1. Introduction

Industrial companies need to be more energy efficient and reduce emissions; this has a direct impact on costs, but also an indirect impact on the companies’ contribution to sustainability. Such energy efficient objectives are in line with the goals of the UN 2030 Agenda for sustainability [

1]. Although many organizations see the energy cost as a rigid factor, it can be reduced by the acquisition of more efficient technologies and behavioral changes [

2,

3]. While the need to reduce energy consumption and associated greenhouse gas emissions is recognized by industry, there are still significant technical and non-technical barriers to achieving this [

4]. The main barriers are related to the lack of capital to invest in new technologies and the existence of other priorities related to ensuring business continuity [

5]. Although there is a significant correlation between the use of technologies for saving energy (and other resources) with environmental performance, this is just one of many aspects affecting economic performance. Nonetheless, rising prices of energy and growing environmental awareness of the markets is making energy efficiency a top priority [

6]. In fact, energy efficiency is the most cost-effective path to a cleaner future [

7,

8]. Furthermore, the efforts to restrain global carbon emissions and reverse the consequences of climate change are equally important in these times of uncertainty. There is a strategic opportunity to establish a sustainable path by taking advantage of the post-pandemic recovery schemes to boost the climate agenda [

9].

Currently, most industrial companies identify active participation in energy efficiency programs as a recommended practice [

10], particularly in what concerns monitoring energy consumptions, auditing the use of raw materials and carbon dioxide emissions, and the integration of these activities in a decision support system to mitigate risks. In fact, the development of decision support systems for energy savings has been attracting attention.

Moreover, European energy policy has contributed with its clear orientation towards the preservation of energy and the improvement of indoor environmental quality in buildings through the adoption of the European Commission’s Energy Performance of Buildings Directive [

11]. As a result, there have been significant efforts towards designing, operating, and maintaining energy-efficient and environmentally conscious buildings. Additionally, some research has been conducted in the development of decision support systems for environmental management [

12,

13].

Some of the approaches developed for buildings can be adopted to industry, but the specificities of the problems are obviously different and require tailor-made solutions. Consequently, there are not many systems specifically developed for the industrial domain, and the existing ones are based on modeling and simulating industrial facilities, not considering important aspects such as keeping the decision-making criteria aligned with business targets [

14]. On the other hand, in recent decades, industrial companies have been investing in improving the energy efficiency of their production units guided by existing rule-based “recipes” to reduce energy consumption for almost all different industrial sectors. Therefore, plant managers feel that somehow the work is finished and there is little room for improvement. Nonetheless, experience tells us that, here and there, new opportunities for optimization can be found outside and beyond the usual prescribed solutions. Because the new opportunities and corresponding measures are specific to a particular plant, they do not appear in general energy efficiency handbooks. For instance, the way plants are operated by human actors [

15], or the influence of the characteristics of raw materials, are plant-specific, but they can have relevant impacts on energy consumption. A well-structured, multiple criteria decision-making approach has also been used in the development of energy management frameworks aimed at creating decision support mechanisms for complex situations [

16].

Thus, this article is focused on these indirect and plant-specific factors that can contribute to reduce energy consumption in manufacturing processes. All these indirect factors combined represent the context in which a plant is operating. Becoming conscious of how the context variables and hidden relationships affect the energy consumption and corresponding emissions is the first step in finding new opportunities for improvement.

This research work started in the scope of the LifeSaver project [

17]. Its general objective was to develop a method and a support platform to help companies in optimizing their operations and enable them to increase energy savings (and thus reduce carbon dioxide emissions) beyond the usual available measures. Project LifeSaver’s basic assumption and innovation aspect was exactly the use of “context information”, on top of the usual process data, to support decision making with a positive impact on energy efficiency and emissions. This approach, based on finding additional explanations on the context of operations, enables tackling the top tier of energy efficiency beyond the classical prescribed recipes. In LifeSaver, the support is given in the form of a set of software building blocks that combine context awareness, ambient intelligence monitoring, and standard energy consumption data measurement. It provides (i) a comprehensive information about the energy consumption to be processed in enterprise management systems, for the purpose of achieving energy savings; (ii) a knowledge-based decision support system for optimization of energy performance of operations; and (iii) appropriate almost online and predicted cumulative data on the carbon emissions, as input for the decision support services to enable emission trading across industries and among companies. Of course, these three project outcomes are intertwined, and any improvement in each of them has a positive impact on the other two. The work here presented refers to the second listed result of the project, on how to support the decision process towards the energy performance of operations.

To effectively use the context knowledge to make informed decisions, predictability is a key factor. Having insight about additional factors that contribute to energy consumption allows plant managers to plan production in a more efficient and effective way. An example of this planning improvement capability by involving additional factors from our daily life is the modern car navigation systems. The estimated time of arrival is no longer only dependent on the distance and speed limits of roads (as in the former systems), but additional information such as the time of the day, day of the week, and expected weather give us more accurate predictions for alternative routes.

Therefore, in practical terms, it is expected that the addition of contextual information will allow us to narrow the expected variance of predicted energy consumption and support informed decisions regarding the management of production and its planning. A suitable indicator of the existence of such opportunities is the dispersion of the energy-related data in industrial scenarios, which calls for an effort to collect and integrate context awareness factors.

Context awareness is a concept propagated in the domains of ubiquitous computing [

18]. It is the idea that computers can be both sensitive and reactive, based on their environment. As context integrates different knowledge sources and binds knowledge to the user to guarantee that the understanding is consistent, context modeling is extensively investigated within knowledge management research. Using context information (for context-sensitive or ubiquitous computing) is an active area of research, with various context capture methods and context languages defined. In the case of energy consumption in manufacturing, the notion of context refers to (actual) characteristics of the manufacturing process and products, devices, and physical capabilities of the equipment and environment conditions. The modeling of context in this case presents an additional challenge, as the mentioned processes are highly dynamic and reside in distributed environments. The most common approaches to context-modeling are key-value models, Markup Scheme Models, Graphical Models such as UML, OOM, Logic-Based Models, and Ontology-Based Models. Present research on context modeling is mostly focused on ontologies [

19]. Ontologies allow context-modeling at a semantic level, establishing a common understanding of terms and enabling context sharing, reasoning, and reuse.

The subject of accuracy and prediction stability of energy forecasting has been studied using many statistical and machine learning-based models, such as k-Nearest Neighbor, Support Vector Machines, Decision Trees, and Recurrent Neural networks [

20].

Therefore, the contribution of the study is to demonstrate that the use of “context information”, on top of the usual energy-related data, provides improved support to decision-making with a positive impact on energy efficiency.

The remaining parts of this article are organized as follows:

Section 2 introduces the proposed context-based solution;

Section 3 describes the experience of applying the proposed solution in two industry case studies, highlighting the main findings; and finally,

Section 4 presents some conclusions and directions for further research.

2. Proposed Solution

The proposed solution integrates the use of context information in the scope of manufacturing processes to develop a decision-making approach with a positive impact on energy consumption. The goal is the development of a software platform to facilitate and support the method in an operational environment.

