3.1. Energy Indices for Wheat Production

The energy indices for irrigated wheat production are presented in

Table 4. The analysis of these indices at the national level shows that the average energy equivalent to the inputs is about 59.54 GJ ha

−1, which is higher than the energy output (equivalent to the wheat produced) (45.82 GJ ha

−1). Thus, the

EUE and NE are estimated to be 0.77 and −13.71 GJ ha

−1, respectively. This means that the production of irrigated wheat in Iran is not an energy-efficient process. It is more energy-intensive than wheat cultivation in Bangladesh and China, for instance [

38,

43]. The NER is 0.95 for the production of irrigated wheat, indicating that the non-renewable energy used in wheat production is greater than the energy output produced. In other words, the sum of diesel fuel and electricity, along with the energy embodied in the chemical fertilizers, pesticides, and machinery, is greater than the energy equivalence of the wheat produced. The EP index is estimated to be 0.06 kg MJ

−1. Specific energy, or SE, is the inverse of energy productivity and is thereby about 16.89 MJ kg

−1, meaning that 1 kg of wheat produced in Iran uses a lot of energy: more than thrice what Unakıtan and Aydın [

29] calculated for Turkish wheat production.

Analysis of the indices in wheat-producing provinces indicates that the input energy (direct + indirect) ranges from 31.985 GJ ha

−1 in Bushehr to 101.28 GJ ha

−1 in Yazd. Isfahan, Kerman, and Tehran follow Yazd with values of 85.29 (in line with what has been reported in [

2]), 84.95, and 83.32 GJ ha

−1, respectively. The energy output produced from wheat production in different provinces varies from 27.25 (in Sistan and Baluchestan, in line with what has been reported in [

30]) to 71 GJ ha

−1 (in the province of Alborz). Alborz is followed by Tehran, Kermanshah, and Mazandaran with values of 62.87, 54.86, and 54.74 GJ ha

−1, respectively. The predominant reason for the variation in the output is the climate. The climatic conditions in some provinces of Iran—in the northern parts, for instance—are more conducive to wheat production. Sistan and Baluchestan in the south, for instance, have higher temperatures and greater soil salinity, and they also experience strong winds and drought.

The EUE value ranges between 0.39 (in Yazd) and 1.16 (in East Azerbaijan), with the value exceeding unity only in 6 of the 30 provinces, all of which lie in the northern and northwestern parts of the country. The five provinces, in addition to East Azerbaijan, are Golestan, Ardabil, Kohgiluyeh and Boyer-Ahmad, Alborz, and West Azerbaijan. The variation in NE among the provinces is considerable, ranging from −62.04 GJ ha−1 in Yazd to 6.55 GJ ha−1 in East Azerbaijan. In addition to East Azerbaijan, the Iranian provinces of Golestan, Ardabil, Kohgiluyeh and Boyer-Ahmad, Alborz, and West Azerbaijan also have a positive energy balance.

The NER ratio varies from 0.48 in Yazd to 1.52 in East Azerbaijan. In 50% of the provinces of Iran, mostly located in the north, the index value is greater than one. This means that the energy output of the wheat production systems is greater than the amount of non-renewable energy used. This finding is in line with the results of Nasseri [

22] in the northwest of Iran. The energy productivity indicates that the quantity of wheat produced per unit of energy input is low in all provinces of Iran—with the highest being 0.09 kg/MJ (in Ardabil, East Azerbaijan, and Golestan) and the lowest in Yazd at 0.03 kg MJ

−1. In other words, the quantity of wheat produced in the northern parts of Iran is thrice as much as what is produced in provinces such as Yazd, which combat aridity [

43]. It follows that the specific energy (SE), which is the inverse of energy productivity (EP), is the highest in Yazd and the lowest in Ardabil, East Azerbaijan, and Golestan.

