, lean principles have become a methodology for development in various sectors, including higher education [

41]. HEIs are seeking new methods to stay competitive in an ever-changing world. This means going above and beyond the competitors in terms of education and service and keeping expenses reasonable. In higher education, sustainable development is a critical concern. As a systematic approach, lean principles in HEIs play a significant role in sustainability.

Lean principles are relevant to be applied to HEIs, taking into consideration of their application, especially regarding the distinctive attributes of service operations. Hess and Benjamin [

42] used lean principles in the university to improve processes in curriculum delivery, business and auxiliary services, admissions and enrollment management, and research. They found that the key to successful implementation in a university setting is to avoid a top-down approach instead of focusing on faculty involvement in the design and implementation of the lean methodology. Cudney et al. [

43] found that in lean implementation, engaging internal and external customers and emphasizing the value of direct involvement, stakeholders’ commitment, and participation can improve quality and decrease waste in learning, teaching, and administration.

In lean principles, the different categories of waste are overproduction, over-processing, waiting or delay, motion waste, excess inventory, waste talent, transportation, and defect or reworking [

44]. In the manufacturing sector, each waste form is defined as follows: overproduction refers to products for which there is no demand; over-processing refers to unnecessary production line processes; waiting may occur as products, waiting in queues or delays that keep employees waiting; motion waste refers to unnecessary movements of workers; transportation waste means unnecessary traffic in the manufacturing area; inventory waste may be a shortage and excessive stocking of raw materials or finished goods; defects refer to avoidable production of defective products, and talent waste refers to the non-use of workers’ abilities or skills [

10]. Because the eight categories of waste refer to the manufacturing sector, they must be adapted to the context of HEIs [

10,

25,

26,

42,

43,

44,

45,

46]. Kazancoglu dan Ozkan-Ozen [

10] investigated eight wastes in HEIs by proposing a multi-stage model. They are classified into overproduction, over-processing, waiting, motion, transportation, inventory, defects, and talent. Douglas et al. [

26] classified wastes as overproduction, over-processing, waiting, motion, transportation, inventory, defect, and underutilized people. The examples of waste modes in HEI are shown in

Table A1, which are briefly described as follows:

A defect is defined as an error in the process or service support requirements. Such wastes are the lecturer having trouble finding a file, typographical mistakes, and making mistakes in learning materials and preparation.

Overproduction occurs when doing services that do not need or earlier than scheduled. Such as wastes are lecturers printing too many copies of materials, the teaching load is too much to handle, and the lecture adds extra hours to accomplish their work.

Waiting is defined as delays in a process. For example, the lecturer takes a long time to respond to messages and questions from students, waits in a meeting, the lecturer misses a deadline for submitting reports.

Non-utilized talent represents inappropriate work allocation or non-use of lecturer/staff abilities or skills. The lecturer exemplifies non-utilized talent is given a task that is outside of their area of competence, and the lecturer does not do research or community services every semester

Extra transportation is defined as unnecessary traffic in HEIs areas. For example, when distributing documents/files across work units, the lecturer makes mistakes.

Excess inventory represents goods or services that are no longer required to meet current needs. Examples of excess inventory in HEIs are the lecturer storing too many documents and the lecturer hoarding office stationery.

Extra motion or unnecessary movement: This waste occurs when lecturers or staff have to spend more time/energy to provide a service. Consider the examples such as the distance between classrooms and office/workspace is far, and the lecturer’s workplace is always disorganized.

Over-processing or doing more work than required. Such as waste are the lecturer spends a significant amount of time locating documents, files, and journals, information is received through various channels (WhatsApp, email, hard copy, etc.), repeatedly posting the same information or announcement. Underutilization of a highly talented and educated lecturer/staff is common in education; furthermore, the disconnection between stakeholders in education prevents real learning for change [

44].

The FMEA approach has been widely used in analyzing failure modes and their effects on product/service quality because it can assist manufacturers/service providers in identifying product/service failures/defects, as well as the severity levels of those failures and their impacts on related stakeholders and business performance [

47]. In this study, waste modes that have been identified were ranked based on WPN. The WPN values were between 3 and 67.5. There were eighteen waste modes as critical waste, as shown in

Table 2.

According to the result of w-FMEA, a structural model was developed. The model was built regarding the ISM technique, consisting of eight levels. The structural model at the end of the ISM reveals the interrelationships between numerous aspects, their dependency/independence, and the level of each element [

48].

Table 3 presents the hierarchy level of waste modes. The waste mode at level eight is the one that has an impact on the waste modes at the higher levels. As a result, the waste elimination procedure will begin at level eight and progress to level one. From the model developed with the identified waste modes in this study, it is clear that the most critical waste mode is repairing facilities that take a long time, which comes as the base of the ISM hierarchy. The facilities are an essential part of teaching and learning activities. If the facility is damaged and fixing it takes a lengthy time, it has the potential to generate other waste modes. The instructor takes a long time to respond to messages and questions from students, and information is received through a variety of channels (WhatsApp, email, hard copy, etc.); the lecturer uses the same exam questions from the previous year; the lecturer does not do research every semester; lecturers are late for meetings; the lecturer waiting for students to enter class, which is dependent on other waste modes have appeared on the top hierarchy.