2.1. Context in Manufacturing

According to Merriam-Webster, “context” is the set of interrelated conditions in which something exists or occurs. In terms of engineering, it is difficult to find a single definition for the notion of context, but its importance in communication, categorization, intelligent information retrieval, and knowledge representation has been recognized for many years. In the artificial intelligence domain, the concept of context is usually defined as the generalization of a collection of assumptions [

21,

22,

23]. A common, pragmatic definition for context-aware applications defines context as “any information that can be used to characterize the situation of an entity” [

24].

Adapting this concept to the manufacturing environment, we can specify several factors that indirectly influence the operation of the equipment and shopfloor personnel.

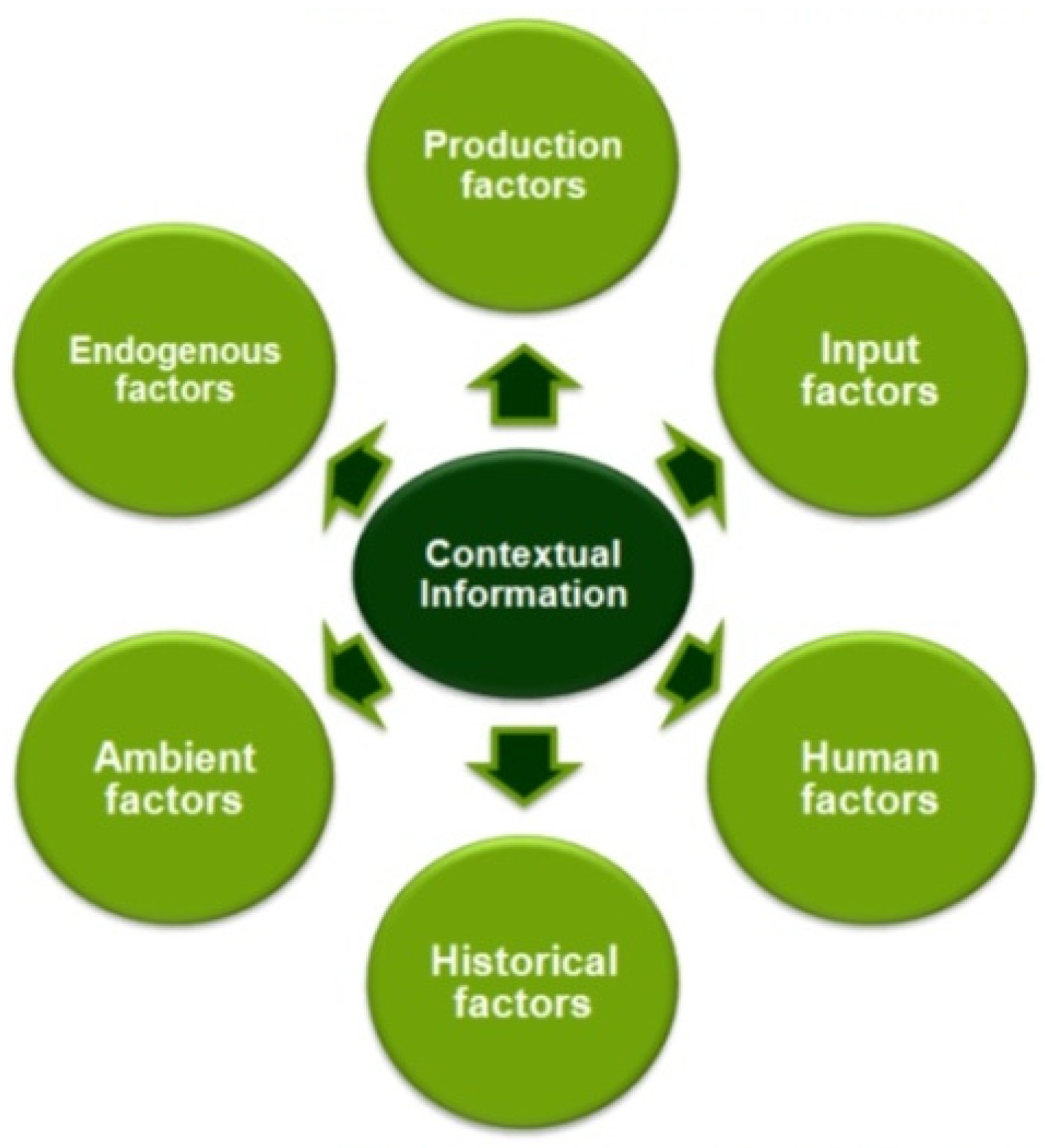

Figure 1 proposes a categorisation of the various types of contextual information in the scope of industrial manufacturing.

From the experience of working with industrial processes and consultations with industrial partners, the authors compiled a comprehensive list of possible factors that can influence the performance of production processes. In the scope of this research work, such factors can be aggregated in the following six categories:

Production factors: related to production aspects, e.g., the product type.

Input factors: related to the production inputs, e.g., quality of the raw materials.

Human factors: related to the human intervention involved, e.g., the level of expertise of operators.

Historical factors: related to the history of the production unit, e.g., cumulated production hours.

Ambient factors: related to external uncontrolled variables, e.g., ambient temperature.

Endogenous factors: related to the equipment itself, e.g., machine generation.

2.2. Decision Support Approach

The search for energy efficiency opportunities related to the influence of context variables is a mix between engineering insight and data processing. Engineering insight is related to the initial suggestion of installing certain sensors (or data input procedures) based on the physical relationships between variables. For instance, it is somehow expectable that humidity in raw materials has some impact on the energy necessary to process them, but only installing a sensor at the materials’ storage point and having those data available allow us to find the extent of the influence. Once the data are available, we can imagine a system that looks for the variables that are most critical and helps identify where we can find more opportunities for savings.