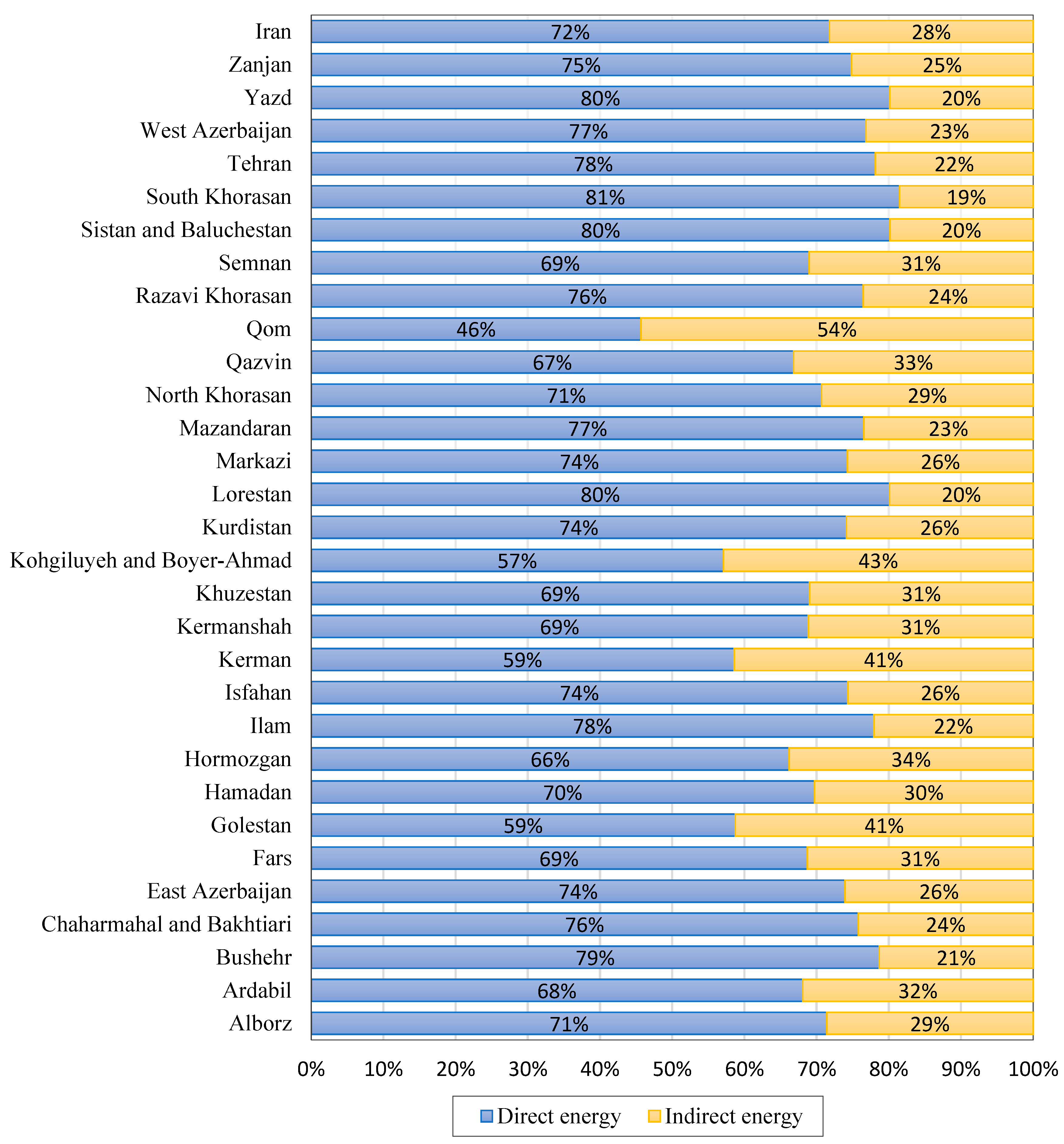

The distribution of direct and indirect energy use in irrigated wheat production is shown in

Figure 1. At the national level, the average direct energy (irrigation water, electricity, diesel fuel, and human labor) is approximately 42.73 GJ ha

−1 (72%), while indirect energy (seed, pesticides, chemical fertilizers, farmyard manure, and machinery) is 16.81 GJ ha

−1 (the remaining 28%). Direct energy and indirect energy for Iran are higher and lower, respectively, than the values reported for China in Yuan et al. [

26] and Wang et al. [

44]. Among the provinces, the direct energy contribution ranges from 46% to 81%. The highest direct energy shares are noticed in South Khorasan (81%), Yazd (80%), Sistan and Baluchestan (80%), and Lorestan (80%). This indicates that wheat production in these provinces is based largely on the ‘direct energy’ inputs: irrigation water, electricity, human labor, and diesel fuel.

On the other hand, the indirect energy contribution varies from 19% (South Khorasan) to 54% (Qom). Qom is followed by Kohgiluyeh and Boyer-Ahmad (43%), Kerman (41%), and Golestan (41%). It can be concluded on the basis of these findings that wheat production in most Iranian provinces is dependent on the ‘direct energy’ inputs (in agreement with [

2,

29,

36]).