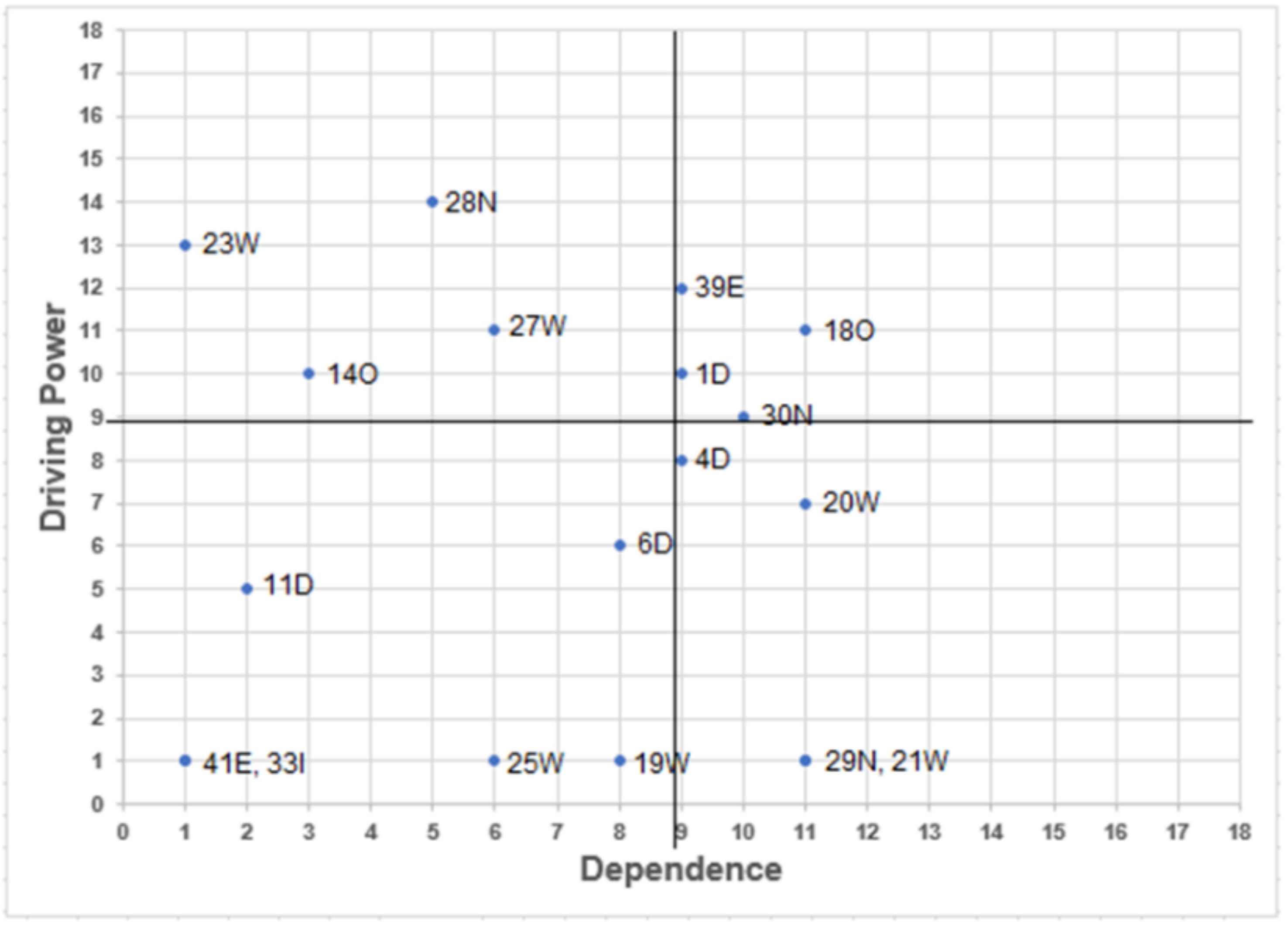

The developed eight-level ISM model is further analyzed using MICMAC analysis based on each determinant’s driving and dependence power (attribute) of interest. The determinants are categorized into autonomous, dependent, linkage, and driver determinants. The dependence and the driving power of waste modes are shown in

Figure 1.

Table 5 provides more details about determinants and their characteristics.