Based on this idea,

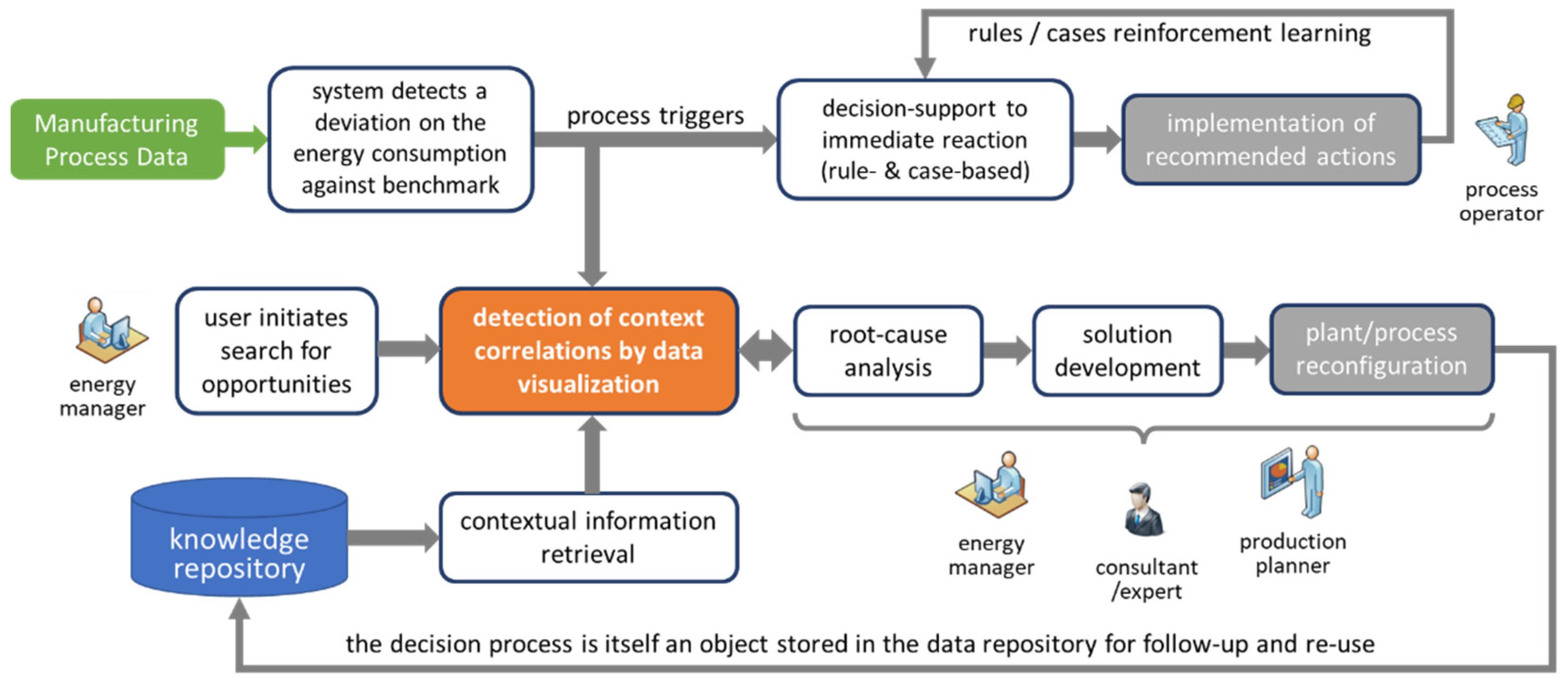

Figure 2 depicts the proposed approach for an energy efficiency decision support system based on the use of contextual information on top of the usual process data.

The approach includes the usual monitoring, detection, identification, and action functionalities. Therefore, the top sequence in the diagram describes the detection of a deviation in the energy consumption against benchmark/average values (previously stored as benchmarks or as models that estimate them for specific conditions) to always trigger an immediate reaction process. The recommendation of the best immediate action to mitigate the problem can be derived from a combination of classical rule-based reasoning (RBR) and case-based reasoning (CBR) and is essentially based on classical energy efficiency handbook prescriptions (rules) and experience stored as cases. The context is not used directly in this top sequence.

In parallel, the observed deviation will also trigger the process responsible to find new opportunities by signaling the energy manager about a potential situation. If the deviation was in the direction of a higher consumption, it is important to identify the contextual situation to avoid. If it was in the opposite direction of an unusual lower consumption, it is a context to look for and, if possible, to control.

The current situation is complemented with all available contextual information, and visually compared against previous observations for a similar context. The data visualization can also be initiated by, e.g., the energy manager, to search for opportunities in the stored data. Therefore, the detection of a deviation against benchmark/average values is performed automatically and the system offers a set of tools (e.g., filters) that the energy manager can use to find correlations with the available context variables. This partially manual step surely gives room for future work so that this search can be made automatic by continuously estimating models between the available context variables and the system performance. A challenge here is finding the correlation between discrete events with time constants much higher than the process dynamics. For the moment, the insight of human expertise is key, proposing hypotheses that cut the multi-dimensional space of variables.

From this point on, a decision process is developed towards understanding the root cause and developing and implementing permanent solutions. Included in these solutions are also the rules that are used in the production planning and distribution of resources. The decision processes are themselves represented as objects that are stored in the data repository for further use. The specific details of the base algorithms of the decision support system implemented in the scope of the LifeSaver project can be found in [

25].

2.3. Platform Architecture

To support the proposed methodology, the LifeSaver consortium developed a software platform. The platform is composed of several independent modules that are aggregated and configured according to the needs of each end-user, i.e., industrial client.

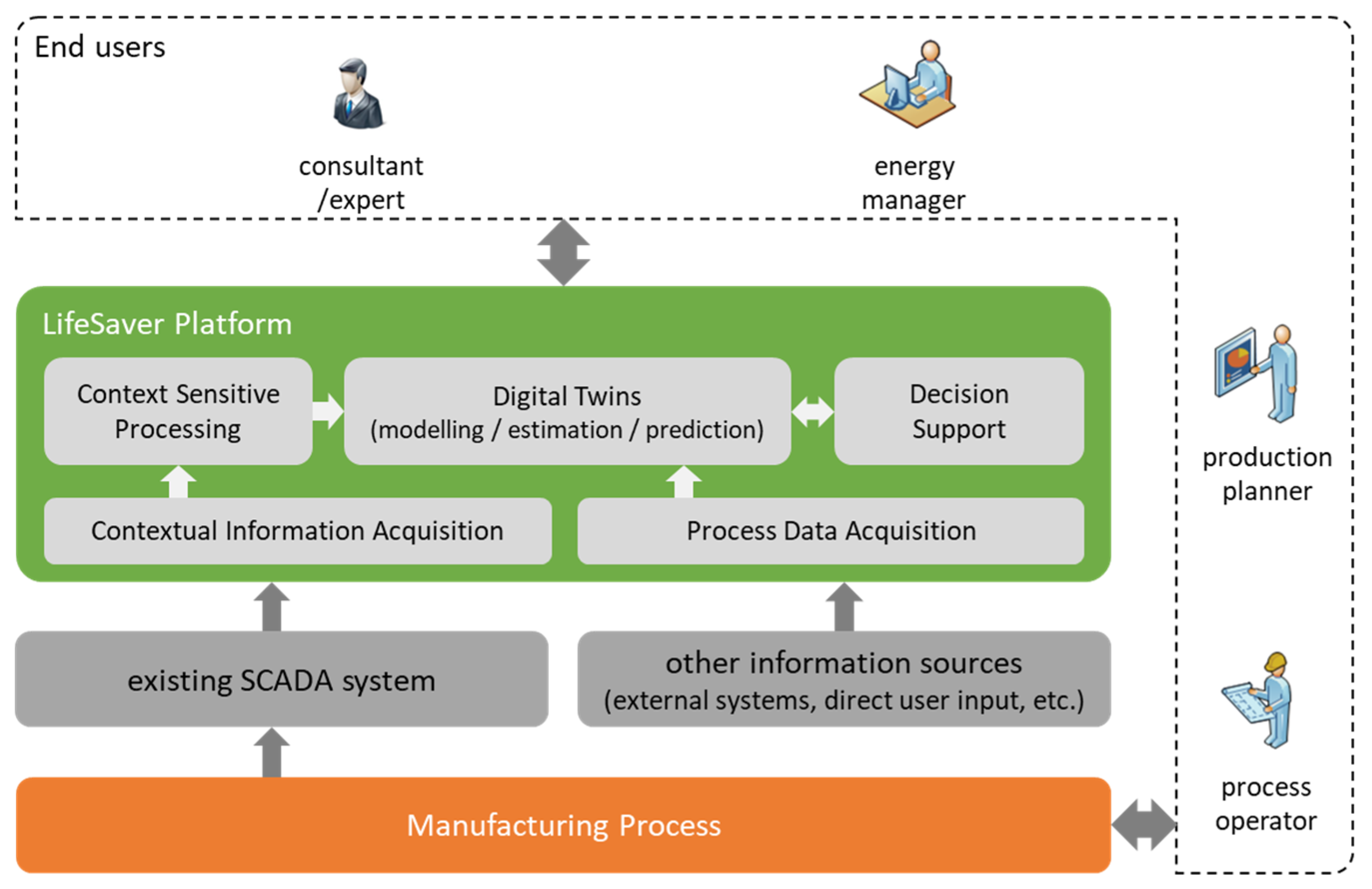

Figure 3 presents the architecture of the platform.