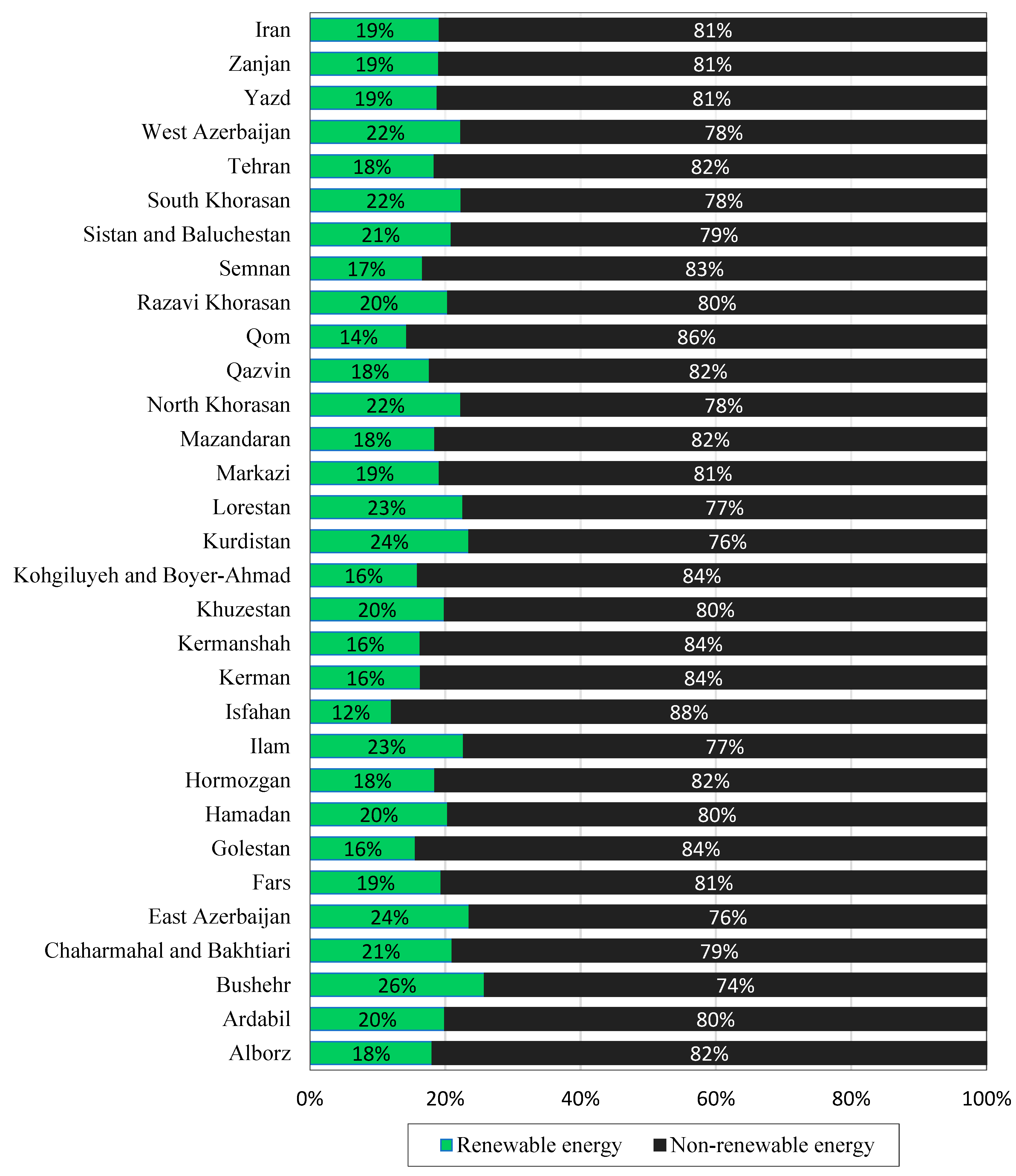

The shares of renewable and non-renewable energy are displayed in

Figure 2. At the national level, the average renewable and non-renewable energy usages are estimated as 11.39 GJ ha

−1 (19% of total energy) and 48.14 GJ ha

−1 (81%), respectively. This suggests that wheat production heavily relies on non-renewable energy in Iran, which is similar to the report by Yuan et al. [

26] and Sun et al. [

43] in China. In other words, chemical fertilizers, pesticides, electricity, machinery, and diesel fuel are used too much for wheat production. Provincial analysis reveals that the contribution of renewable energy to the total energy input is in the range of 12% to 26%, with Bushehr (26%), Kurdistan (24%), and East Azerbaijan (24%) emerging as the top three in this regard. On the other hand, non-renewable energy accounts for more than 70% of the total energy input, on average seven times more than the renewable energy input (in agreement with Houshyar and Grundmann [

24] and Khoshnevisan et al. [

2]). Isfahan (88%), Qom (86%), Kohgiluyeh and Boyer-Ahmad (84%), Golestan (84%), Kermanshah (84%), and Kerman (84%) topped the NER list. The high use of non-renewable energy not only reduces the access of future generations to these resources [

45], but also has adverse environmental effects [

46].