Based on the developed ISM model and MICMAC analysis, mitigating actions for minimizing waste modes are being proposed, such as:

Department heads should allocate an adequate workload of lecturers. This helps lecturers in resolving the waste modes, namely, every semester, the teaching load is too much to handle (14O); working outside of regular business hours to complete administrative tasks (18O); the lecturer misses a deadline for submitting reports (20W); the lecturer does not do research every semester (29N); lecturers do not participate in community service every semester (30N).

Proper planning is required to ensure the adequate availability of resources. This helps in eliminating waste modes such as lecturers altering the course schedule (4D); the connection wire for the projector being broken (11D); repairing a facility taking a long time (23W); the lecturer being given a task that is outside of their area of competence. (28N); the same exam questions from the previous year are used by the lecturer (33I).

Coordination and communication between the academicians must be open and transparent. This helps in mitigating waste modes; namely, the lecturer conducts a re-examination of the students (6D); the instructor takes a long time to respond to messages and questions from students (19W); lecturers are late for meetings (21W); the lecturer waiting for students to enter class (25W); students fail to submit assignments on time (27W); information is received through a variety of channels (WhatsApp, email, hard copy, etc.) (41E).

Training and workshops help lecturers develop a solid commitment to their work. This helps mitigate the waste modes; namely, the lecturer is having trouble finding a file (1D); The lecturer spends a significant amount of time locating documents, files, and journals (39E).

This paper shows that identification wastes have massive potential for lean in HEIs for HEIs sustainability and develop propositions for future studies. Furthermore, this research outlines mitigating strategies for minimizing waste modes in HEIs.

5. Conclusions

The lean principle is a concept for improving systems and maximizing value. Lean has its origin in the private sector generally and the manufacturing sector particularly. It has been proven effective in strengthening operation systems in various sectors, including higher education. It is acknowledged that there is a significant difference between the manufacturing sector and HEIs sectors in terms of system, process, and product.

HEIs can be thought of as a collection of systems and processes. HEIs are organized around academic and non-academic departments and implement process management techniques to deliver the output that should meet student satisfaction. There is, for example, a registration process, an administration process, a financial process, and a teaching and learning process. Many functions in HEIs cut beyond functional and departmental boundaries. The product of HEIs is intangible and difficult to quantify because it is reflected in the transformation of individuals in their knowledge, character, and attitude. There is a fundamental concern of HEIs regarding the level of knowledge and skills graduates are legitimately supervised by academics.

The first step to implementing lean principles is understanding what value is and what activities and resources are vital to achieving it. Value and flow must be established according to the processes and circumstances of the HEI’s system to implement lean principles. Waste reduction and increased efficiency have been identified as critical goals of lean principles in HEIs. There is a gap in the literature regarding the eight waste types in HEIs and a lack of specific definitions for these wastes. This study is to add to the literature by first providing explicit definitions of the eight wastes in HEIs before proposing a model based on these wastes. This study presents a combination of well-established methodologies, i.e., w-FMEA and ISM.

The actual results extracted from the w-FMEA analysis during Phase 1 were potential failure modes, their effects, and their causes. Regarding the FMEA analysis, 18 waste modes have been identified as critical wastes in the HEI.

In Phase 2, the ISM technique was applied to identify and assess each waste mode’s driving and dependent powers using the MICMAC analysis. The integrated ISM-MICMAC model was created to provide the relevance of waste elimination as part of routine services operations in HEIs.

Information is received through a variety of channels (WhatsApp, email, hard copy, etc.); the same exam questions from the previous year are used by the lecturer; the lecturer waiting for students to enter class; the instructor takes a long time to respond to messages and questions from students; the connection wire for the projector is broken; the lecturer conducts a re-examination of the students have been identified as autonomous determinants.

Meanwhile, the dependent determinants are: The lecturer does not do research every semester; lecturers are late for meetings; the lecturer misses a deadline for submitting reports; lecturers alter the course schedule.

Also, the linkage determinants are that lecturers do not participate in community service every semester; the lecturer is having trouble finding a file; working outside of regular business hours to complete administrative tasks; the lecturer spends a significant amount of time locating documents, files, and journals.

Finally, the driver determinants are: facility repairs take a long time; every semester, the teaching load is too much to handle; students fail to submit assignments on time; the lecturer is given a task that is outside of their area of competence.

The limitation of the study should be pointed out in obtaining data. This study is a preliminary study with a sample size of two faculties in HEI. A small sample led to the results of this study may not be generalizable, but coherent and comprehensive writing allows this study to be transferable in similar cases with minor modifications. Therefore, this study should be seen as the first step in a broad set of other studies integrating lean implementation and sustainability in HEIs. Future studies are needed to expand data using all scope of HEI, compare lean principles implementation between HEIs, and find pathways for lean principles to be augmented with sustainability pillars in HEIs.

This study is expected to help academicians and practitioners understand HEI’s waste types by listing the critical wastes, mapping their interrelationship, identifying the driving power and dependence, and proposing mitigation actions. It will also contribute to the growing body of literature highlighting the wastes in HEI.