2.3.1. Context and Process Data Acquisition

The bottom layer of the architecture is in connection with the manufacturing units, acquiring sensorial process data from the supervisory control and data acquisition (SCADA) system (including data from the control and PLC units), thus being a kind of edge computing layer.

Additionally, all available information about the operating conditions that surround the energy consumption units is also collected, such as operator identification, supplier of the raw materials in use, ambient temperature/humidity, etc. Additional information can also be acquired from external systems (e.g., assets management system) or direct user input (e.g., information about how the machine sounds). Note that the process data can also contribute to the identification of the context. An example is the control set-point of a production unit that sets the operating point of the process.

2.3.2. Context Sensitive Processing

The collected data and additional information are processed in the Context Sensitive Processing module to generate the context. Its main role is to map the acquired contextual information against the current plant/process layout. This module is composed of a set of different functionalities that filter and combine data to increase their meaning. For instance, the relative position of a machine must be taken into consideration while processing the ambient temperature taken by two different measures apart within the plant.

Furthermore, the context processing module can generate new contextual knowledge from the context information. For example, the information about the raw material coming from a specific supplier plus a measure of the storage room humidity can be combined as new context information.

Wherever possible, ontology-based context models and rule-based reasoning are used to support the processing. This includes:

Operator-related info (identification, location…);

Process-related info (setpoint, product, locations…); and

Ambient-related info (temperature, humidity, light…).

2.3.3. Digital Twin Module

The digital twin module supports the decision support process by providing state estimation, energy consumption forecast, and estimated impact of plant reconfiguration. It provides a virtual representation of the manufacturing process and its equipment. The digital twin includes plant models (based on both data and laws of physics) that are used, via simulation, to estimate present and future values of the plant state, under current or hypothetical conditions. The module uses the context information by:

Including additional variables in the models;

Identifying the model parameters’ dependency with context variables; or

Managing different models for different context situations.

Then, the simulations of the models:

Run in parallel with the plant, fed with the input/output data, providing visibility on the internal non-measured state (observer approach);

Are used to forecast and detect unsought energy consumption situations in anticipation; and

Are used offline to test what-if scenarios to support the search of new solutions.

The digital twin module also includes support for process modeling and model parameter estimation. An example of an included approach for prediction based on recursive least squares (RLS) estimation was previously described in [

26].

Finally, the decision support module supports decisions in the short (immediate reaction), medium (rescheduling of the production plan) and long term (reconfiguration of the plant layout on a more permanent basis).

Following the adopted methodological approach, a classical case-/rule-based reasoning (CBR/RBR) system provides support to short-term reaction to detected abnormal situations. Essentially, this is “reacting by the book” (rule-based) complemented with consolidated experience stored in cases.

For a longer term, the module provides an analytical interface allowing the user to visualize data from different angles (i.e., different context variables), break down existing models (at the digital twin module) for different contexts, create and evaluate alternative scenarios (including energy-cost analysis), and develop new prescribed recommendations.

Note that for a matter of simplification, the notion of digital twin is used above mainly from the perspective of modeling and simulation of the physical system. If a more general notion of digital twin is adopted [

27], also considering the real-time connection to the physical system, then the whole platform can be seen as a digital twin of the manufacturing system.

2.3.4. Modular Approach

The LifeSaver platform was developed following a client–server approach, using Enterprise JavaBeans (EJB) and Java Server Pages technologies on the server side. Specific middleware was developed in the scope of the LifeSaver project to connect the companies’ legacy systems (e.g., the SCADA systems) with the platform. The users access the platform installed in the companies’ private intranets using a regular web browser.

The developed LifeSaver platform should not be seen as a one-size-fits-all application, but a modular toolset of functionalities (implemented following a service-oriented architecture) to be adapted case-by-case to the specific needs of industrial end-users. Thus, from the software perspective, all modules described above are toolsets with a collection of different functionalities. The platform is adapted for each business case, by configuring which functionalities are kept active and the way they interact with the user. This means that even the user interfaces for the different modules are tailor-made according to the needs of the business clients of the platform. This also means that the business exploitation is mainly related to the services of set-up and maintenance of the platform.

2.3.5. Global System Orchestration

The success of the proposed approach relies on the orchestration of all functionalities provided by the independent modules. The process data and context information continuously flow to the platform through the respective acquisition modules. The context-sensitive processing unit identifies regions of operation that can be already known or new and, therefore, unexploited ones.

For the known regions, the system (digital twin) has models proving expected indicators. The variance of the energy consumption against the expected means is key to determine if we should look for additional explanation for the fluctuations. This is accomplished by data visualization and by relying on the expertise and cognitive analysis of the engineers who will propose hypotheses, eventually resulting in the installation of additional sensors for measuring additional context variables.

For the new regions of context (within the current set of acquired variables), the system identifies them as opportunities (with lower consumption for the same results) or as ruinous, and consequently, a context to avoid is possible. The identification immediately creates new models, like a map that is being drawn by explorers as they progress in unknown territory.

The collection of identified regions with different energy performances (represented as models in the digital twin) comprise a set of alternative scenarios that are then used in the decision support module according to the needs of a specific industry. For instance, the system can support deciding which batches should be put in production (controllable context), taking into consideration the prediction of ambient temperature (uncontrollable context).

3. Results

In the scope of the LifeSaver project, the proposed methodology and platform were tested and validated in two business cases:

A cement production plant, characterized by being a continuous production process and having high consumption of fossil fuels and a strong dependency of the operation by humans; and

A paint and varnishes production plant, characterized by being a batch production process and having high consumption of electric energy and dependency of the product grade to be produced.

Details of these cases are presented in the following sub-sections.

3.1. Business Case 1—Cement Factory

The first business case was tested in a cement plant owned by one of the beneficiaries of the LifeSaver project. The cement industry is one of the topmost intensive energy consumers in all industrial sectors, with its energy consumption representing c.a. 50% of the total production cost. In addition, the cement industry is responsible for about 5% to 8% of the total human-made carbon dioxide emissions [

28].

Figure 4 depicts in a simplified way the cement production process considered in this test case. The main raw material of the process is limestone that is ground at the input of the process. Clay is also added to the input, among other materials, to stabilize the kilning process and give the cement the required characteristics. After a pre-heating process, the raw material mix goes through the rotary kiln where the calcination occurs to produce clinker. The clinker is then milled to produce cement that is packed and ready to dispatch.