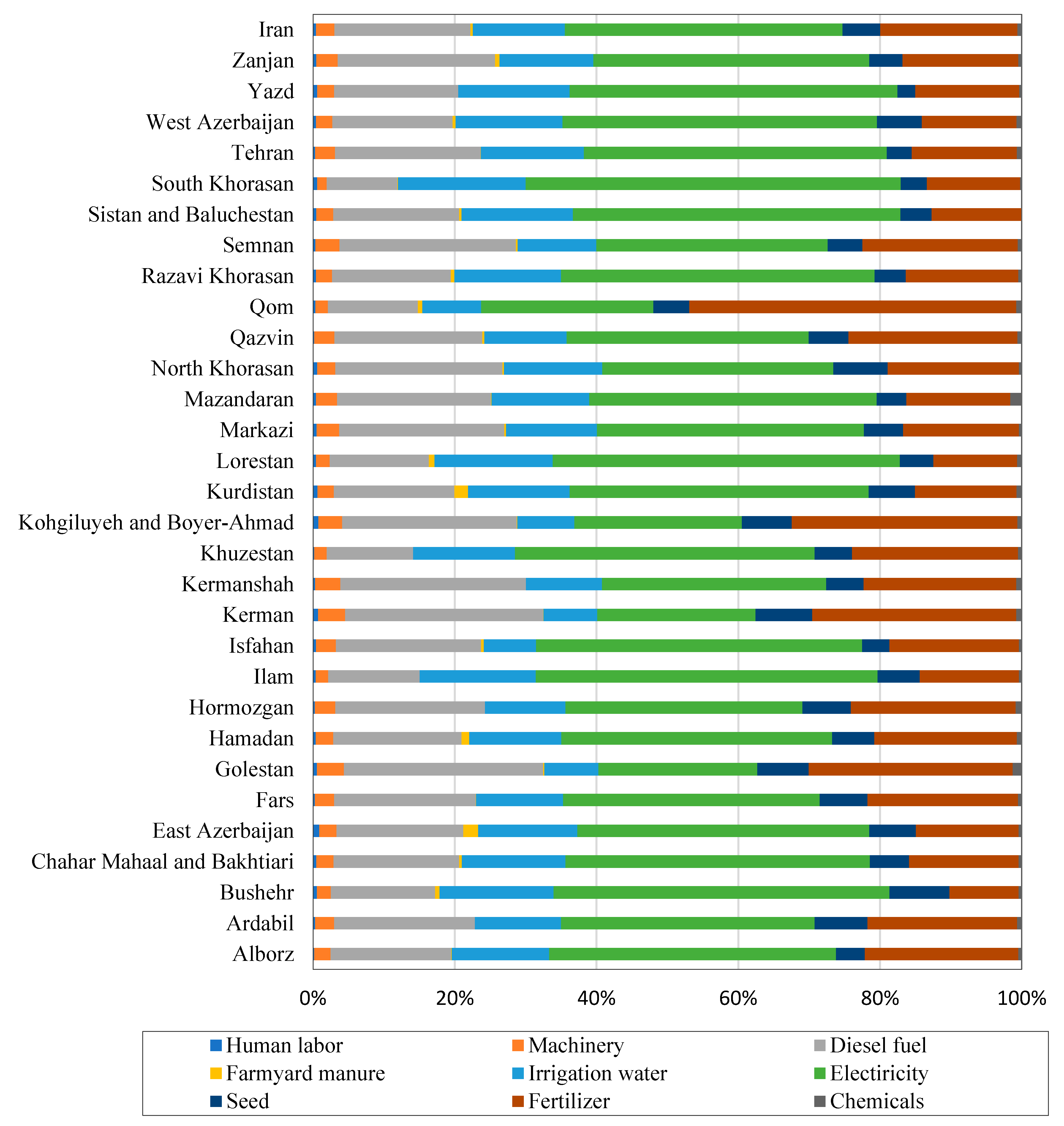

Various inputs including human labor, machinery, diesel fuels, farmyard manure, irrigation water, electricity, seeds, fertilizer, and chemicals are used in wheat production.

Figure 3 reveals the share of energy from each of these inputs to the total energy input. Electricity emerges as the main energy input, accounting for between 22% and 53% of the total energy input for all provinces except Qom. South Khorasan, Lorestan, and Ilam provinces are the main users of electricity for wheat production with 53%, 49%, and 48% of the total energy input, respectively. This suggests that electricity is the main energy input in wheat production; this may be due to the use of water pumps for irrigated wheat production, which requires more electricity [

29]. Fertilizer energy ranked second among the energy inputs, ranging from 10% to 46% of the total energy input, with Qom leading this list. One may infer from this finding that irrigated wheat production is also fertilizer-intensive in the country. Diesel fuel energy constitutes 10%-28% of the total input energy, with an average of 19% among Iran’s provinces (as shown in

Figure 3). The highest diesel fuel energy contributions are in Golestan (28%), Kerman (28%), and Kermanshah (26%). Several studies such as Unakıtan and Aydın [

29], Yuan et al. [

26], Soltani et al. [

47], as well as Safa and Samarasinghe [

48] have confirmed the importance of diesel fuel energy in wheat production. Irrigation water is an essential input for irrigated wheat. On average, the share of the equivalent energy in irrigation water is about 13%, with South Khorasan (18%), Lorestan (17%), Ilam (16%), and Bushehr (16%) being the top quartet in the list, and Golestan (7%), Kerman (7%), and Isfahan (7%) being the bottom three. The value of 13%, incidentally, is lower than that reported in the study done by Kardoni, Ahmadi, and Bakhshi [

36].

Seeds, machinery, chemicals, farmyard manure, and human labor are the other inputs used in wheat production. Seeds are the inputs for wheat cultivation; machinery are used in the processes of sowing, ploughing, and harvesting: these include combines, tractors, moldboard plows, disk plows, levelers, centrifugal broad casters, grain drills, and sprayers. These inputs—on an energy-equivalence basis—contribute less than 10% of the total energy input.

3.2. Carbon Footprint of Wheat Production

Table 5 summarizes the GHG emission values for the production of irrigated wheat in the provinces of Iran. The carbon footprint amounts to 24,304.24 kg CO

2-eq. ha

−1, where electricity (55.36%), fossil fuels (29.35%), and nitrogen fertilizer (11.86%) are the major contributors. In contrast, according to Wang et al. [

44] and Sun et al. [

43], fertilizers account for the largest share of greenhouse gas emissions from wheat production in China.

The calculated GHG emissions in wheat-producing provinces vary between 1162.8 and 3953 kg CO

2-eq. ha

−1. Among the provinces, Yazd (3953), Isfahan (3564), and Tehran (3287) have the highest emissions and thereby the highest shares of electricity and diesel fuel in the input mix. The GHG values reported in other publications are 2711.6 kg CO

2-eq. ha

−1 for Isfahan (Khoshnevisan et al. [

2]), and 2281.5 kg CO

2-eq. ha

−1 (Khoshnevisan et al. [

2]) and 4184 kg CO

2-eq. ha

−1 (Mondani et al. [

28]) for Kermanshah [

2]. The results of these two studies and the present study show that a substantial share of the GHG emissions is caused by the use of electricity and diesel fuel. Improvement is possible if standard electric pumps for irrigation are recommended to farmers, and diesel fuel is replaced gradually by renewable bio-fuel. From

Table 5, it is clear that the GHG index has the lowest values in Bushehr, Kohgiluyeh and Boyer-Ahmad, and Golestan provinces with 1162.8, 1304.7, and 1349.57 kg CO

2-eq. ha

−1, respectively. Diesel fuel makes up a larger share of the carbon footprint than electricity only in the provinces of Kerman, Golestan, and Kohgiluyeh and Boyer-Ahmad. The shares of electricity and diesel fuel in the GHG emissions are the second smallest for Golestan, with 29.9% and 42.5%, respectively. Mohammadi et al. [

37] calculated the carbon footprint for wheat cultivation as 1171.1 kg-CO

2-eq per hectare, with diesel fuel and electricity accounting for more than 62%. Golestan being one of the major wheat production centers in the country, the carbon footprint for the province can serve as a benchmark that other provinces can target.

Machinery accounts for less than 8% of the GHG emissions in all provinces of Iran, with 7.19% (Kerman) being the highest. In fact, in a study by Mondani et al. [

28], the share of machinery was reported to be as low as 4.6%. The relatively smaller contribution can be explained by the fact that Iranian agriculture is not sufficiently mechanized vis-à-vis many other parts of the world.

Several researchers have found that nitrogen fertilizers account for the largest share in GHG emissions among chemical fertilizers [

2,

29,

37]. In this study, they account for an average of 11.86% of the total carbon footprint, with the share going up to 31.73% for Qom province. The efficient consumption of chemical fertilizers (especially nitrogen) plays an important role in reducing water and soil pollution. The use of farmyard manure helps minimize the requirement for synthetic fertilizers and thereby GHG emissions. Subsidies are provided by the government to farmers for the purchase of chemical fertilizers.

Herbicides, with 0.27% of the carbon footprint, dominate as the family of pesticides with the highest contribution, while fungicides bring up the rear with 0.02%. Biological control is an appropriate solution for reducing pesticide usage.