About 70–80% of the total energy required for cement production is thermal energy (the other 20–30% is electrical energy, especially in the cement milling process) [

29], in which the calcination process of the plant takes around 90% of the total energy consumption. Therefore, any improvement in the energy efficiency of the rotary kiln has a huge impact on reducing the plant’s total energy consumption.

To evaluate the solution in this sector, the LifeSaver platform was installed at a cement factory in Slovenia. In this case, an up-to-date supervisory control and data acquisition system for process control enabled data acquisition and storage, but the analysis of the stored data required a significant amount of time due to a lack of expert software and a decision support system.

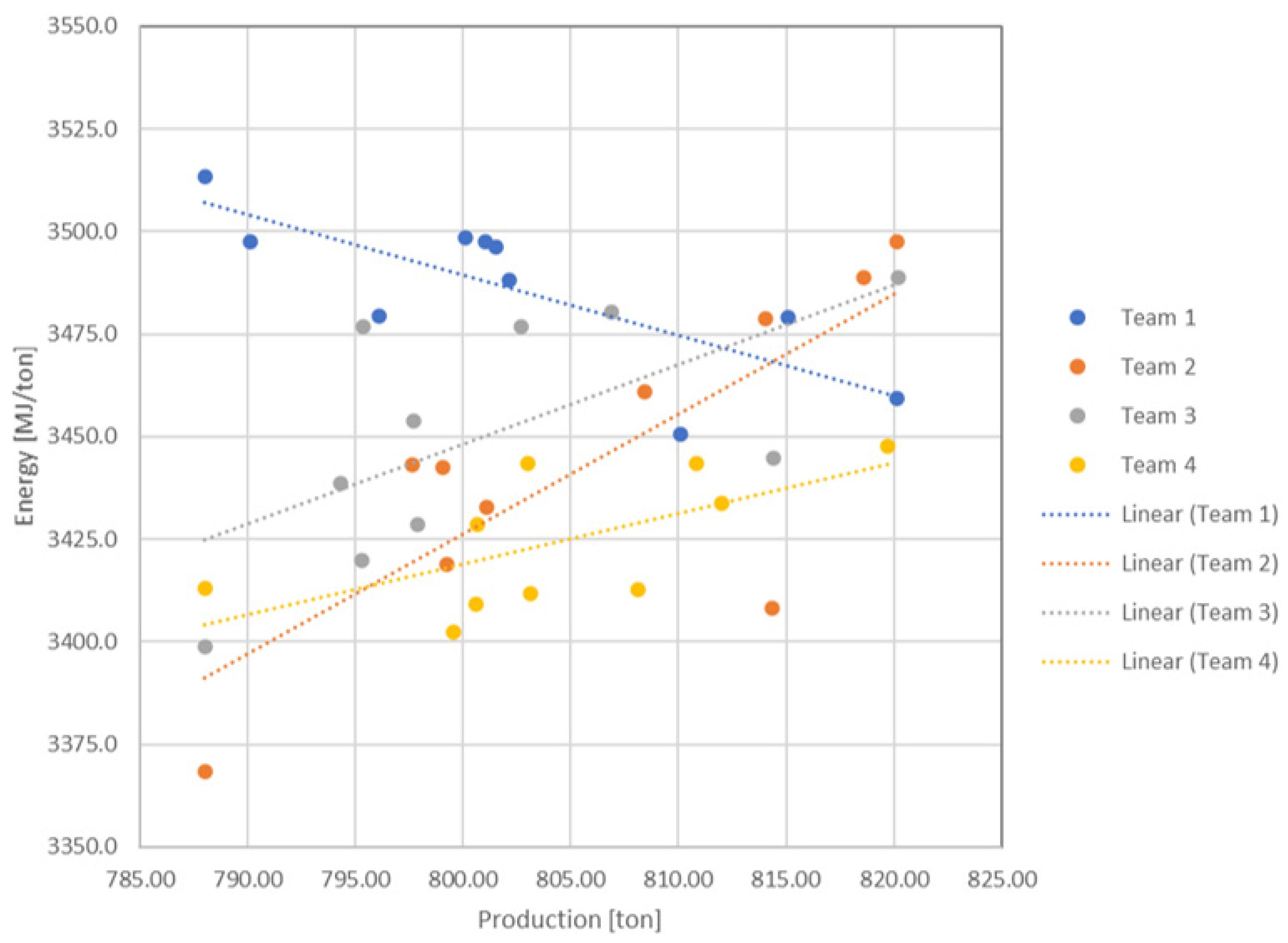

A set of performance indicators relevant for the clinker burning and cement milling process was selected based on requirements of the potential end-users (process operator, energy manager, energy and emission trader, and production planner). The selected performance indicators focus on raw material, energy consumption, emissions, and costs. The purpose of the selected performance indicators is to enable end-users to react appropriately to changes in the production process related to the context of energy use. Benchmarking values of all performance indicators relevant for the process operator are context-specific. In the initial phase of testing, five context-specific situations were selected: control room team, shift, production stage, production volume, and fuel mix.

The LifeSaver platform was then used to acquire, process, contextualize, and visualize energy data and to provide operational information to enable the control room team, energy manager, and energy trader to execute preventive or corrective actions to optimize energy and cost performance, according to the decision approach presented above in

Section 2.2.

Using the platform, information about current and expected future energy consumption is presented to the operators in a simple and straightforward way. For instance, before and after each shift, the kiln process control room teams are informed about the previous team performance. This awareness of energy performance is introduced using an Energy Performance Coefficient (EnPC), added to the classic set of key performance indicators. The EnPC is the ratio of actual to predicted or benchmark energy consumption. During the testing phase, the predicted values of energy consumption (for each type of fuel and electricity) were compared with context-specific benchmark values (for each control team depending on fuel mix, production stage, and production volume). This was to facilitate the understanding of energy use patterns and trigger early warnings and emergency actions if needed, as presented in