3.3. Evaluation of Energy Indices and GHG Emissions across Provincial Segments

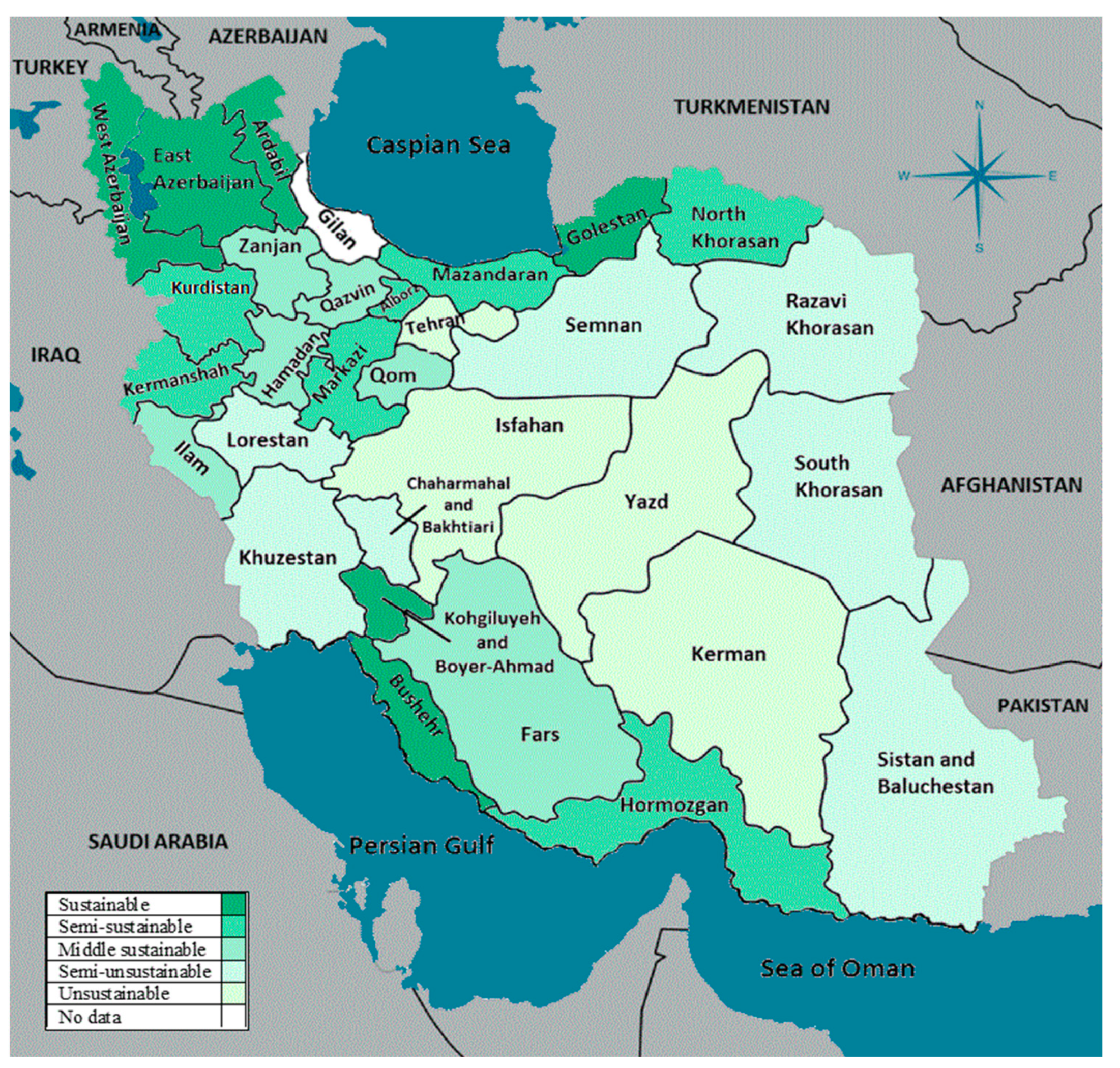

The clustering results of the wheat-producing provinces based on the energy use efficiency and GHG emissions indices are shown in

Table 6 and

Figure 4. According to the Calinskie-Harabasz criterion index, the most appropriate number of clusters is five—called

sustainable,

semi-sustainable,

middle sustainable,

semi-unsustainable,

and unsustainable.The provinces of Ardabil, Bushehr, East Azerbaijan, Golestan, Kohgiluyeh and Boyer Ahmad, and West Azerbaijan belong to the sustainable cluster with the highest average EUE (1.05) and the lowest GHG emissions (1421.77 kg CO2-eq. ha−1). The NE, NER, EP, and SE values are 2.32 GJ ha−1, 1.33, 0.08 kg MJ−1, and 12.46 MJ kg−1, respectively. This cluster accounts for 19.38% of the total national wheat production and 20.86% of the irrigated area from which wheat is harvested. The high energy efficiency in this cluster can be attributed to the climatic conditions of the provinces included in the cluster. For example, Golestan province, which lies in the Caspian coastal zone, is endowed with wet and humid conditions and blessed with fertile soil.

The provinces of Alborz, Hormozgan, Kermanshah, Kurdistan, Markazi, Mazandaran, and North Khorasan were classified in the semi-sustainable cluster with a value of 0.95 for

EUE and 2123.37 kg CO

2-eq. ha

−1 for GHG emissions. They account for 13.69% of the area harvested. The NE, NER, EP, and SE indices for this cluster are −2.77 GJ ha

−1, 1.18, 0.07 kg MJ

−1, and 13.79 MJ kg

−1, respectively. There is a great deal of ecological diversification in the semi-sustainable cluster, as the provinces are not in close proximity to each other. However, the lowest standard deviation, which indicates the highest homogeneity within the cluster, is observed in this cluster for most indicators; this indicates a similarity of input and production management in these provinces. This reduces the risk of energy management policies not being effective enough, though the diversity in the wheat production units in the cluster does add to some uncertainty (

Figure 4).

The provinces of Fars, Hamadan, Ilam, Qazvin, Qom, and Zanjan are in the middle sustainable cluster with a production share of 24.13% and a 3690.58 kg ha−1 average yield. The EUE and GHG emissions are 0.79 and 2228.62 kg CO2-eq. ha−1, respectively. In the middle sustainable cluster, the values of NE, NER, EP, and SE are −12.72 GJ ha−1, 0.97, 0.06 kg MJ−1, and 16.55 MJ kg−1, respectively. The input and output energy values in this cluster have the lowest standard deviation.

Further, Chaharmahal and Bakhtiari, Khuzestan, Lorestan, Razavi Khorasan, Semnan, Sistan and Baluchestan, and South Khorasan belong to the semi-unsustainable cluster with an average and standard deviation of EUE equal to 0.62 and 0.09, respectively; the average and standard deviation of GHG emissions equal 2401.11 and 158.78 kg CO2-eq. ha−1, respectively. NE, NER, EP, and SE values are −24.39 GJ ha−1, 0.78, 0.05 kg MJ−1, and 21.56 MJ kg−1, respectively. This cluster has the largest share of wheat production in the country (31.72%) as well as the largest percentage of the harvested area (34.03%). Due to the regional and climatic conditions, the input use patterns in the sustainable and semi-sustainable clusters are a good benchmark for the provinces in the semi-unsustainable cluster to adopt and strive to attain.

Only four provinces, including Isfahan, Kerman, Tehran, and Yazd find themselves in the unsustainable cluster with the lowest average EUE (0.56) and the highest GHG emissions (3499.13 kg of CO2 ha−1). The provinces in the unsustainable cluster represent less than 10% of the harvested area and the production of wheat from irrigated farms. NE, NRE, EP, and SE for this last-place cluster are −39.71 GJ ha−1, 0.67, 0.04 kg MJ−1, and 24.53 MJ kg−1, respectively. A point to be emphasized, for this cluster, is the greater standard deviation vis-à-vis the other clusters for all the indicators measured. This is a challenge for policymakers, as the uniform effectiveness of energy management and GHG-footprint truncation policies ‘across the provinces’ is questionable. Therefore, despite the homogeneity of the members of all clusters according to the Calinskie-Harabasz criterion, the authors would like to suggest that policies need to be tailormade for different provinces as far as the unsustainable cluster is concerned.