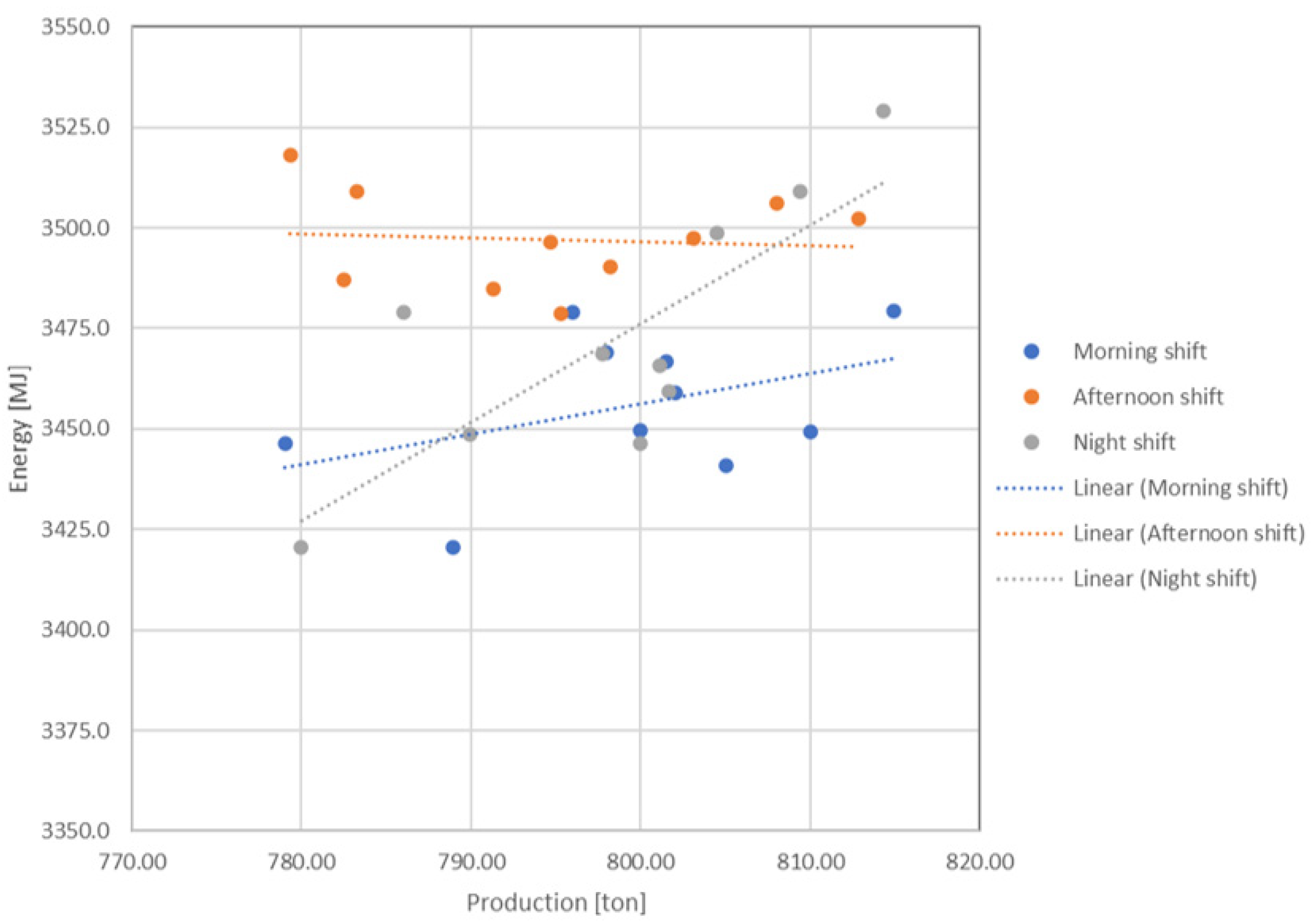

Figure 5 and

Figure 6, where different contexts are presented. In particular, the figures show two illustrative examples of the insights gained form the use of the system.

The use of the system brought visibility to opportunities that were lost in data. In this case, the contextualized data show that (i) different teams of operators perform differently (

Figure 5), with a maximum deviation of c.a. 3.7%, and (ii) the same team of operators in different shifts also perform differently (

Figure 6), with a maximum deviation of c.a. 1.8%. The root cause analysis found that, among other reasons such as ambient temperature variations, there were unbalanced expertise and experience in the composition of the teams and, furthermore, there were procedures with a positive impact that were not being shared among teams. Regarding the difference in performance between shifts, the analysis determined that they were related to the level of attention of the operators. Note that the calcination process happens when the temperature is kept above a certain threshold. Keeping the fuel flow above the required minimum with a certain margin allows it to cope with possible fluctuations without needing too much attention from the operators. After the identification of the root cause, the problem was solved through training activities and by bringing consciousness to the operators about the importance of keeping consumption at a minimum. It should be noted that, in general, the main goal of companies is to correct the large deviations in the shortest time possible and not so much to deeply invest in finding explanations for all possible causes.

Based on the initial deviations between teams and shifts, but also by making a comparison of the regular steady-state consumptions with the energy balance theoretical values, initial testing results confirmed the potential of energy savings up to 4% enabled by proper and tailor-made consumption feedback to the operators. The energy gains did not derive only from bringing the performance of the teams closer, but there was also the opportunity for a general improvement in how the process was being handled. Achieving 4% energy savings should result in a payback period of less than 3 years regarding the necessary investment. Furthermore, information about past performance initiated a positive competitiveness between different control room teams. Since nitrogen oxides (NOx) and sulfur dioxide (SO2) emissions are assigned to combustion, 4% energy savings results in the same percentage of NOx and SO2 emissions reduction. On the other hand, because only a fraction of the carbon dioxide (CO2) emissions derives from the fuel burning (as most of the CO2 emissions are process induced), it is expected that 4% energy savings results in a 1.2% reduction of CO2 emissions.

The initial contribution of the platform for this case was the detection of the dispersion of consumption values and the contextualized visualization of data. After the root cause analysis process, the consumption models based on the energy balance have been included to display in real-time the deviation between the current consumption and the potential minimum that still guarantees the calcination to occur. The operators are free to establish the comfort margin to allocate possible fluctuations. In summary, the installation of the LifeSaver platform brought increased awareness to the operators about the way they were running the plant.

3.2. Business Case 2—Paint and Varnishes Plant

The second tested business case was developed in a paint and varnishes plant owned by a second LifeSaver project beneficiary participating as an end-user. The challenge in this case is to manage the peak load of the overall factory and keep it below a specific threshold to avoid contractual cost penalties.

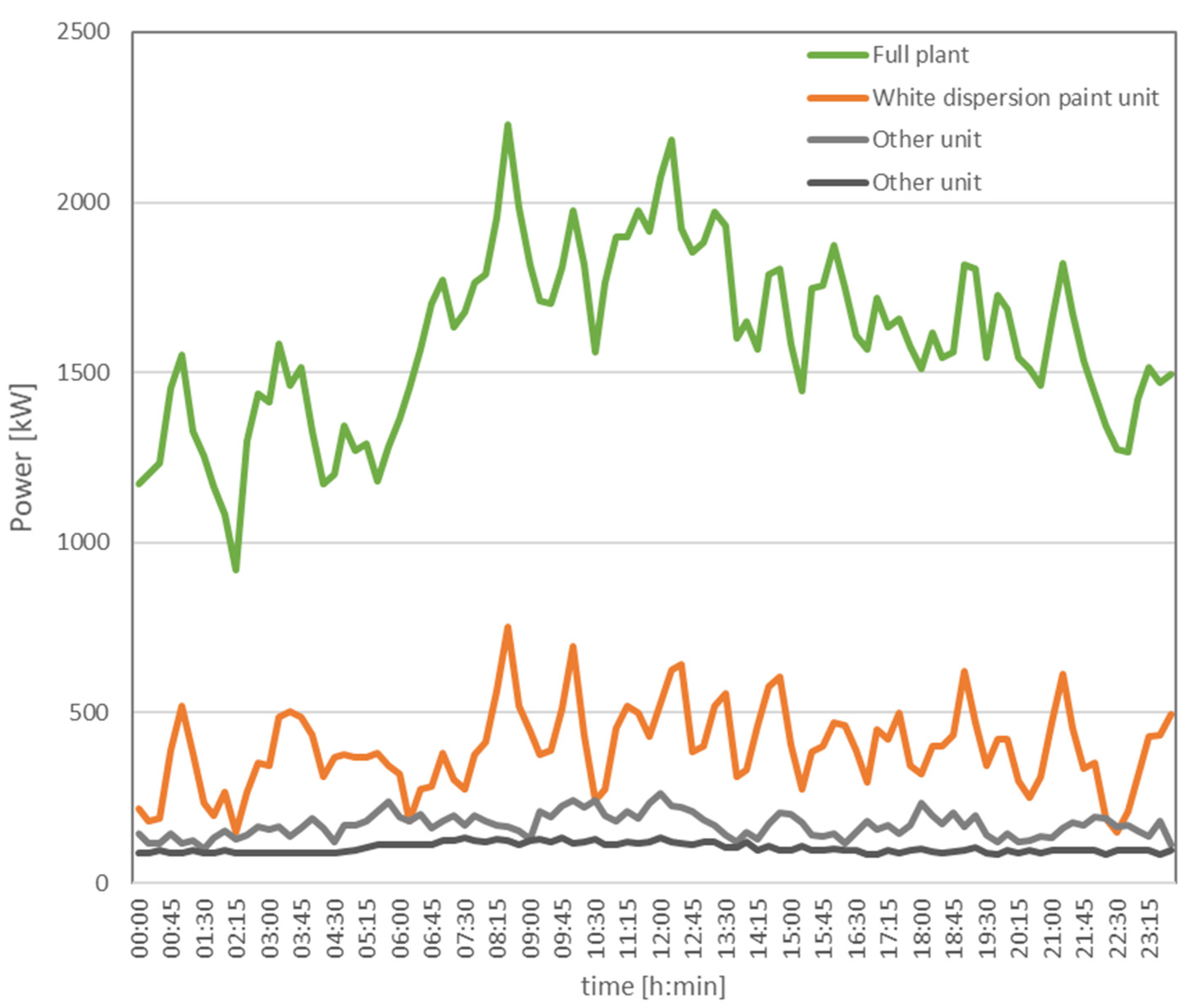

The plot in

Figure 7 shows the total factory consumption and the partial consumptions of the several industrial areas for a period of 24 h, highlighting the total energy consumption and the white dispersion paint unit. The other two plots are the third and fourth most representative (the others following are not represented in the figure). After analyzing these consumption data, it was concluded that the white paint dispersion unit, from which all other colored paints are made, is the most energy-relevant sector of the factory. Therefore, this sector was selected to test the proposed approach.

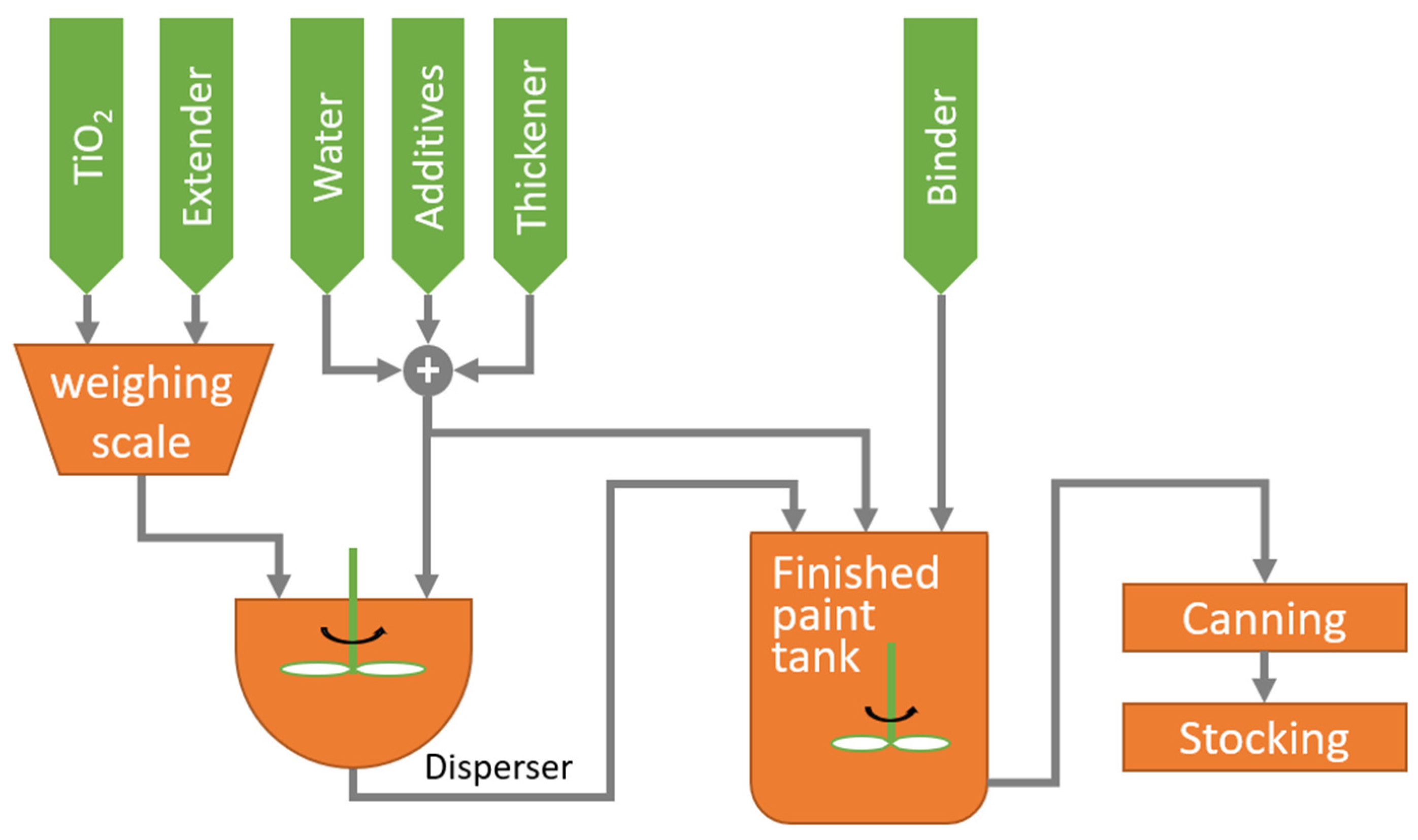

Figure 8 depicts a schematic overview of the white dispersion paint plant sector. The plant has several mixers with a drive power between 100 kW and 215 kW (totaling 1245 kW of installed capacity), two cooling units with capacities of 132 kW and 160 kW, and several compressors with an energy demand of up to 90 kW (totaling 450 kW of installed capacity).

Different white paint quality grades (the most relevant contextual variable) consume different amounts of energy and time. This is mainly due to the viscosity of the mixed elements. The plant managers also have knowledge that it is possible to trade time by speed if the same number of rotations are made, and the speed does not go below a known threshold.