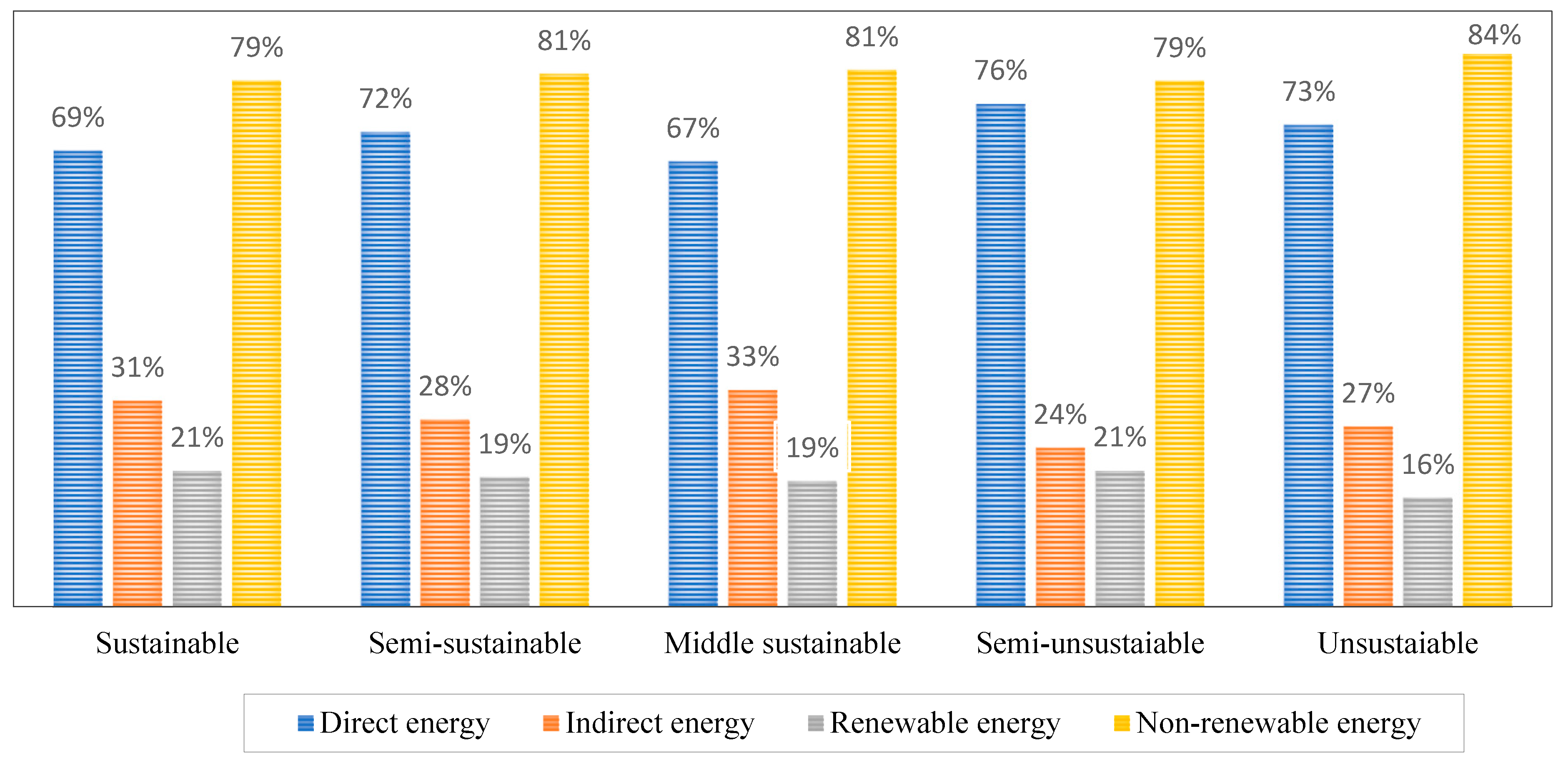

Figure 5 displays the shares of direct and indirect energy, and also of renewable and non-renewable energy, in all the five clusters. The results show that the share of direct energy is greater than that of indirect energy in all clusters, ranging from 67% (middle sustainable cluster) to 76% (semi-unsustainable cluster). This implies that irrigation water, electricity, diesel fuel, and human labor account for more of the energy-equivalent inputs in all the clusters and thereby in the country as a whole.

The share of non-renewable energy is higher than that of renewable energy in all the clusters, ranging from 79% (sustainable cluster) to 84% (unsustainable cluster). The unsustainable cluster—the provinces of Isfahan, Kerman, Tehran, Yazd—used more of these energy-equivalent (or energy) inputs. This finding was also reported by other studies in Turkey [

49] and Serbia [

50], where non-renewable energy represented a greater proportion compared to renewable energy for wheat production.

Using organic fertilizers or soil amendments such as biochar in cropping systems has been advocated as a potential approach to the reduction of the demand for synthetic fertilizers [

51]. Soil application of biochar can reduce losses of nutrients through leaching and/or volatilization. This is particularly important for nitrogen-based fertilizers, the production of which is an energy- and GHG-intensive process. Biochar addition in agricultural systems can deliver a range of other co-benefits, such as the mitigation of GHG emissions from soils, the enhancement of the carbon stocks in the soil [

52,

53], as well as an improvement in the soil function and crop yield that may provide farmers with greater financial benefits [

54,

55]. However, further study is recommended to determine the effect of soil amendments on wheat productivity in the region to see if they have the potential to replace synthetic chemical fertilizers.