The objective was to provide decision support to the operator who controls the production of white dispersion paint and organizes the scheduling of the different batches, producing paint of different quality grades based on a variety of different recipes. The paint quality grade was the context variable used to demonstrate the benefits of the system.

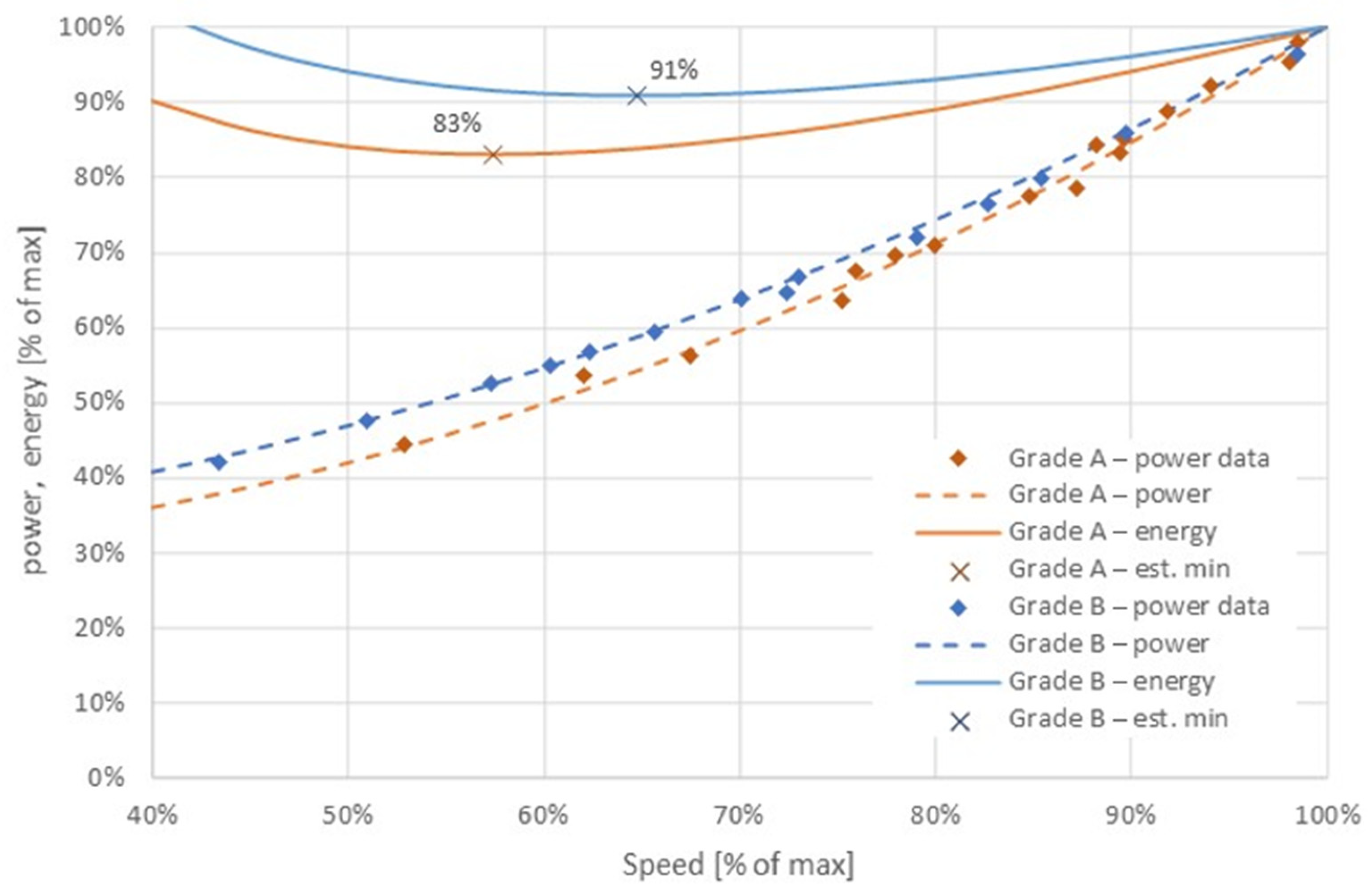

Figure 9 depicts normalized power and energy data for two different paint grades. The dotted lines are estimated quadratic power curves for different equipment speed regimes (diamond markers). The solid lines represent the estimated normalized total energy and are obtained from the power curves dividing by the speed (as the necessary time to mix the product to the same number of turns is inverse of speed). The visibility of these curves separated by product grade (context variable) brought awareness of the potential savings.

Figure 8 shows that it is possible to consume 17% less energy operating the equipment at 57% of maximum speed for product grade A (taken from point marked 83%) and save around 9% when operating at 65% of the maximum for product grade B (taken from the point marked 91%). The observed variation can be explained by several factors (e.g., different quality of raw materials), but these are all aggregated in the context variable, which is the paint grade.

Of course, there is a trade-off with the necessary time to develop the product, but the important aspect to underline here is that, with the system, the operator has more insight about the available options in the decision process related to production planning.

Three months after the system was put in place, the benefits have been estimated as a 14% reduction in the frequency of peak loads above the maximum.

For this second business case, the LifeSaver platform was completed with additional modules to estimate the curves above from process data while introducing new product grades and recommend the best operating point balancing energy consumption and production rate.

3.3. Discussion of the Business Cases’ Results

The proposed approach and supporting platform were tested in two industrial business cases. This section highlights and summarizes the main insights and lessons learned from each business case.

The cement production case is characterized by having high consumption of fossil fuels, continuous process, and being dependent on human operation. Any percentual savings in the regular operation provides considerable direct financial and environmental impact benefits. There is the saying, “What the eyes don’t see, the heart doesn’t feel”, and this is one of the main insights of this study—the importance of creating awareness among people about the consequences of their own performance as plant operators. The visualization of the energy (and corresponding emissions) data and having the feeling that they were part of the solution brought a more conscious behavior in the plant operation. An additional important aspect is the natural gamification that emerges between plant operators when these data are publicized internally.

The paint production case is characterized by high consumption of electric energy, batch processes, and being dependent on the characteristics of the clients’ orders to be satisfied. Besides the direct benefits of improved energy efficiency, the performance of peak load management has a considerable financial impact due to contractual penalties. The main insight from this study case is that it pays to explore other regions of operation. It is important to make careful cost-benefit analyses and experiment with the possible plant downtimes. For example, simplifying for illustrative purposes, it is preferable to operate a plant at a more efficient 50% regimen twice as long if that is the case, than full power in the prescribed time. Here, the saying would be: “If you always do what you’ve always done, you’ll always get what you’ve always got”.

Something that was common to both cases is that many of the interventions needed to improve the energy performance do not require any investment in additional equipment, but rather require having a better understanding of how the operation context influences the performance. Having this knowledge, two possibilities arise:

The context is controllable, in the sense that there are specific measures we can take to modify it, such as deciding on a supplier providing the adequate raw material.

The context is an uncontrollable disturbance, and the best we can do is identify/predict the contextual conditions and, if possible, schedule the production accordingly. For instance, if the ambient temperature is an impacting factor, we can schedule the most energy-intensive batches to the periods under the most favorable conditions, and vice versa.